Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

267results about "Throwing machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

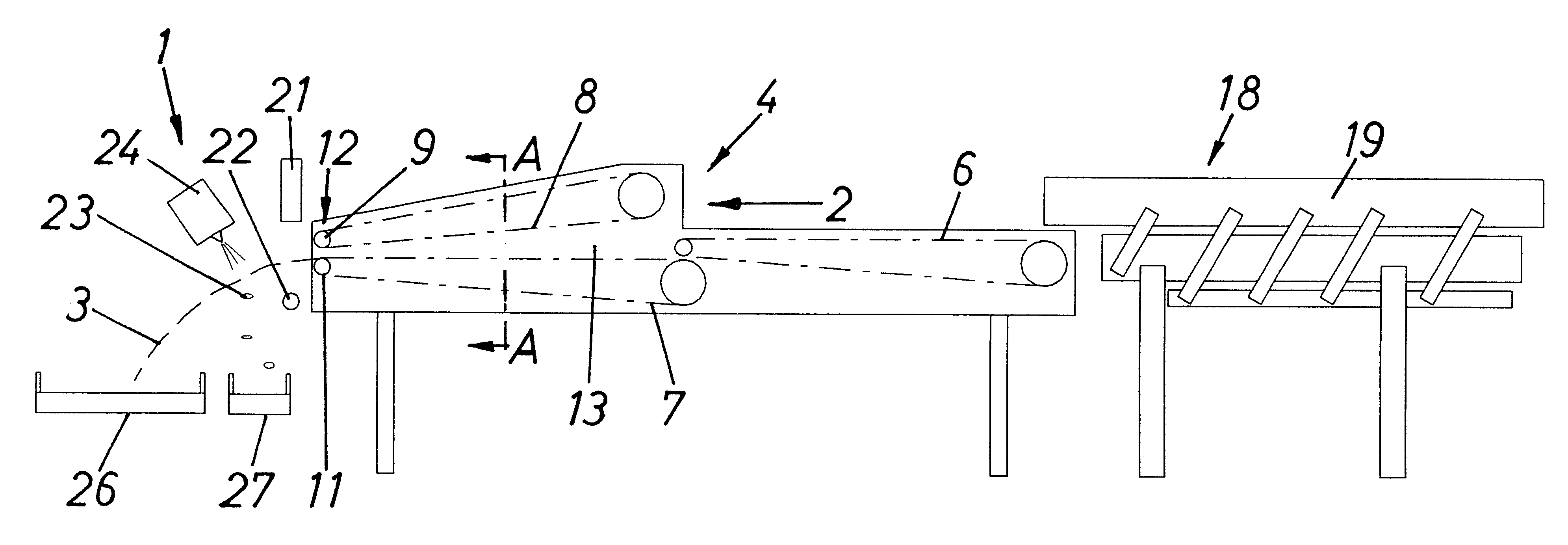

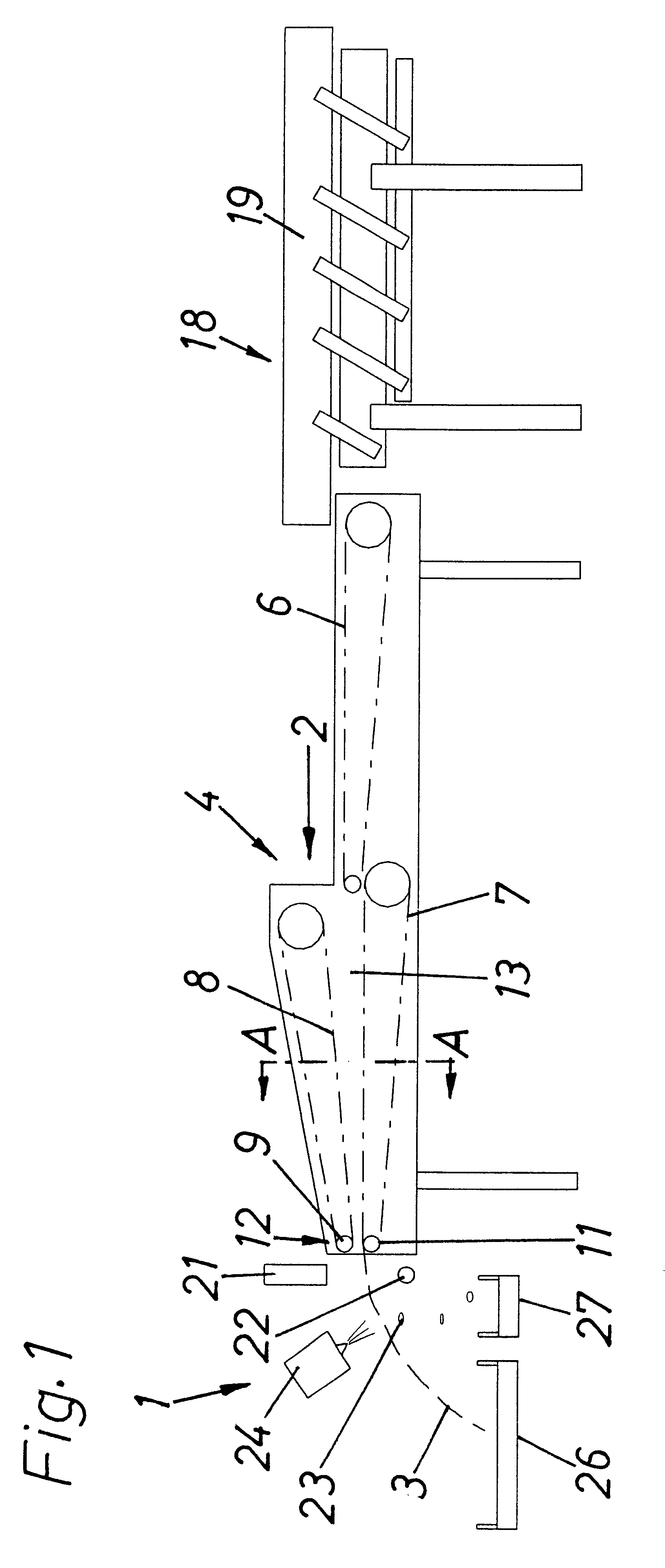

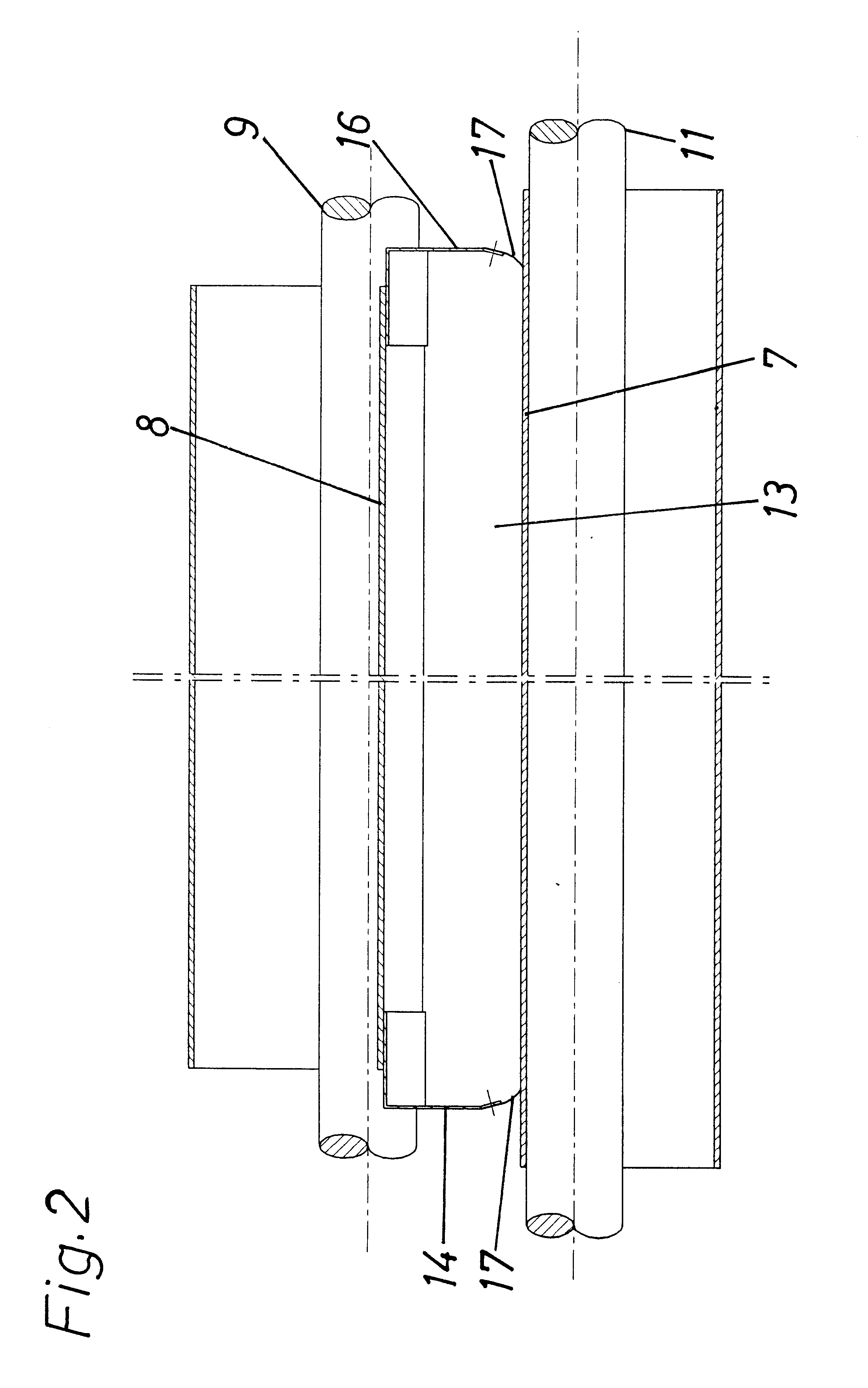

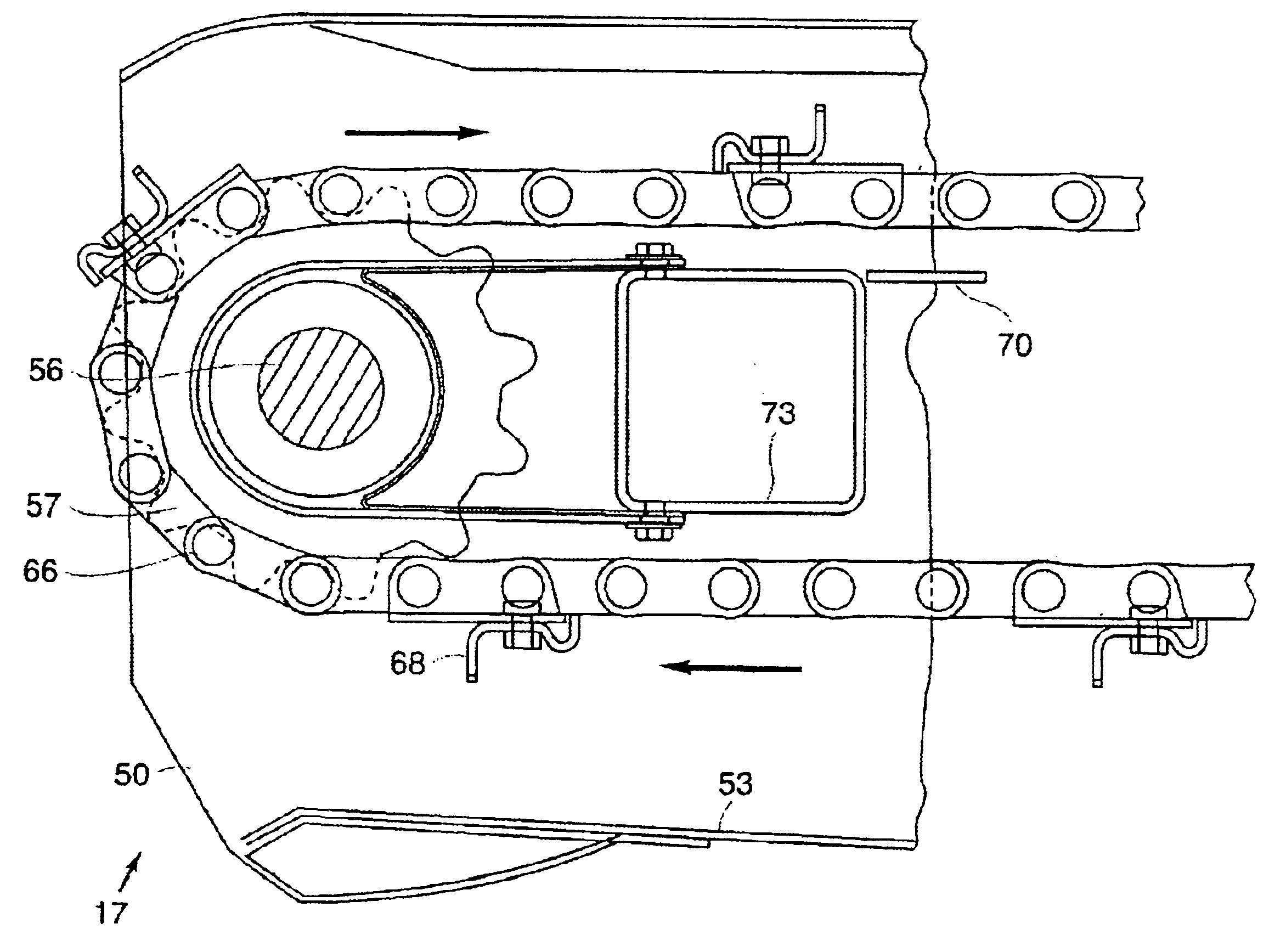

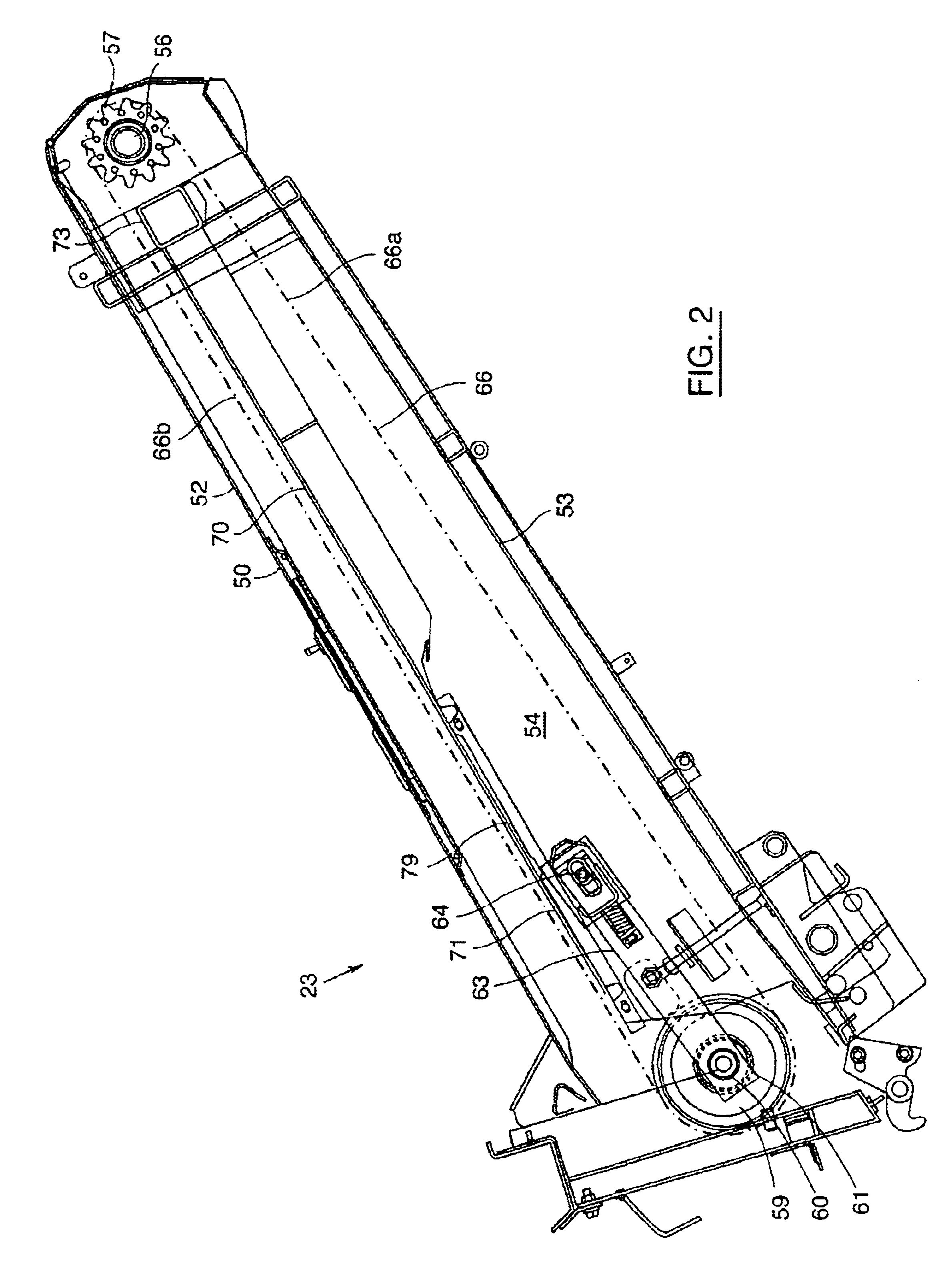

Apparatus for converting a continuously supplied material flow into a single layer

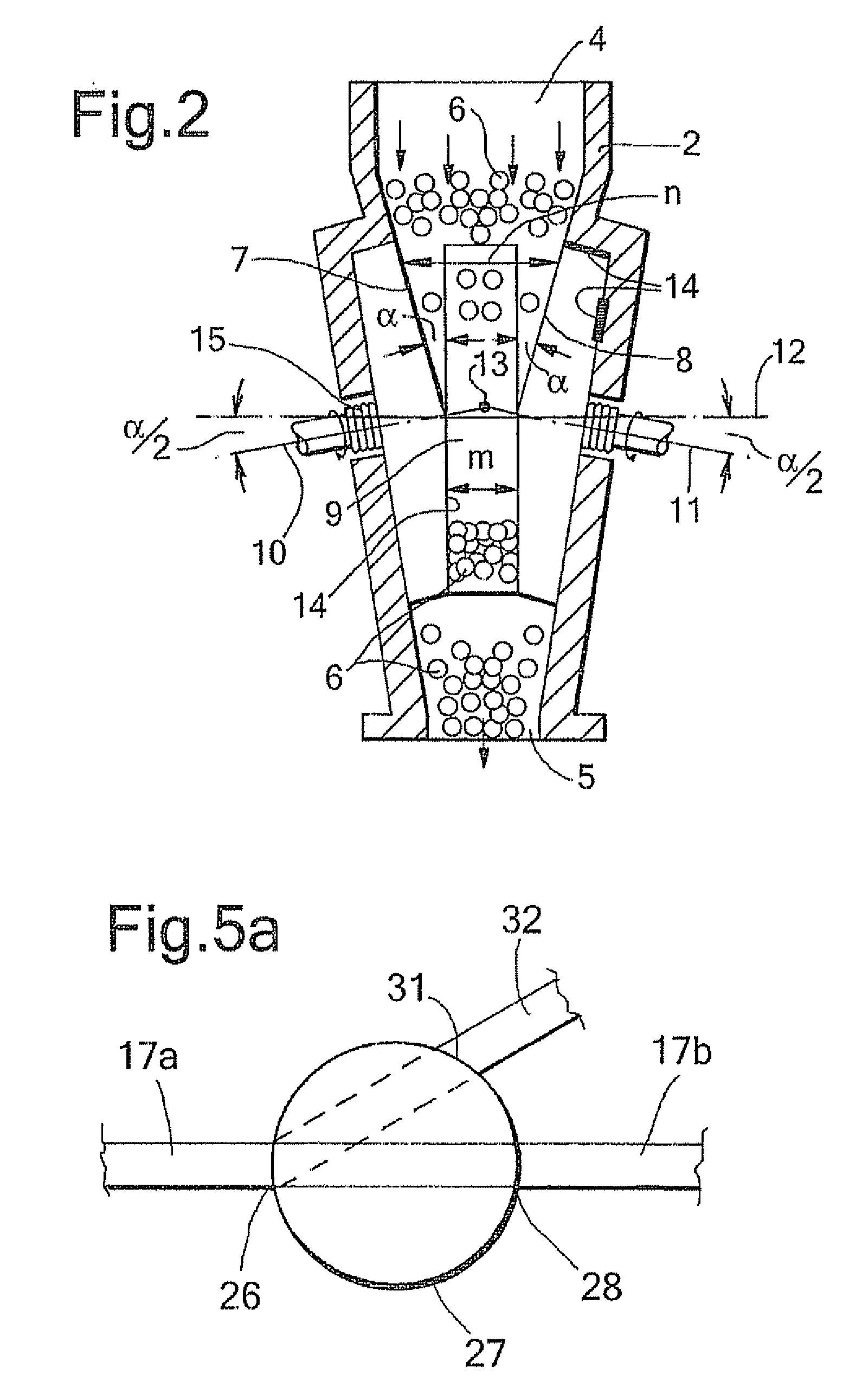

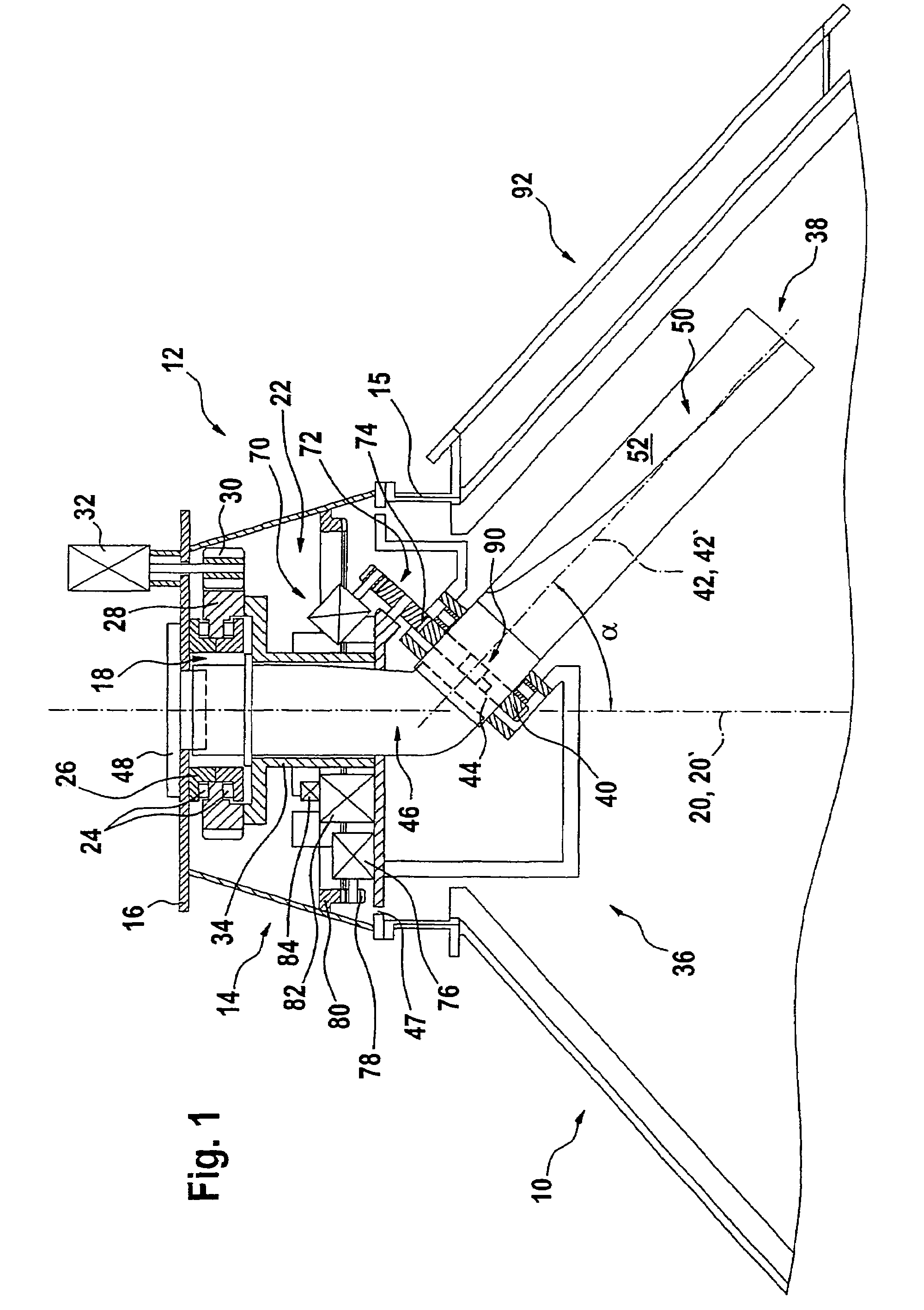

InactiveUS6332543B1Reliably flowIncrease ratingsThrowing machinesTobacco preparationEngineeringStreamflow

There is provided an apparatus which can simplify, expedite and enhance the segregation of undesirable particles from desirable particles in a multiple-layer flow wherein the desirable and undesirable particles are randomly intermixed with each other. This is accomplished by a stepwise reduction of the thickness of the flow to thus locate all or nearly all undesirable particles at or close to the exposed sides of the resulting relatively thin flow so that the undesirable particles can be readily detected and segregated from the thin flow. The stepwise reduction of thickness of the original flow is effected by a cascade of successive accelerating conveyors including a first conveyor which receives successive increments of the original flow from a vibratory trough, and a faster second conveyor which receives successive increments of the accelerated flow from the first conveyor and cooperates with an overhead conveyor to define a channel for advancement of the repeatedly accelerated original flow into the range of instrumentalities for detection and segregation of undesirable particles.

