Reducing foam formation

A foam, developer technology applied to the oxidation of developer liquid. field, which can solve problems such as reduced performance of plate development processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention describes a developer liquid circulation system in a printing plate developing system that significantly reduces the resulting foam formation during injection of developer liquid into a developer liquid container. The resulting foam accelerates the oxidation process of the developer liquid due to its inherently large surface area exposed to air.

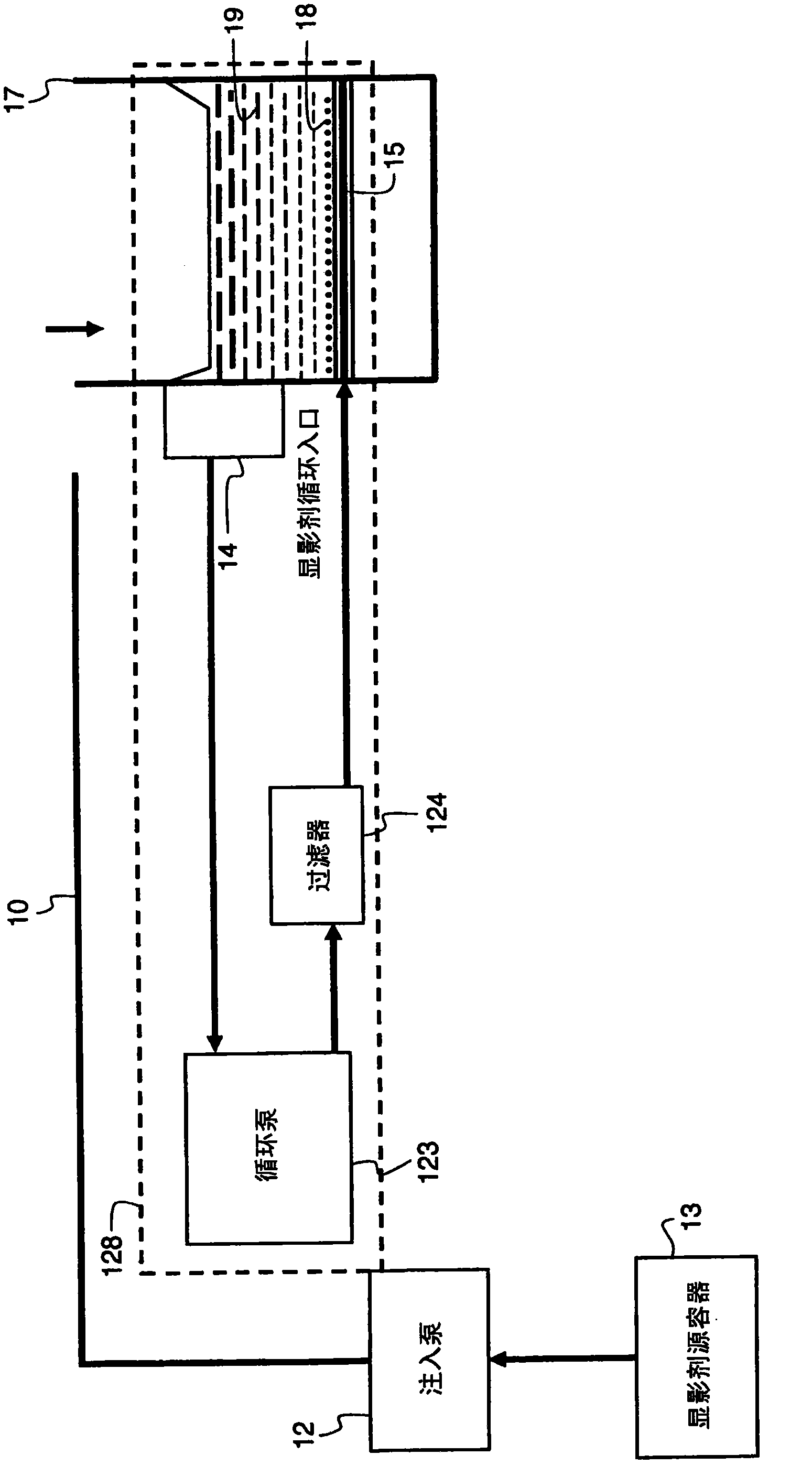

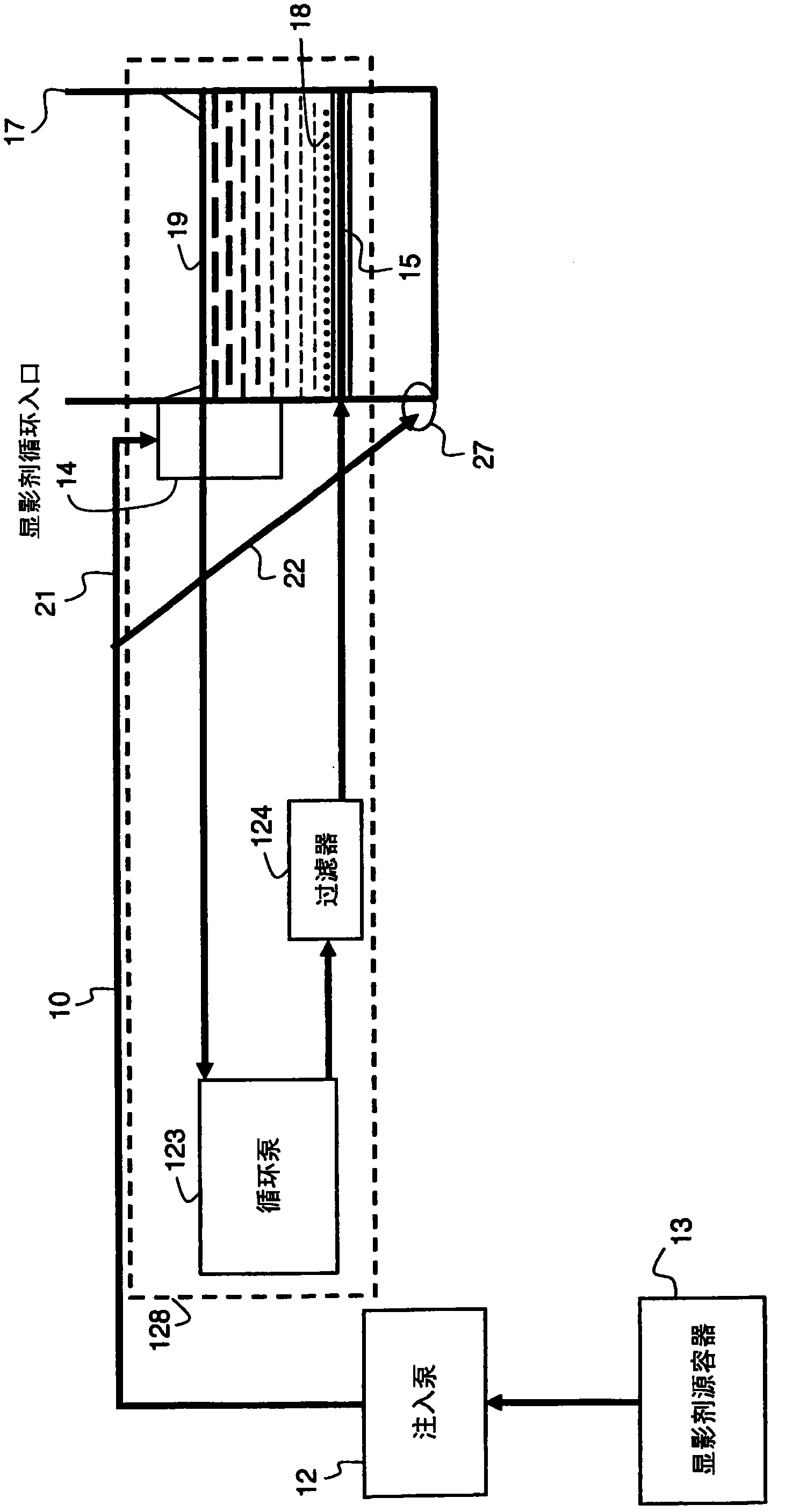

[0009] Figure 1 shows a prior art developer circulation and injection system. figure 2 The essence or basic content of the improved developer circulation and injection system proposed by the present invention to reduce foam formation is shown. Injection pump 12 pumps developer liquid from developer source container 13 into developer liquid container 17 via main injection line 10 .

[0010] The main injection line 10 is split or separated into two line sections. The first pipeline segment 21 is used to flow the developer liquid into the circulation system 128 . The circulation system includes a develope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com