Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "No need to vibrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of marine self-compacting high-performance concrete and its preparation method

The invention provides marine engineering self-compacting high-performance concrete, which comprises the following raw material components in part by weight: 450 to 540 parts of gel material, 1,640 to 1,725 parts of aggregate, 7 to 8 part of polycarboxylic acid water reducer and 160 to 175 parts of water, wherein the gel material, based on the total weight of the gel material, consists of 30 to 45 percent of type-II 52.5 portland cement, 20 to 40 percent of fly ash and 30 to 50 percent of slag powder. The self-compacting high-performance concrete doped with fly ash and slag has high flowability, fallibility, high passing capacity and high segregation-resistance stability. In addition, the marine engineering self-compacting high-performance concrete also has long-lasting chlorine salt corrosion resistance, high freezing resistance and high thermal performance.

Owner:CCCC THIRD HARBOR ENG +2

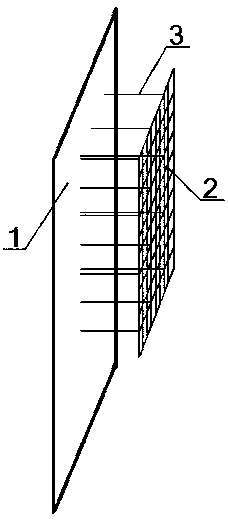

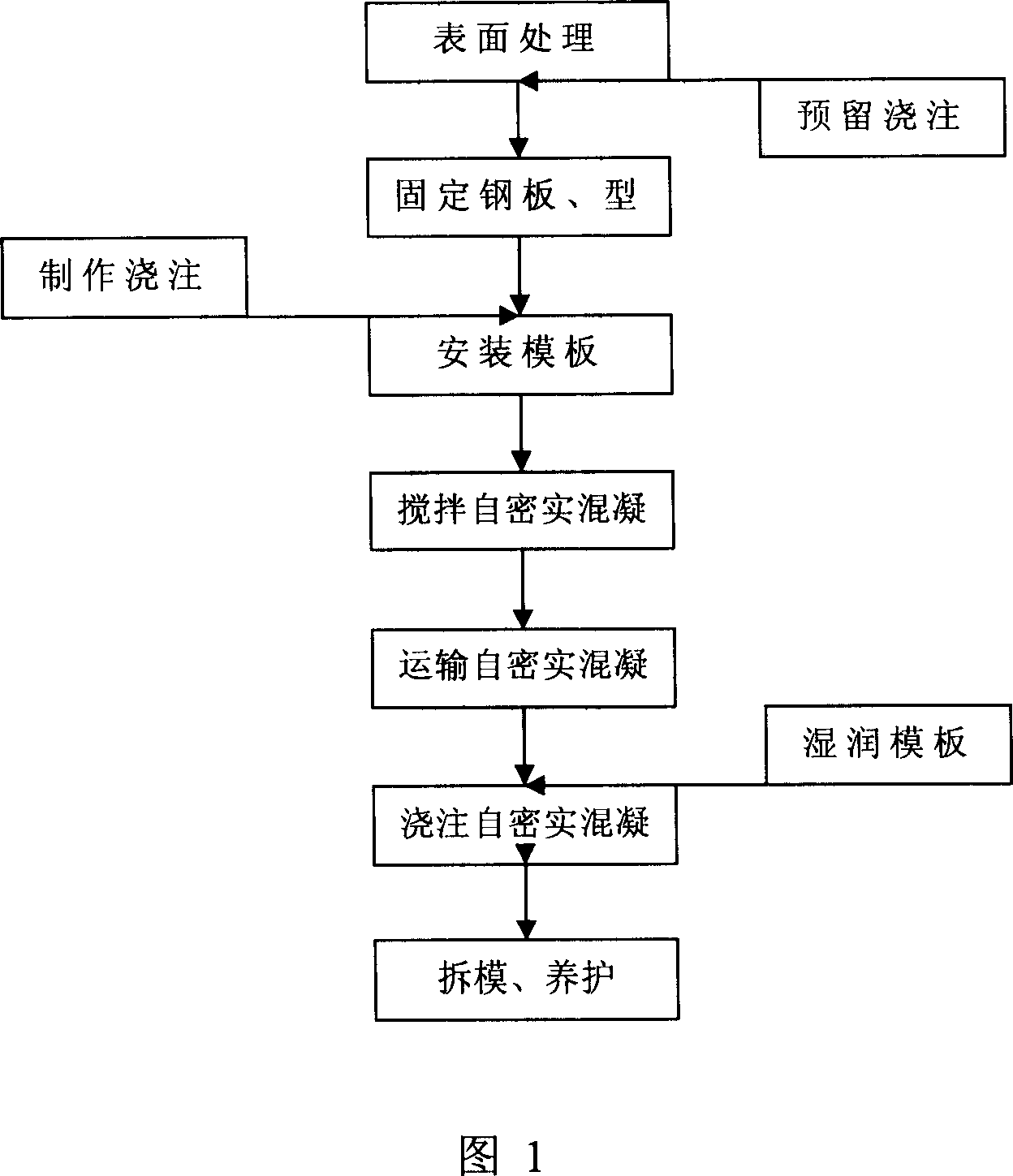

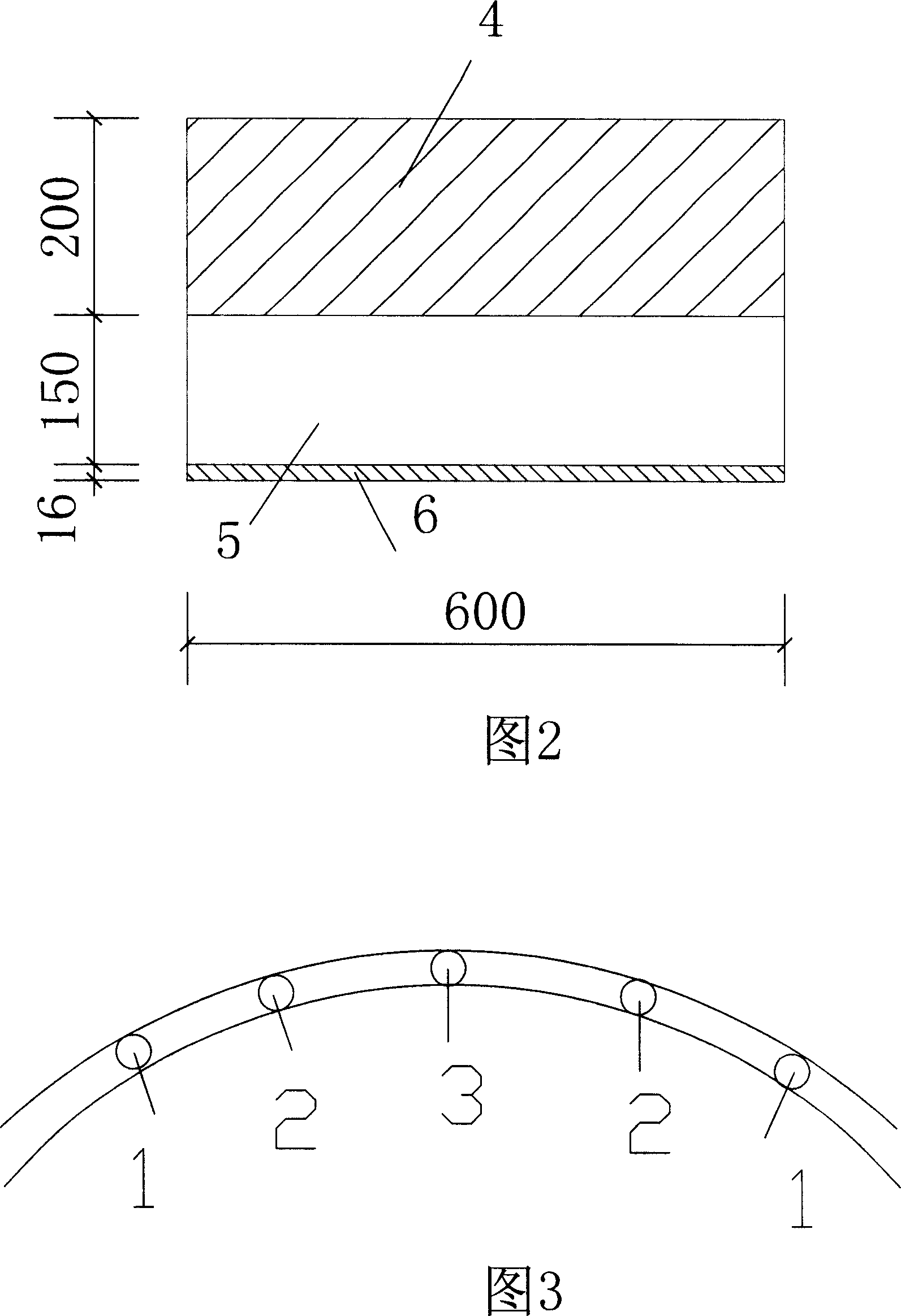

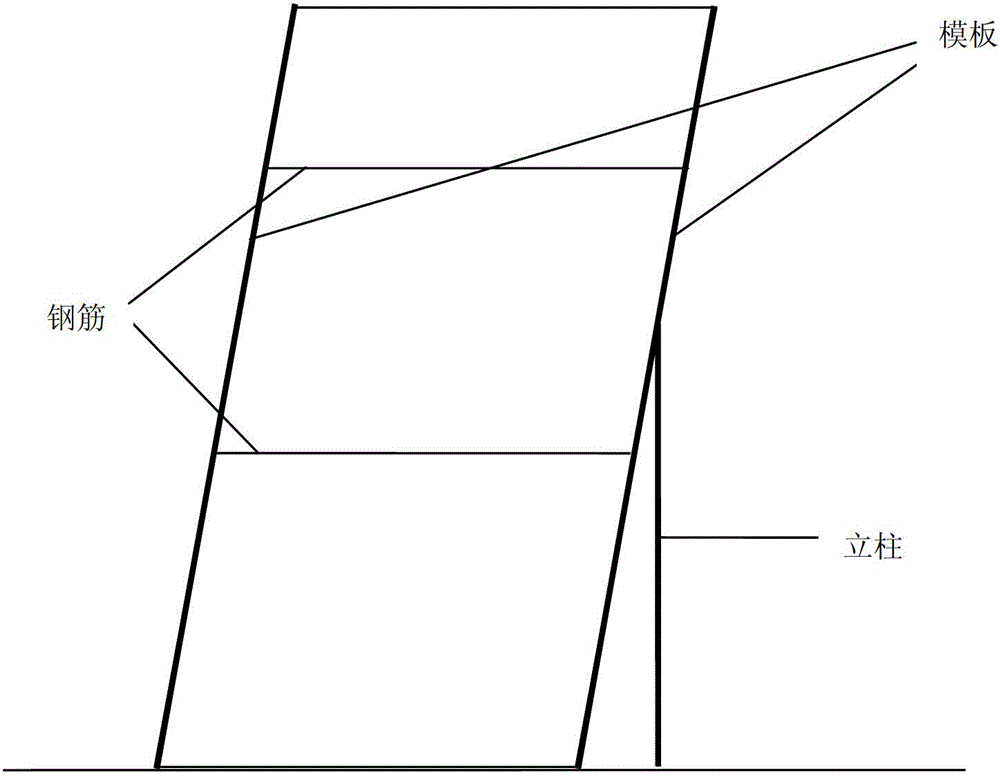

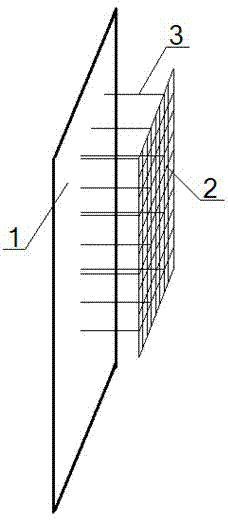

Transformation and construction method used for facing bare concrete of existing building outer wall

ActiveCN103470067AMeet the stiffness requirementsEasy to fixBuilding repairsForms/shuttering/falseworksRebarMaterials science

The invention discloses a transformation and construction method used for facing bare concrete of an existing building outer wall. The method comprises the steps of processing of a formwork, binding of reinforcing steel bars, installation of bare formwork, casting of the bare concrete, removal of the bare formwork, maintenance of the bare concrete, cutting of visible joints, blocking and repairing of split bolt holes and coating of protective paint. According to the method, a steel formwork of which the inner surface is attached to a stainless steel board servers as the bare formwork,, reinforcing steel bar meshes serve as structural bars, the self-compaction bare concrete serves as a bare concrete mixture, and the construction of a thin-type bare concrete faced wall is finished in the mode that many times of rolling over construction are conducted from the bottom to the top of the existing building outer wall. The method not only improves the appearance quality of the bare concrete, but also ensures close integration between the newly-cast bare concrete and the existing building outer wall.

