Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about "Liquid processing by liquid sprays" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

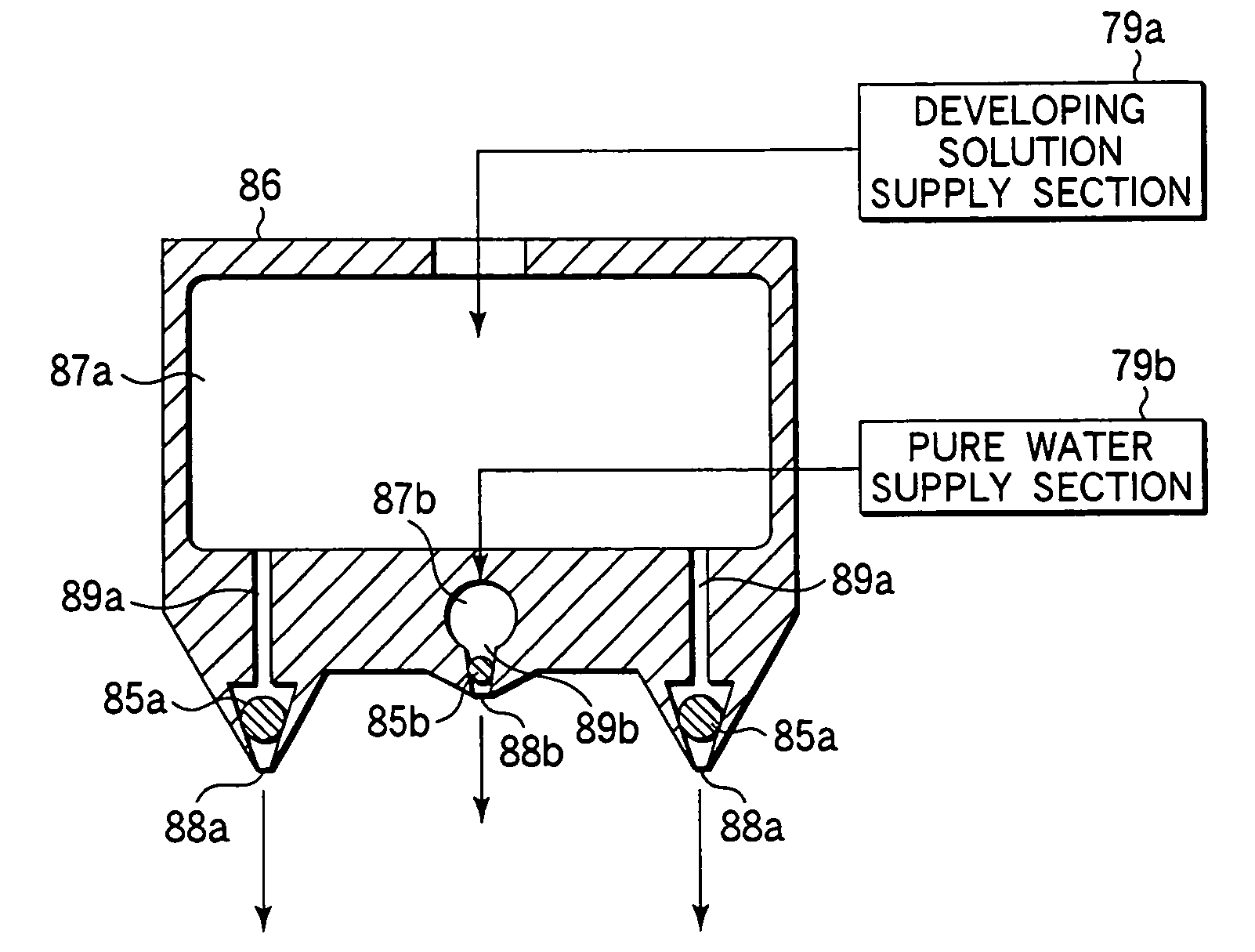

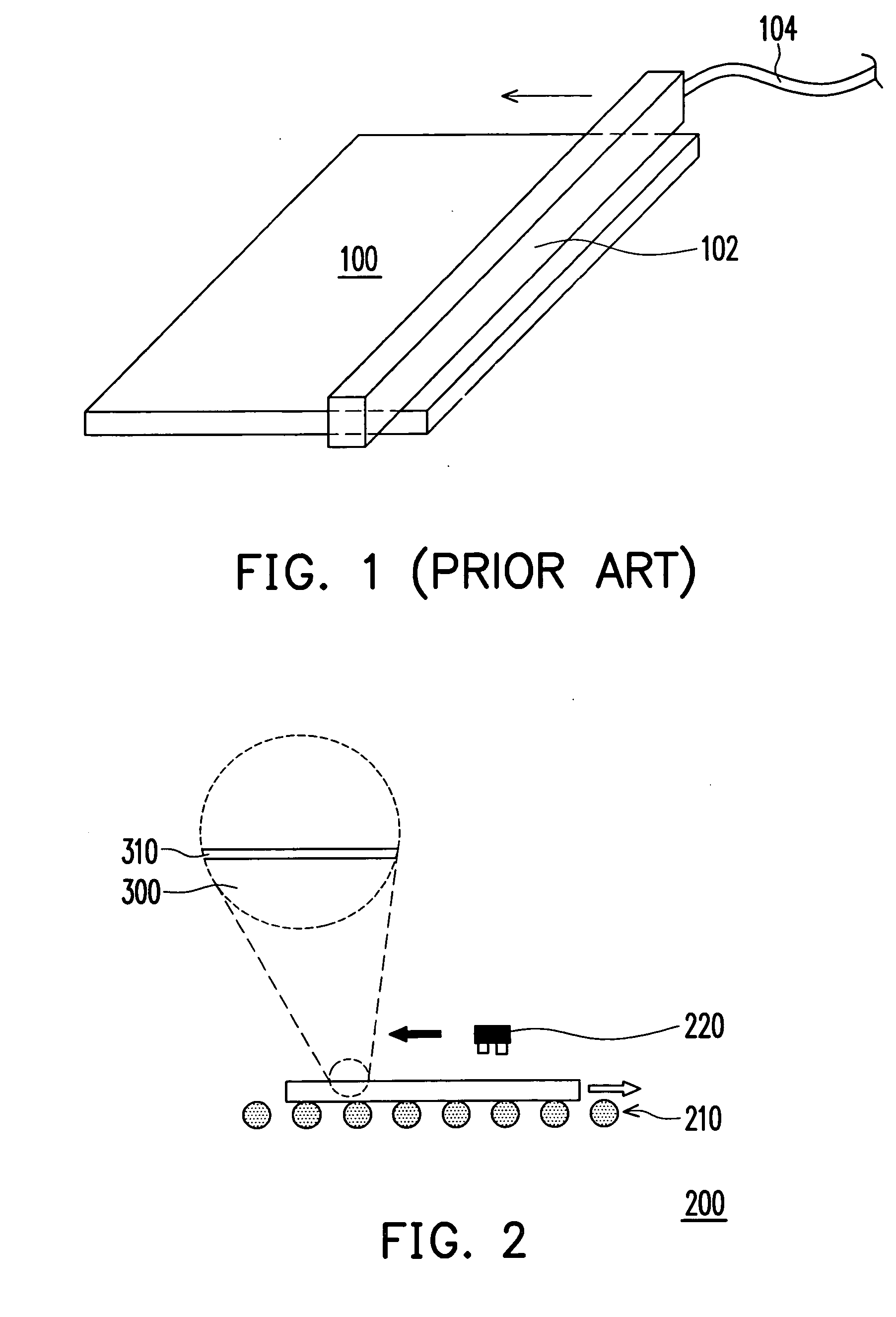

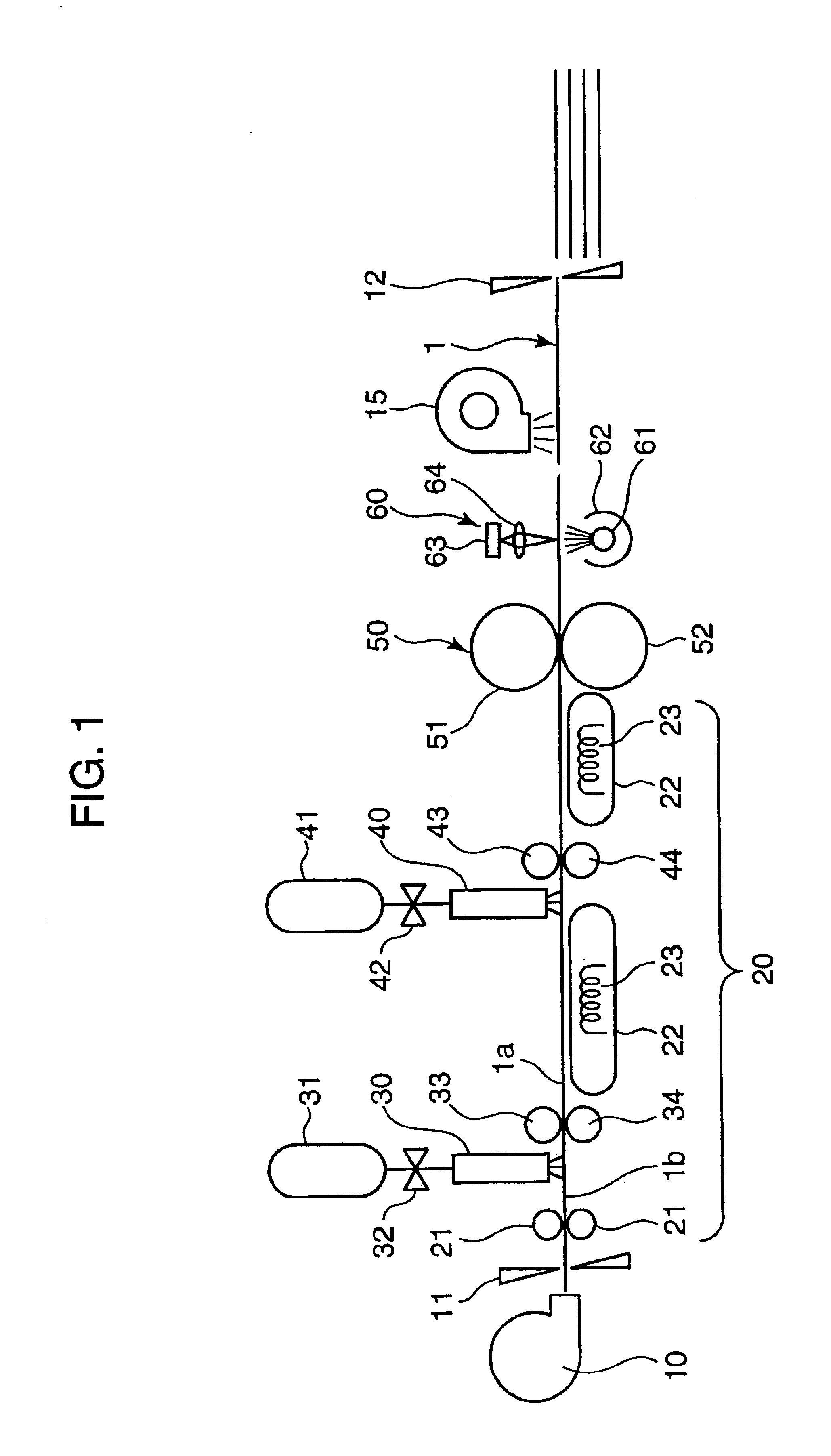

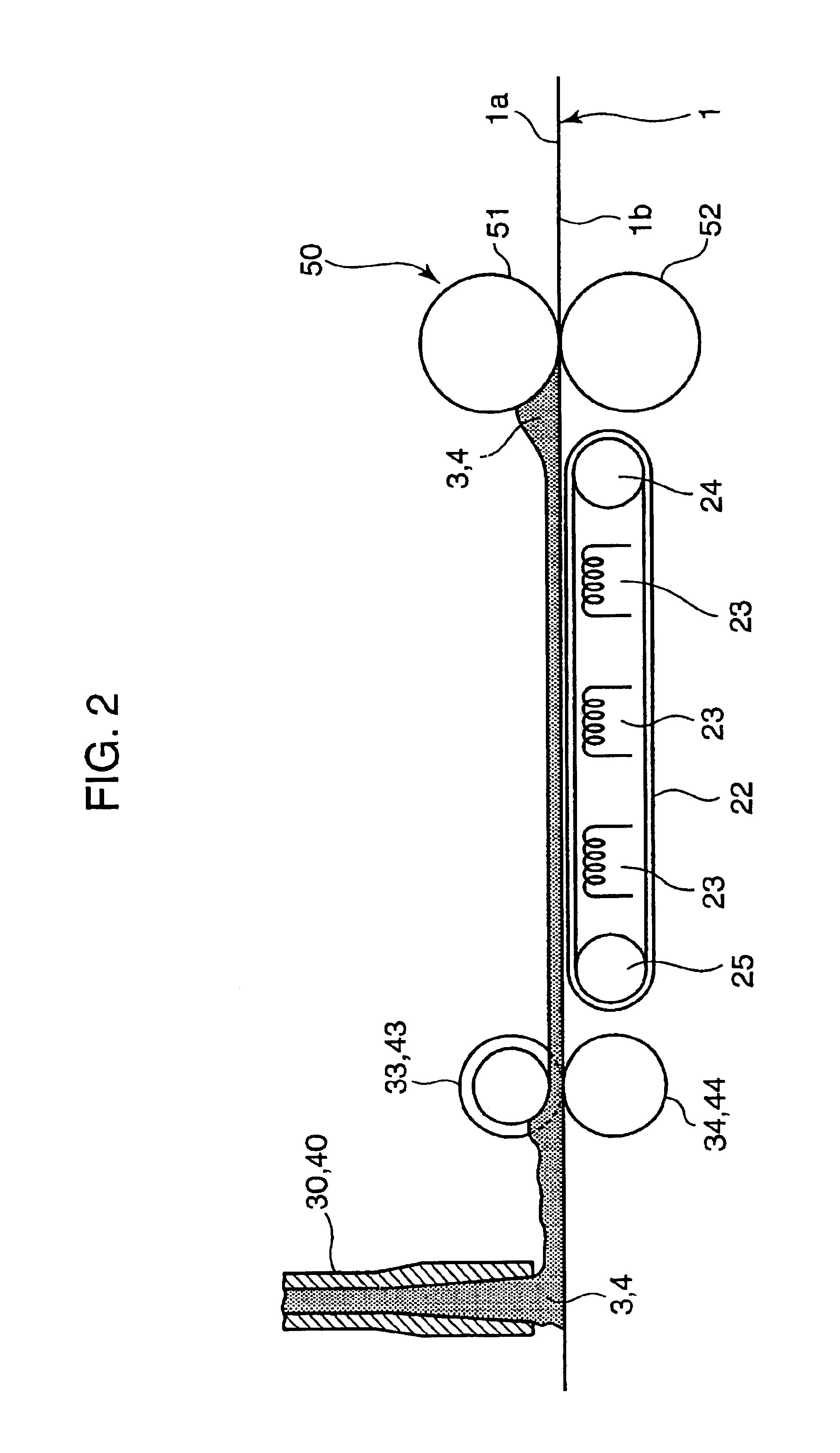

Developing process and developing unit

InactiveUS6419408B1Liquid processing by liquid spraysSemiconductor/solid-state device manufacturingResistChemistry

When a developing process is performed, a mixture of developing solution and pure water is supplied while the ratio of developing solution and pure water is gradually increased from pure water to developing solution. Thus, a developing solution component and a resist component gradually react. Even if a resist component dissolves in the mixture of pure water and developing solution, the equality of the concentration of the developing solution can be maintained. Thus, the developing process can be suppressed from being unequally performed. When a rinsing process is performed, a mixture of developing solution and pure water is supplied while the ratio of developing solution against pure water is gradually decreased from developing solution to pure water. Consequently, the substitution from developing solution to pure water can be gradually performed. As a result, particles due to the solidification of unsolved resist can be prevented.

Owner:TOKYO ELECTRON LTD

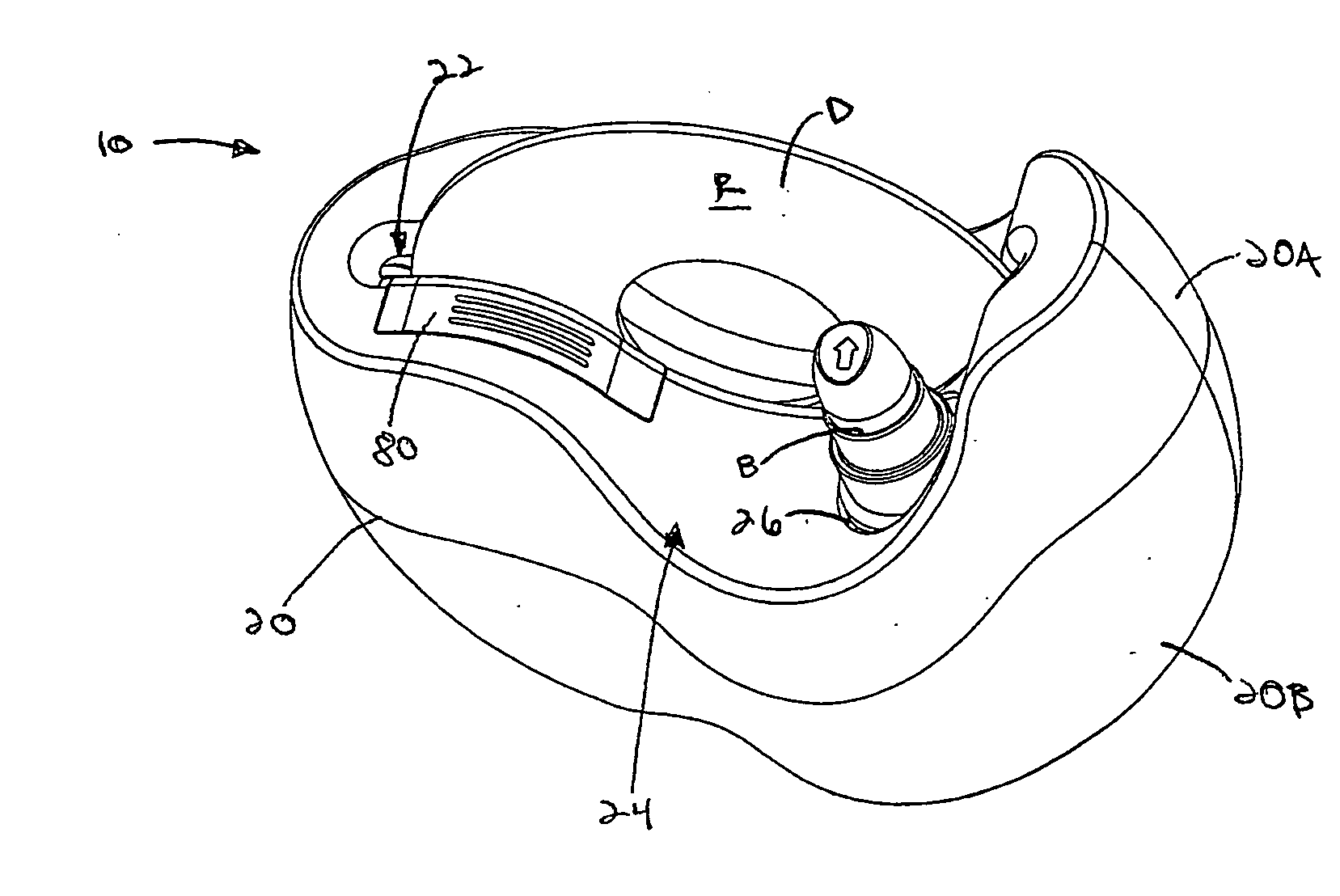

Disc Cleaner

InactiveUS20070245505A1Easy to carryLiquid processing by liquid spraysCarpet cleanersEngineeringCleansing Agents

A disc cleaner (10) for cleaning discs (D), which in some aspects can clean vertically oriented discs. The disc cleaner may include a housing (20) for supporting a disc, a drive assembly supported by the housing and engageable with the disc to rotate the disc, and means for applying cleaning agent (B) to a data recording surface of the disc (R) while the disc is supported by the housing. The disc cleaner may include housing that facilitates handling of the disc by its central hole, a drive assembly disposed within the housing, the drive assembly frictionally rotating the disc by its perimeter, and a switch (75) for actuating the drive assembly when the disc is at least partially inserted in the housing.

Owner:DIGITAL INNOVATIONS

Substrate processing method and substrate processing apparatus

InactiveUS20080008973A1Prevent crashLiquid processing by liquid spraysPhotoprinting processesResistEngineering

The invention provides a method capable of preventing the occurrence of collapse of resist pattern accompanied by size reduction in pattern dimensions can be prevented when processing a resist film having been exposed and formed on the surface of a substrate, and in which there is no fear that posterior processes are adversely affected. In the step of processing a resist film having been exposed and formed on the surface of a substrate, a developer mixed with a hydrophobizing agent is fed onto the resist film on the substrate surface; or before rinsing the resist film having been processed, a solvent containing a hydrophobic resin is fed onto the resist film on the substrate surface. Thus, a resist exposed surface is made to be hydrophobic before the rinsing, and thereafter rinsed and dried by spinning.

