Sealing structure and sealing method of non-welded metal plate single battery

A sealing structure, single cell technology, applied in fuel cell parts, fuel cells, sealing/supporting devices, etc., can solve the problems of high scrap rate, difficulty in dispensing, affecting sealing performance and reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

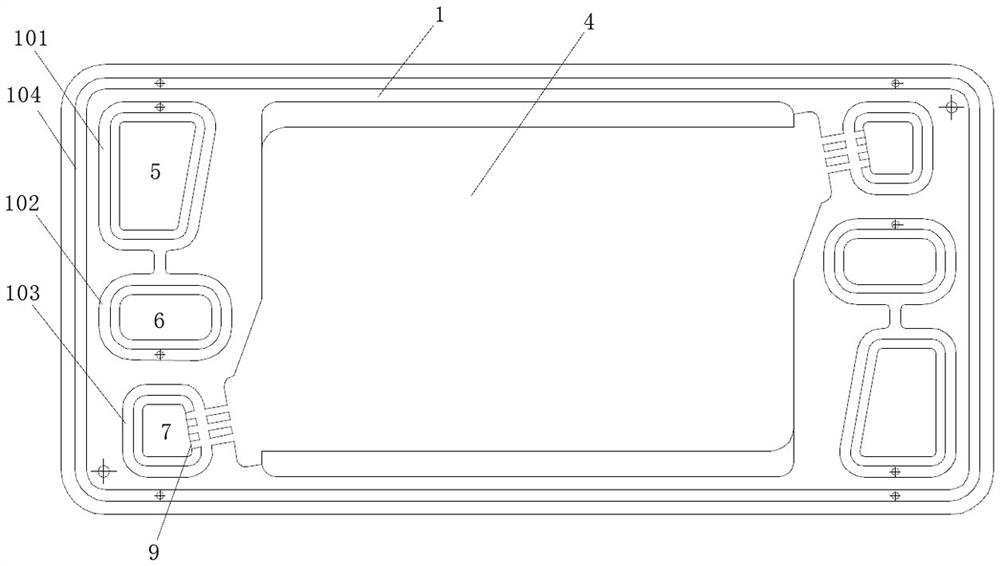

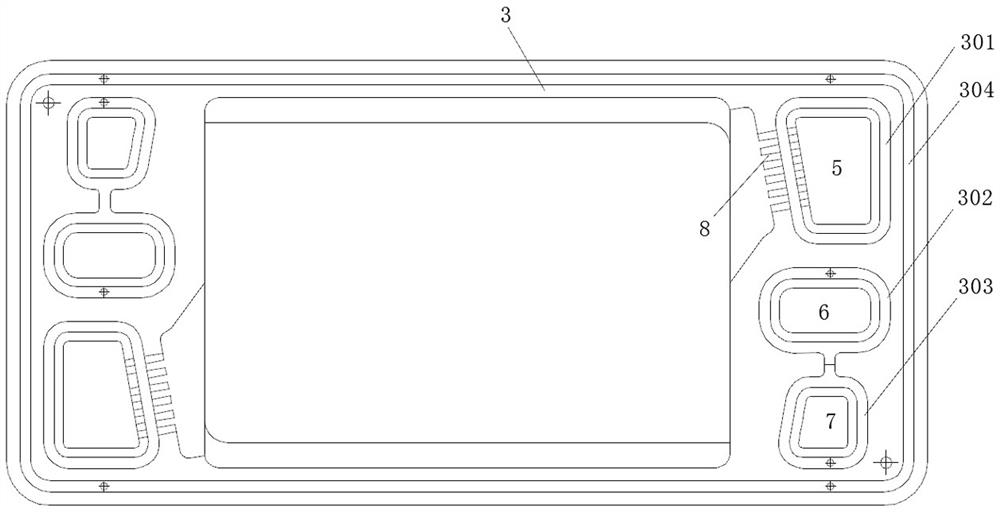

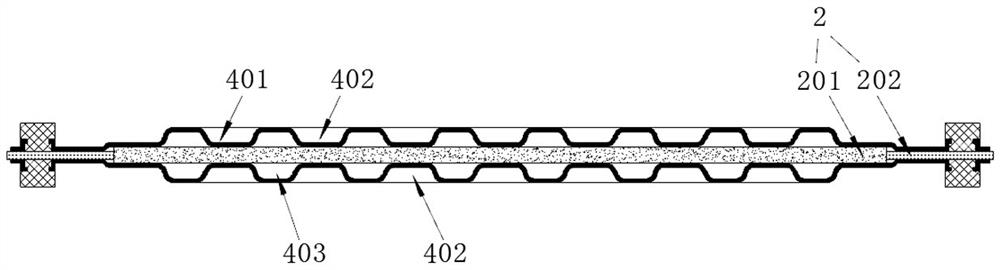

[0034] Such as Figure 1-6 As shown, this embodiment provides a sealed structure of a non-welded metal plate single cell, including a single cell formed by stacking an anode plate 1, a membrane electrode 2 and a cathode plate 3, and the membrane electrode is formed by a middle The membrane electrode main body 201 and the membrane electrode frame 202 on its outer periphery are composed. The middle part of the single cell is a flow field area 4 with an anode flow field 401, a cooling flow field 402 and a cathode flow field 403. The left and right sides of the flow field area 4 are There are air main passages 5, cooling main passages 6 and hydrogen main passages 7 communicated with the cathode flow field, cooling flow field and anode flow field respectively; the air main passages, cooling main passages and hydrogen main passages on the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com