Owner:BEST & CO

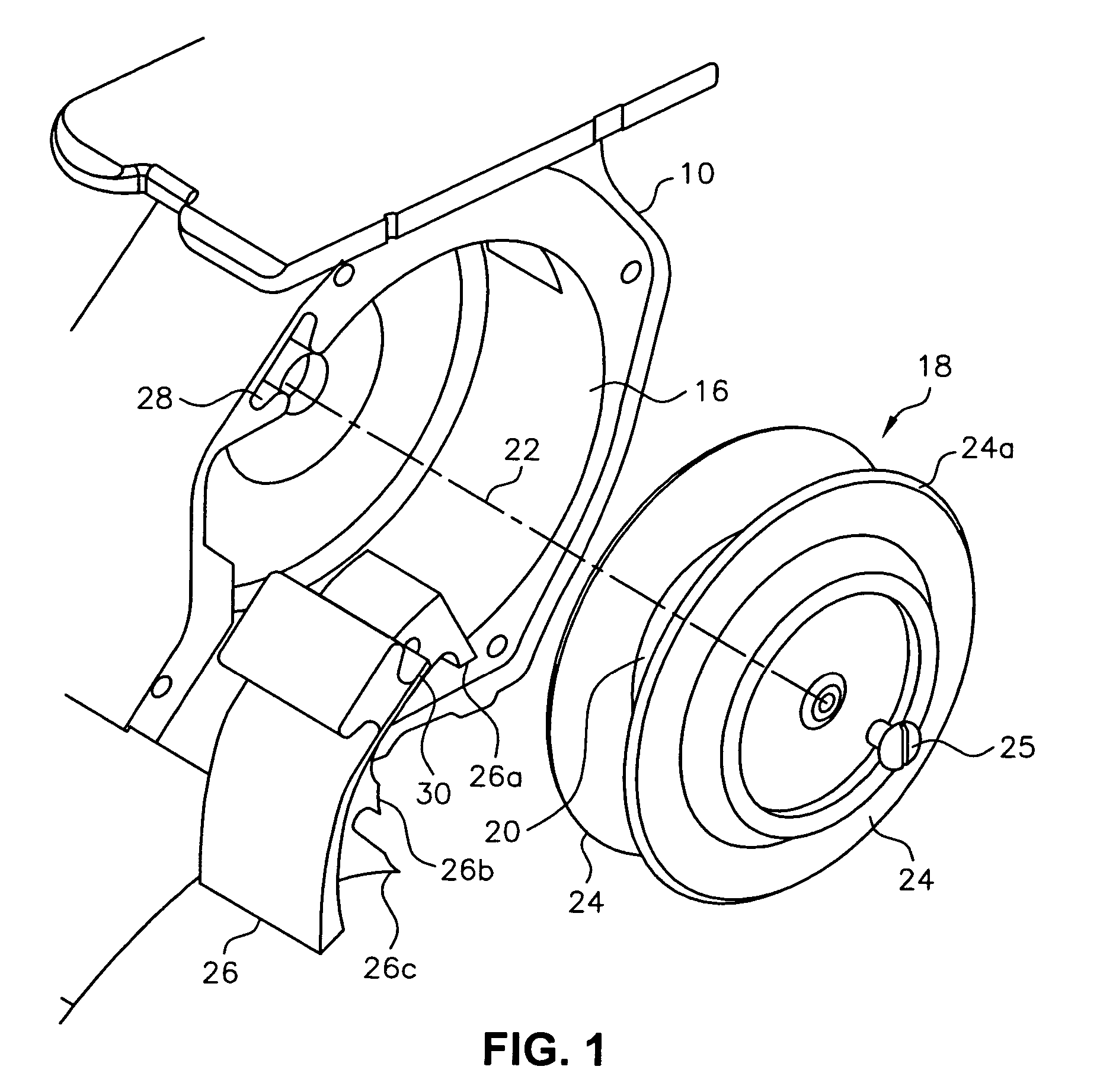

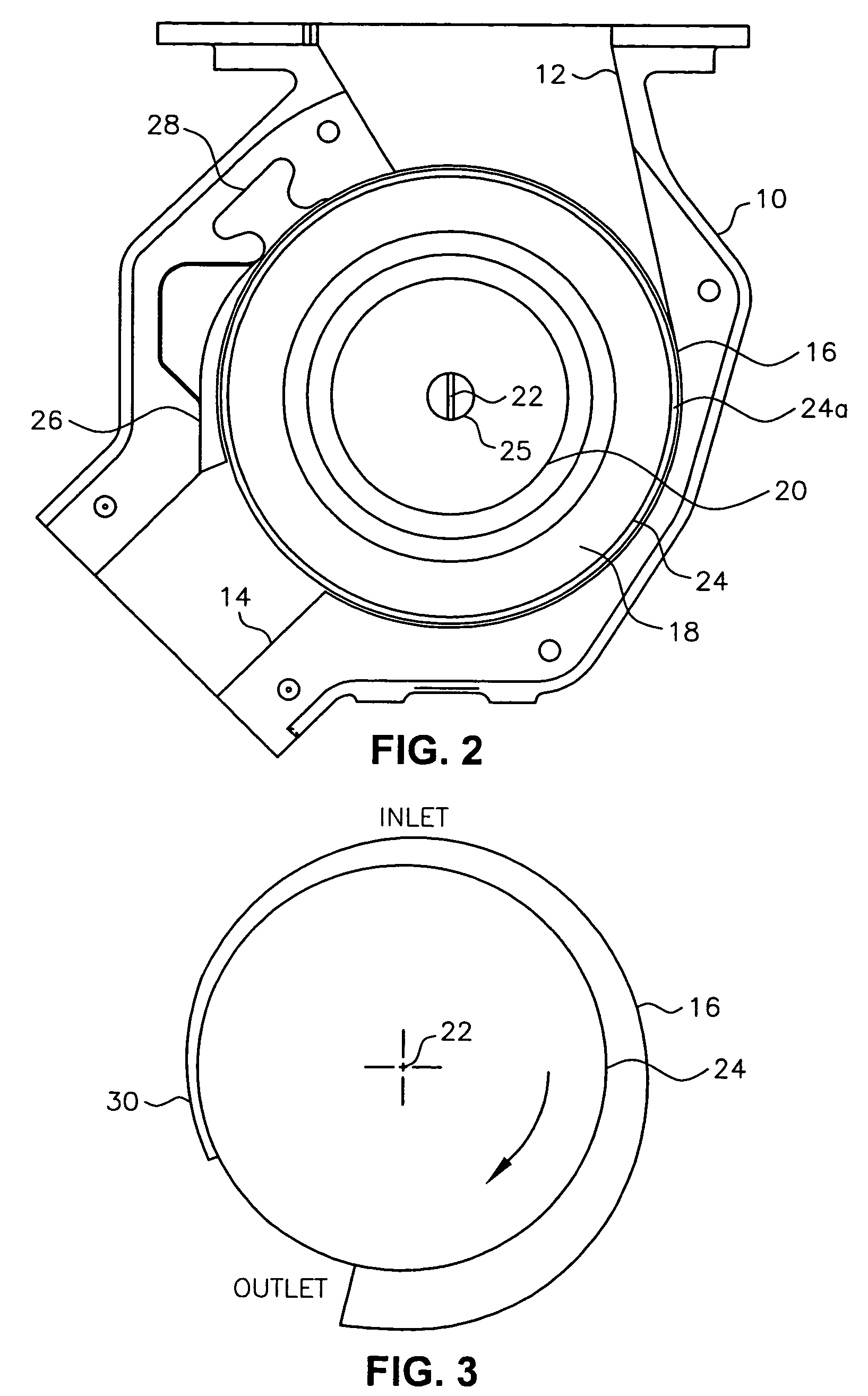

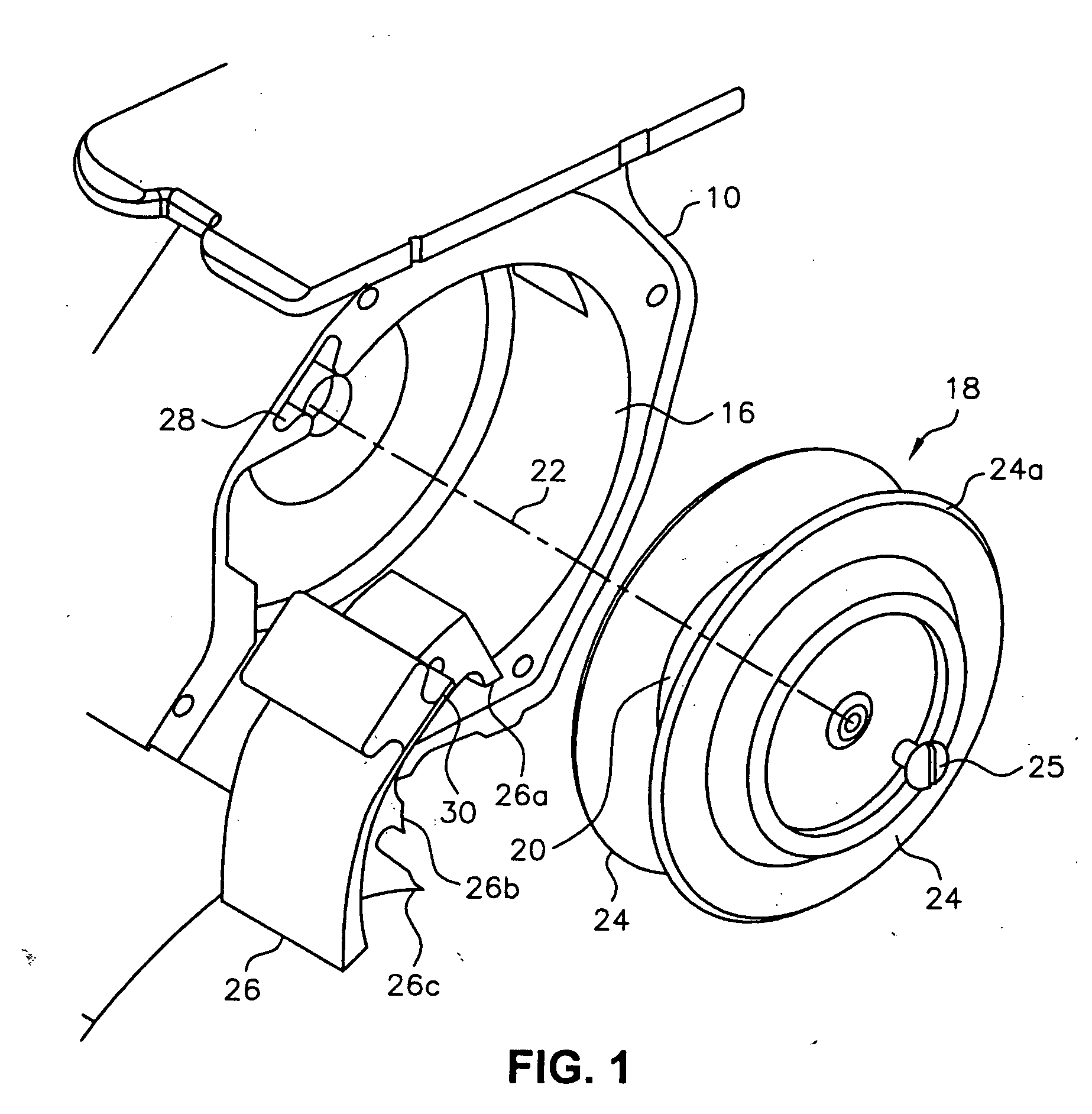

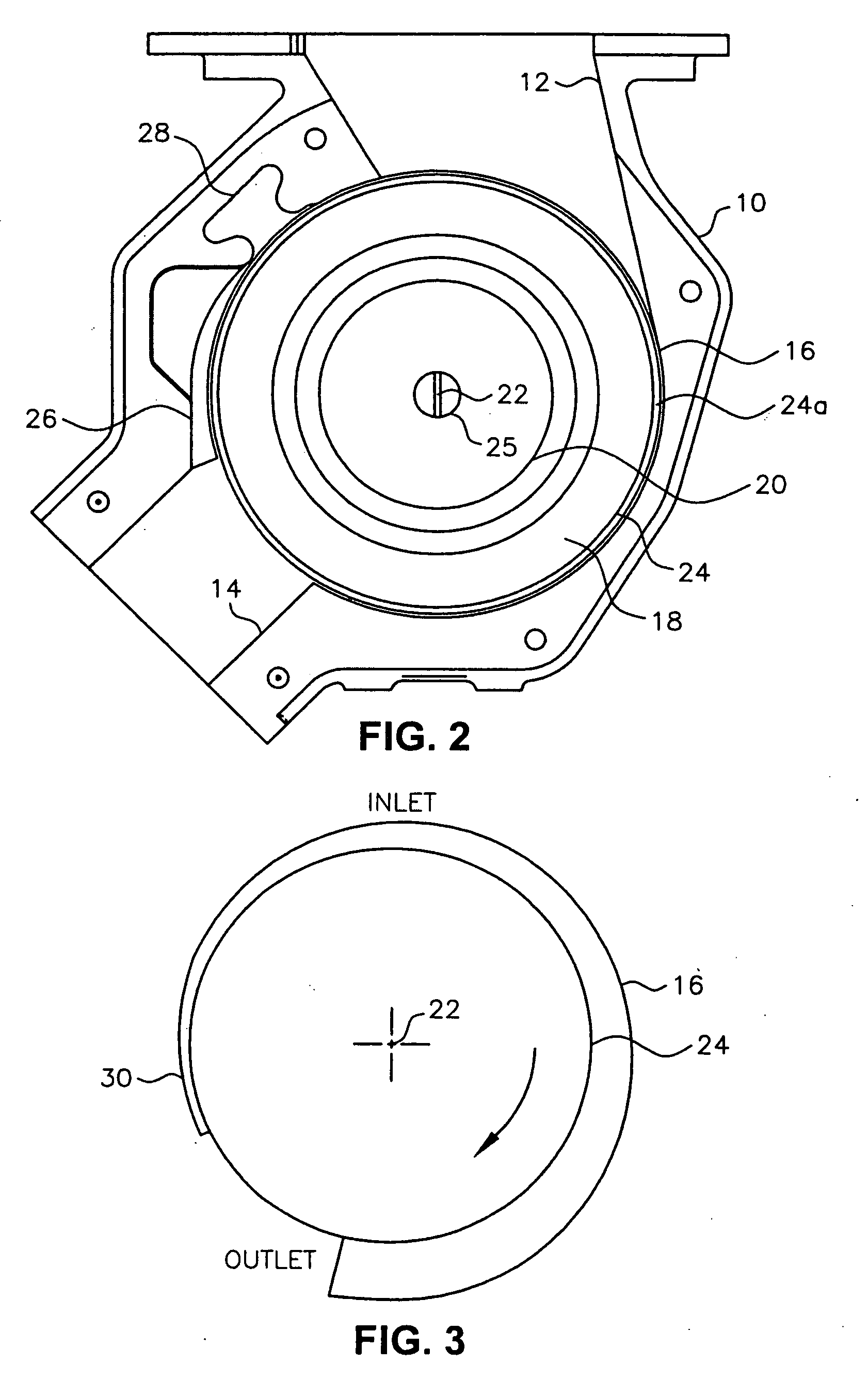

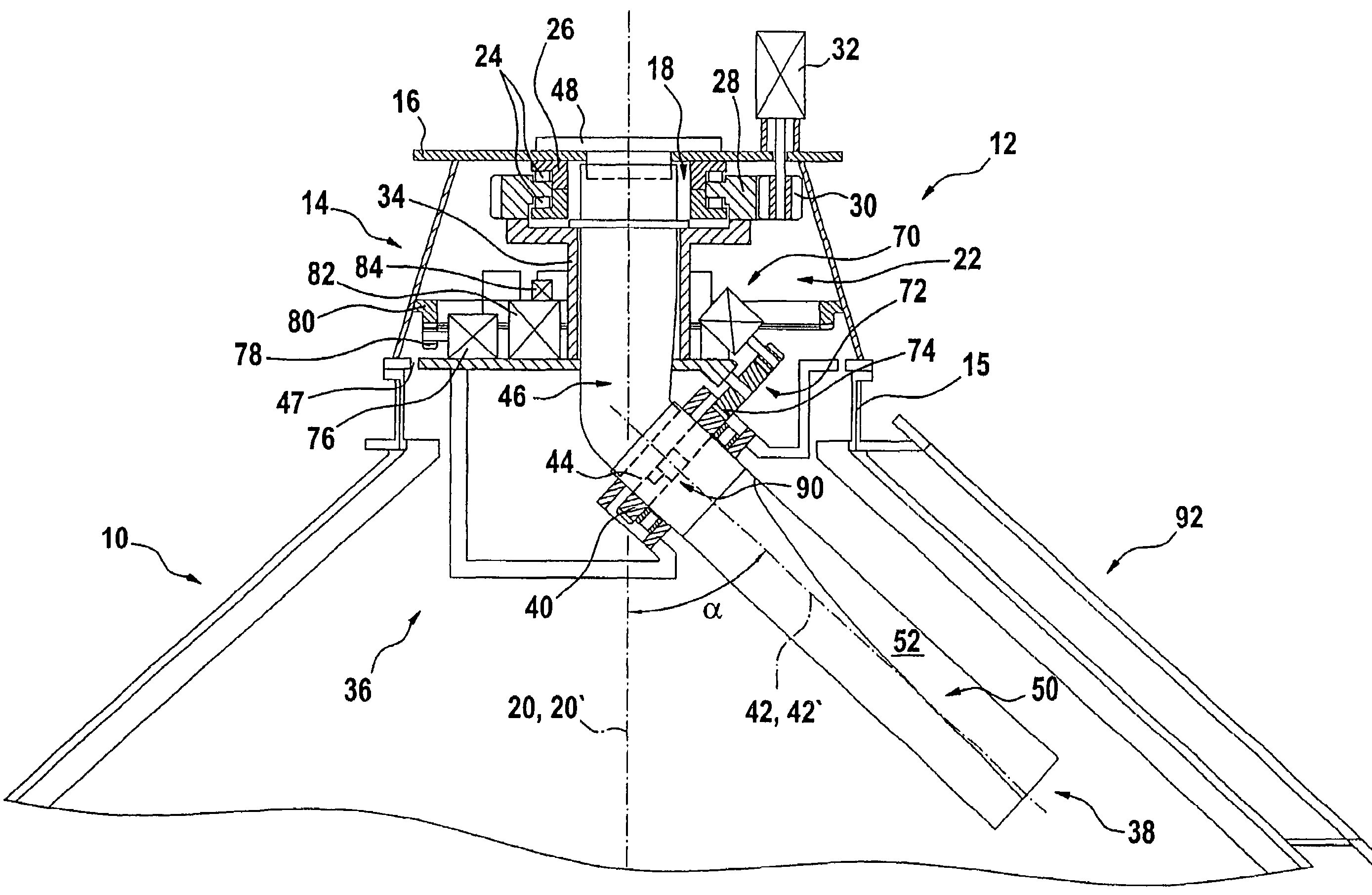

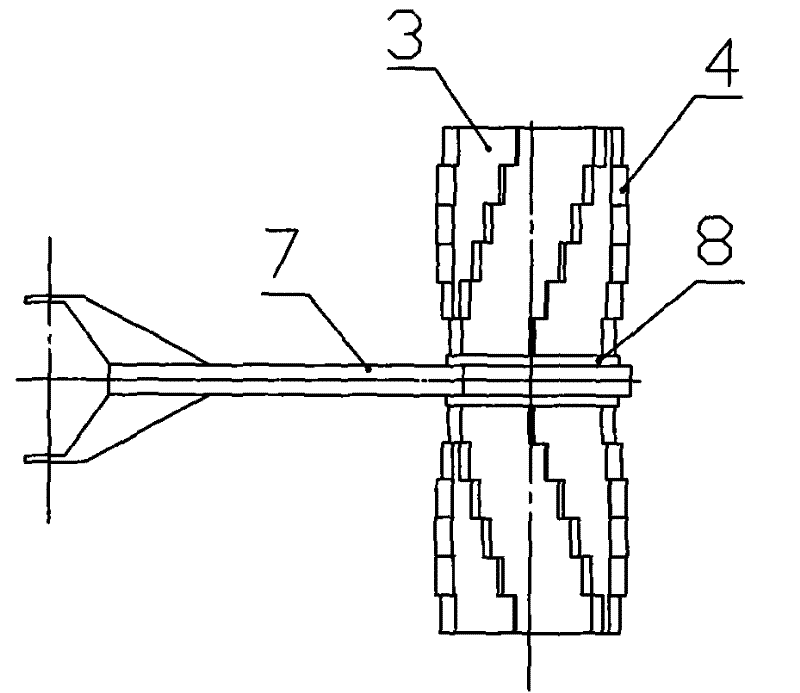

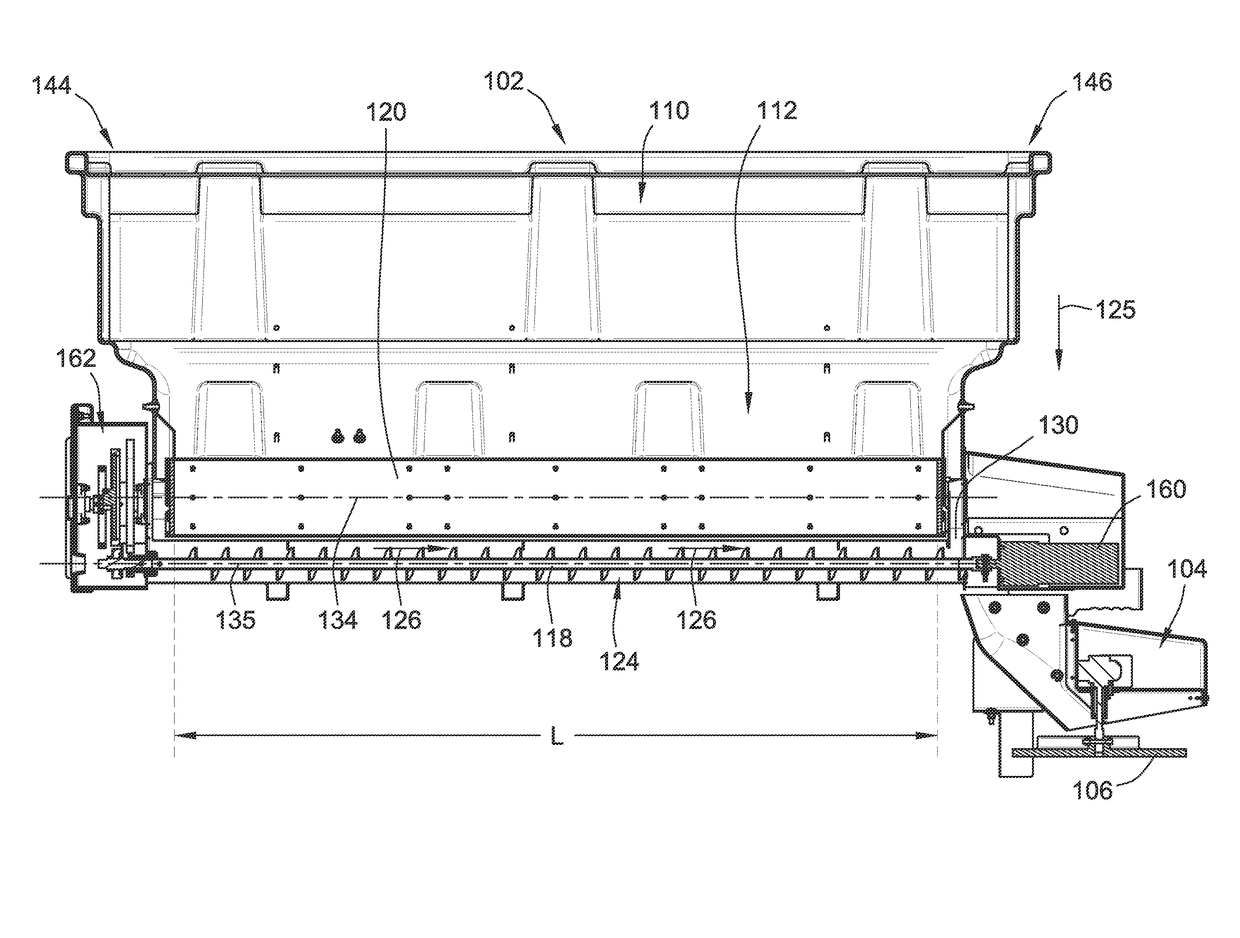

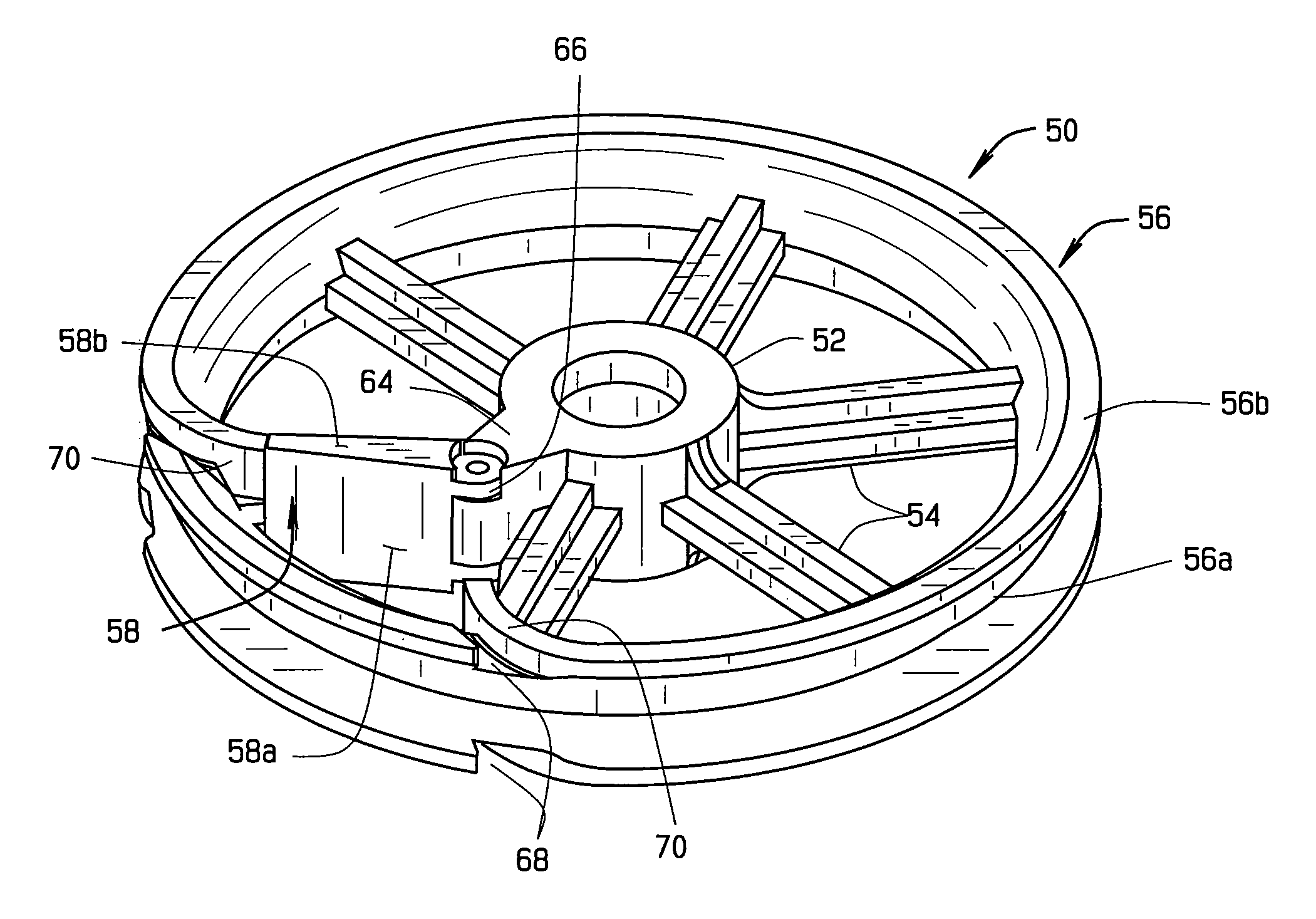

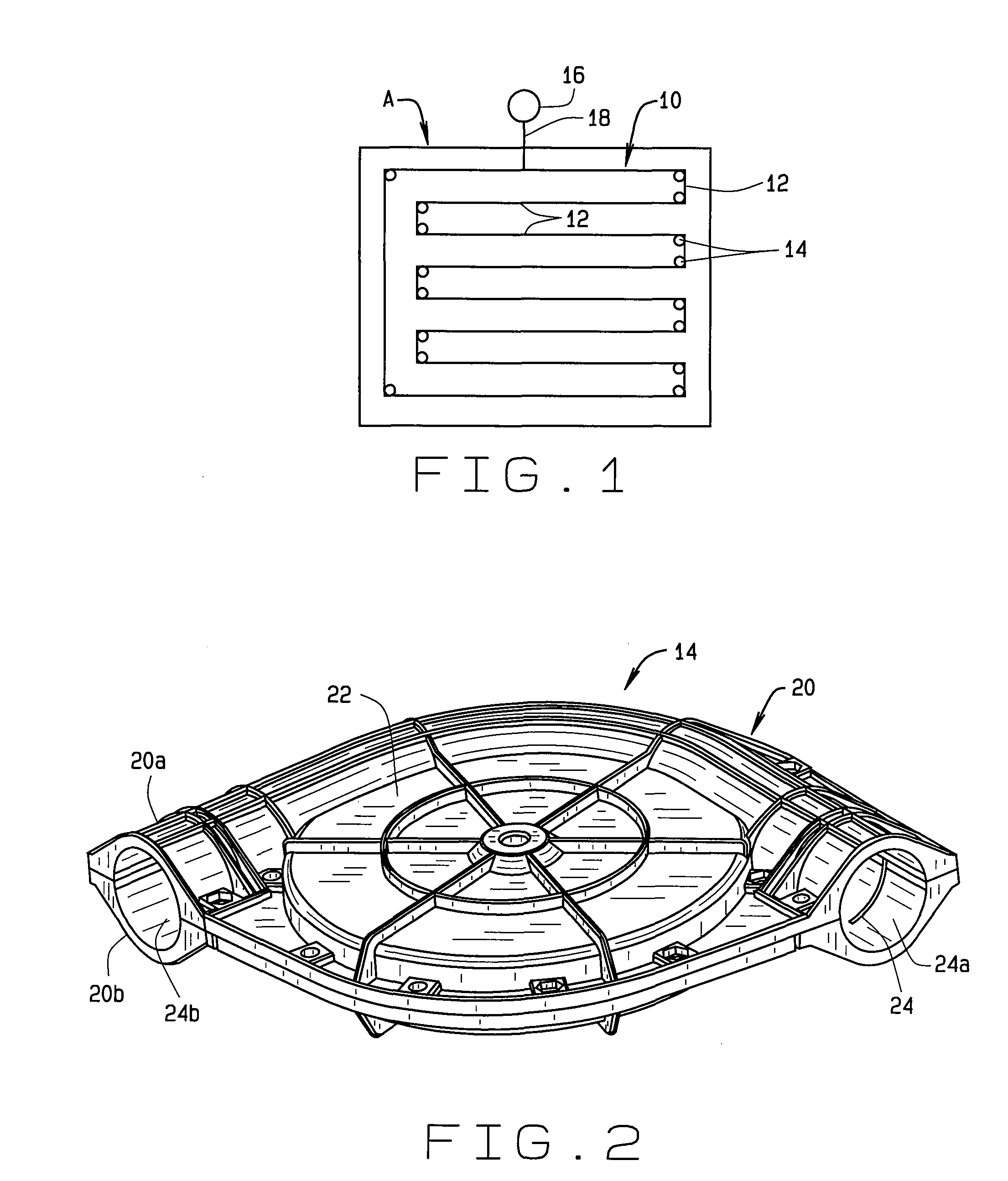

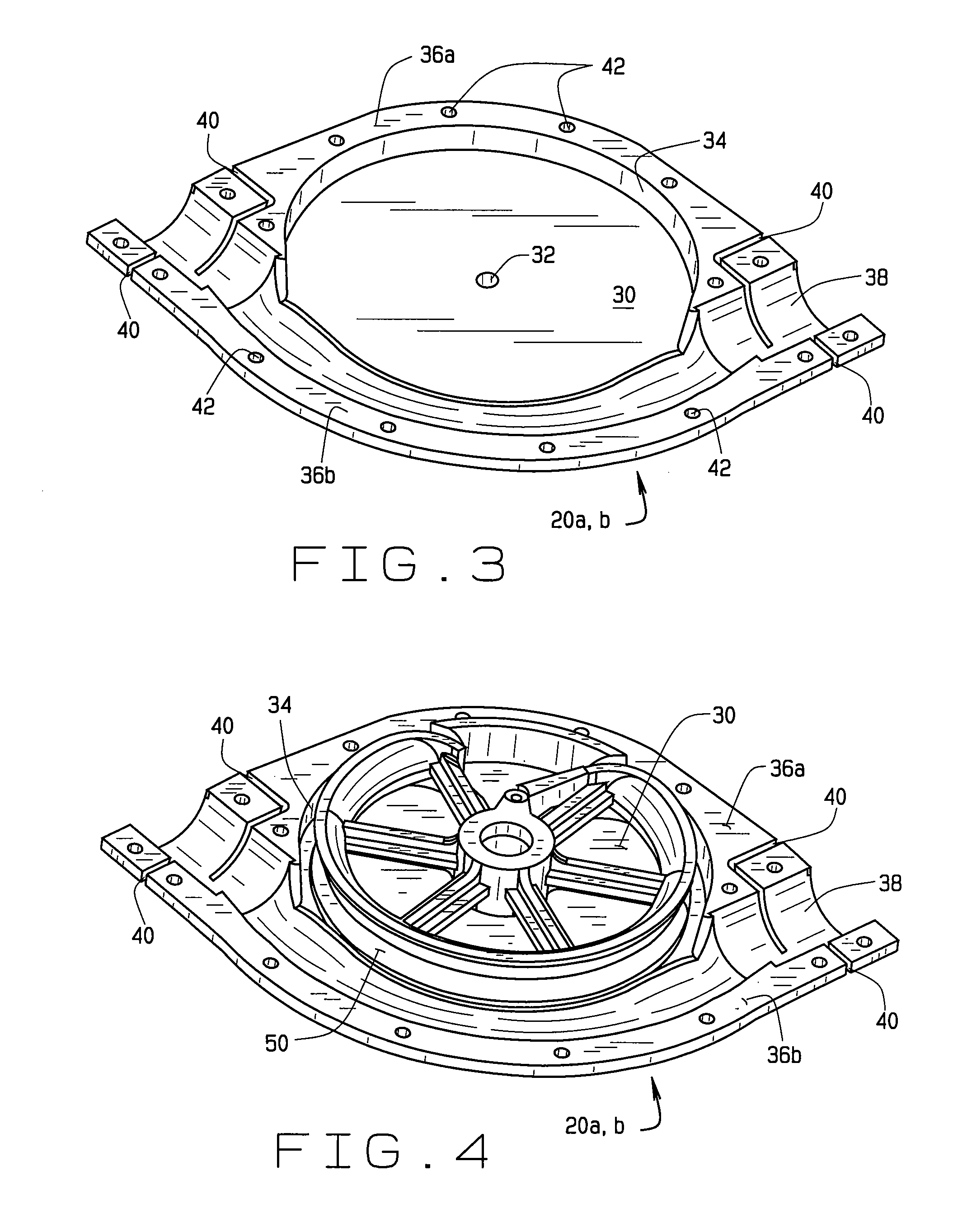

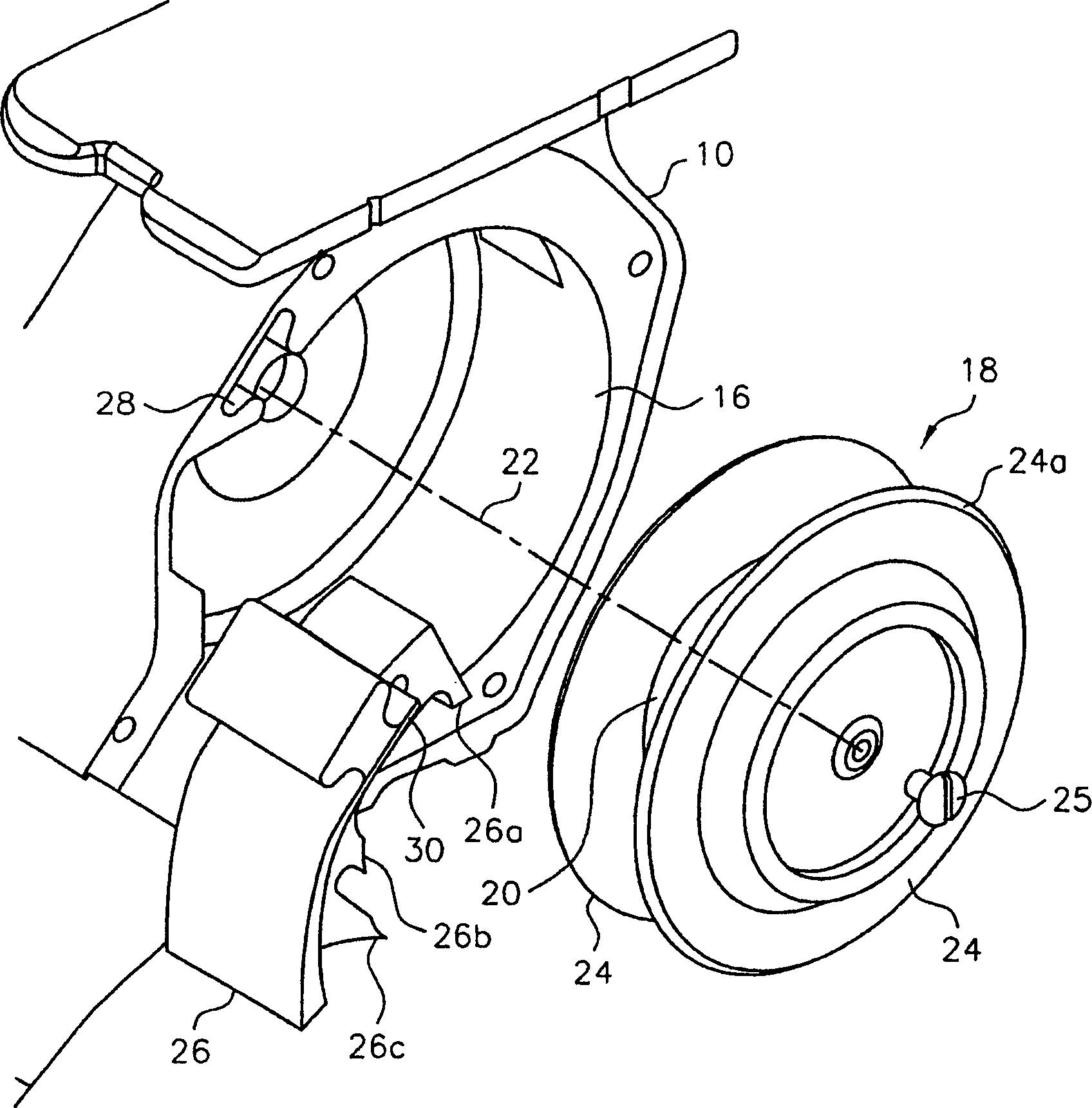

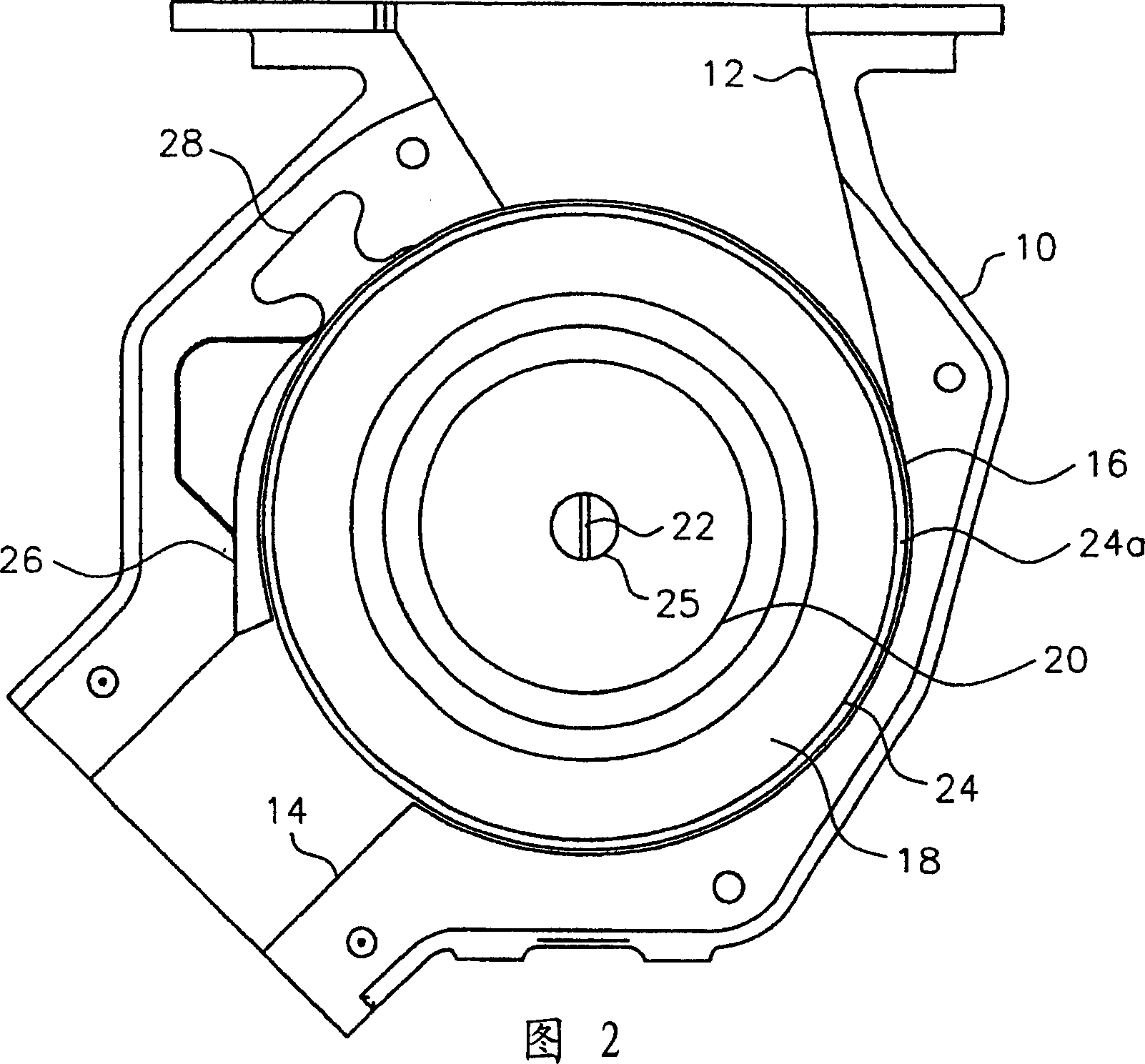

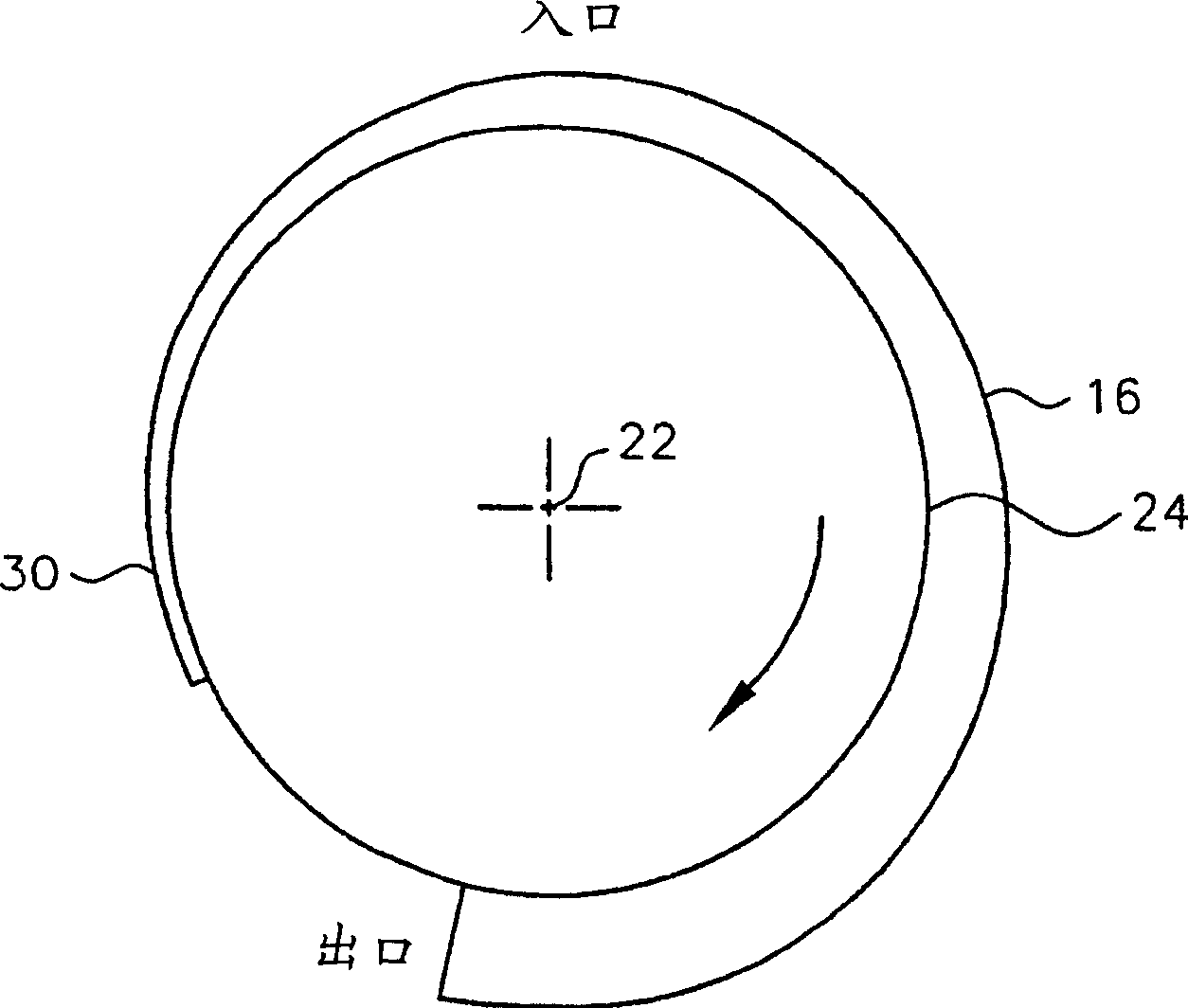

Bulk material pump feeder with reduced disk jamming

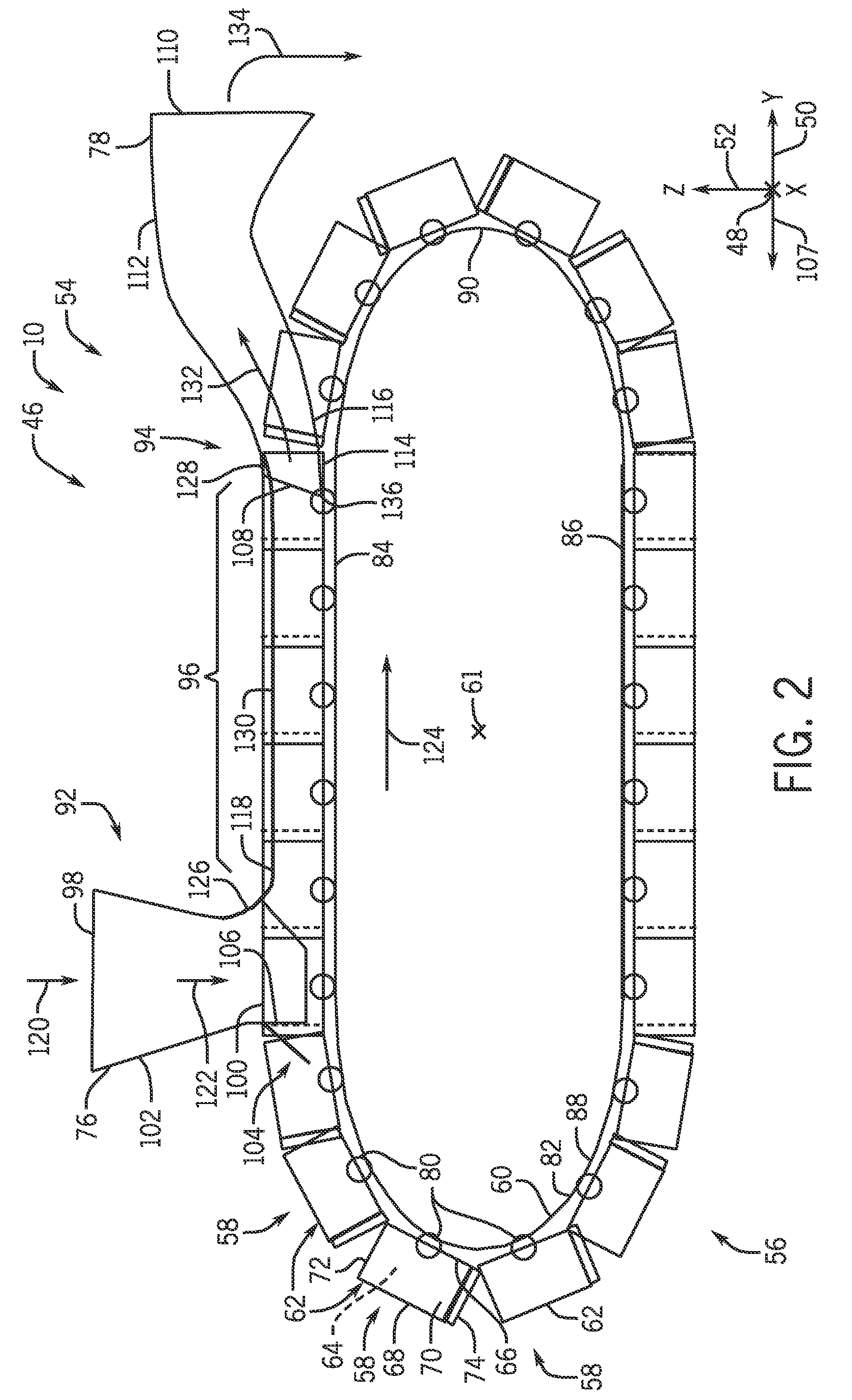

A bulk materials pump feeder having a housing and a rotating drive rotor for transferring material from an inlet to an outlet of the housing. The drive rotor has a hub. Drive disks extend away from the hub toward a housing inner wall. Three structural features of the feeder reduce the tendency of material to jam between the drive rotor and the housing or other stationary parts. First, the distance between the circumferential edges of the drive disks and the housing inner wall increases from the inlet to the outlet in the direction of rotation of the drive rotor. Second, a low-friction brush seal disposed on the periphery of the drive disks seals the area between the periphery of the drive disks and the inner wall. Finally, a materials scraper having a flexible tip is mounted in the housing and extends into the drive rotor between the drive disks.