Owner:DAINIPPON SCREEN MTG CO LTD

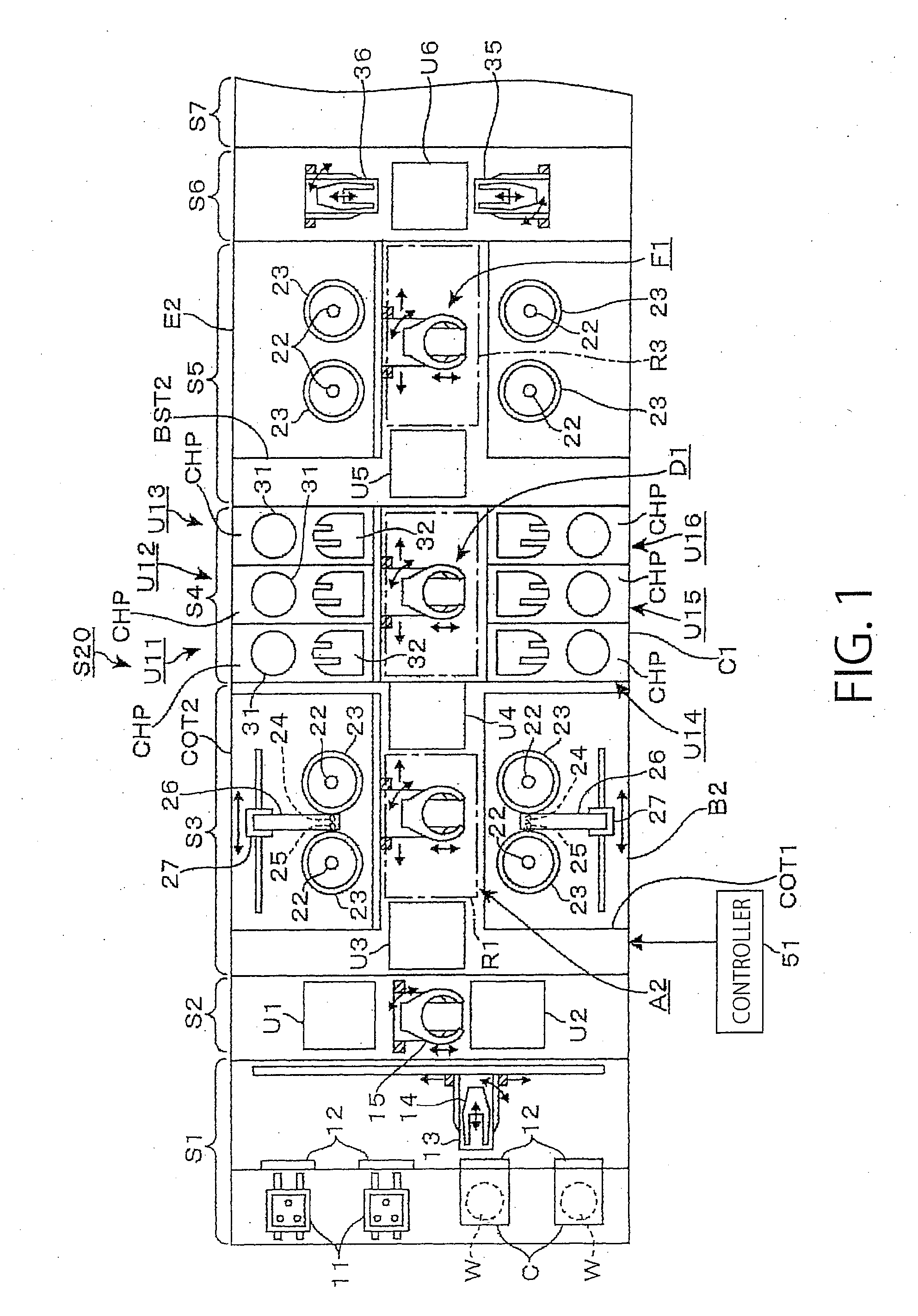

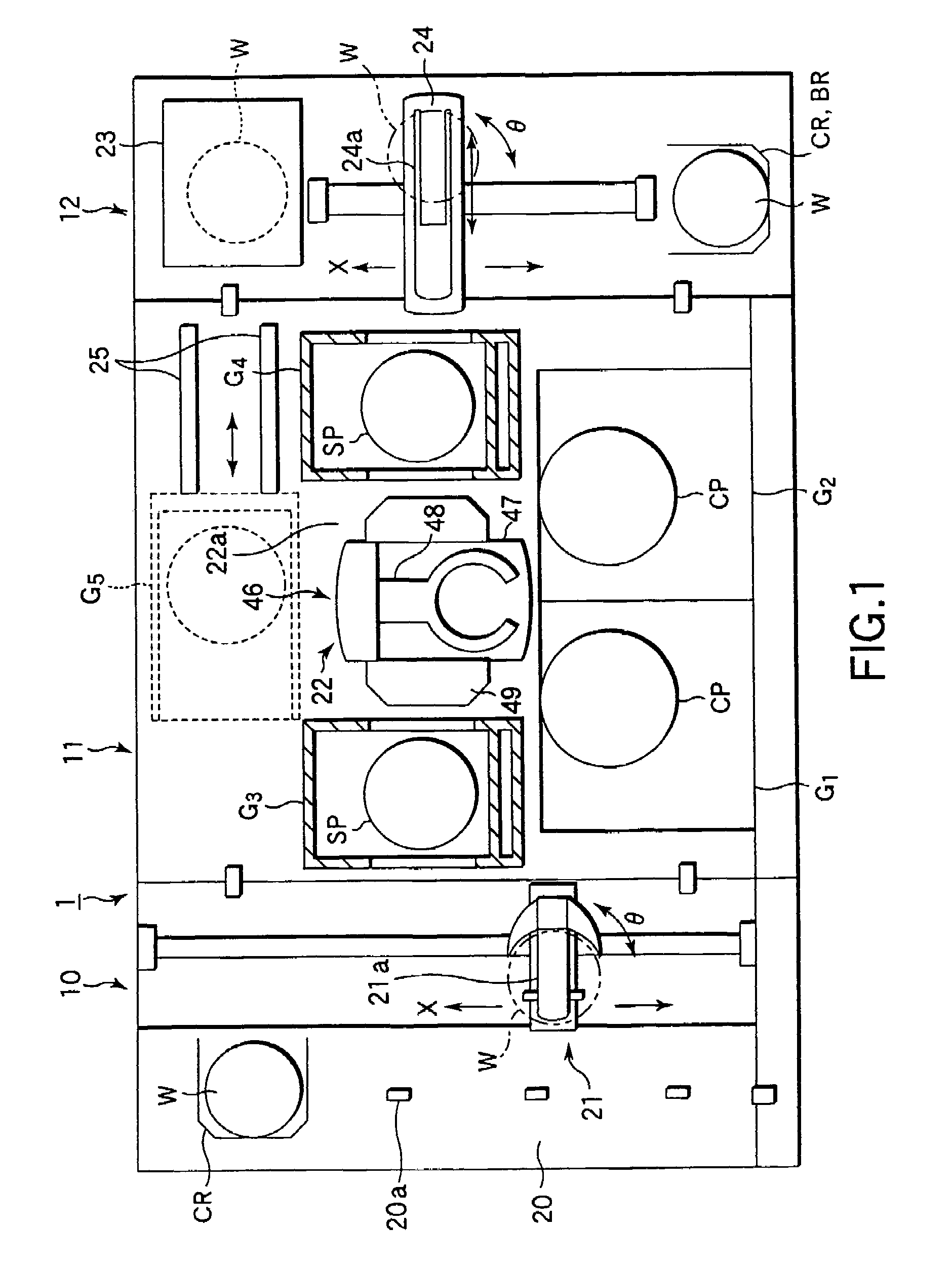

Coating and developing apparatus and method, and storage medium

ActiveUS20120057861A1Reduce throughputReduced installation areaLiquid processing by liquid spraysLiquid surface applicatorsEngineeringThermal treatment

In one embodiment, a coating and developing apparatus is provided with a processing block including a liquid processing block disposed on the carrier block side and a heating processing block disposed on the interface block side. The liquid processing block includes a first unit block, a second unit block, and one or more of developing unit blocks overlying or underlying a stack of the first unit block and the second unit block. The first unit block includes antireflection film-forming modules and resist film-forming modules disposed on both sides of the transport passage thereof. The second unit block includes upper film-forming modules and hardening modules disposed on both sides of the transport passage thereof.

Owner:TOKYO ELECTRON LTD

Coating/developing device and method

ActiveUS8408158B2Suppressing deterioration of throughputSave spaceLiquid processing by liquid spraysPhotomechanical apparatusResistEngineering

A coating / developing device includes a processing block having a plurality of coating unit blocks stacked and a developing unit block stacked on the coating unit blocks. Each of the unit blocks is provided with a liquid processing unit for coating a liquid chemical on a substrate, a heating unit for heating the substrate, a cooling unit for cooling the substrate and a transfer unit for transferring the substrate between the units. The liquid processing unit is provided with a coating unit for coating a resist liquid on the substrate, a first bottom antireflection coating (BARC) forming unit for coating a liquid chemical for a BARC on the substrate before the resist liquid is coated thereon, and a second BARC forming unit for coating a liquid chemical for the BARC on the substrate after the resist liquid is coated thereon.

Owner:TOKYO ELECTRON LTD

Substrate transfer apparatus

InactiveUS7632028B2Improve liquid saving efficiency of a processing solutionSmooth transferLiquid processing by liquid spraysSemiconductor/solid-state device manufacturingTransfer functionEngineering

Owner:DMS CO LTD

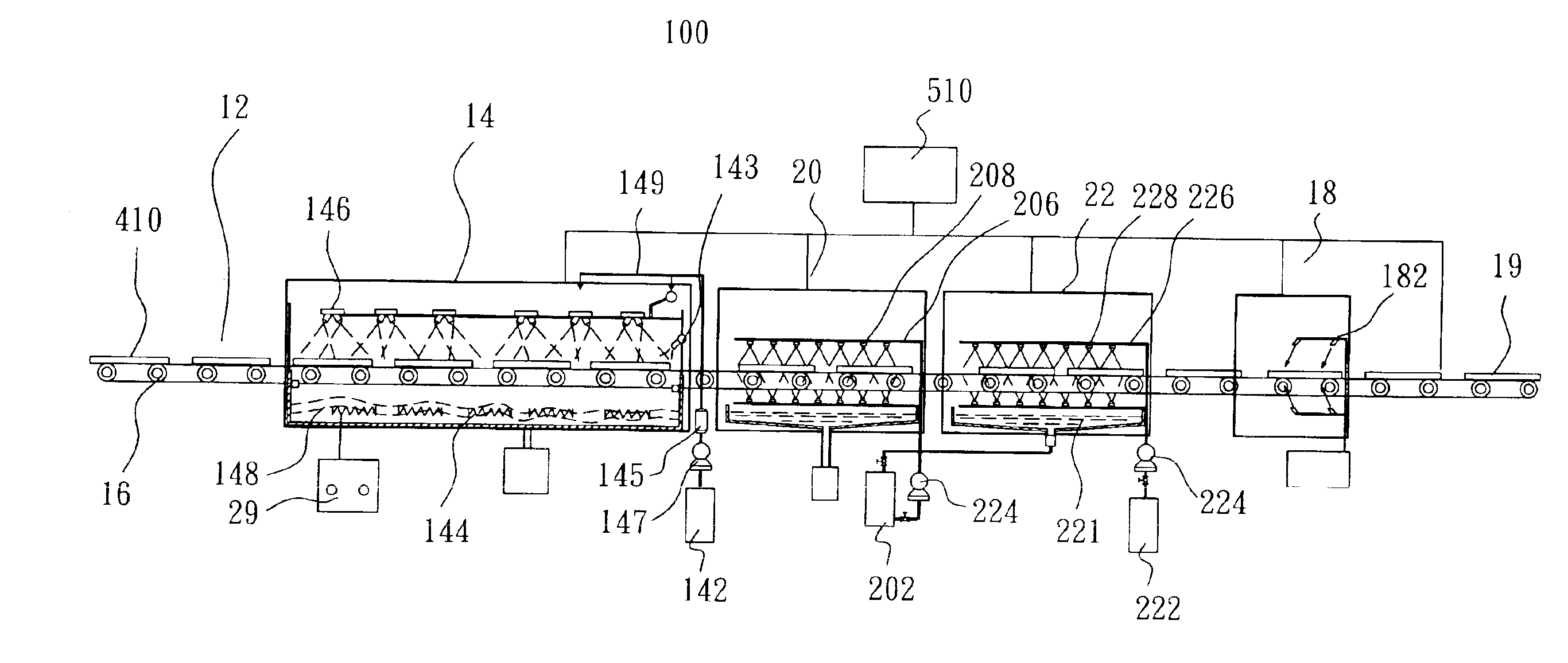

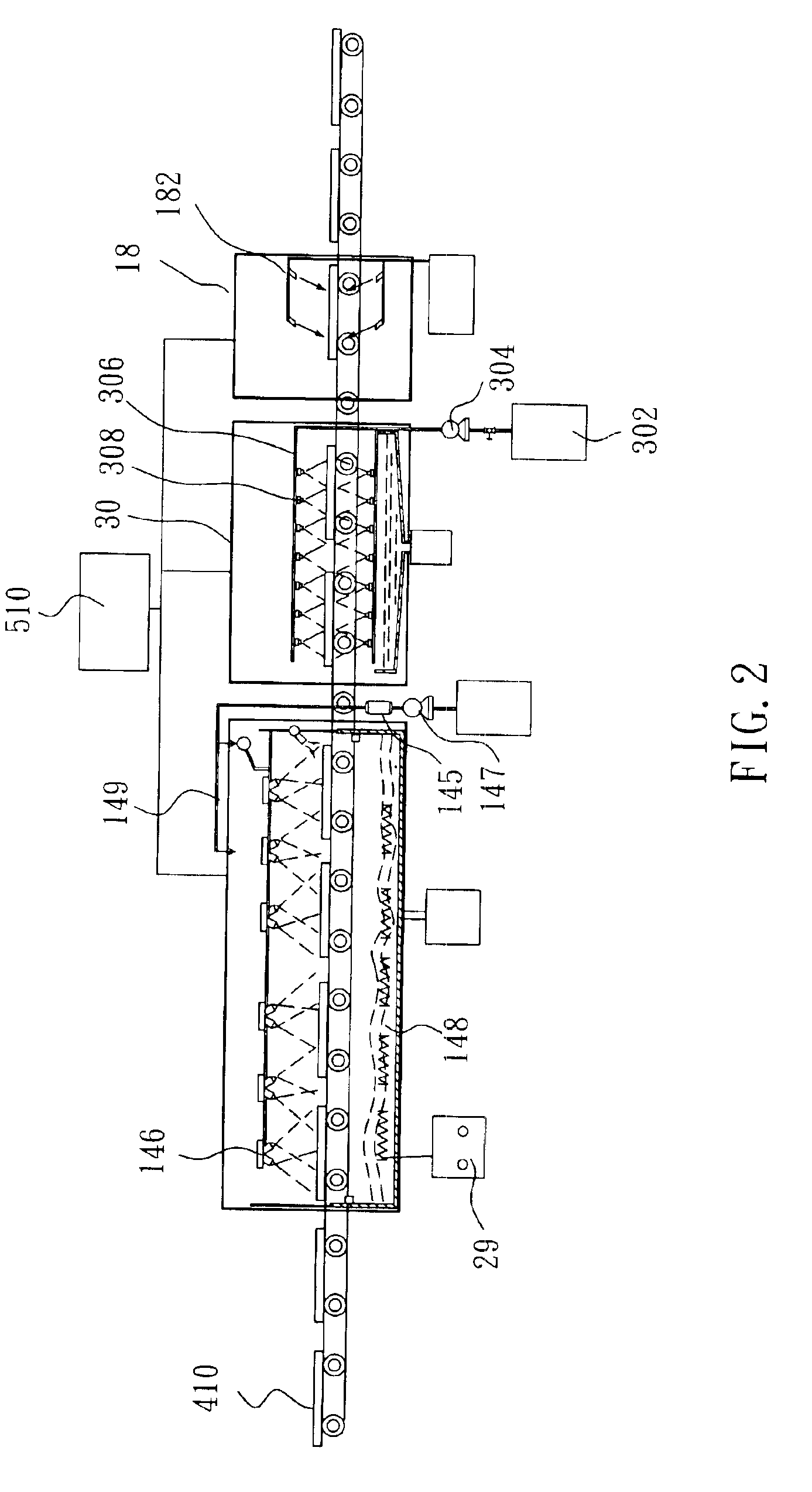

Developing apparatus and method for developing organic electroluminescent display panels

InactiveUS6857795B2Simple and compact structureEasy maintenanceLiquid processing by liquid spraysSolid-state devicesEngineeringOrganic electroluminescence

A developing apparatus for organic electroluminescent display panels comprises a developing unit for supplying a developing solution to be uniformly dispensed to the surface of an organic electroluminescent display panel by immersing the organic electroluminescent display panel into the developing solution or spreading the developing solution over the organic electroluminescent display panel, a cleaning unit having at least a bath connected to the end of the developing unit for spraying a recycled cleaning liquid or cleaning liquid over the organic electroluminescent display panel, a drying unit having at least an airflow driers, and a transporting unit for transporting the electroluminescent display panel; wherein the organic electroluminescent display panel is transported at a constant speed by the transporting unit of the developing apparatus.

Owner:RITDISPLAY

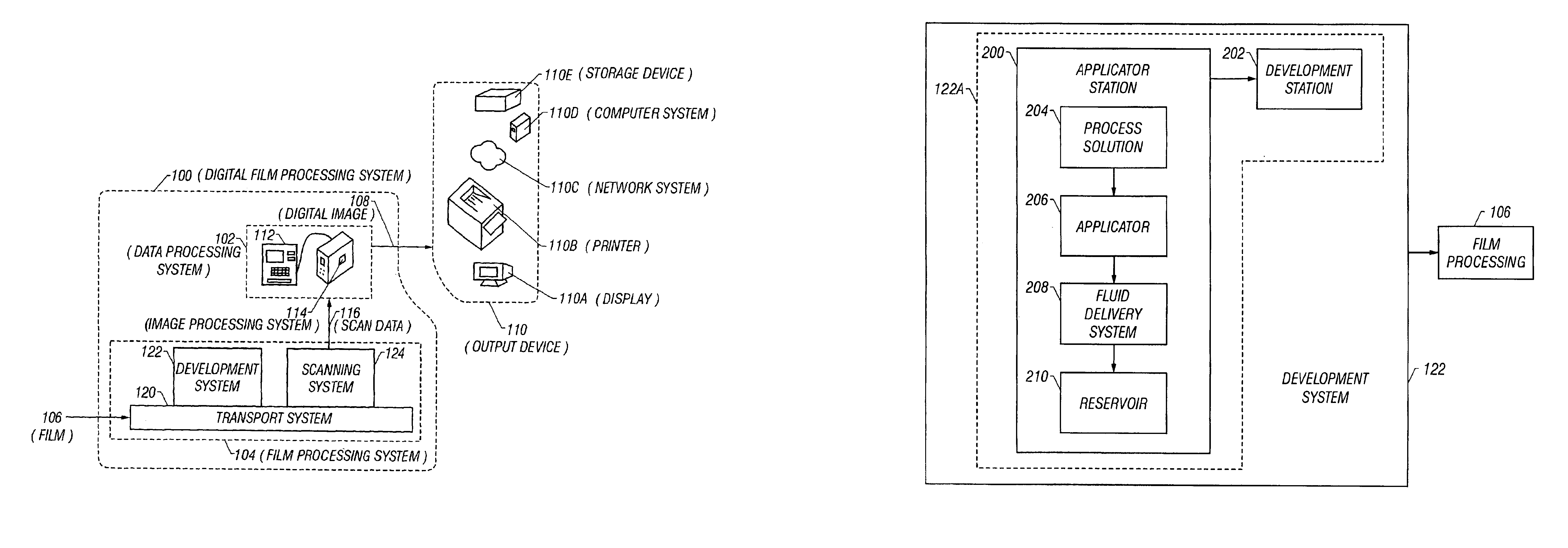

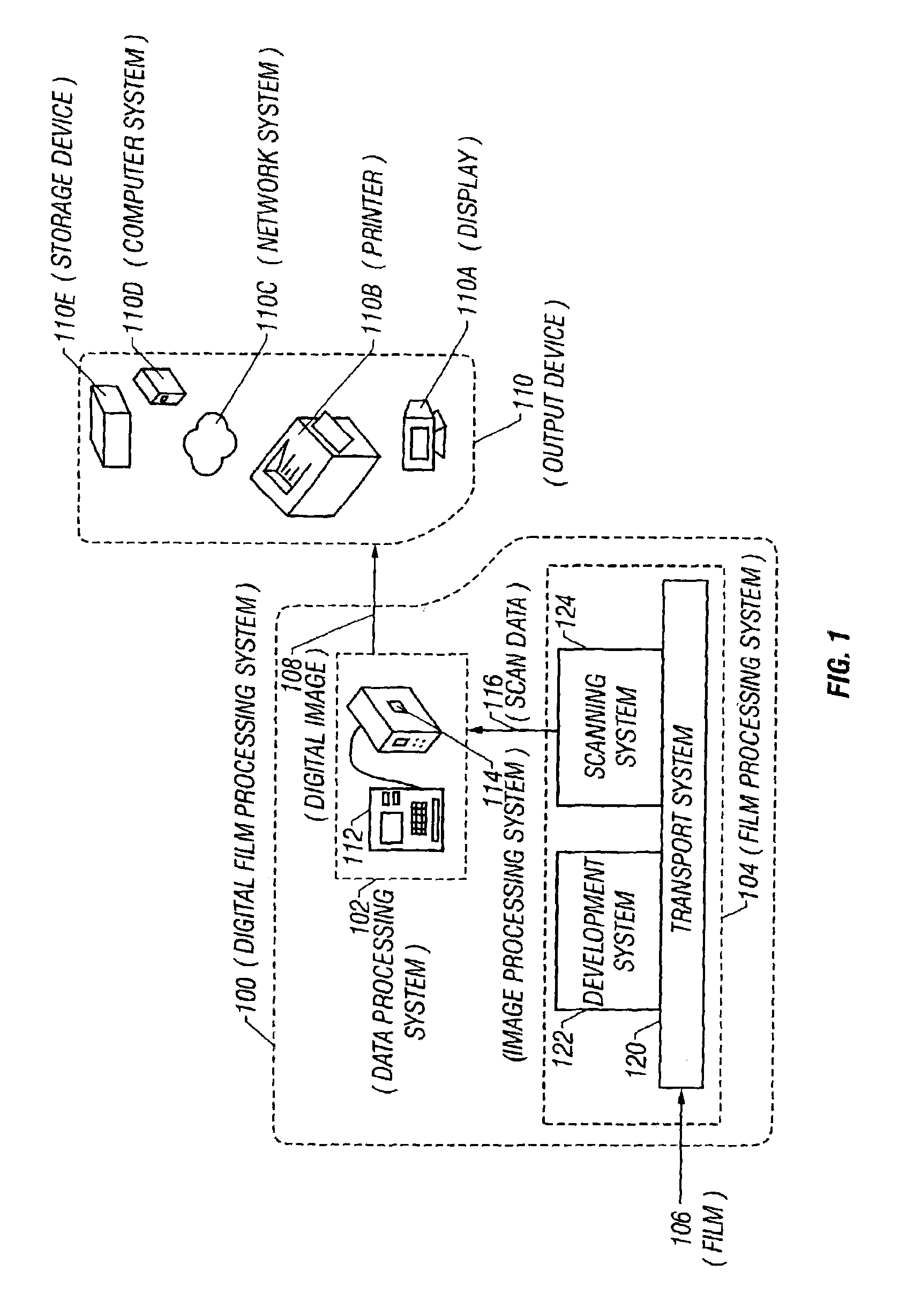

Film processing solution cartridge and method for developing and digitizing film

InactiveUS6913404B2Quickly and conveniently replacedReduce equipmentLiquid processing by liquid spraysLiquid processing circulationSheet filmEngineering

A digital film processing system and film processing solution cartridge are disclosed. The cartridge comprises a housing and a chamber for storing a film processing fluid. The processing solution may be contained within a flexible bladder within the chamber. The cartridge may also include an integral applicator for coating the processing solution onto undeveloped film. The cartridge is generally removeably attached to the film processing system, but may also be refillable.

