Stirring type wet process machine and stirring type wet process

A wet process and machine technology, applied in printed circuit manufacturing, electrical components, liquid spray liquid treatment, etc., can solve the problem that the line width and spacing of circuit boards cannot meet the line width and spacing of high-density circuit boards, water stagnation, etc. , to achieve the effect of improving manufacturing precision, improving process precision, improving quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

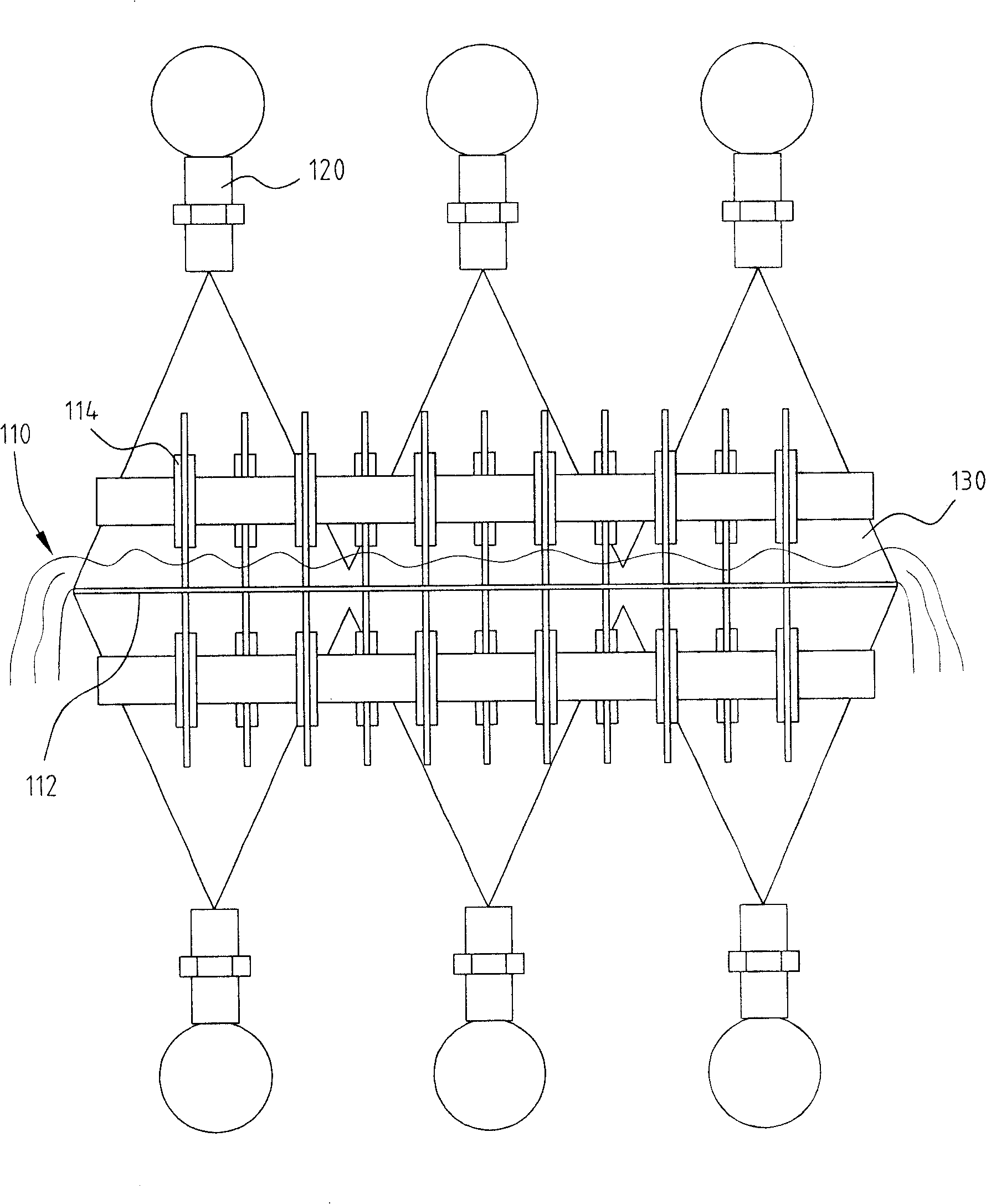

[0022] The following will take the manufacturing process of the circuit board as an example to illustrate the concept of the present invention, but the present invention is not limited to the manufacturing process of the circuit board. In fact, due to the advancement and development of science and technology in recent years, the wet process has been applied to circuit boards from the early stage, and has spread to other industries. Now, whether it is semiconductor, liquid crystal display or plasma display panel production, it can See examples of successful wet process applications in these industries. Therefore, the present invention can also be applied to the above-mentioned industries to improve the process quality of these industries.

[0023] The manufacturing of circuit boards can be divided into three categories according to their manufacturing types: mechanical processing, wet process and image transfer. Among them, the wet process mainly refers to the process involvin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com