Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Low chlorine content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

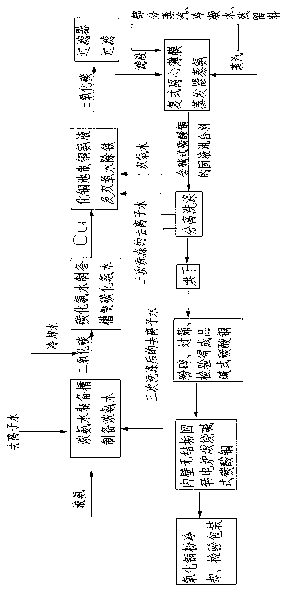

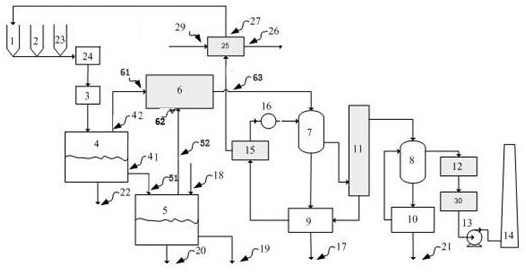

Plasma fly ash fusion treatment and metal recycling system

ActiveCN108704926ARealize deep purificationRealize harmless treatmentElectrostatic separationTransportation and packagingPollutantActivated carbon

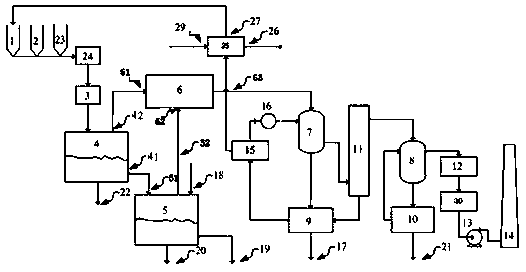

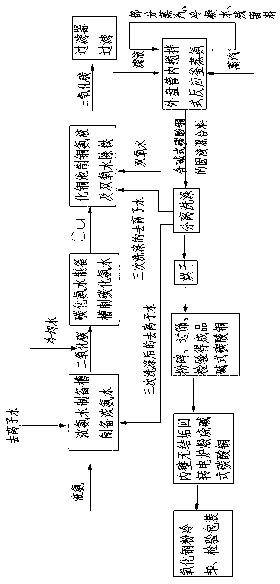

The invention discloses a plasma bottom ash and fly ash fusion treatment and metal recycling system. The plasma bottom ash and fly ash fusion treatment and metal recycling system comprises a feeding device, a two-segment type ash fusion device, a combustion chamber, a wet type temperature reduction washing device, a demister, an activated carbon material layer and an induced draft fan. The feedingdevice is connected with the two-segment type ash fusion device. The two-segment type ash fusion device is connected with the combustion chamber. The combustion chamber is connected with the wet typetemperature reduction washing device. The wet type temperature reduction washing device is connected with the demister, and the demister is connected with the activated carbon material layer. The activated carbon material layer is connected with the induced draft fan. The two-segment type ash fusion device is adopted in the plasma bottom ash and fly ash fusion treatment and metal recycling system, harmless treatment of bottom ash and fly ash is achieved, and meanwhile alkali metal and heavy metal in the bottom ash and the fly ash and other metal reduced in a fusion furnace are recycled; through the combustion chamber, it is guaranteed that combustible components in smoke and other pollutants are sufficiently removed; and through the wet type temperature reduction washing device, capturingrecycling of the alkali metal, the heavy metal and other volatile salt substances and deep purification of smoke are achieved.

Owner:加拿大艾浦莱斯有限公司 +1

Method for preparing high-activity electroplating grade copper oxide from basic cupric carbonate

InactiveCN103101958AGuaranteed purityOvercoming the disadvantages of static calcinationCopper oxides/halidesBASIC CUPRIC CARBONATEBasic copper carbonate

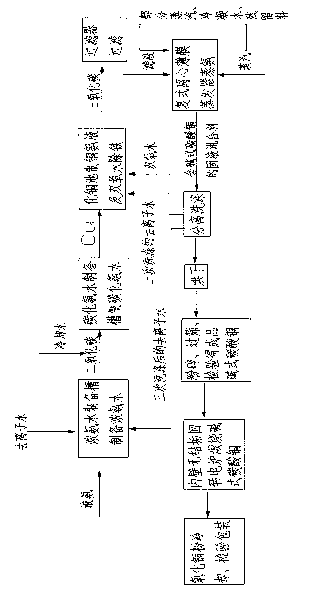

The invention discloses a method for preparing high-activity electroplating grade copper oxide from basic cupric carbonate. According to the method, pure copper, liquid nitrogen and high-purity carbon dioxide are taken as materials to prepare the high-purity basic cupric carbonate through a centrifugal film evaporator or a scraper reaction kettle; the problem of impurities such as chlorine which may be caused by production of the basic cupric carbonate material by the traditional method is avoided; the purity of the basic cupric carbonate is improved; the high-purity low-chorine electroplating grade copper oxide is burnt from the high-purity basic cupric carbonate through a rotary kiln; the defects of inactivation, a plurality of impurities, large labor intensity, un-continuous production, long period, high energy consumption, large cost and the like due to the fact that the basic cupric carbonate at the low-temperature part is not burnt thoroughly and the content is not enough when a pushed slab kiln statically burns while copper oxide at the high-temperature part is burnt to death are overcome; the product activity is ensured; and the method is high in product quality, less in energy consumption, small in cost and more environment-friendly.