Owner:WUDA JUCHENG STRUCTURE CO LTD

Self-compacted concrete of resisting erosion of sulfate and its preparing method

The invention relates to a sulfate corrosion-resistant self-compacted concrete and the preparing method, adopting fly ash, slag and siliceous dust and cement as concrete cementitous material and adding in water reducer and thickening agent to prepare a high-fluidity self-compacted concrete. And the components in the concrete which are corroded by sulfate are remarkably reduced so as to reduce possibility of corrosion to the concrete. And the concrete has high fluidity, slump above 25 cm, extensibility above 60 cm, and blocking ratio above 0.8; and the corrosion test of above 9 months with 10% sodium sulfate solution shows that compressive ratio is above 0.8 and the surface is complete. And the preparing method is simple, and has low cost and wide application.

Owner:TONGJI UNIV

Steel-self dense concrete built-up construction reinforcing means

InactiveCN101096885AIncrease bearing capacityIncrease stiffnessBuilding repairsSurface finishingStructuring element

The invention discloses a fastening method of steel-self density concrete composite construction, which is characterized by the following: adopting steel-concrete composite structure; adopting self density concrete on concrete material; proceeding original concrete structure element surface treat; assembling steel; stirring and casting self density concrete; demoulding; curing. This invention possesses simple and stable construction, which can increase bearing capacity, stability and fatigue resistance property of the concrete structure.

Owner:CENT SOUTH UNIV

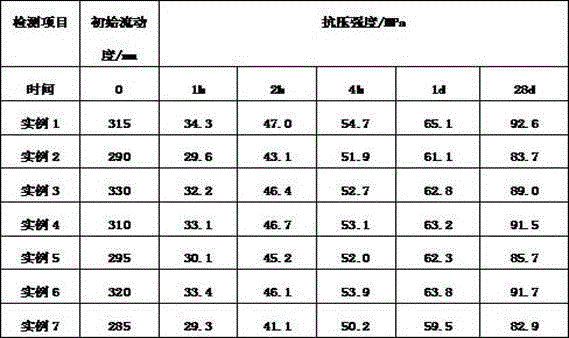

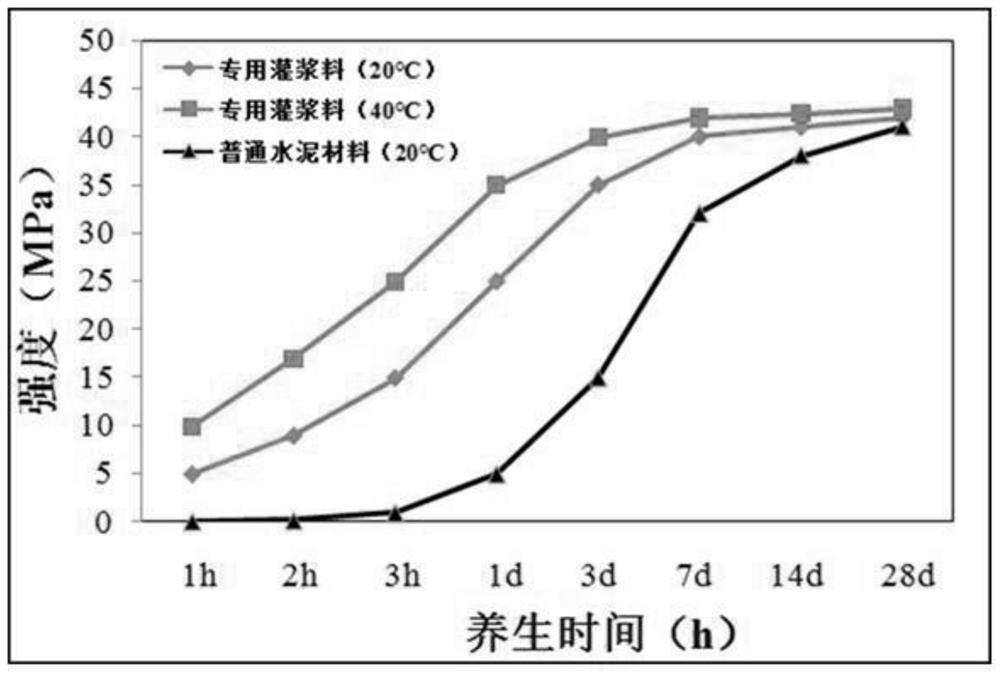

Super early-strength mortar

The invention discloses super early-strength mortar. The key point of the technical scheme is that the super early-strength mortar is prepared from the following components in percentage by weight: 40-50% of an inorganic bond material, 1-3% of an enhancer, 45-55% of aggregates, 0.3-1.5% of an early-strength agent, 0.05-0.4% of a retarder, 0.1-0.5% of a water reducer and 0.03-0.15% of anti-cracking fibers. The invention provides the super early-strength mortar which does not bleed or shrink and is high in liquidity; in addition, the 1h compressive strength can reach 30MPa and the long-term strength is not decreased.

Owner:苏州大乘环保新材有限公司

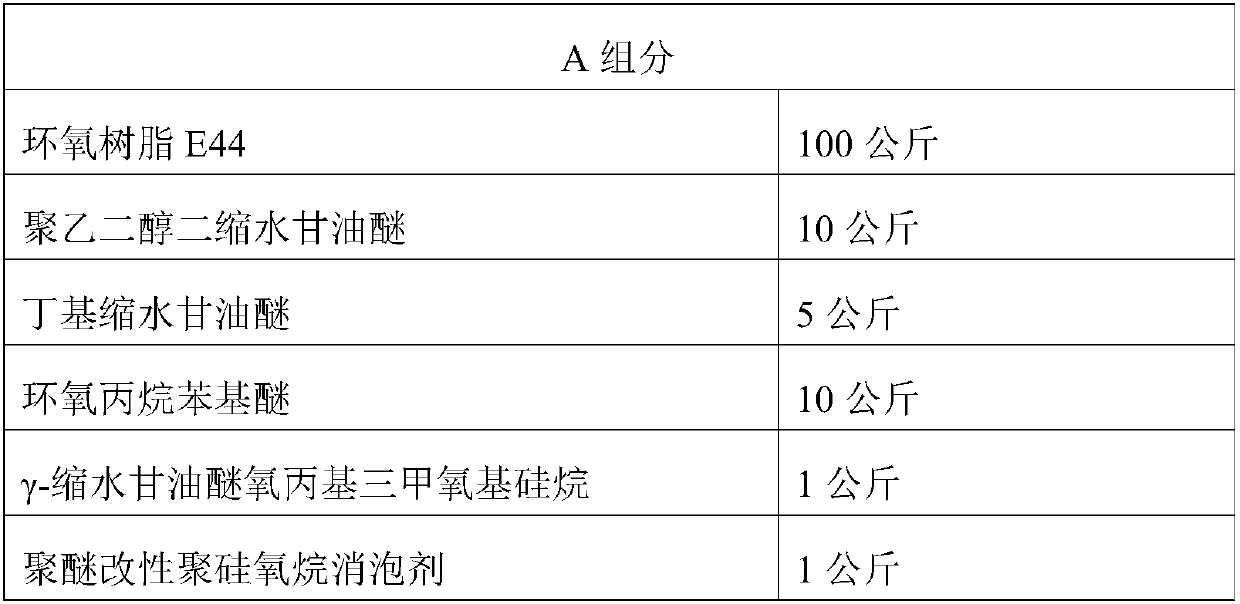

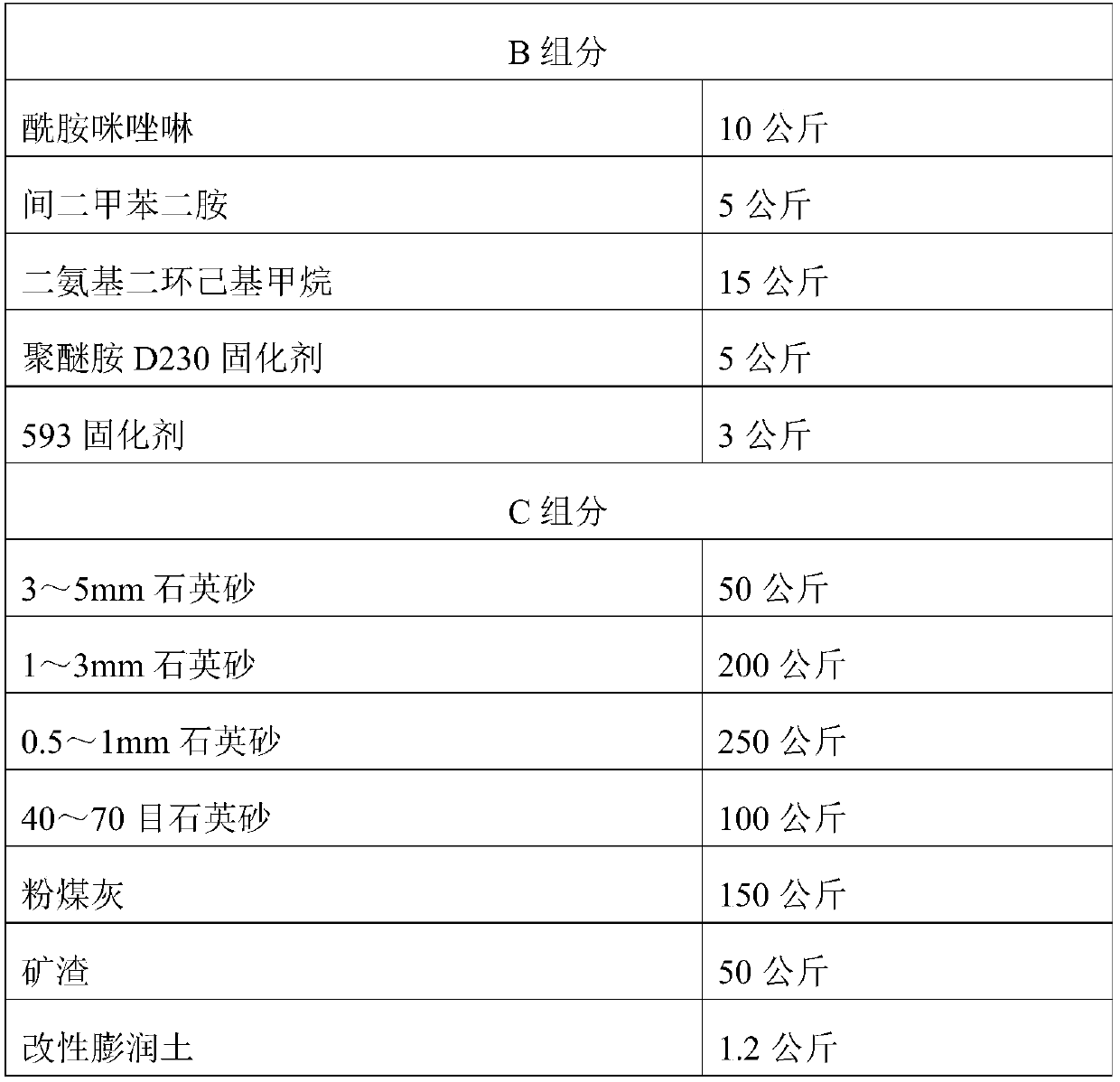

High-strength high-mobility epoxy resin grouting material and preparation method thereof

ActiveCN108047657AGood mechanical properties and medium corrosion resistanceSimple production processDiamineDefoaming Agents

The invention discloses a high-strength high-mobility epoxy resin grouting material and a preparation method thereof. The high-strength high-mobility epoxy resin grouting material comprises componentA, component B and component C; the component A comprises, by weight, 100 parts of epoxy resin, 5-30 parts of a diluent, 1-2 parts of a coupling agent and 0.5-2 parts of a defoaming agent; the component B comprises, by weight, 5-15 parts of aliphatic amide polyamine, 0-10 parts of aliphatic amine containing aromatic rings, 5-20 parts of alicyclic diamine, 0-10 parts of a polyether amine curing agent, and 0-10 parts of 593 curing agent; the component C comprises, by weight, 1-5 parts of a thixotropic agent, 0-100 parts of quartz sand 3-5 mm, 0-300 parts of quartz sand 1-3 mm, 0-400 parts of quartz sand 0.5-1 mm, 100-400 parts of quartz sand 40-70 mesh, 150-400 parts of flyash, and 0-100 parts of mineral waste. The high-strength high-mobility epoxy resin grouting material has high strength and mobility; by adjusting powder ratio and addition, the high-strength high-mobility epoxy resin grouting material can adapt to different grouting thicknesses; the performance of the high-strength high-mobility epoxy resin grouting material can be improved, and the requirement for better simplicity and environmental friendliness in production can also be met.