Owner:EASTMAN KODAK CO

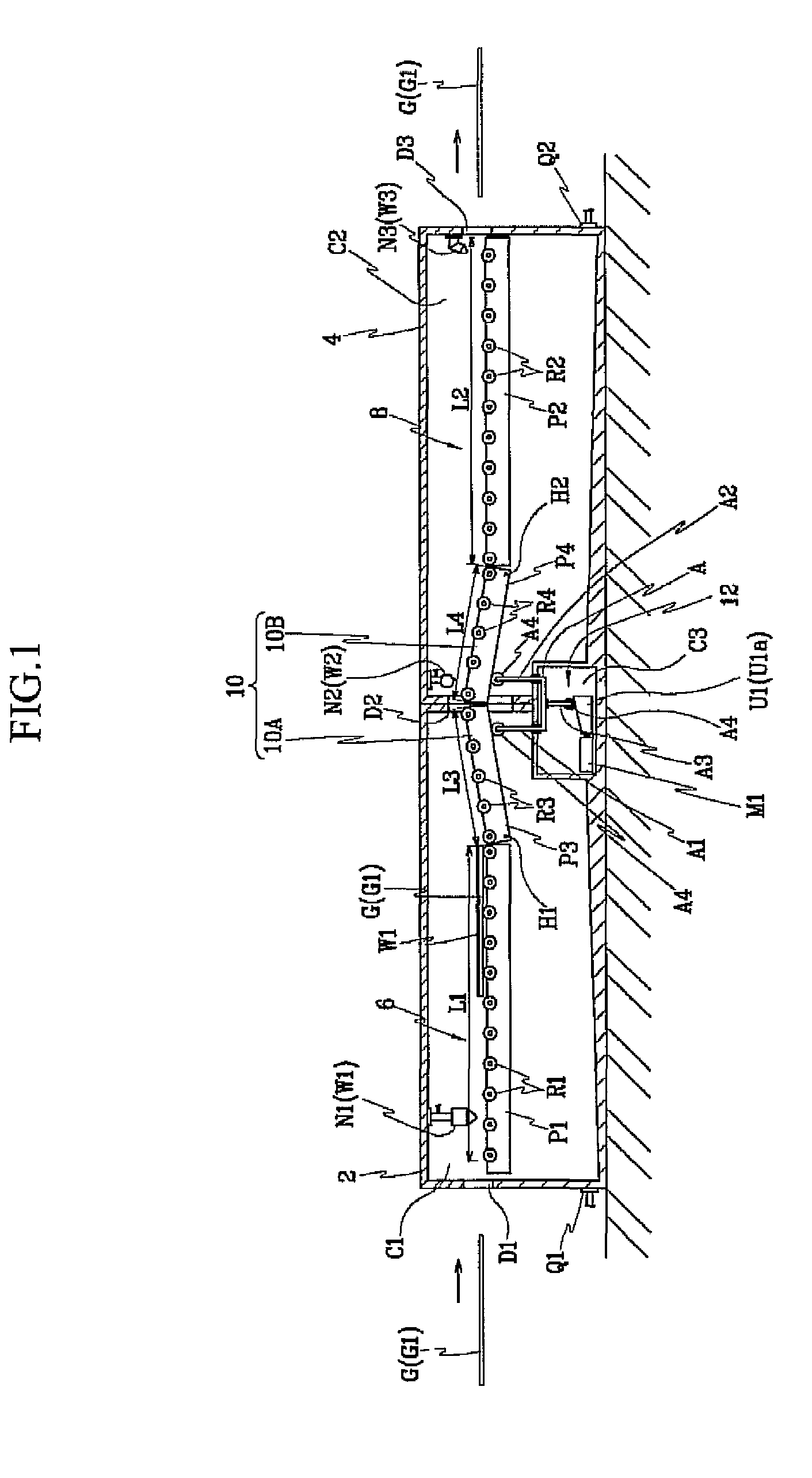

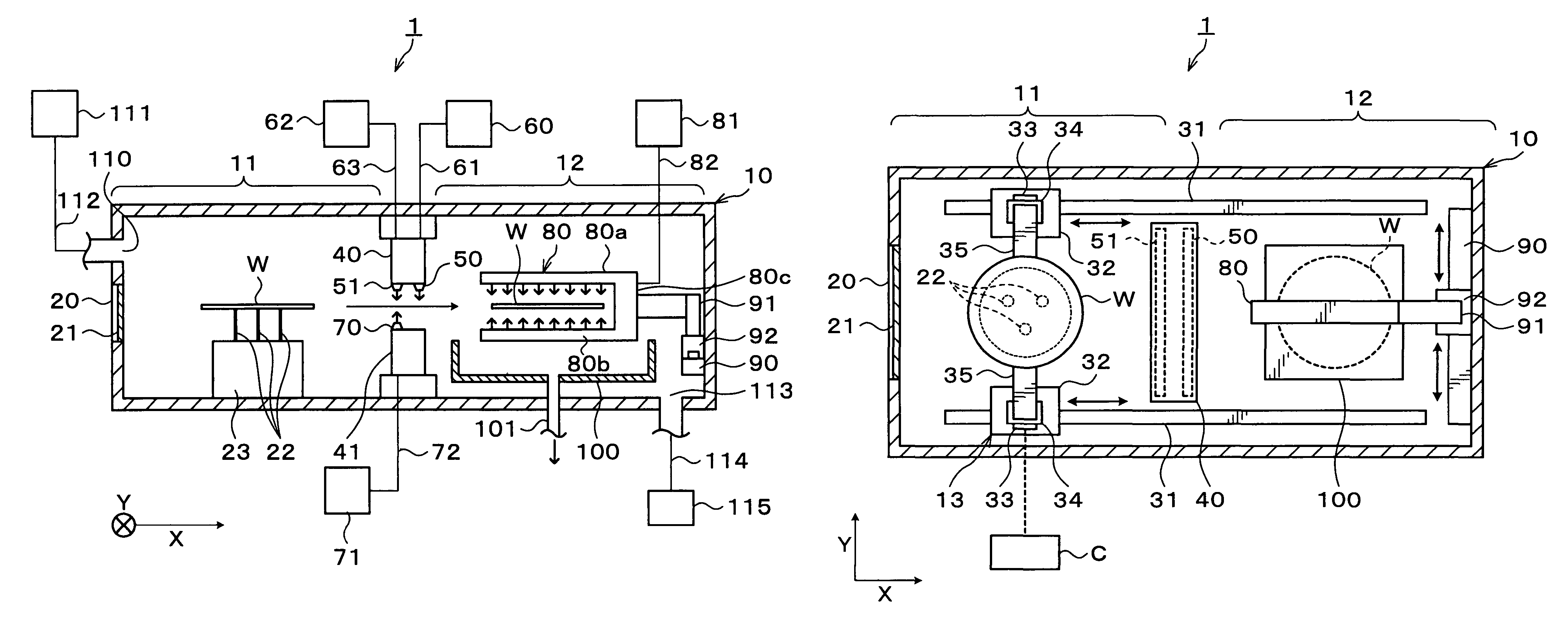

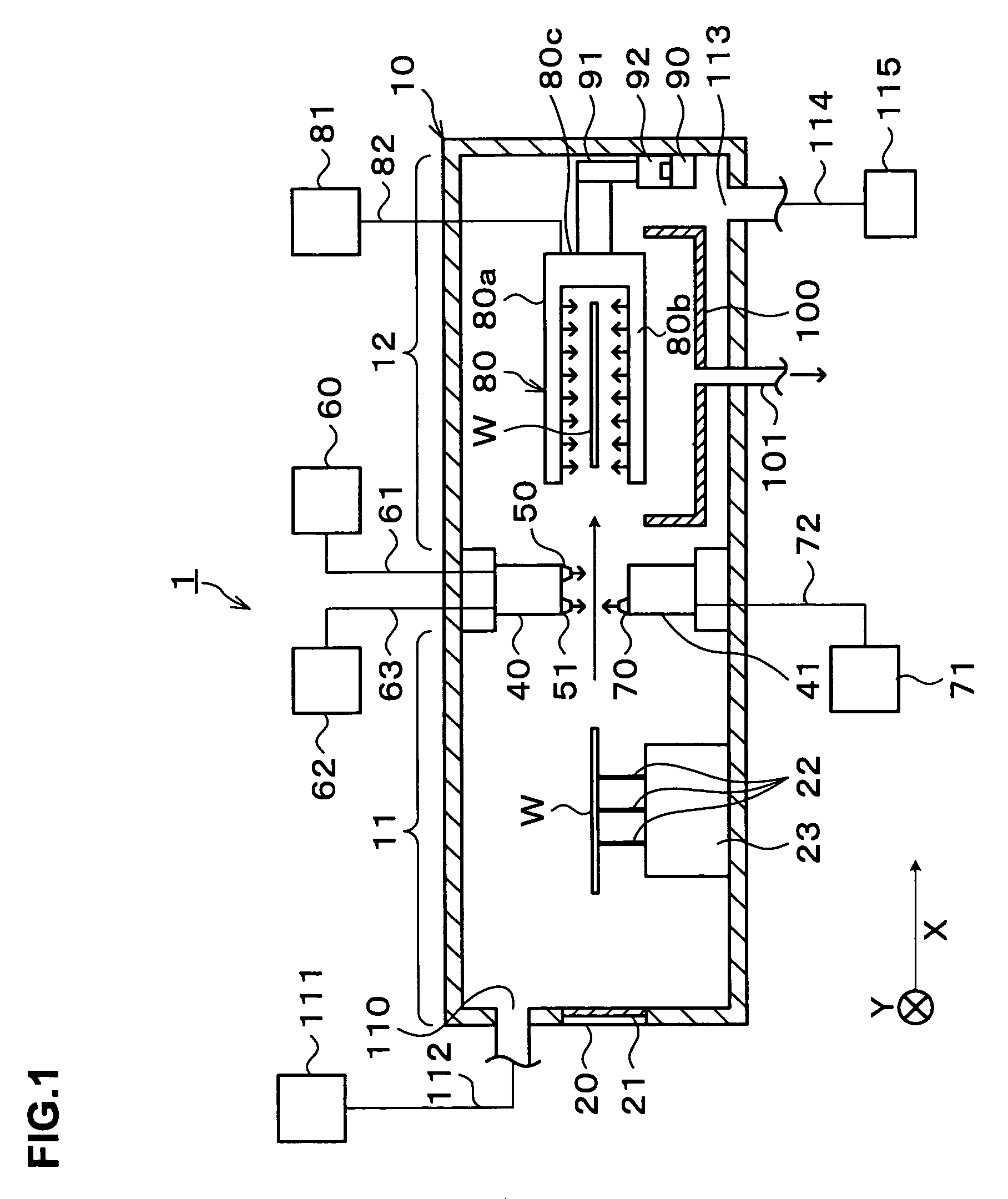

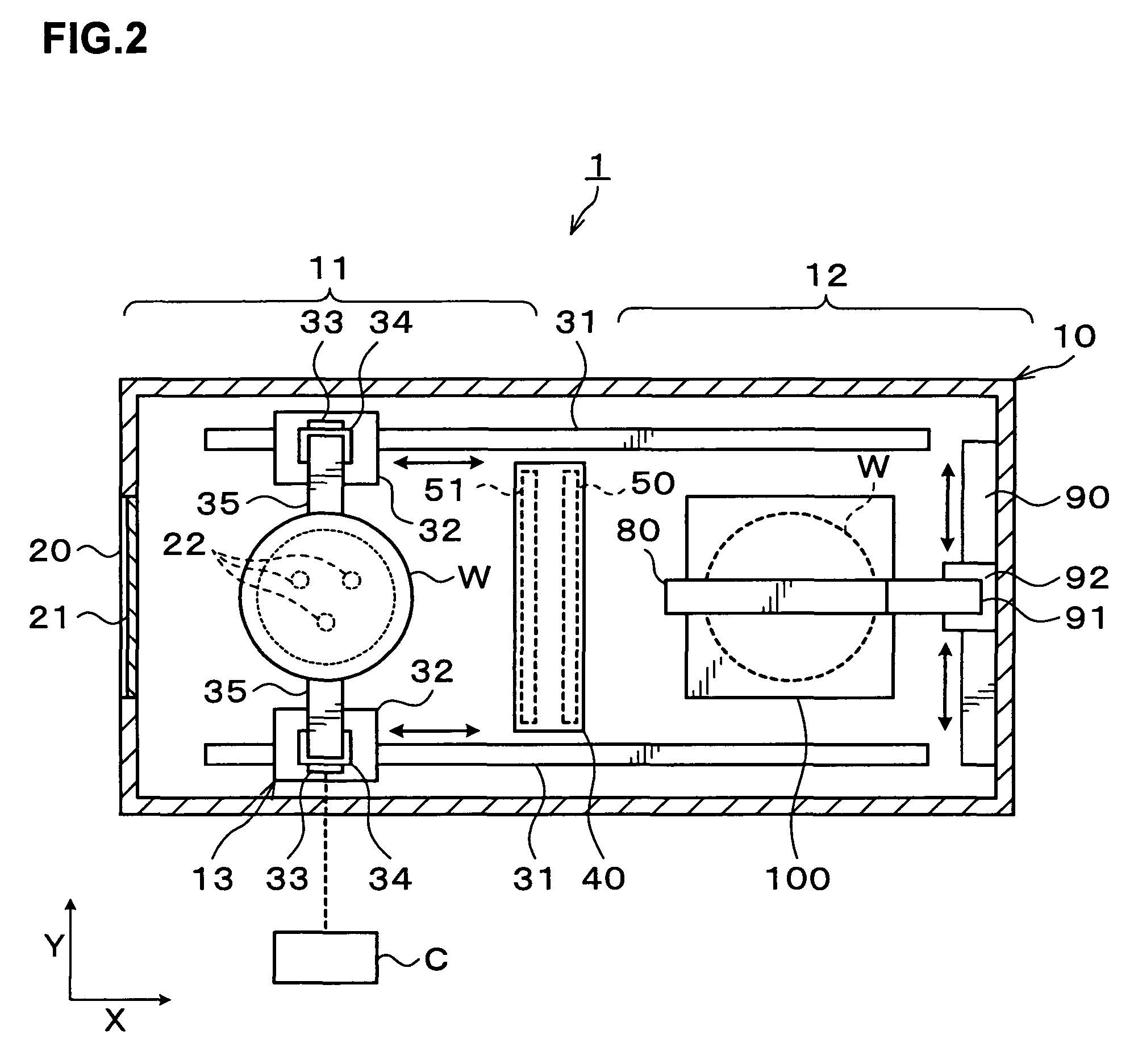

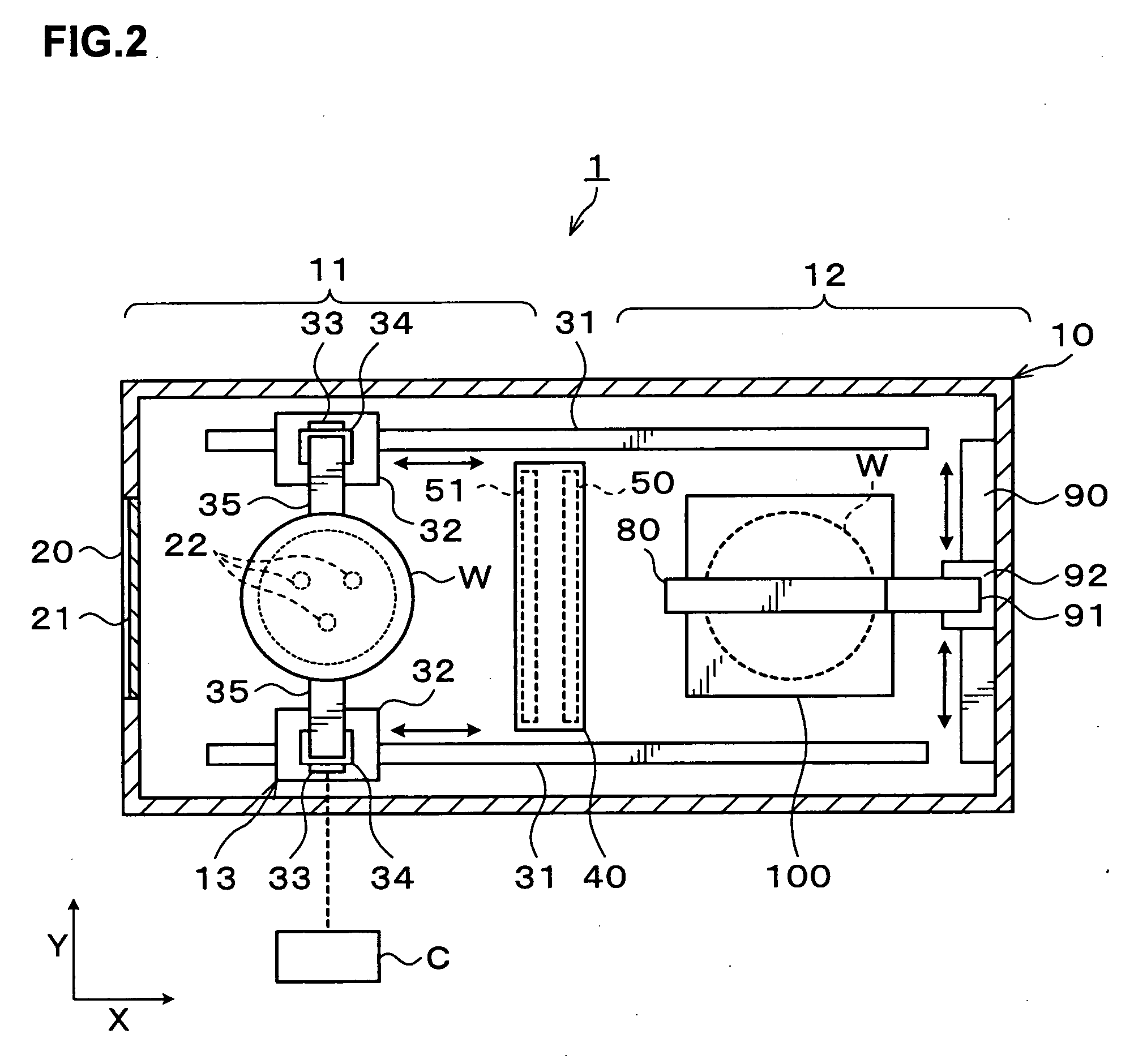

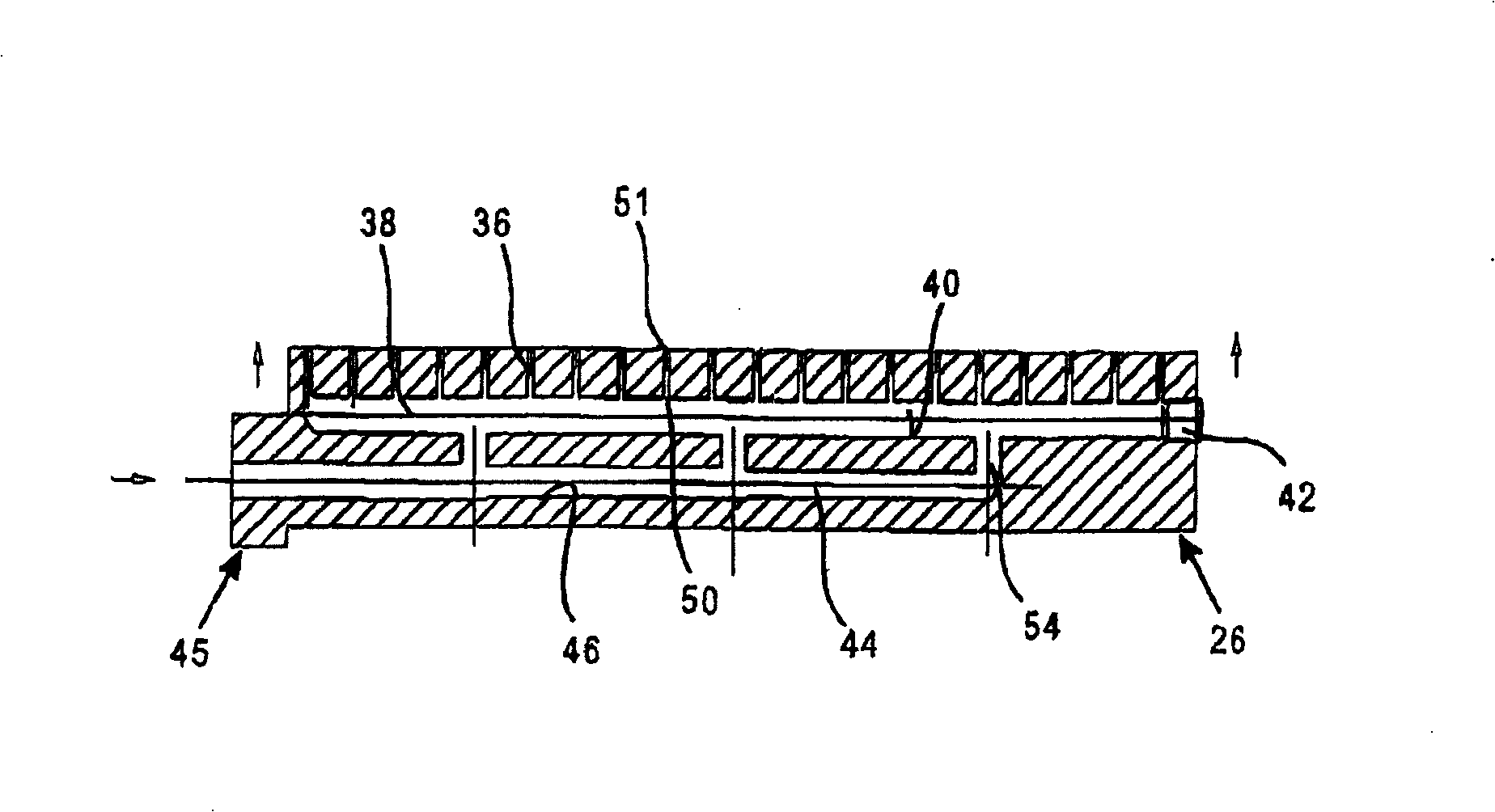

Developing treatment apparatus and developing treatment method

InactiveUS7766566B2Improve uniformityAvoid it happening againLiquid processing by liquid spraysSemiconductor/solid-state device manufacturingTherapeutic DevicesEngineering

In the present invention, a substrate transfer unit into / from which a substrate is transferred from / to the outside of a treatment container and a developing treatment unit in which development of the substrate is performed are arranged side by side in the treatment container, and a carrier mechanism is provided which carries the substrate while grasping an outside surface of the substrate from both sides, between the substrate transfer unit and the developing treatment unit. A developing solution supply nozzle for supplying a developing solution onto the substrate and a gas blow nozzle for blowing a gas to the substrate, are provided between the substrate transfer unit and the developing treatment unit and above a carriage path along which the substrate is carried, and a cleaning solution supply nozzle is provided in the developing treatment unit for supplying a cleaning solution onto the substrate. According to the present invention, since the substrate is carried with its outside surface being grasped, spread of contamination can be prevented to restrain generation of particles in the treatment container.

