Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Satisfactory shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hair treatment composition containing a combination of at least three different polymers

InactiveUS20060051311A1Without impairing application property and product performanceAttractive consistencyCosmetic preparationsHair cosmeticsCross-linkMeth-

The hair treatment composition contains a combination of an anionic polysaccharide, a second homopolymer or copolymer, which is built up from acrylamidoalkylsulfonic acids, methacrylamidoalkylsulfonic acids, or their salts, and a third polymer, which is an amphiphilic polymer. Preferably the hair treatment composition is a hair styling gel containing xanthan as a first polymer, ammonium acryloyldimethyltaurate / vinylpyrrolidone copolymer as a second polymer and, as a third polymer, cross-linked copolymers made from (meth)acrylic acid and C10- to C30-alkyl esters of (meth)acrylic acid. The preferred gel has a shaky pudding-like consistency and is suitable as a 2-in-1 gel that can be used as either a hair styling gel for increasing hairstyle volume or as a finishing gel for structuring a hairstyle.

Owner:WELLA GMBH

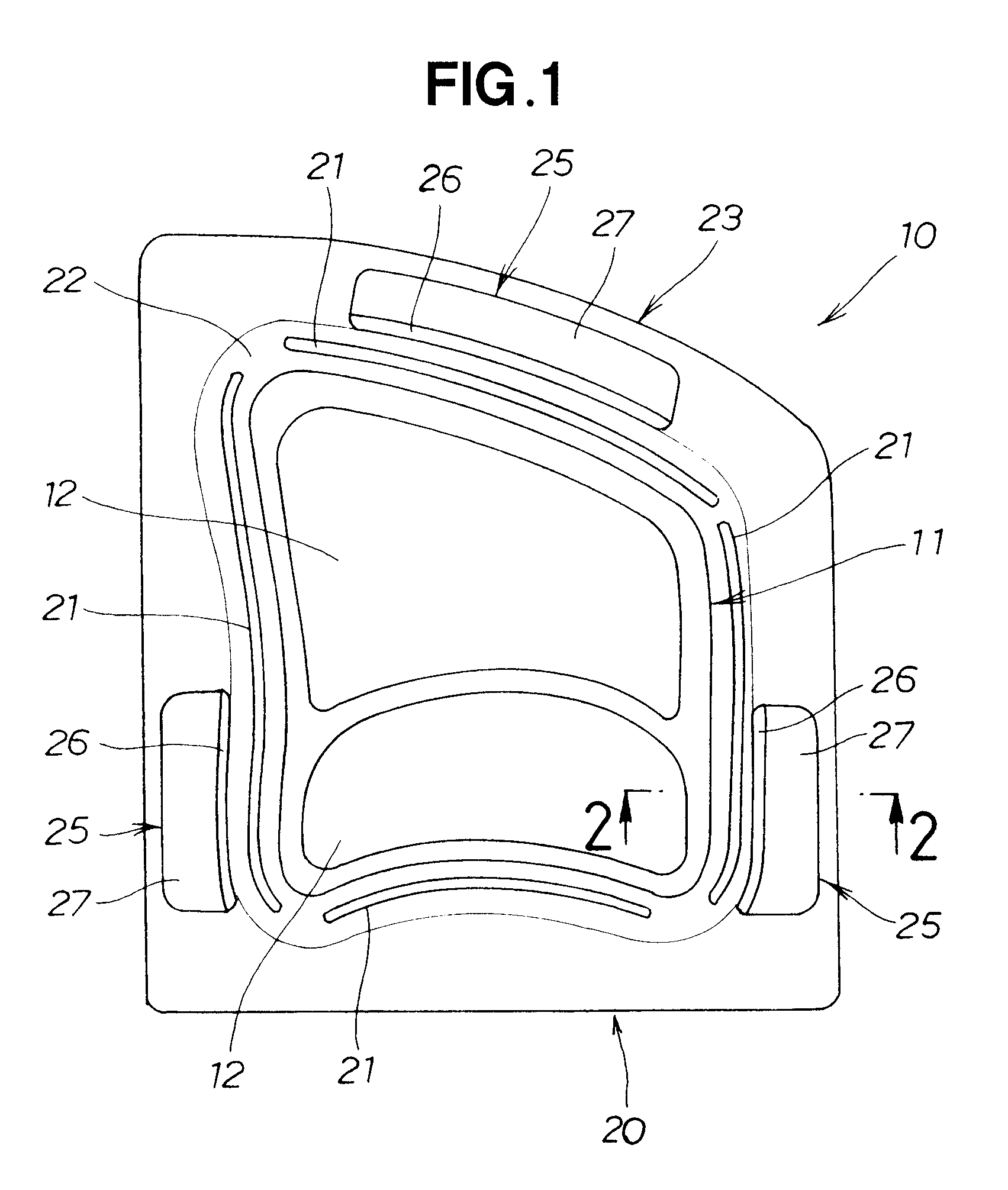

Press forming die set and method

A die set for press-forming a blank of thin metallic sheet. The die set has a punch and a blank holder. The blank holder has a first bead for restraining an edge of the blank with a constant force. The first bead is disposed further to an inside than a second bead for restraining the edge of the blank with a force that varies during pressing of the blank.