Owner:BEIJING NEW VISION BUILDING CONSTR TECH +2

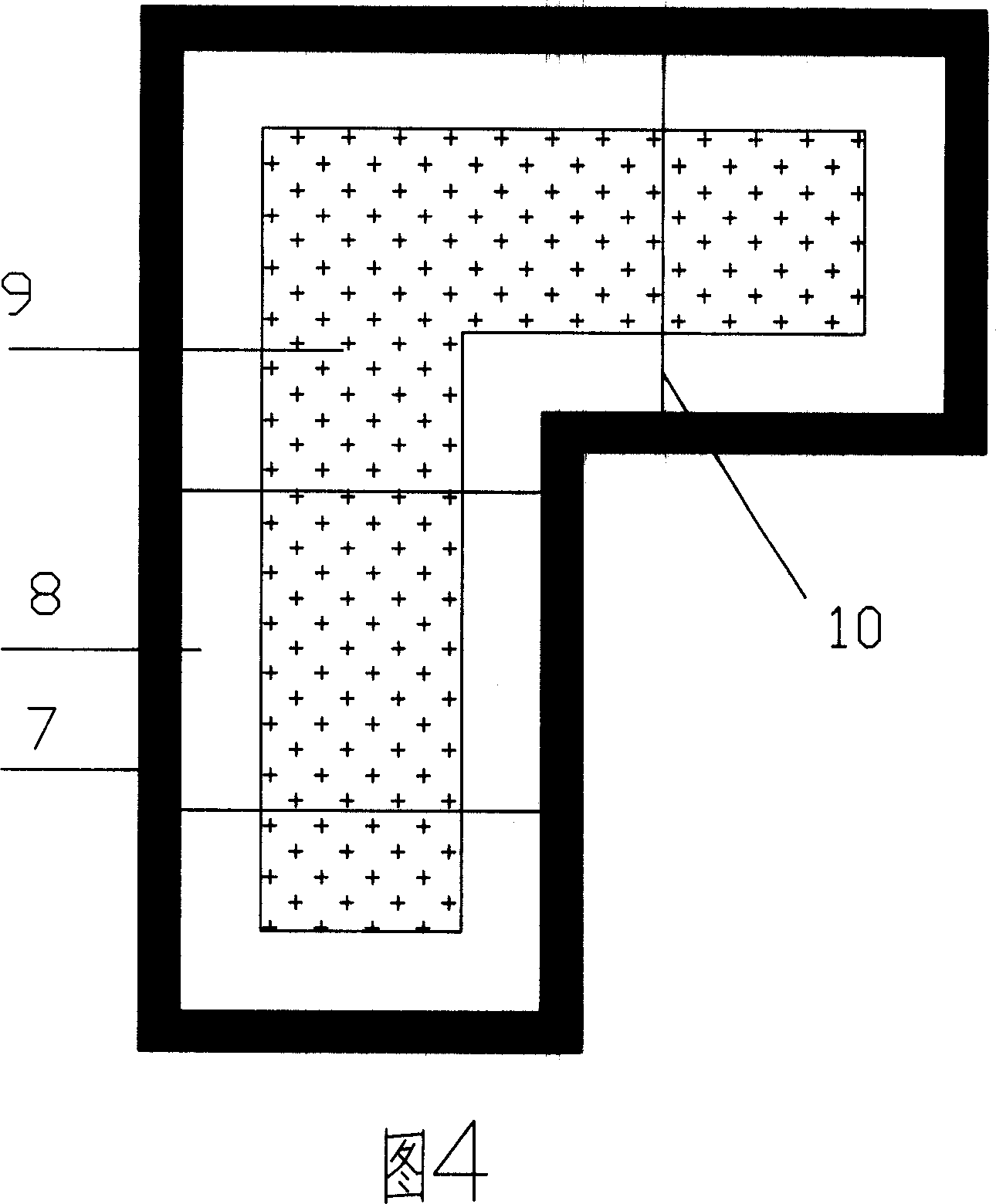

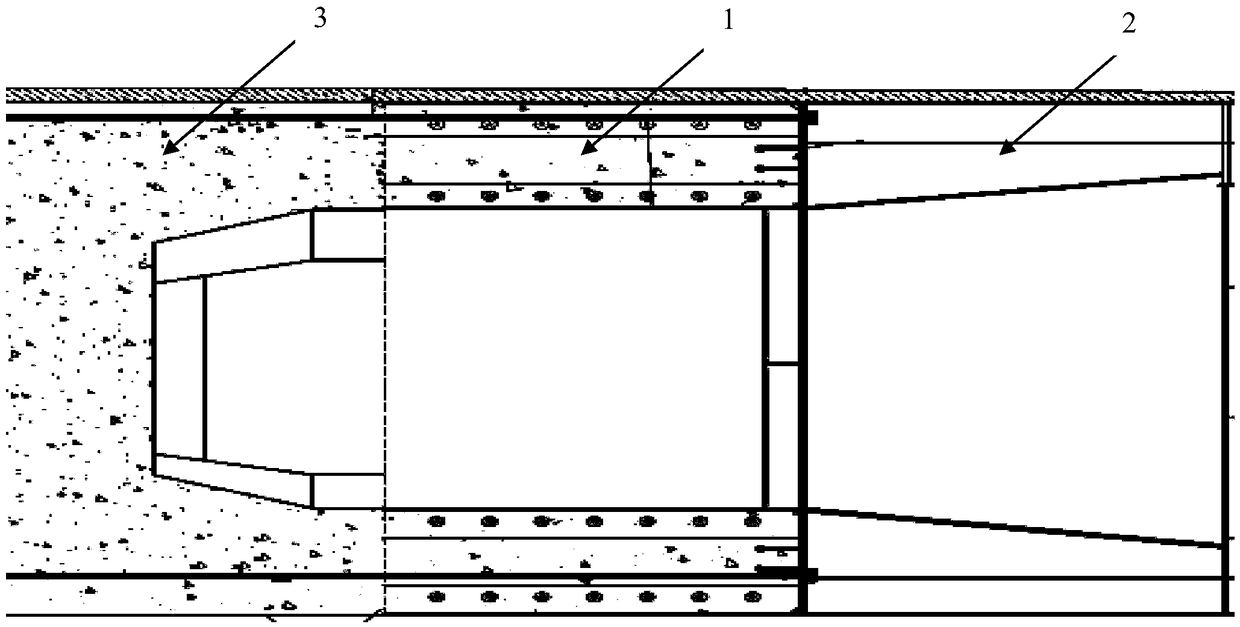

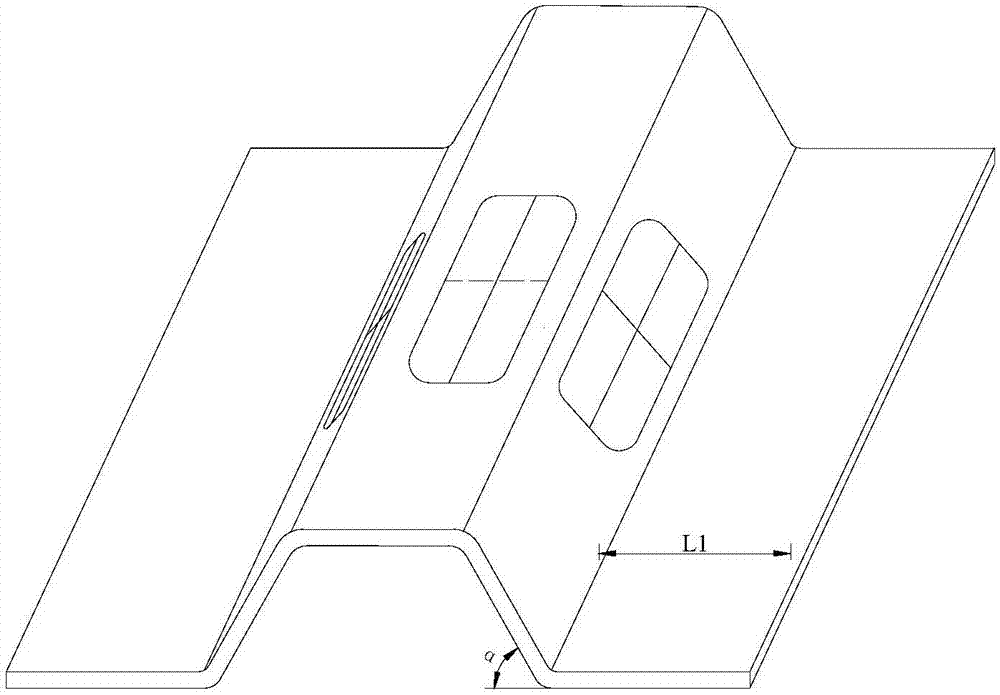

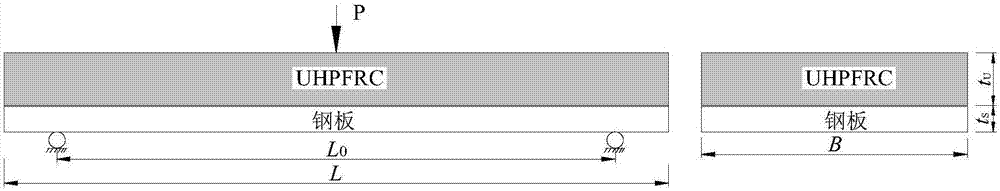

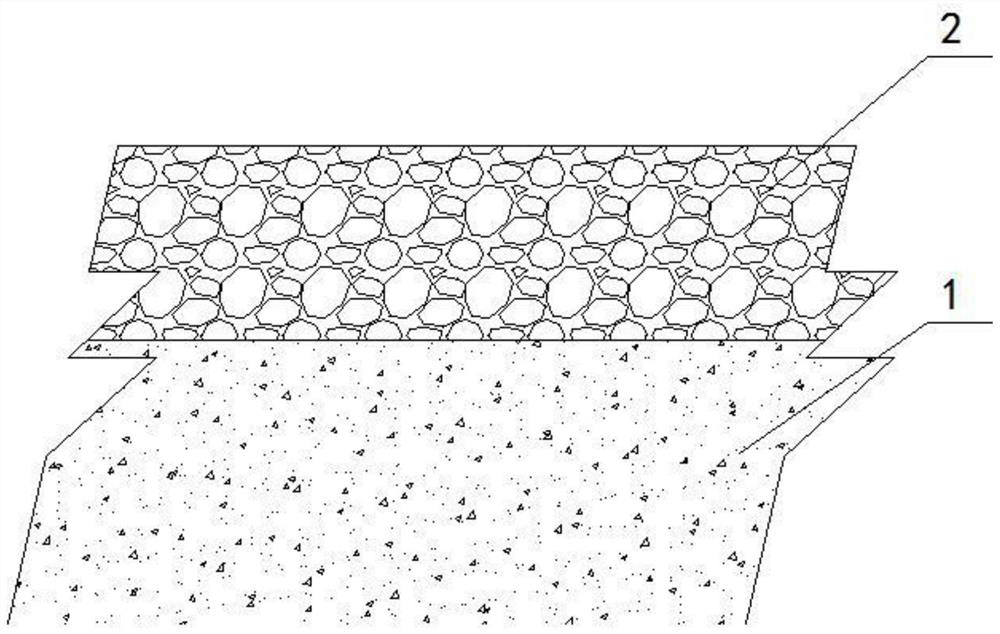

Composite steel fiber-concrete steel bridge deck based on cohesive cotter groups

ActiveCN107237259AHigh compressive strengthHas tensile strengthBridge structural detailsBridge deckHigh pressure

The invention provides a composite steel fiber-concrete steel bridge deck based on cohesive cotter groups. The preparation method comprises the following steps that 1, cleaning and shot blasting are conducted on the cover plate of the steel bridge deck by means of a high-pressure air gun; 2, cotter connecting components are arranged on the cover plate of the steel bridge deck in a bonding mode; 3, a fiber-concrete pavement layer is casted on the cover plate of the steel bridge deck with the cohesive cotter groups and the cotter connecting components in situ. By means of the composite steel fiber-concrete steel bridge deck based on the cohesive cotter groups, the structure stiffness can be improved, the stress amplitude of a fatigue detail place is reduced, and long service life design of an orthotropic steel bridge deck is achieved.