Owner:TOKYO ELECTRON LTD

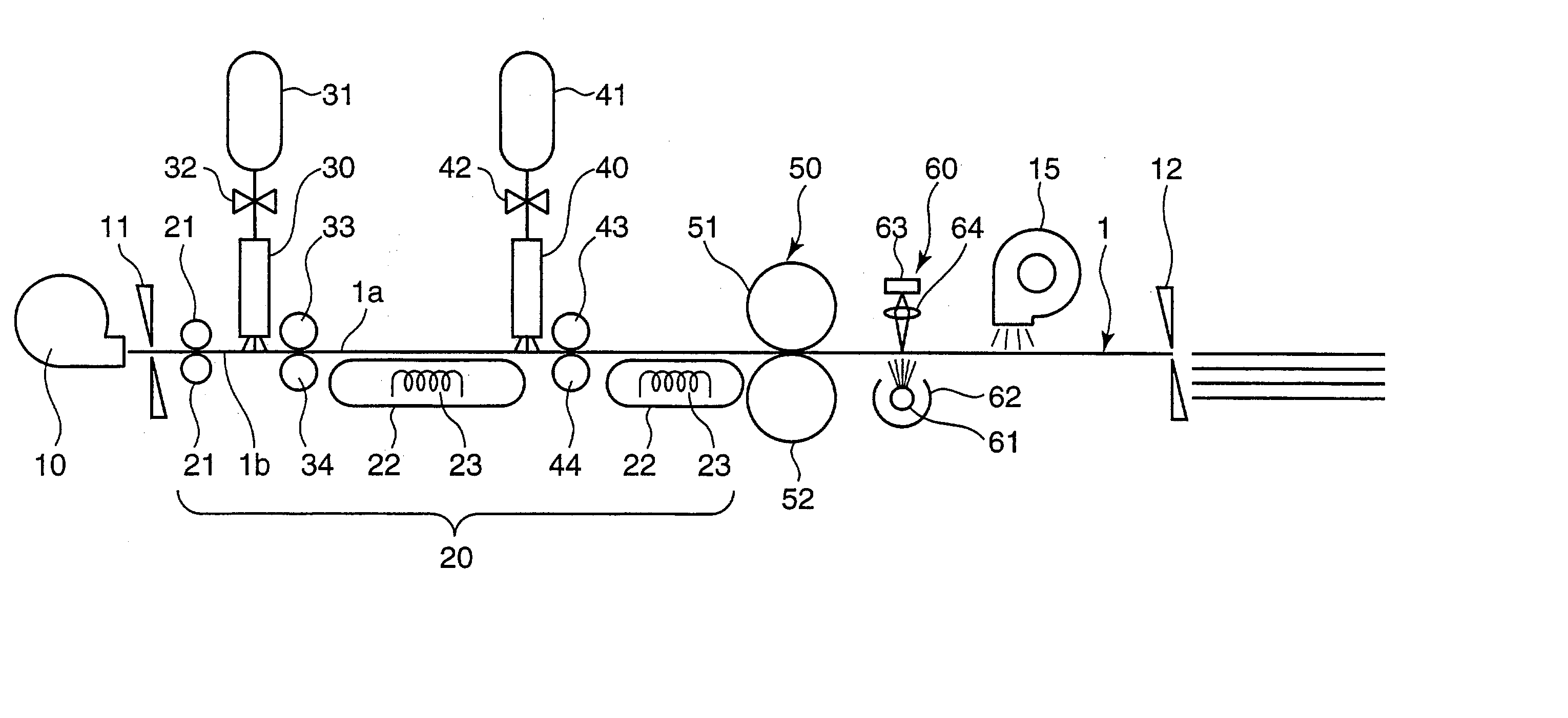

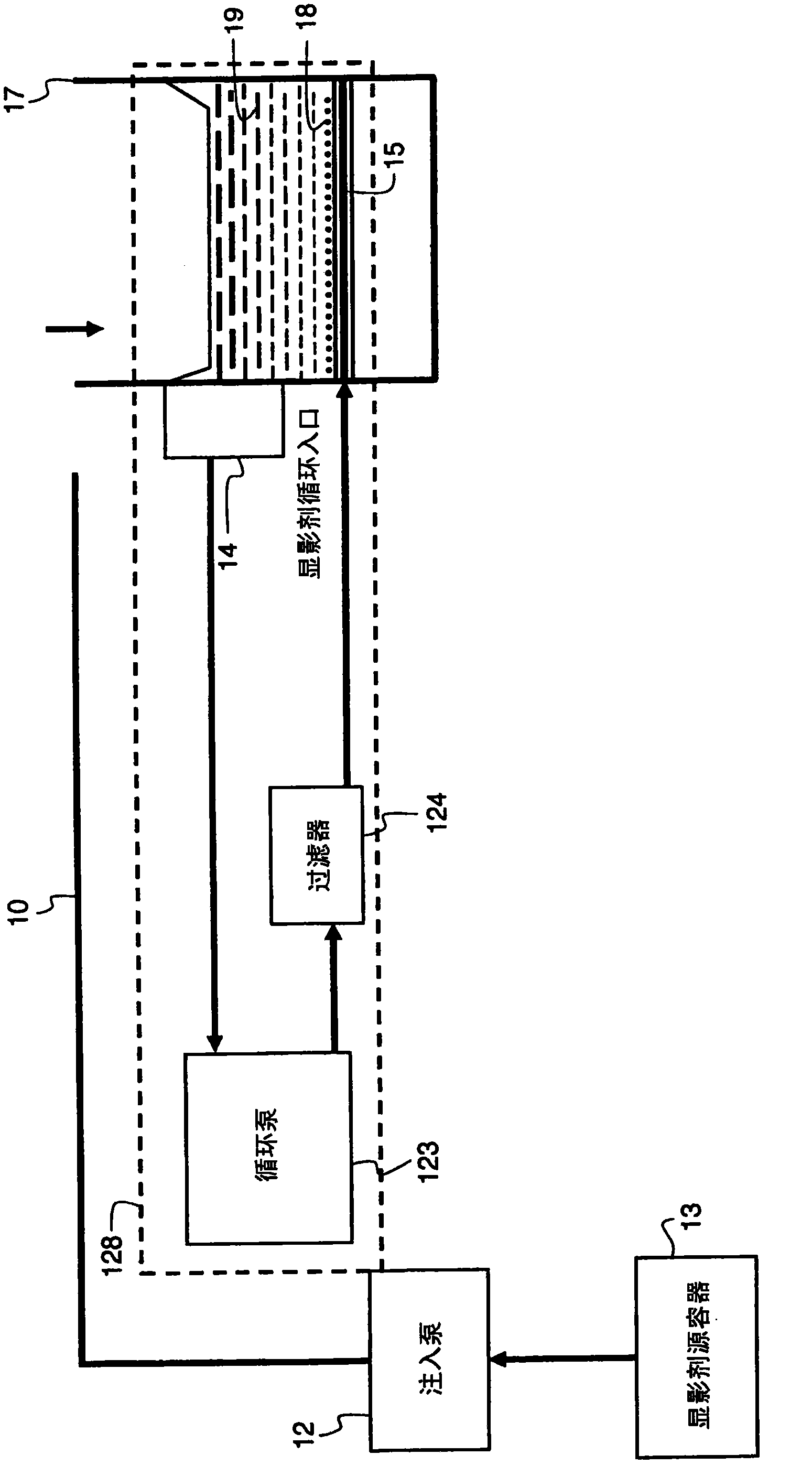

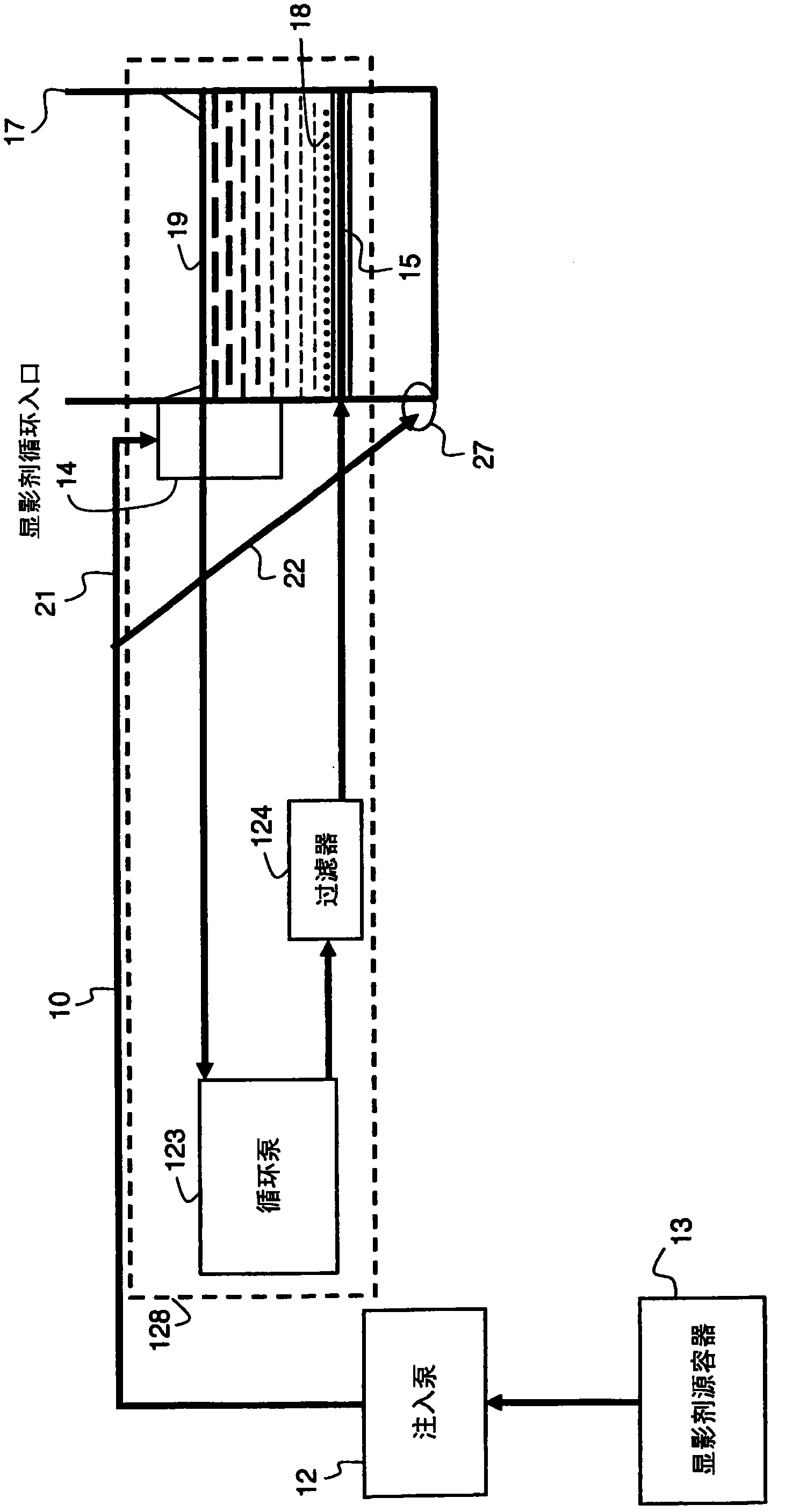

Method for developing processing and apparatus for supplying developing solution

InactiveUS6991385B2Improve uniformityInhibition of defect generationLiquid processing by liquid spraysPhotoprinting processesLine widthEngineering

In a developing processing of a wafer having a resist film low in the dissolving rate in a developing solution formed thereon and subjected to an exposure treatment, a developing solution of a low concentration is supplied first onto a wafer and the wafer is left to stand for a prescribed time to permit a developing reaction to proceed, followed by further supplying a developing solution having a concentration higher than that of the developing solution supplied first onto the wafer, leaving the substrate to stand and subsequently rinsing the wafer, thereby improving the uniformity of the line width in the central portion and the peripheral portion of the wafer.

Owner:TOKYO ELECTRON LTD

Developing treatment apparatus and developing treatment method

InactiveUS20070031145A1Work resistanceWave is obstructedLiquid processing by liquid spraysPretreated surfacesEngineeringMicroparticle generation

In the present invention, a substrate transfer unit into / from which a substrate is transferred from / to the outside of a treatment container and a developing treatment unit in which development of the substrate is performed are arranged side by side in the treatment container, and a carrier mechanism is provided which carries the substrate while grasping an outside surface of the substrate from both sides, between the substrate transfer unit and the developing treatment unit. A developing solution supply nozzle for supplying a developing solution onto the substrate and a gas blow nozzle for blowing a gas to the substrate, are provided between the substrate transfer unit and the developing treatment unit and above a carriage path along which the substrate is carried, and a cleaning solution supply nozzle is provided in the developing treatment unit for supplying a cleaning solution onto the substrate. According to the present invention, since the substrate is carried with its outside surface being grasped, spread of contamination can be prevented to restrain generation of particles in the treatment container.

Owner:TOKYO ELECTRON LTD

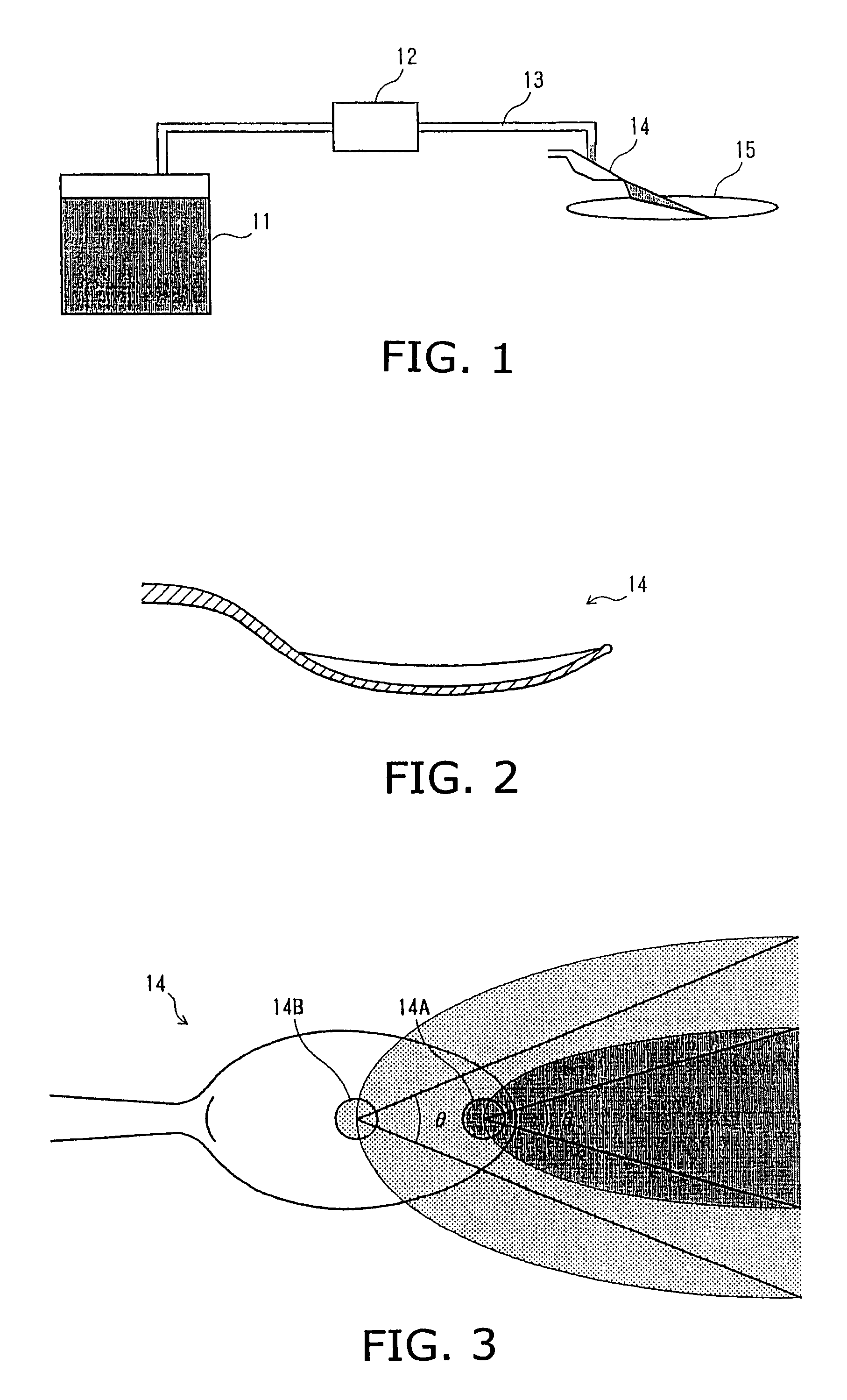

Development apparatus for manufacturing semiconductor device

InactiveUS7025514B2Effective applicationLiquid processing by liquid spraysLiquid surface applicatorsSpray nozzleEngineering

A development apparatus for discharging a developer onto a surface of a semiconductor substrate (15) comprises a nozzle pipe (13) for supplying the developer, and a nozzle (14) having a shape of a spoon with a taper and discharging the developer supplied by the nozzle pipe onto the surface of the substrate. The nozzle sprays the developer onto the surface of the substrate at any spray angle under a low and constant pressure.

Owner:LAPIS SEMICON CO LTD

Portable image-forming device

InactiveUS20160291473A1Small sizeLow power operationLiquid processing by liquid spraysPhotomechanical exposure apparatusDisplay deviceImage formation

A portable image-forming device includes a housing, an exposure member for exposing an instant film disposed inside of the housing by means of a light radiating from the screen of a portable display device, a shading member linked in movement with the exposure member so as to shade the instant film, a traction member connected to the exposure member so as to move the exposure member to a pre-exposure position, and a developing-agent-spreading member for spreading a developing agent, which is provided on the instant film, over the entire instant film. The traction member and the developing-agent-spreading member are manually operated by a user.

Owner:HEWLETT PACKARD DEV CO LP

Apparatus for removing developer

InactiveCN1690860AReduce chanceImprove securityLiquid processing by liquid spraysDiffusion developmentEngineeringNozzle

The invention discloses developing solution movement device, which comprises a workbench to support basal plate and a bracket; wherein, set deionized water nozzle and a gas nozzle on the bracket, the two nozzles connect separated to two hinges. This device can clear away developing solution on surface of basal plate quickly and safety.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