Owner:K TRON TECH INC

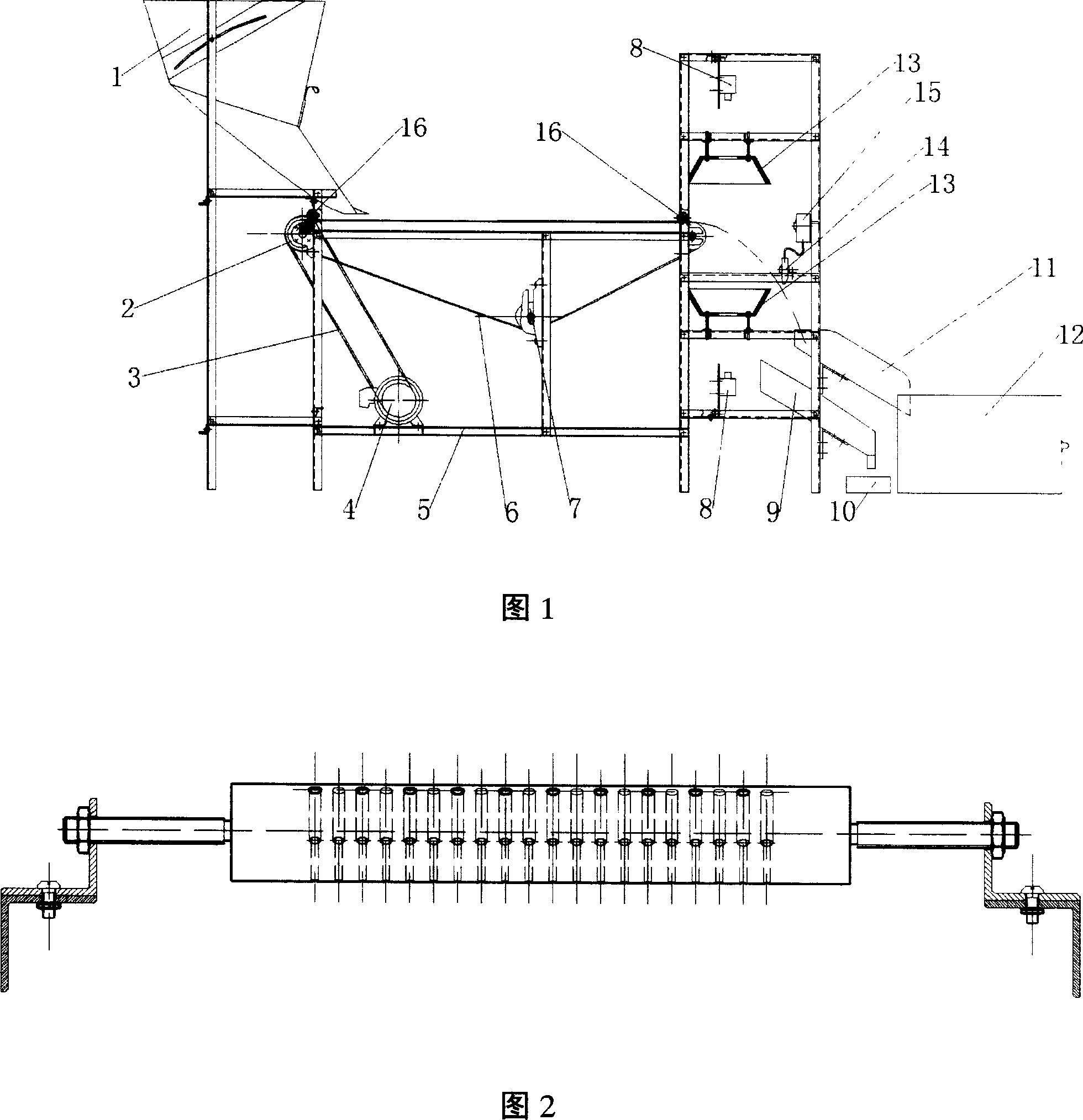

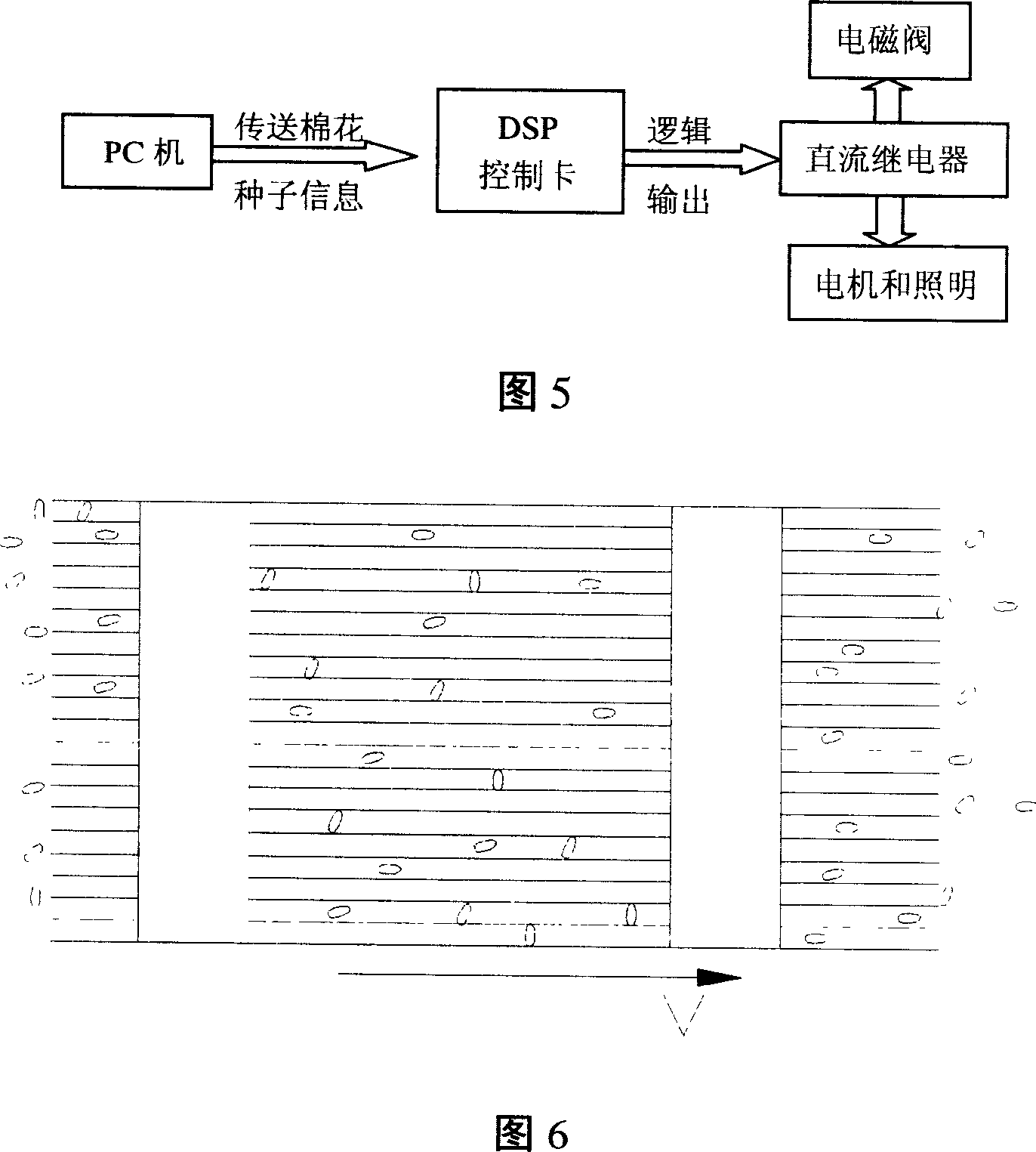

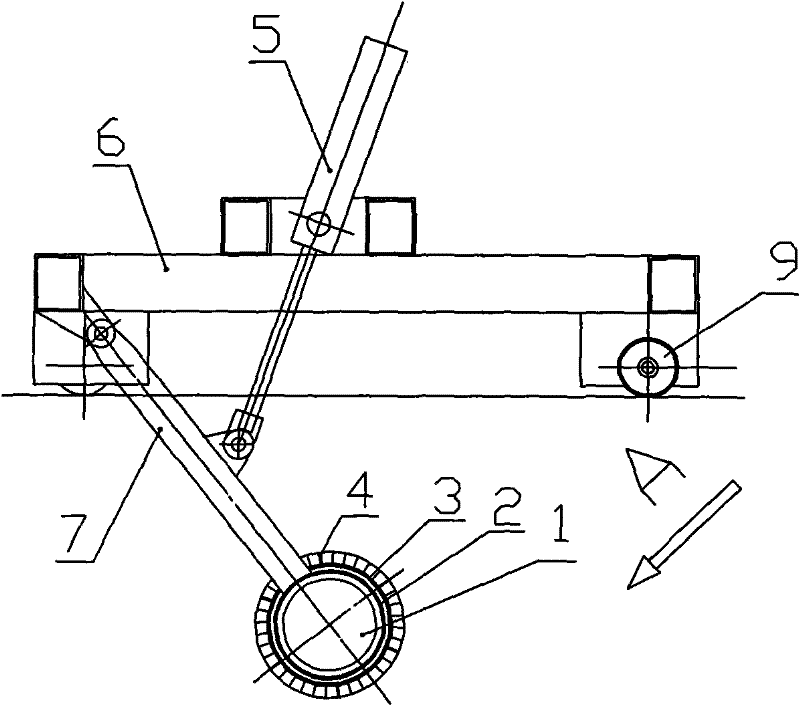

Automated system and method for cotton seed refining

InactiveCN1970173AImprove detection accuracyQuick checkTelevision system detailsThrowing machinesMagnetic valveEngineering

It relates to computerized automatic seed quality inspection and screening. The cotton seed selection automatic system comprises feeding hopper, belt wheel, belts, electric motor, conveyer belts, output hopper, receiving hopper, CAM, nozzle, electromagnet, a pair of light box and the computerized processing system collecting and analyzing cotton seed color information, screening disqualified seeds through the control of electromagnet and nozzle. It solves the target seed selection, separation and control with high speed movement.

Owner:CHINA AGRI UNIV

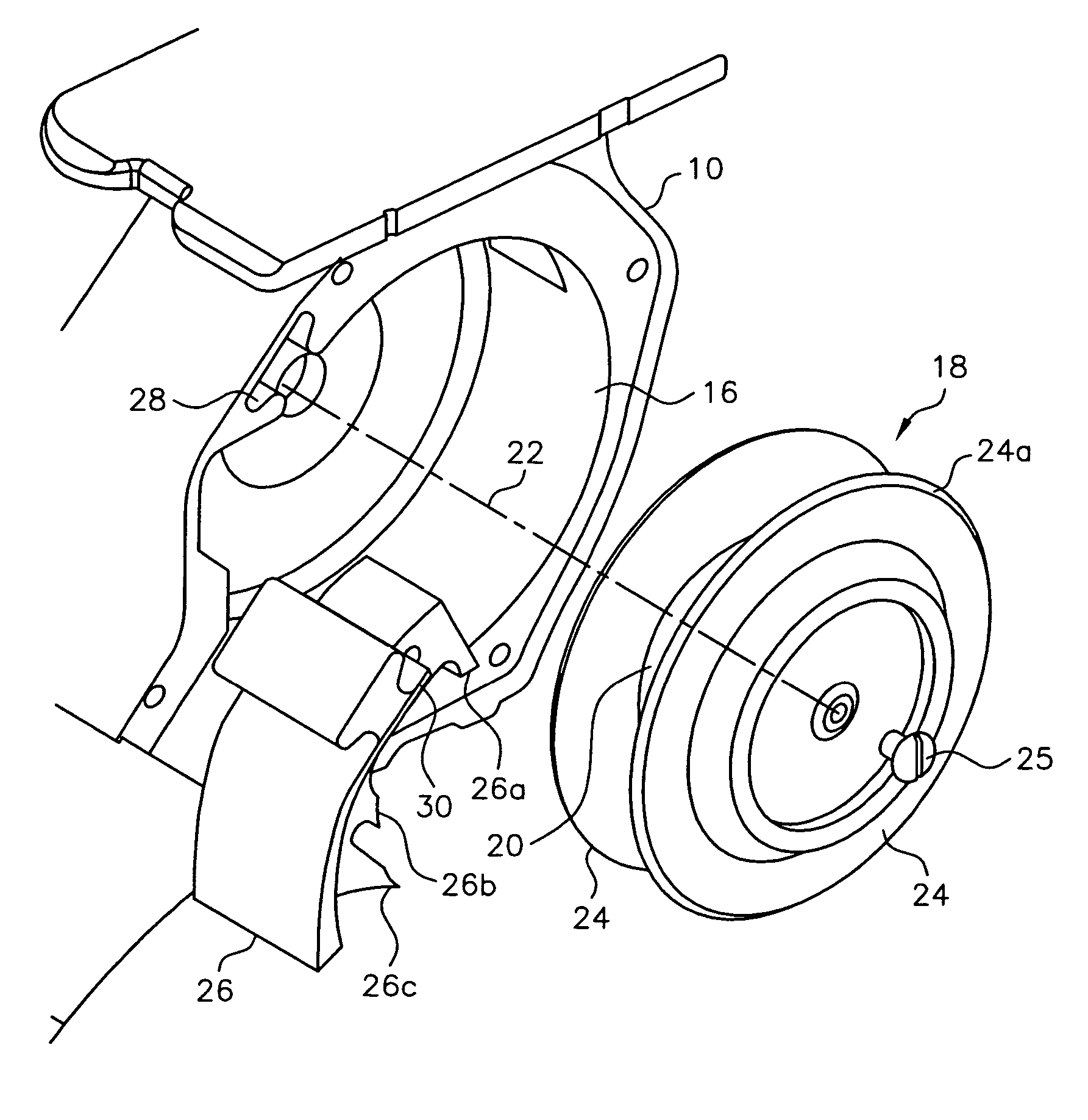

Bulk material pump feeder with reduced disk jamming

InactiveUS20060157322A1Trend downThrowing machinesSpecific fluid pumpsEngineeringMechanical engineering

A bulk materials pump feeder having a housing and a rotating drive rotor for transferring material from an inlet to an outlet of the housing. The drive rotor has a hub. Drive disks extend away from the hub toward a housing inner wall. Three structural features of the feeder reduce the tendency of material to jam between the drive rotor and the housing or other stationary parts. First, the distance between the circumferential edges of the drive disks and the housing inner wall increases from the inlet to the outlet in the direction of rotation of the drive rotor. Second, a low-friction brush seal disposed on the periphery of the drive disks seals the area between the periphery of the drive disks and the inner wall. Finally, a materials scraper having a flexible tip is mounted in the housing and extends into the drive rotor between the drive disks.

Owner:K TRON TECH INC

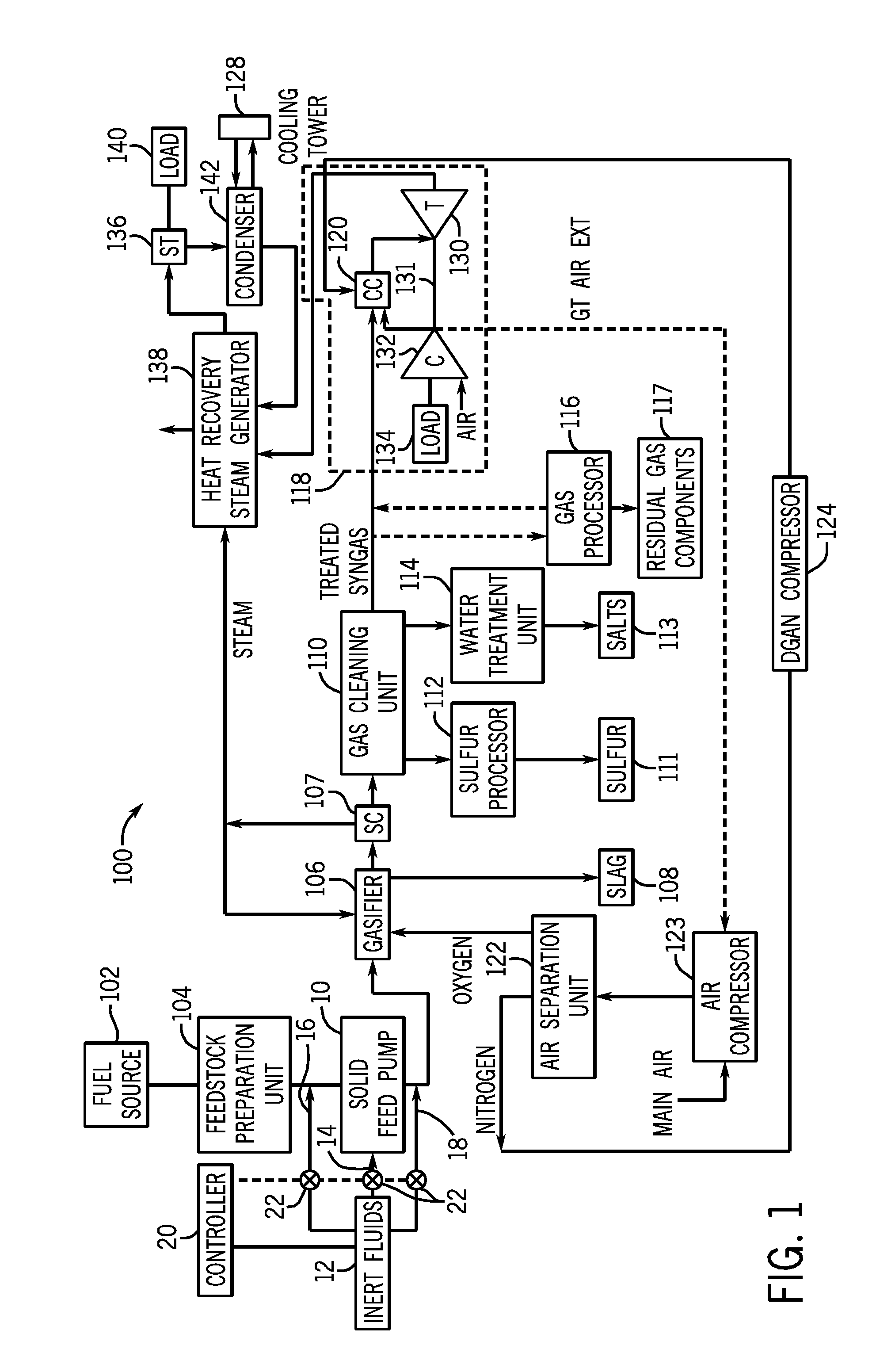

Process to provide a particulate solid material to a pressurised reactor

The invention is directed to a process to provide a particulate solid carbonaceous material to a pressurised gasification reactor comprising following steps, (a) transporting the solid material from a first lower pressure zone to a higher pressure zone using a bulk materials pump comprising a housing having a flow path for the solid material between an inlet fluidly connected to the first lower pressure zone and an outlet fluidly connected to the higher pressure zone, wherein said flow path in said housing is further defined by a space between two rotatable drive disks spaced from each other and wherein a materials scraper is present between said drive disks at the outlet to route a cake of solid material that is being transported between said drive disks to a transport conduit, which transport conduit fluidly connects the outlet of said housing and a burner as present in the gasification reactor, and (b) injecting a gaseous stream into the cake of solid material where the cake of solid material is discharged from the housing and enters the transport conduit, and (c) transporting the solid material and the gaseous stream in a transport conduit to the burner.