Owner:HONDA MOTOR CO LTD

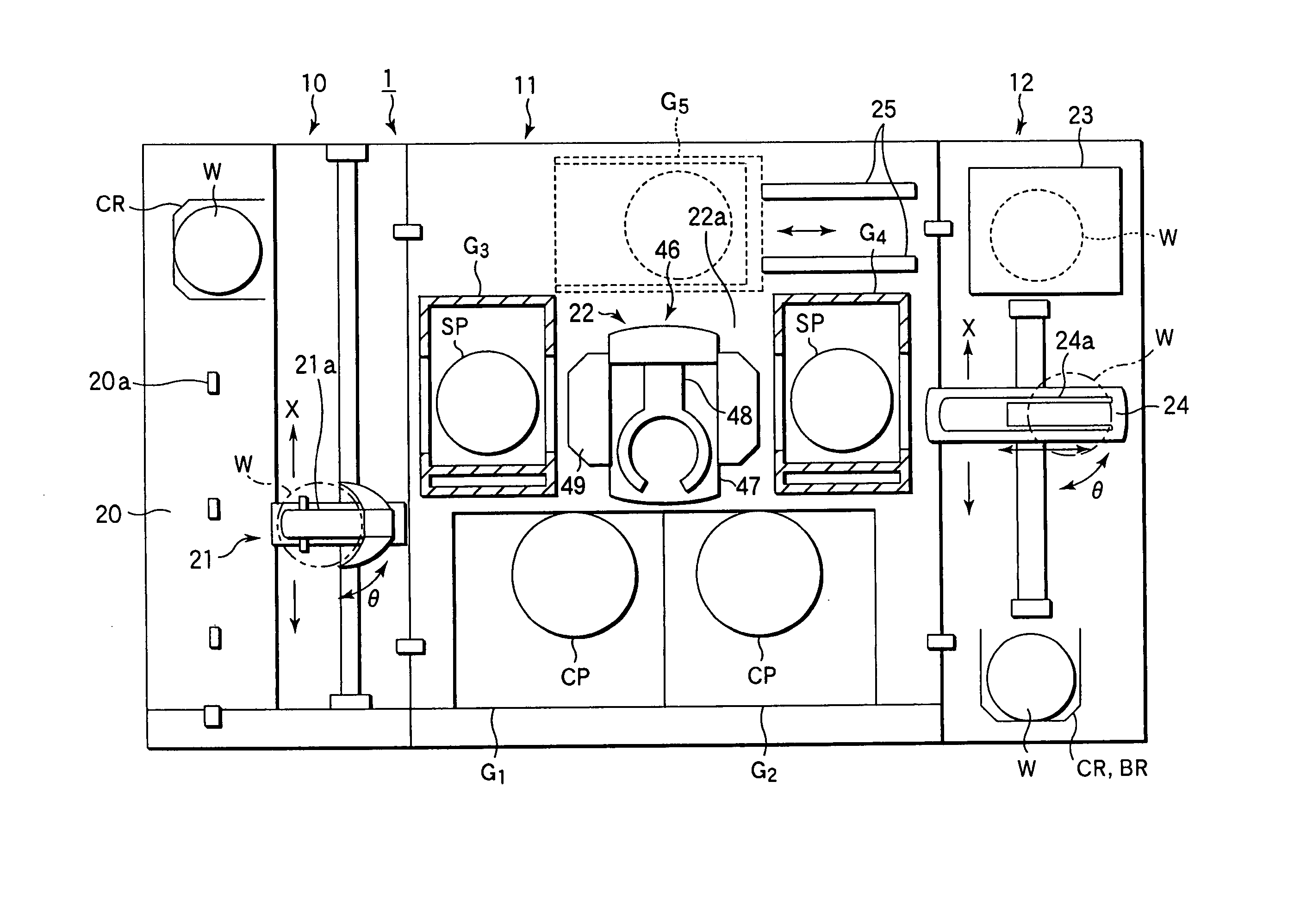

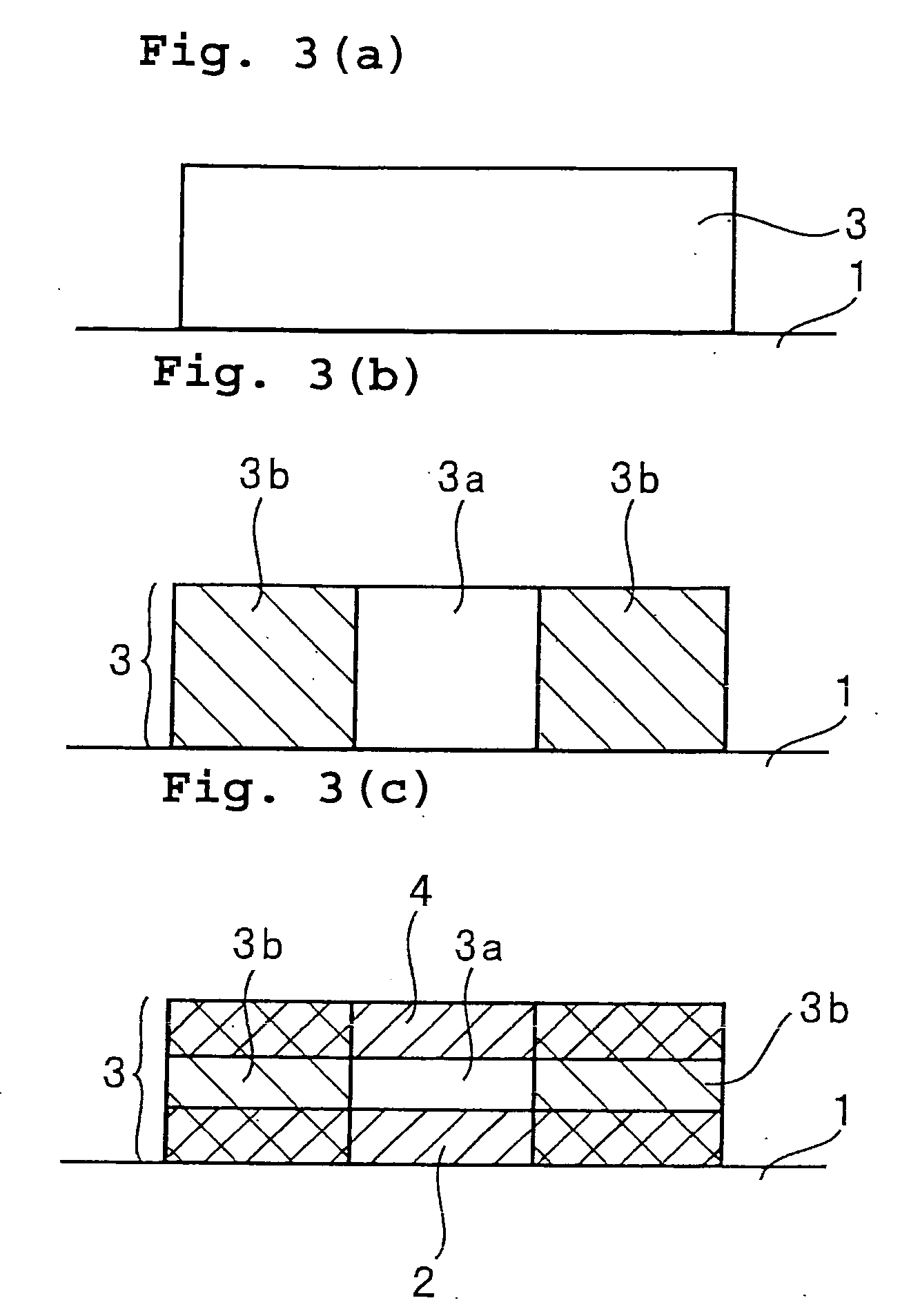

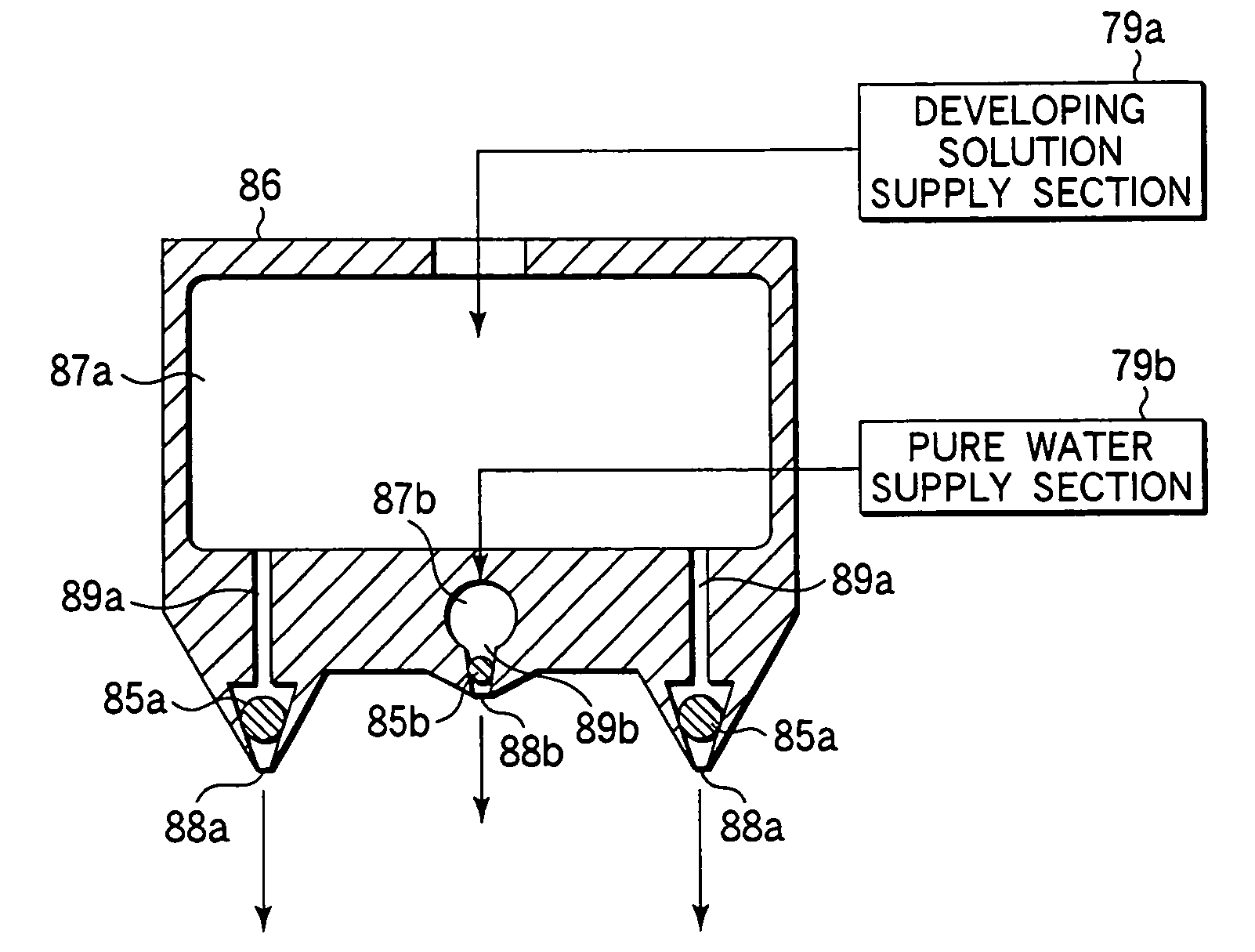

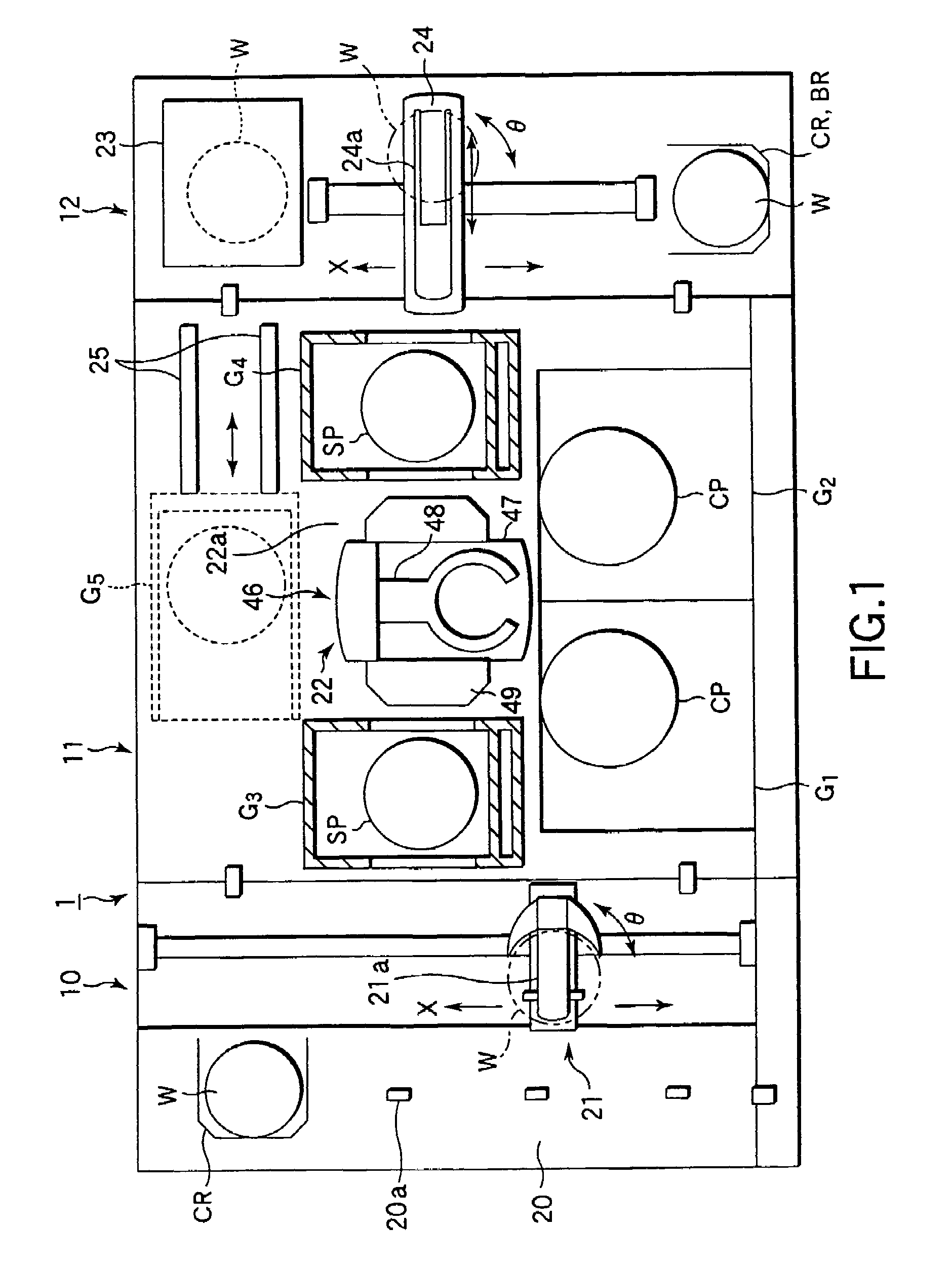

Method for developing processing and apparatus for supplying developing solution

InactiveUS20050053874A1Improved CD uniformityInhibition of defect generationPhotoprinting processesSemiconductor/solid-state device manufacturingResistEngineering

In a developing processing of a wafer having a resist film low in the dissolving rate in a developing solution formed thereon and subjected to an exposure treatment, a developing solution of a low concentration is supplied first onto a wafer and the wafer is left to stand for a prescribed time to permit a developing reaction to proceed, followed by further supplying a developing solution having a concentration higher than that of the developing solution supplied first onto the wafer, leaving the substrate to stand and subsequently rinsing the wafer, thereby improving the uniformity of the line width in the central portion and the peripheral portion of the wafer.