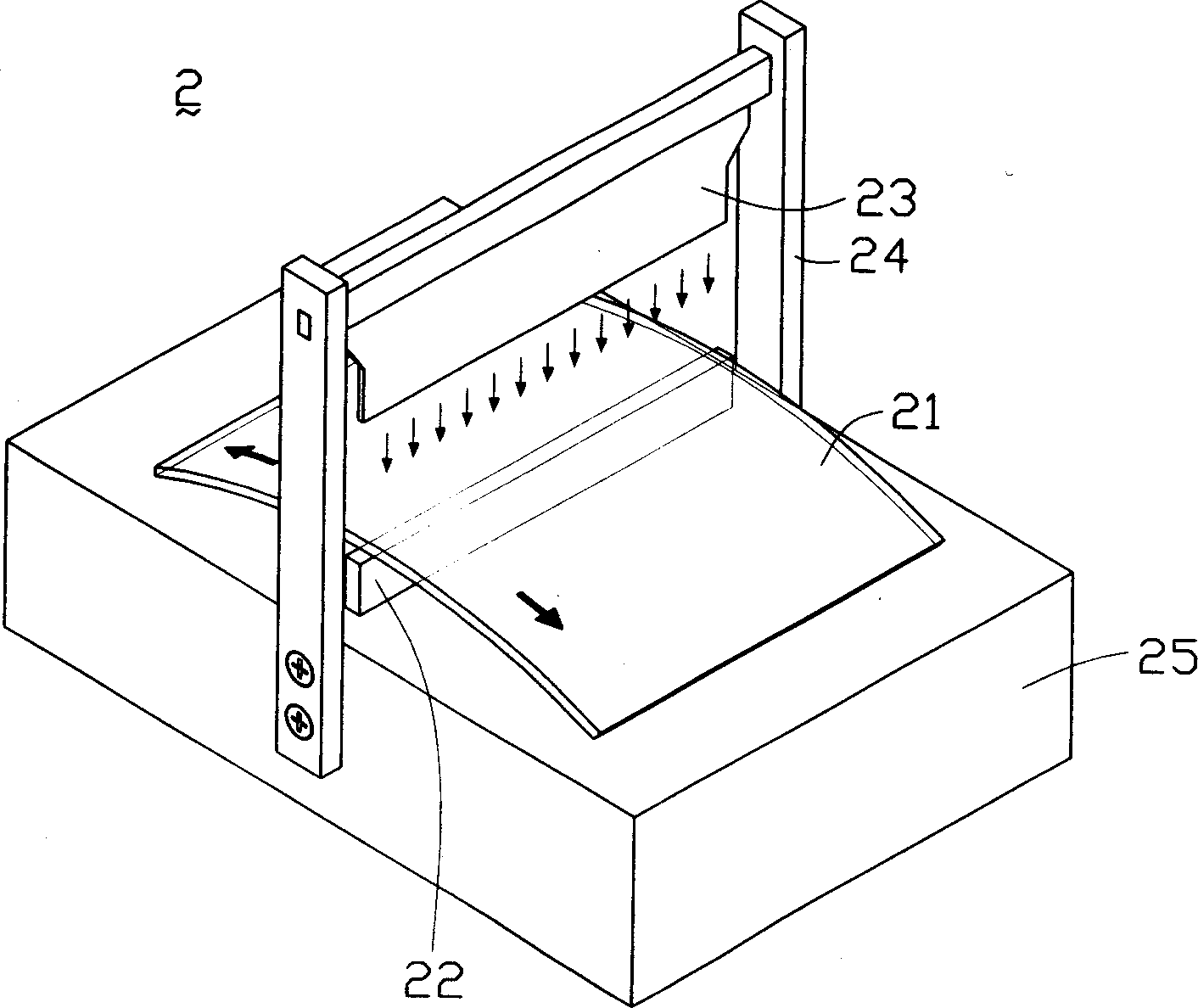

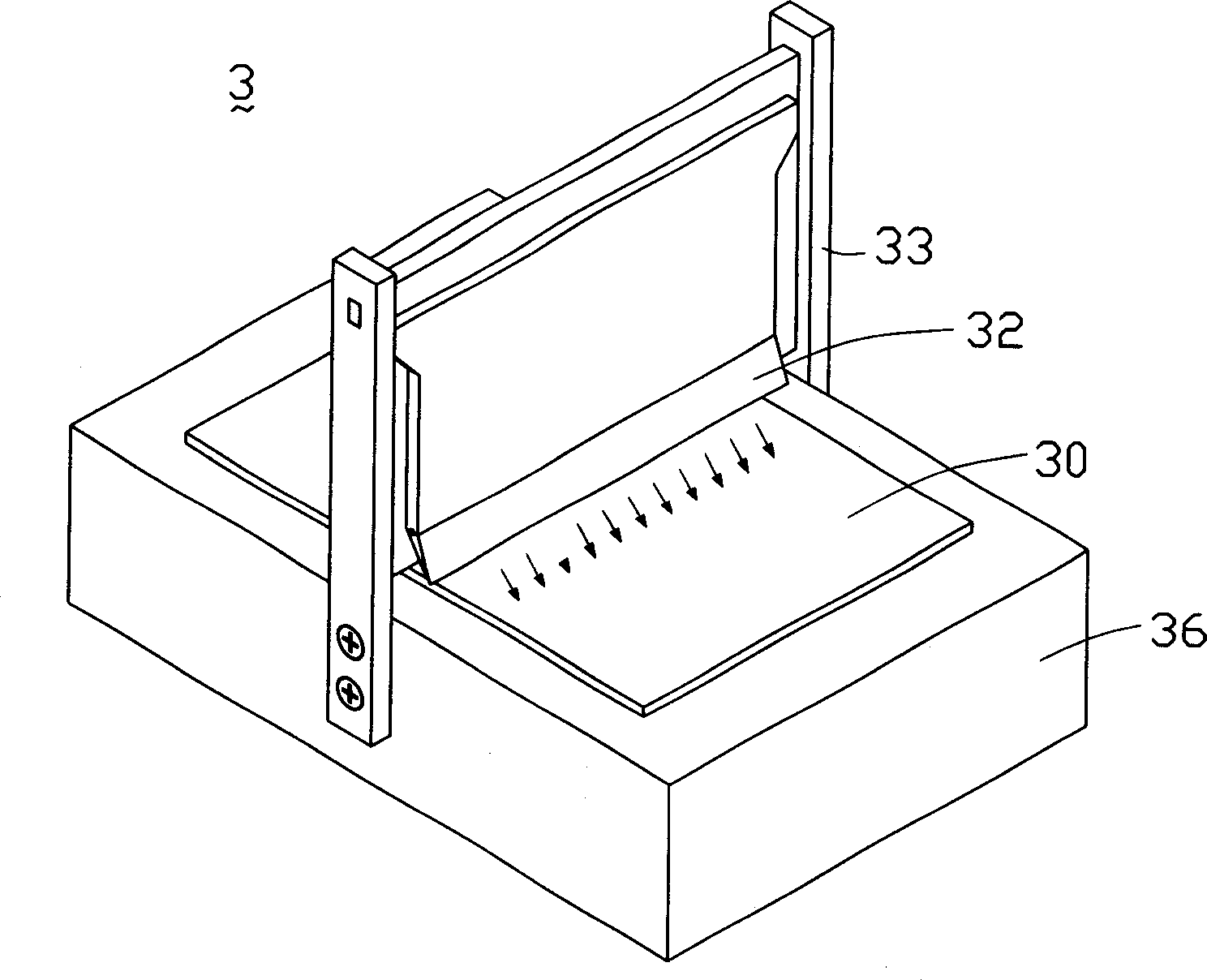

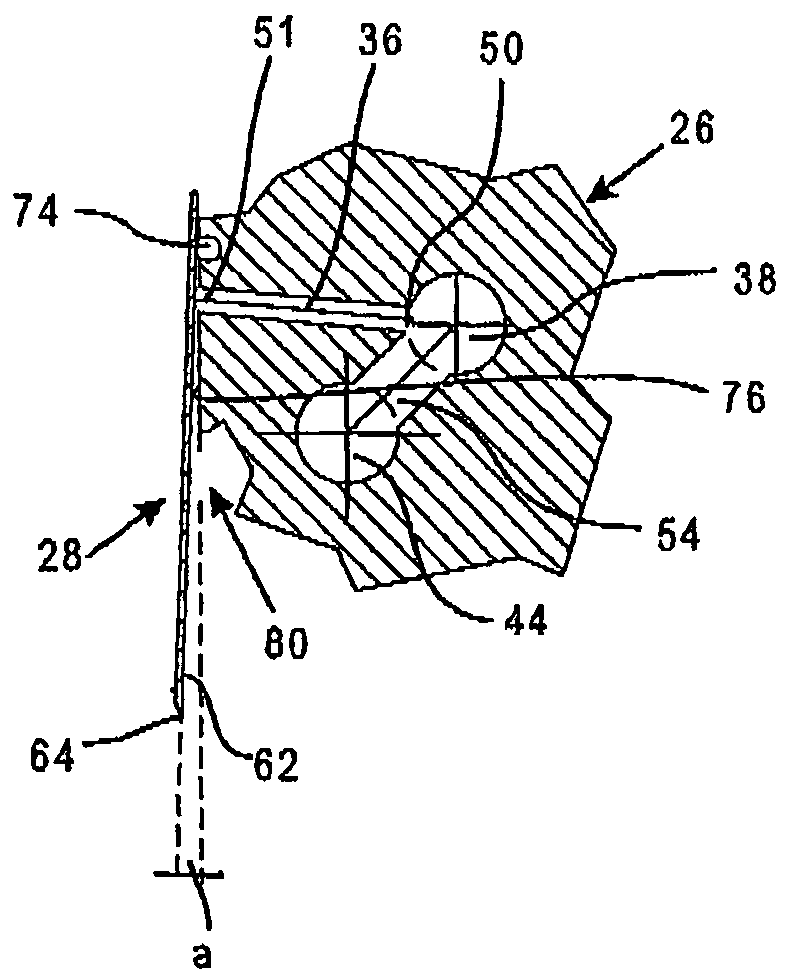

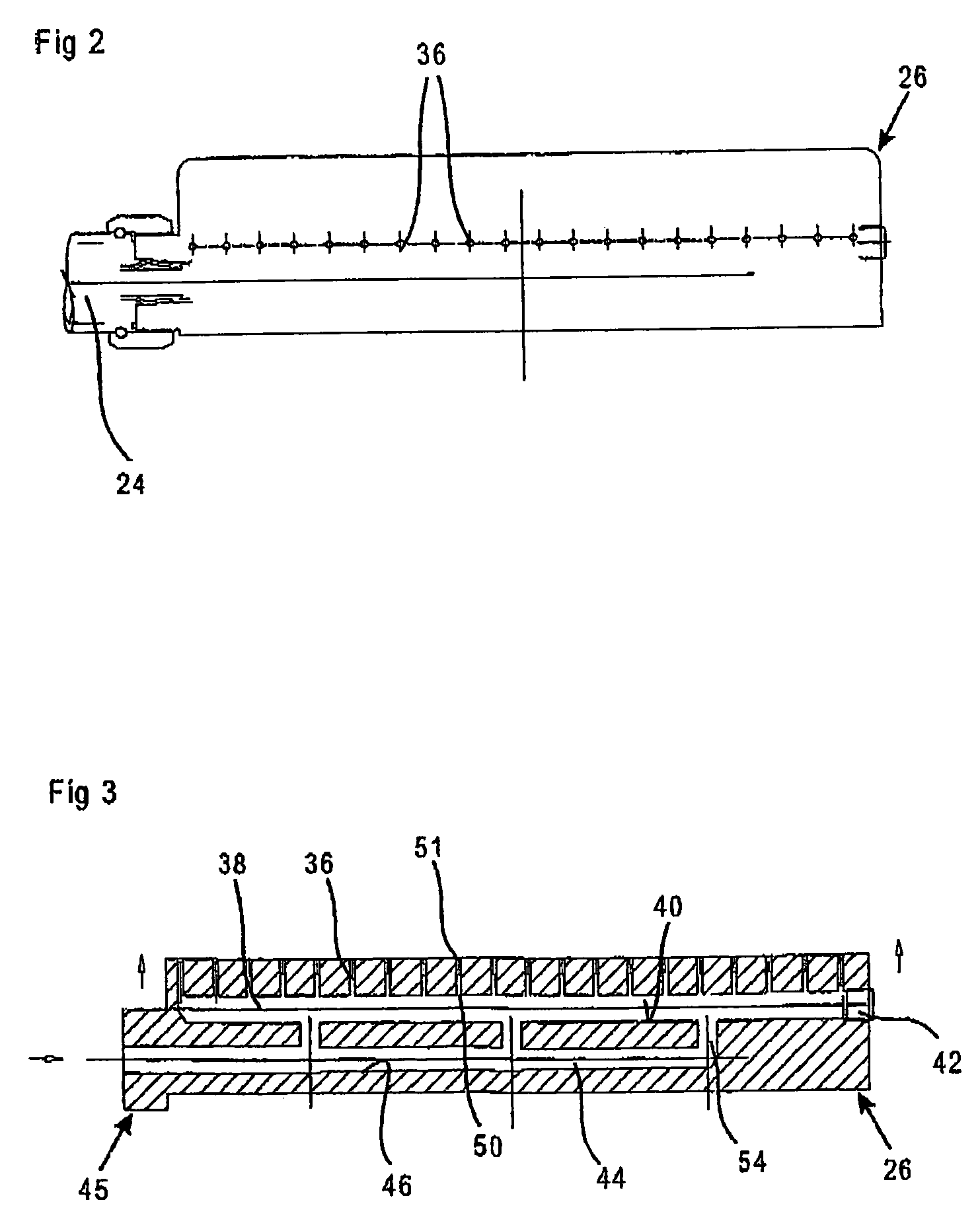

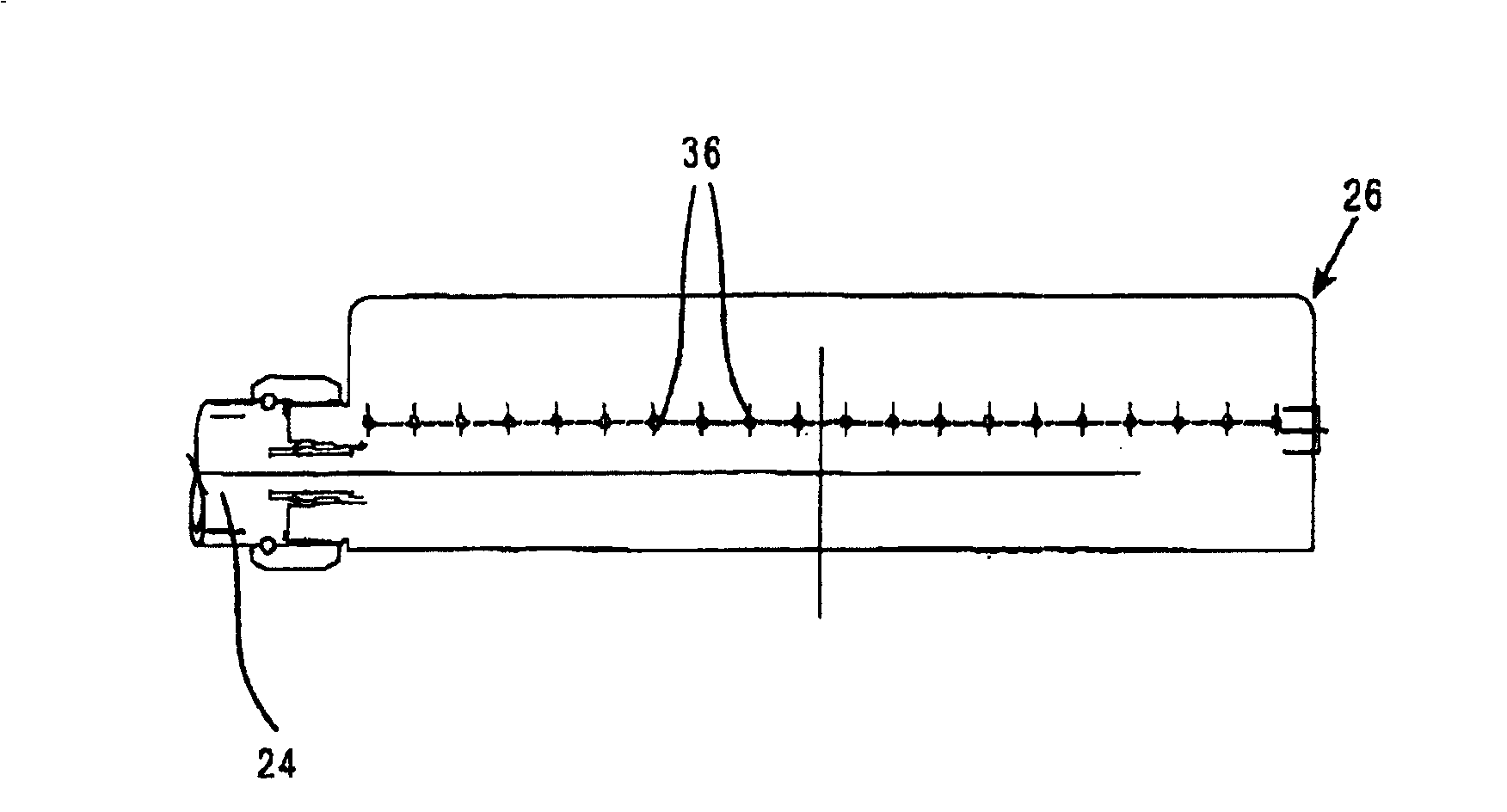

Nozzle assembly for applying a liquid to a substrate

ActiveUS7419549B2Easy constructionAvoid changeLiquid processing by liquid spraysLiquid surface applicatorsEngineeringNozzle

The aim of the invention is to achieve a rapid, homogeneous application of a liquid with as little force as possible to a substrate. To achieve this, the invention provides a nozzle assembly (22) for applying a liquid to a substrate, said assembly having a nozzle body (26) comprising a plurality of nozzles (36) that are substantially arranged in a line and a guide plate (28) that extends essentially in a vertical direction with a straight lower edge. According to the invention, the nozzles (36) above the lower edge are directed towards the guide plate (28) in such a way that a film of liquid forms on the guide plate (28) and flows over the lower edge (64).

Owner:INFINEON TECH AG +1

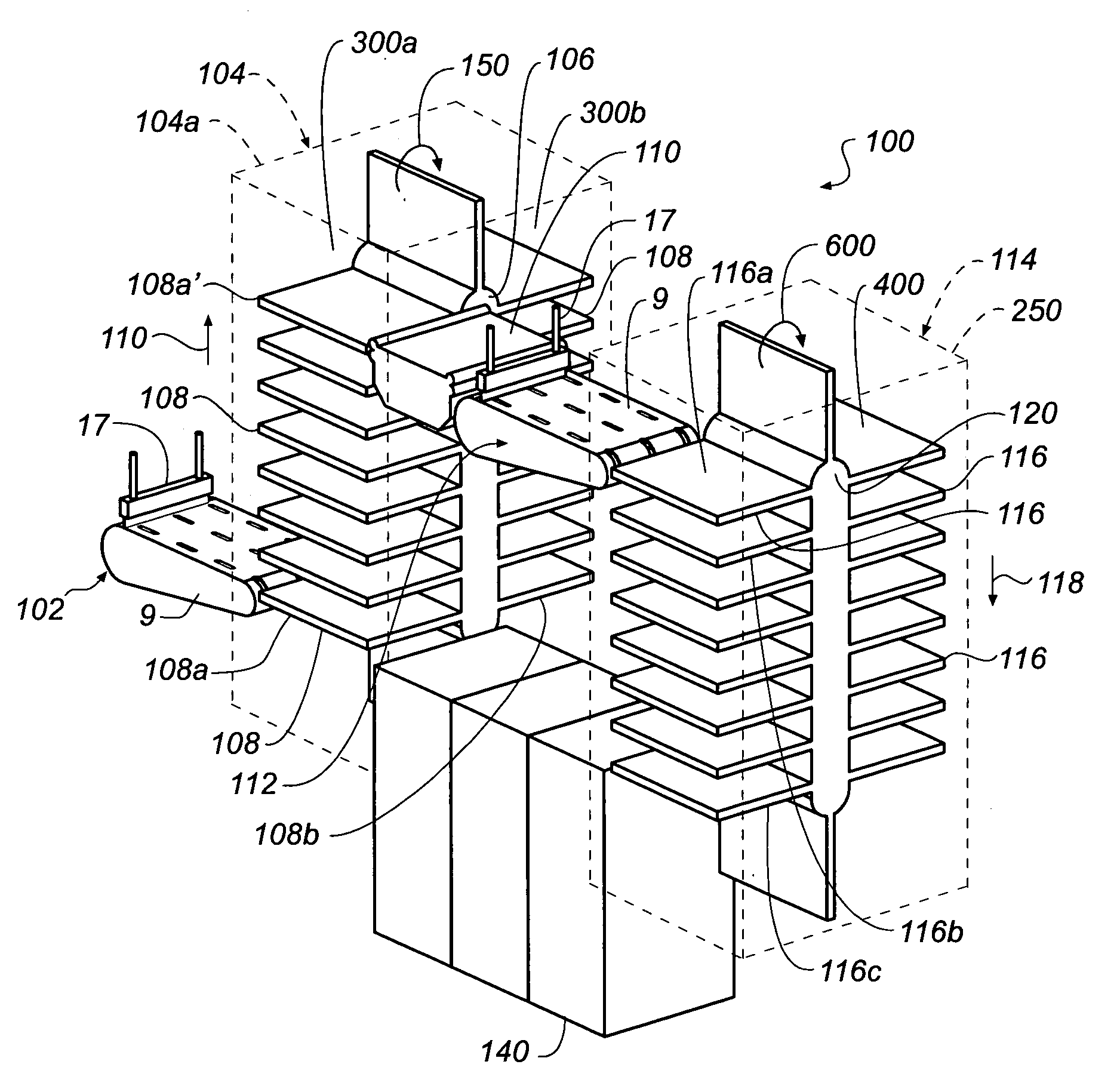

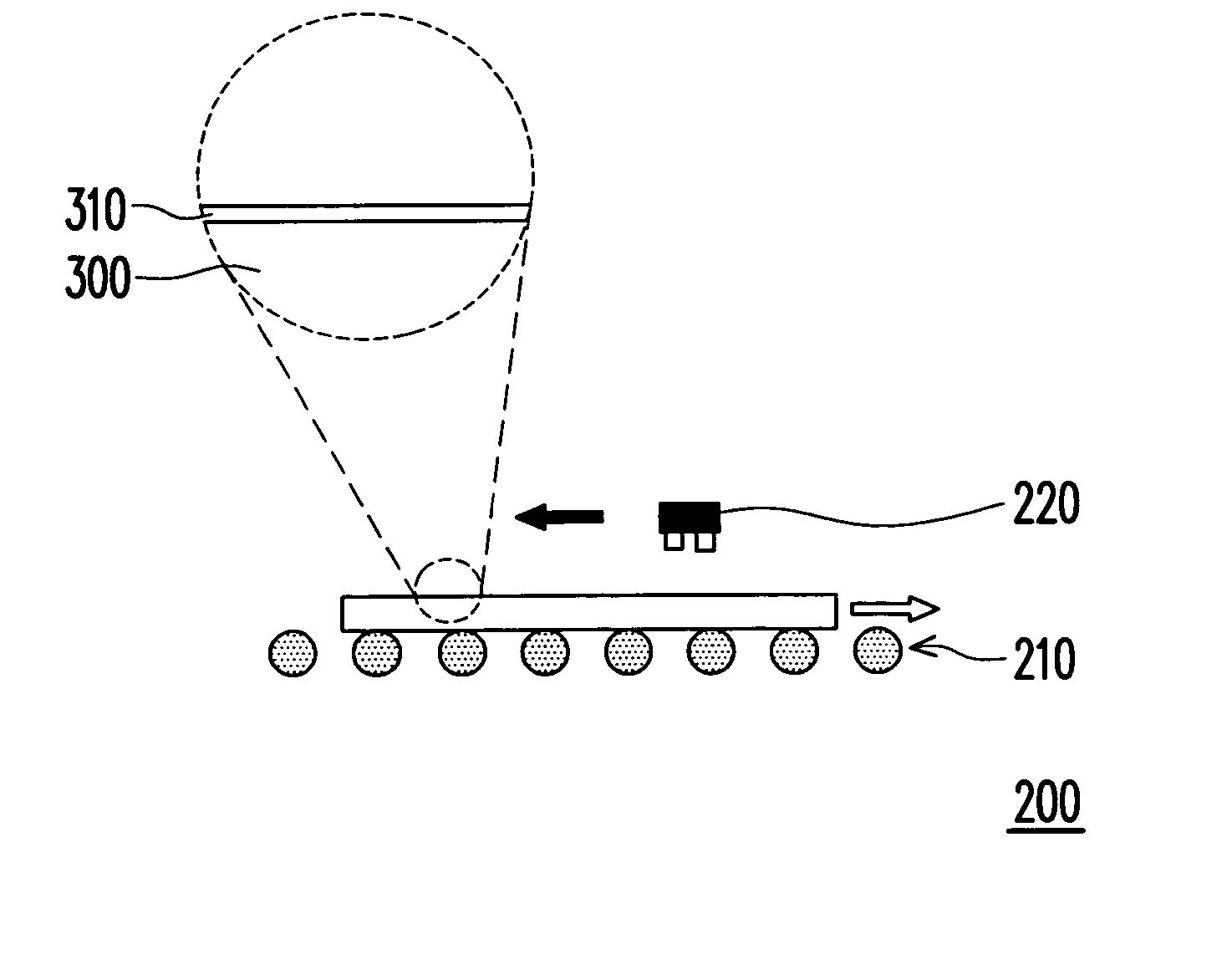

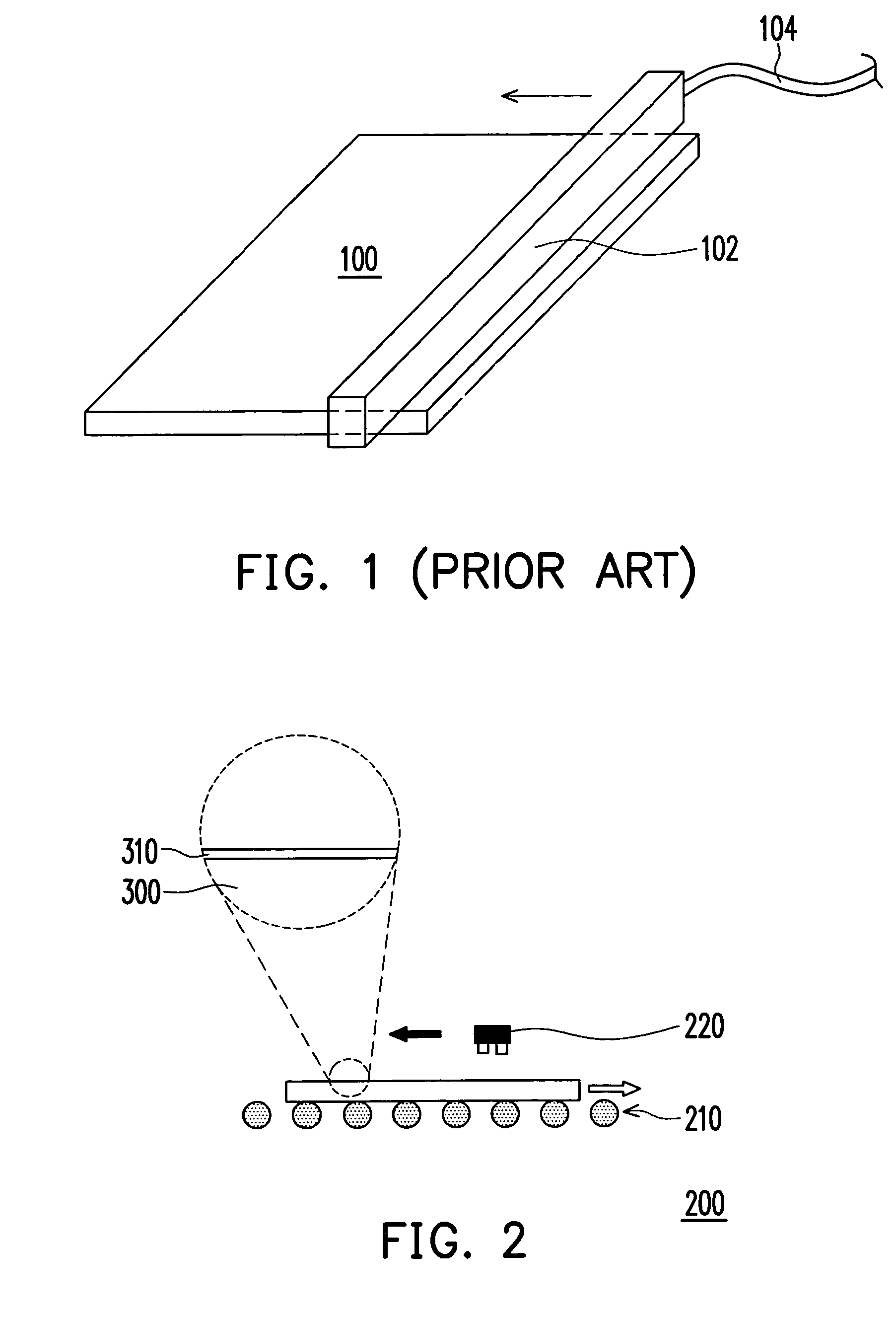

Developing process and apparatus

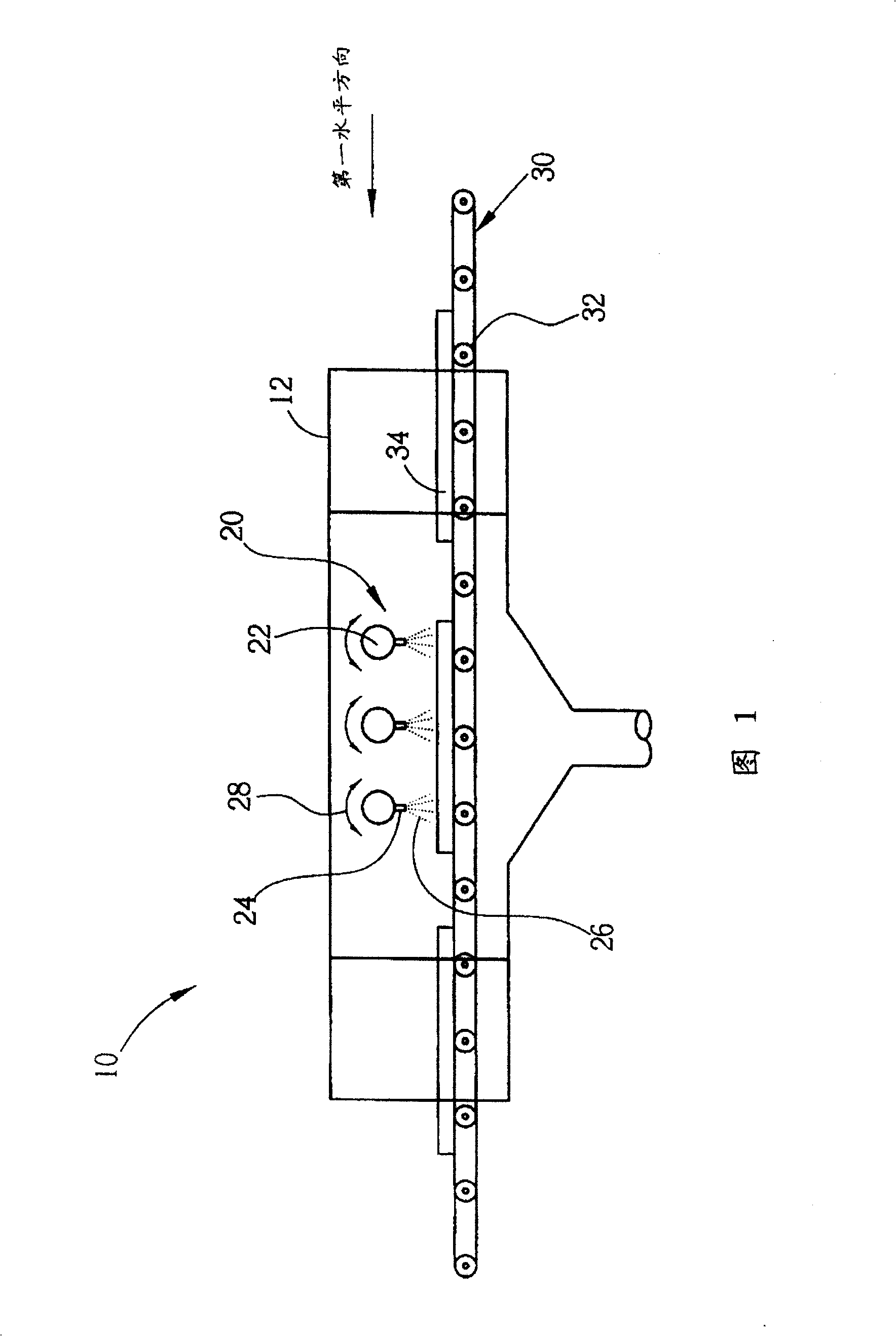

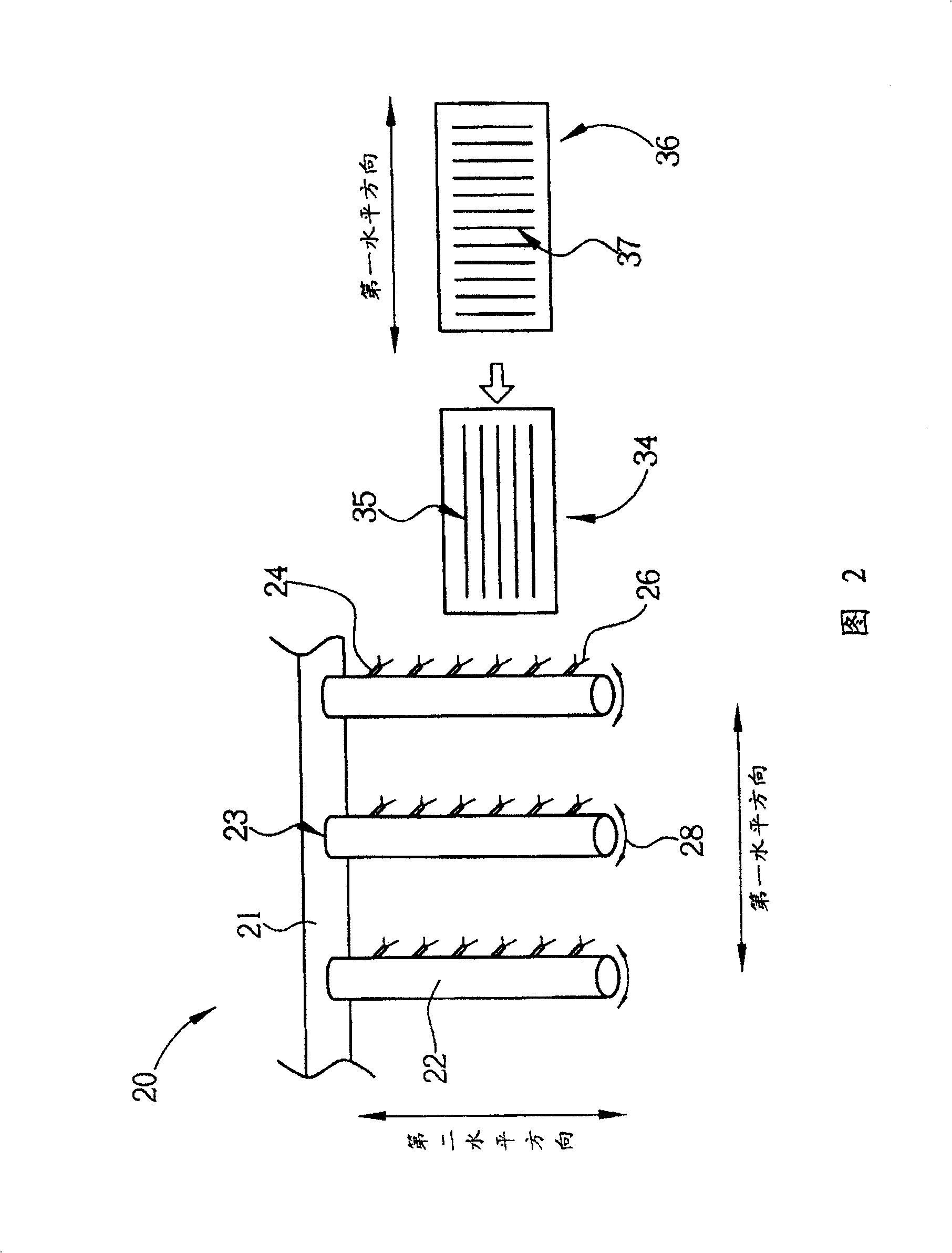

ActiveUS20060280501A1Shorten the timeReduce usageLiquid processing by liquid spraysLiquid surface applicatorsEngineeringMechanical engineering

The invention discloses a developing apparatus and a developing process. Wherein the developing process comprises following steps. First, a developing apparatus and a substrate are provided, wherein the developing apparatus comprises a conveyer and a nozzle. Then, the substrate is conveyed along a first direction by the conveyer, and the nozzle is driven to move along a second direction opposite to the first direction, wherein the nozzle sprays a developer over the substrate as moving. As mentioned above, the non-uniformity of development can be reduced.

