High-performance self-compacting concrete and preparation method thereof

A self-compacting concrete, high-performance technology, applied in the field of building materials, can solve the problems of high air content of self-compacting concrete, difficult to meet the rapid opening of traffic, unable to achieve rapid hardening, etc. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

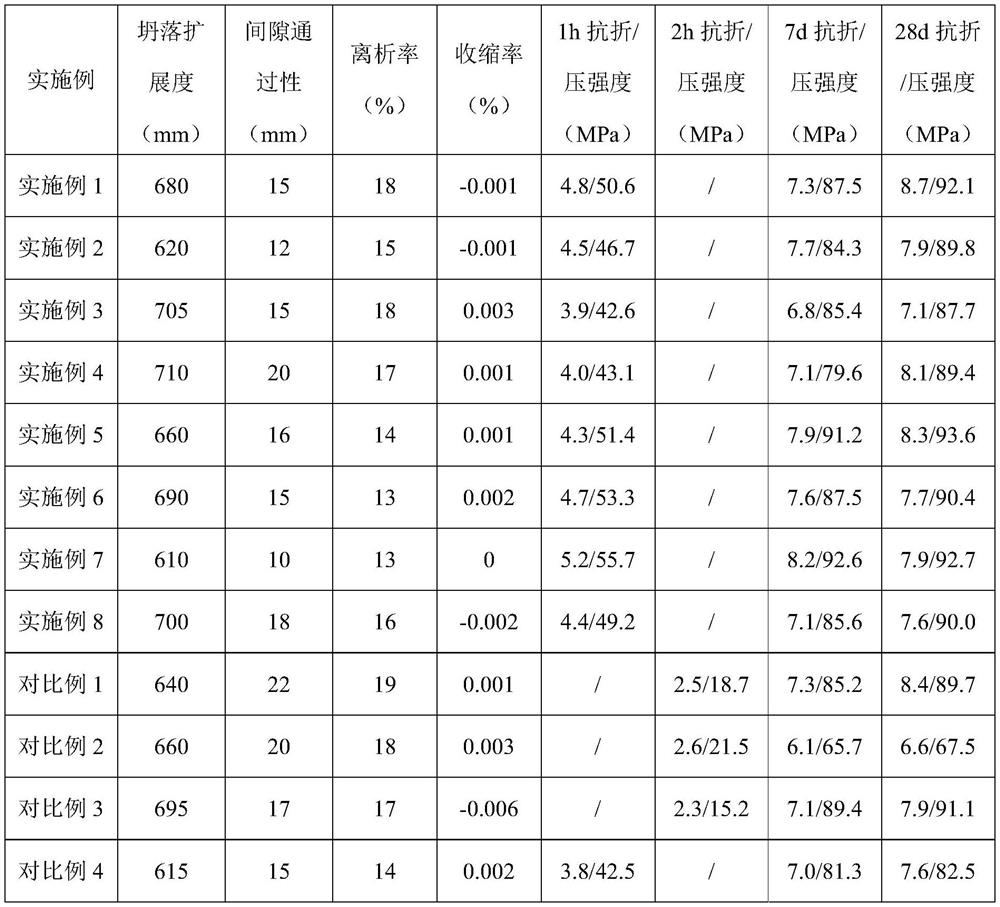

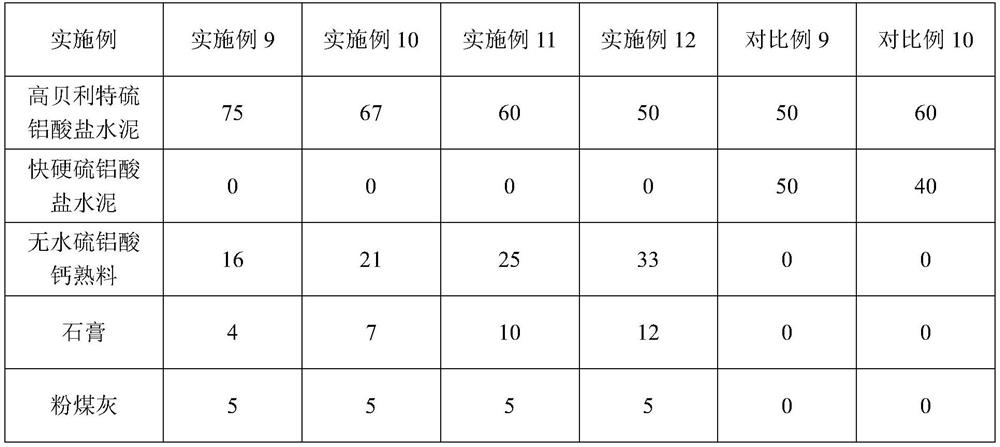

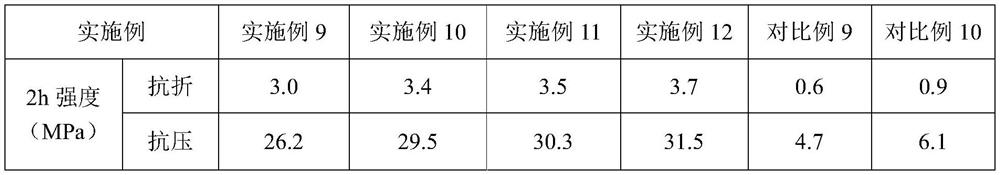

Examples

preparation example Construction

[0038] The invention also discloses a preparation method of high-performance self-compacting concrete, comprising the following steps:

[0039] 1. The preparation method of anhydrous calcium sulfoaluminate clinker: firstly grind limestone, bauxite and dihydrate gypsum to 180 meshes respectively, the pass rate is more than 90%, then limestone, bauxite and dihydrate The three raw materials of water gypsum are mixed evenly in the planetary mill according to the weight ratio of 10:(6~10):(3~5), and water that accounts for 10% of the total weight of the three raw materials is added and mixed evenly, and is pressed with a steel mold. The test block was dried at 105 °C, and finally the test block was calcined at 1300 °C for 1 hour, and cooled to room temperature to obtain anhydrous calcium sulfoaluminate clinker.

[0040] 2. Mix the anhydrous calcium sulfoaluminate clinker and gypsum evenly in a weight ratio of 1:(0.2~0.4), and grind until the specific surface area reaches 400~500m ...

Embodiment 1

[0044] A high performance self-compacting concrete comprising the following weight fractions of raw materials:

[0045] 85 parts of high belite sulfoaluminate cement, 8 parts of anhydrous calcium sulfoaluminate clinker, 2 parts of gypsum, 5 parts of fly ash, 0.4 part of water reducing agent, 0.05 part of early strength agent, 0.2 part of fiber, retarder 0.1 part of coagulant, 1 part of stabilizer, 0.05 part of defoamer, 26 parts of water, 100 parts of fine aggregate and 130 parts of coarse aggregate. The gypsum is anhydrous gypsum, the fly ash is grade I fly ash, the water reducing agent is polycarboxylate high-performance water reducing agent, the early strength agent is lithium carbonate, the fiber is polypropylene fiber, and the retarder is lemon Sodium, stabilizer is low-viscosity cellulose ether, bentonite, calcium aluminosilicate three materials are compounded in a weight ratio of 1:10:10, defoamer is polyether modified silicon defoamer, water is Tap water.

Embodiment 2

[0047] A high performance self-compacting concrete comprising the following weight fractions of raw materials:

[0048] 80 parts of high belite sulfoaluminate cement, 11 parts of anhydrous calcium sulfoaluminate clinker, 4 parts of gypsum, 5 parts of fly ash, 1.5 parts of water reducing agent, 0.04 parts of early strength agent, 2 parts of fiber, slow 0.3 part of coagulant, 0.9 part of stabilizer, 0.02 part of defoamer, 29 parts of water, 110 parts of fine aggregate and 150 parts of coarse aggregate. The gypsum is anhydrous gypsum, the fly ash is grade I fly ash, the water reducing agent is melamine high-efficiency water reducing agent, the early strength agent is lithium hydroxide, the fiber is filament steel fiber, and the retarder is boric acid, The stabilizer is composed of low-viscosity cellulose ether, bentonite, and calcium aluminosilicate in a weight ratio of 1:10:10. The defoamer is a polyether-modified silicon defoamer, and the water is tap water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com