A kind of marine self-compacting high-performance concrete and its preparation method

A high-performance concrete and self-compacting technology, applied in the field of marine self-compacting high-performance concrete and its preparation, can solve the problems of construction vibration difficulties, the influence of concrete strength and durability, voids, etc., and achieve excellent resistance to chlorine salt corrosion and durability. Good effect of resistance and frost resistance

Active Publication Date: 2011-12-14

CCCC THIRD HARBOR ENG +2

View PDF3 Cites 34 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the process of pouring high-performance concrete, the lack of skilled workers and other objective conditions cannot ensure that the concrete is completely dense, which has become one of the important reasons for its poor durability.

(2) Workability of concrete

(3) The problem of vibrating compactness

Nowadays, the reinforcement of large structures is dense and complicated, and it is not easy to vibrate; some thin-walled structures, tunnels and underground structures have no room for vibrating at all, and construction vibrating is very difficult

(4) Production efficiency and safety issues

The Yangshan deep-water port project is eroded by seawater, and has high requirements on the durability of concrete structures. There are often large-volume concrete components. The concrete reinforcement of these components often has a small spacing between the reinforcement bars, and mechanical vibration is likely to produce honeycombs, pockmarks, air bubbles, voids and other defects, thus affecting the strength and durability of the concrete; the pile core concrete of the steel pile pipe also needs to be poured with self-compacting concrete

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0028] The present invention is further set forth below in conjunction with embodiment. It should be understood that these examples are only used to illustrate the present invention, not to limit the scope of the present invention.

[0029] 1. Selection of raw materials

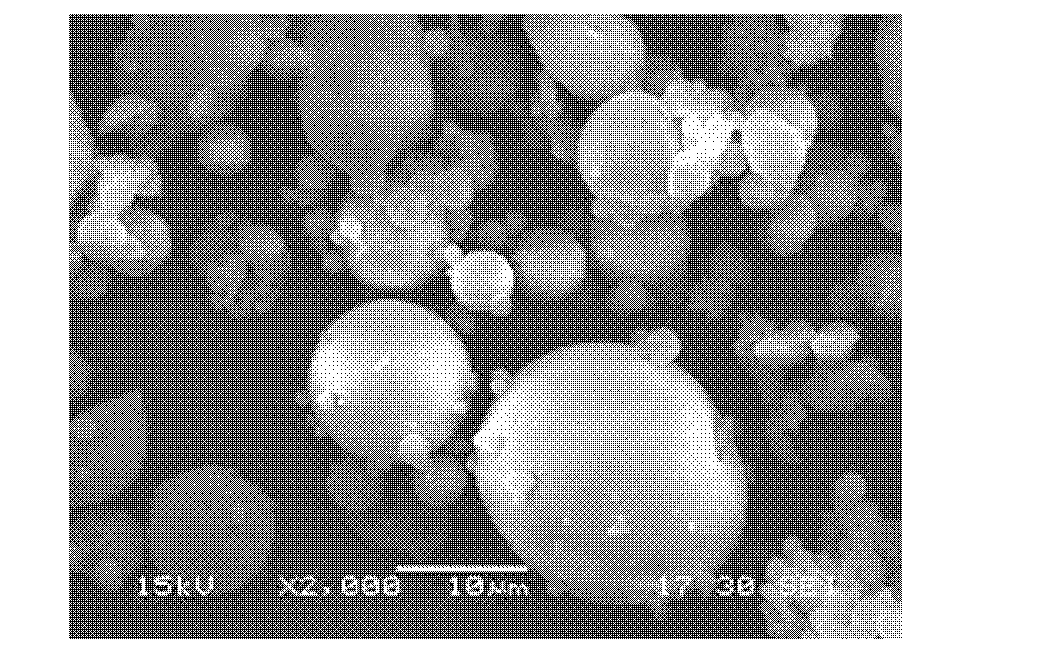

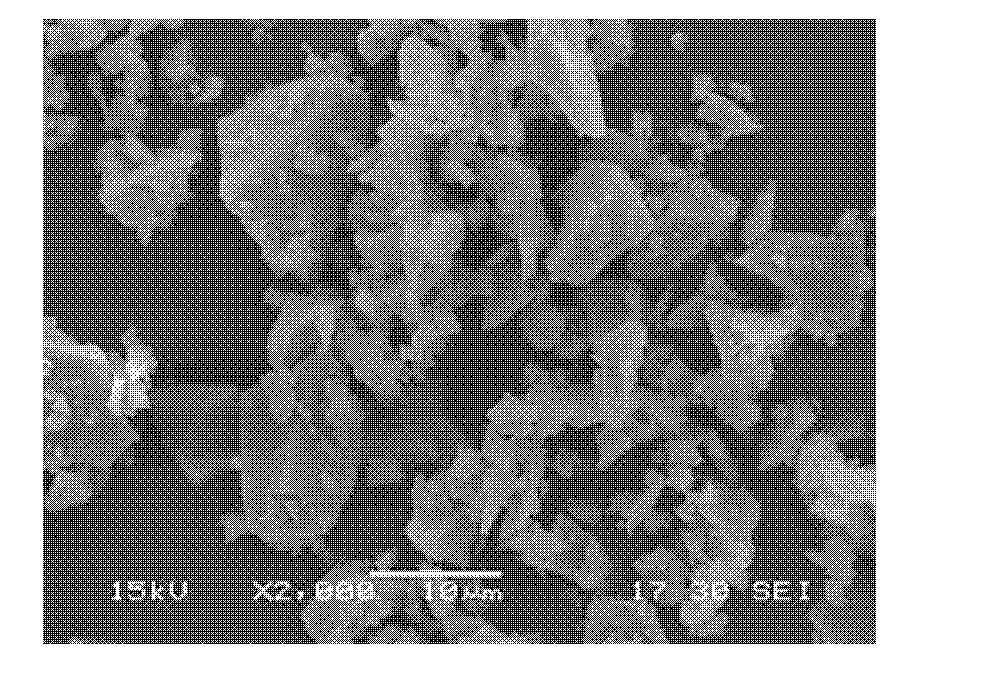

[0030] (1) gelling material

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides marine engineering self-compacting high-performance concrete, which comprises the following raw material components in part by weight: 450 to 540 parts of gel material, 1,640 to 1,725 parts of aggregate, 7 to 8 part of polycarboxylic acid water reducer and 160 to 175 parts of water, wherein the gel material, based on the total weight of the gel material, consists of 30 to 45 percent of type-II 52.5 portland cement, 20 to 40 percent of fly ash and 30 to 50 percent of slag powder. The self-compacting high-performance concrete doped with fly ash and slag has high flowability, fallibility, high passing capacity and high segregation-resistance stability. In addition, the marine engineering self-compacting high-performance concrete also has long-lasting chlorine salt corrosion resistance, high freezing resistance and high thermal performance.

Description

technical field [0001] The invention relates to a marine self-compacting high-performance concrete and a preparation method thereof. Background technique [0002] With the continuous development of engineering construction in our country, concrete has become the main material of modern engineering structures, but higher requirements are put forward for the performance of concrete in the application process, mainly in the following aspects: (1) The durability of concrete. The durability of concrete has attracted widespread attention all over the world, especially in marine engineering and sea-crossing bridges. Therefore, a large number of high-performance concrete technologies are currently used. However, in the process of pouring high-performance concrete, the lack of skilled workers and other objective conditions make it impossible to ensure that the concrete is completely dense, which has become one of the important reasons for its poor durability. (2) Workability of conc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/08

Inventor 王成启张悦然谷坤鹏汪冬冬

Owner CCCC THIRD HARBOR ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com