Owner:CHUNGHWA PICTURE TUBES LTD

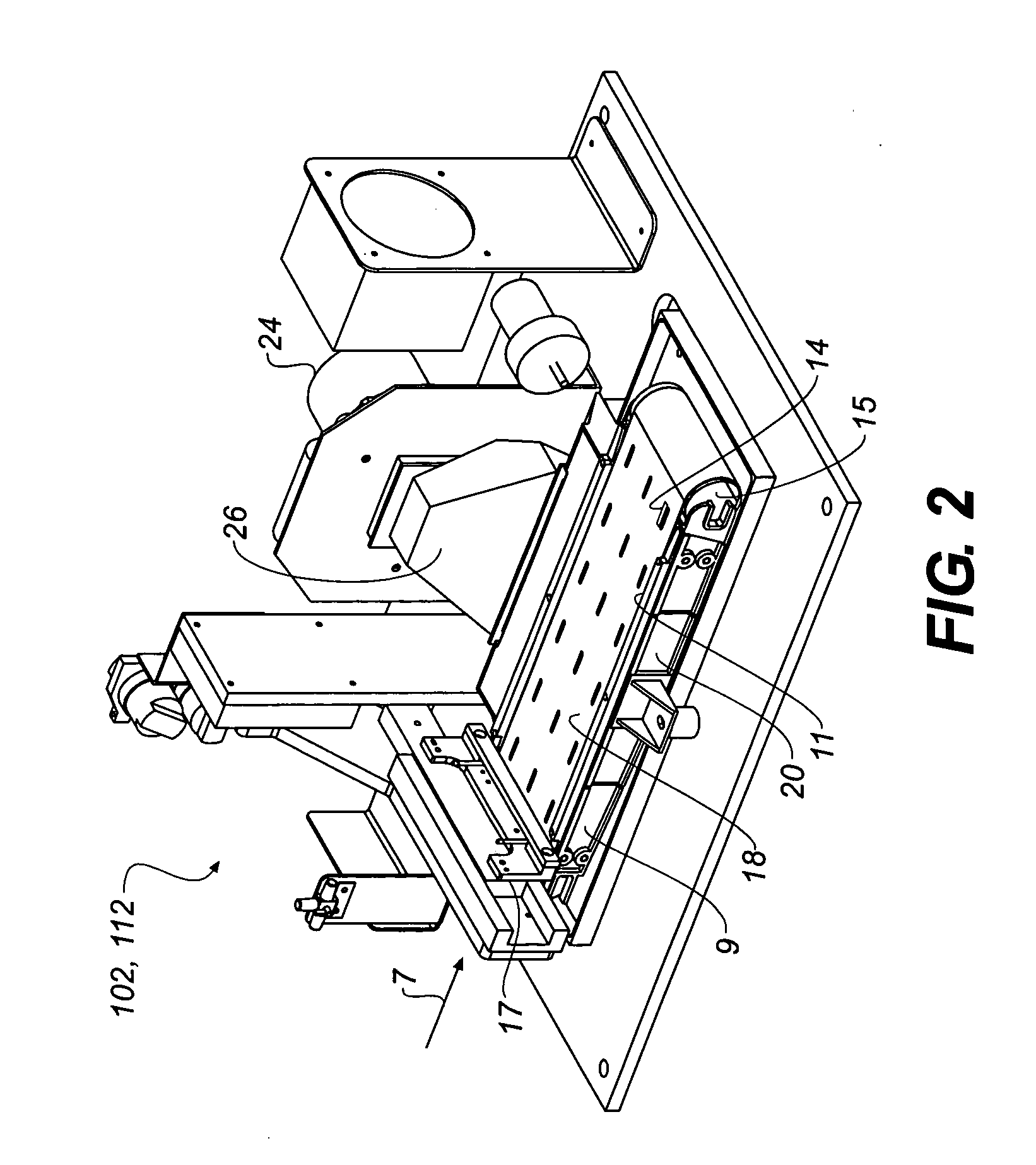

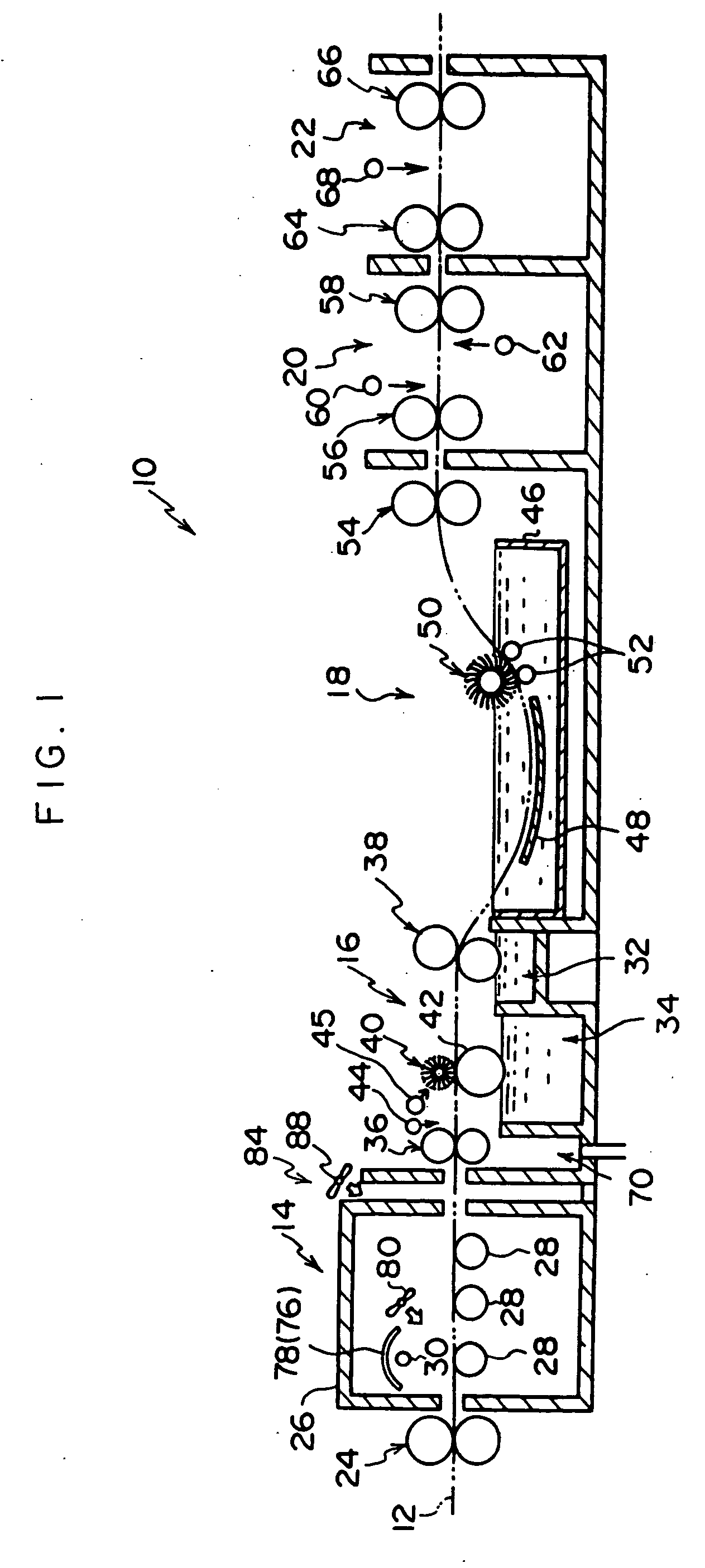

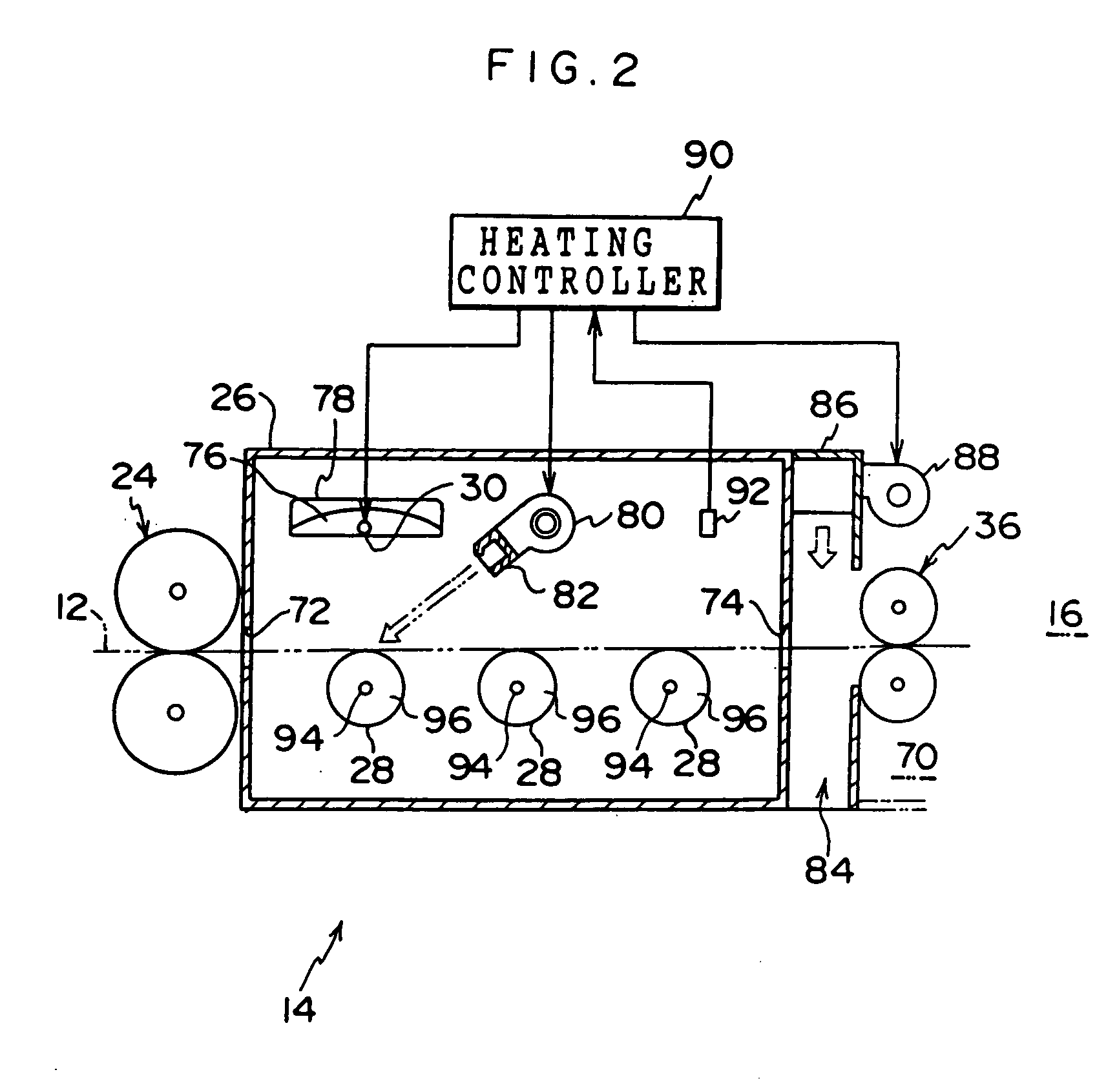

Photographic processing system having a vertical stacker arrangement

InactiveUS6942401B2Liquid processing by liquid spraysLiquid processing with progressive mechanical movementPhotographic processingEngineering

The invention relates to a photographic processor and a method of processing photographic material. The photographic processor is adapted to achieve a high speed processing of photographic material by utilizing the combination of a vacuum platen and a stacker arrangement that is adapted to hold the media for a time necessary to process and / or dry the media. The system permits media to be fed to a first vacuum platen where a first solution is applied. The platen transports the media to a first vertical stacker arrangement, which holds the media for a desired processing time for the first solution. The media can then be pushed through a stop solution, if needed, and onto a second vacuum platen where a second solution can be applied. The media is then delivered to second vertical stacker arrangement that is designed to assure the proper amount of processing time for the second solution.

Owner:EASTMAN KODAK CO

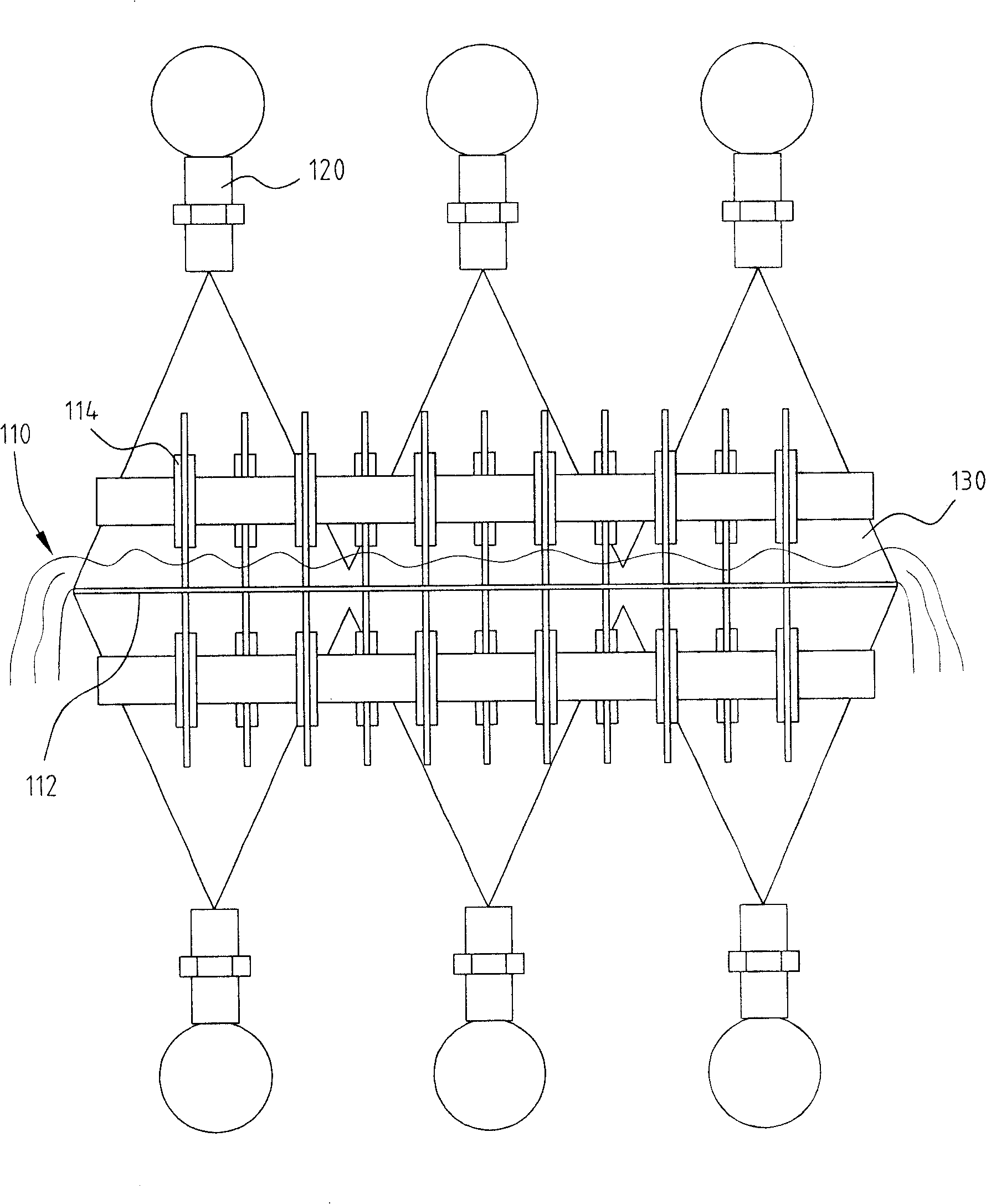

Stirring type wet process machine and stirring type wet process

InactiveCN101247700AOvercoming the phenomenon of "water stagnation"Overcoming water stagnationLiquid processing by liquid spraysPrinted circuit manufactureSpray nozzleEngineering

The invention discloses an agitation type wet process machine station and an agitation type wet process, therein, the agitation type wet process machine station comprises a conveying system and a plurality of nozzles. The conveying system comprises a plurality of idler wheels, the idler wheels are located on upside and downside of said conveying system conveying path, the idler wheels between upside and downside are used for driving plate shape object to be processed. The idler wheel added with vane can agitate chemical agent. The nozzle is located on upside or downside of the conveying path for spraying or supplementing chemical agent to object that is to be processed.

Owner:UNITED BENEFIT

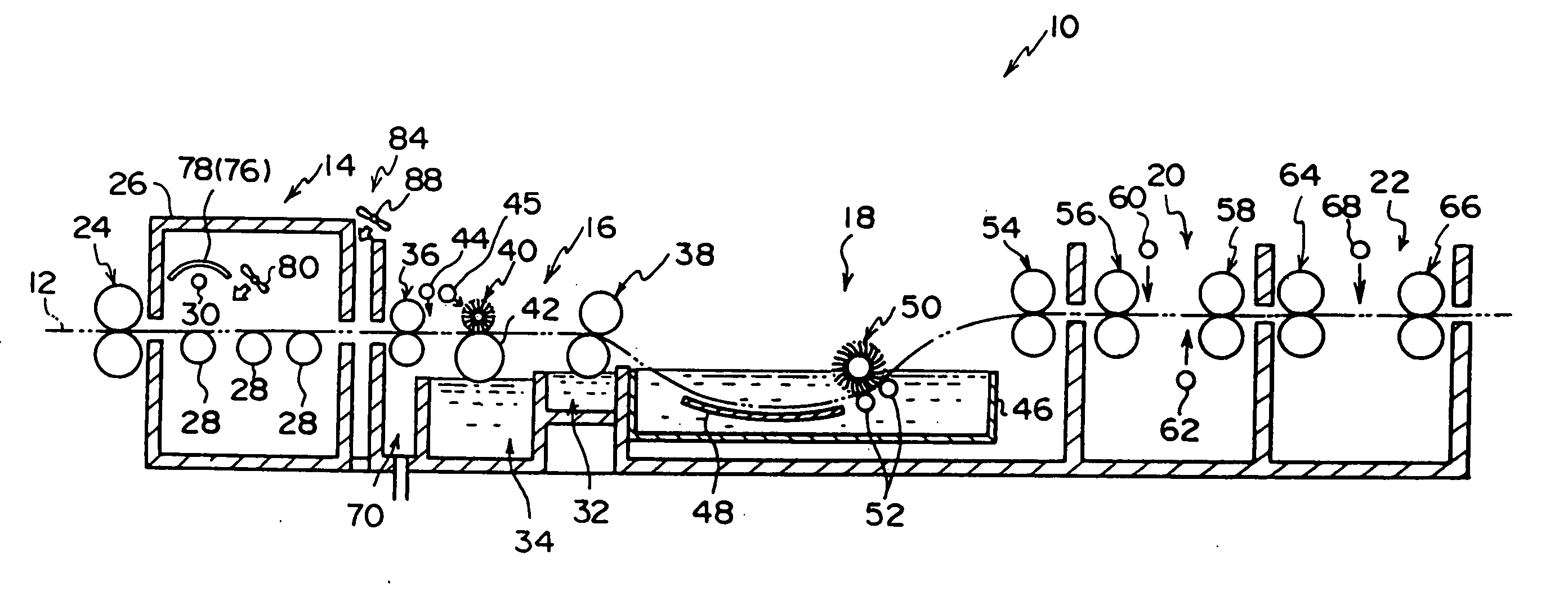

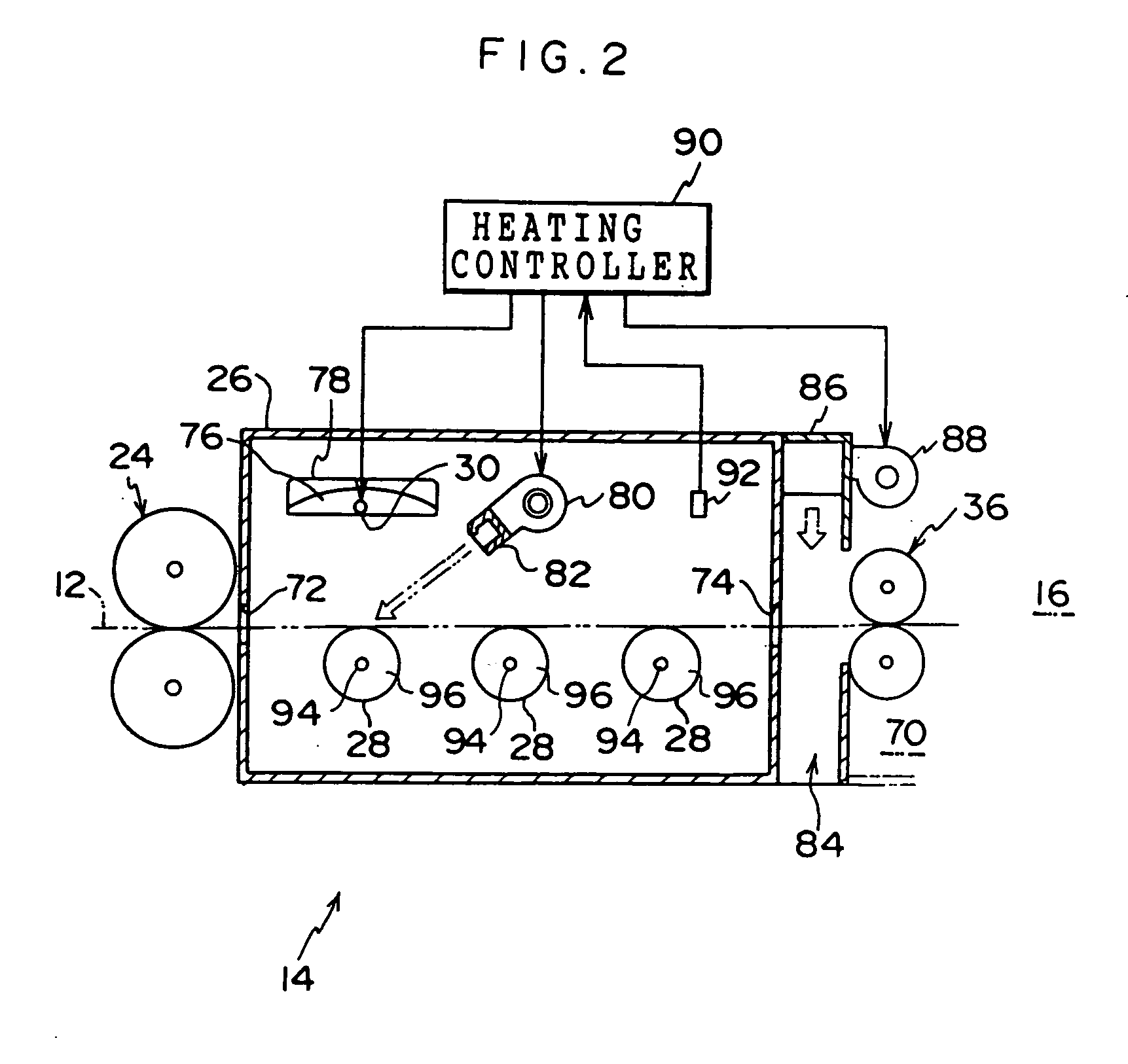

Photographic film developing apparatus

InactiveUS20030113113A1Liquid processing by liquid spraysLiquid processing with progressive mechanical movementEmulsionBiochemical engineering

A photographic film developing apparatus maintains a photographic film, a developer solution and a second processing solution at a specific temperature while performing film development operation by directly applying the individual solutions to an emulsion side of the photographic film. After the developer solution and the second processing solution have been applied from respective processing solution application heads to the emulsion side of the photographic film, the quantity of each solution on the emulsion side is adjusted to form a layer of a specified thickness. While transfer belts advance each successive portion of the photographic film up to a processing solution wipe-out device, heaters provided close to the transfer belts heat the individual solutions applied to the photographic film through the transfer belts to maintain the solutions at the specific temperature.