Owner:AIR PROD & CHEM INC

Transporting particulate material

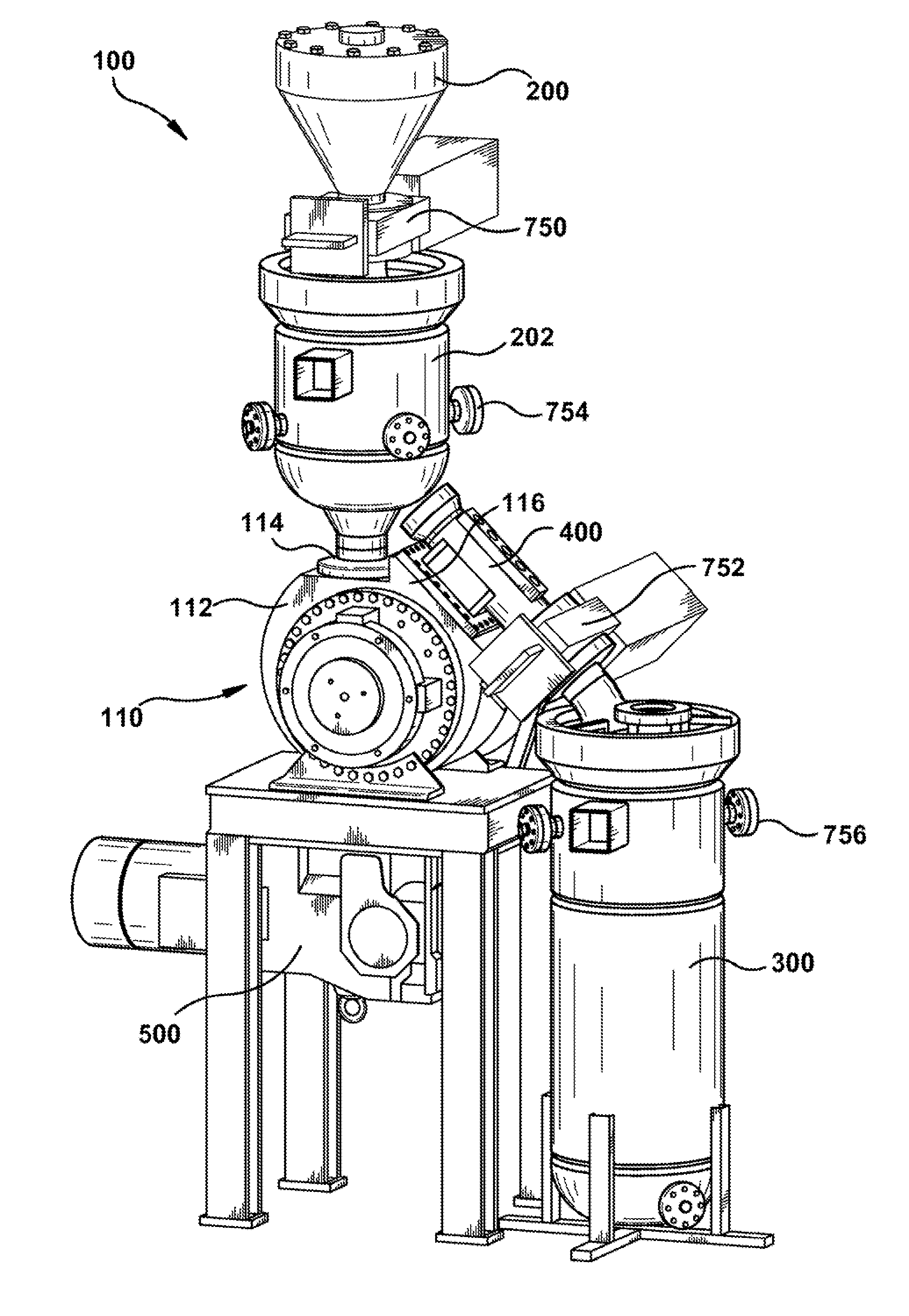

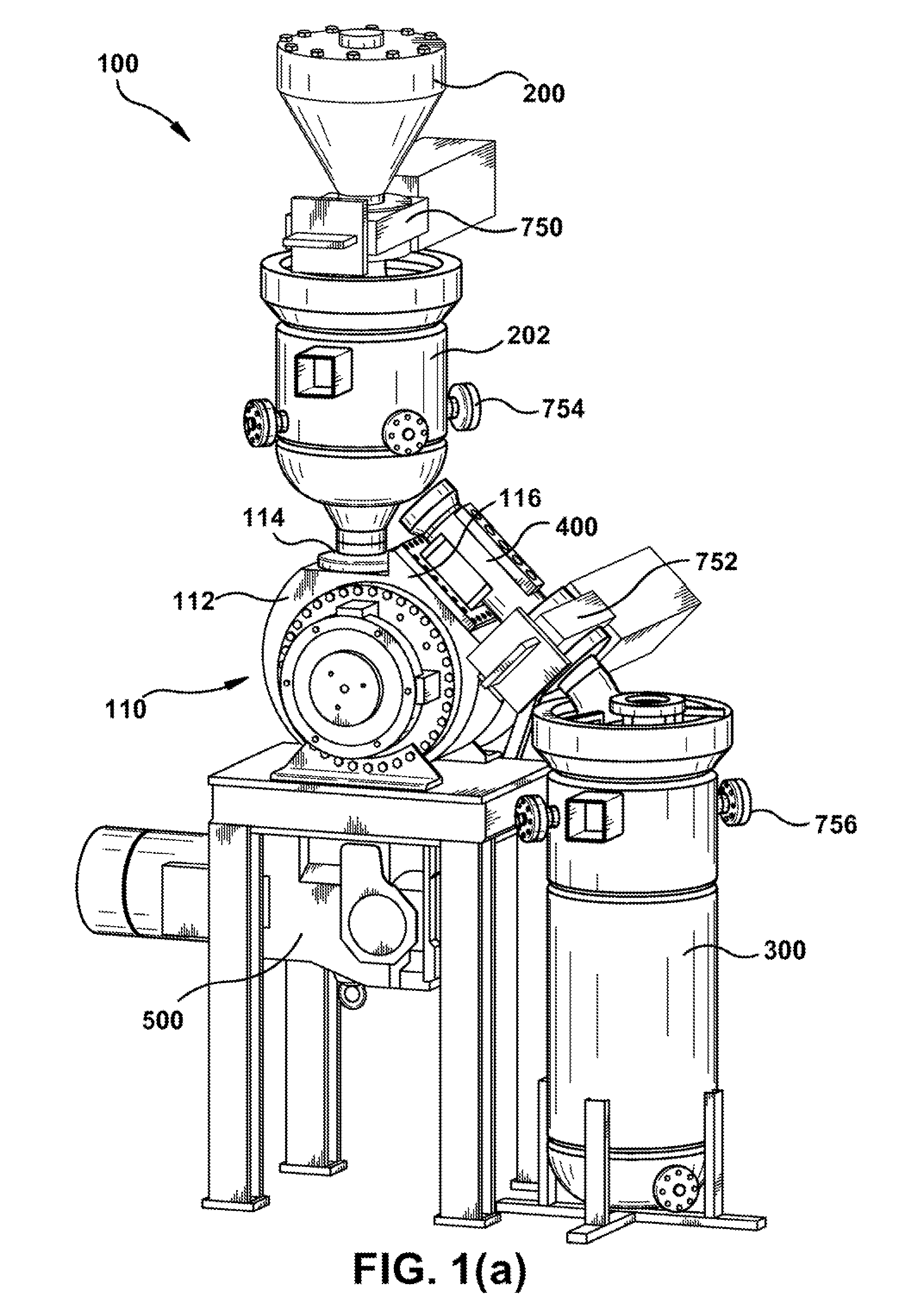

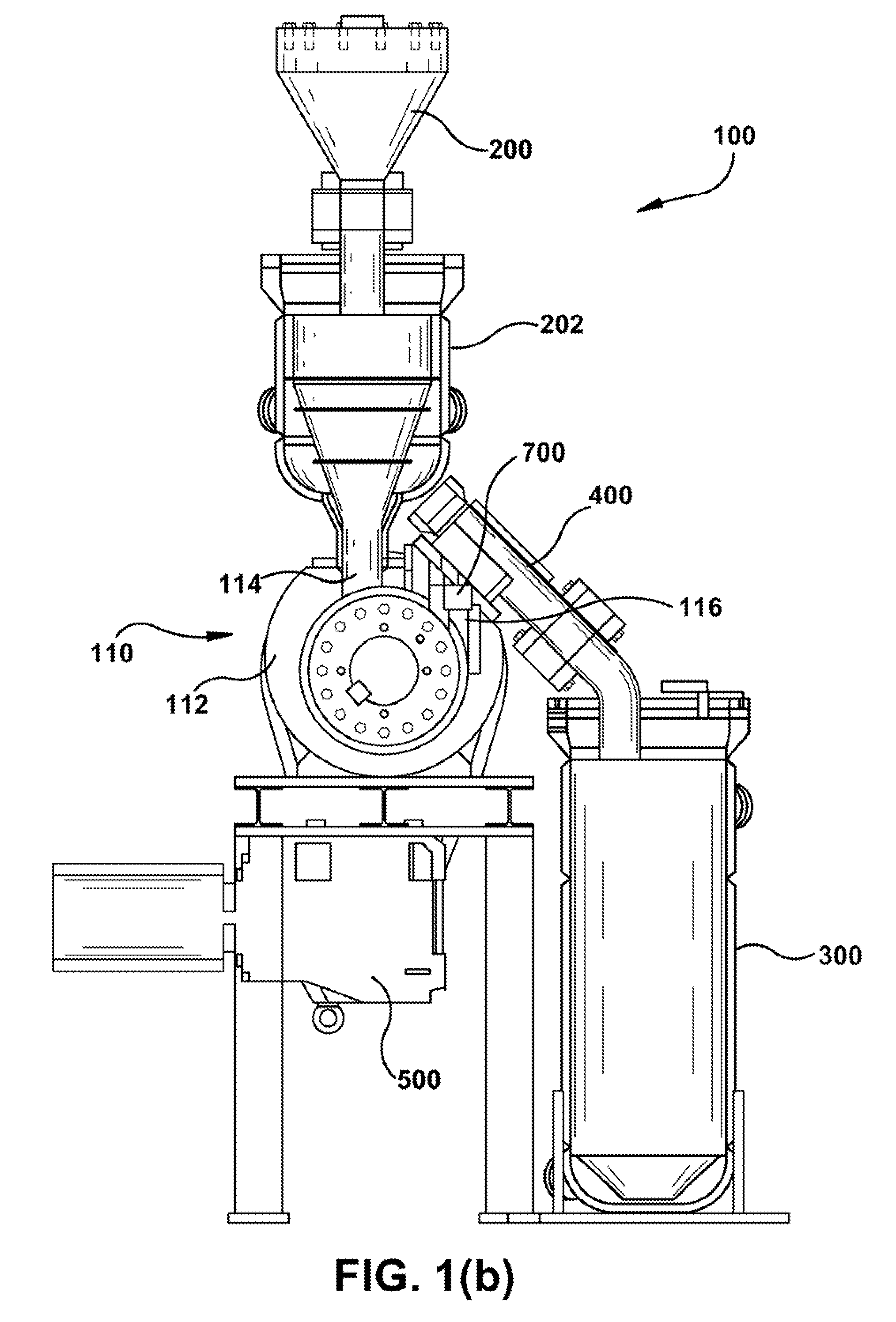

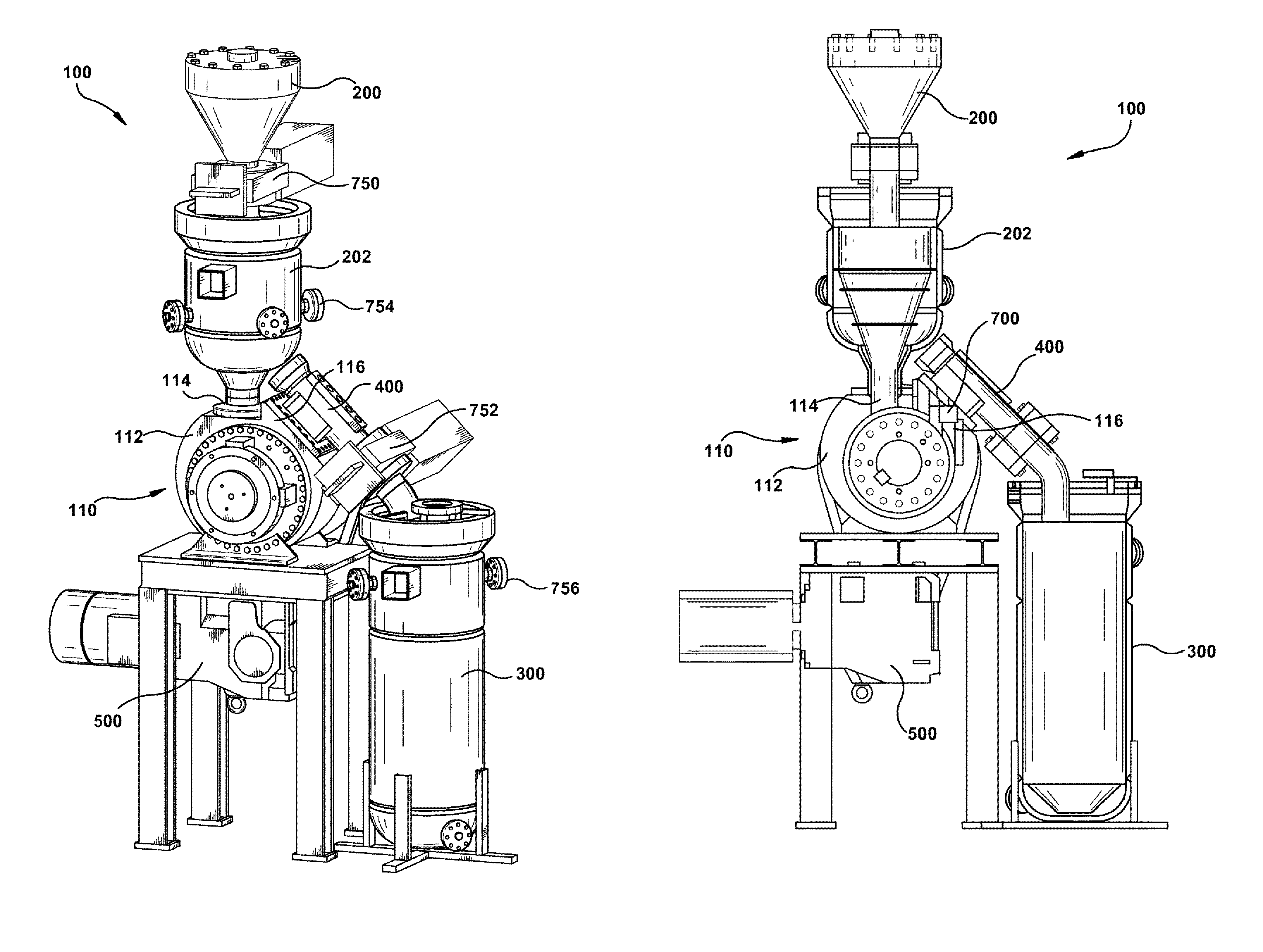

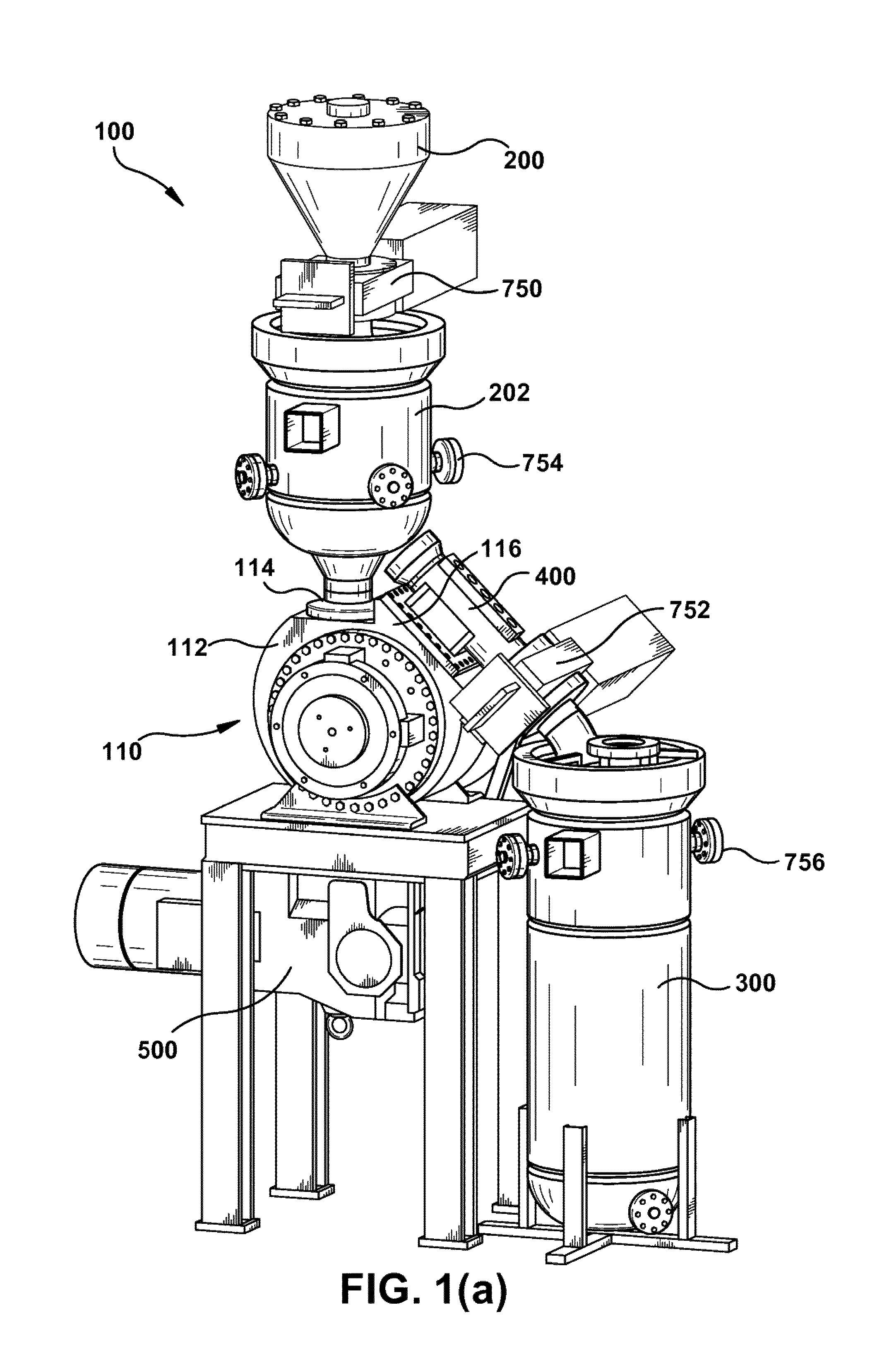

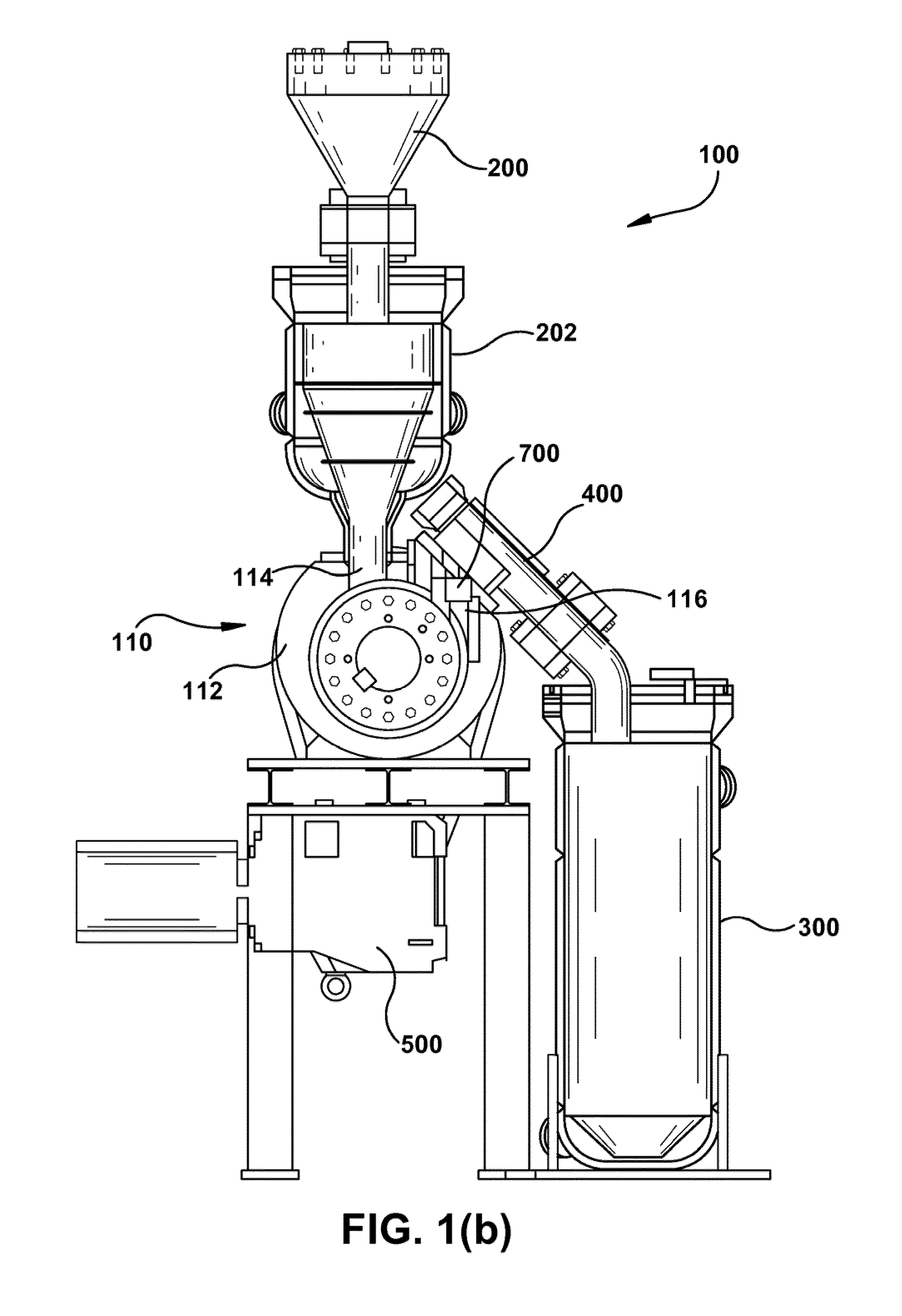

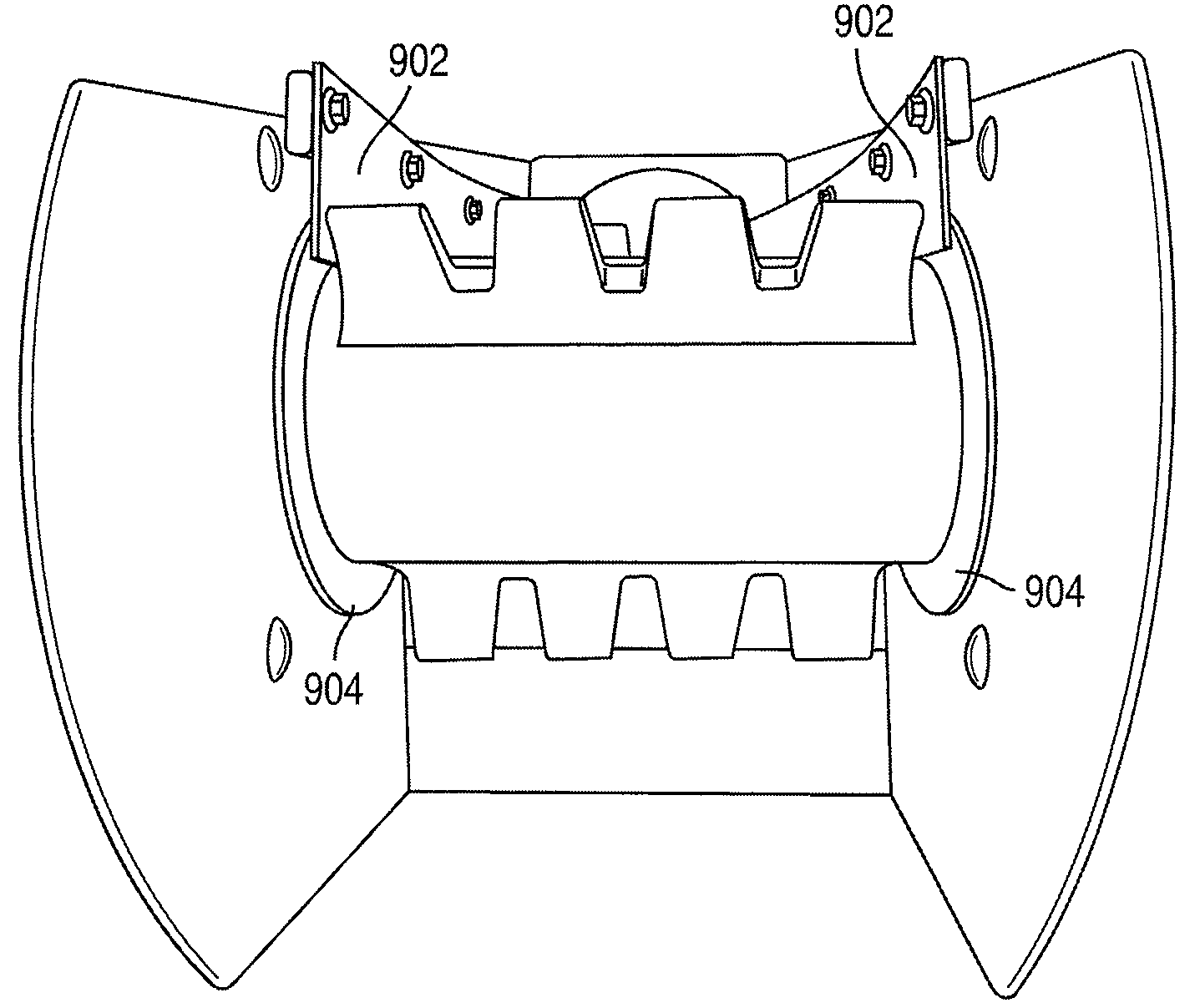

A material transporting system comprises a material transporting apparatus (100) including a material transporting apparatus hopper structure (200, 202), which comprises at least one rotary transporting apparatus; a stationary hub structure (900) constraining and assisting the at least one rotary transporting apparatus; an outlet duct configuration (700) configured to permit material to exit therefrom and comprising at least one diverging portion (702, 702′); an outlet abutment configuration (800) configured to direct material to the outlet duct configuration; an outlet valve assembly from the material transporting system venting the material transporting system; and a moving wall configuration in the material transporting apparatus capable of assisting the material transporting apparatus in transporting material in the material transporting system. Material can be moved from the material transporting apparatus hopper structure to the outlet duct configuration through the at least one rotary transporting apparatus, the outlet abutment configuration, and the outlet valve assembly.

Owner:AIR PROD & CHEM INC

Transporting particulate material

A material transporting system comprises a material transporting apparatus (100) including a material transporting apparatus hopper structure (200, 202), which comprises at least one rotary transporting apparatus; a stationary hub structure (900) constraining and assisting the at least one rotary transporting apparatus; an outlet duct configuration (700) configured to permit material to exit therefrom and comprising at least one diverging portion (702, 702′); an outlet abutment configuration (800) configured to direct material to the outlet duct configuration; an outlet valve assembly from the material transporting system venting the material transporting system; and a moving wall configuration in the material transporting apparatus capable of assisting the material transporting apparatus in transporting material in the material transporting system. Material can be moved from the material transporting apparatus hopper structure to the outlet duct configuration through the at least one rotary transporting apparatus, the outlet abutment configuration, and the outlet valve assembly.

Owner:AIR PROD & CHEM INC

Charging device with rotary chute

InactiveUS7311486B2Simple driveEasy mounting and dismountingThrowing machinesConveyorsMechanical engineeringVertical axis

A charging device for bulk material comprises a rotor having a substantially vertical axis of rotation a first drive for rotating the rotor and a chute supported by the rotor so as to be rotated with the latter. The chute can be rotated about its longitudinal axis. Its concavely curved sliding surface has a width that is diminishing from the top end to the bottom end of the chute, so that it is possible to vary the location where bulk material sliding down the chute channel leaves the latter by rotating the chute about its longitudinal axis.

Owner:PAUL WURTH SA

Tube conveyor with sealing belt edges

A tubular conveyor for conveying grain or seed includes an intake end having a first roller and a discharge end having a second roller. A tubular portion is disposed between the intake end and the discharge end. A continuous flexible conveyor belt is coupled with the first and second rollers. Seal means are provided for sealing edges of the conveyor belt at a point approximately where the conveyor belt meets at least one of the first and second rollers.

Owner:UNVERFERTH MFG

Drum-type turner

ActiveCN102126602AQuality improvementHigh strengthThrowing machinesSludge treatmentFriction lossSludge

The invention discloses a drum-type turner which is characterized in that a motor is arranged in a roller; and the roller is directly arranged on a power output shaft of a speed reducer. The drum-type turner has the advantages of compact structure, high mechanical efficiency, stable operation and no noise; a stepped web plate is adopted; the cutting edge is sharp; the friction loss is less and the scarifying and material smashing operation quality is good; and the turner is provided with a feed distribution cabin and a lifting workbench, thus various types of work, such as material paving, detection and the like can be finished simultaneously. The equipment can be used for processing solid wastes, such as rubbish, excrement, mud and the like.

Owner:BEIJING ZHONGKE BOLIAN ENVIRONMENT ENG

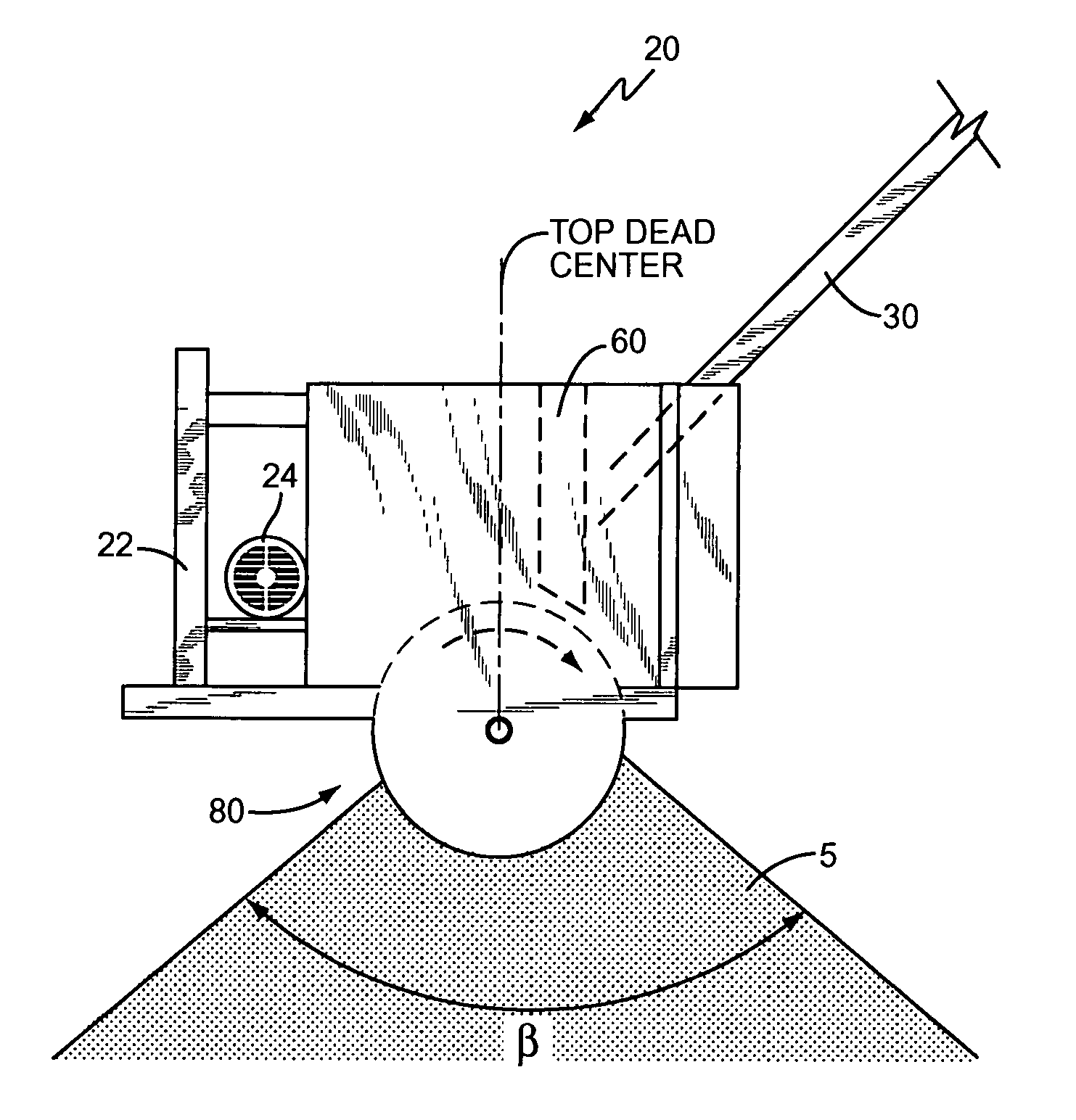

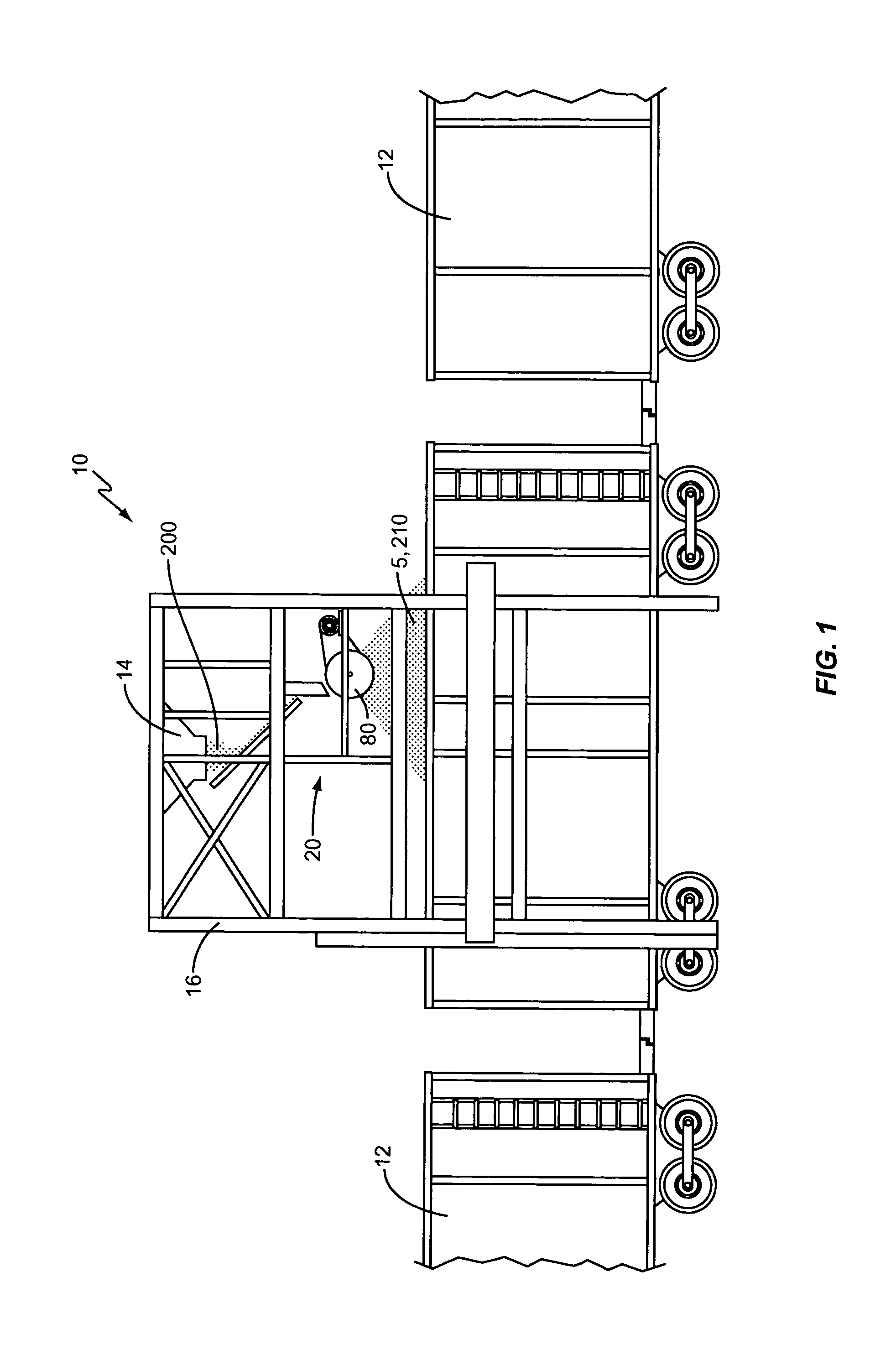

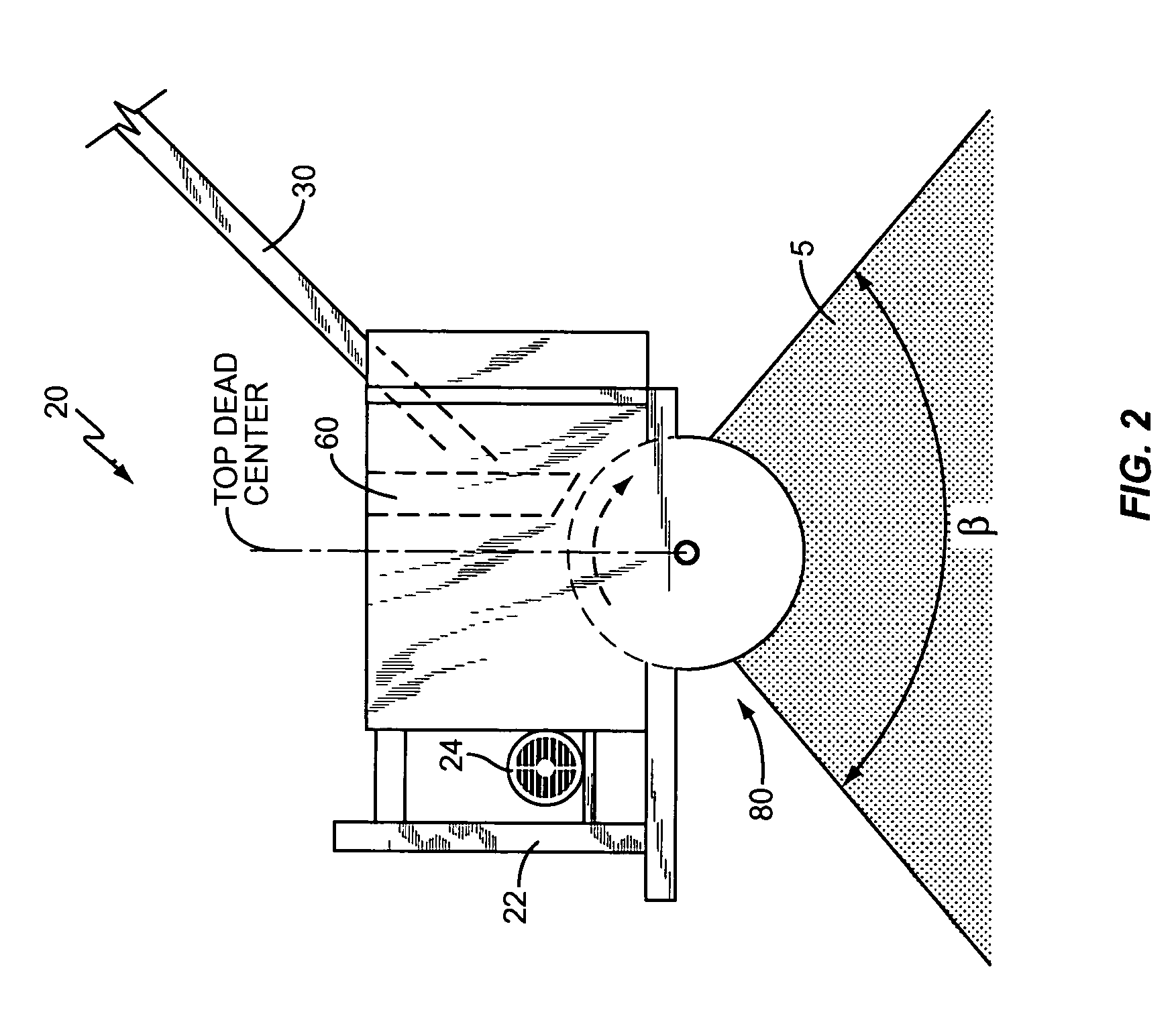

Wood chip flinger and method of densely packing wood chips with large angle output

A handling device packs wood chips with a density greater than that achieved using conventional free-fall techniques by ≧20%-35%. The device includes a drum rotating about a generally horizontal axis that includes a plurality of outwardly extending blades that act to fling the wood chips so as to land with a substantially uniform orientation. The blades may comprise a leading face with at least a first face section that extends in a first direction and at least a second face section extending at a forward angle relative to the first section. The first direction may be generally normal to the drum core's peripheral surface. The output from the drum, when an input stream of wood chips is fed to the drum, covers an arc of at least 90°, typically in the range of 90°-120° and generally downwardly facing, when viewed from the side along the axis.

Owner:BAILEY CONSULTING

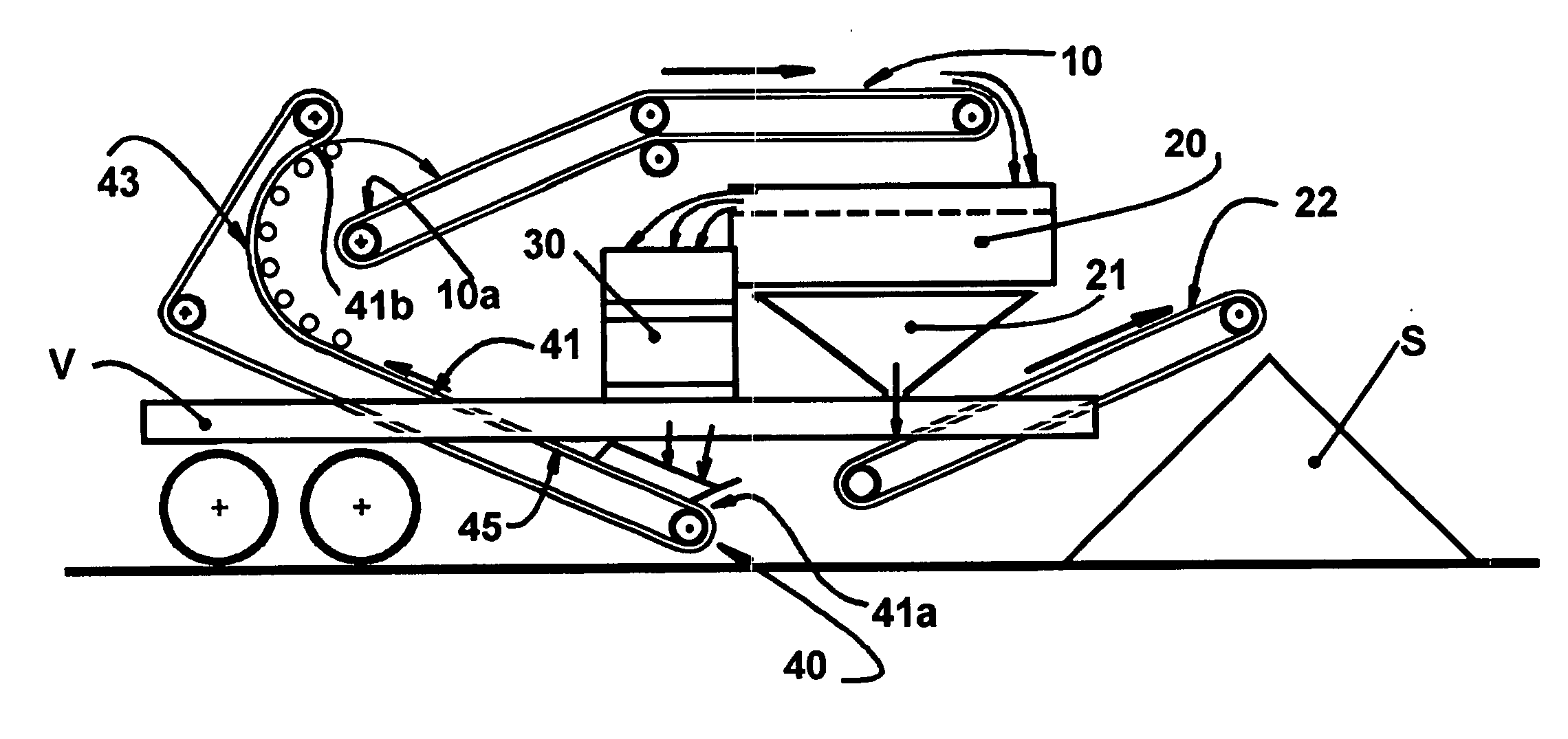

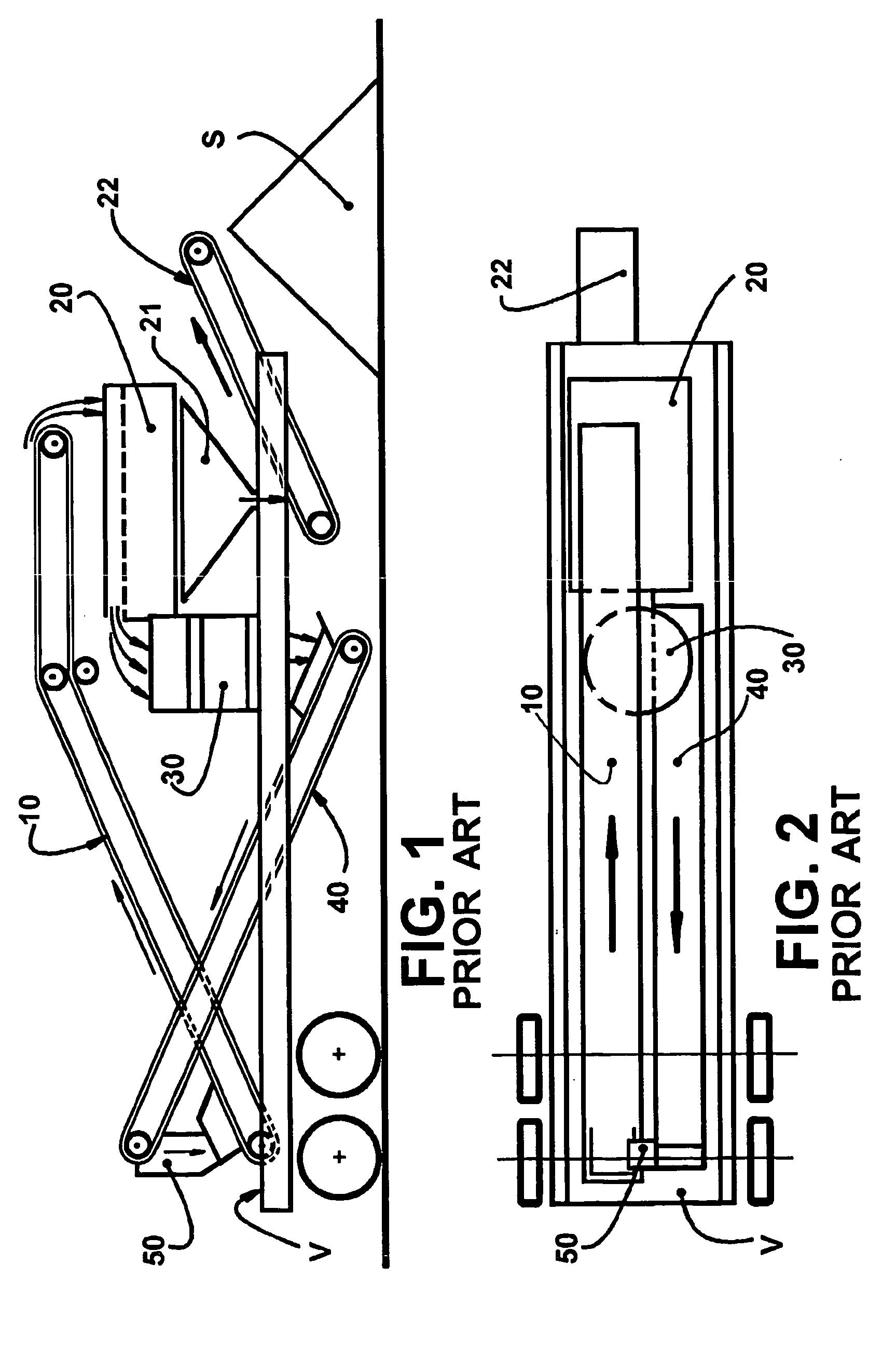

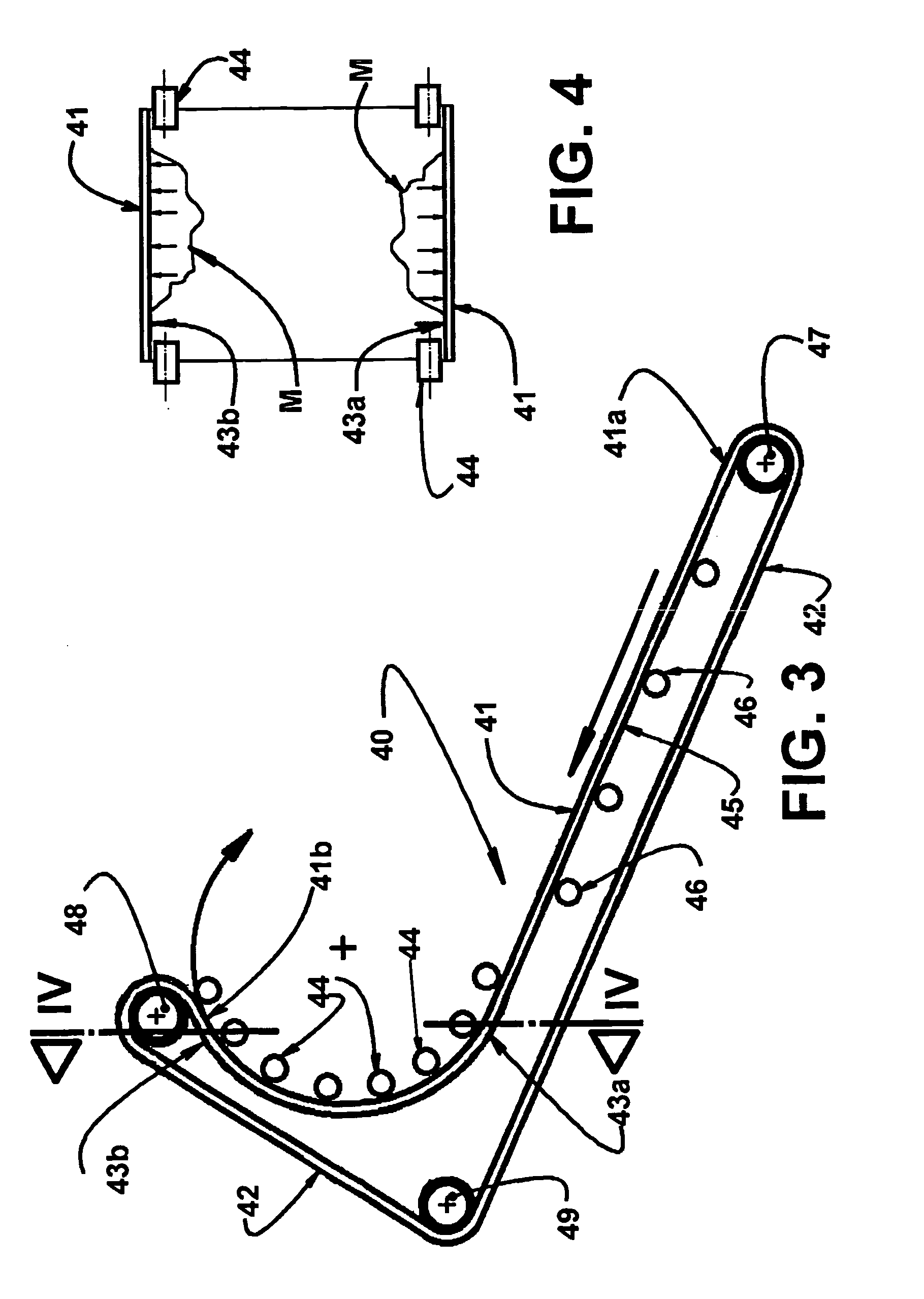

Belt conveyor and crushing unit

InactiveUS20050121295A1Reduced longitudinal extensionReduce widthThrowing machinesSupporting framesEngineeringUpper segment

A belt conveyor and a crushing unit includes a conveying upper run presenting a feed end and a discharge end, and a return lower run, with the conveying upper end including a curved extension, which is concave and ascending and presents an inlet lower portion and an outlet upper portion of the conveying upper run, where the belt conveyor imparts to the material a path that is substantially coplanar and opposite in relation to that imparted to the material in the inlet portion, and with ascending curved path presenting at a determined belt speed, a centrifugal force sufficient to maintain the material seated against the curved extension of the conveying upper run until reaching the discharge end.