Owner:TOKYO ELECTRON LTD

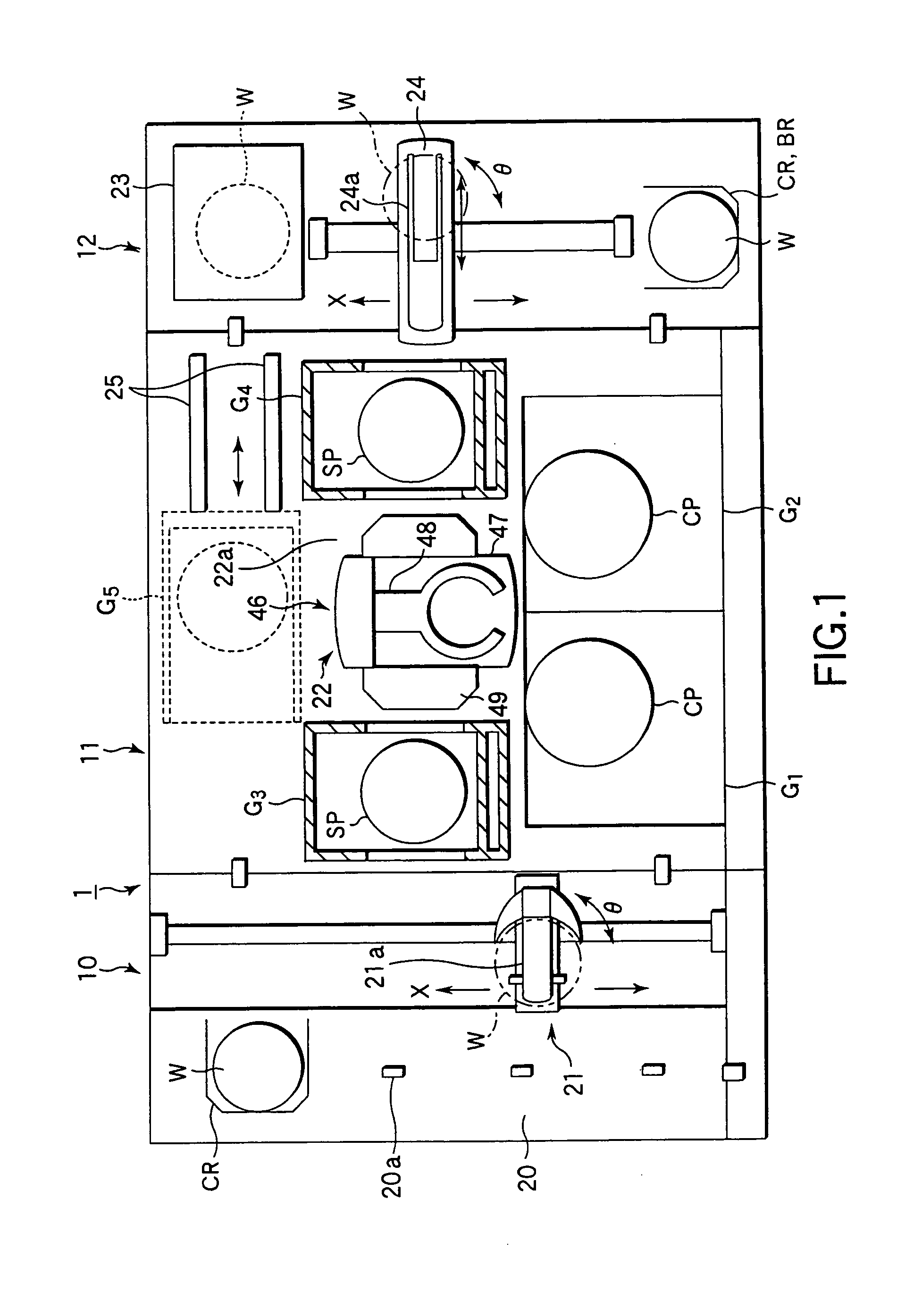

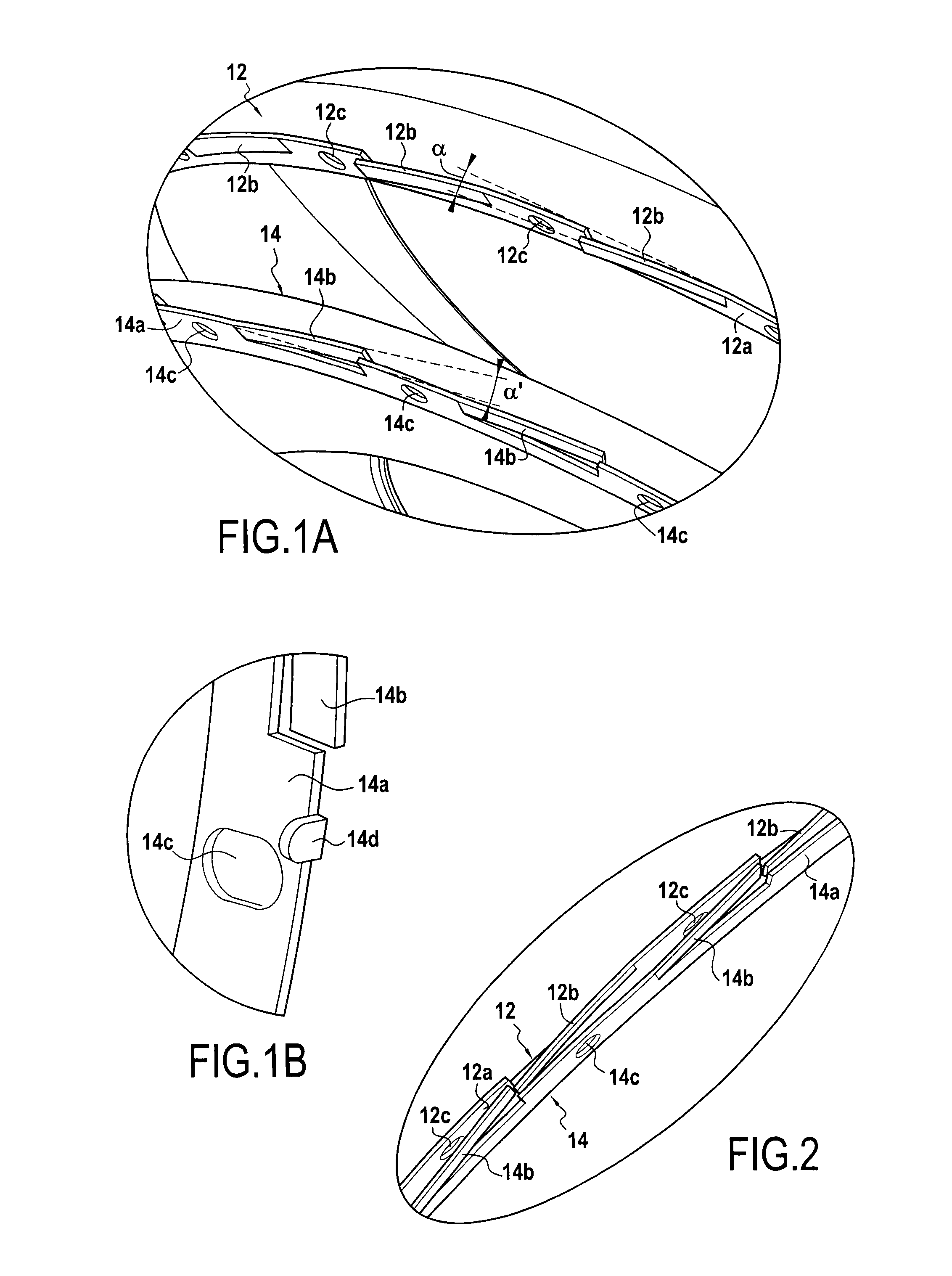

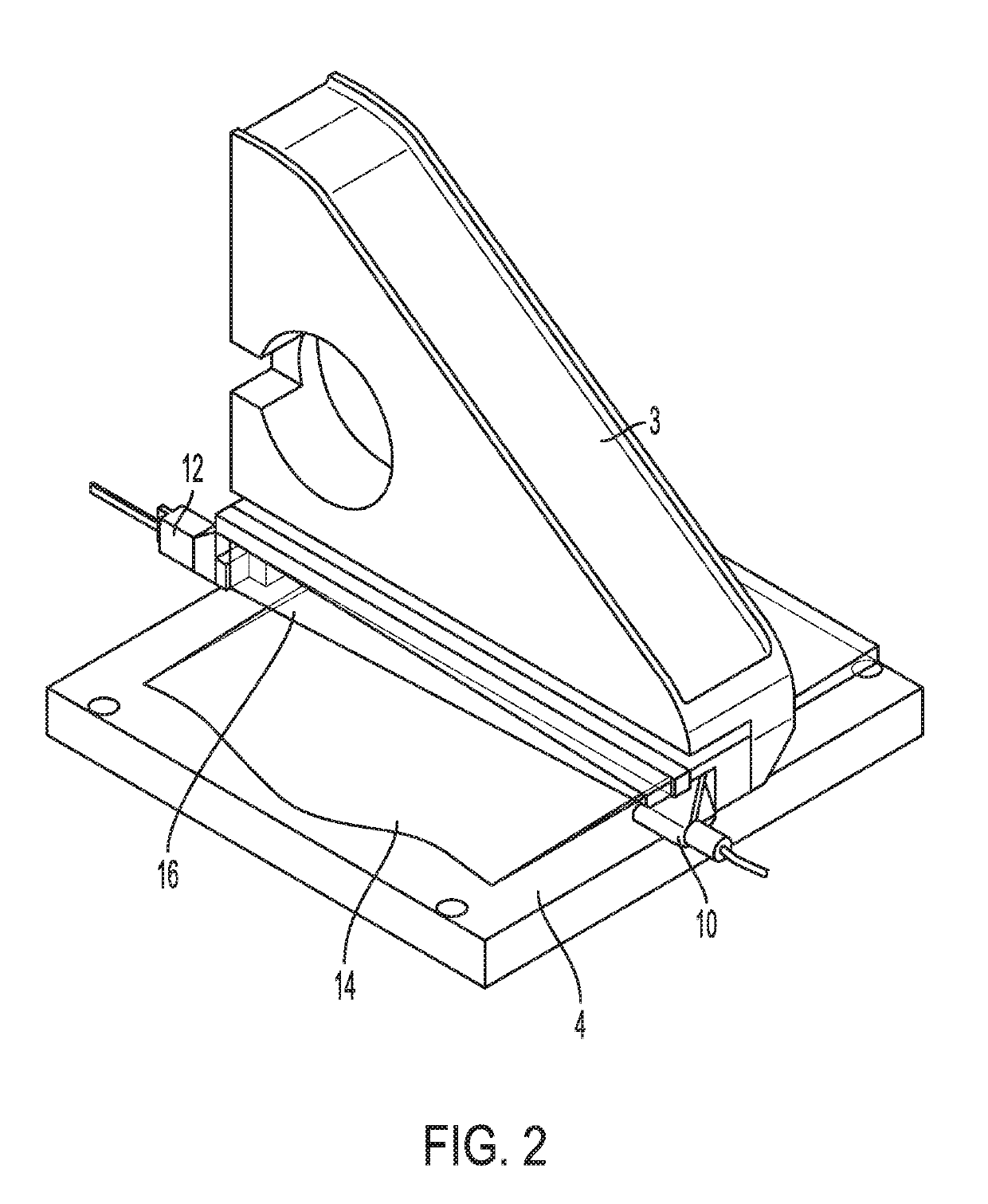

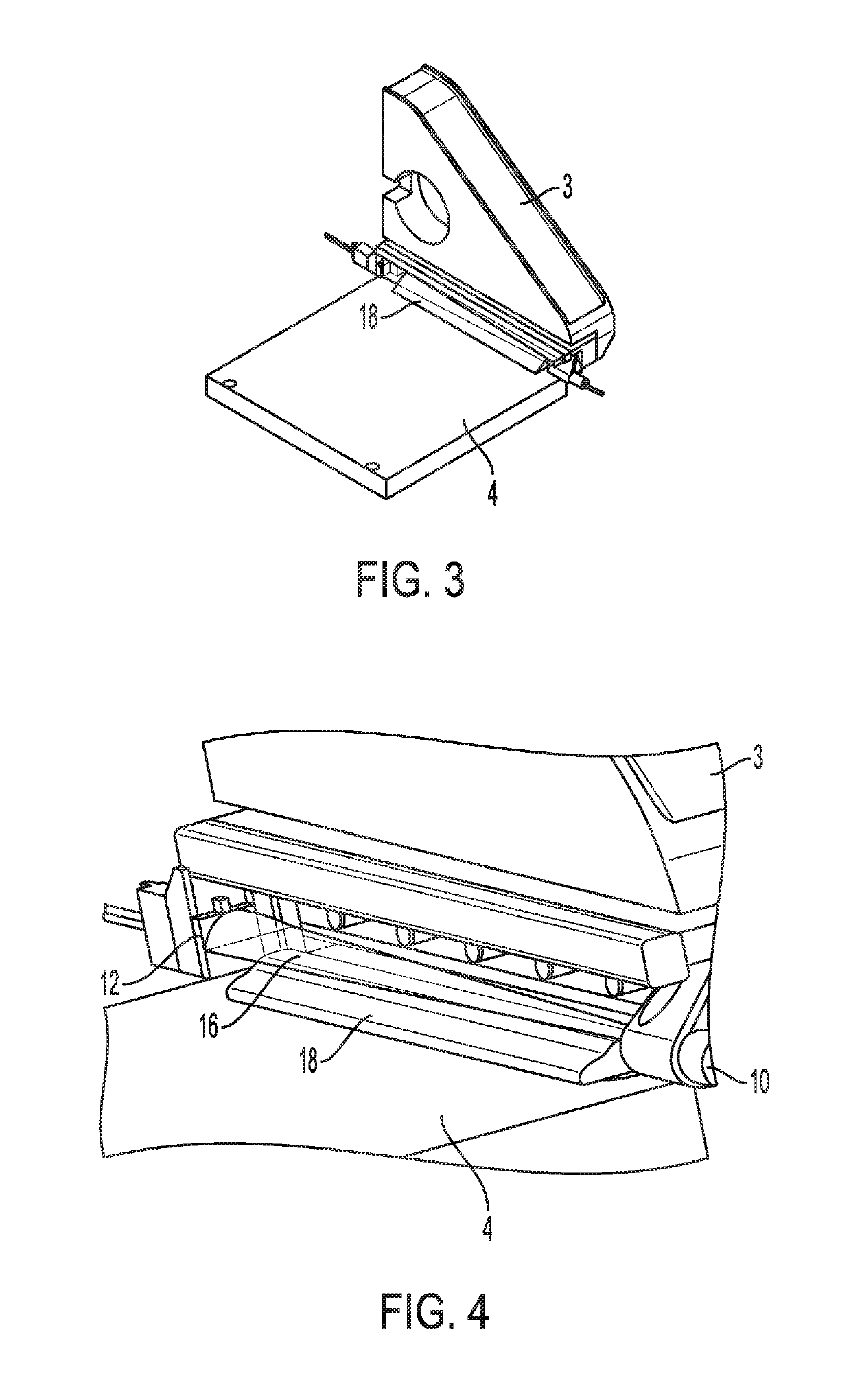

Method for producing an extruded stiffened panel, and device for implementing same

ActiveUS20140251529A1Satisfactory application of pressureSatisfactory shapeLamination ancillary operationsLaminationFiberMaterials science

A method for producing a part made of a composite material, including a skin and at least one stiffener made of strips, which are in turn made of one or more plies of fibers impregnated with a non-polymerized resin. The method includes the steps of: producing a preform of the part by pulling the strips through a die for shaping and positioning the skin and the stiffeners, a polymerization core being provided between a first strip and a second strip prior to the passage thereof through the die; and pressing the resulting preform in a hot press for a duration dt while applying a pressure P and at a temperature T for polymerizing the resin of the strips in the hot press over a pressing length L that is shorter than the length of the panel.

Owner:AIRBUS OPERATIONS (SAS)

Dry Etching Gas and Method of Dry Etching

InactiveUS20080274334A1Highly plasma-resistantSatisfactory shapeOrganic compound preparationGroup 5/15 element organic compoundsSemiconductor materialsNoble gas

A dry etching gas comprising a C4-6 fluorine compound which has an ether bond or carbonyl group and one or more fluorine atoms in the molecule and is constituted only of carbon, fluorine, and oxygen atoms and in which the ratio of the number of fluorine atoms to the number of carbon atoms (F / C) is 1.9 or lower (provided that the compound is neither a fluorine compound having one cyclic ether bond and one carbon-carbon double bond nor a saturated fluorine compound having one carbonyl group); a mixed dry etching gas comprising the dry etching gas and at least one gas selected from the group consisting of rare gases, O2, O3, CO, CO2, CHF3, CH2F2, CF4, C2F6, and C3F8; and a method of dry etching which comprises converting either of these dry etching gases into a plasma and processing a semiconductor material with the plasma. The dry etching gases can be safely used, are reduced in influence on the global environment, and can highly selectively dry-etch a semiconductor material at a high dry etching rate to form a satisfactory pattern shape. The dry etching method employs either of these dry etching gases.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

Alloy steel for low temperature vacuum carburizing

The present invention relates to an alloy steel for low temperature vacuum carburizing, and more particularly, to an alloy steel for low temperature vacuum carburizing, wherein, where the thermal processing of carburizing and quenching is performed at 810° C. or so of an available minimum carburizing temperature of a conventional vacuum carburizing furnace, it is able to securing an adequate ferrite phase (α) to improve the thermal distortion according to the thermal processing of an annulus gear, and to satisfying shape restrictions such as a roundness or a cylindricity of the annulus gear to be manufactured. An alloy steel for a low temperature vacuum carburizing according to the present invention, the alloy steel is composed of a chief element of Fe, wherein the alloy steel is formed so that dissolved oxygen (DO) is 10 ppm or less in an alloy system which comprises 0.17˜0.24 weight percent of C, 0.8˜1.2 weight percent of Cr, 0.4˜0.8 weight percent of Mn, 0.80˜1.20 weight percent of Si, 0.020 weight percent or less of P, 0.020 weight percent or less of S, 0.015˜0.045 weight percent of V, and the remaining weight percent of Fe.

Owner:HYUNDAI MOTOR CO LTD +1

Polysilane composition, optical waveguide and method for fabrication thereof

InactiveUS20060240269A1Low refractive indexHigh hardnessCladded optical fibreSynthetic resin layered productsDouble bondWaveguide

A polysilane composition characterized as containing a polysilane compound and a silicone compound in the ratio (polysilane compound:silicon compound) by weight of 80:20-5:95, and also containing an organic peroxide in the amount of 1-30 parts by weight, based on 100 parts by weight of the polysilane compound and silicone compound, wherein the silicone compound contains 40-100% by weight of a double bond containing silicon compound.

Owner:NIPPON PAINT CO LTD

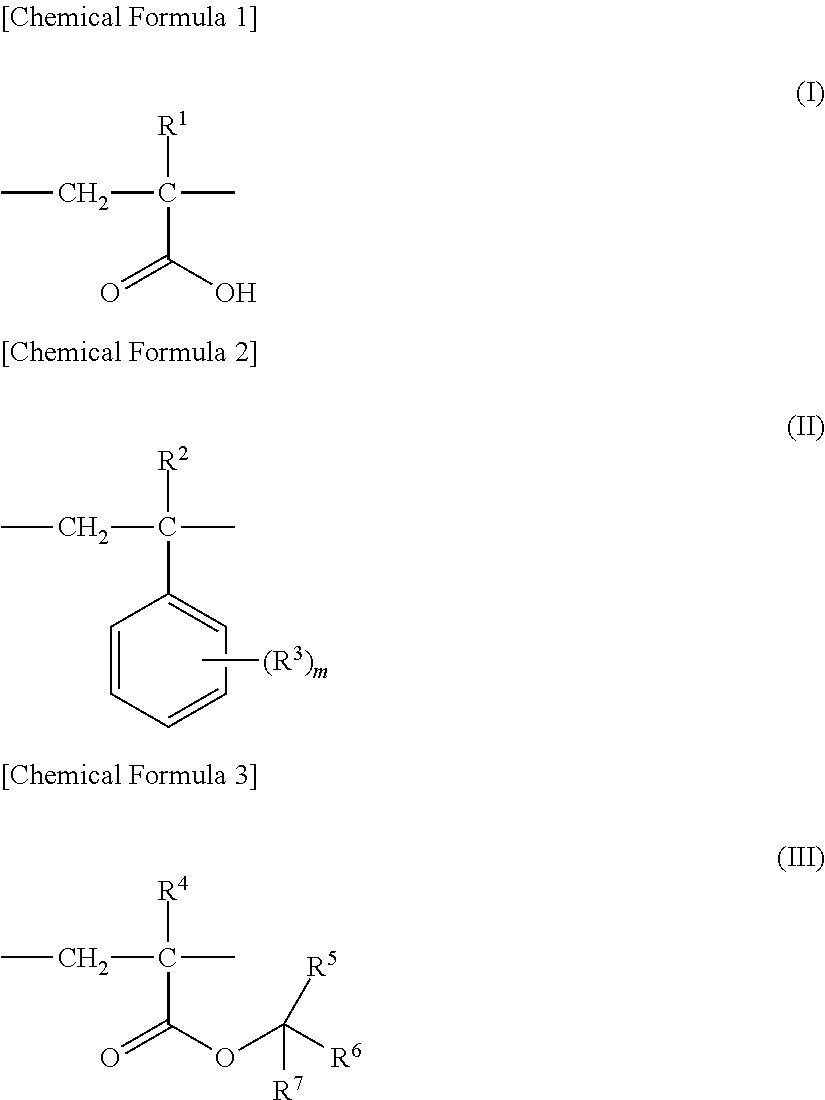

Photosensitive resin composition, photosensitive element, method of forming resist pattern and method of producing printed wiring board

InactiveUS20110159430A1High sensitivityHigh resolutionPhotosensitive materialsSemiconductor/solid-state device manufacturingResistHydrogen atom

A photosensitive resin composition comprising: (A) a binder polymer having a divalent group represented by formula (I), (II) and (III); (B) a photopolymerizing compound; and (C) a photopolymerization initiator.[In formulas (I), (II) and (III), R1, R2, R4 each independently represents a hydrogen atom or a methyl group, R3 is C1-C3 alkyl group, etc., m is an integer of 0-5, R5, R6 and R7 each independently represents a hydrogen atom or a C1-C5 alkyl group, and at least two among R5, R6 and R7 are C1-C5 alkyl groups.]

Owner:HITACHI CHEM CO LTD

Annular combustion chamber of a turbomachine

ActiveUS8925331B2Reduce leakageSatisfactory shapePump componentsGas turbine plantsCombustion chamberAzimuth direction

An annular combustion chamber for a turbomachine presenting an axial direction, a radial direction, and an azimuth direction, the combustion chamber including a first annular wall and a second annular wall, each annular wall defining at least a portion of an enclosure of the combustion chamber. The first annular wall and the second annular wall present complementary assembly mechanisms that co-operate by engagement in azimuth.