Owner:CHANGAN UNIV

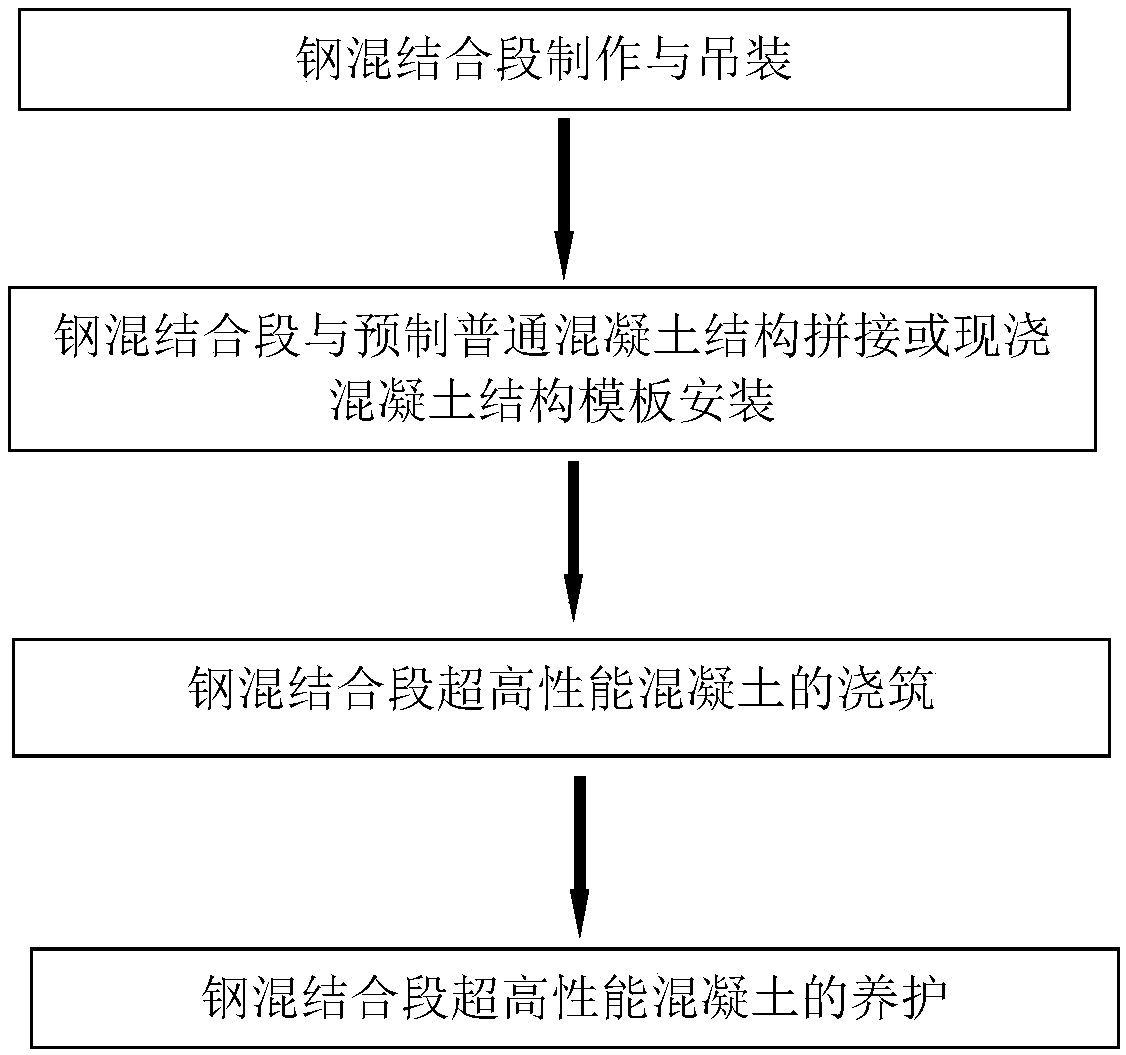

Construction method of steel-concrete joint section

The invention provides a construction method of a steel-concrete joint section, which relates to the field of bridge construction and is carried out according to the following steps: 1) manufacturingand hoisting of the steel-concrete joint section; 2) splice that steel-concrete joint section with the precast ordinary concrete structure or installing the cast-in-situ concrete structure formwork; 3) pour the ultra high performance concrete of the steel-concrete joint section; 4) curing the ultra high performance concrete of the steel-concrete joint section. The invention is fast, convenient, reliable, suitable for the construction of the long-span mixed bridge, greatly shortens the construction period and improves the construction quality.

Owner:HUNAN UNIV +1

Preparation method of super high-early-strength mortar

The invention discloses a preparation method of super high-early-strength mortar, which solves the problems that the high-early-strength mortar is slow in growth and short in operation time and is characterized in that cement, sand, mineral powder, solid early-strength component, liquid early-strength component and tap water are mixed and fully stirred by weight ratio into preferred cementing material, the best ratio of the mineral powder and sulphoaluminate cement is searched, construction aggregate is preferred, and the best ratio of the construction aggregate and the cementing material is researched, the early-strength and setting time are adjusted by the early-strength component and water-reducing and low-setting component, the weight ratio of the super high-early-strength mortal is finally determined as follows: 100 parts of the cement, 270-290 parts of the sand, 45-55 parts of the mineral powder, 5-7 parts of the early-strength component, 6-9 parts of the water-reducing and low-setting component, and 45-50 parts of the tap water, and the super high-early-strength mortar prepared by the preparation method is fast in strength growth, is good in concretion fluidity, is long in operation time, is wide in application and can be applied to occasions of the site repair with time limit.

Owner:阳泉昌达混凝土搅拌站

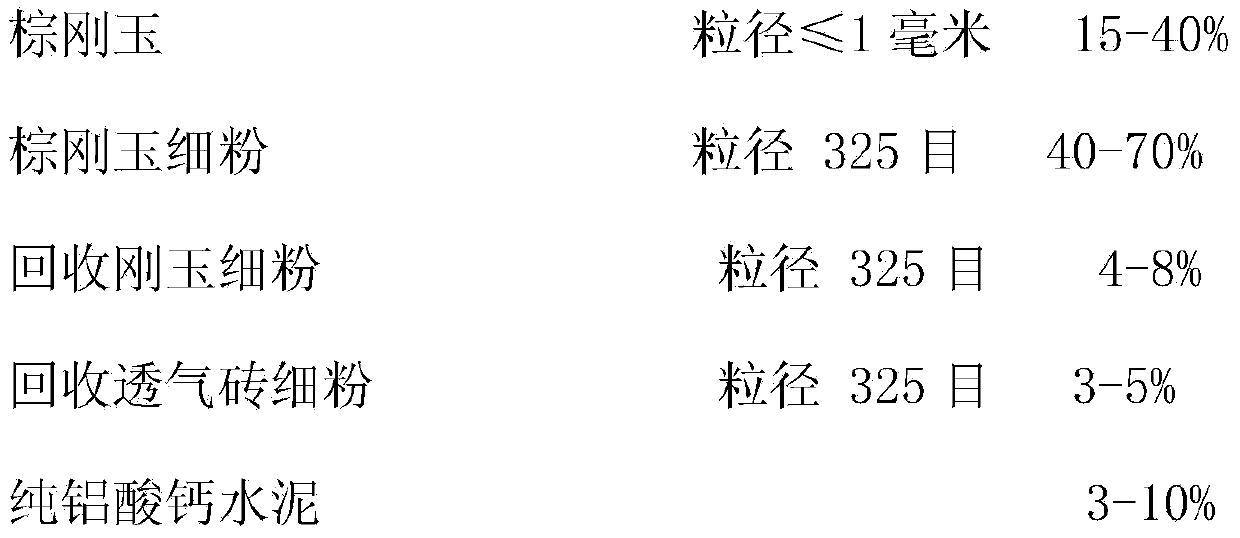

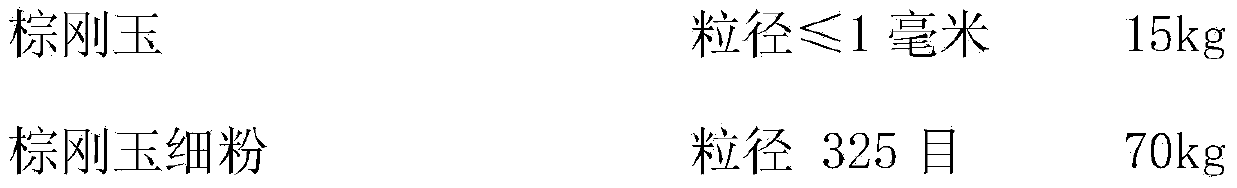

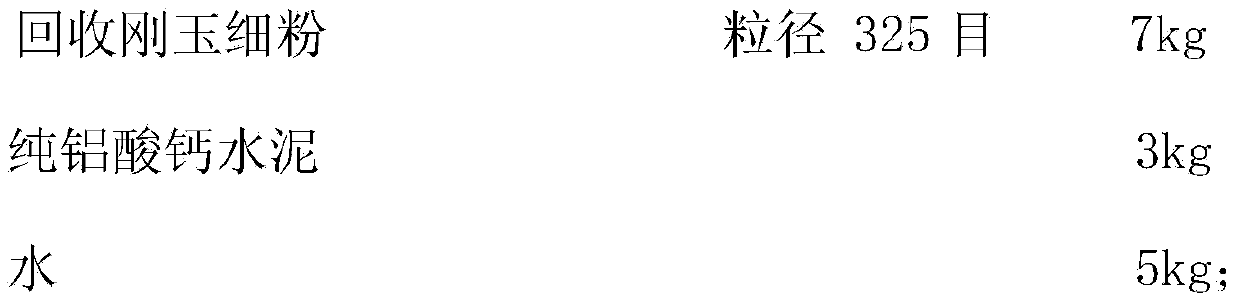

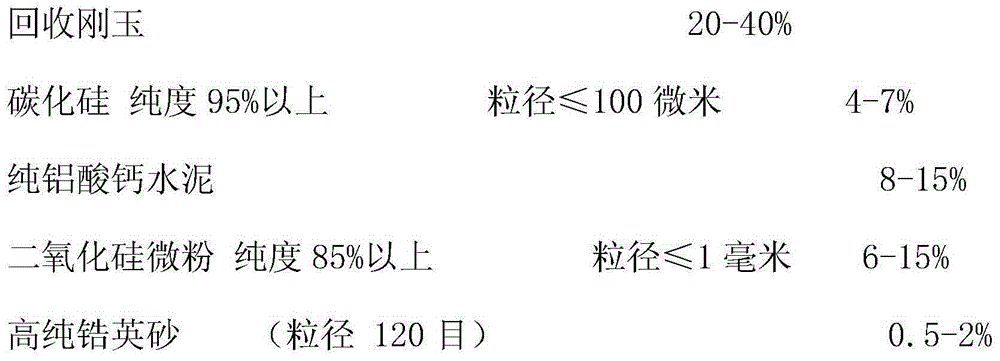

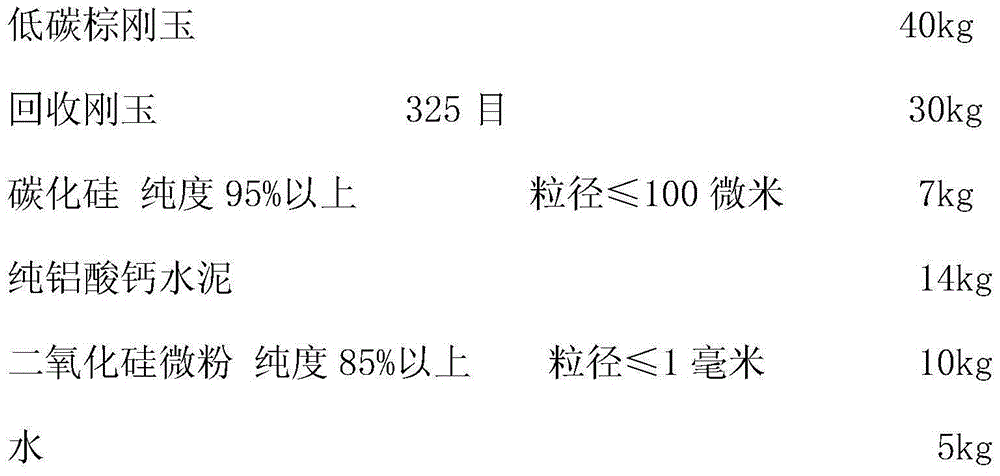

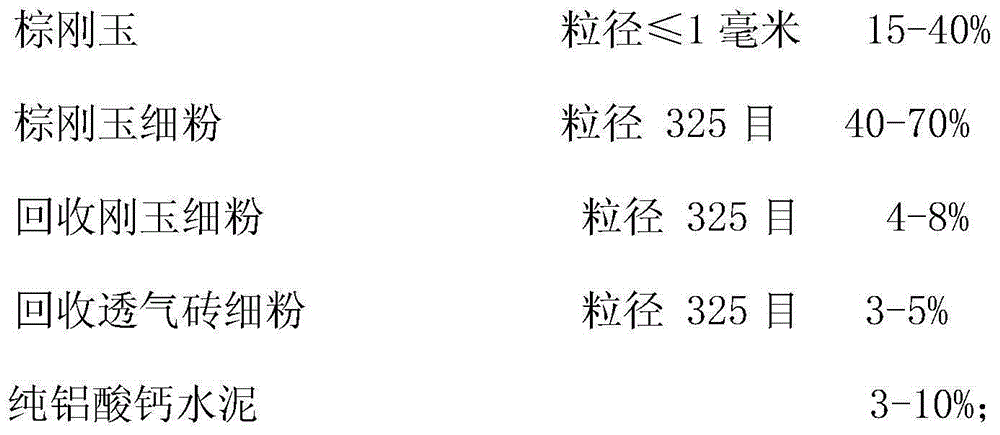

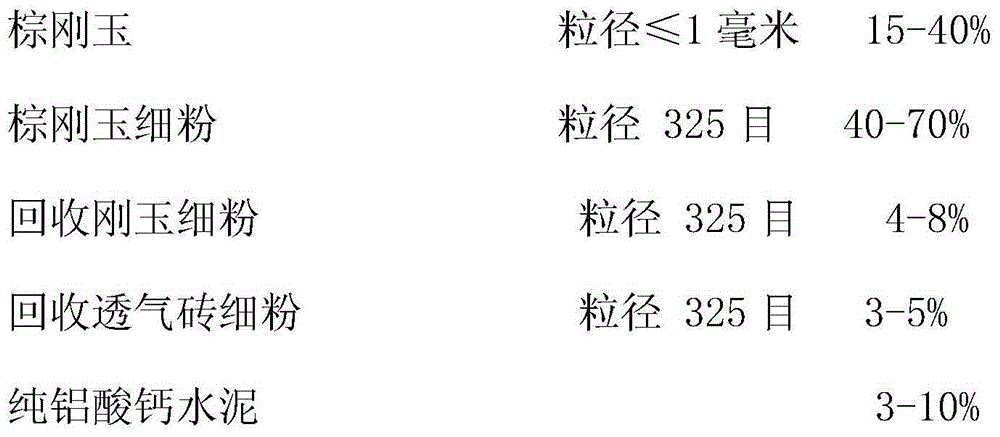

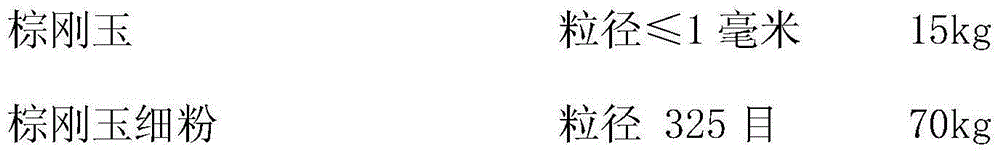

Special corundum self-flowing casting material for stainless steel ladle and construction method of special corundum self-flowing casting material

The invention discloses a special corundum self-flowing casting material for stainless steel ladle and a construction method of the special corundum self-flowing casting material. The special corundum self-flowing casting material comprises the following components in percentage by weight: brown corundum, fine brown corundum powder, recycled fine corundum powder, recycled fine air brick powder and pure calcium aluminate cement, and a dispersing agent and water further need to be added in construction. In construction, a mold needs to be constructed, the water, the dispersing agent and the self-flowing casting material which are well stirred are poured into the mold, and the material can flow through any surface, can be filled in any space and can be rapidly bonded with residual materials. The special corundum self-flowing casting material for stainless steel ladle, which is disclosed by the invention, is good in high-temperature resistance and can meet the high-temperature condition of the stainless steel ladle.