Owner:METSO MINERALS BRASIL

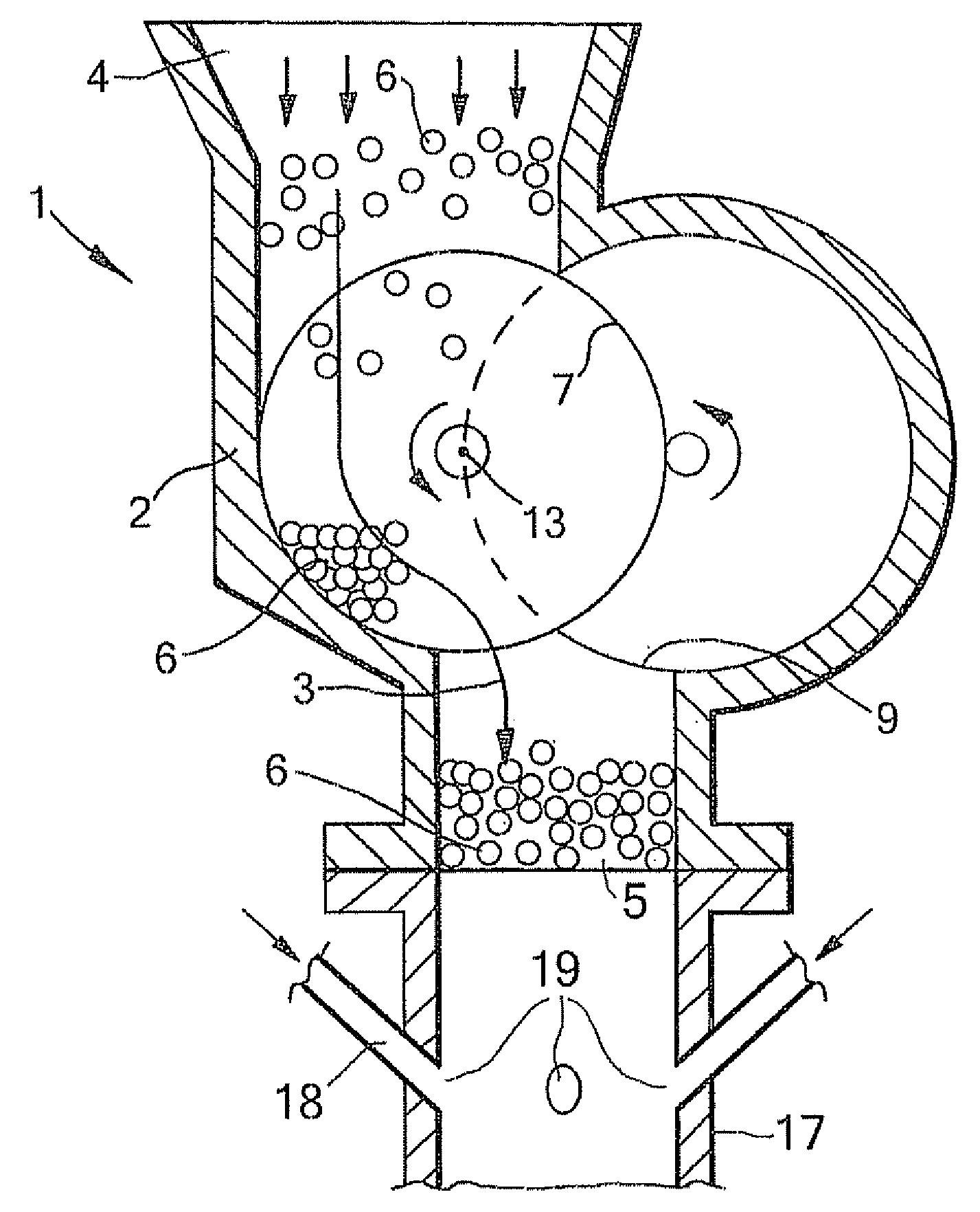

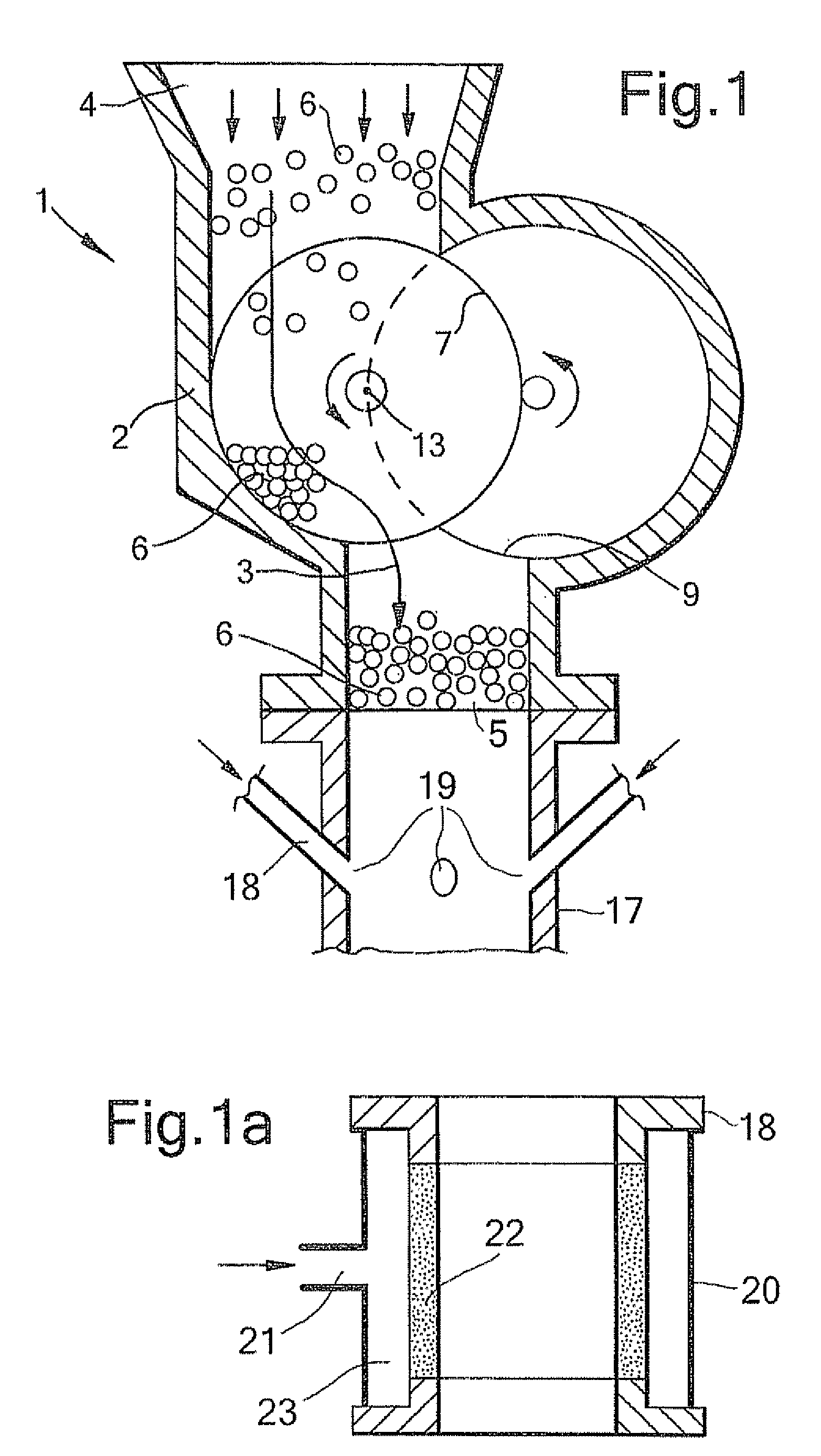

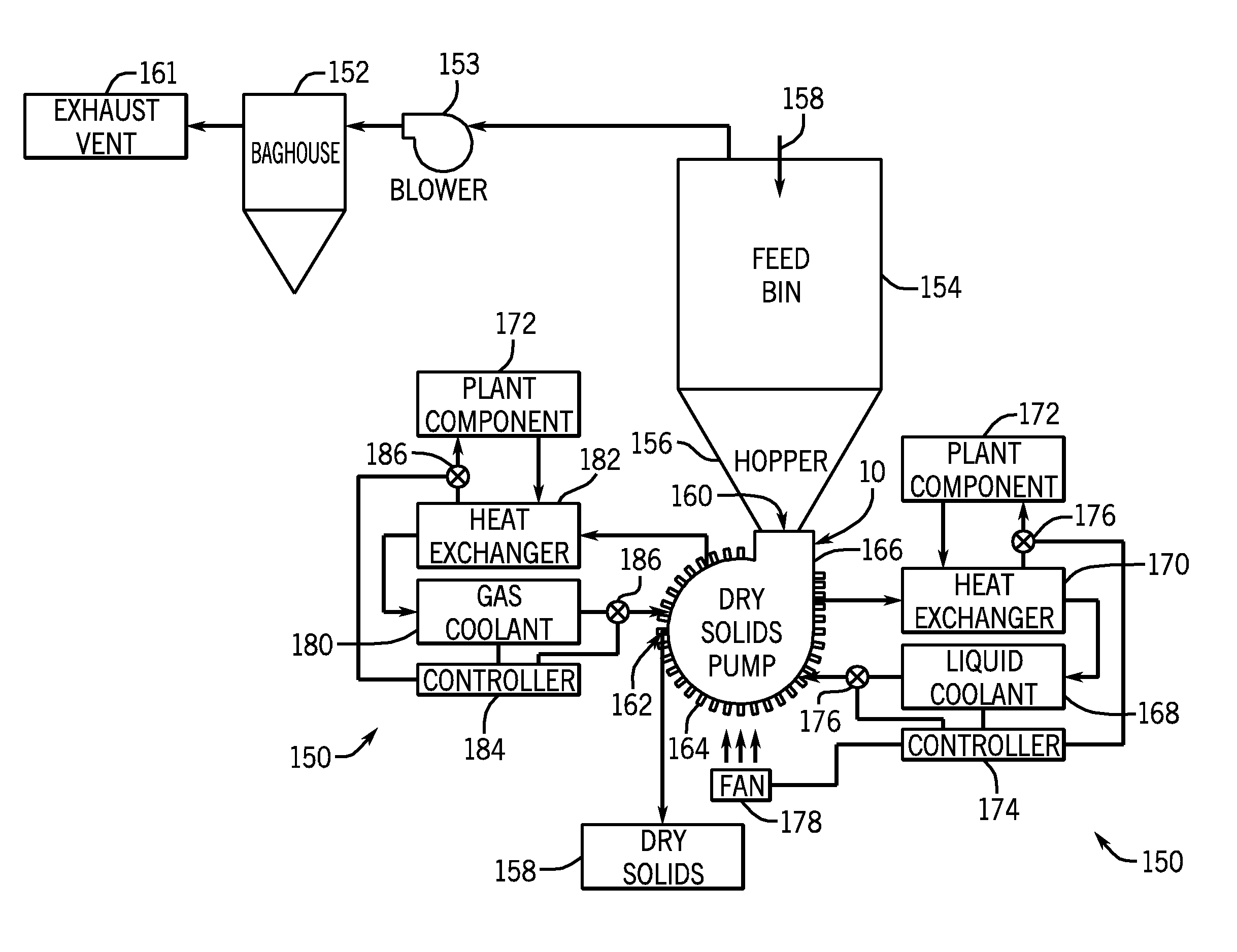

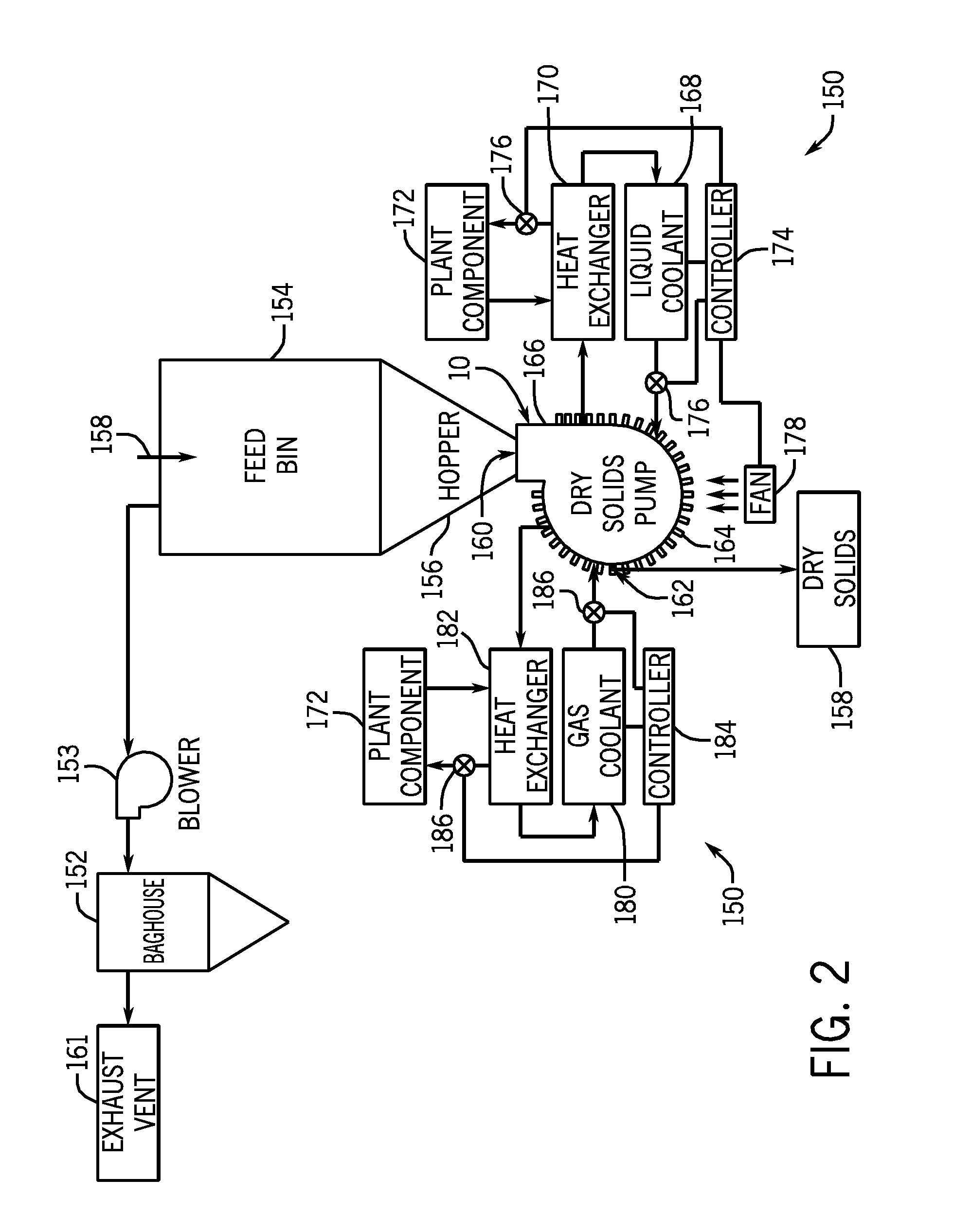

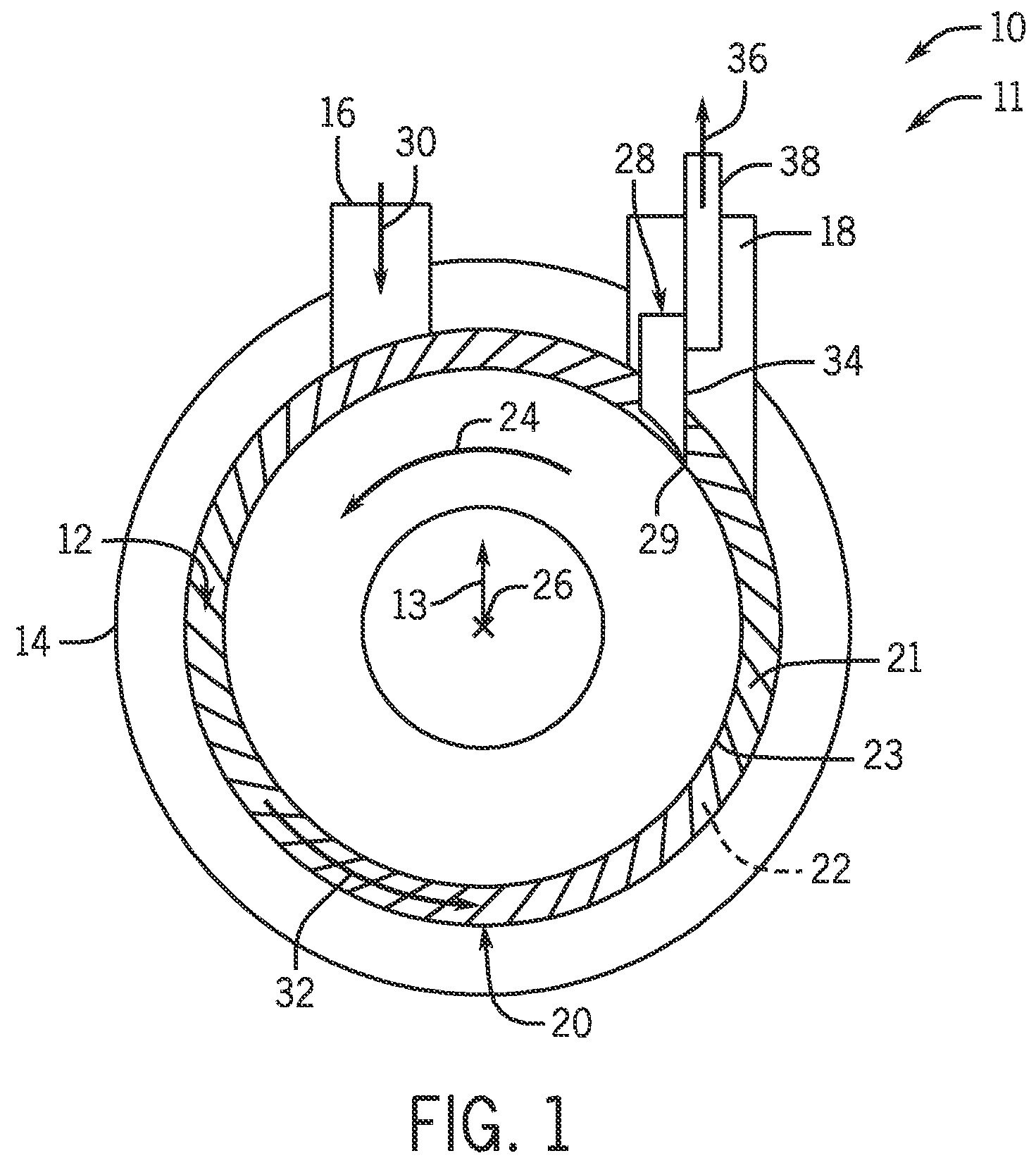

System for thermally controlling a solid feed pump

According to various embodiments, a system includes a solid feed pump. The solid feed pump includes a housing, a rotor disposed in the housing, a curved passage disposed between the rotor and the housing, an inlet coupled to the curved passage, an outlet coupled to the curved passage, a solid feed guide extending across the curved passage, and a thermal control path through a portion of the solid feed pump.