Owner:SAFRAN HELICOPTER ENGINES

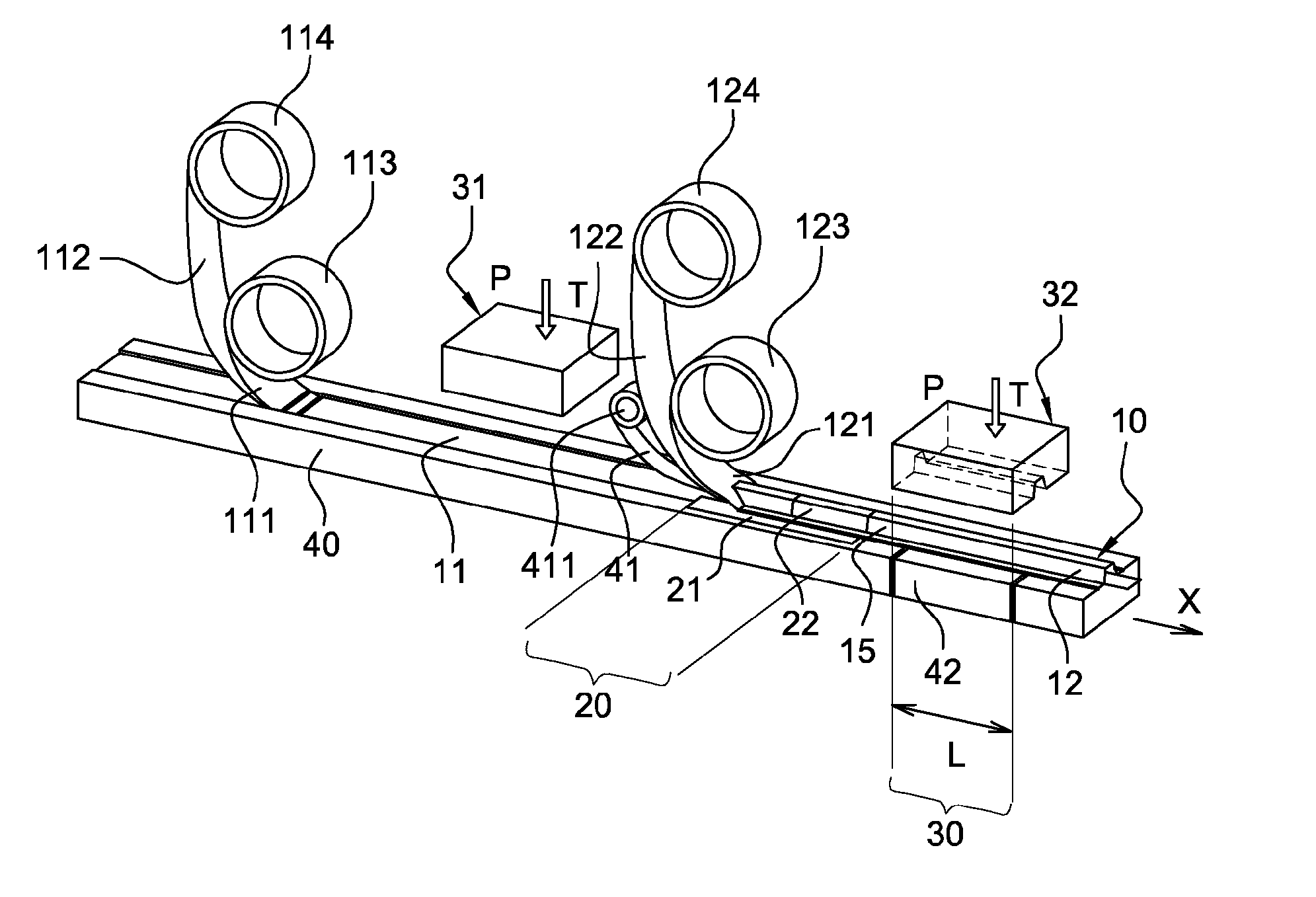

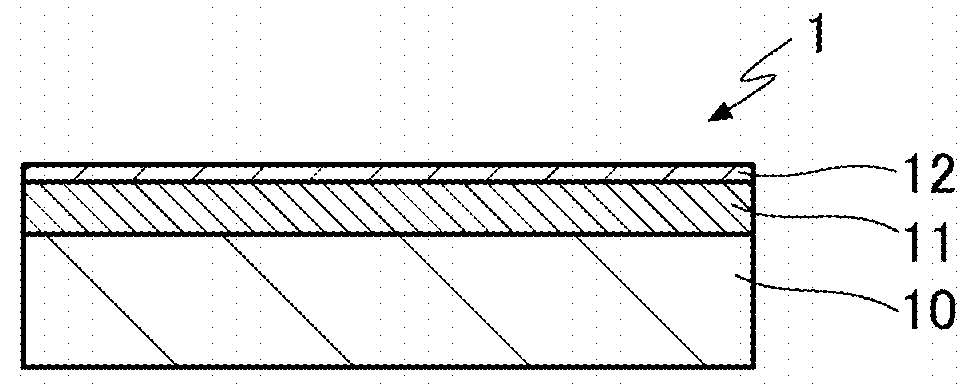

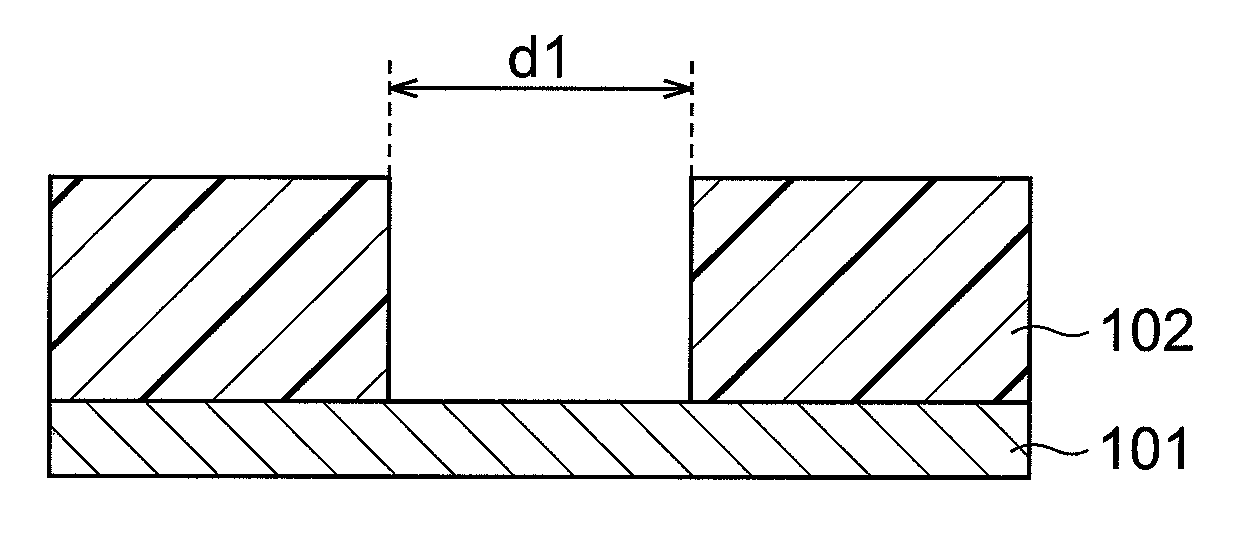

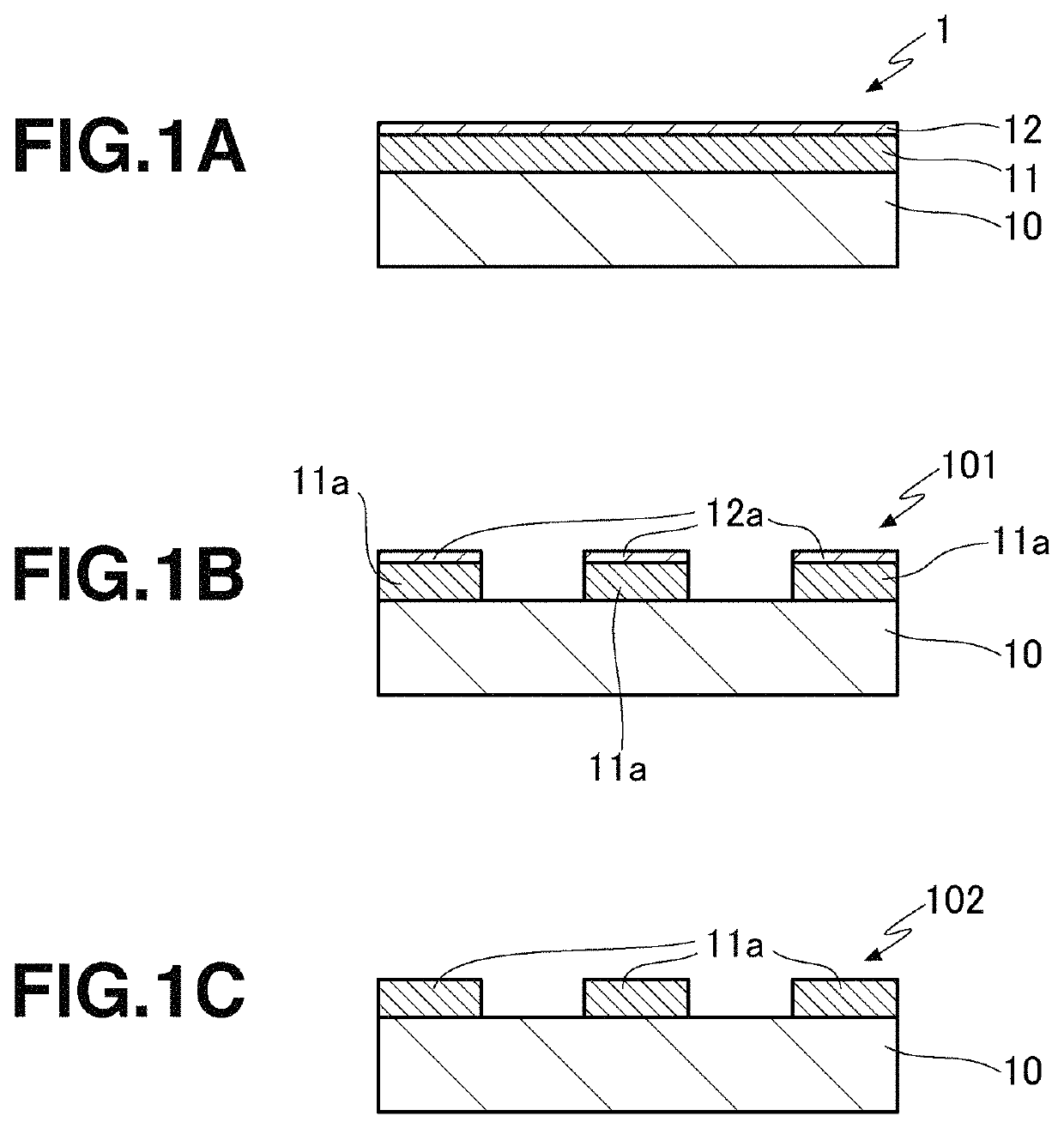

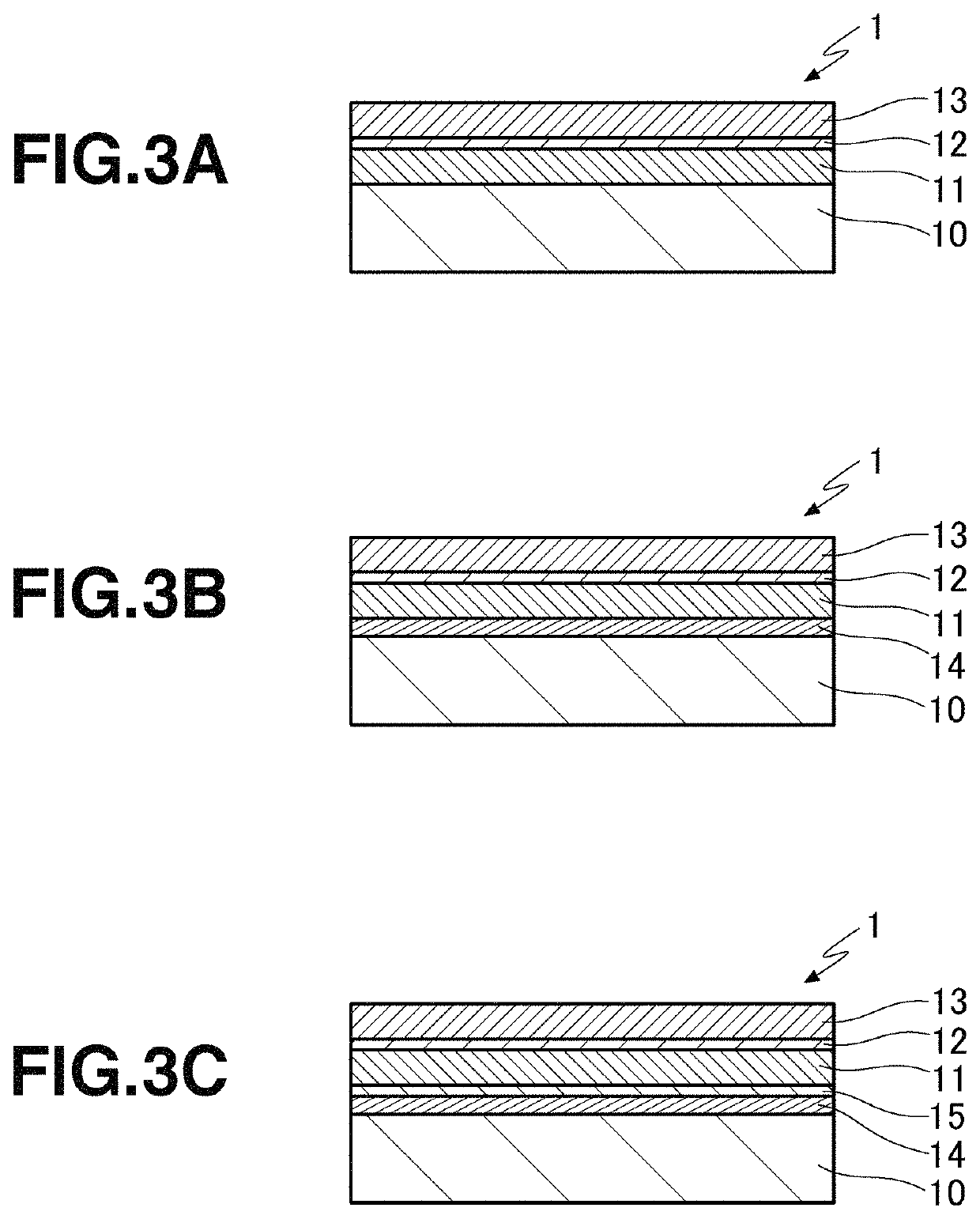

Photomask blank, method for manufacturing photomask, and mask pattern formation method

ActiveUS20180267398A1Satisfactory dimensional accuracySatisfactory shape accuracySemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentResistNitrogen

A photomask blank (1) having: a transparent substrate (10); a first film (11) etched by chlorine / oxygen-based dry etching and made of a material having resistance against fluorine-based dry etching; and a second film (12) formed adjacent to the first film and made of a material which comprises silicon and oxygen or silicon, oxygen, and nitrogen and has an Si—Si bond and which is substantially not etched by chlorine / oxygen-based dry etching, wherein: the photoresist adhesive performance is improved; the resist pattern is stably maintained without degrading, collapsing, or peeling even when a fine resist pattern is formed from a photoresist film; and an excellent shape and dimensional accuracy is obtained in regard to etching of a lower layer film in which the resist pattern is used.