Owner:HUZHOU AONENG CHARGING

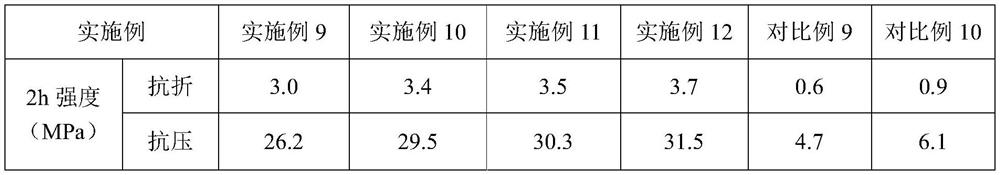

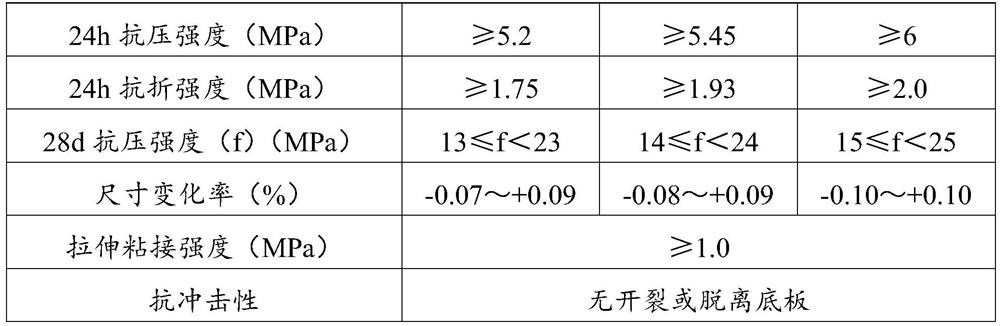

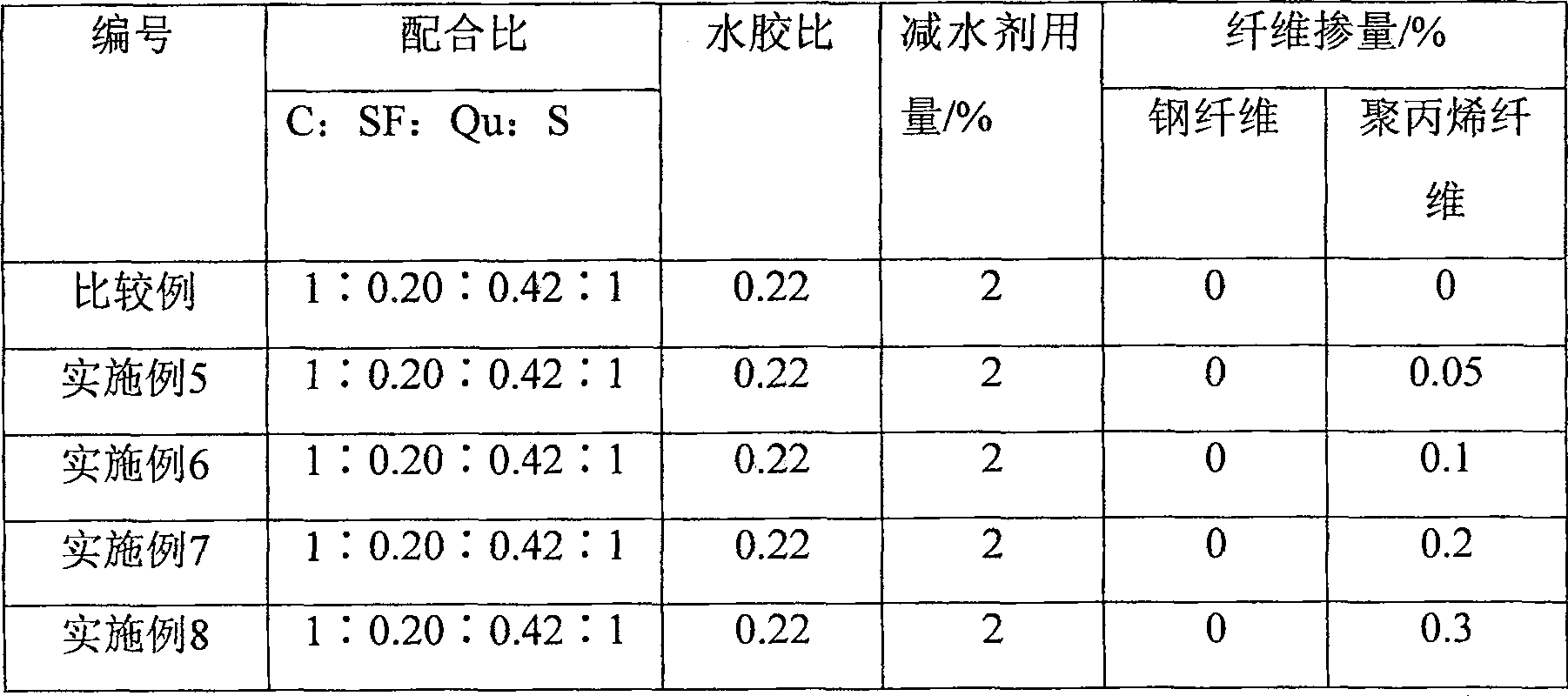

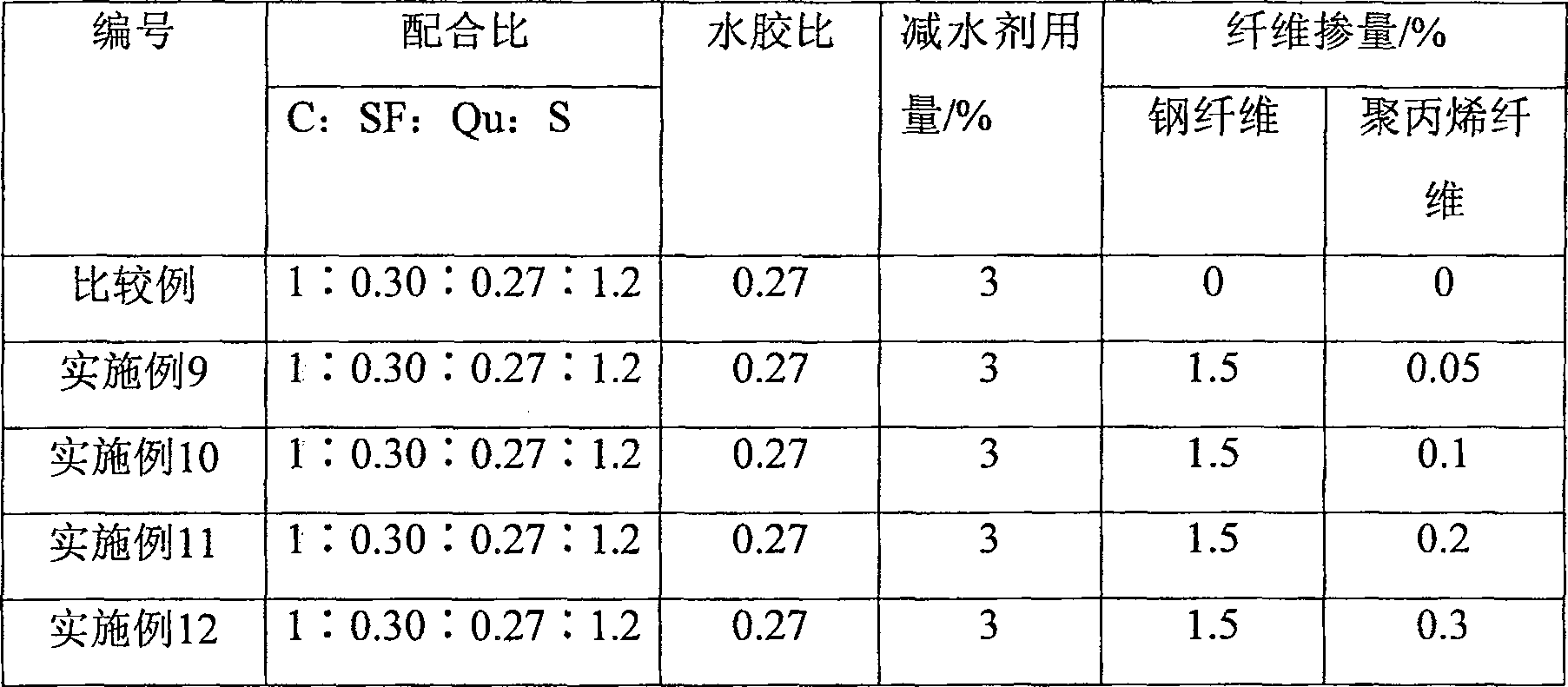

Large-flow-state cement-based grouting material for semi-flexible pavement and preparation method of large-flow-state cement-based grouting material

ActiveCN113135723AGive full play to the "ball effect"Improve mobilitySolid waste managementAluminateRoad engineering

The invention discloses a large-flow-state cement-based grouting material for a semi-flexible pavement and a preparation method of the large-flow-state cement-based grouting material. The large-flow-state cement-based grouting material comprises the components in parts by weight: 35-60 parts of quick-hardening sulfoaluminate cement, 15-40 parts of modified microbeads, 10-30 parts of fine aggregate, 0.01-0.3 part of an early strength agent, 0.1-0.5 part of a water reducing agent, 0.05-0.2 part of a water-retaining agent, 0.001-0.1 part of a defoaming agent, 4-5.5 parts of an expanding agent and 20-35 parts of water. Through cooperative matching of the components, on the basis of relatively high hour strength, the performance improvement of high fluidity, high flow velocity and high pouring rate is realized, and the concrete has the advantages of short construction period, no need of vibration, convenience in construction, high cost performance and the like, and meets the requirement of rapid traffic opening in road engineering.

Owner:CHINA CHEM TRANSPORTATION CONSTR GRP NO 4 ENG CO LTD +2

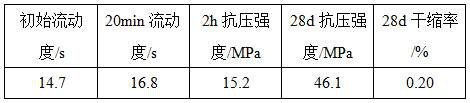

Self-compacting reactive powder concrete as well as preparation method and application thereof

The invention relates to self-compacting reactive powder concrete as well as a preparation method and application thereof. The self-compacting reactive powder concrete is mainly prepared from the following components, in parts by mass: 100 parts of cement, 20-25 parts of silica fume, 10-20 parts of fly ash, 4-6 parts of microbeads, 30-40 parts of quartz powder, 80-200 parts of quartz sand and 3-6parts of a water reducing agent. The self-compacting reactive powder concrete combines the advantages of self-compacting concrete and reactive powder concrete, has higher strength and durability and excellent cohesiveness, is suitable for the harsh corrosive environment in coastal areas, and provides great convenience in cast-in-place construction.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

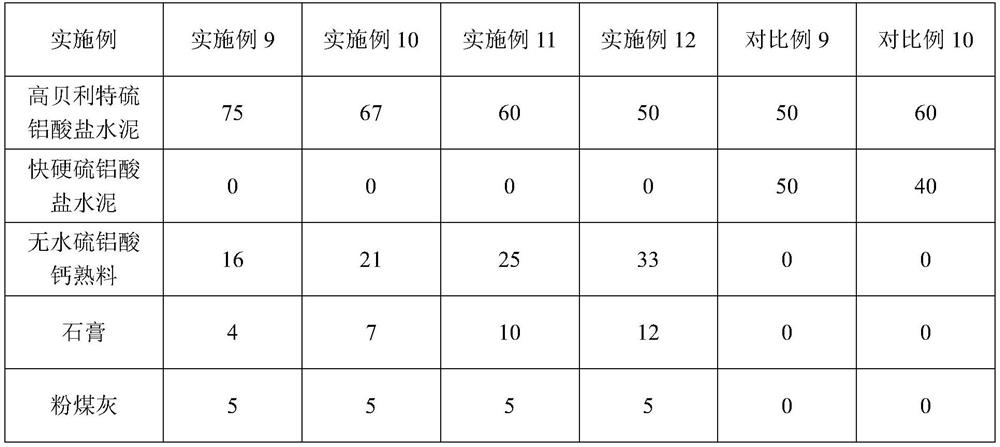

High-performance self-compacting concrete and preparation method thereof

The invention relates to high-performance self-compacting concrete and a preparation method thereof. The high-performance self-compacting concrete is prepared from 40 to 90 parts of high belite sulphoaluminate cement, 5 to 40 parts of anhydrous calcium sulphoaluminate clinker, 1 to 15 parts of gypsum, 5 to 15 parts of fly ash, 0.3 to 1.5 parts of water reducing agent, 0.02 to 0.1 part of early strength agent, 0.1 to 5 parts of fiber, 0 to 1 part of retarder, 0.05 to 5 parts of stabilizer, 0.02 to 0.5 part of defoaming agent, 24 to 35 parts of water, 60 to 300 parts of fine aggregate and 80 to 200 parts of coarse aggregate. The material has good self-compacting performance and high volume stability, can be rapidly hardened in a negative temperature environment of-5 DEG C, and is simple and convenient to construct.