Owner:AIR PROD & CHEM INC

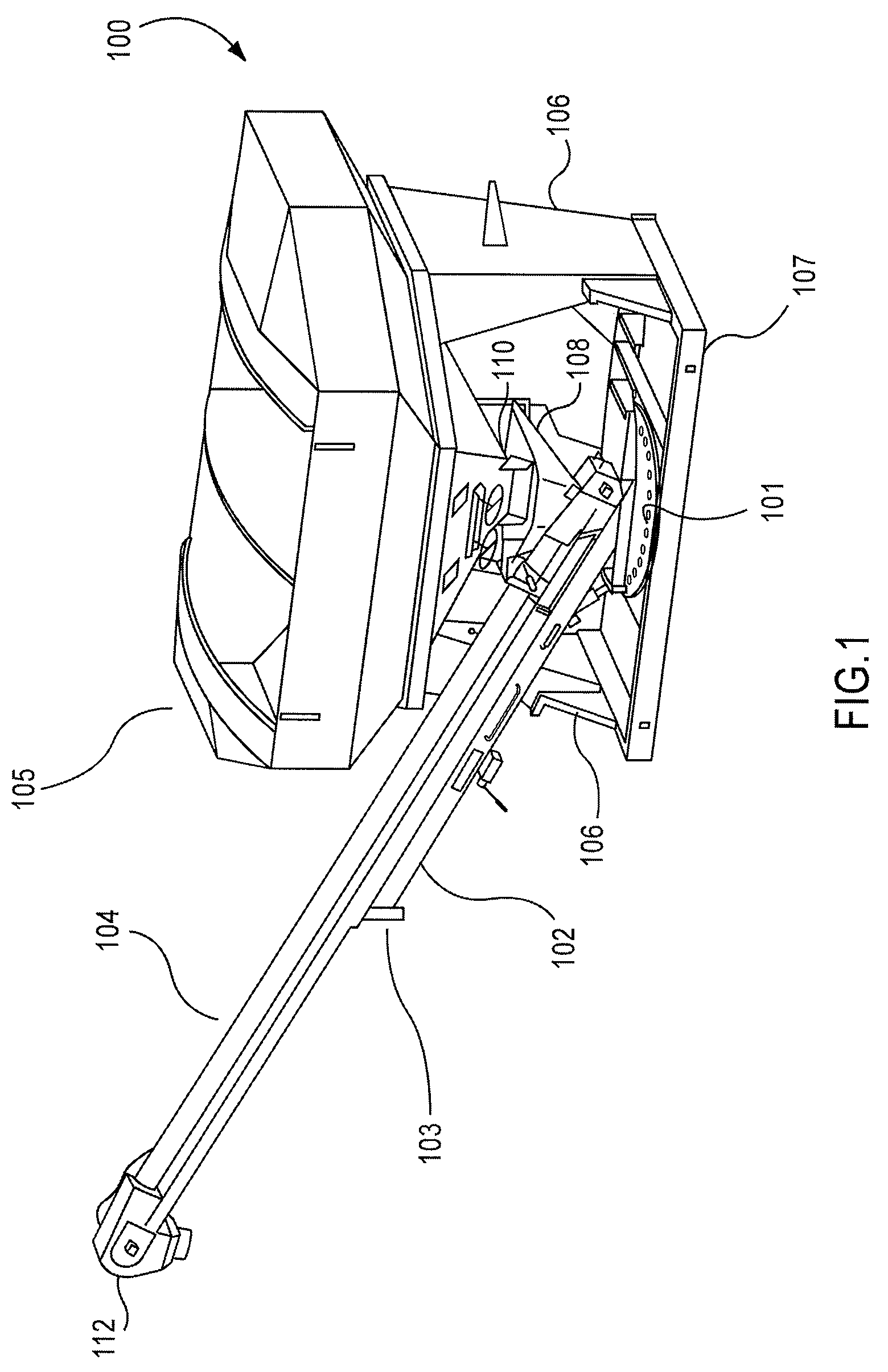

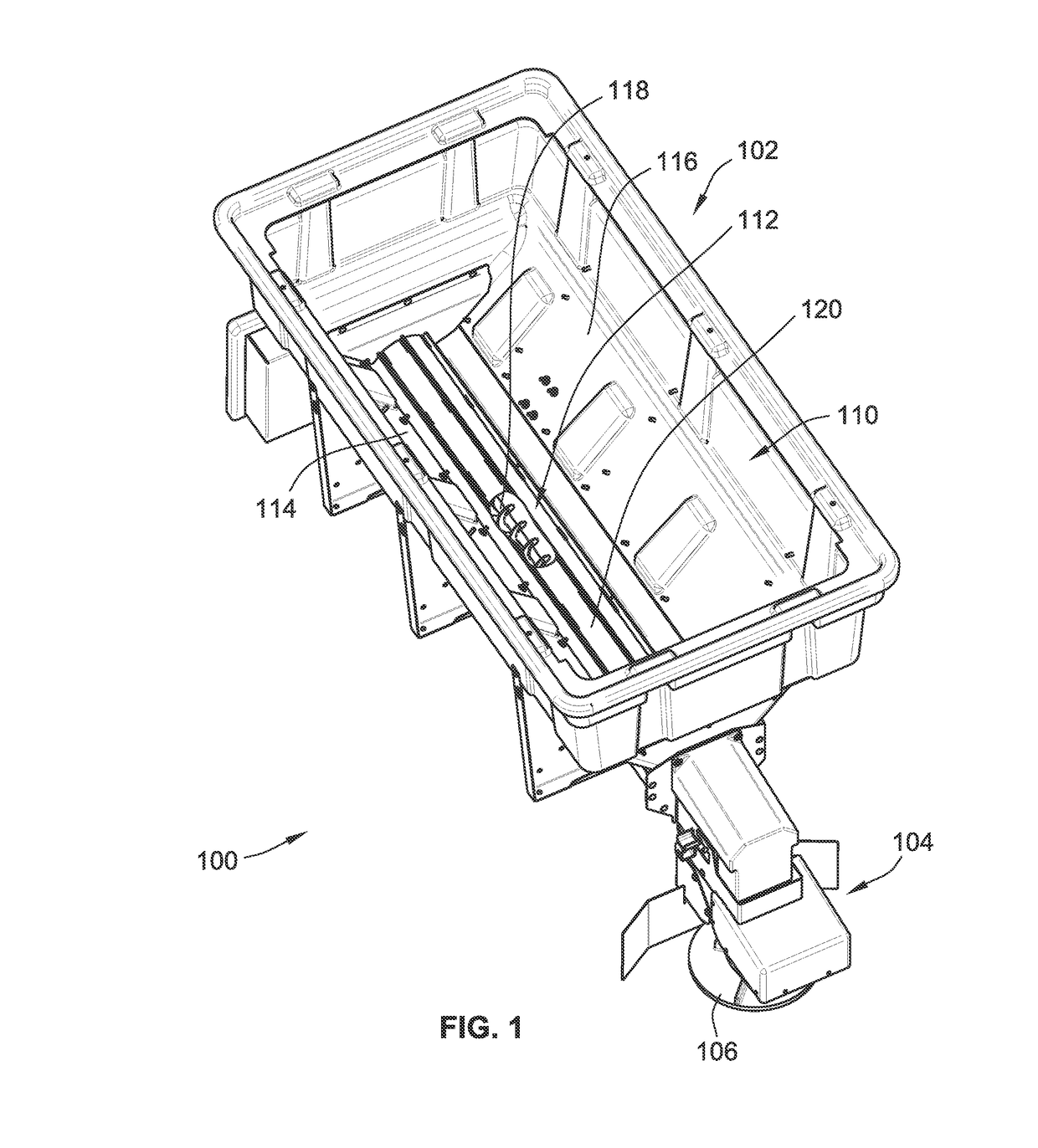

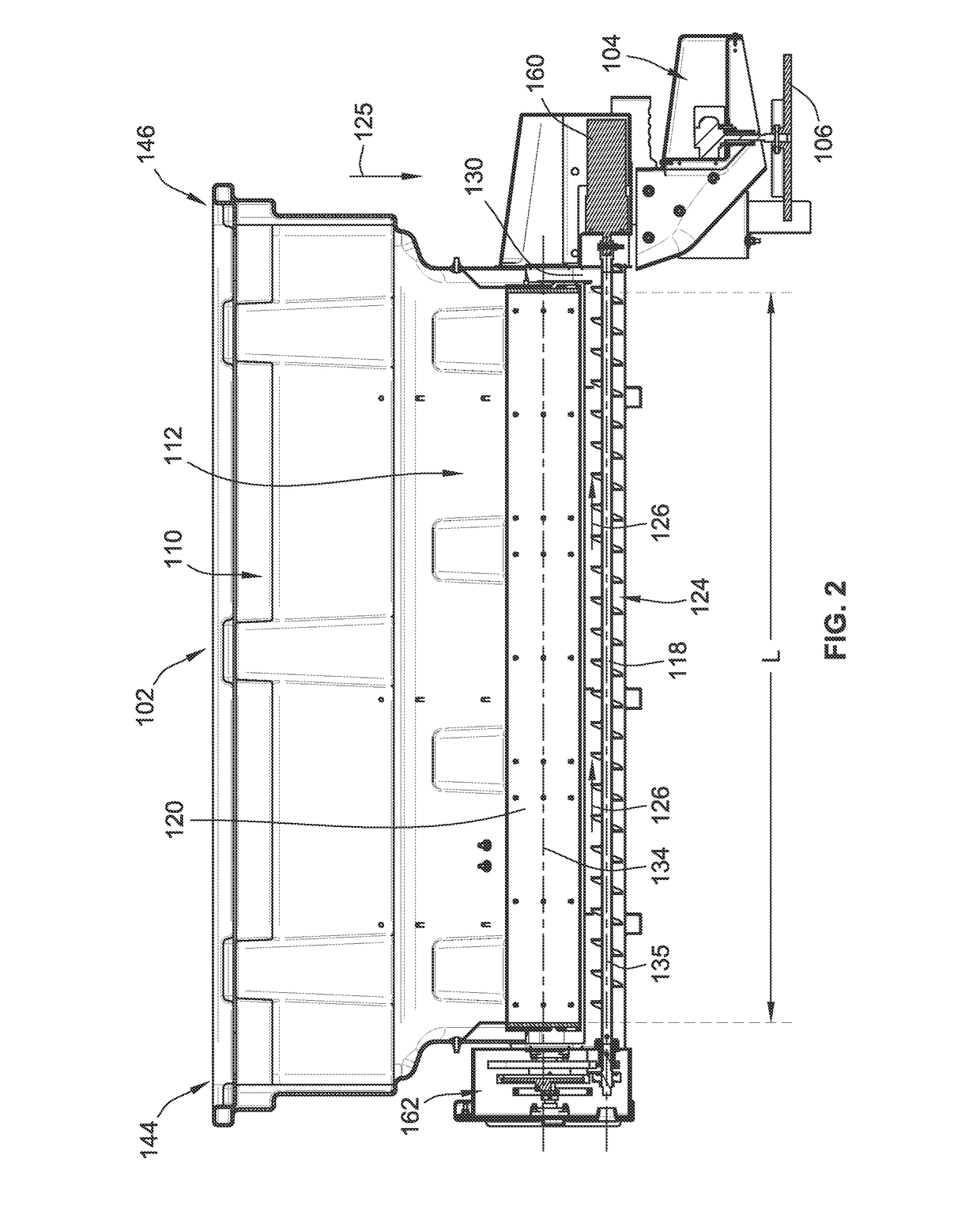

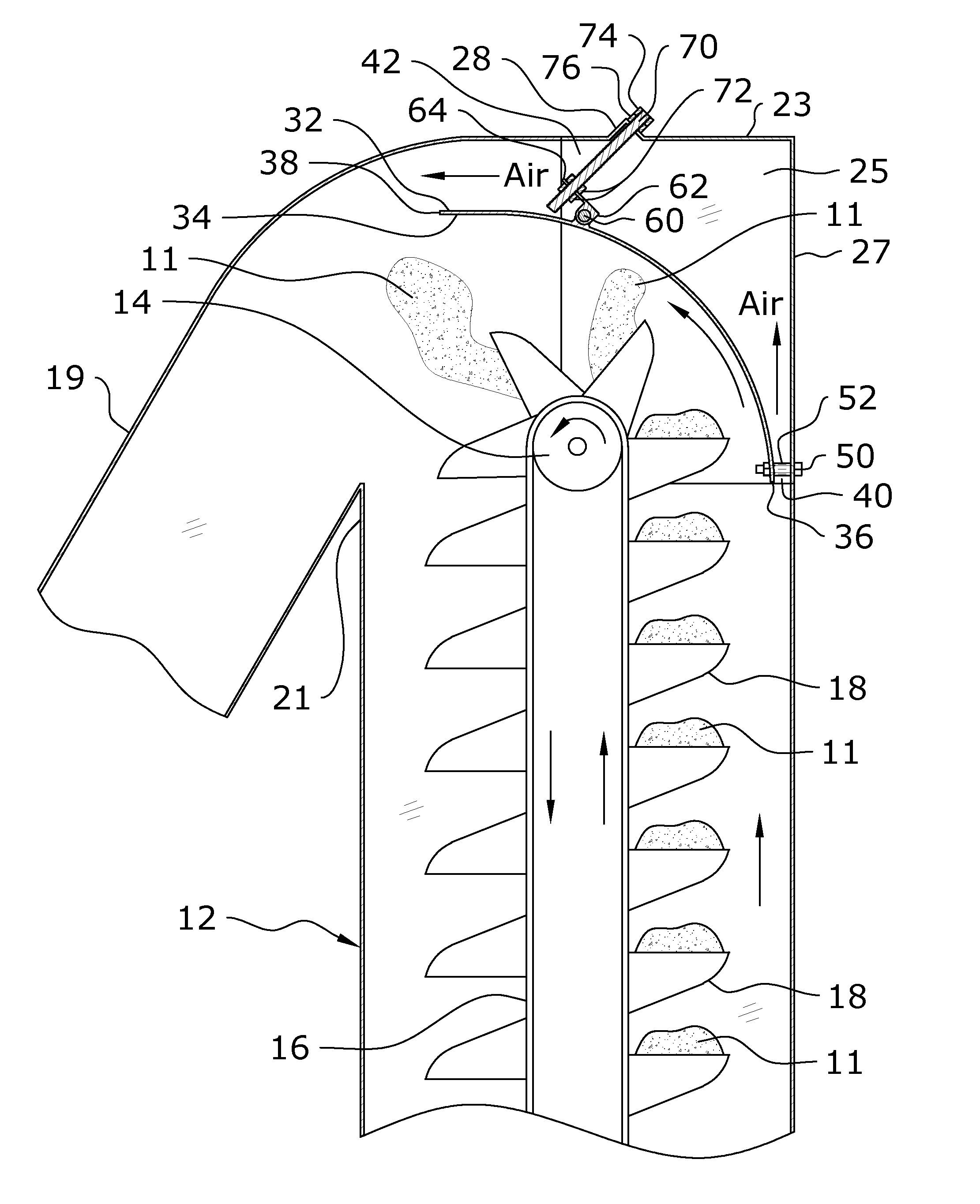

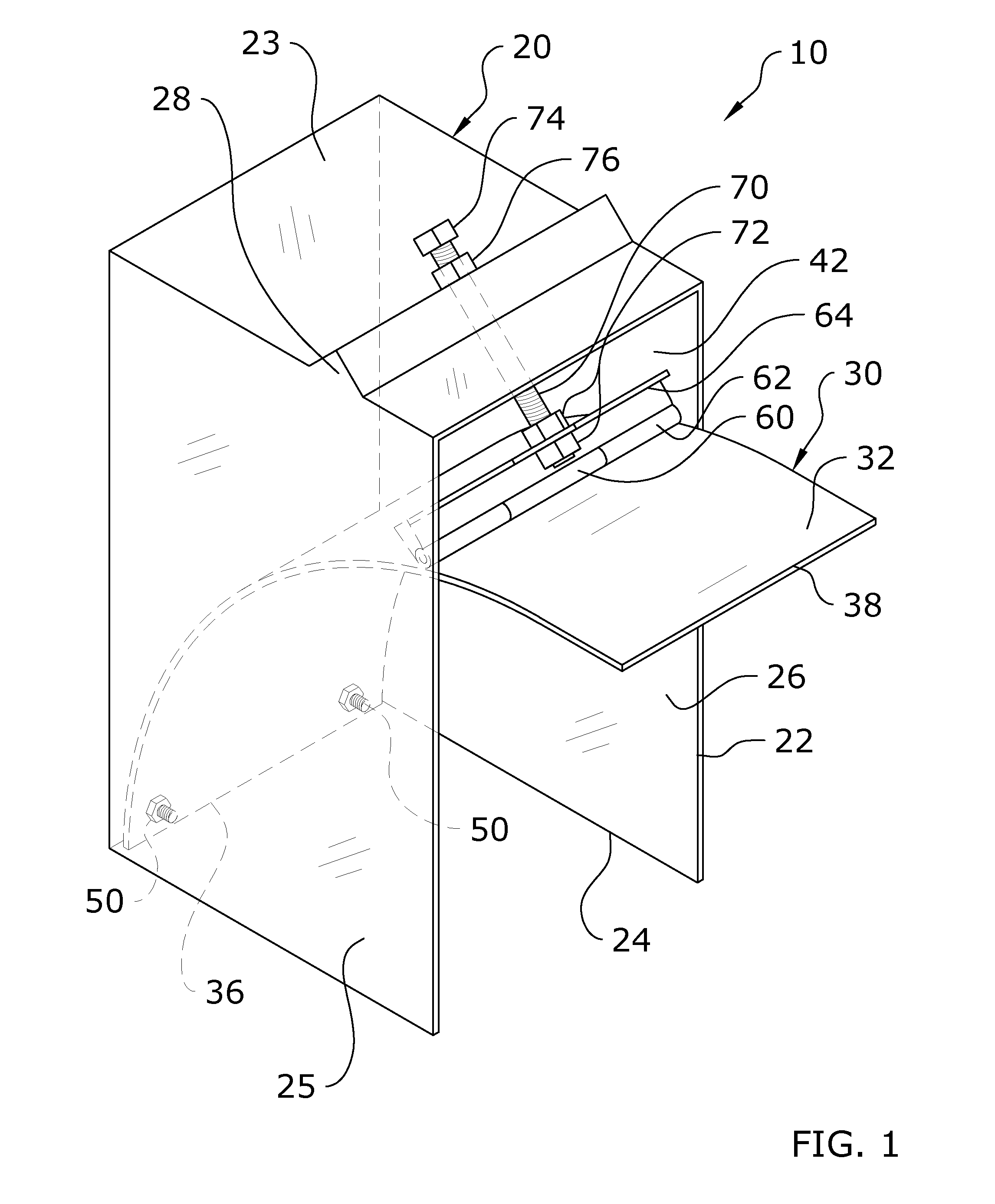

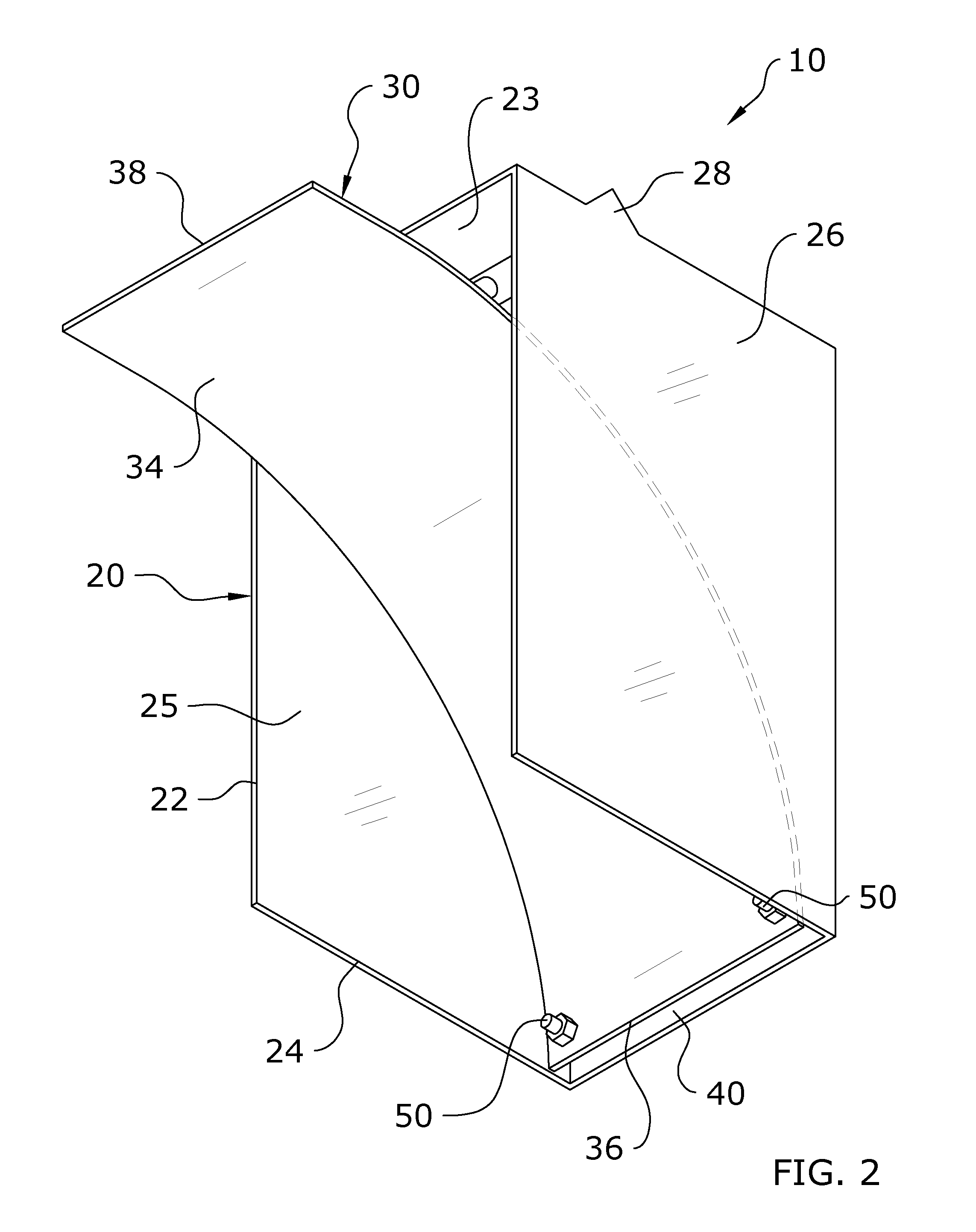

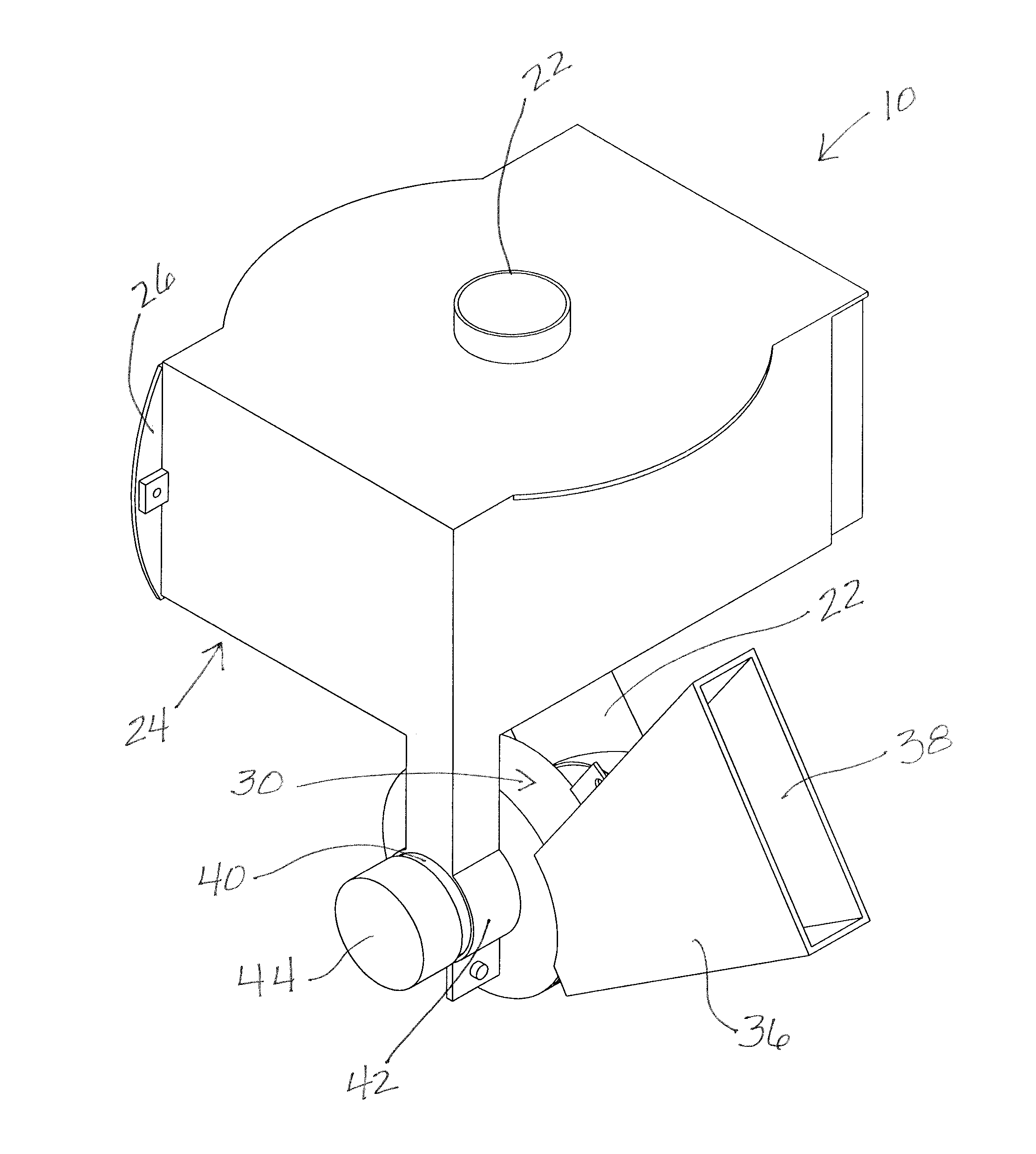

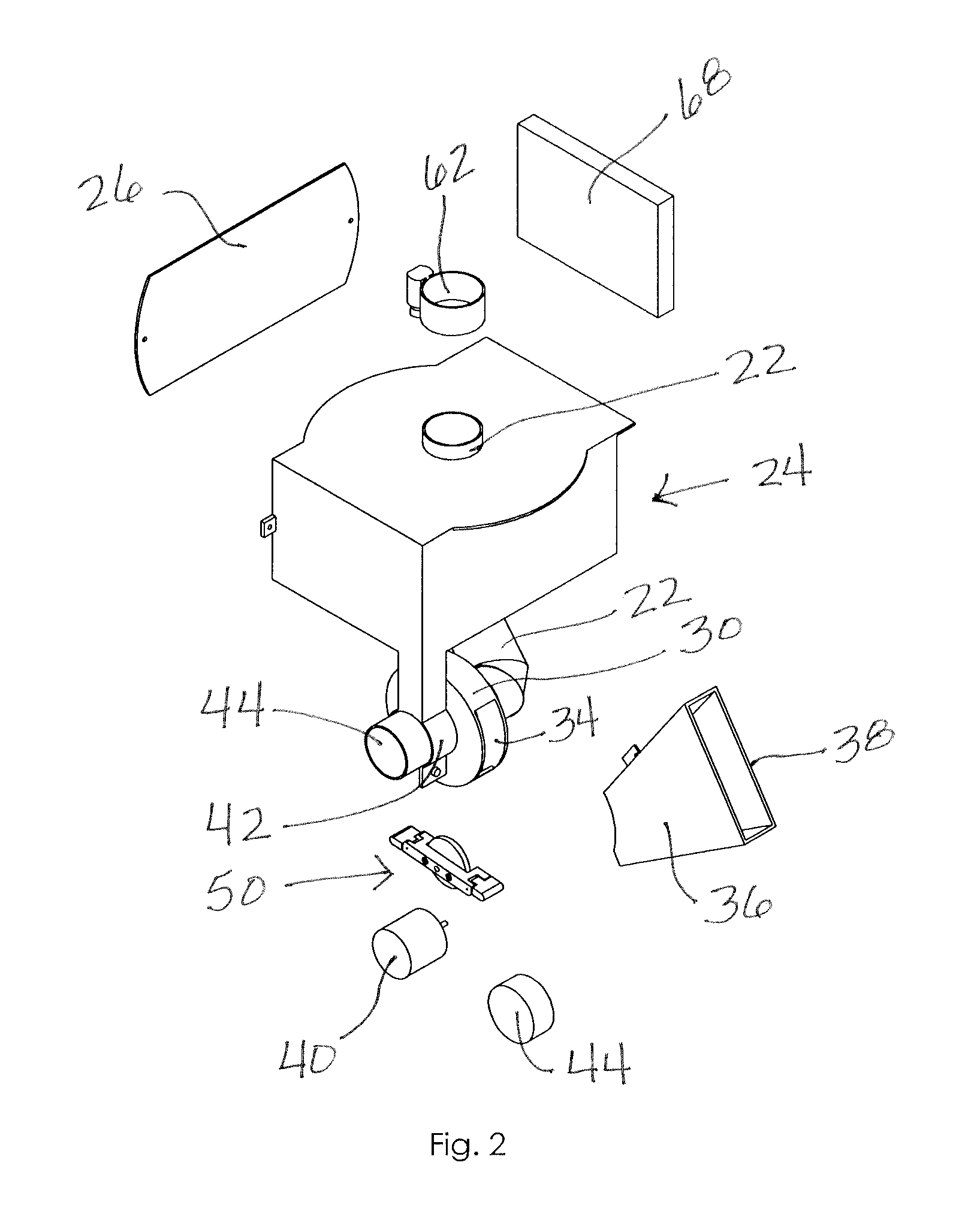

Spreader for spreading granular material and method of spreading granular material

ActiveUS20170107680A1Easy to handleImproved break-upThrowing machinesConveyorsEngineeringMechanical engineering

In one embodiment, a hopper spreader apparatus for spreading granular material is provided. The hopper spreader apparatus includes a hopper, a spreading unit, and a dispensing unit. The hopper has a storage cavity for storing the granular material to be spread. The spreading unit spreads the granular material. The dispensing system transports the granular material from the hopper to the spreading unit. The dispensing system includes a conveying unit and a rotating first roll. The conveying unit conveys the granular material toward the spreading unit. The rotating first roll controls a flow of granular material from the hopper to the conveying unit. The use of the rotating roll allows for control of high flow material (such as for example dry salt) while allowing for improved collapse and break-up of low flow material (such as for example wetted sand).

Owner:SNO WAY INT

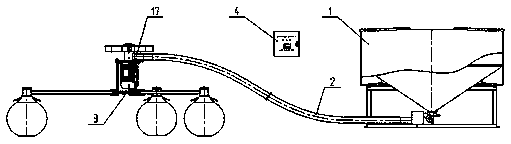

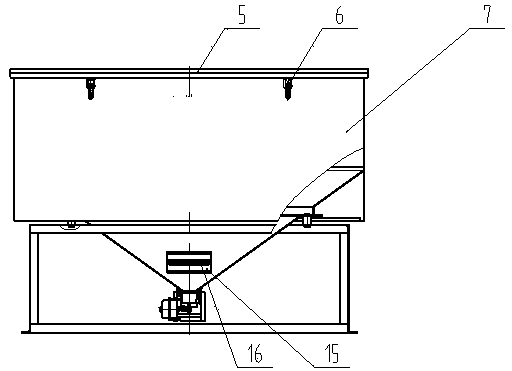

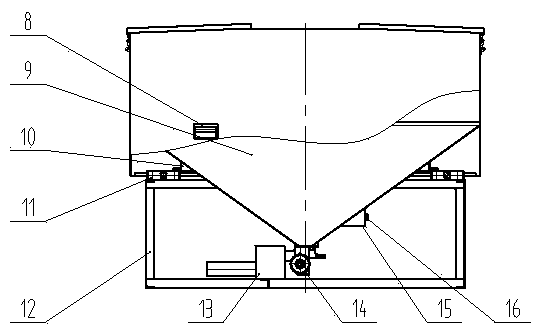

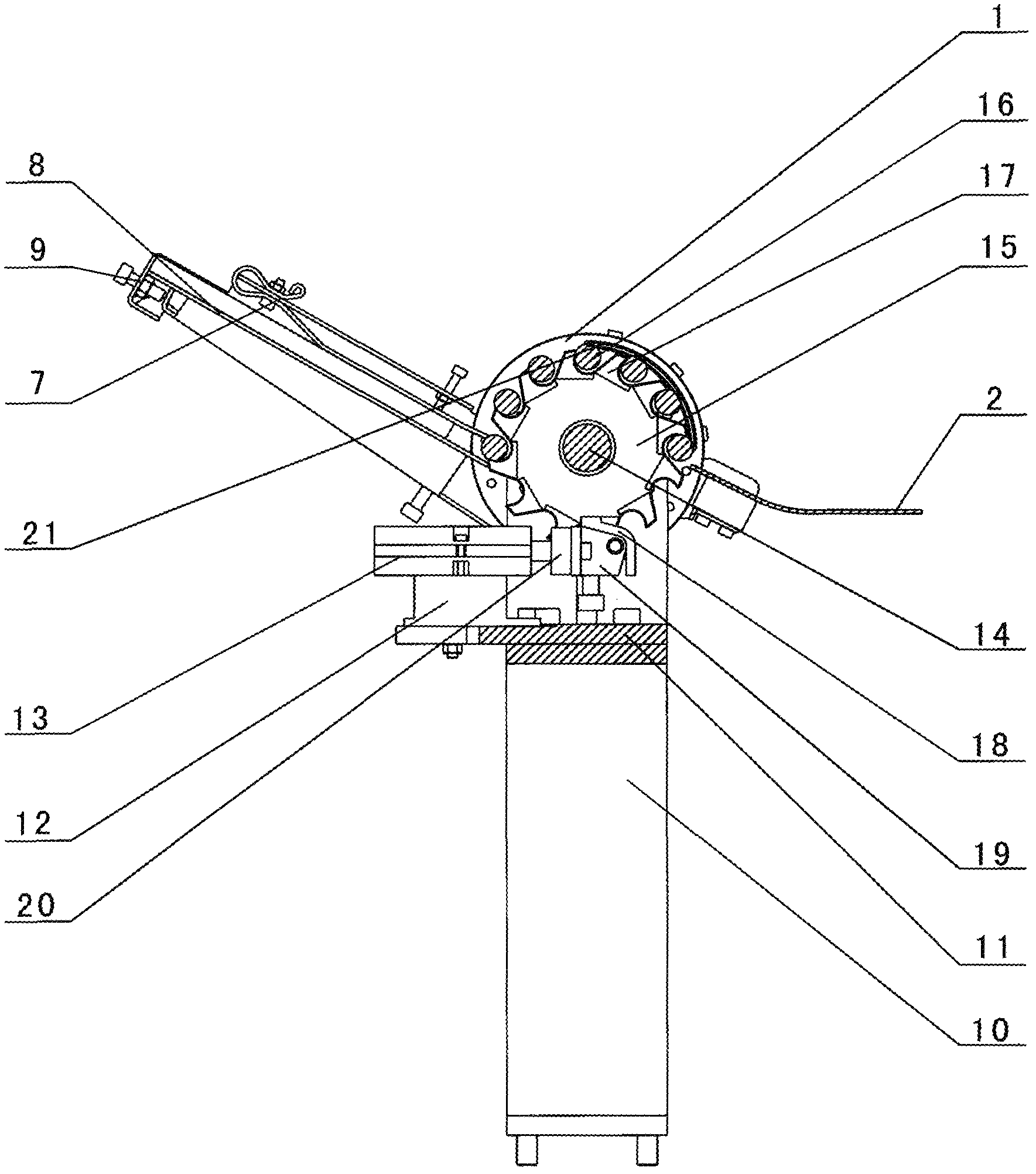

Remote pneumatic feeding and weighing feeder

InactiveCN104381183AConvenience needsMeet needsThrowing machinesPisciculture and aquariaPower gridThree-phase

The invention discloses a remote pneumatic feeding and weighing feeder. The remote pneumatic feeding and weighing feeder is characterized in that a material collecting output pipe (13) of a weighing feeding tank (1) is connected with a material transport pipeline (2), one end of the material transport pipeline (2) is connected to the material collecting output pipe (13) of the weighing feeding tank (1), the other end of the material transport (2) is connected with a feeding connector pipe (17) of a pneumatic material throwing machine (3), connecting terminals in a control box (4) are respectively connected with a connecting terminal (16) of the weighing feeding tank (1) and a motor of the pneumatic material throwing machine (3), an input end of the control box (4) is connected with a three-phase power grid, and the remote pneumatic feeding and weighing feeder is integrally formed. According to the remote pneumatic feeding and weighing feeder disclosed by the invention, remote large-area weighing feeding is realized, installing and use are convenient, the automation degree is high, the labor intensity is low, the labor is saved, the feeding distance is far, and market needs are wide.

Owner:JIANGSU HENGSHENYANG MACHINERY

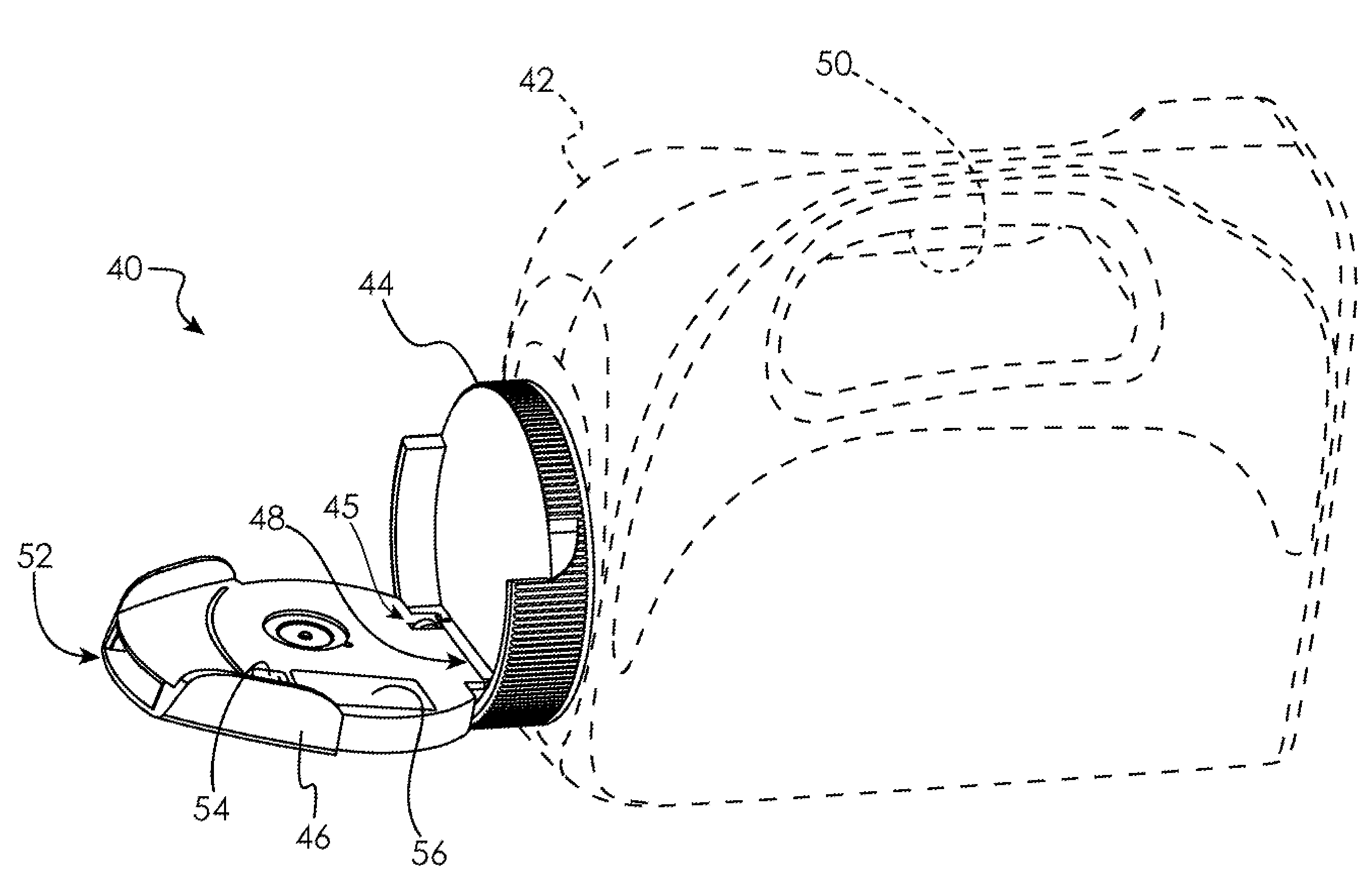

Electrically-powered spreader

An electrically-powered spreader for spreading a granular product is disclosed. The spreader may comprise a cap used to close a bottle containing the granular product. When in the open position, the bottle may be tilted into a position in which the granular product is fed by the force of gravity through an opening and into the spreader cap. A moving member within the spreader cap interacts with the granular product to propel it out of an opening in the spreader cap. In this way, the granular product is broadcast out of the bottle and onto the treatment area around the bottle.