Owner:SHIN ETSU CHEM IND CO LTD

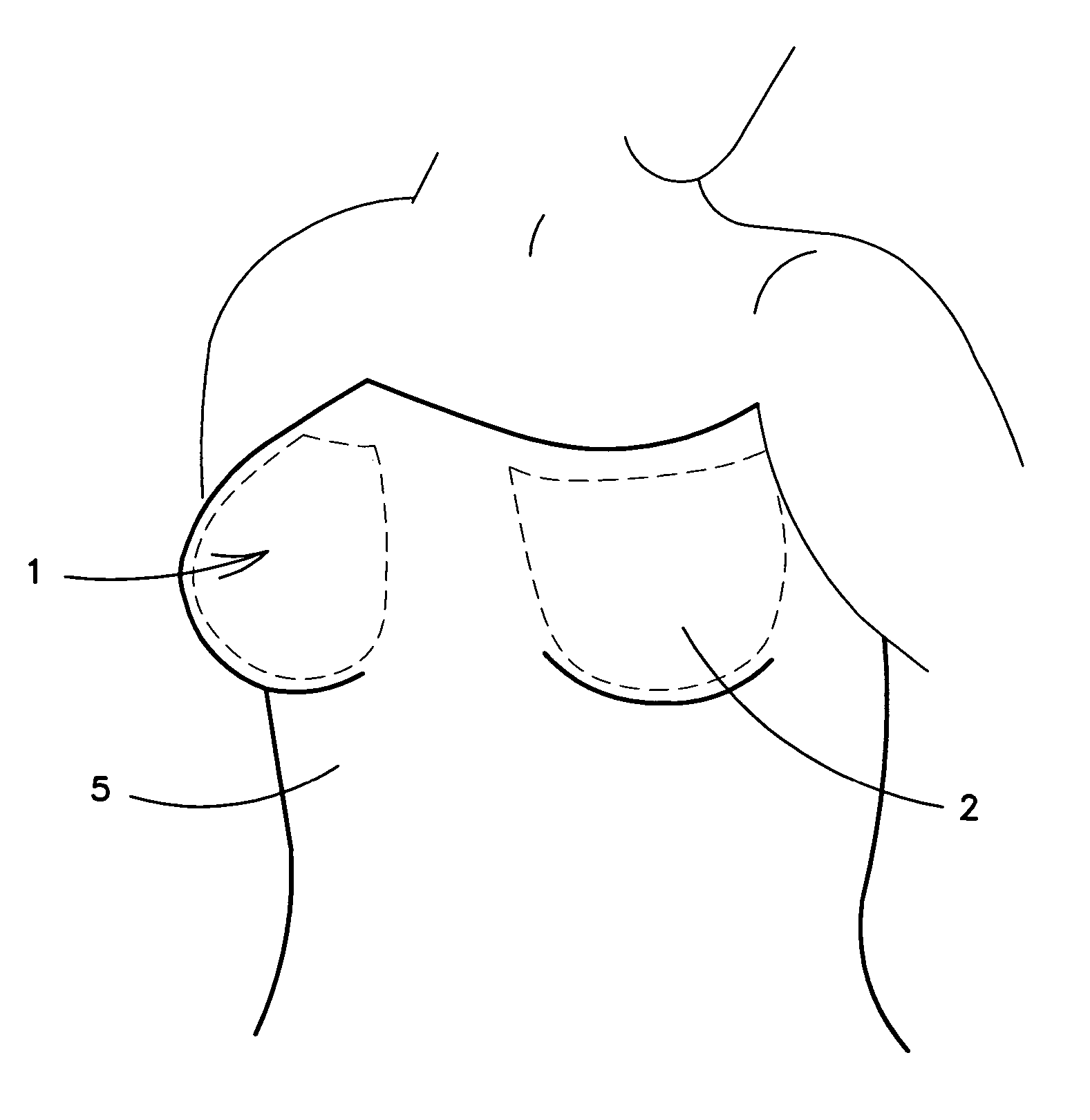

Breast complement clothing adhesive pocket systems

InactiveUS20060010577A1Satisfactory shapeAlteration can be preventedGarmentsBrassieresGynecologyMastectomy

An adherable breast pocket that may self-attach to an inside of a garment to secure and hold a breast enhancement element, such as padding, an artificial breast or mastectomy prosthesis. An adherable breast pocket may have a planar surface adhesive and may be removably attached to a garment. A garment may be unaltered for use with an adherable breast pocket. Specific pocket structures, in embodiments, are also described, as are various adhesive systems, and methods of attaching breast pockets to garments.

Owner:SARIKELLE SARAH J

Optical Powder Spreadability Sensor and Methods for Powder-Based Additive Manufacturing

ActiveUS20190105843A1Quality improvementImprove smoothnessAdditive manufacturing apparatusAuxillary shaping apparatusAdditive layer manufacturingMaterials science

Disclosed is an apparatus for and method of determining spreading behavior of a powder material during an additive manufacturing process. The method deposits a powder mound, moves a spreader to distribute a layer of powder over a build supported on a build area, operates an energy source to cast intercept the powder mound in the path of the source and onto an optical sensor during displacement of the powder mound, and analyzes an output of the optical sensor to identify features relating to the spreading behavior of the powder.

Owner:EOS OF NORTH AMERICA INC

Press forming die set and method

A die set for press-forming a blank of thin metallic sheet. The die set has a punch and a blank holder. The blank holder has a first bead for restraining an edge of the blank with a constant force. The first bead is disposed further to an inside than a second bead for restraining the edge of the blank with a force that varies during pressing of the blank.

Owner:HONDA MOTOR CO LTD

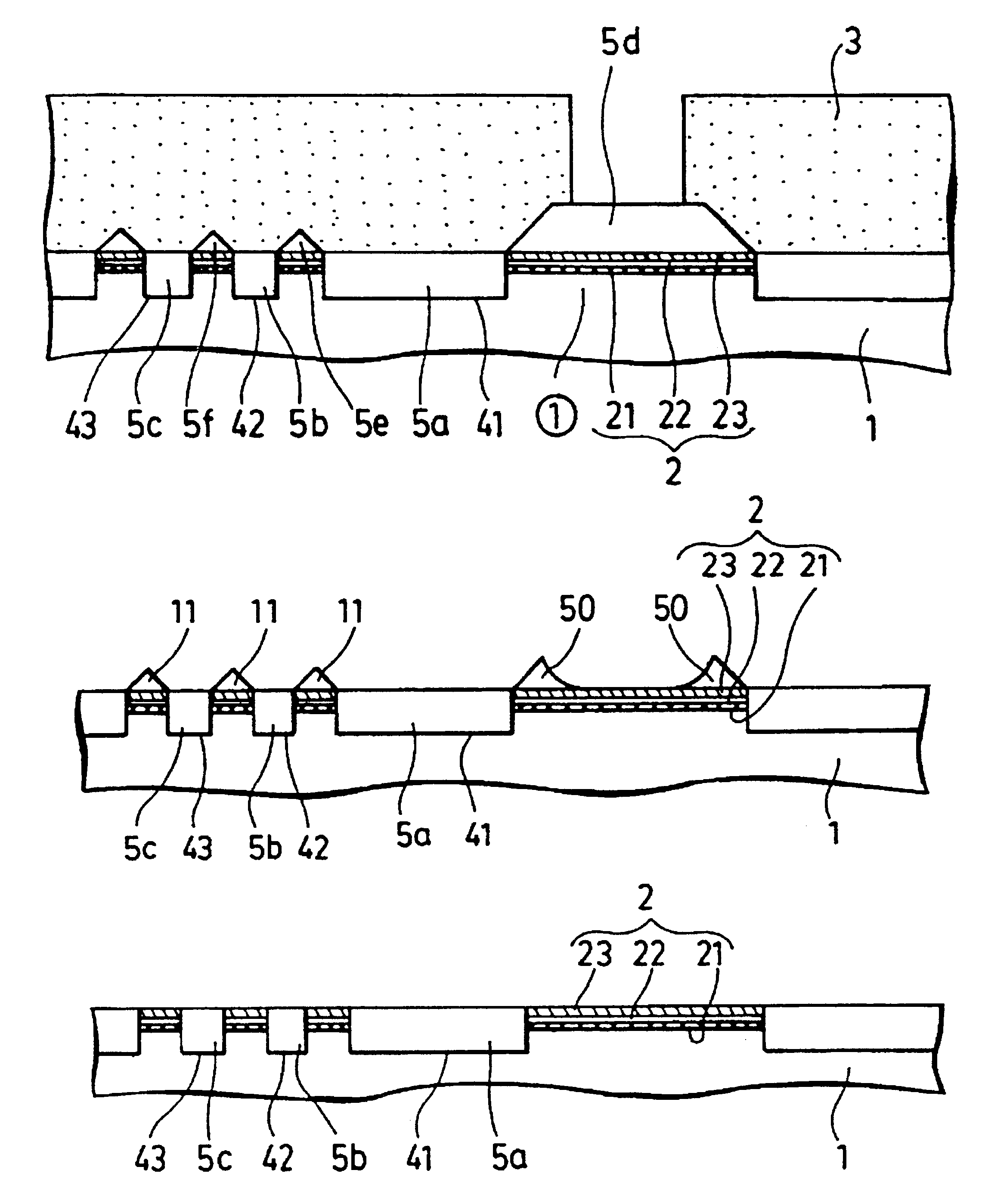

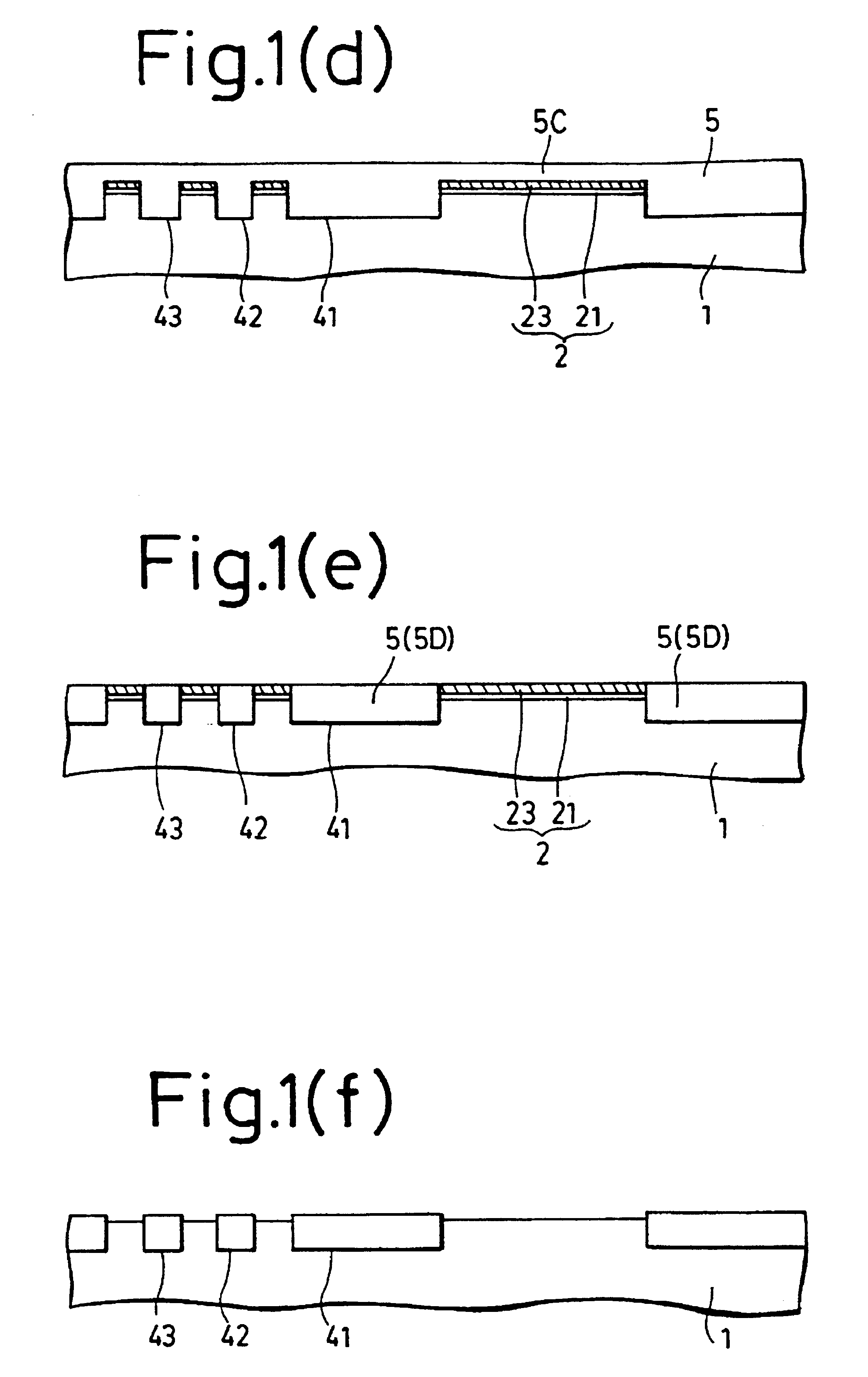

Method of forming trench isolation having polishing step and method of manufacturing semiconductor device

InactiveUSRE38363E1Satisfactory flattened shapeEasy to disassembleSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A method of forming trench isolation including a burying step of burying trenches by a deposition means for conducting etching and deposition simultaneously and a polishing step of flattening a burying material by polishing is conducted by disposing an isotropic etching step, a multi-layered etching stopper and a protrusion unifying structure. Polishing can be attained with satisfactory flatness uniformly or with no polishing residue even in a portion to be polished in which the etching stopper layer is distributed unevenly. The method can be applied to manufacture of a semiconductor device or the like.

Owner:SONY CORP

Method for developing processing and apparatus for supplying developing solution

InactiveUS6991385B2Improve uniformityInhibition of defect generationLiquid processing by liquid spraysPhotoprinting processesLine widthEngineering

In a developing processing of a wafer having a resist film low in the dissolving rate in a developing solution formed thereon and subjected to an exposure treatment, a developing solution of a low concentration is supplied first onto a wafer and the wafer is left to stand for a prescribed time to permit a developing reaction to proceed, followed by further supplying a developing solution having a concentration higher than that of the developing solution supplied first onto the wafer, leaving the substrate to stand and subsequently rinsing the wafer, thereby improving the uniformity of the line width in the central portion and the peripheral portion of the wafer.