Owner:HANGZHOU ROADMENDER TECH CO LTD

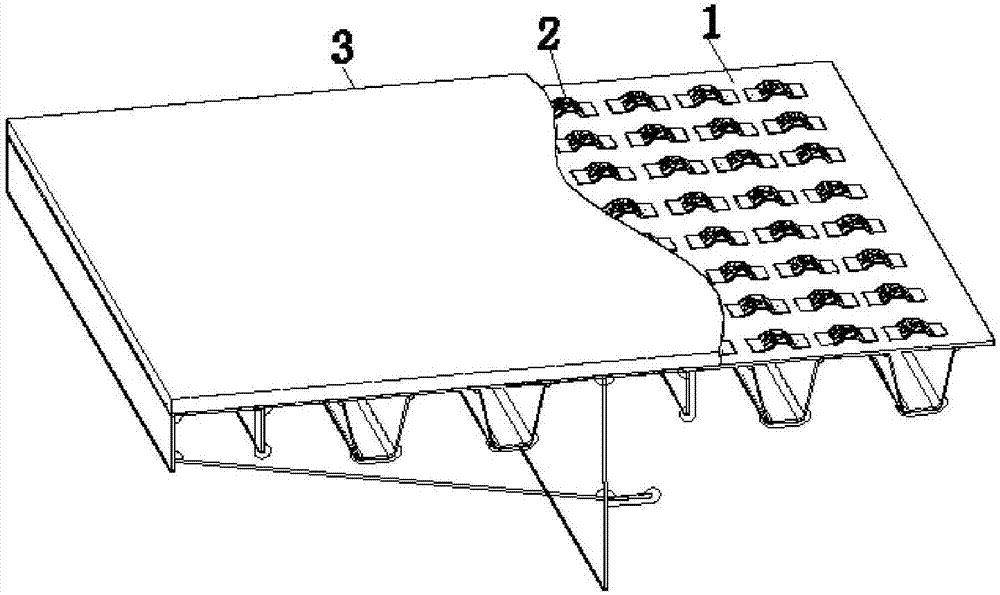

Adhesive zigzag piece-based steel fiber concrete assembled steel bridge panel

ActiveCN107201720AAvoid Fatigue DetailsEasy to combineSolid waste managementMaterial strength using tensile/compressive forcesFiberAdhesive

The invention discloses an adhesive zigzag piece-based steel fiber concrete assembled steel bridge panel. The following steps are provided: S1, dedusting and cleaning a steel bridge panel cover plate through a high pressure air gun; S2, adhering shear connection pieces to the steel bridge panel cover plate, wherein a longitudinal distance between every two adjacent shear connection pieces is 10 to 20 cm, and a transverse distance is 8 to 15 cm; S3, casting in situ ultrahigh-performance steel fiber concrete spreading layers on the steel bridge panel cover plate and the shear connection pieces. According to a design method disclosed by the invention, on the basis of considering the gravity of a structure, the local rigidity of the structure is enhanced, the fatigue stress level at a fatigue detail position is lowered, and the performance of the spreading layers is optimized; the design method is the most economic and effective design method in the field of design methods.

Owner:CHANGAN UNIV

Production process for producing flow-state self-compacting backfill solidified soil by using solidifying material, application and equipment thereof

PendingCN114716205AReduce shippingReduce the storage areaSolid waste managementEmbankmentsPtru catalystSoil science

The invention discloses a production process, application and equipment for producing flow-state self-compacting backfill solidified soil by using a solidifying material, which comprises the following steps: taking soil, sludge and building residue soil as main solidifying materials, taking a catalyst and a solidifying agent as catalytic materials, taking tailings such as Portland cement, fly ash, phosphogypsum and lithium slag as auxiliary cementing materials, and adding a certain proportion of water, the mixture which has flowability and self-compaction performance and has certain strength and impermeability after being cured is formed, and the mixture can be widely applied to fertilizer groove backfilling, foundation reinforcement, road subgrade backfilling, mine goaf backfilling, municipal pipe gallery backfilling and wall decoration; according to different requirements of component properties of soil and strength of a finished product, the mass percent of each component material is as follows: 70-80% of soil; 5%-10% of a catalyst; 0.05% to 0.10% of a curing agent; 10%-20% of an auxiliary cementing material; the flowability and the water required by the reaction process are met. The material not only has high strength, but also has good flowability and water stability, is convenient to construct, is green and environment-friendly, and has a good application prospect.

Owner:中建三局四川建筑装备有限公司 +1

Grouting reinforcement method of dam foundation rock mass

The invention discloses a grouting reinforcement method of a dam foundation rock mass. The grouting reinforcement method of the dam foundation rock mass comprises the following steps that a hollow pile is prefabricated, specifically, the hollow pile is prefabricated in a factory, a through hole is concentrically formed in the hollow pile, and grout outlet holes are formed in the outer circle of the hollow pile at intervals in the height direction; a reinforcing cage is fabricated, specifically, the cylindrical reinforcing cage is fabricated in the factory or a construction site; drilling is carried out, specifically, the drilling is carried out at a dam foundation to obtain a pile hole; assembling is carried out, specifically, the reinforcing cage is lifted into the pile hole; and grouting is carried out, specifically, high-pressure expanded concrete is poured inward through the through hole of the hollow pile, so that the expanded concrete overflows from the grout outlet holes, and part of the expanded concrete penetrates into gaps of the inner wall of the pile hole. According to the grouting reinforcement method of the dam foundation rock mass, the prefabricated hollow pile is specially designed, and through the cooperation of the hollow pile and the reinforcing cage, a composite pile body is obtained by utilizing the cast-in-situ expanded concrete, and thus the integrity of the composite pile body and the dam foundation rock mass is strengthened.

Owner:SHAZHOU PROFESSIONAL INST OF TECH +2

Liquefied consolidation material and preparation method thereof

The invention belongs to the field of comprehensive utilization of solid wastes, and particularly relates to a liquified consolidation material and a preparation method thereof. Solid wastes in industry, mining and construction industries as raw materials, a low-activity composite cementing material, a filling material, pulping liquid and an additive are prepared into a vibration liquefied consolidation material which is uniform in macrocosmic and microcosmic, large in flow state and capable of being pumped through a vibration stirring process. The liquified consolidation material has the advantages of being high in mobility, free of backfilling dead corners, self-hardening, free of vibration during forming, high in strength, anti-seepage, anti-seismic, stable in size, environmentally friendly and the like, is suitable for backfilling of fertilizer grooves, pipe culverts, cavities and abutment backs, reinforcing of building foundations, filling of road roadbeds, reinforcing and seepage prevention of river channels, lakes and coastline embankments and the like, and solves the problems that the space is narrow, tamping of special-shaped end faces is uneven, non-excavation cavity backfilling is not in place, and traditional stirring equipment for the flow-state solidified soil is not uniform in stirring.

Owner:河南绿岩工程科技有限公司

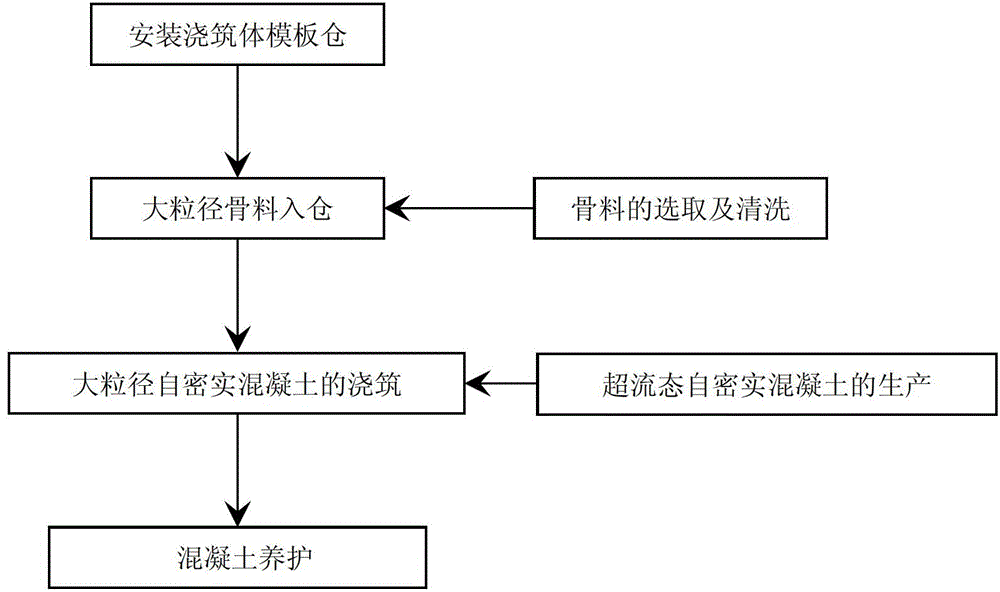

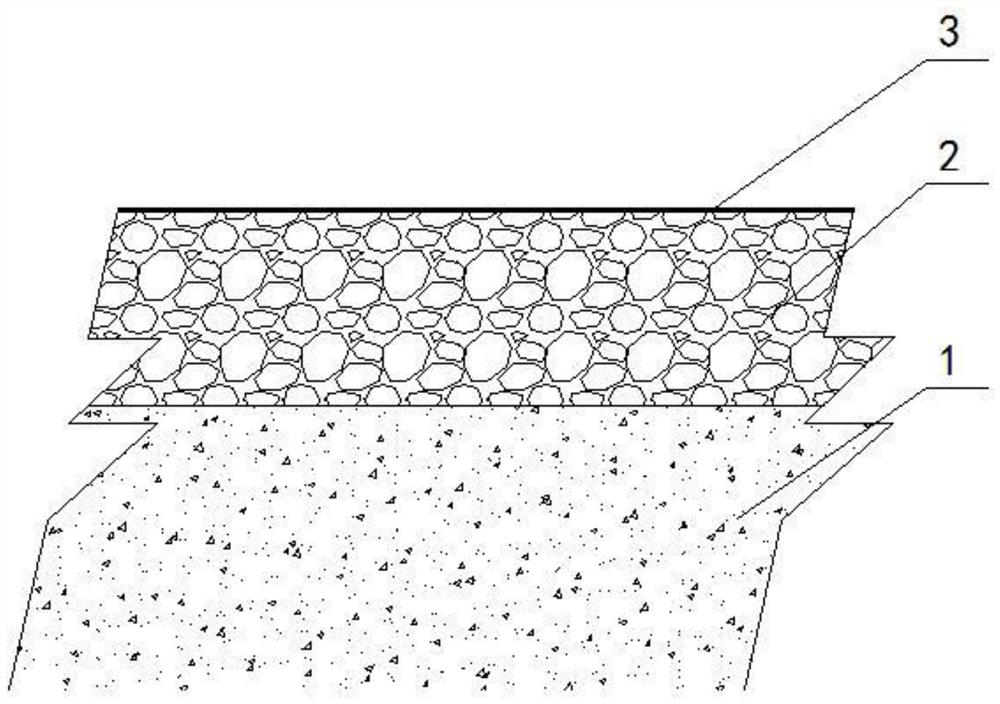

Block stone/chip stone self-compaction concrete

The invention discloses block stone / chip stone self-compaction concrete. The block stone / chip stone self-compaction concrete is characterized in that block stone / chip stone is directly placed in a construction bin to form a chip stone body, wherein the accumulation rate of the chip stone is 50-60%; and then superfluid self-compaction concrete is poured on the chip stone body and is hardened so as to obtain the block stone / chip stone self-compaction concrete, wherein the slump SL of the superfluid self-compaction concrete is greater than or equal to 250 mm and less than or equal to 290 mm, and the slump flow SL is greater than or equal to 650 mm and less than or equal to 800 mm. The block stone / chip stone self-compaction concrete has the advantages of low construction cost, high construction speed, quality assurance, energy conservation and environmental protection.