Owner:NORITZ CORP

Automatic developing device, roller washing method, photosensitive material processing device, and preparation method for processing liquid

InactiveUS20050061625A1Ensure correct executionReduce waste volumeLiquid processing by liquid spraysControl devices for conveyorsEngineeringMaterials processing

A photosensitive material processing device for processing a photosensitive material with a processing liquid while conveying the photosensitive material by a roller pair. A driving device for providing a rotation drive to the roller pair. A drive controlling device that gradually raises voltage of the electric power at the time of starting the rotation drive of the roller pair.

Owner:FUJIFILM HLDG CORP

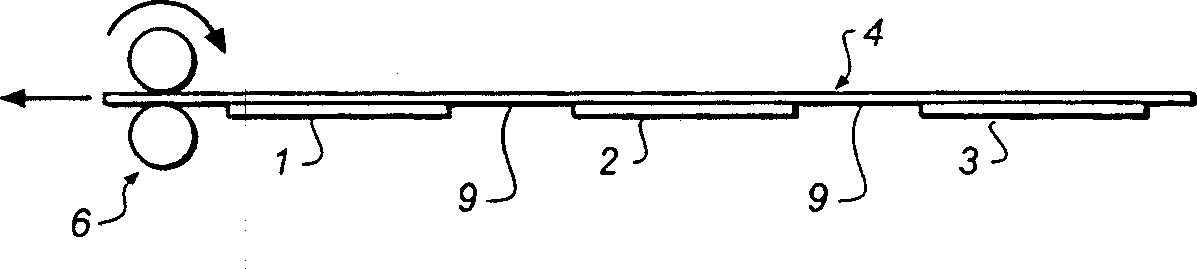

Method for processing photographic material

InactiveCN1360227AAccurate volumeEasy to operateLiquid processing by liquid spraysLiquid processing by liquid ampoulesPhotographic paperComputer science

A method of delivering processing solution to a processing device wherein the processing solutions are provided within sealed members fixedly arranged on a movable web. The web moves relative to the processing area and the sealed members are ruptured when the processing solution within is required.

Owner:EASTMAN KODAK CO

Reducing foam formation

Owner:EASTMAN KODAK CO

Developing process and apparatus

ActiveUS7287919B2Reduce unevennessGood effectLiquid processing by liquid spraysLiquid surface applicatorsNozzle

Owner:CHUNGHWA PICTURE TUBES LTD

Liquid sprayer

InactiveCN100451843CImprove efficiencyLiquid processing by liquid spraysMovable spraying apparatusSprayerEngineering

The liquid sprayer for cleaning, development, etching and other wet process includes a casing with hollow compartment, several conveying pipes set to the compartment vertically, several nozzles below the pipes a connector to drive the conveying pipes for spraying liquid toward the same direction, a driver to drive the connector to move in different direction, a horizontal pedestal inside the compartment for setting substrate.

Owner:AU OPTRONICS CORP

Nozzle assembly for applying a liquid to a substrate

InactiveCN100476582CNo torque boostFast coatingLiquid processing by liquid spraysLiquid surface applicatorsEngineeringNozzle

The aim of the invention is to achieve a rapid, homogeneous application of a liquid with as little force as possible to a substrate. To achieve this, the invention provides a nozzle assembly (22) for applying a liquid to a substrate, said assembly having a nozzle body (26) comprising a plurality of nozzles (36) that are substantially arranged in a line and a guide plate (28) that extends essentially in a vertical direction with a straight lower edge. According to the invention, the nozzles (36) above the lower edge are directed towards the guide plate (28) in such a way that a film of liquid forms on the guide plate (28) and flows over the lower edge (64).

Owner:聚斯微技术光掩膜设备有限责任两合公司

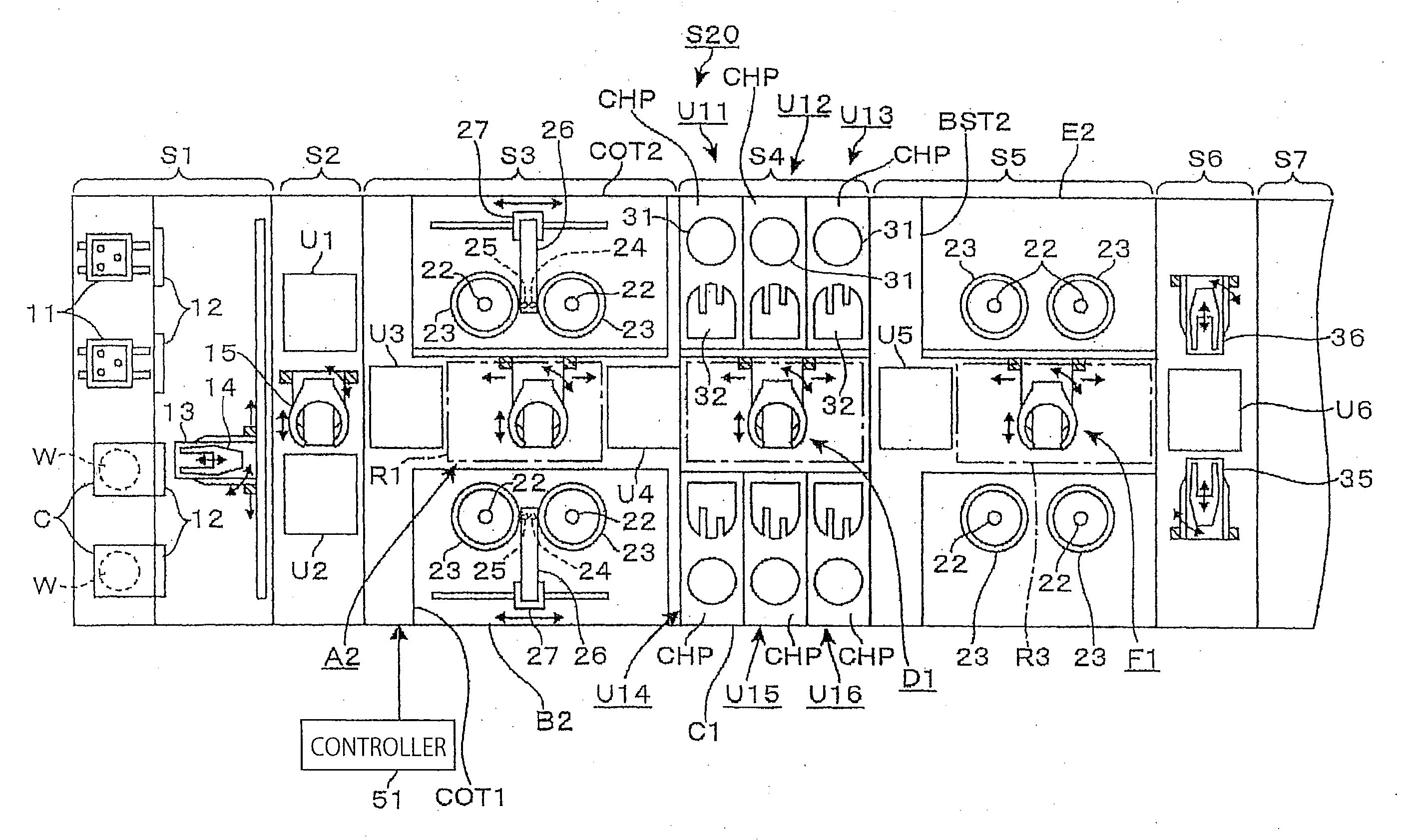

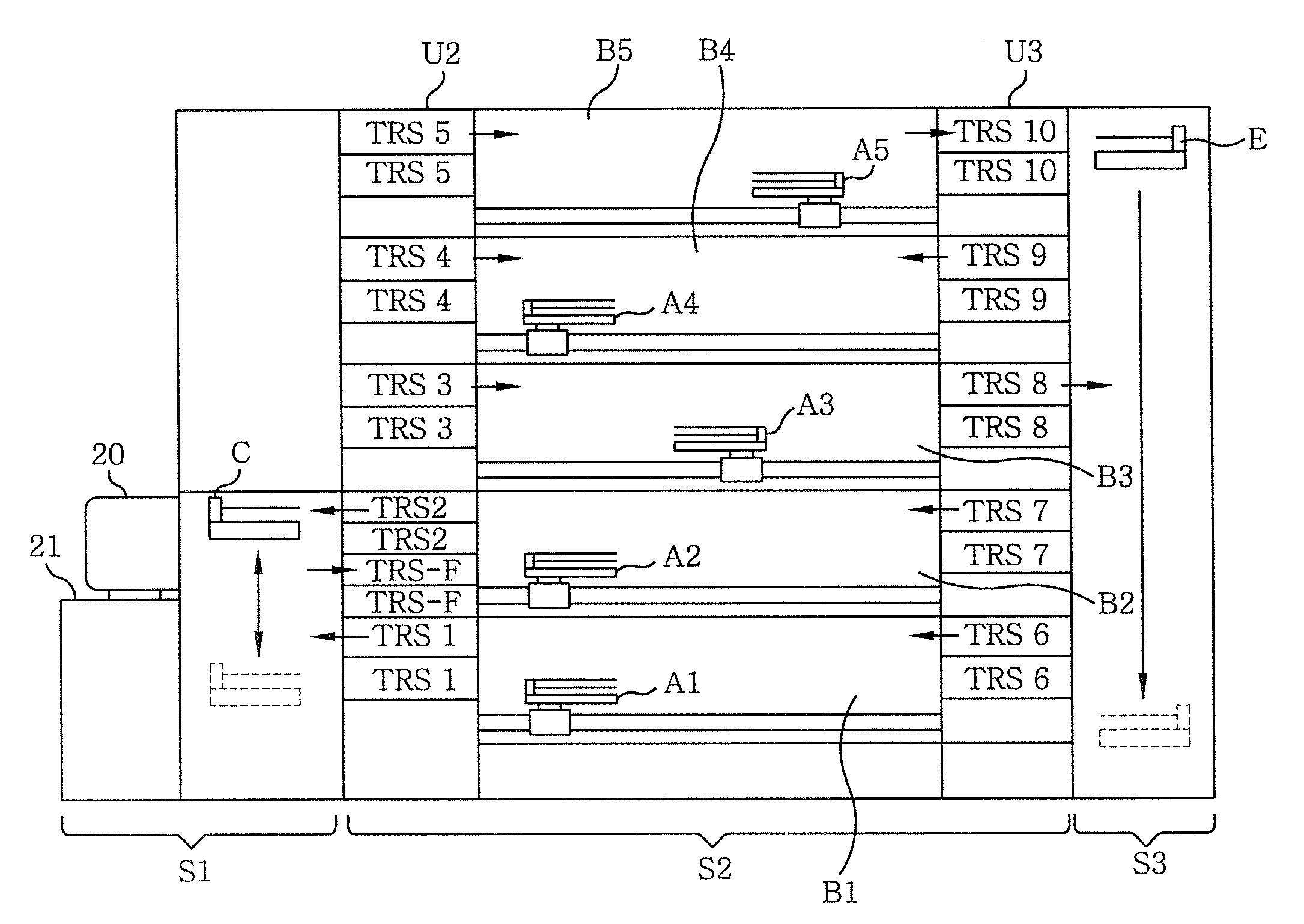

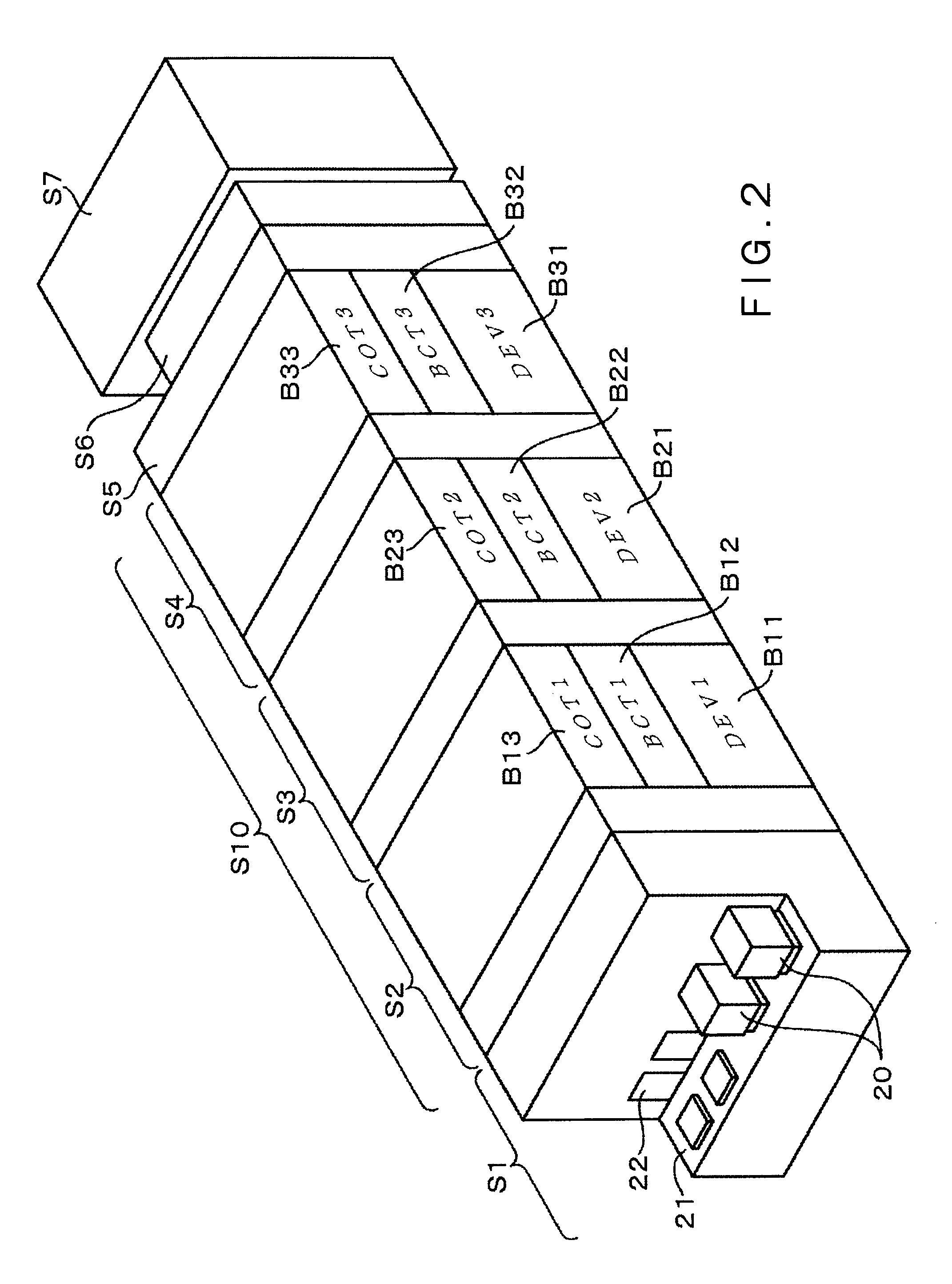

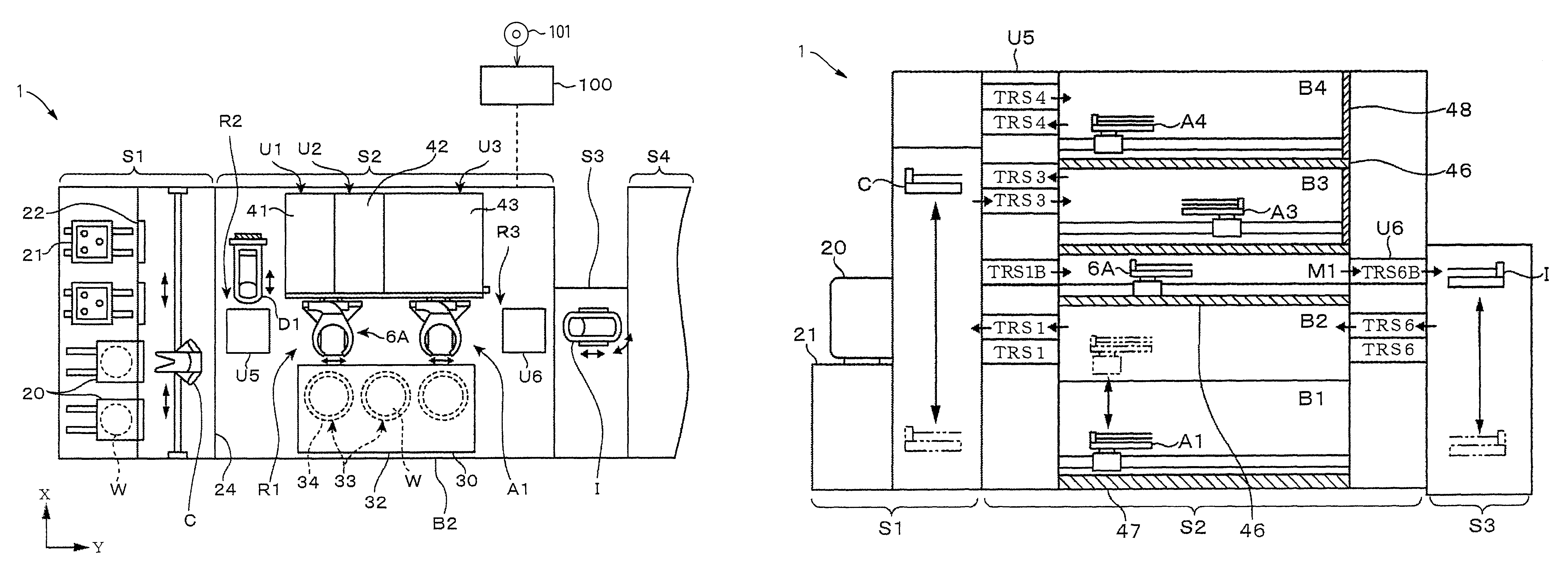

Coating and developing system with a direct carrying device in a processing block, coating and developing method and storage medium

ActiveUS7997813B2Designing can be facilitatedSimple designLiquid processing by liquid spraysProgramme controlEngineeringMechanical engineering

A coating and developing system includes processing blocks of the same construction each built by stacking up a plurality of unit blocks including a film forming unit block and a developing unit block in layers. The processing blocks are arranged longitudinally between a carrier block and an interface block. The number of processing blocks like the processing blocks arranged between the carrier block and the interface block is adjusted to adjust the throughput of the coating and developing system. Thus, a coating and developing system capable of achieving a desired throughput can be easily designed and manufactured.

Owner:TOKYO ELECTRON LTD

Automatic developing device, roller washing method, photosensitive material processing device, and preparation method for processing liquid

InactiveUS20050115803A1Reduce waste volumeReliable washingLiquid processing by liquid spraysControl devices for conveyorsEngineeringMaterials processing

A photosensitive material processing device for processing a photosensitive material with a processing liquid while conveying the photosensitive material by a roller pair. A driving device for providing a rotation drive to the roller pair. A drive controlling device that gradually raises voltage of the electric power at the time of starting the rotation drive of the roller pair.