Owner:TOKYO ELECTRON LTD

Positive-type photosensitive resin composition, method for producing resist pattern, semiconductor device, and electronic device

ActiveUS8461699B2High sensitivity and resolutionGood adhesivenessPhotosensitive materialsSemiconductor/solid-state device detailsAcrylic resinImage resolution

The positive tone photosensitive composition of the invention comprises an alkali-soluble resin having a phenolic hydroxyl group, a compound producing an acid by light, a thermal crosslinking agent and an acrylic resin. It is possible to provide a positive tone photosensitive composition that can be developed with an aqueous alkali solution, has sufficiently high sensitivity and resolution, and can form a resist pattern with excellent adhesiveness and thermal shock resistance.

Owner:RESONAC CORPORATION

Photosensitive resin composition, photosensitive element, method of forming resist pattern and method of producing printed wiring board

InactiveUS8592130B2Excellent sensitivity and resolution and adhesivenessSatisfactory propertyPhotosensitive materialsSemiconductor/solid-state device manufacturingResistHydrogen atom

A photosensitive resin composition comprising: (A) a binder polymer having a divalent group represented by formula (I), (II) and (III); (B) a photopolymerizing compound; and (C) a photopolymerization initiator.[In formulas (I), (II) and (III), R1, R2, R4 each independently represents a hydrogen atom or a methyl group, R3 is C1-C3 alkyl group, etc., m is an integer of 0-5, R5, R6 and R7 each independently represents a hydrogen atom or a C1-C5 alkyl group, and at least two among R5, R6 and R7 are C1-C5 alkyl groups.]

Owner:RESONAC CORPORATION

Annular combustion chamber of a turbomachine

ActiveUS20140109595A1High mechanical strengthReduce leakageContinuous combustion chamberGas turbine plantsCombustion chamberAzimuth direction

An annular combustion chamber for a turbomachine presenting an axial direction, a radial direction, and an azimuth direction, the combustion chamber including a first annular wall and a second annular wall, each annular wall defining at least a portion of an enclosure of the combustion chamber. The first annular wall and the second annular wall present complementary assembly mechanisms that co-operate by engagement in azimuth.

