Air injection air vortex spinning apparatus capable of producing composite yarn

A technology for vortex spinning and bag production, which is applied in the field of air-jet vortex spinning devices, and can solve the problems of uneven quality of core yarn, unstable position and tension of core yarn in core yarn, and inability to wrap core yarn.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

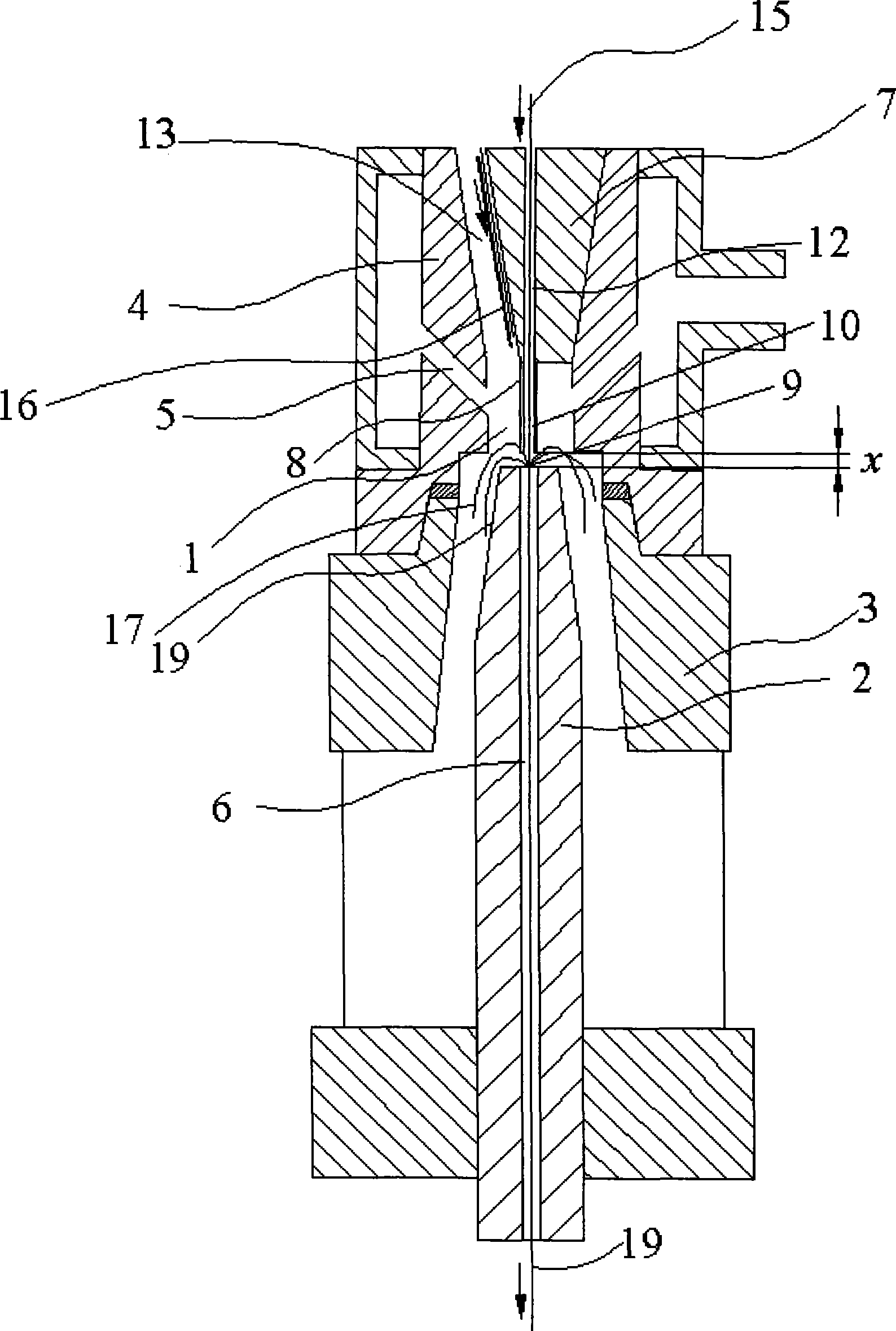

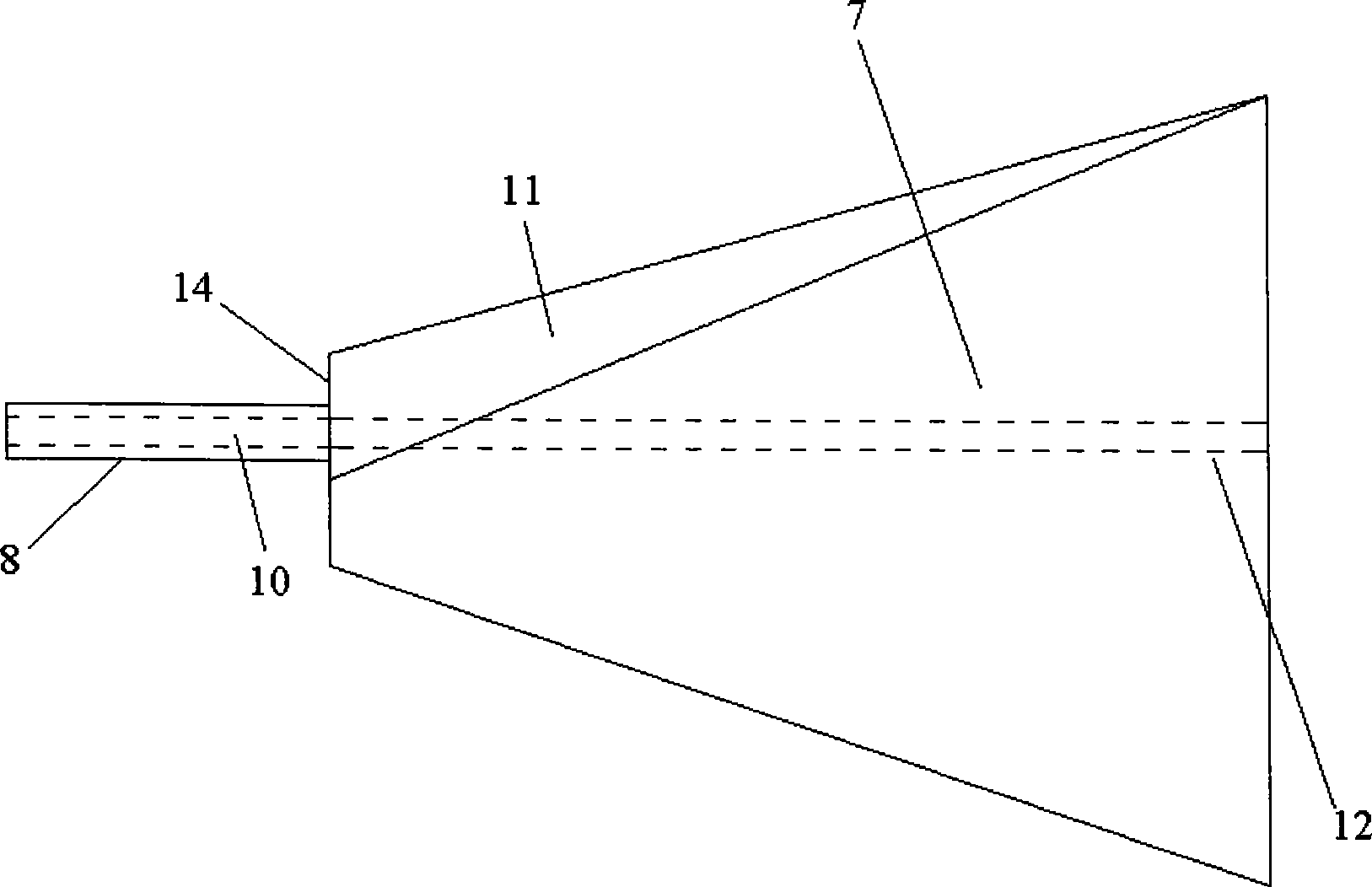

[0020] Such as figure 1 , shown in Fig. 2 (a) and Fig. 2 (b), a kind of that the present invention provides comprises vortex chamber 1, passes into the spindle shape yarn drawing tube 2 in the vortex chamber 1, the vortex tube 4 that is connected with fixed support 3 And the air jet hole 5 placed in the vortex tube 4, the center of the spindle-shaped yarn-drawing tube 2 is provided with a channel 6, and it is characterized in that a conical or cylindrical fiber and core wire guide are provided at the entrance of the vortex tube 4. The guide part 7 is provided with a needle-shaped core wire guide tube 8 at the top of the fiber and core wire guide part 7, and a width is set between the inlet 9 of the spindle-shaped yarn guide tube 2 and the needle-shaped core wire guide tube 8 A gap x of 2mm. The needle-shaped core wire guide tube 8 is penetrated with a core wire through hole 10 .

[0021] The fiber and core wire guiding part 7 is composed of a fiber spiral guiding surface 11 ...

Embodiment 2

[0026] Such as image 3 and Figure 4 As shown, the difference between embodiment 2 and embodiment 1 is that the fiber and core wire guiding component 7 is cylindrical. Other structures and their working principles are the same as those in Embodiment 1.

Embodiment 3

[0028] Such as Figure 5 As shown, the difference between Embodiment 3 and Embodiment 1 is that the axis of the core wire guide hole 12 forms an included angle β of 20 degrees with the axis of the forming fiber and the core wire guide member 7 . Other structures and their working principles are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com