Processing apparatus for jet vortex spinning core spun yard

A processing device and core-spun yarn technology, which is applied to spinning machines, open-end spinning machines, continuous winding spinning machines, etc., can solve problems such as slow spinning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

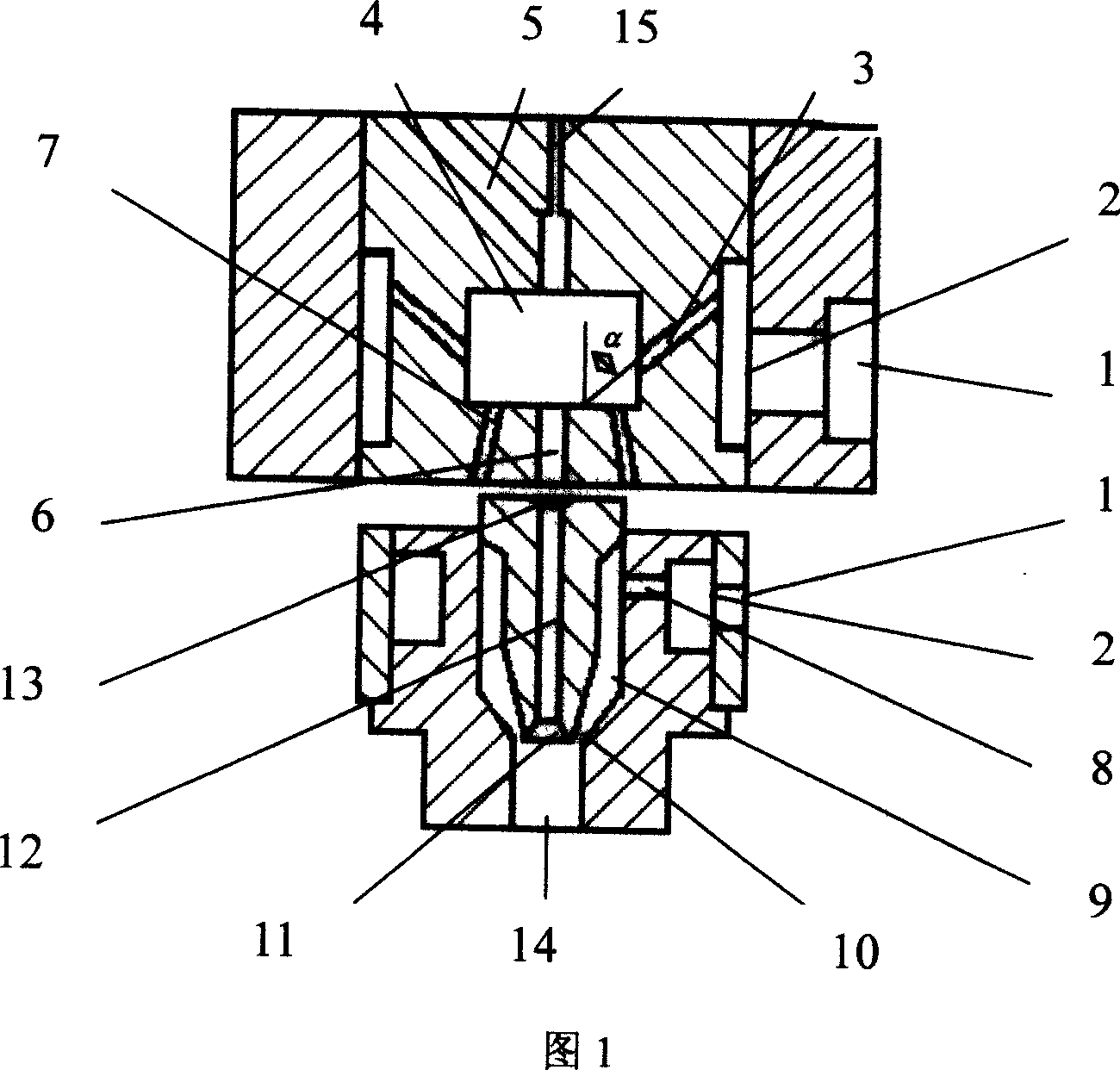

[0013] An air-jet vortex spinning core-spun yarn processing device is composed of an upper twister and a lower twister, which includes an air inlet (1), a fiber inlet (5), an air outlet (7), and a yarn outlet (14 ), the chemical fiber filament inlet (15), is characterized in that the upper twister also includes an air chamber (2), a nozzle (3), a vortex chamber (4), a strip outlet (6) and a lower twister also It is composed of an air storage chamber (2), a channel (8), an annular chamber (9), a shrink tube (10), an air delivery channel opening (11), an air intake channel (12), and a whisker inlet (13). The upper twister and the lower twister are integrated through the interface of the sliver outlet (6) and the sliver inlet (13), which is integrally installed on the frame between the drafting area and the winding area of the spinning machine.

[0014] The fiber inlet (5) is 3 mm, and the chemical fiber filament inlet (15) is 1 mm.

[0015] The nozzle (3) of the upper twister...

Embodiment 2

[0018] An air-jet vortex spinning core-spun yarn processing device is composed of an upper twister and a lower twister, which includes an air inlet (1), a fiber inlet (5), an air outlet (7), and a yarn outlet (14 ), the chemical fiber filament inlet (15), is characterized in that the upper twister also includes an air chamber (2), a nozzle (3), a vortex chamber (4), a strip outlet (6) and a lower twister also It is composed of an air storage chamber (2), a channel (8), an annular chamber (9), a shrink tube (10), an air delivery channel opening (11), an air intake channel (12), and a whisker inlet (13). The upper twister and the lower twister are integrated through the interface of the sliver outlet (6) and the sliver inlet (13), which is integrally installed on the frame between the drafting area and the winding area of the spinning machine.

[0019] The fiber inlet (5) is 5 millimeters, and the chemical fiber filament inlet (15) is 2 millimeters.

[0020] The nozzle 3 of t...

Embodiment 3

[0023] An air-jet vortex spinning core-spun yarn processing device is composed of an upper twister and a lower twister, which includes an air inlet (1), a fiber inlet (5), an air outlet (7), and a yarn outlet (14 ), the chemical fiber filament inlet (15), is characterized in that the upper twister also includes an air chamber (2), a nozzle (3), a vortex chamber (4), a strip outlet (6) and a lower twister also It is composed of an air storage chamber (2), a channel (8), an annular chamber (9), a shrink tube (10), an air delivery channel opening (11), an air intake channel (12), and a whisker inlet (13). The upper twister and the lower twister are integrated through the interface of the sliver outlet (6) and the sliver inlet (13), which is integrally installed on the frame between the drafting area and the winding area of the spinning machine.

[0024] The fiber inlet (5) is 8 millimeters, and the chemical fiber filament inlet (15) is 3 millimeters.

[0025] The nozzles (3) o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com