Owner:SAFRAN HELICOPTER ENGINES

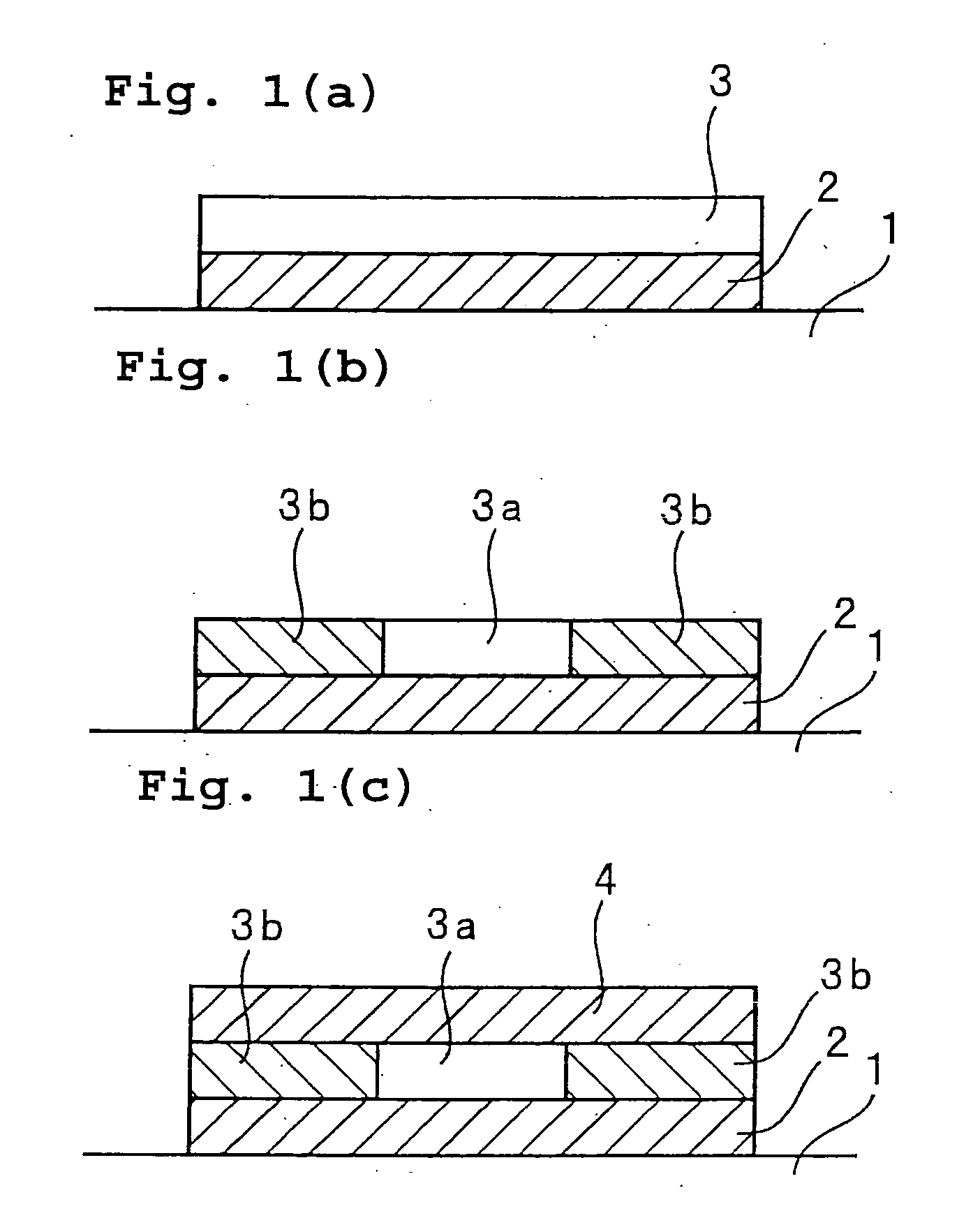

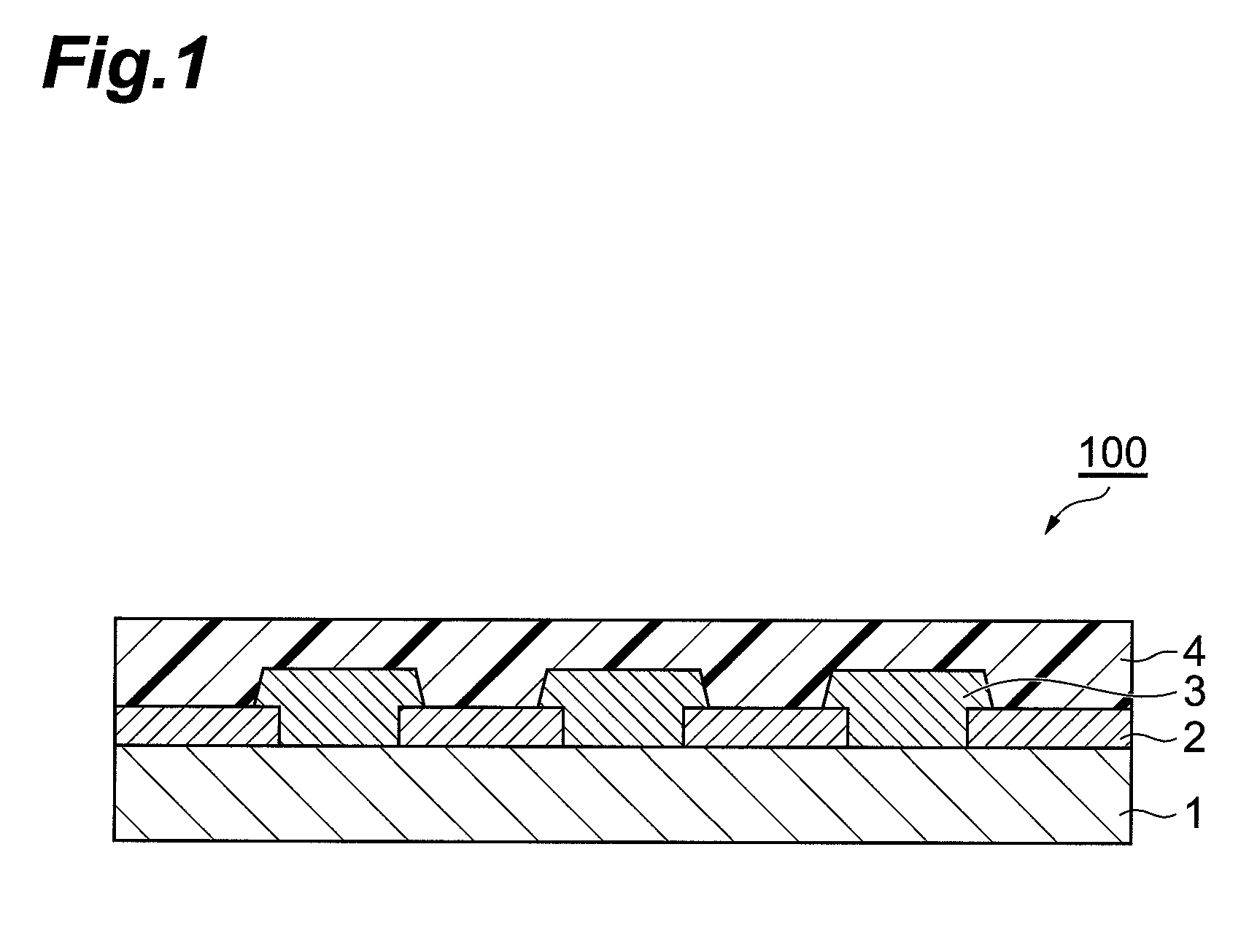

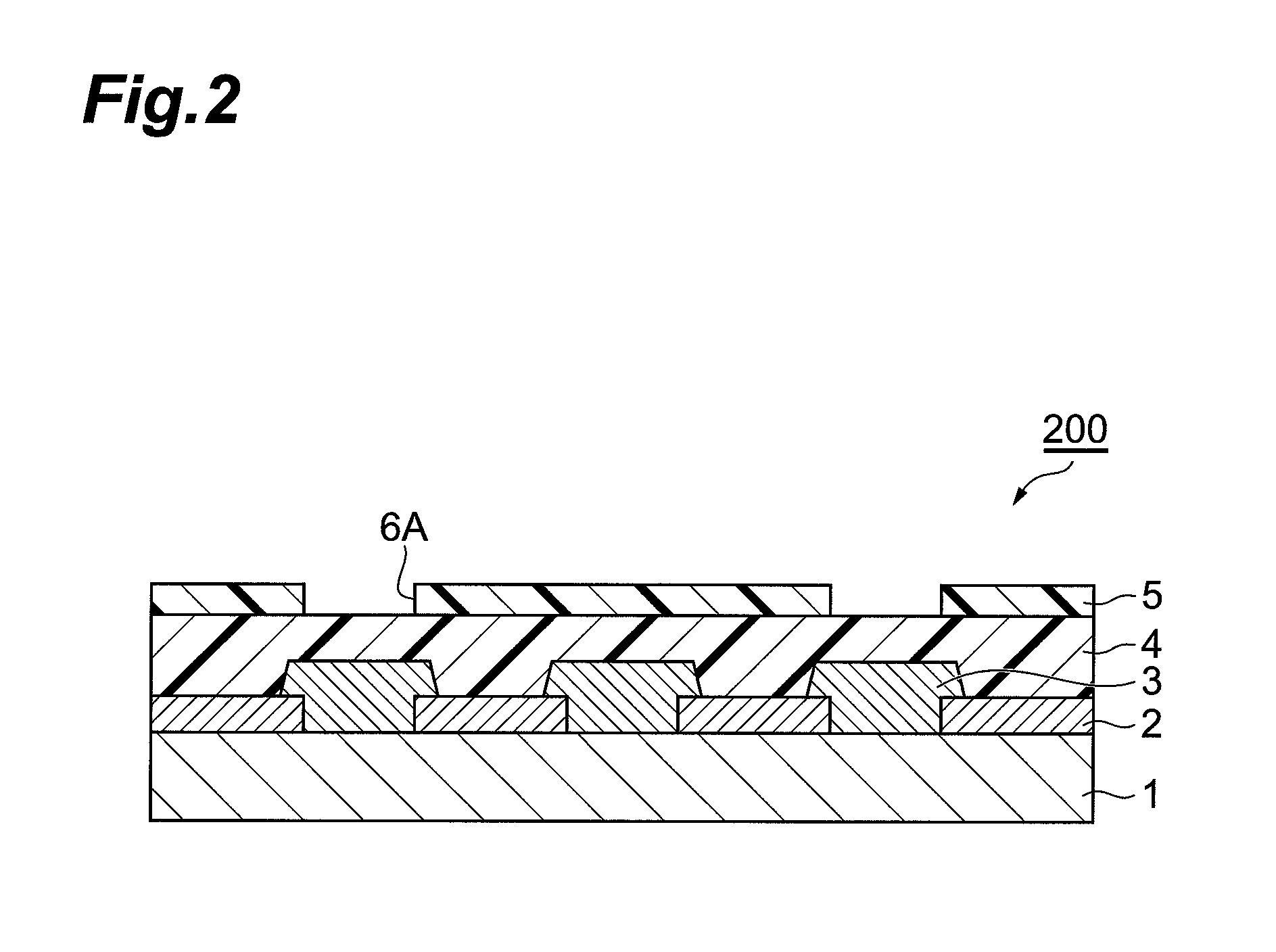

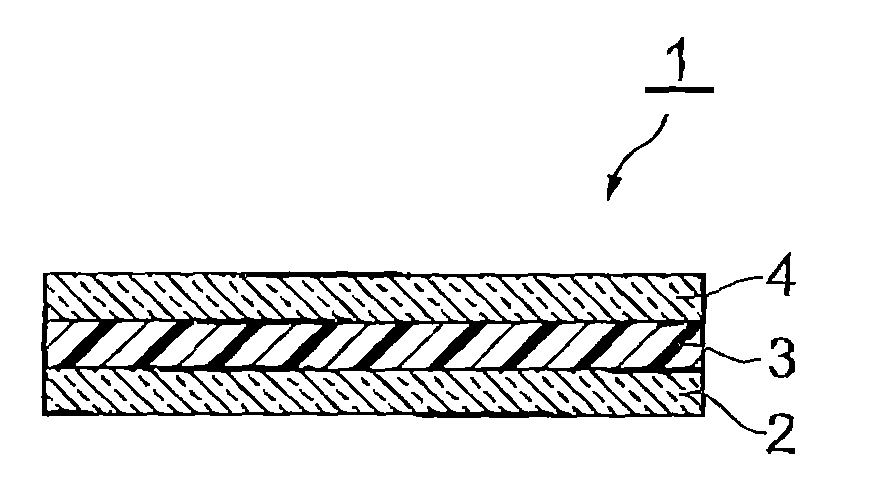

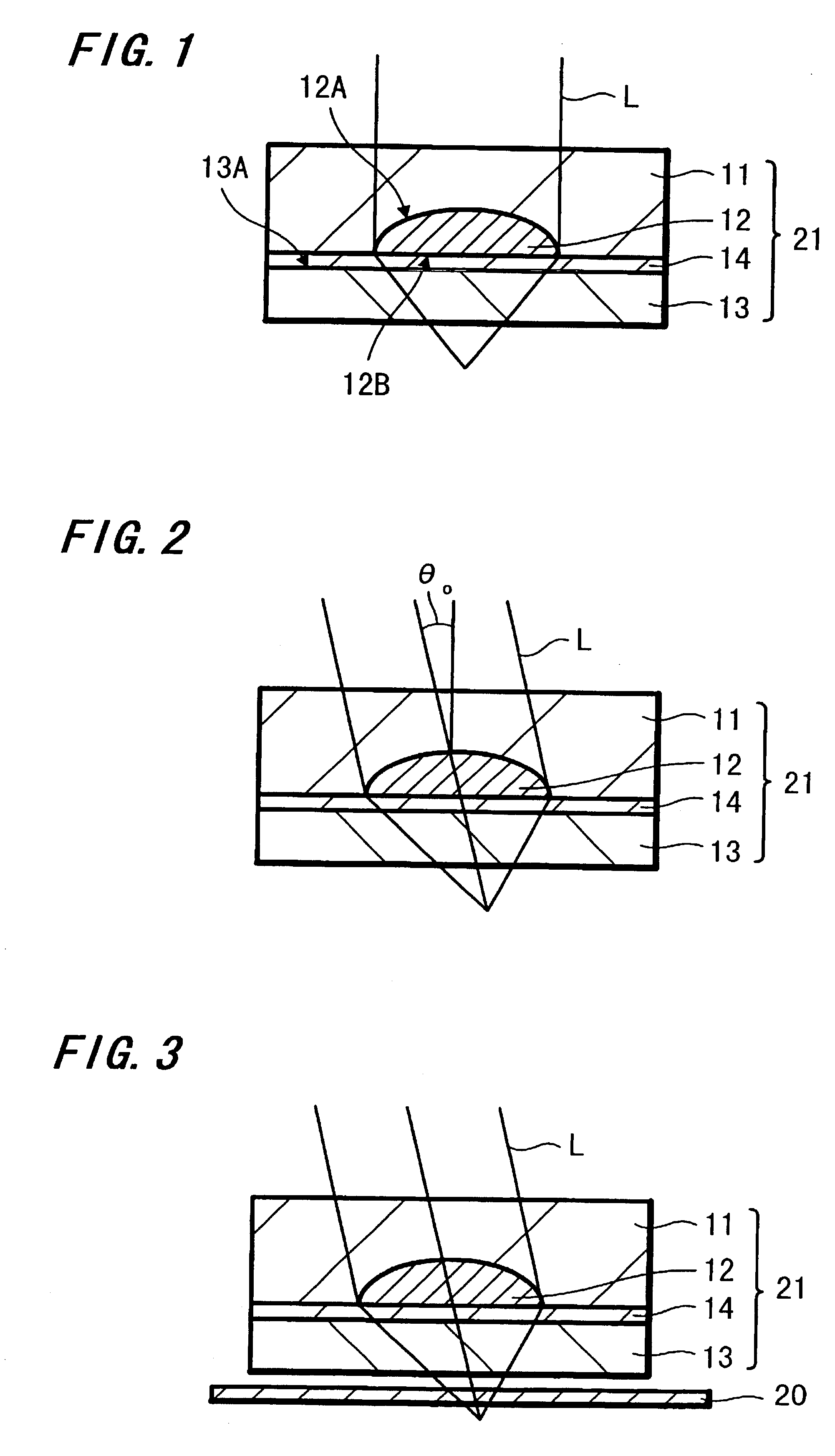

Optical element and optical pickup

InactiveUS6839188B2Reduce the overall diameterRadius of curvature of lens can be increasedRecord information storageOptical beam guiding meansOptical pickupOptical axis

The system and methods of the present invention are directed to an optical pickup. The optical includes at least a light source, a lens for focusing and irradiating light from the light source on a recording medium, and an optical pickup element. The optical pickup element includes a lens base plate in which a lens made of a material having a high refractive index is embedded within a transparent base plate to pass incident light. The optical element further includes an aberration correction base plate formed of a transparent parallel flat plate-like base plate to pass light and correcting a comatic aberration produced on the lens. The lens base plate and the aberration correction base plate are integrated such that the lens base plate and the aberration correction base plate are parallel to each other. Moreover, the aberration correction base plate is located on the side of a point at which incident light is focused by the lens.. The optical element can reduce the diameter of the lens, increase the radius of curvature of the lens, and correct a comatic aberration produced when an optical axis of incident light is inclined relative to the lens.

Owner:SONY CORP

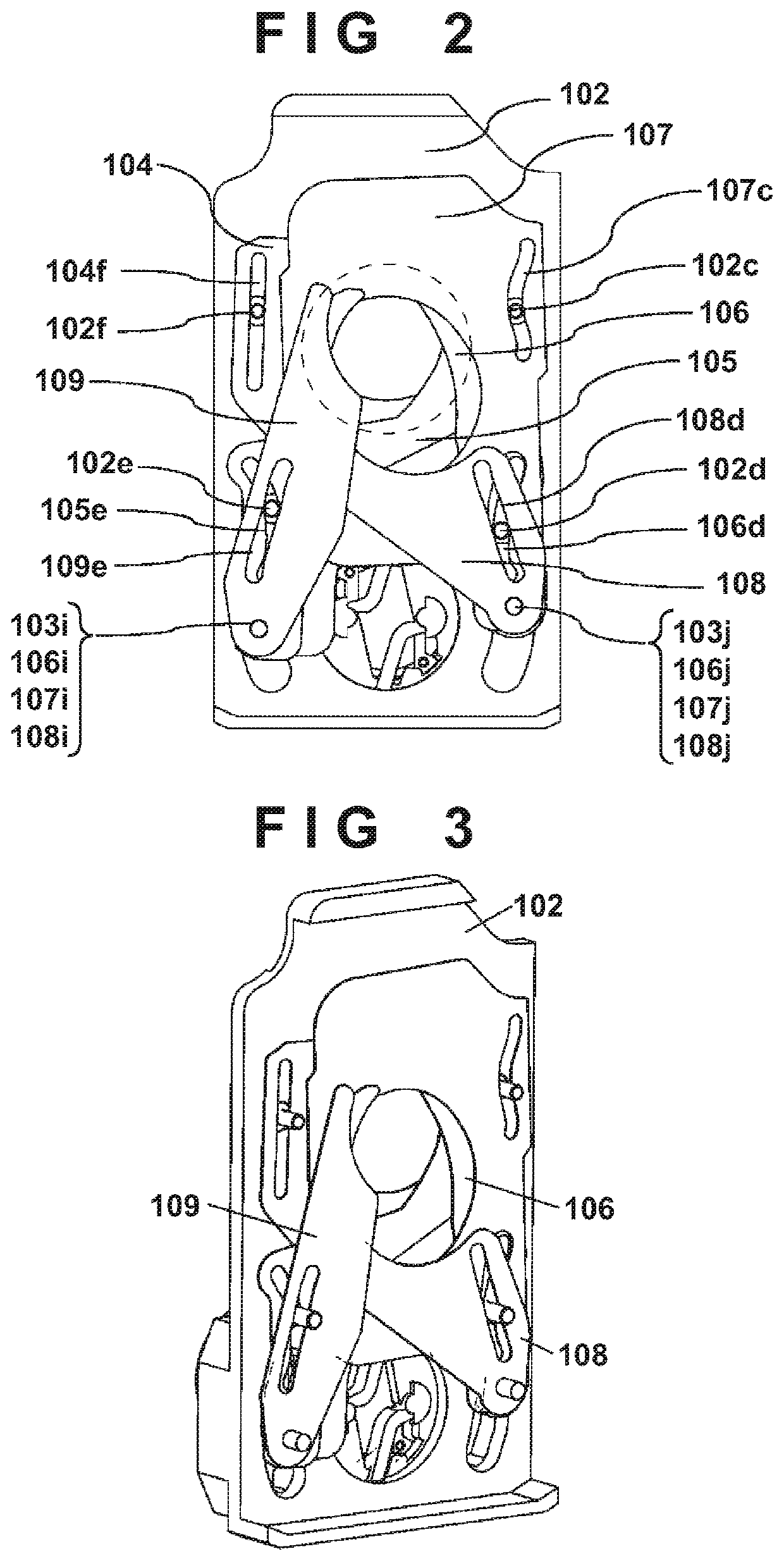

Light amount adjusting device and optical device

ActiveUS20190018304A1Reduce device sizeSatisfactory diaphragm opening shapeCamera diaphragmsTransmitted powerEngineering

A light amount adjusting device includes an opening forming member configured to form an opening portion through which light passes, a blade group configured to move on the opening forming member and form a part of a light passing opening in the opening portion, and a power transmission member arranged outside the opening portion and engaging with the blade group to transmit power. The blade group includes a straight blade configured to move linearly and a swing blade configured to swing from both sides in a straight-ahead operation of the straight blade toward a center of the light passing opening. An edge portion of the light passing opening on a side of the power transmission member or an edge portion on a side opposite to the side of the power transmission member is formed by the blade group.

Owner:CANON DENSHI KK

Photomask blank, method for manufacturing photomask, and mask pattern formation method

ActiveUS10585345B2Improve adhesionResist pattern is maintained stableDigital data processing detailsSemiconductor/solid-state device manufacturingDry etchingSilicon

A photomask blank (1) having: a transparent substrate (10); a first film (11) etched by chlorine / oxygen-based dry etching and made of a material having resistance against fluorine-based dry etching; and a second film (12) formed adjacent to the first film and made of a material which comprises silicon and oxygen or silicon, oxygen, and nitrogen and has an Si—Si bond and which is substantially not etched by chlorine / oxygen-based dry etching, wherein: the photoresist adhesive performance is improved; the resist pattern is stably maintained without degrading, collapsing, or peeling even when a fine resist pattern is formed from a photoresist film; and an excellent shape and dimensional accuracy is obtained in regard to etching of a lower layer film in which the resist pattern is used.