Owner:LEBANON SEABOARD CORP

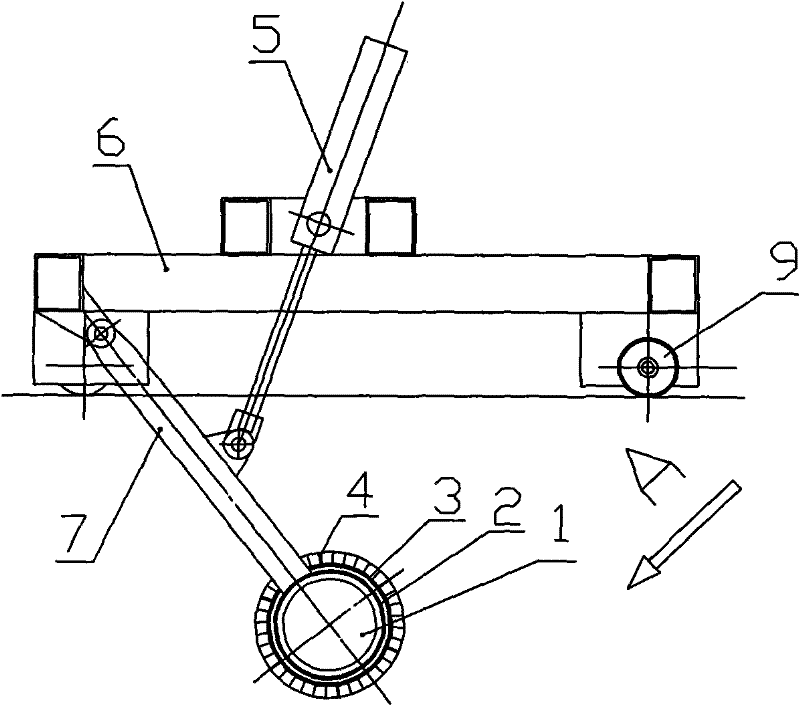

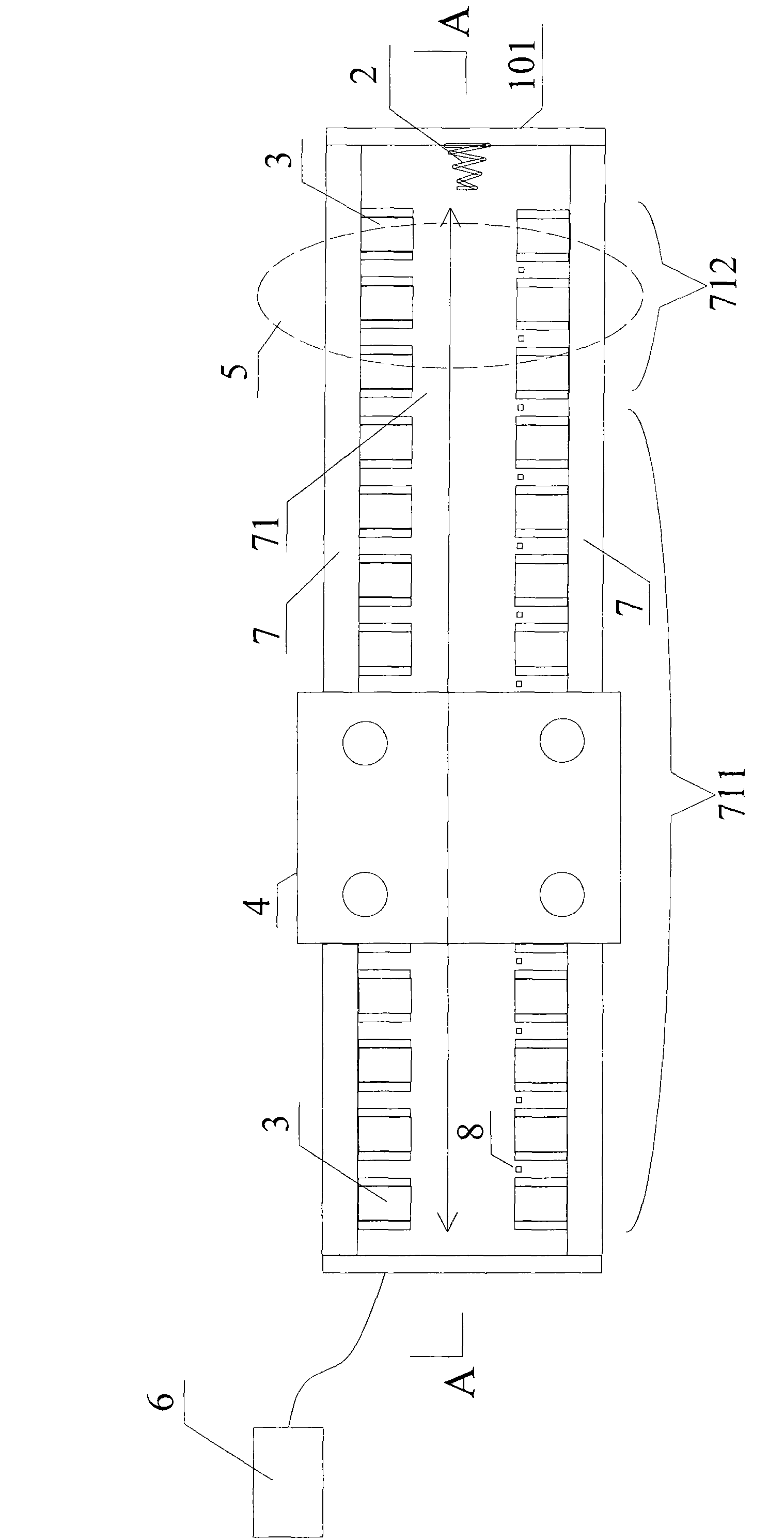

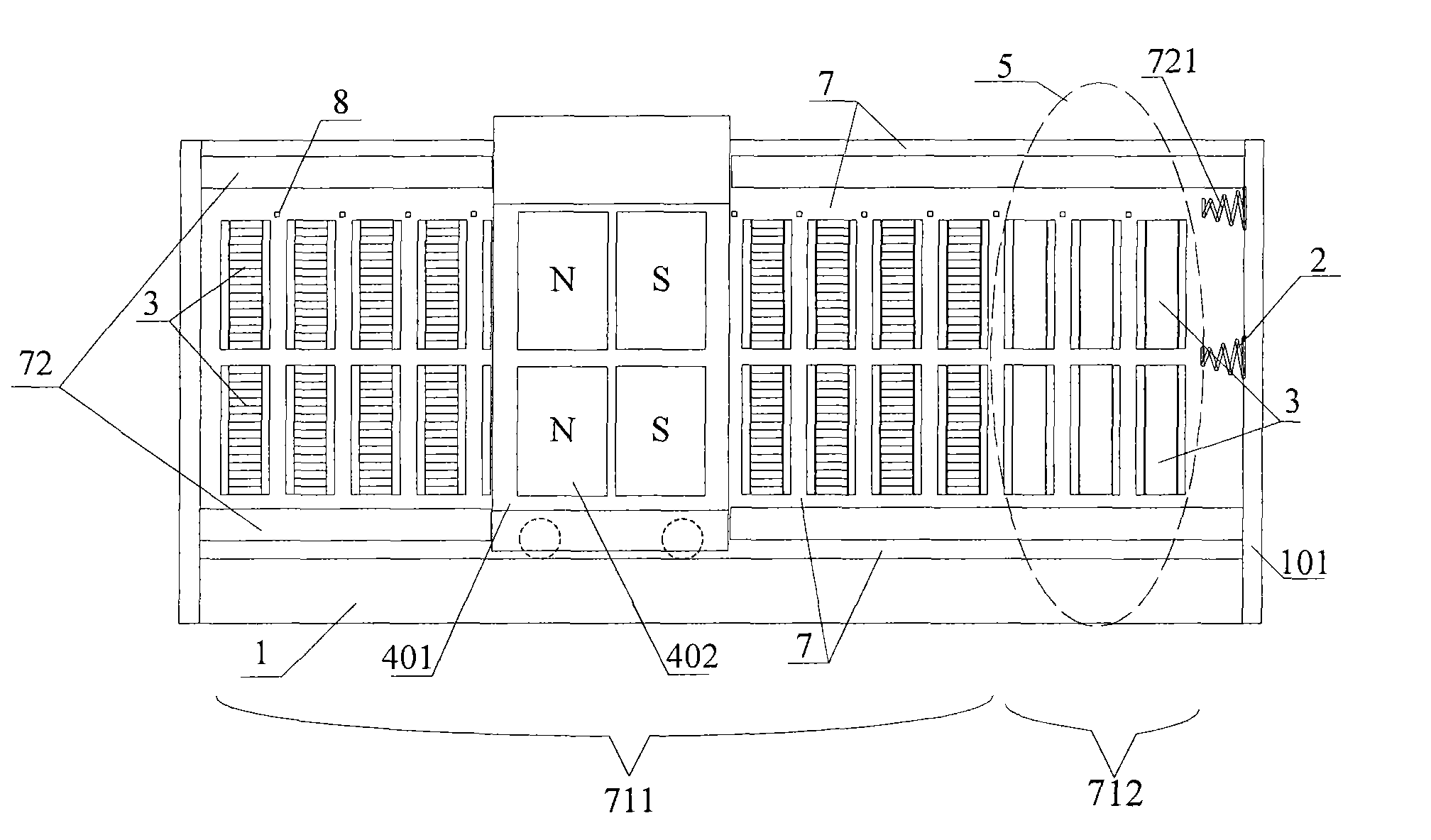

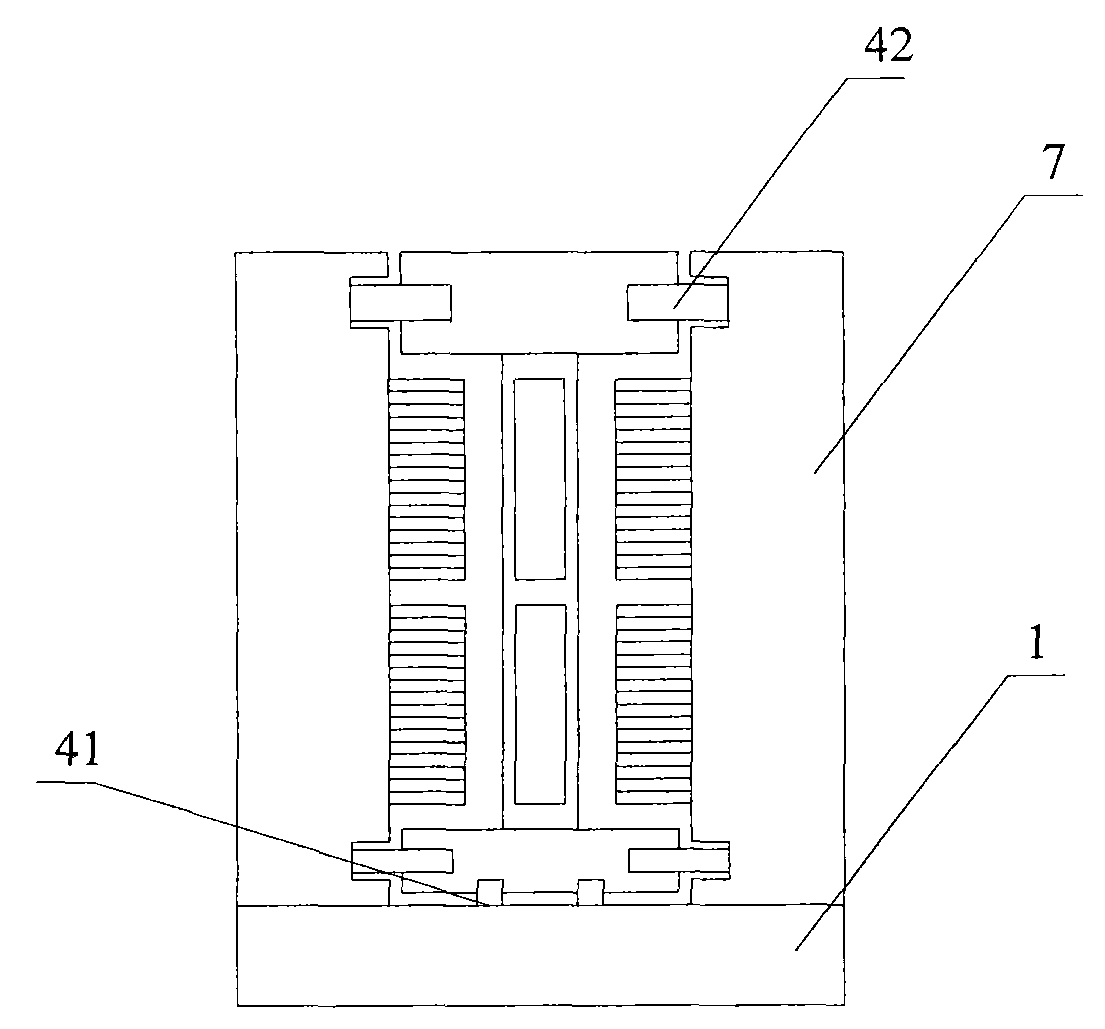

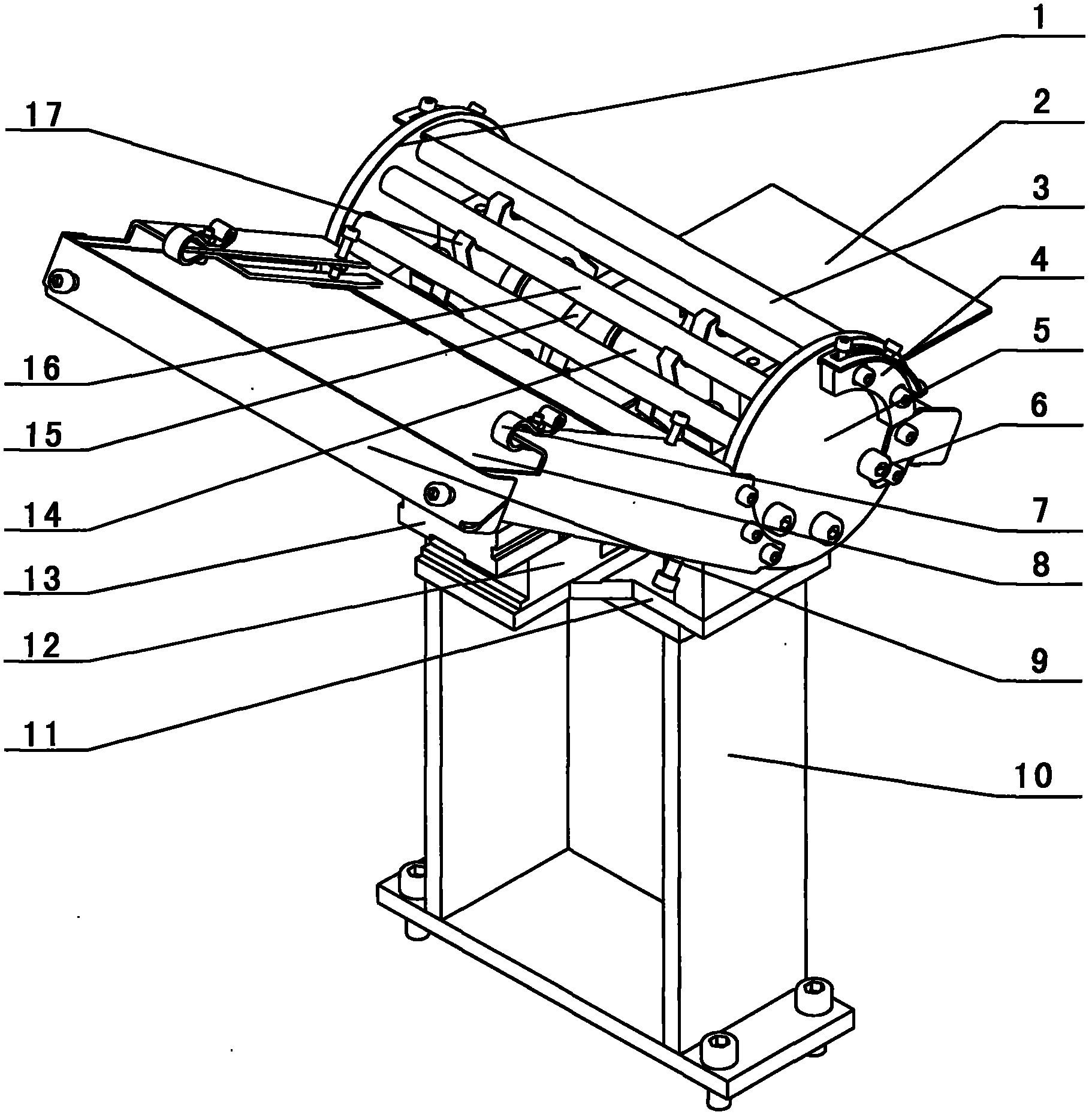

Permanent magnet linear motor-based throwing platform

ActiveCN101774476ALarge throwing qualityShorten braking timeThrowing machinesPropulsion systemsPermanent magnet rotorPermanent magnet linear motor

The invention discloses a permanent magnet linear motor-based throwing platform, which comprises a base, two oppositely arranged iron yoke backplates, stator teeth, a permanent magnet rotor, an eddy current braking device and a control mechanism, wherein the iron yoke backplates are fixed on the base; each iron yoke backplate is provided with more than one row of stator teeth along the height direction; two stator teeth at corresponding positions on the different iron yoke backplates form a group; the stator teeth are wound with a three-phase winding connected with the control mechanism; the permanent magnet rotor is arranged in a motion channel formed between the two iron yoke backplates; the motion channel is divided into a front-end accelerating section and a tail-end braking section along the motion acceleration direction of the permanent magnet rotor; and the tail-end braking section is provided with the eddy current braking device. The permanent magnet linear motor-based throwing platform has the advantages of simple and compact structure, low cost, good reliability, large throwing force, and stable structure.

Owner:NAT UNIV OF DEFENSE TECH

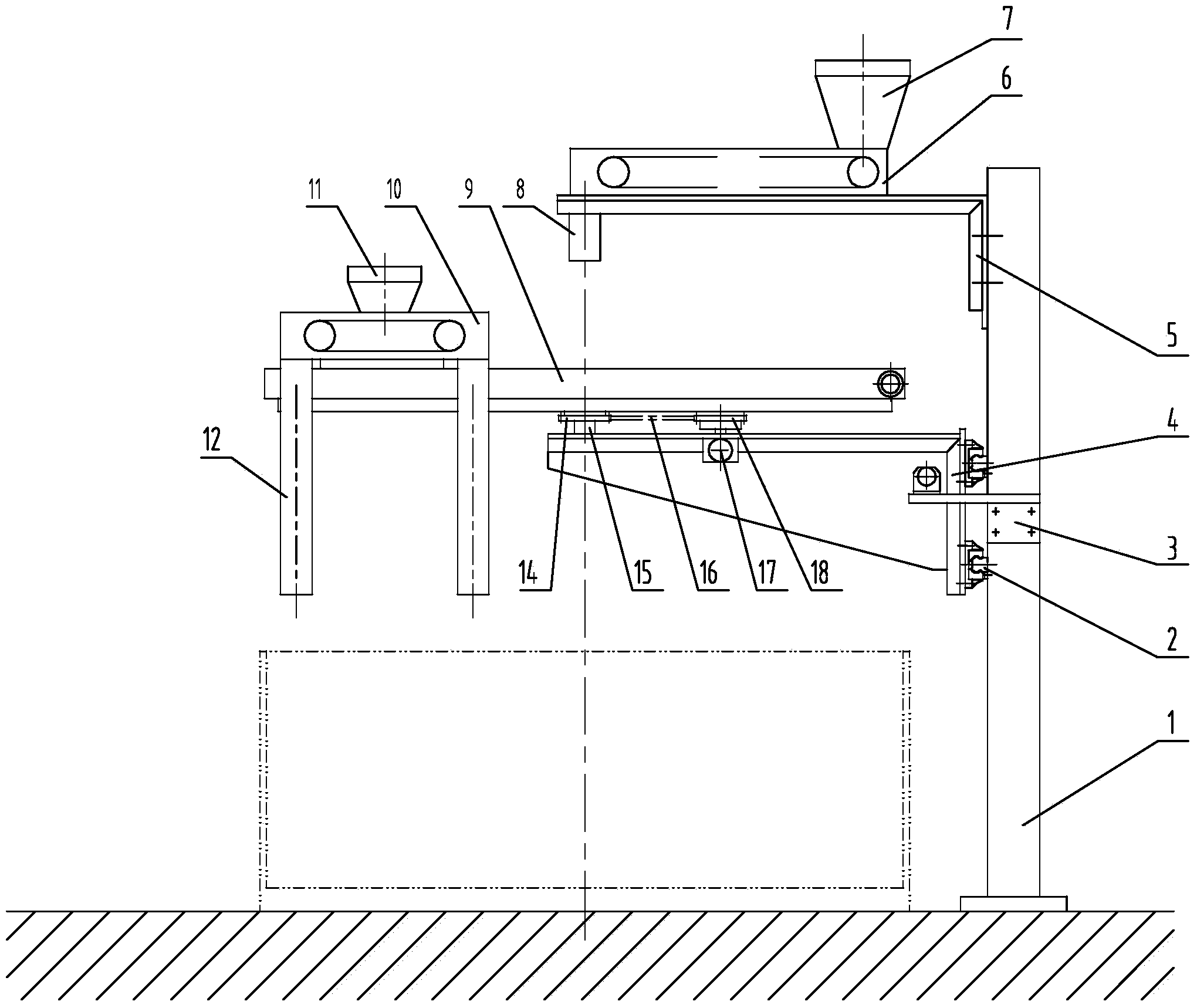

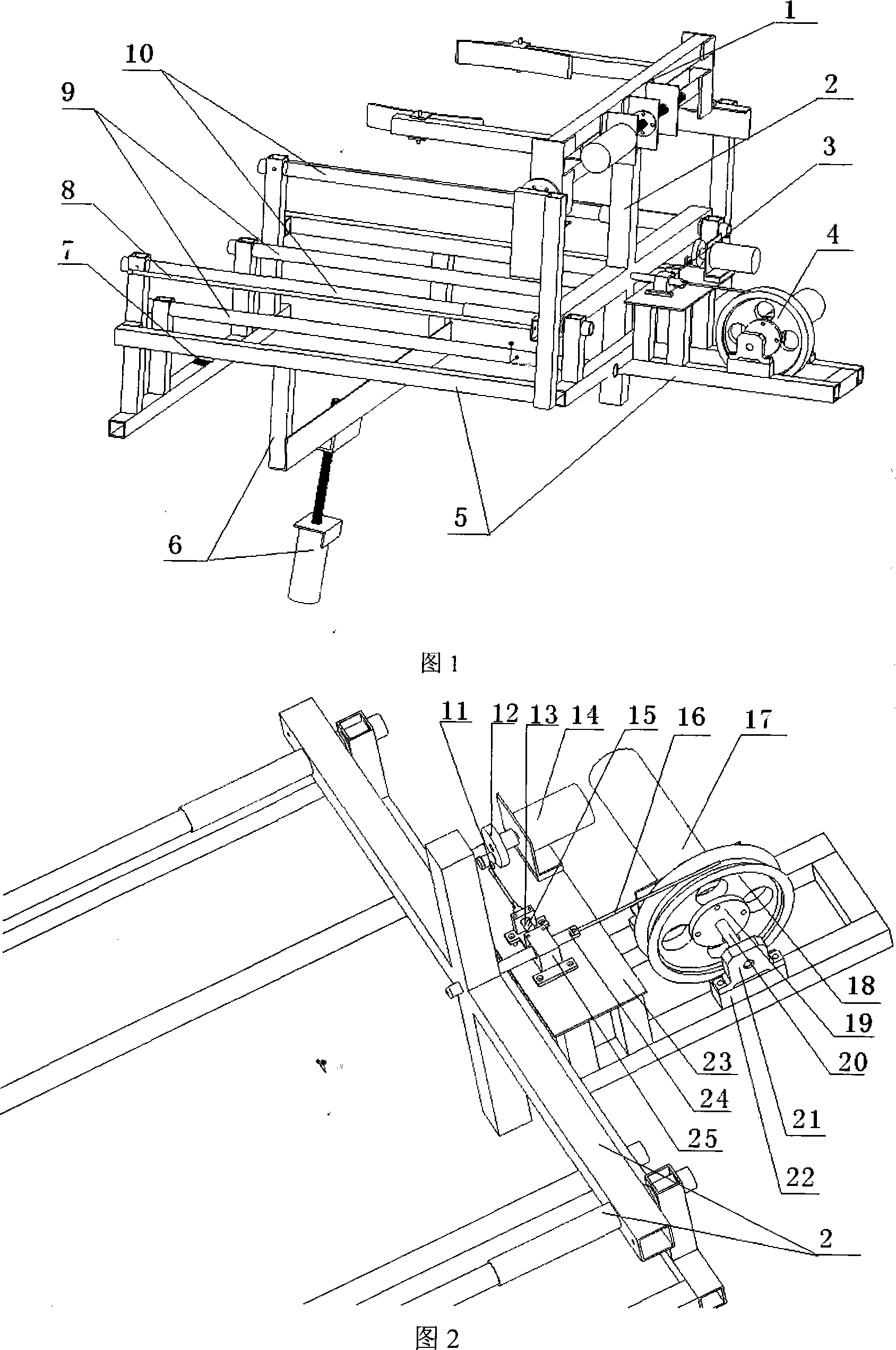

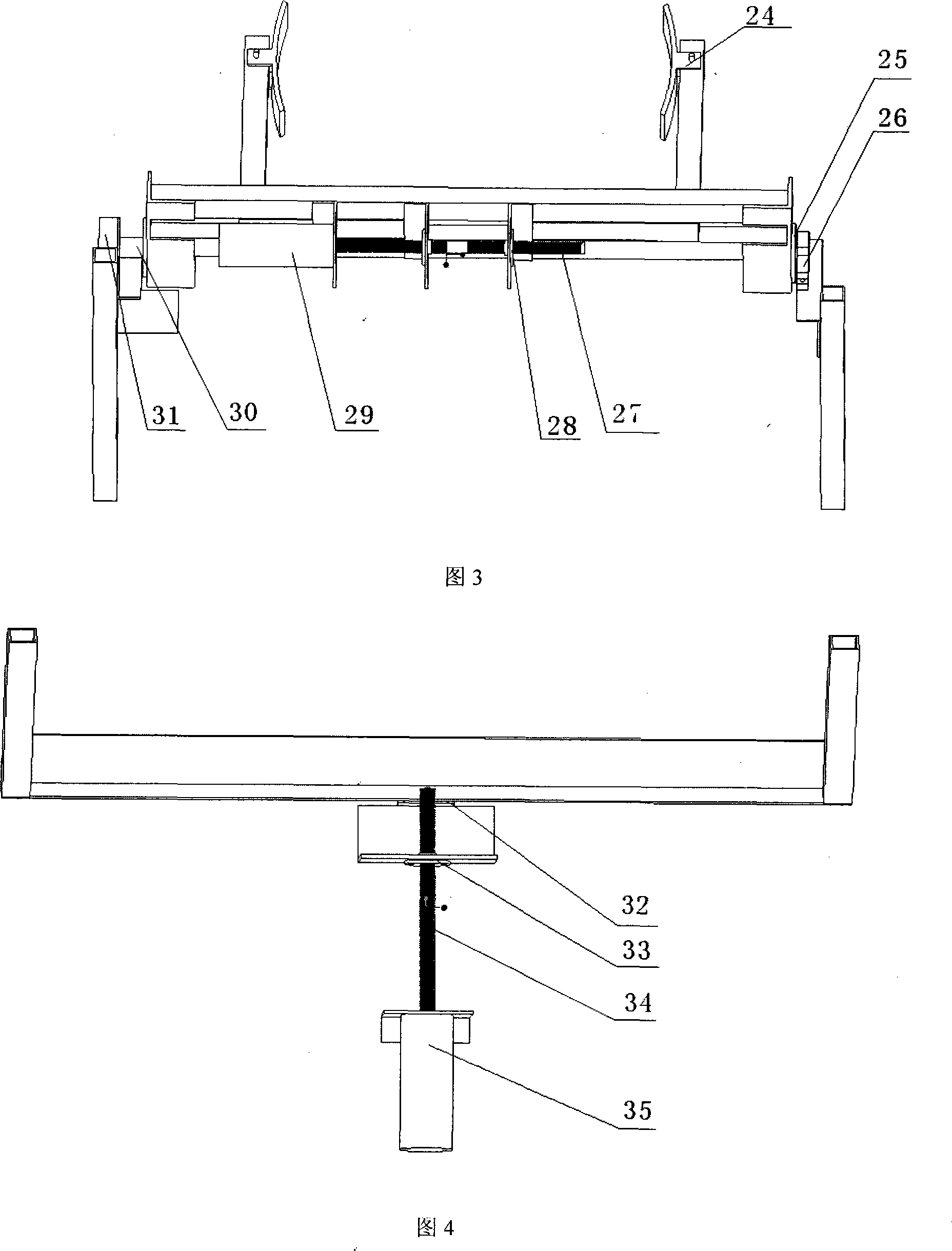

Automatic material spreading device for wine making

ActiveCN103950692ASpread evenlyReduce labor intensityThrowing machinesSupporting framesEngineeringBelt conveyor

The invention discloses an automatic material spreading device for wine making. The automatic material spreading device comprises an upright post, a movable support frame, a raw material feeding mechanism, a slide table and a material spreading belt conveyor, wherein the movable support frame is arranged on the upright post through a slide block guide rail pair, in addition, a transverse driving mechanism is arranged between the movable support frame and the upright post so that the movable support frame is driven to transversely move on the upright post, the slide table is rotationally born on the movable support frame through a fixing shaft, in addition, a rotary driving mechanism is arranged between the slide table and the movable support frame so that the slide table is driven to rotate on the movable support frame, the material spreading belt conveyor is glidingly matched on the slide table so that the material spreading belt conveyor longitudinally moves on the slide table, the raw material feeding mechanism is arranged on the upright post and is positioned above the movable support frame, the raw material feeding mechanism is provided with a material discharging opening, and the material spreading belt conveyor is provided with a material collecting opening matched with the material discharging opening, and is also provided with a material discharging pipe. The automatic material spreading device has the advantages that the manual material spreading action can be simulated, the uniform material paving and spreading is realized, the manual operation is not needed, the work intensity of workers is reduced, and the production efficiency is greatly improved.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Bucket elevator adjustable guide system

A bucket elevator adjustable guide system for efficiently dispensing grain from a bucket elevator with reduced grain dispersion. The bucket elevator adjustable guide system generally includes a head housing for a bucket elevator and a guide member attached to a lower portion of the head housing. The guide member is distally spaced from the head housing forming a lower vent and an upper vent between the exterior surface of the guide member and the head housing for air to pass through thereby preventing the accumulation of particulate material.

Owner:S &M ENTERPRISES INC

Chain disk conveyor corner housing

Owner:THE GSI GRP LLC

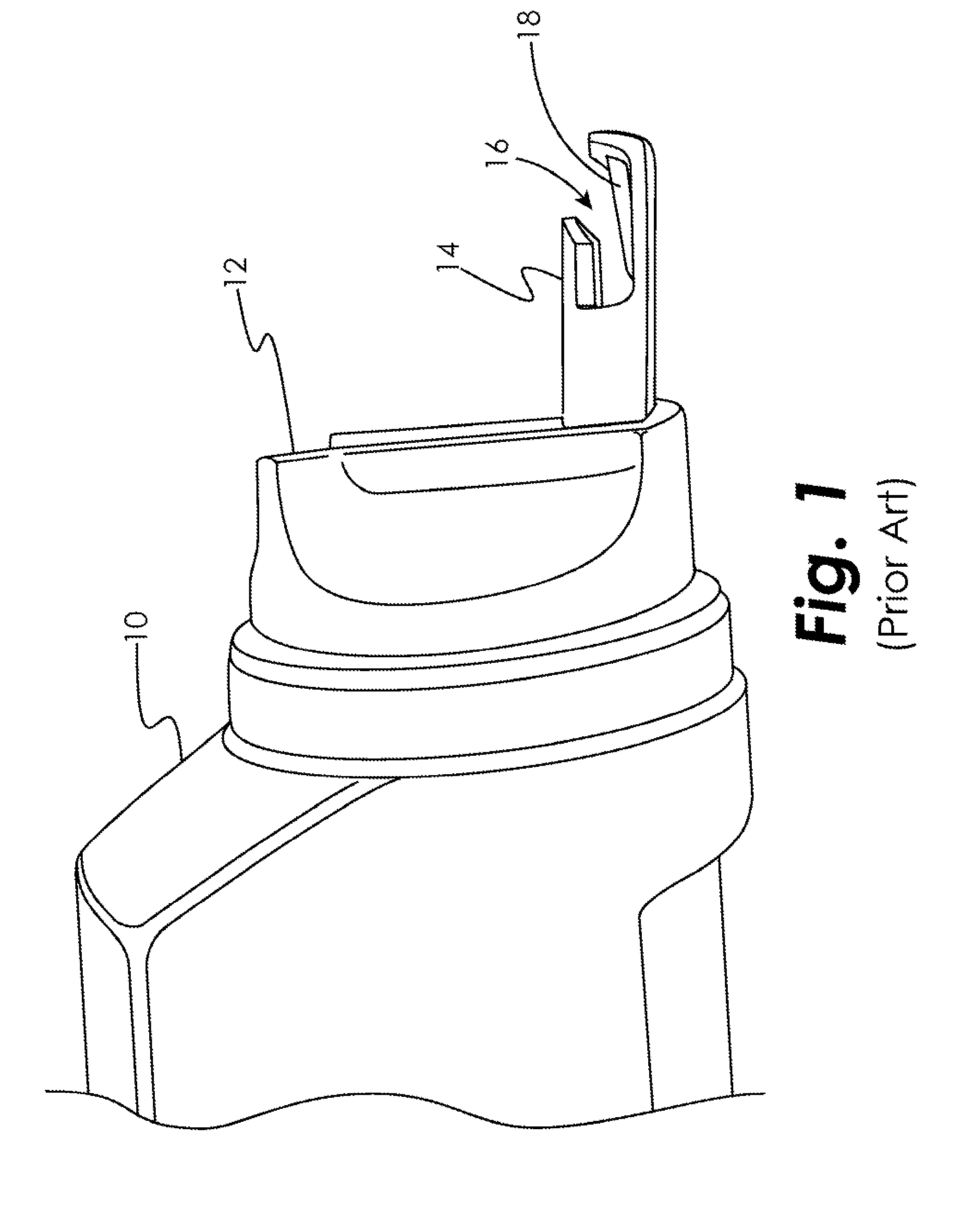

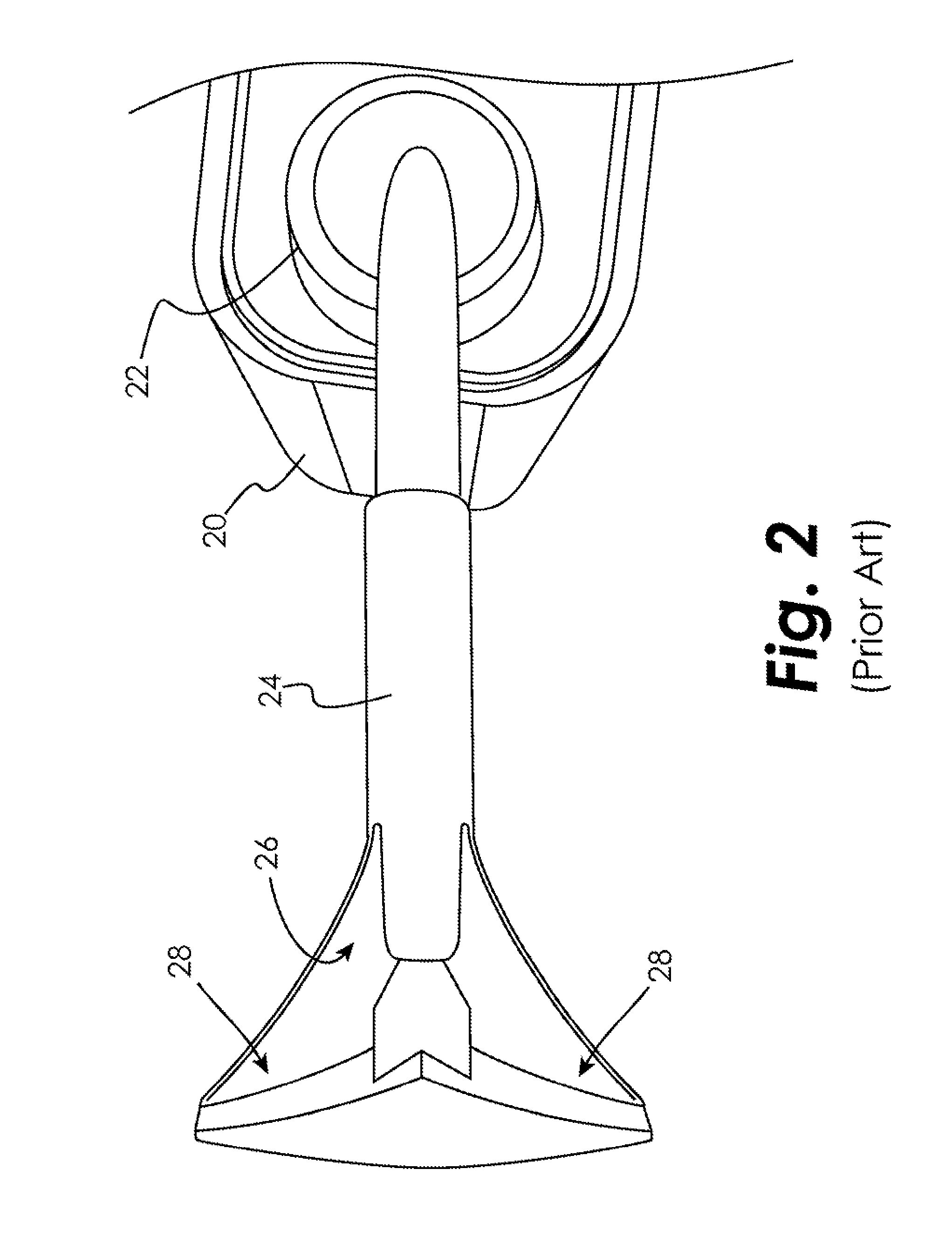

Bulk material pump feeder

A bulk materials pump feeder having a housing and a rotatable drive rotor mounted in the housing for transferring material introduced into the housing through an inlet to an outlet for discharge of the material from the housing. The drive rotor has a hub and a plurality of drive discs extending away from the hub toward an inner wall of the housing. To reduce the tendency of material passing through the housing to wedge between the inner wall of the housing and the circumferential edges of the drive discs, the distance between the circumferential edges of the drive discs and the inner wall of the housing increases from the inlet of the housing to the outlet of the housing in the direction of rotation of the drive rotor.

Owner:K TRON TECH INC

Rotary Feed Dispensing Apparatus

A rotary feed dispensing apparatus includes a reservoir configured to hold feed. The apparatus includes a rotary dispenser having an inlet operatively coupled to the reservoir and a rotary dispenser outlet, the rotary dispenser defining a rotary dispenser interior area configured to selectively receive the feed from the reservoir through the rotary housing inlet. An impellor assembly is rotatably mounted in the rotary dispenser, the impellor assembly having an impellor body portion and at least one impellor end portion pivotally coupled to the impellor body portion. The impellor end portion is movable between an extended configuration and a folded configuration. A motor is operatively coupled to the impellor assembly and configured to rotate the impellor assembly when energized. The impellor end portion is configured to eject the feed from the rotary dispenser through the outlet when the motor is energized and the impellor end portion is at the extended configuration.

Owner:WISECARVER ROBERT TODD

Elevator slats for an agricultural harvesting machine

InactiveUS6922983B2High strengthNot to damageThrowing machinesHarvestersAgricultural engineeringBatten

Owner:BLUE LEAF I P INC +1

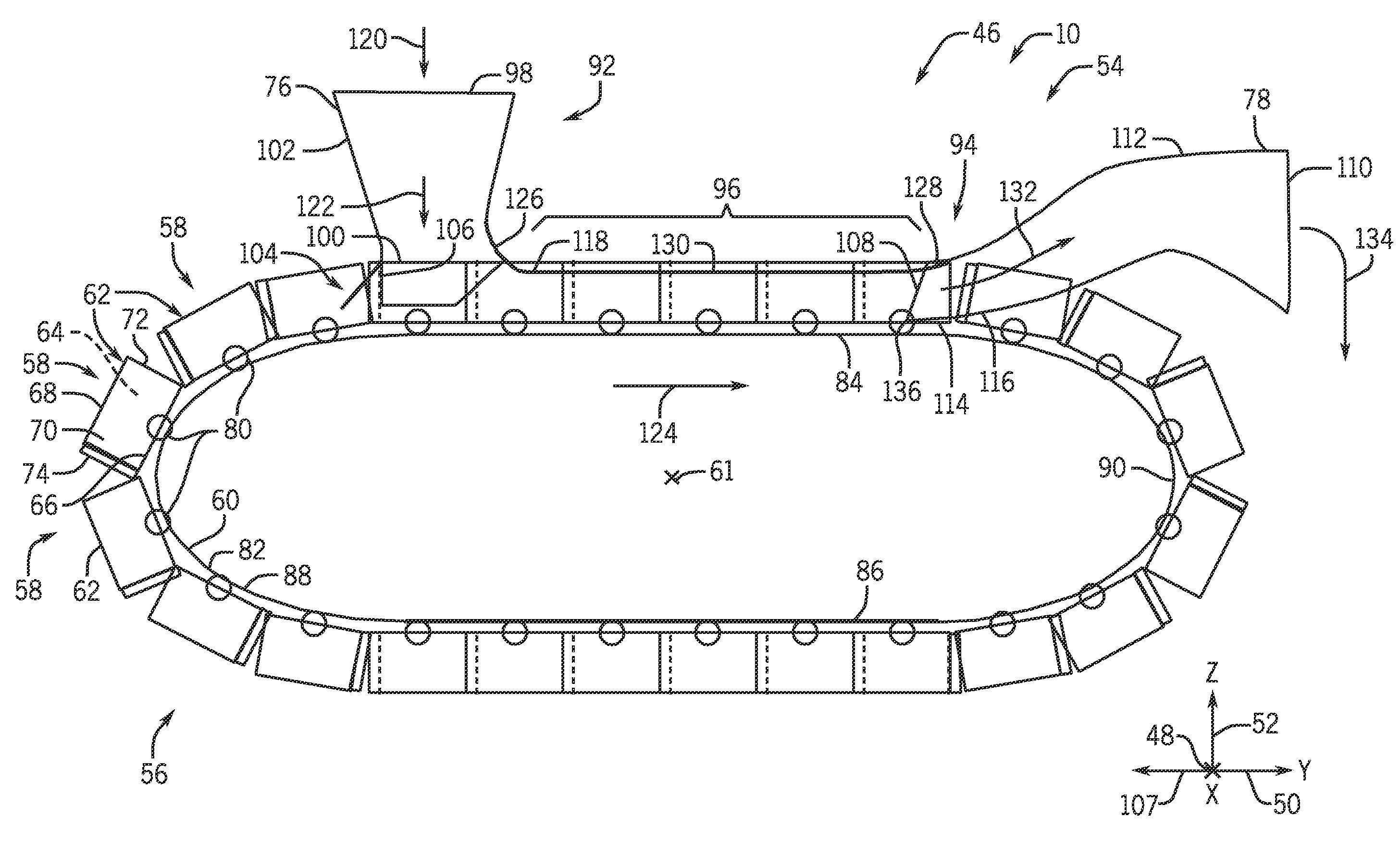

System and method for transporting solid feed in a solid feed pump

A system includes a solid feed pump configured to transport a solid feedstock. The solid feed pump includes at least one passage for the transport of the solid feedstock. The solid feed pump also includes at least one movable wall configured to move along the passage. The solid feed pump further includes a retractable gripping element configured to extend from the at least one movable wall into the at least one passage to grip a portion of the solid feedstock. In addition, the retractable gripping element is configured to retract away from the at least one passage.