Owner:GUIZHOU HIGHWAY ENG GRP

A recycled corundum self-flowing castable and its construction method

Owner:HUZHOU AONENG CHARGING

Dynamic gangue concrete used for filling beside gob-side entry retaining

InactiveCN102276221AReduce shrinkage and crackingImprove ultimate compressive strengthSolid waste managementPulverised fuel ashMaterials science

The invention discloses a dynamic gangue concrete for filling beside gob-side entry retention, which is composed of 1000 parts of gangue with a particle size of less than 1.5 cm, 200 parts of ordinary Portland cement, 100 parts of fly ash from a power plant, and 3 hydration agents. part, 2 parts of internal curing agent, 50 parts of non-alkali liquid quick-setting agent and 500 parts of water are uniformly stirred and mixed; the above-mentioned parts all refer to parts by weight; The compressive strength is 6-9Mpa, and the uniaxial compressive strength at 28-day age is 16-24Mpa, which can fully meet the support requirements of gob-side entry retaining.

Owner:XINWEN MINING GROUP

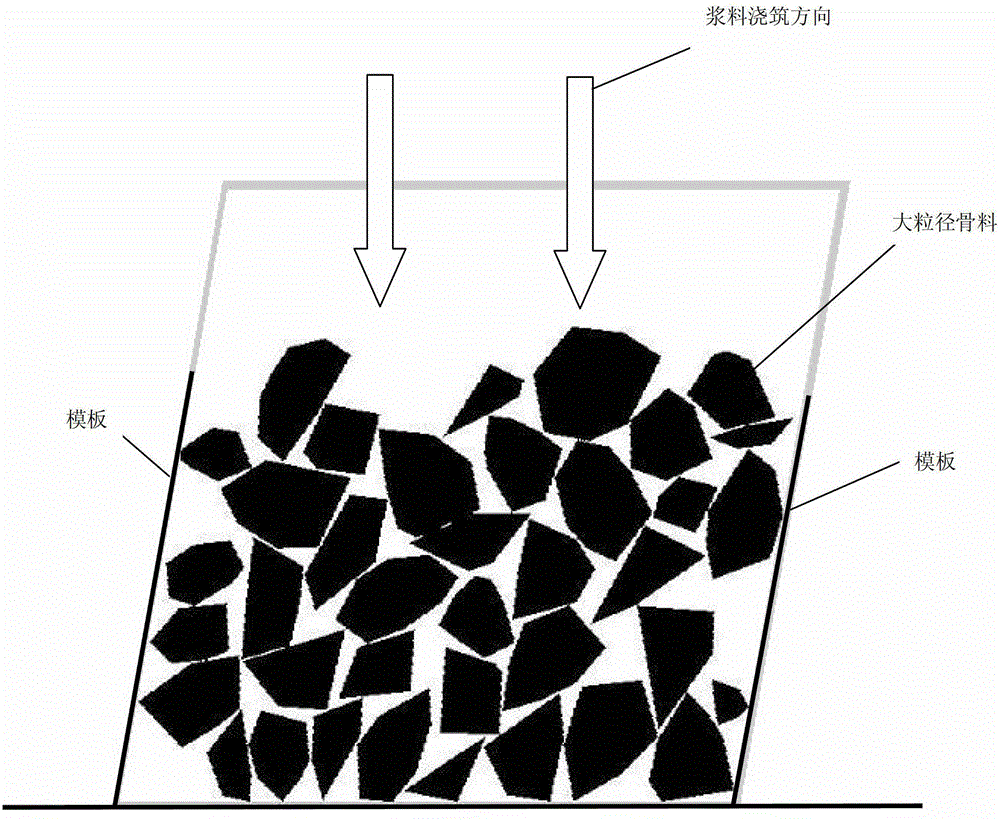

Self-compacting concrete with ultra-large particle size aggregate and its construction technology

The invention relates to a self-compact concrete with oversized-particle aggregate. The self-compact concrete is prepared by pouring large-particle-size aggregate with particle size of 100mm-1500mm and superfluid self-compact concrete slurry, wherein the superfluid self-compact concrete slurry is prepared by adding water into cement, pulverized coal ash, silica fume, dedicated superfluid additive, sand, stones and other mineral admixtures and mixing. The construction technology comprises the steps of directly placing the oversized-particle aggregate into a construction bin to form large-particle-size aggregate accumulation body with certain natural clearances, then pouring the superfluid self-compact concrete slurry on the surface of the large-particle-size aggregate, filling the clearances of the large-particle-size aggregate by means of self gravity, forming a complete, compact and low-hydration-heat concrete structure together with the large-particle-size aggregate after the superfluid self-compact concrete slurry is hardened, wherein the strength grade of the concrete can meet different design demands. The self-compact concrete with oversized-particle aggregate is not only applicable to mass concrete construction, but also applicable to reinforcing bar system engineering.

Owner:GUIZHOU HIGHWAY ENG GRP +1

Novel self-leveling thermal insulation material and preparation method thereof

InactiveCN111646735AReduce plastic shrinkage cracksImprove penetration resistanceCeramicwareFoaming agentThermal insulation

The invention provides a novel self-leveling thermal insulation material and a preparation method thereof. The novel self-leveling thermal insulation material comprises, by mass, 65-75 parts of cement, 11-15 parts of hydrophobic expanded perlite, 7-9 parts of glass beads, 9-13 parts of pottery sands, 5-7 parts of fine aggregates, 10-14 parts of EC-polymer plastering mortar, 3-6 parts of a foamingagent and 2-4 parts of a curing agent. The novel self-leveling thermal insulation material has the advantages of being good in permeation resistance, high in freezing resistance and resistant to abrasion, and also has good constructability and environment-friendly characteristics.

Owner:江苏三友建材科技有限公司

Transformation and construction method used for facing bare concrete of existing building outer wall

ActiveCN103470067BMeet the stiffness requirementsEasy to fixBuilding repairsForms/shuttering/falseworksRebarMaterials science

Owner:WUDA JUCHENG STRUCTURE CO LTD

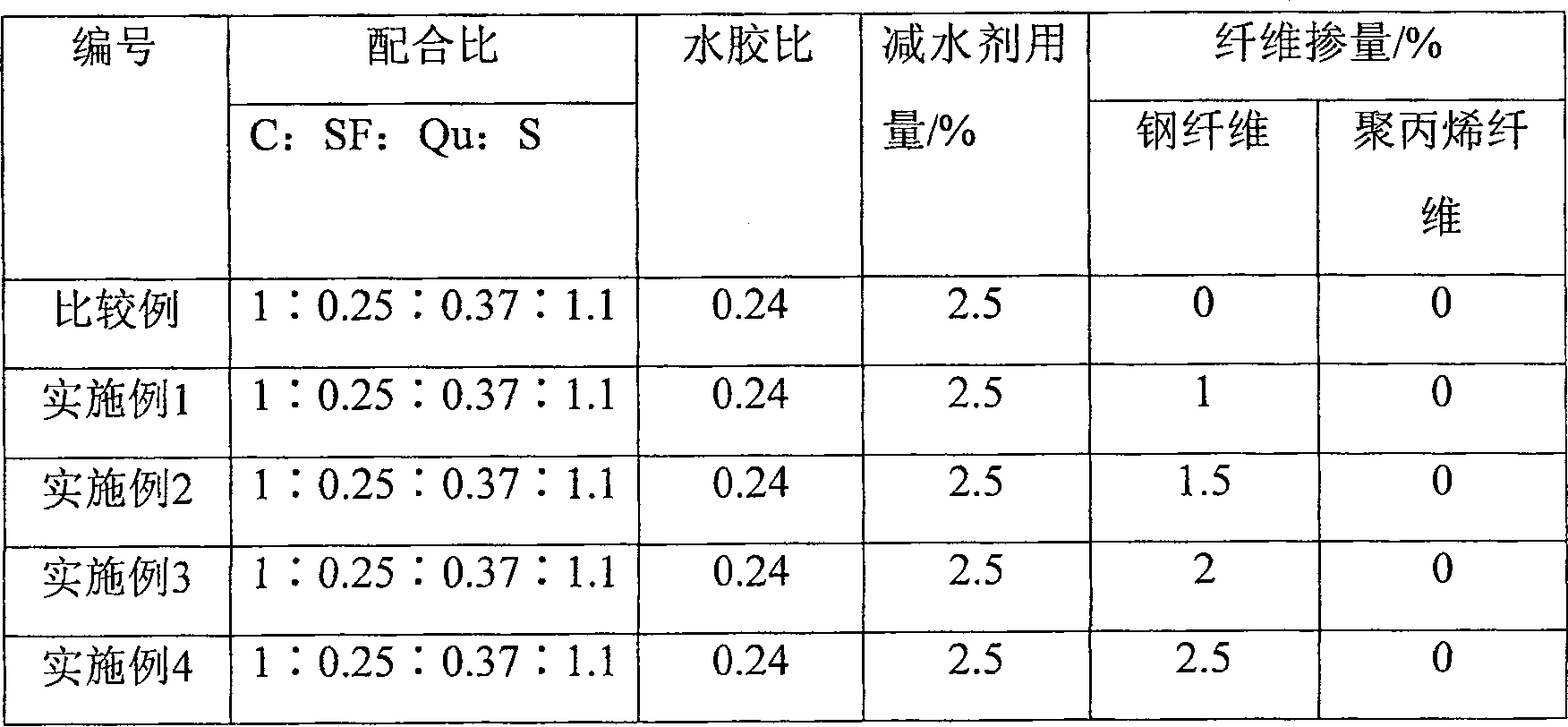

Self-compacting fiber reinforcement active powder concrete and method for making same

ActiveCN100522865CImprove liquidityNo need to vibrateSolid waste managementCompressive strengthUltimate tensile strength

Owner:广东利盈投资集团有限公司

Self compacting high strength mortar

The present invention belongs to the field of building material technology, and is especially one kind of self compacting high strength mortar. The self compacting high strength mortar consists of portland cement, stone powder, silica fume, expansion agent and water reducing agent of polycarboxylate in certain weight proportion. The self compacting high strength mortar with new type of water reducing agent has very low flowability loss, 28 day compressive strength as high as 70-90 MPa and construction convenience and low cost.

Owner:TONGJI UNIV

An integral anti-rutting pavement structure for heavy-duty traffic based on composite materials

The invention discloses a heavy-duty traffic integrated anti-rutting paving structure based on a composite material, and belongs to the technical field of road paving. The paving structure comprisinga base layer is characterized in that a single composite material structure layer is paved on the top surface of the base layer, and the composite material structure layer is paved with a matrix high-viscosity elastic asphalt mixture and the polyurethane composite material, wherein the weight ratio of the matrix high-viscosity elastic asphalt mixture to the polyurethane composite material is (75-85%): (15-25%). Compared with the prior art, the paving structure has the advantages of small thickness, remarkable anti-rutting performance and high popularization and application value.

Owner:SHANDONG TRANSPORTATION INST +2

A kind of active powder concrete and preparation method thereof

The invention provides reactive powder concrete. The reactive powder concrete comprises the following components in parts by weight: 30-40 parts of dry powder phase, 1-5 parts of water, and 1-5 parts of reinforced fiber, wherein the dry powder phase comprises the following components in parts by weight: 75-85 parts of cement, 24-28 parts of silica fume, 130-150 parts of hill sand, and 0.4-0.8 part of water reducer, and the reinforced fiber is steel fiber. The reactive powder concrete has high strength without being steamed, so that the construction maintenance cost can be lowered; the hill sand frequently-used in a construction site is used as aggregate, thus lowering the material cost and being beneficial for engineering application of the concrete; by regulating the proportion, the concrete has high fluidity, thus being free of vibration in construction, and improving convenience in construction. The reactive powder concrete can be used for manufacturing key bearing elements in the structure and can improve the durability and bearing capacity, can be used in the structure alone for reducing the dead weight of the structure, lowers basis cost and total structure cost, and also has application value in outer coating and reinforcing and repairing of the structure.

