An integral anti-rutting pavement structure for heavy-duty traffic based on composite materials

A composite material and integral technology, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problems of rapid repair of unfavorable heavy-duty rutted road sections, reduced anti-rutting and anti-fatigue performance, difficult construction quality, etc. , achieve significant economic and social benefits, avoid temperature and dry shrinkage, and facilitate construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

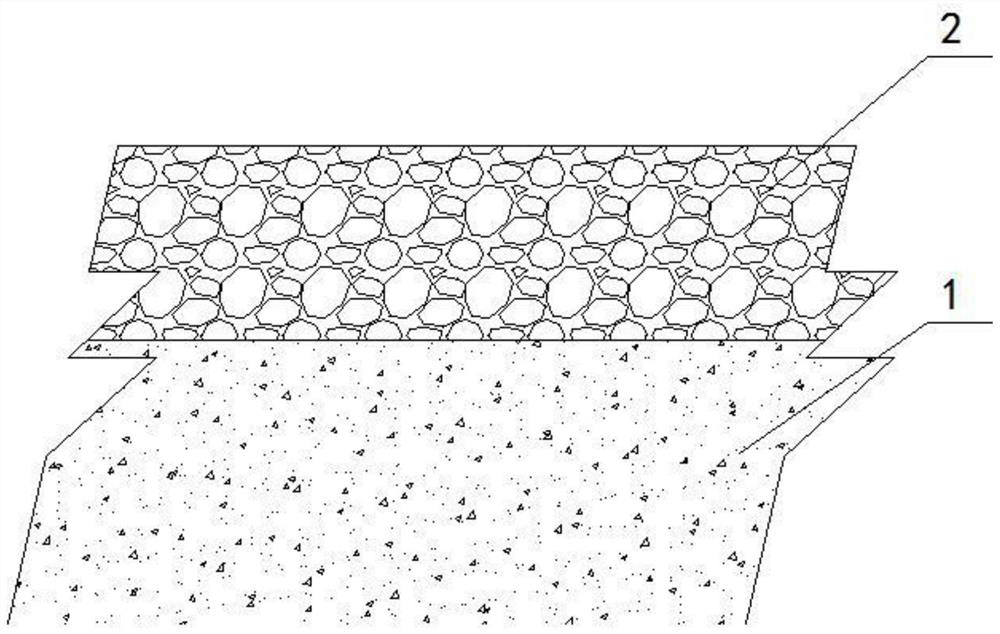

[0045] as attached figure 1 As shown, the heavy-duty traffic road pavement structure of this embodiment is composed of a base layer 1 and a composite material structure layer 2 . A single composite material structure layer 2 is paved on the top surface of the base layer 1 .

[0046] Base 1 adopts cement stabilized crushed stone base.

[0047] The thickness of the composite material structure layer 2 is 14 cm, and it is paved with a base high-viscosity elastic asphalt mixture and a polyurethane composite material. The weight ratio of the base high-viscosity elastic asphalt mixture and the polyurethane composite material is 80%:20%.

[0048] 【Matrix High Viscosity Elastic Asphalt Mixture】

[0049] The design porosity of the mixture is 31%.

[0050] Synthetic grading is based on the percentage of mineral materials with various particle sizes passing through the standard size sieve hole. The 19mm sieve hole pass rate is 100%, the 16.0mm sieve hole pass rate is 97.4%, the 13.2mm...

Embodiment 2

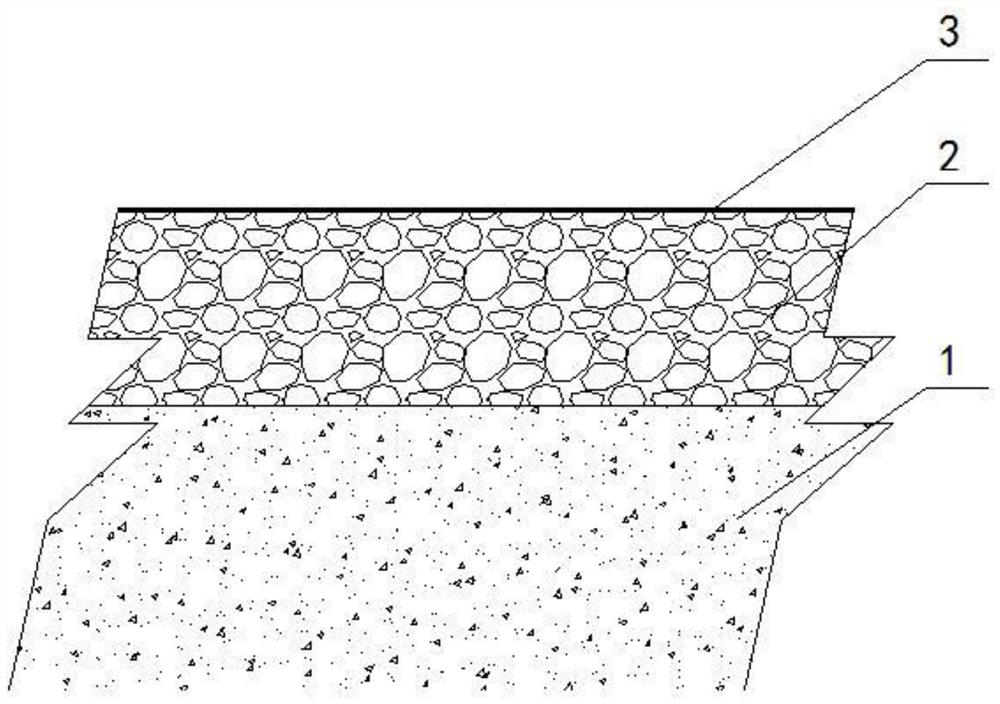

[0072] as attached image 3 As shown, the heavy-duty traffic road pavement structure of this embodiment is composed of a base layer 1 , a composite material structure layer 2 and an anti-skid surface layer 3 .

[0073] After laying the paving material and paving method described in Example 1, after the matrix asphalt mixture with uneven surface is exposed, the following methods are used to lay the anti-skid surface layer 3:

[0074] Stir and mix water-soluble polyurethane emulsion, carbon black, and basalt mineral powder with a weight ratio of 100:20:10 to form a cementing material, use gold tailings as wear-resistant aggregates, and use a sprayer to synchronize the cementing material and wear-resistant materials at one time Spray on the road surface to form a non-slip surface. Among them, by weight, the spraying amount of cement is 0.4kg / m 2 , the spraying amount of gold tailings is 0.4kg / m 2 , the spraying vehicle travels at a speed of 5.5km / h. After spraying, cure for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com