Owner:SHIN ETSU CHEM IND CO LTD

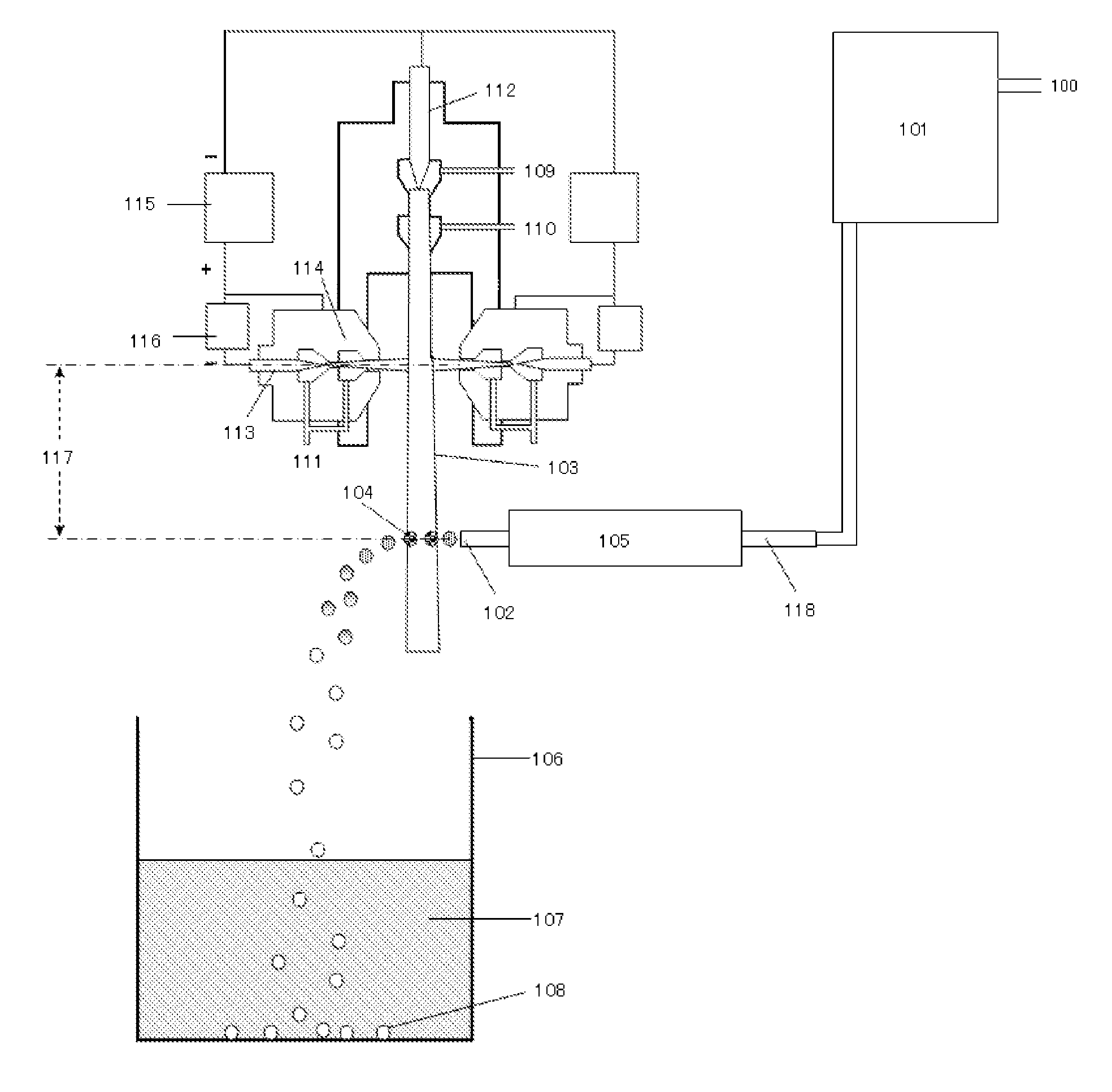

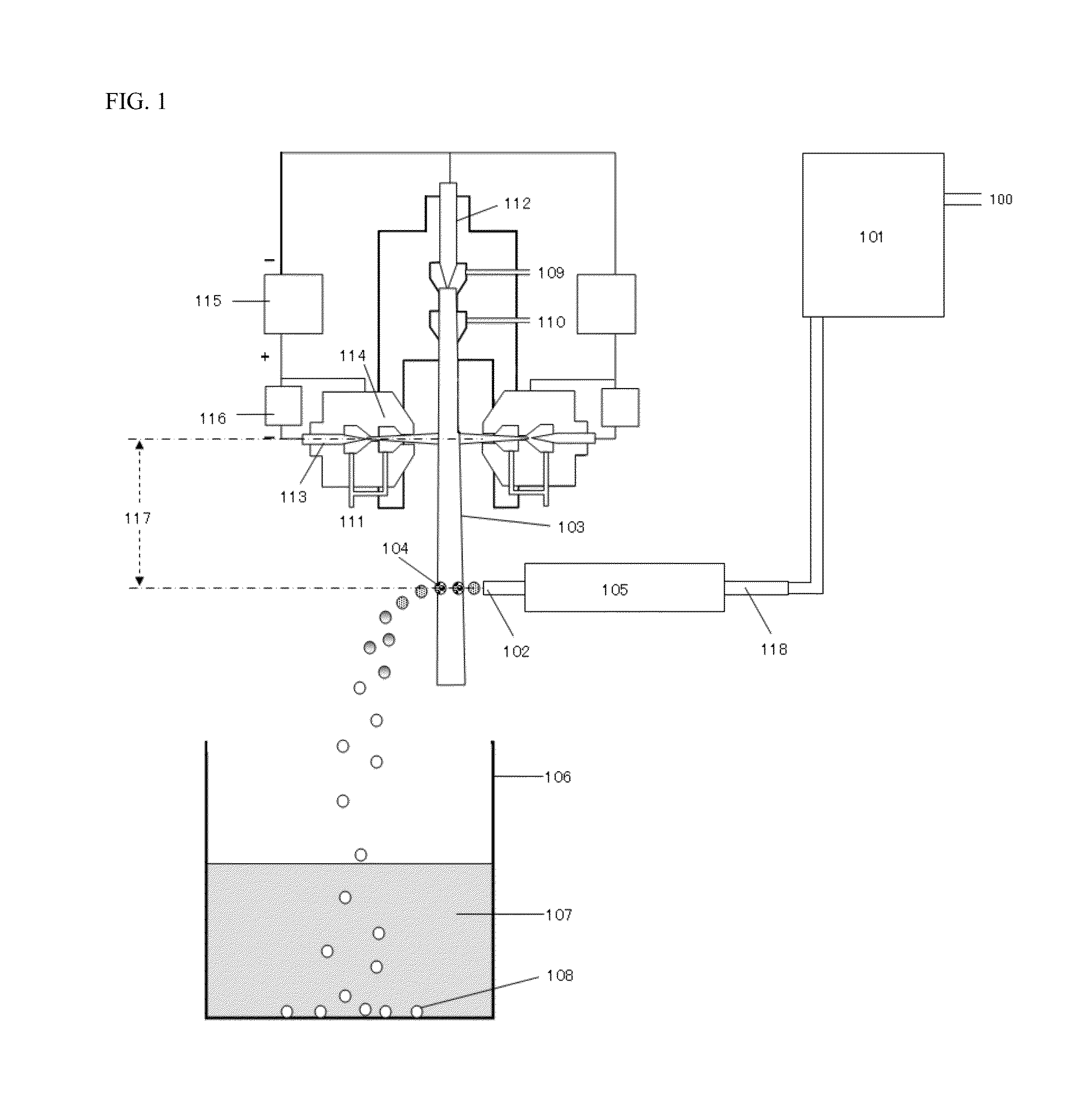

Ceramic beads with smooth surfaces and process for producing the same

ActiveUS20110244239A1Efficiently obtainedHigh yieldSynthetic resin layered productsCellulosic plastic layered productsMetallurgyHigh voltage

A subject for the invention is to provide a process for ceramic bead production in which ceramic beads with smooth surfaces are obtained by a simpler method without using a complicated process involving, for example, a DC plasma / radio-frequency plasma combination or a two-stage radio-frequency plasma. Another subject is to provide such ceramic beads. The invention relates to a technique in which a preheated raw ceramic material is introduced into a laminar-flow thermal plasma obtained using a high-voltage type direct-current (DC) plasma gun and is cooled and solidified and the resultant ceramic beads are collected. It is preferred that the raw ceramic material should be preheated by passing the raw material through a refractory tube which runs through a furnace, while sending the raw ceramic material with a carrier gas, and that the preheated raw-material powder should be introduced into and treated with the thermal plasma under such conditions that the resultant ceramic beads are discharged from the thermal plasma at a discharge angle of 60° or larger with the thermal plasma. Thus, satisfactory ceramic beads which have smooth surfaces and have few crack defects and few internal void defects are obtained.

Owner:TOSOH CORP

Lens pad, lens pad manufacturing method, lens manufacturing method, and adhesive member

ActiveUS8440041B2Reduction factorSatisfactory shapeEdge grinding machinesLamination ancillary operationsEngineeringLens plate

A lens pad includes a blank, first adhesive layer, and release sheet. The first adhesive layer is formed on one surface of the blank. The release sheet comes into tight contact with the surface of the first adhesive layer to protect this surface. The arithmetic average roughness of the surface of the release sheet on the side of the first adhesive layer is 0.1 μm or less. The surface of the first adhesive layer from which the release sheet is peeled off is attached onto a lens as an edging target. A lens pad, a lens pad manufacturing method, a lens manufacturing method, and an adhesive member are also disclosed.

Owner:HOYA CORP +1

Light amount adjusting device and optical device

ActiveUS10884316B2Reduce device sizeSatisfactory shapeCamera diaphragmsEngineeringMechanical engineering

Owner:CANON DENSHI KK

Ceramic beads with smooth surfaces and process for producing the same

ActiveUS8637154B2Less apt to burstEfficiently obtainedSynthetic resin layered productsCellulosic plastic layered productsMetallurgySubject matter

A subject for the invention is to provide a process for ceramic bead production in which ceramic beads with smooth surfaces are obtained by a simpler method without using a complicated process involving, for example, a DC plasma / radio-frequency plasma combination or a two-stage radio-frequency plasma. Another subject is to provide such ceramic beads. The invention relates to a technique in which a preheated raw ceramic material is introduced into a laminar-flow thermal plasma obtained using a high-voltage type direct-current (DC) plasma gun and is cooled and solidified and the resultant ceramic beads are collected. It is preferred that the raw ceramic material should be preheated by passing the raw material through a refractory tube which runs through a furnace, while sending the raw ceramic material with a carrier gas, and that the preheated raw-material powder should be introduced into and treated with the thermal plasma under such conditions that the resultant ceramic beads are discharged from the thermal plasma at a discharge angle of 60° or larger with the thermal plasma. Thus, satisfactory ceramic beads which have smooth surfaces and have few crack defects and few internal void defects are obtained.

Owner:TOSOH CORP

Optical element and optical pickup

InactiveUS20030174415A1Reduce comaSatisfactory shapeRecord information storageOptical beam guiding meansOptical pickupOptical axis

An optical element (21) comprises a lens base plate (11) in which a lens (12) made of a material having a high refractive index is embedded into a transparent base plate to pass incident light and an aberration correction base plate (13) formed of a transparent parallel flat plate-like base plate to pass light and correcting a comatic aberration produced on the lens (12) wherein the lens base plate (11) and the aberration correction base plate (13) are integrated in such a manner that the lens base plate (11) and the aberration correction base plate (13) are located in parallel to each other and that the aberration correction base plate (13) is located on the side of a point at which incident light is focused by the lens (12). An optical pickup comprises at least a light source, the lens (12) for focusing and irradiating light from the light source on a recording medium and the optical pickup element (21). The optical element can reduce the diameter of the lens, can increase the radius of curvature of the lens and can correct a comatic aberration produced when an optical axis of incident light is inclined relative to the lens, and the optical pickup may use this optical element.

Owner:SONY CORP

Three-dimensional shape processing method

ActiveUS11433606B2Satisfactory shapeImprove productivityAdditive manufacturing apparatusManufacturing auxillary operationsTarget surfaceThree dimensional shape

A three-dimensional shape processing method processes a workpiece into a predetermined three-dimensional shape by cutting work and additive manufacturing. The method includes forming a target surface for the additive manufacturing to be larger than a shape dimension of the three-dimensional shape, performing the additive manufacturing on the target surface that has been largely formed, and performing the cutting work on a region where the additive manufacturing has been performed to complete the three-dimensional shape.

Owner:OKUMA CORP

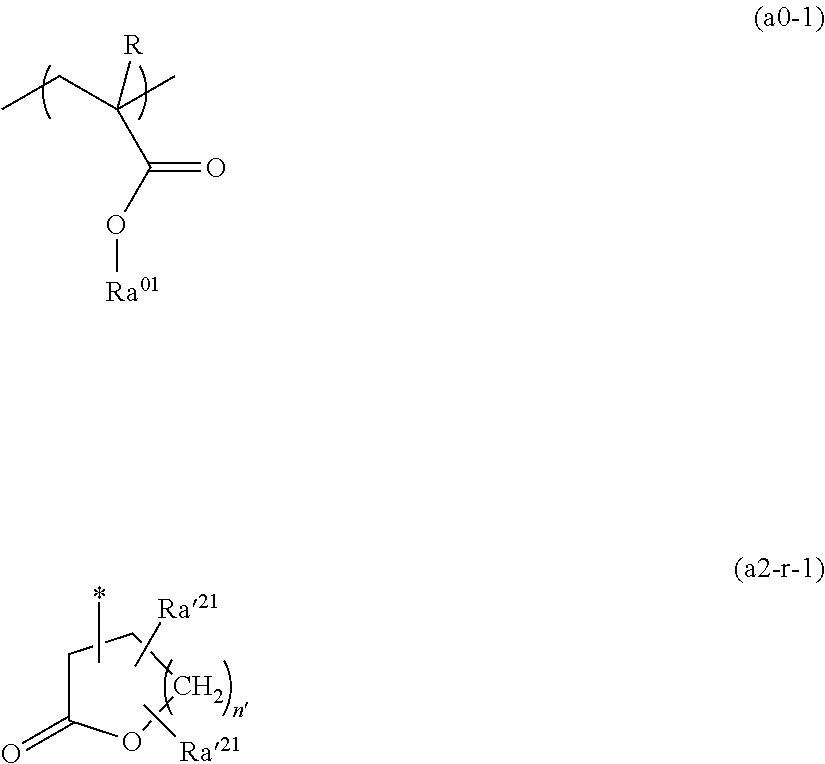

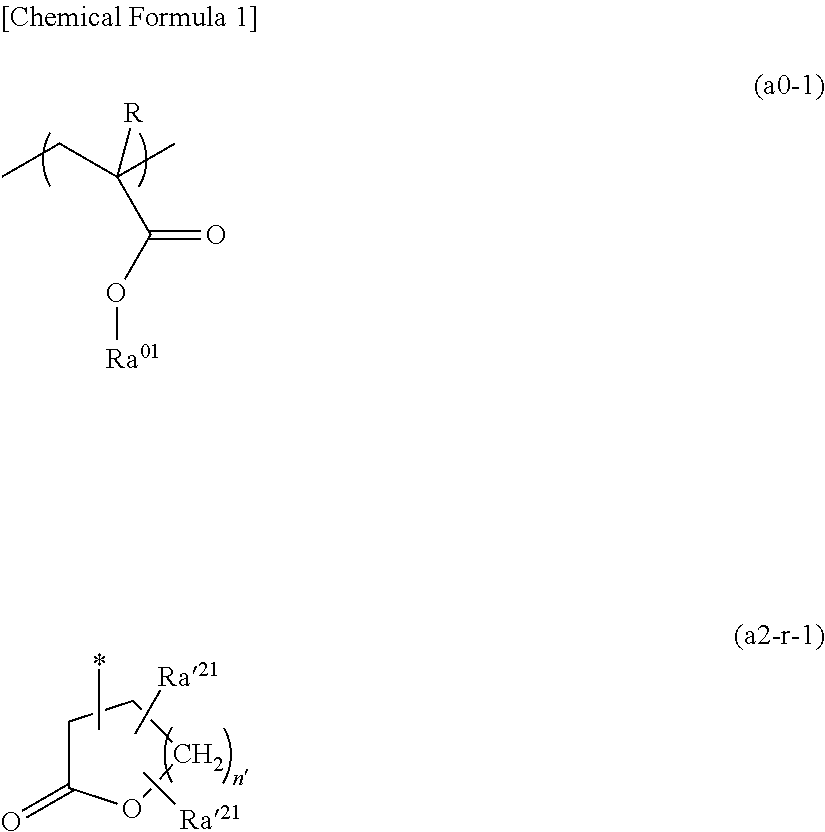

Resist pattern formation method and resist composition

ActiveUS20140093827A1Satisfactory shapePhotosensitive material processingOriginals for photomechanical treatmentResistHydrogen atom

A resist pattern formation method including formation of a resist film, exposure, development, and subsequent rinsing using a resist composition containing a high-molecular compound having a constituent unit represented by the formula (a0-1), a constituent unit containing an acid decomposable group whose polarity increases by the action of an acid, and a constituent unit containing a group represented by the formula (a2-r-1). R represents a hydrogen atom, an alkyl group, or a halogenated alkyl group; Ra01 represents a lactone-containing polycyclic group, an —SO2-containing polycyclic group, or a cyano group-containing polycyclic group; Ra′21 represents a hydrogen atom, an alkyl group, an alkoxy group, a halogen atom, a halogenated alkyl group, a hydroxyl group, —COOR″, —OC(═O)R″, a hydroxyalkyl group, or a cyano group; R″ represents a hydrogen atom or an alkyl group; and n′ represents an integer of from 0 to 2.

Owner:TOKYO OHKA KOGYO CO LTD

Resin-encapsulated semiconductor device and method of manufacturing the same

ActiveUS9275972B2High strengthImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesThin metalEngineering

A resin-encapsulated semiconductor device includes a semiconductor element mounted on a die pad portion, a plurality of lead portions arranged so that leading end portions thereof are opposed to the die pad portion, and thin metal wires connecting electrodes of the semiconductor element to the lead portions. An encapsulation resin encapsulates the die pad portion, semiconductor element and lead portions in such a manner that a bottom surface part of the die pad portion and a lead bottom surface part, lead outer surface part, and lead upper end part of the lead portions are exposed from the encapsulation resin. A plating layer is formed on the lead bottom surface parts and the lead upper end parts. The encapsulation resin has cutouts on a side surface thereof vertically above the portions of the lead upper end parts on which the plating layer is formed.

Owner:ABLIC INC

Device for fixing a cable in a pipe

InactiveUS6889712B2Satisfactory shapeCost-effective manufacturingInsulated cablesPipe elementsEngineeringElectric cables

For the purpose of repairing supply lines such as a waste-water pipe, a plastic hose has been developed which, in the clear state, has a diameter which is the same size as, or larger than, the diameter of the pipe in which it is to be inserted. This plastic hose is used to fix optical or electric cables against the inner wall of the pipe. For this purpose, the plastic hose is introduced into the waste-water pipe in a collapsed state, together with the cable, and is released when the desired positioning has been reached. The collapsed plastic hose will then regain its original shape and thereby fix the cable against the inner wall of the waste-water pipe.

Owner:ALCATEL LUCENT SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com