Owner:WENZHOU UNIV

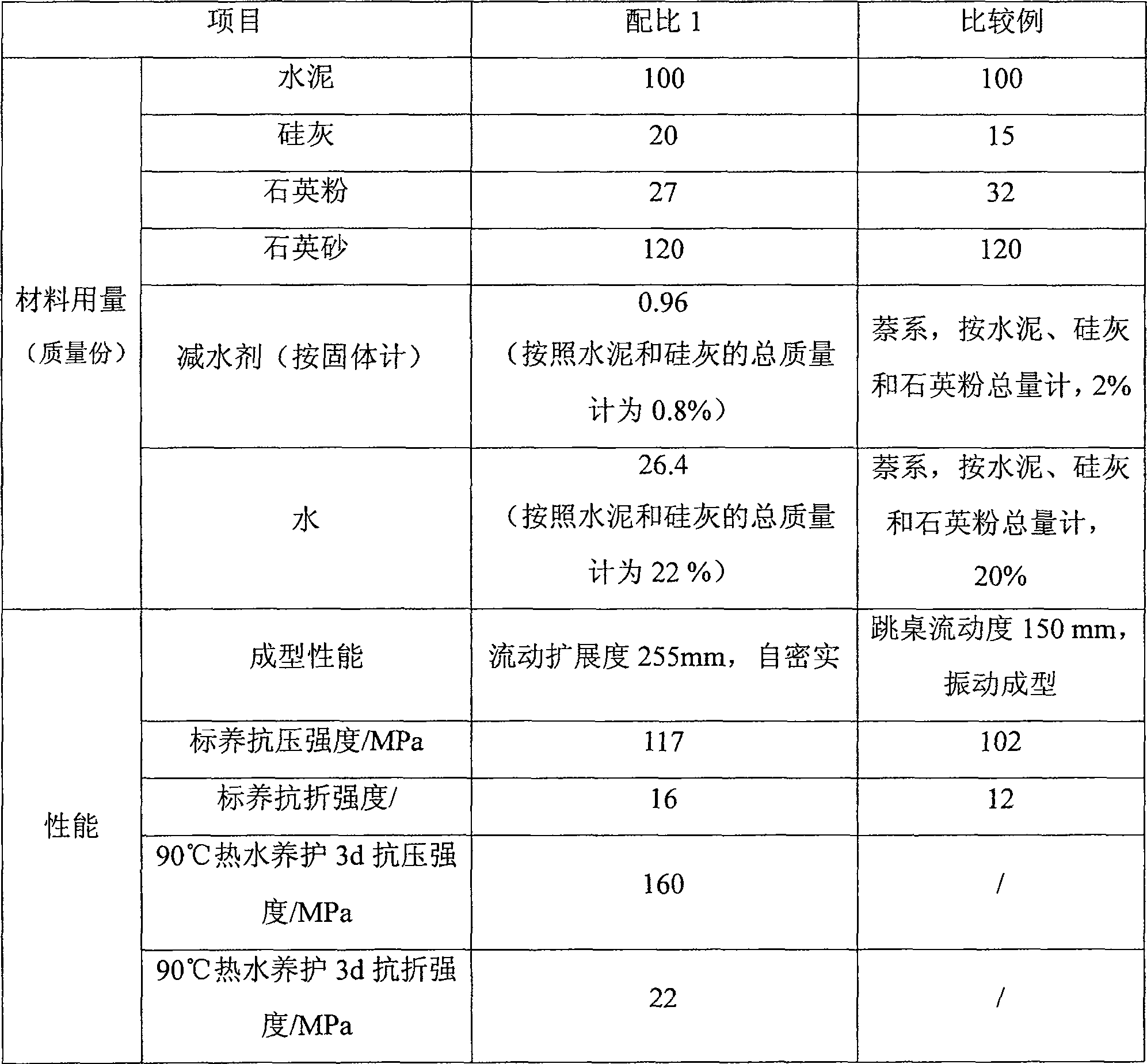

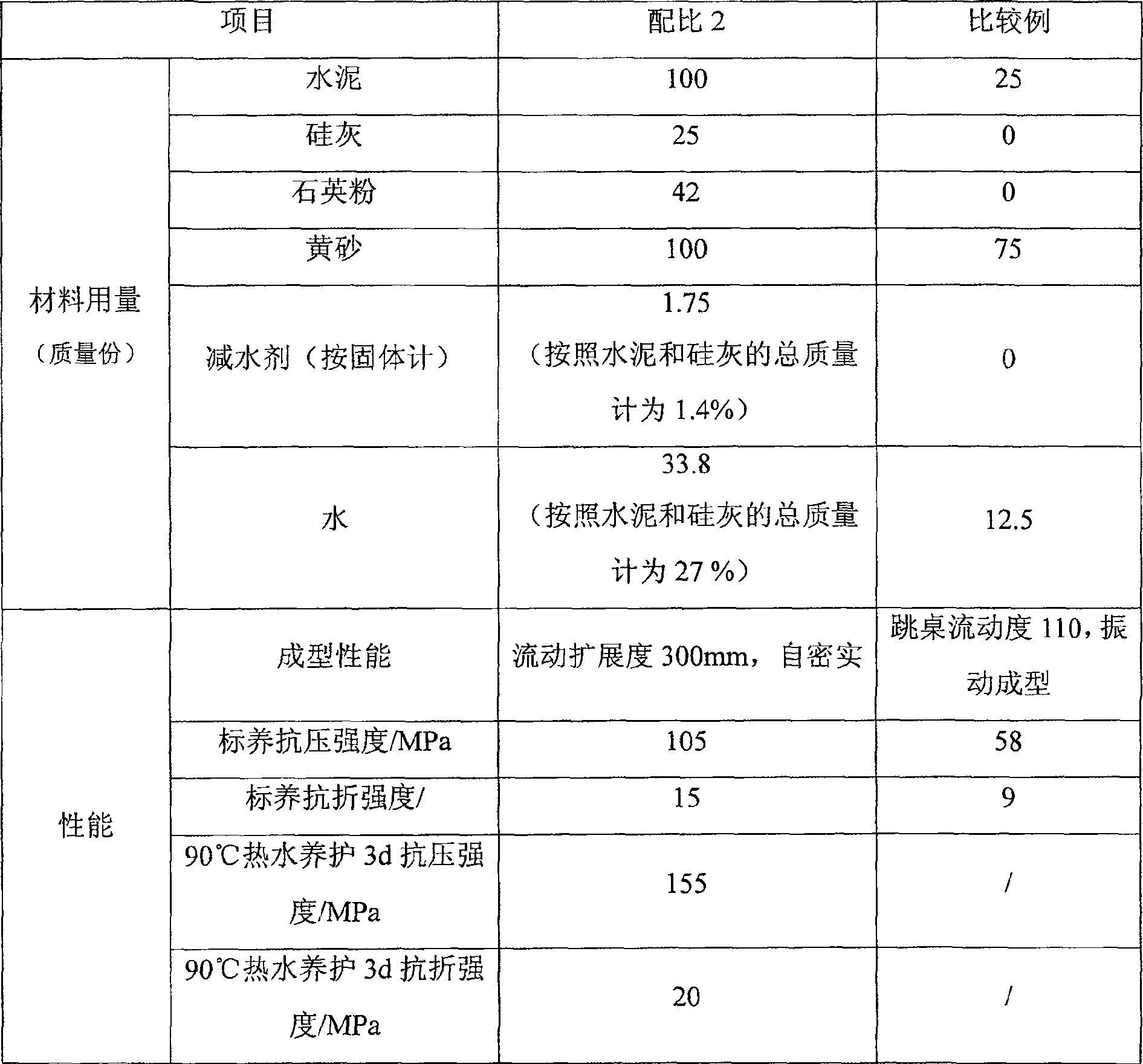

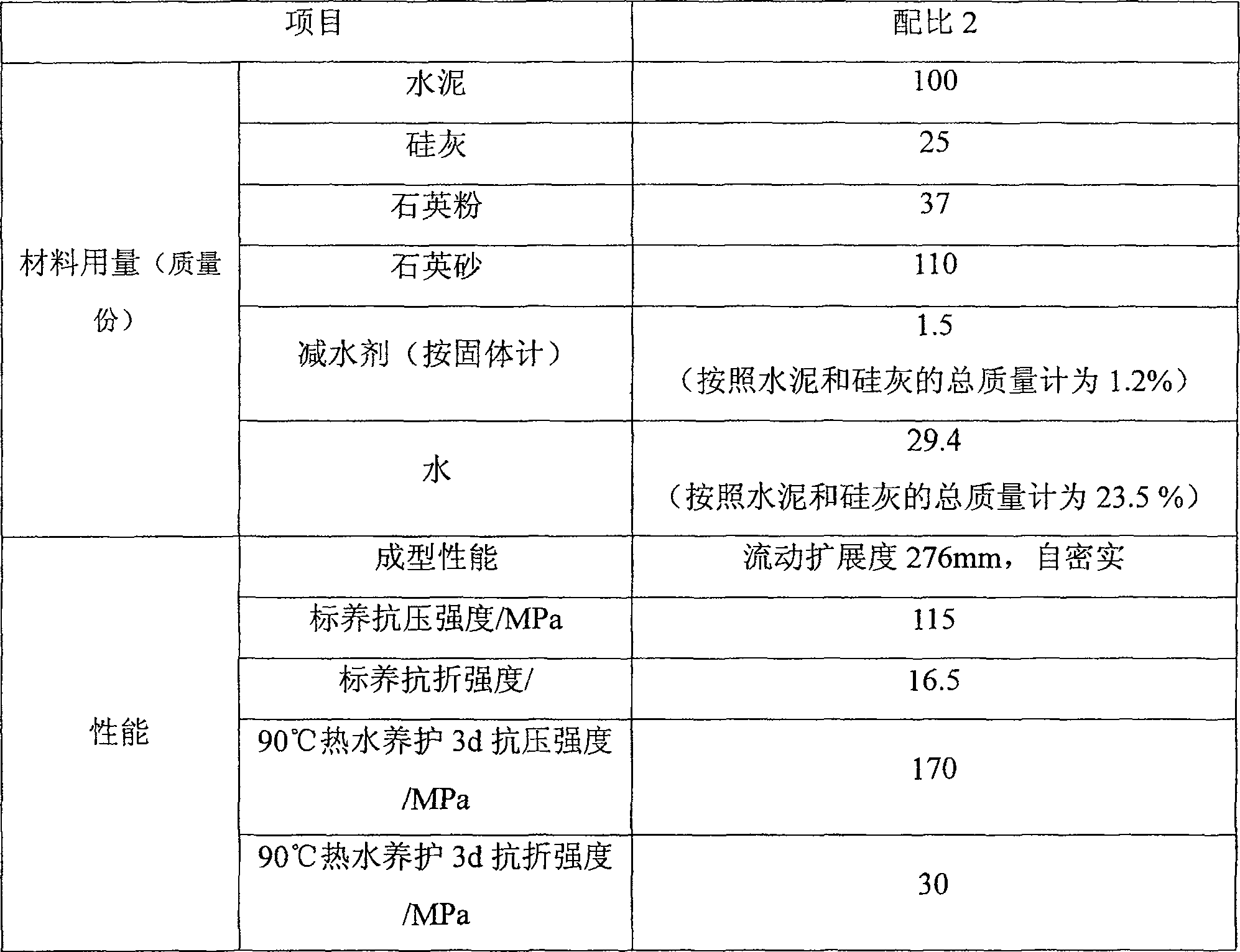

Self-compacting active powder concrete and method for making same

InactiveCN100532313CImprove liquidityNo need to vibrateSolid waste managementPortland cementCompressive strength

The present invention belongs to the building material technology field, in particular to relate to a self-compact active powder concrete and the corresponding preparation method. The self-compact active powder concrete is made of cement, silicon ash, quartz powder, sand, water reducer and water according to the weight ratio. The cement is one of Portland cement or the common silicate; the water reducer is poly carboxylate water reducer. The present invention uses the new type water reducer to make the flow expanding degree for the active powder concrete up to 255mm; and moreover the age losing for the flow degree is much smaller; the flow degree within 2 hours is not changeable basically; so the present invention can enhance the convenience performance for the construction. The compression strength in 28d maintaining reaches up to 100Mpa; the compression strength in 90 DEG C and 3d water maintenance reaches up to 150Mpa. The materials used in the present invention all are the common industrial materials, so the present invention can decrease the manufacturing cost greatly and is convenient to be widely used. The present invention is of simple preparation method and wide application.

Owner:TONGJI UNIV

Sealing grout for water pipe joints and manufacturing method thereof

The present invention discloses perfusion sand pulp that is used for sealing the connector of a conduit pipe, which comprises cement, sand and water, and is characterized in that the ingredients also comprises inner moisture-preservation material, fined mineral additive, fiber flexibility-improved material and water-reducing agent in weight ratio: 100 portions of cement, 0 to 550 portions of sand, 85 to 105 portions of water, 0.2 to 250 portions of inner moisture-preservation material, 10 to 130 portions of fined mineral additive, 0.15 to 0.45 portions of fiber flexibility-improved material, and 0.20 to 2.3 portions of water-reducing agent:. The perfusion sand pulp saves the cement and reduces the environmental pollution; with the self tightness, the connector of the conduit pipe can be filled and sealed with the self-gravity flowing of the sand pulp without vibro. The perfusion sand pulp has higher anti-fracture performance. Being valuated with the test methods such as the circular ring method and the flat-plate method, the anti-fracture performance of the perfusion sand pulp can be improved by one to two times; the perfusion sand pulp has higher anti-invasion of the chloridion, and improves the durance of the sand pulp and the corrosion durance of the steel copper or the steel bar inside the conduit pipe.

Owner:南京瑞迪建设科技有限公司

A special corundum self-flowing castable for stainless steel ladle and its construction method

The invention discloses a special corundum self-flowing casting material for stainless steel ladle and a construction method of the special corundum self-flowing casting material. The special corundum self-flowing casting material comprises the following components in percentage by weight: brown corundum, fine brown corundum powder, recycled fine corundum powder, recycled fine air brick powder and pure calcium aluminate cement, and a dispersing agent and water further need to be added in construction. In construction, a mold needs to be constructed, the water, the dispersing agent and the self-flowing casting material which are well stirred are poured into the mold, and the material can flow through any surface, can be filled in any space and can be rapidly bonded with residual materials. The special corundum self-flowing casting material for stainless steel ladle, which is disclosed by the invention, is good in high-temperature resistance and can meet the high-temperature condition of the stainless steel ladle.

Owner:HUZHOU AONENG CHARGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com