Owner:AIR PROD & CHEM INC

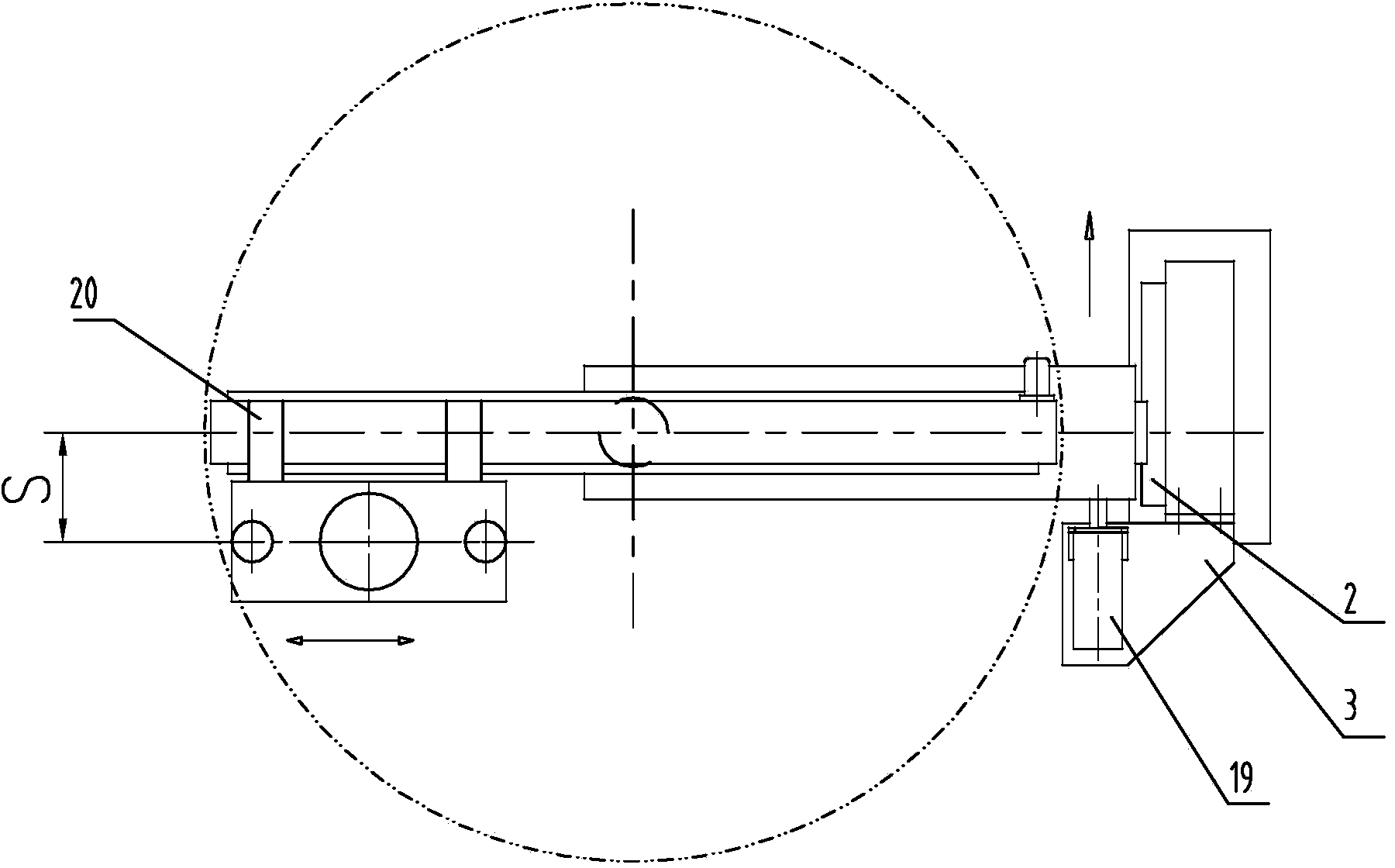

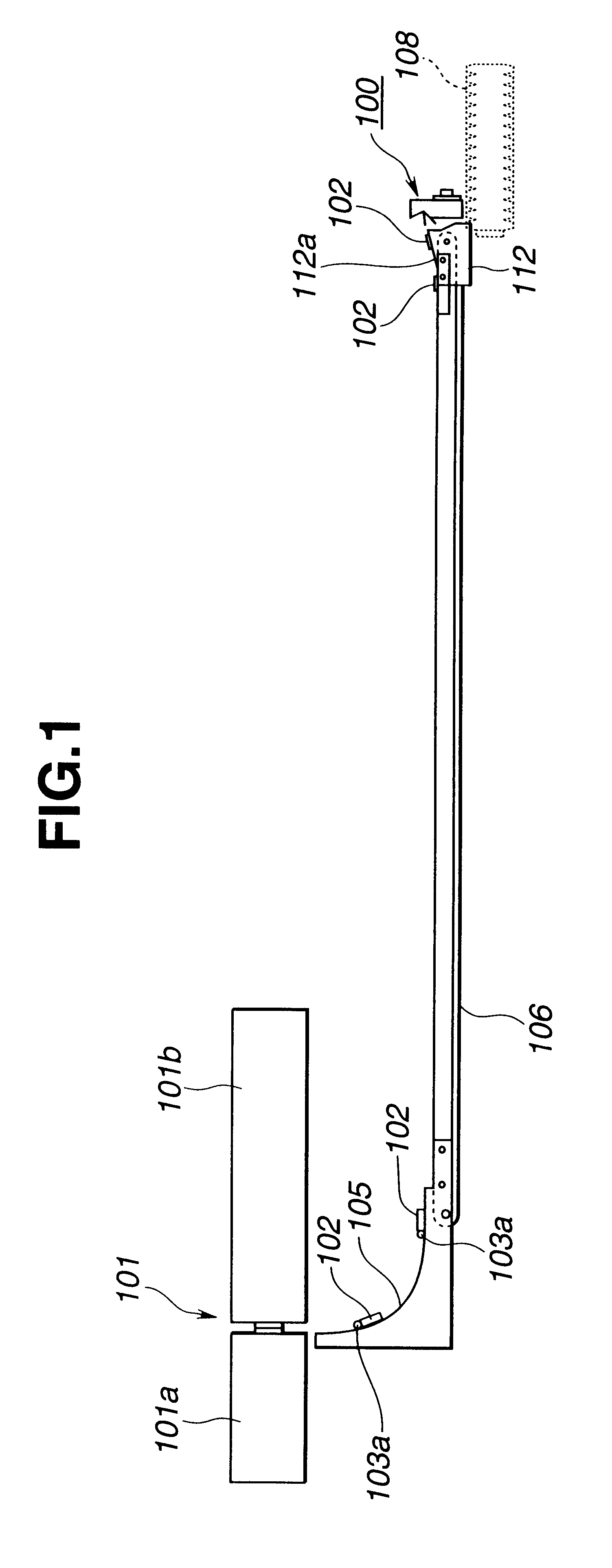

Double rubberbands four sliding rails arrow type ejection mechanism

InactiveCN101234703ATroubleshoot Connection Strength IssuesThrowing machinesManipulatorCouplingEngineering

The invention provides an ejection mechanism of bow type with two rubber bands and four slides, essentially comprising a chassis 5, an orbit of an ejection cabin base 10, an ejection orbit 9, an angel adjusting device 6, a triggering device 3, a line withdrawing and setting device 4 and a turning manipulator 1. A line rolling motor 17 passes through a line rolling wheel 18 through a coupling 20; the other side uses a screw to connect an end cover 19 and the lien rolling wheel into a whole through a bolt; the other end of the coupling is fixed on a bearing block 21; an end of a pin 24 is provided with a screw thread and is connected with an ejection cabin base 2; the other end of the pin 24 is connected with a steel wire 15; the other end of the ejection cabin base is connected with a front end on the chassis through two rubber bands 8; a motor 14 is connected with a cam structure 12 and is fixed on a support board 23; a manipulator 1 is fixed at a corresponding position on the chassis 5 through two aluminum rods; an aiming device 7 is fixed on a centre line at the front end of the chassis. The mechanism of the invention can eject various shapes, automatically grab objects, present positioning of high precision, have the function of instant triggering of elastic potential energy, and be reused.

Owner:HARBIN ENG UNIV

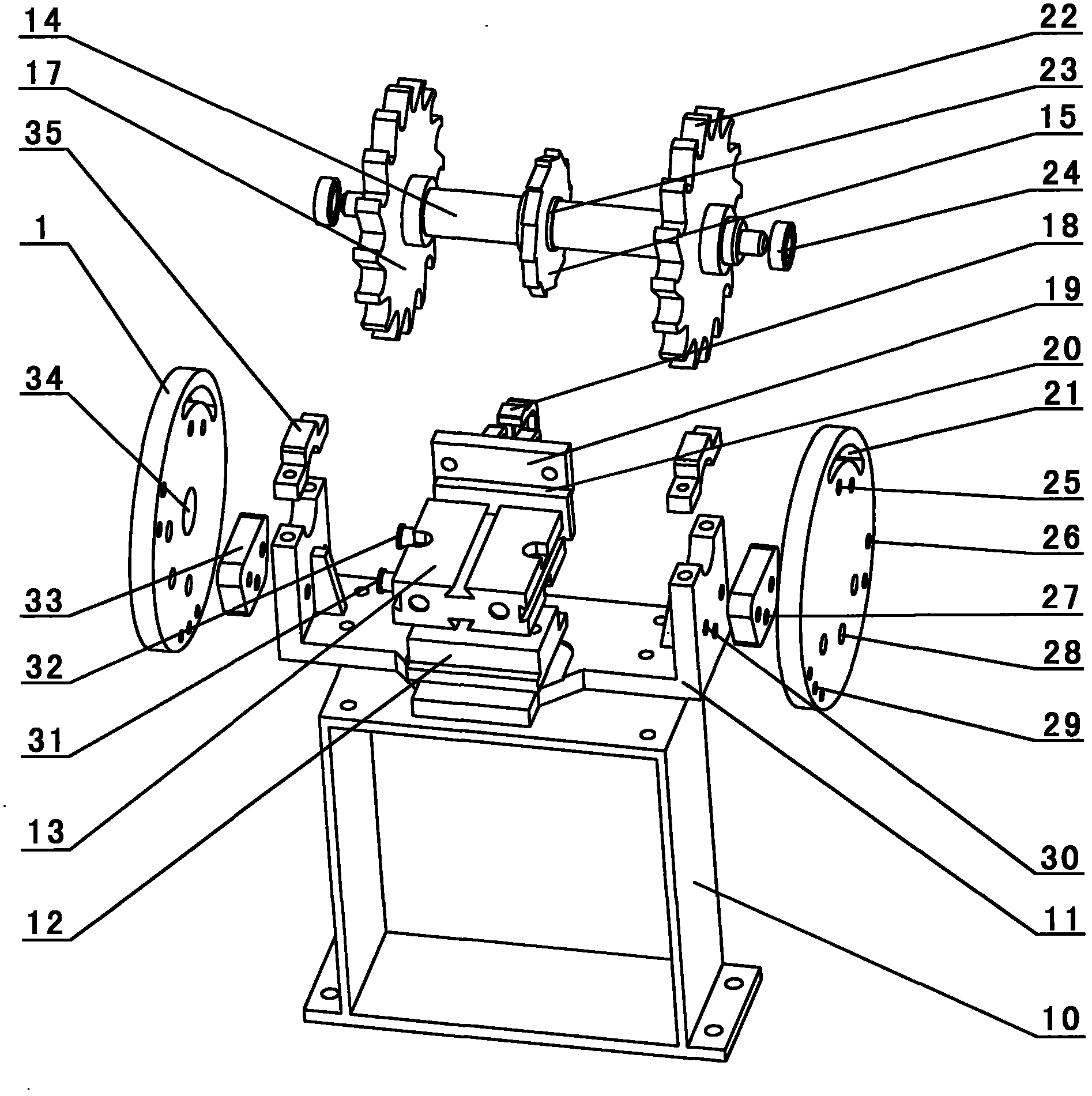

Automatic feeding device during crystal material processing

ActiveCN102424248AAvoid manual long-term on-site monitoringSimple structureThrowing machinesConveyor partsMaterials preparationControl system

The invention relates to an automatic feeding device during crystal material processing, relating to auxiliary devices of crystal processing. A crystal bar storage mechanism for material preparation in early stage is arranged on one side of a distribution feeding mechanism for interval delay, a plurality of mutually relative hook teeth (22) are arranged at outer edges of at least two crystal bar conveying wheels (17), a ratchet wheel (15) arranged on a shaft is connected with a control system of the distribution feeding mechanism, and the control system of the distribution feeding mechanism drives the ratchet wheel to make the hook teeth on the crystal bar conveying wheels drive crystal bars of the crystal bar storage mechanism for the material preparation in early stage to move onto a crystal bar discharge plate (2) for guiding materials on the other side of the distribution feeding mechanism. According to the automatic feeding device disclosed by the invention, silicon cores are conveyed to the distribution feeding mechanism for the interval delay by the crystal bar storage mechanism for the material preparation in the early stage, and the distribution feeding mechanism for the interval delay realizes the interval delay conveyance of the crystal bars onto the crystal bar discharge plate for guiding the materials by the control system of the distribution feeding mechanism, thus the defect that labors need to keep an eye on the production field for a long term in the traditional processing method is prevented.

Owner:洛阳市自动化研究所有限公司

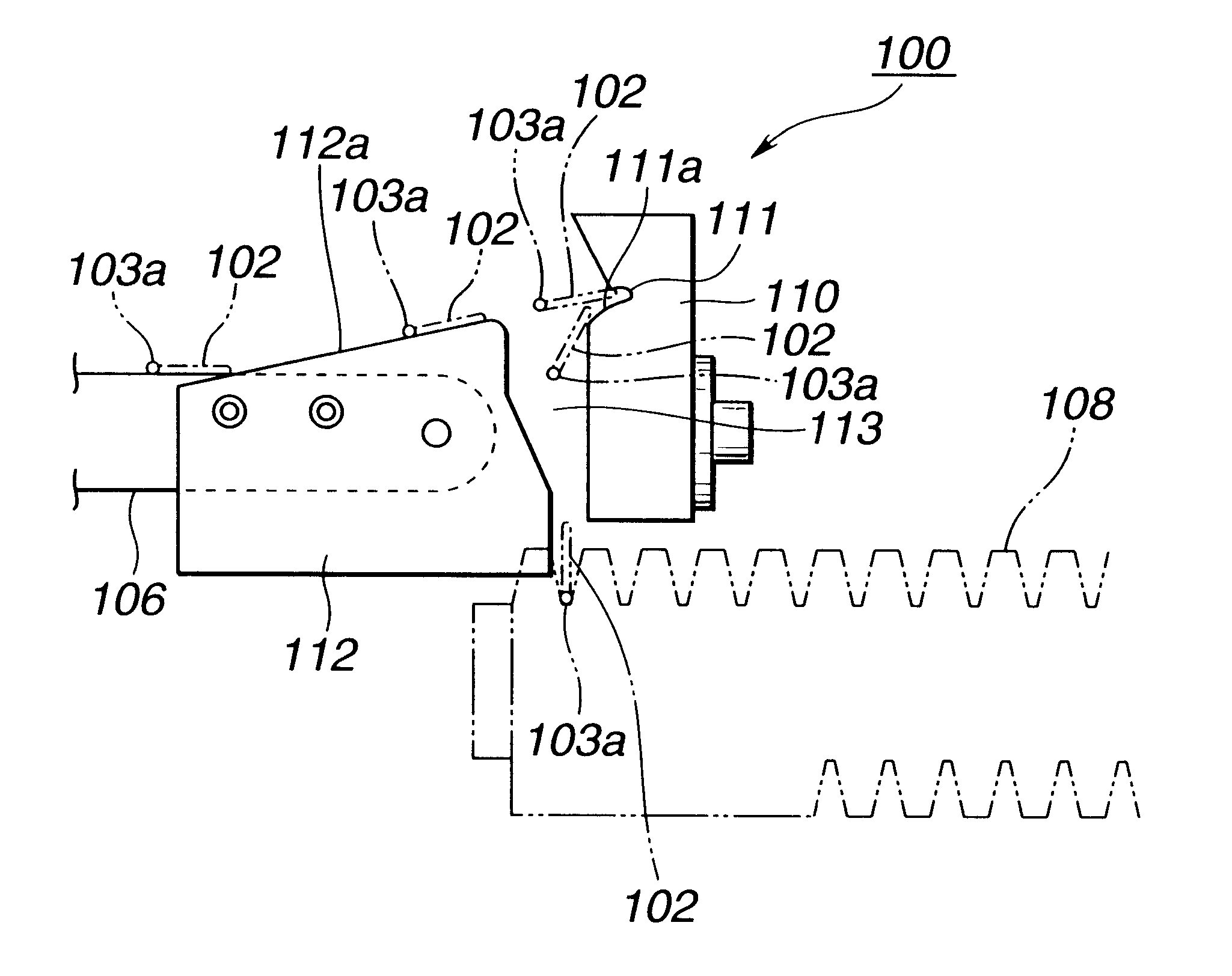

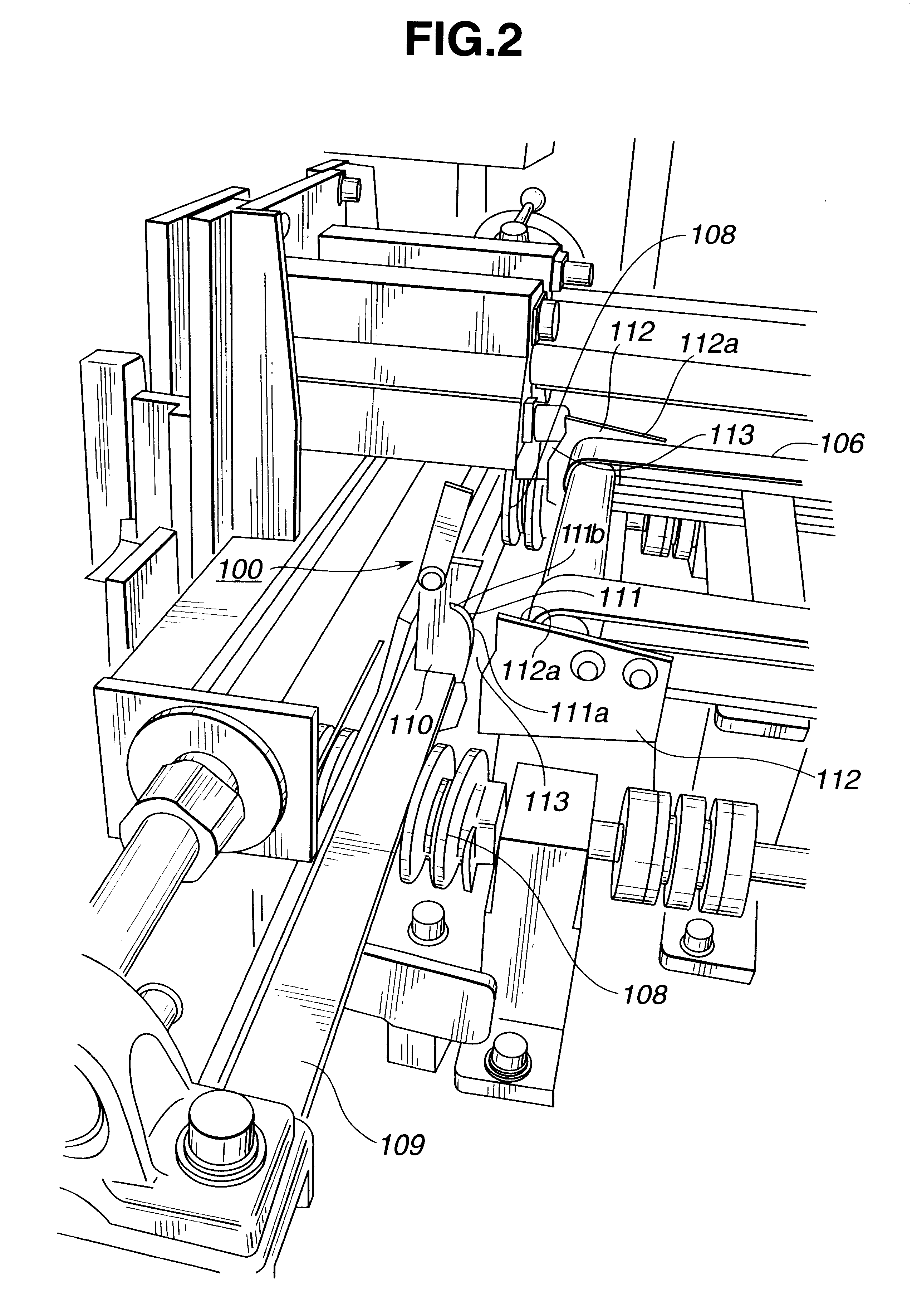

Workpiece handling device

InactiveUS6276513B1Satisfied handling efficiencyThrowing machinesMetal working apparatusManufacturing lineEngineering

For handling elongate and flat workpieces flowing in a manufacturing line, two arrangements are disclosed, one being an arrangement including a workpiece posture changing device which changes the posture of each workpiece at the time when the workpiece is transmitted from a first conveyer to a second conveyer, and the other being an arrangement for bundling the workpiece flowing in the manufacturing line.

Owner:CALSONIC KANSEI CORP

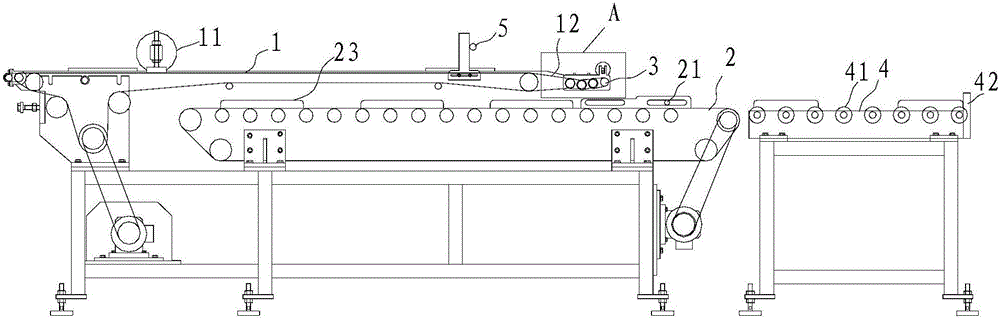

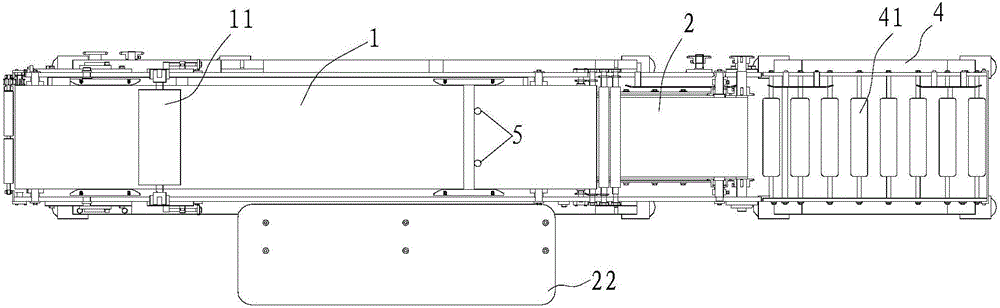

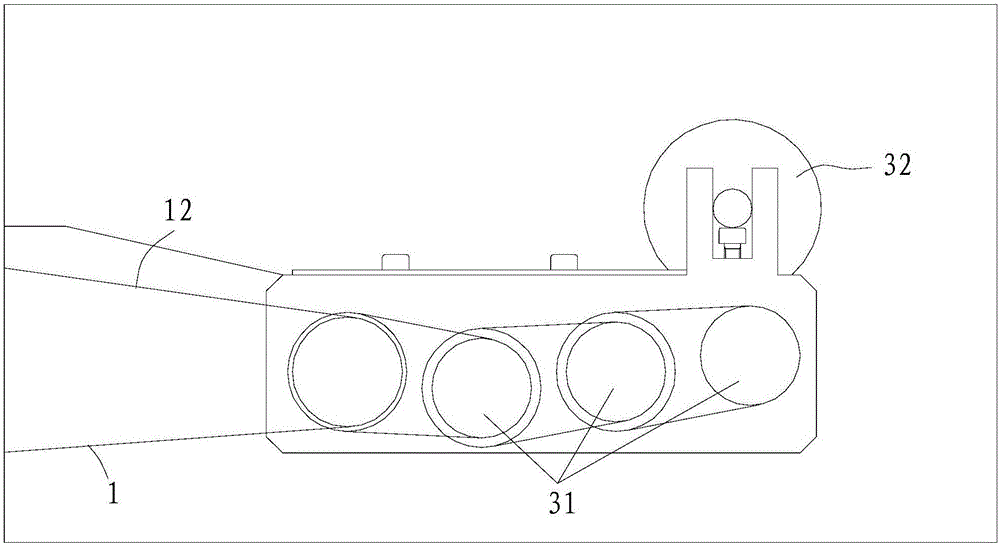

Plate collecting device

ActiveCN106219204ANeat and smooth stack collectionCapable of automationThrowing machinesConveyorsEngineeringAutomation

The invention provides a plate collecting device which comprises a first conveying belt continuously conveying pole plates, a counting sensor used for measuring the number of the pole plates passing through the first conveying belt, a second conveying belt arranged below the first conveying belt for intermittently conveying containing plates and a piece throwing mechanism connected with the discharging end of the first conveying belt. The containing plates are used for containing the pole plates falling from the first conveying belt. The piece throwing mechanism comprises multiple supporting rollers and piece throwing rollers matched with the supporting rollers at the discharging end. The supporting rollers are arranged in an upward oblique manner from the feeding end to the discharging end. According to the plate collecting device, the first conveying belt, the second conveying belt, the counting sensor and the piece throwing device are arranged so that the pole plates can be neatly and stably stacked and collected, meanwhile, a certain automation capability is achieved, and the plate collecting efficiency is high.

Owner:TIANNENG BATTERY GROUP

Long-range conveying haversack throwing machine

The invention discloses a long-range conveying haversack throwing machine. A lower machine frame is arranged at the lower end of an upper machine frame, a front support is arranged at the lower end of the lower machine frame, the bottom end of the front support is provided with a front travelling wheel, the bottom end of a rear support is provided with a rear steering wheel, the front upper end of the upper machine frame is provided with a motor roller, and the rear upper end of the upper machine frame is provided with a rear roller, an upper conveying belt is arranged on the rear roller and the motor roller, and the front lower end of the upper machine frame is provided with a haversack throwing frame. The front end of the haversack throwing frame is provided with an upper bearing block, the rear end of the haversack throwing frame is provided with a lower bearing block, the front end of the haversack throwing frame is provided with a high-speed motor roller, the rear end of the haversack throwing frame is provided with a follow-up roller, a haversack throwing conveying belt is arranged at the upper end of the high-speed motor roller and the upper end of the follow-up roller, and the lower side of the haversack throwing conveying belt is provided with a riding wheel frame. When the long-range conveying haversack throwing machine is used, haversacks are conveyed to the top end through the upper conveying belt, fall onto the haversack throwing conveying belt, are conveyed through the high-speed rotating haversack throwing conveying belt at high speed, and are thrown to front upper space under the action of inertia.

Owner:杨可秀

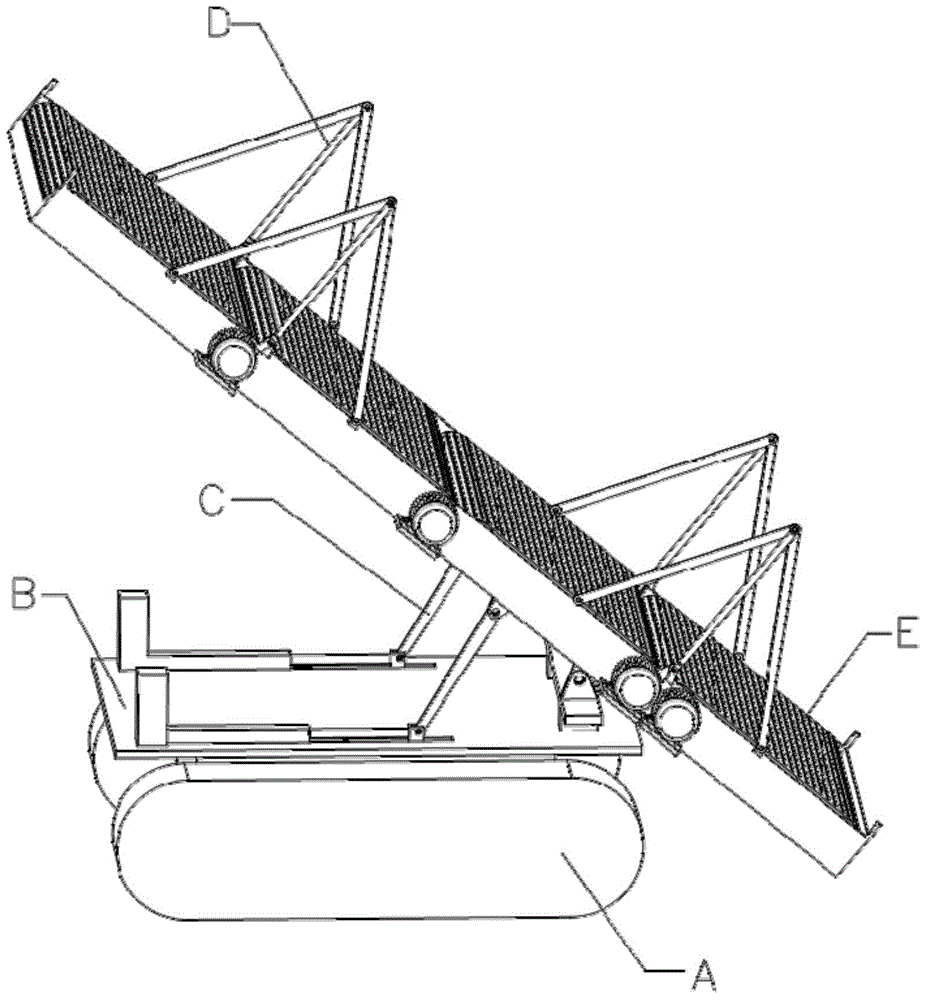

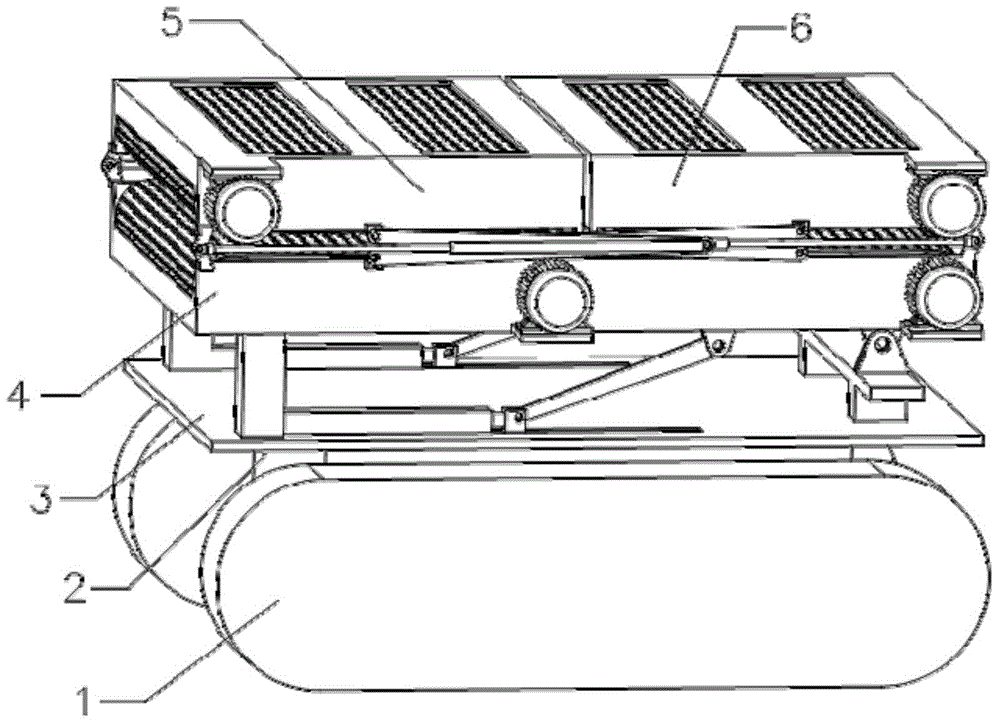

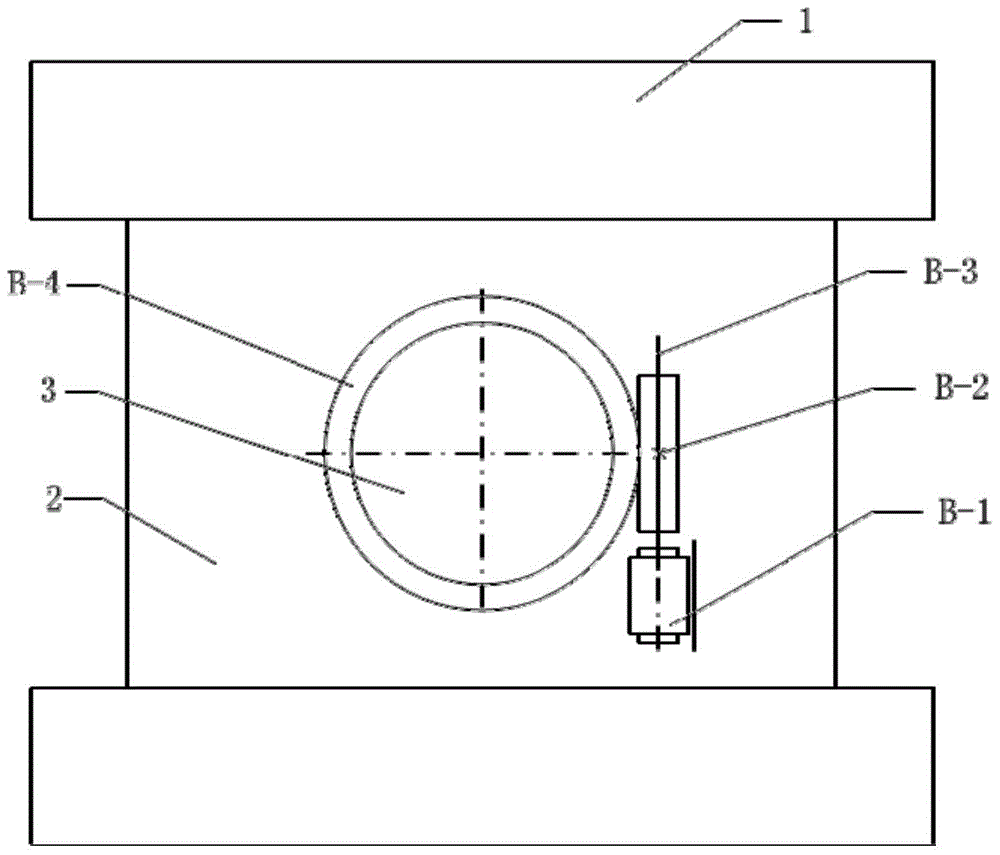

Foldable multi-level special-shaped belt transmission type continuous flood-defense sand bag throwing machine

The invention discloses a foldable multi-level special-shaped belt transmission type continuous flood-defense sand bag throwing machine. At present, a machine capable of quickly throwing sand bags is urgently needed for recover damages as far as possible during flood defense. The foldable multi-level special-shaped belt transmission type continuous flood-defense sand bag throwing machine comprises a tracked traveling device, a rotating platform steering device, a throwing platform lifting device, a foldable throwing platform unfolding device, a belt transmission device and a hydraulic system. The tracked traveling device is capable of operating in severe environment; the rotating platform steering device and the throwing platform lifting device are capable of changing sand bag throwing directions and angles at any time as needed; the foldable throwing platform unfolding device is capable of quickly and efficiently folding and unfolding the throwing platform; the sand bags are stably accelerated by a four-level variable-speed special-shaped belts of the belt transmission device; friction force between the sand bags and the belt is increased, and an acceleration process is quicker. The foldable multi-level special-shaped belt transmission type continuous flood-defense sand bag throwing machine has the advantage that operation efficiency in flood defense can be improved to reduce economic loss as far as possible.

Owner:安徽翰邦科技咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com