Owner:FUJIFILM CORP

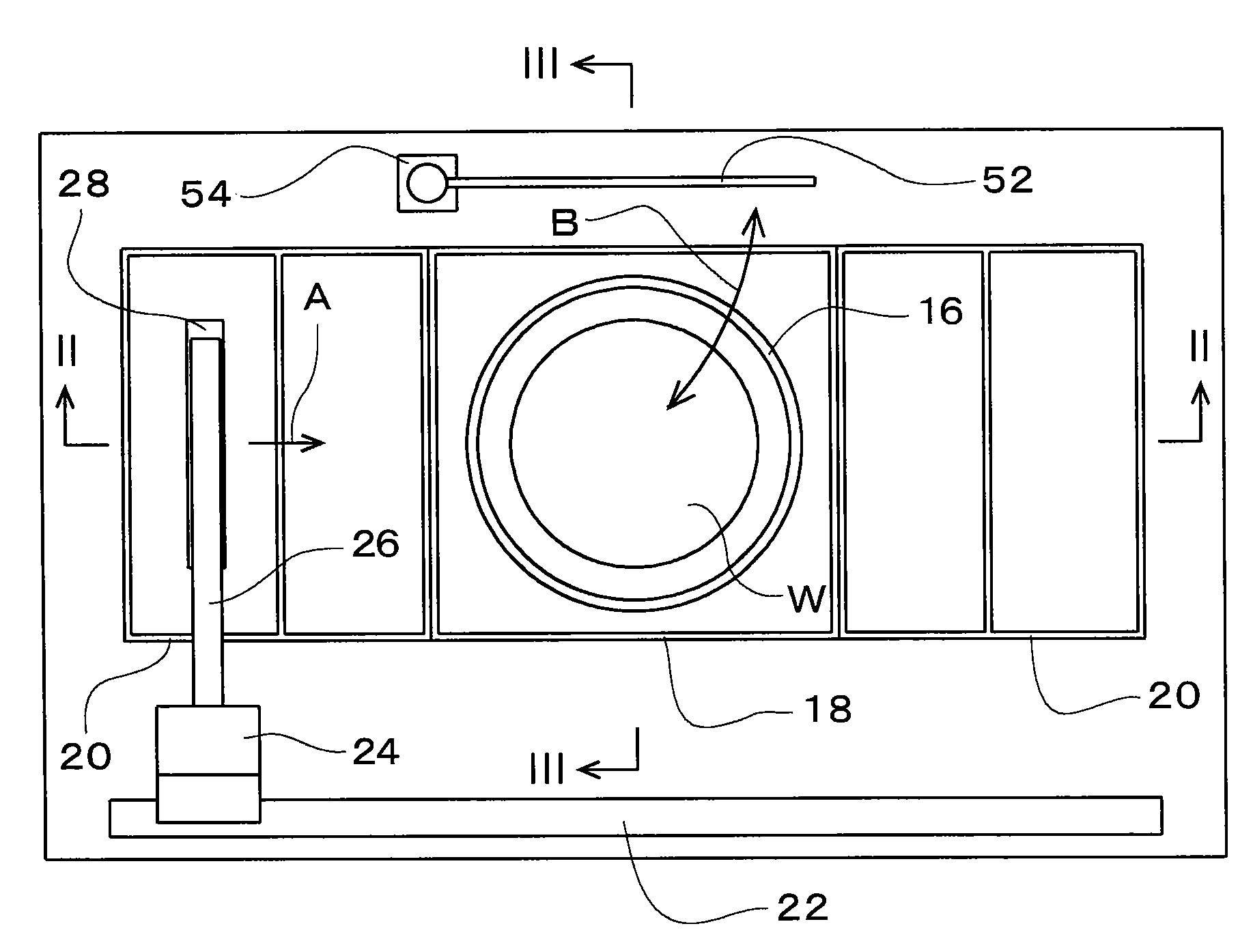

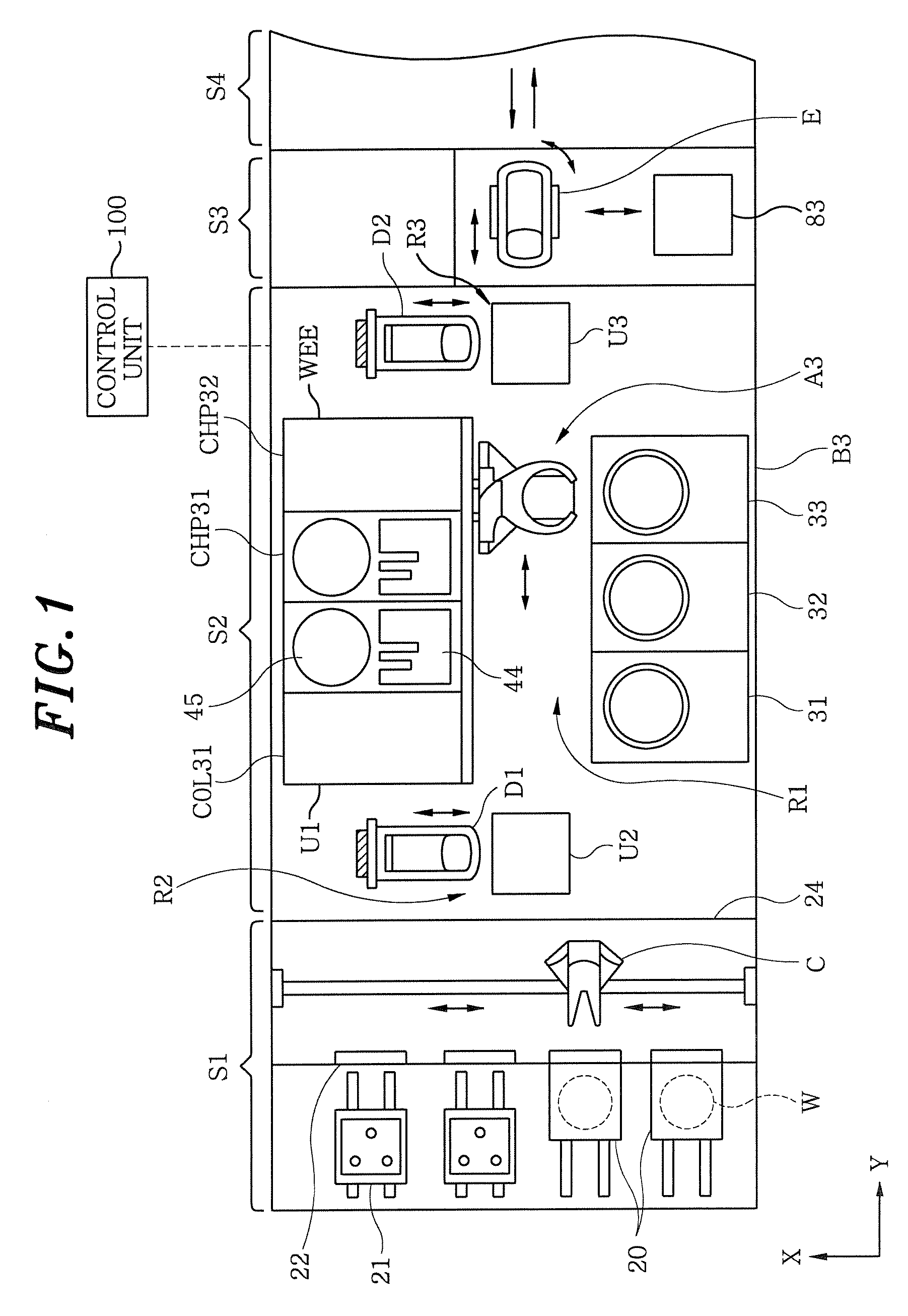

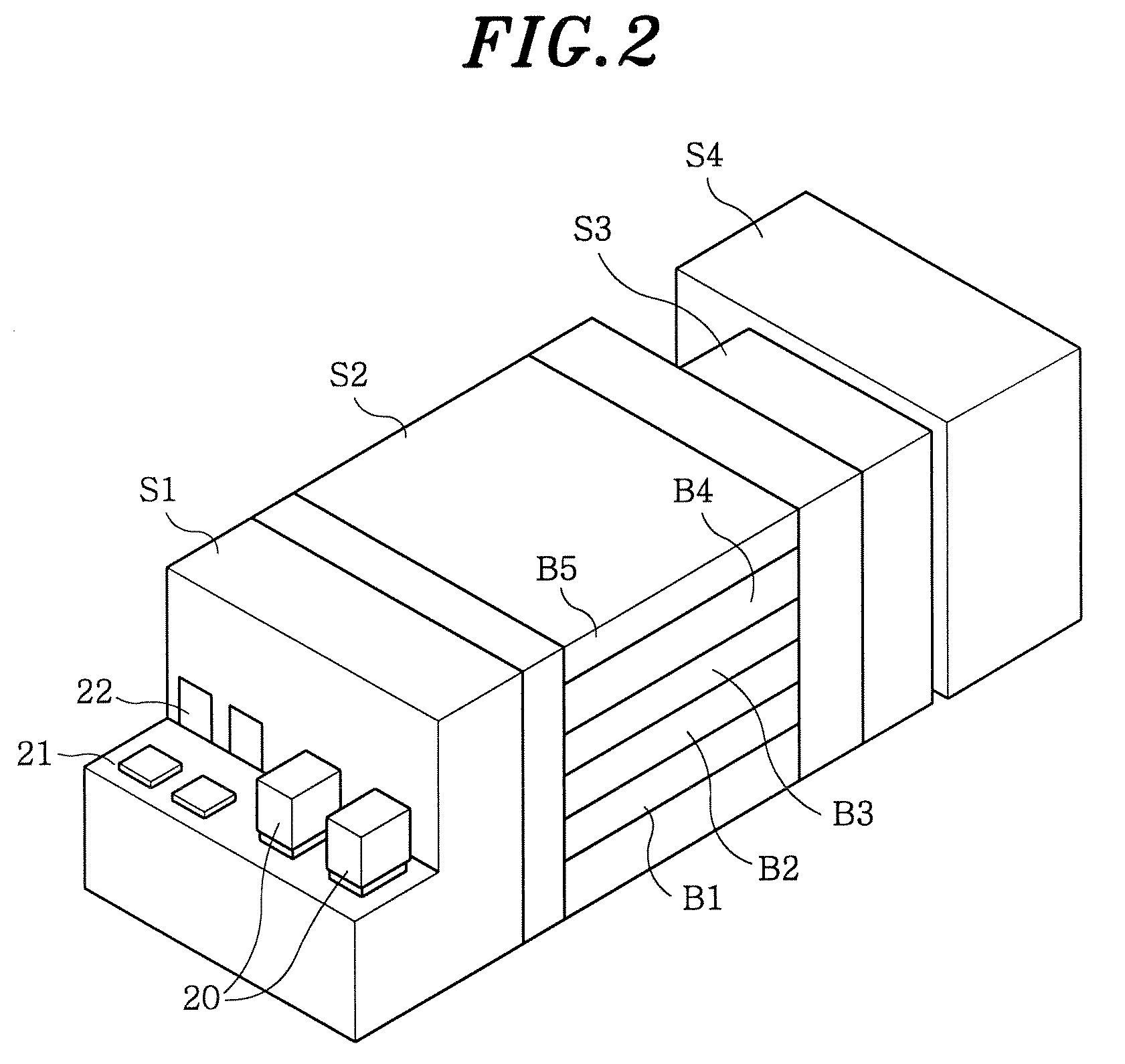

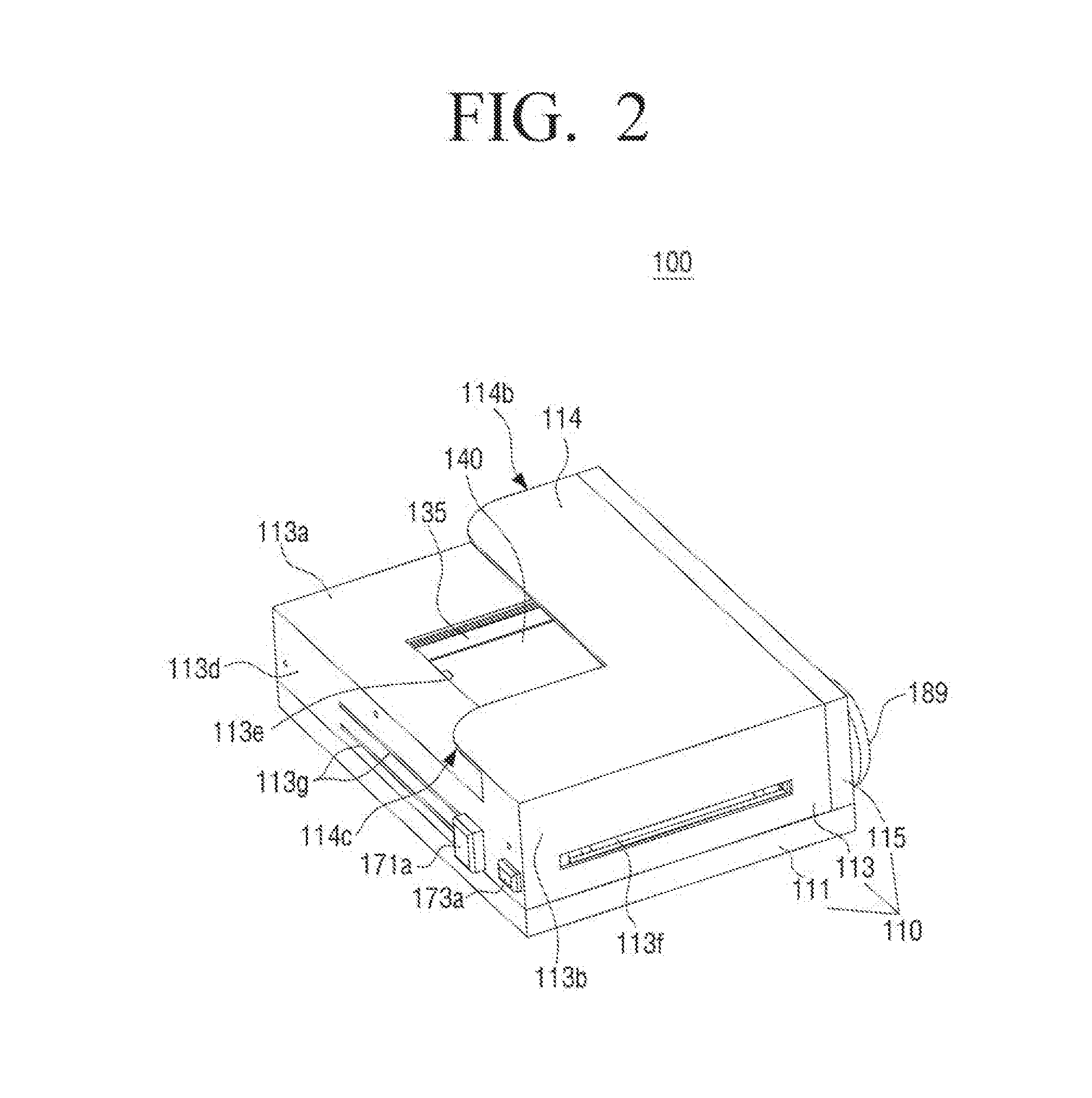

Coating and developing apparatus, substrate processing method, and storage medium

ActiveUS7955011B2Small footprintEliminate disadvantagesLiquid processing by liquid spraysLiquid surface applicatorsEngineeringTransfer mechanism

A coating and developing apparatus is provided which requires a smaller occupation space even when it incorporates a substrate inspection unit, while eliminating a disadvantageous layout. A coating film forming part B3 including a plurality of process units and transfer mechanisms A3 and A4, and a developing part B1 including a plurality of process units 31 and a transfer mechanism A1 are vertically arranged in a process block S2. There are disposed in the process block S2 on a side of a carrier block S1, a plurality of vertically arranged transfer units TRS for transferring a substrate W between the same and transfer mechanisms for the respective parts, and a vertically movable transfer mechanism D1 for the transfer unit for transferring a substrate between these transfer units. At least one of the coating film forming part and the developing part includes a substrate inspection unit 43 for inspecting a substrate transferred by the transfer mechanism for the corresponding part.

Owner:TOKYO ELECTRON LTD

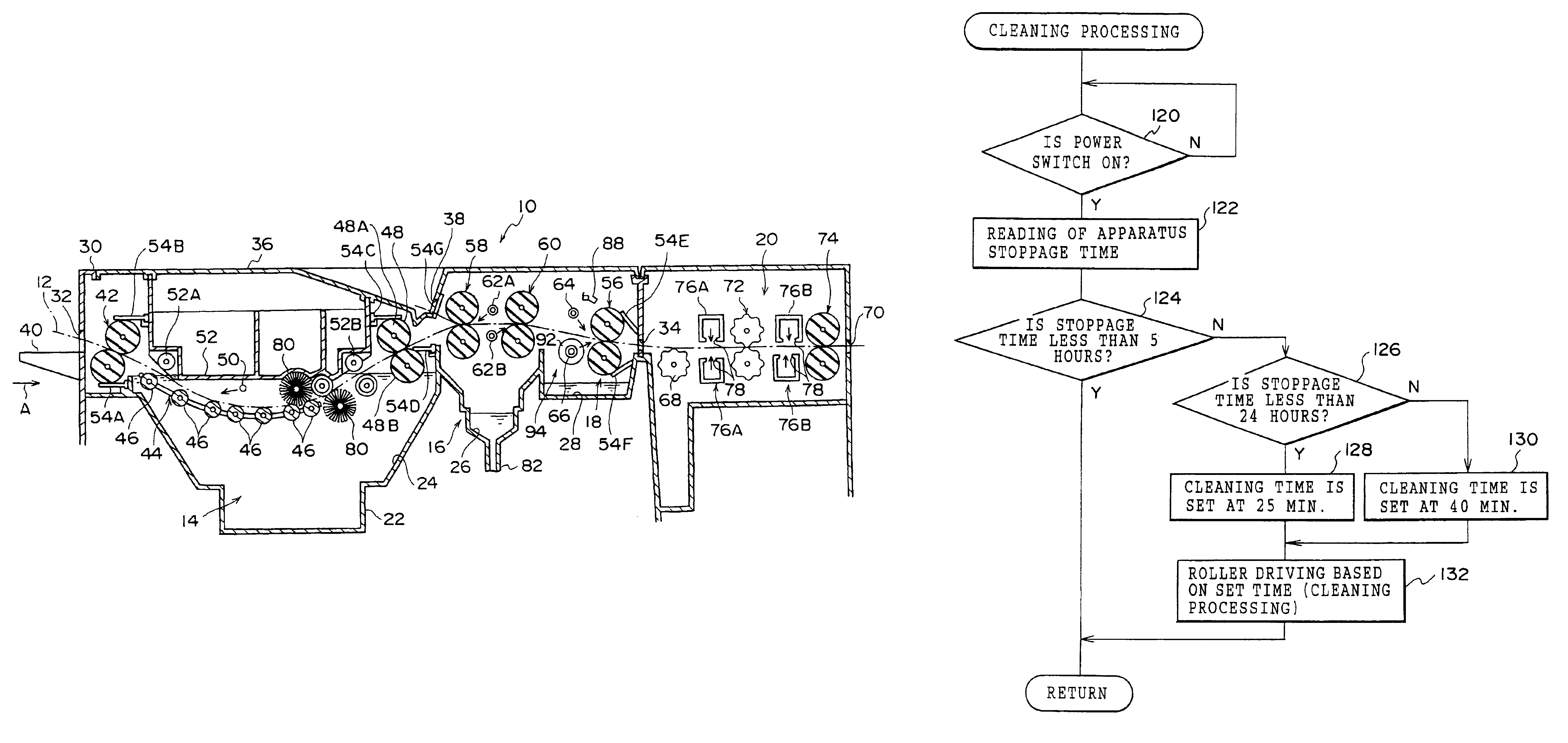

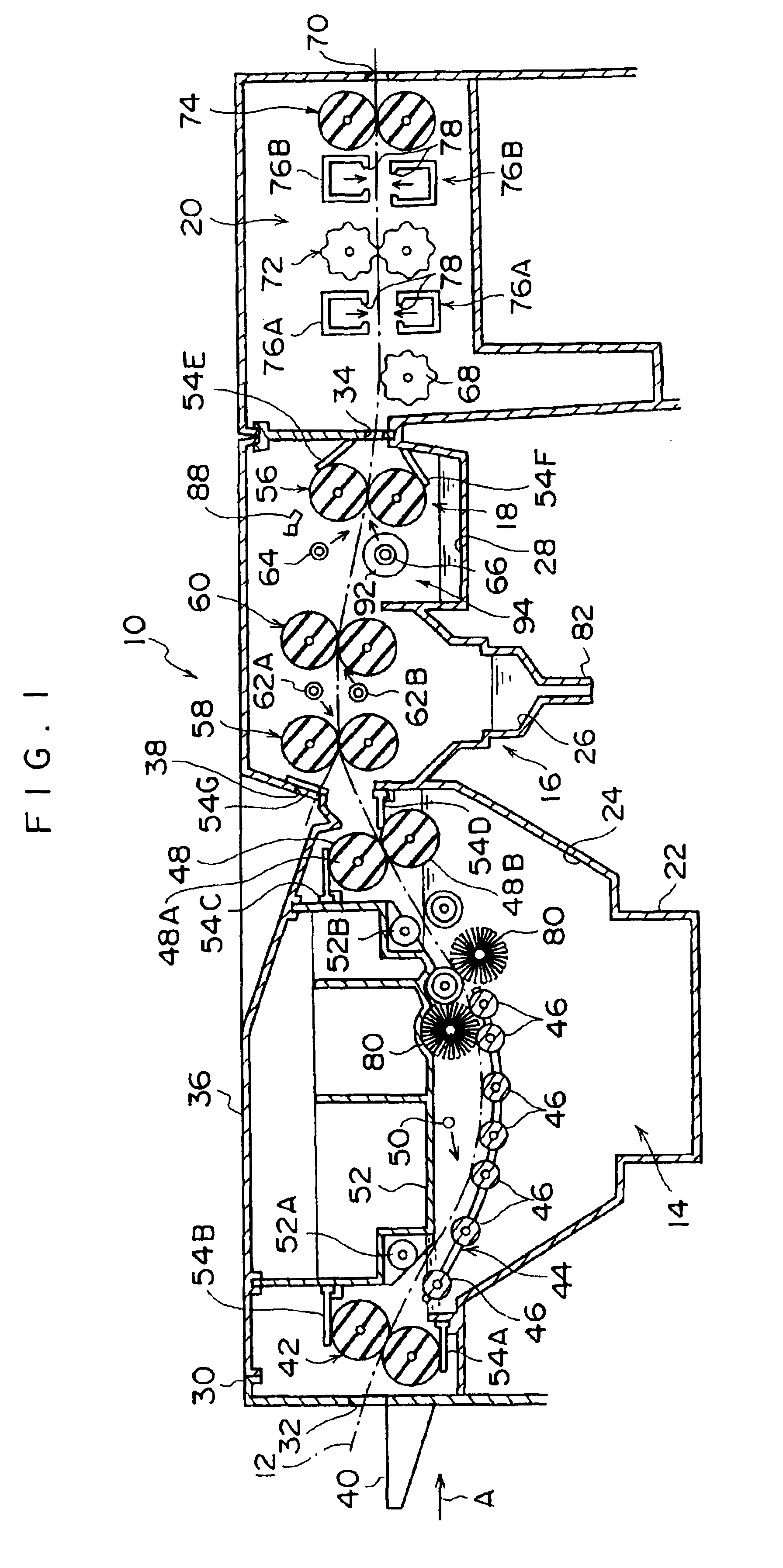

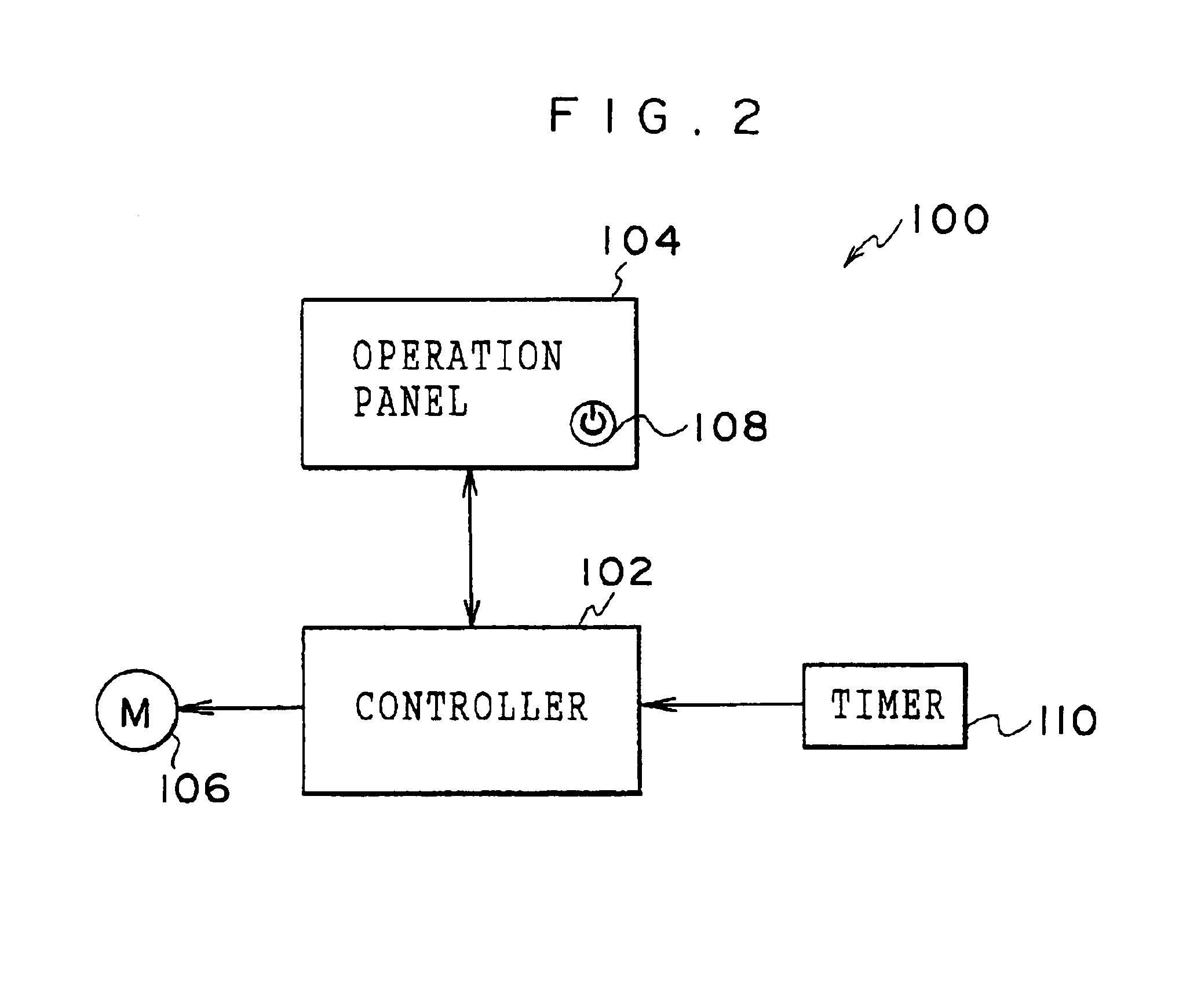

Printing plate processing apparatus

InactiveUS6902330B2Finish quality be deteriorateEfficient and reliable removalLiquid processing by liquid spraysAddressographsEngineeringMechanical engineering

A printing plate processing apparatus provides a step in which a printing plate which has undergone image exposure is processed by being immersed in a developing solution, and the printing plate is delivered while the developing solution is being squeezed out from the printing plate by a conveying roller pair which is partially immersed in the developing solution. A stoppage time of the apparatus is measured, and the conveying roller pair is driven to rotate for an amount of time set in accordance with a measured result of the stoppage time when operation of the apparatus is started, thereby allowing the conveying rollers to be cleaned. A concentration of carbon dioxide in an environment in which the apparatus is installed is detected, and based on the detected result and the measured result of the apparatus stoppage time, the driving time of the conveying roller pair is set.

Owner:FUJIFILM CORP +1

Photographic film developing apparatus

InactiveUS6739769B2Liquid processing by liquid spraysLiquid processing with progressive mechanical movementEmulsionBiochemical engineering

A photographic film developing apparatus maintains a photographic film, a developer solution and a second processing solution at a specific temperature while performing film development operation by directly applying the individual solutions to an emulsion side of the photographic film. After the developer solution and the second processing solution have been applied from respective processing solution application heads to the emulsion side of the photographic film, the quantity of each solution on the emulsion side is adjusted to form a layer of a specified thickness. While transfer belts advance each successive portion of the photographic film up to a processing solution wipe-out device, heaters provided close to the transfer belts heat the individual solutions applied to the photographic film through the transfer belts to maintain the solutions at the specific temperature.

Owner:NORITZ CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com