Owner:TAIXING SMELTING PLANT

Chlorinated propylene random copolymer and compositions containing the same

A novel binder resin which attains good adhesion to various substrates such as polyolefin resins, vinyl chloride resins, polycarbonate resins, polyethylene terephthalate resins, acrylonitrile / butadiene / styrene resins, and nylon resins even by low-temperature baking and is excellent in solvent solubility. Namely, a chlorinated propylene random copolymer produced by subjecting a propylene random copolymer which is obtained by copolymerizing propylene with other alpha-olefin by using a metallocene catalyst as the polymerization catalyst and which has a melting point (Tm) of less than 115 DEG C as determined with a differential scanning calorimeter (DSC) to degradation by heat preferably at a temperature ranging from the melting point of the copolymer to 350 DEG C and chlorination successively.

Owner:NIPPON PAPER CHEM

Method for continuously preparing high-purity low-chloride electroplating copper oxide

InactiveCN103011251AHigh purityQuick responseCopper oxides/halidesBASIC CUPRIC CARBONATEBasic copper carbonate

Owner:TAIXING SMELTING PLANT

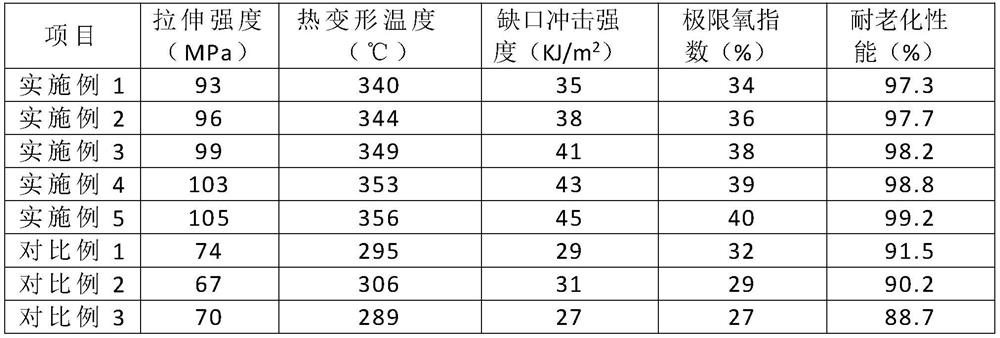

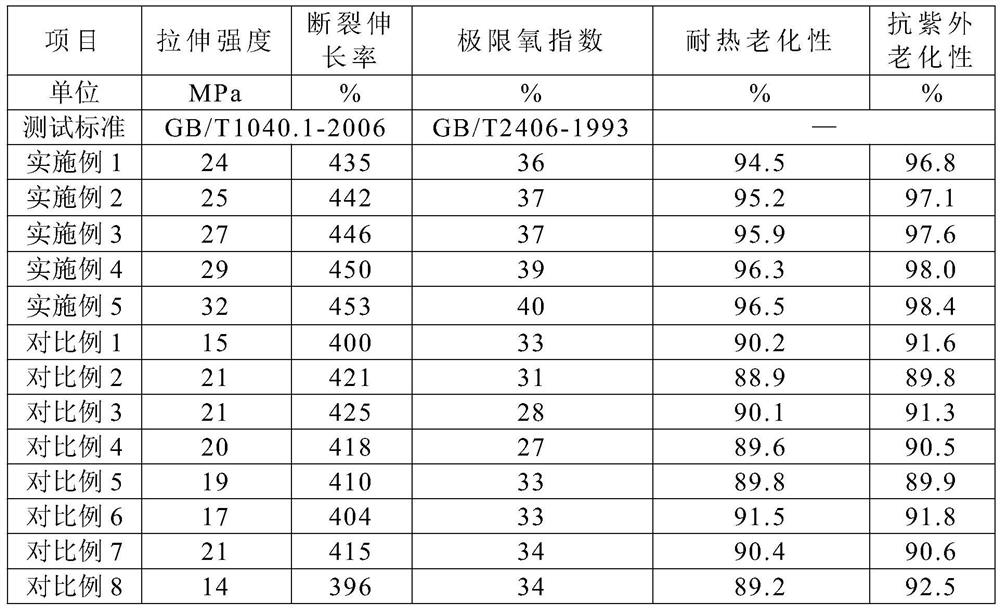

Anti-aging plastic material and preparation method thereof

The invention discloses a preparation method of an anti-aging plastic material. The preparation method is characterized by comprising the following steps: step S1, preparing 5-allyl-3-methoxysalicylic acid methyl ester / 2-[3-(2H-benzotriazol-2-yl)-4-hydroxyphenyl]ethyl methacrylate / 2-acrylamido-2-methylpropanesulfonic acid / acrylonitrile / lambda-cyhalothric acid copolymer; step S2, preparing a benzoguanamine / 2,5-bis(1,2,4-triazol-1-yl)terephthalic acid polycondensation polymer; and step S3, forming the plastic material. The invention also provides the anti-aging plastic material prepared according to the preparation method of the anti-aging plastic material. The anti-aging plastic material provided by the invention is good in comprehensive performance, good in performance stability and excellent in anti-aging performance, weather resistance and mechanical performance.

Owner:纪道红

Method for producing tapping paraffin serving as polyurethane foam crack filler

ActiveCN105733273ALow chlorine contentImprove balancePetroleum chemical modificationParaffin waxHigh carbon

The invention discloses a method for producing tapping paraffin serving as polyurethane foam crack filler.The method comprises the following steps of adding heavy liquid wax into a reaction kettle; introducing chlorine into the reaction kettle, and controlling the reaction temperature; after the heavy liquid wax reacts with the chlorine for a while, detecting the density of chlorinated paraffin, and then blowing off hydrogen chloride gas; after the hydrogen chloride gas is blown off, detecting the acid value, and then adding compound heat stabilizer, so that the tapping paraffin is obtained.The method for producing the tapping paraffin has the advantages that the temperature of the reaction conducted between the heavy liquid wax and chlorine and the introducing amount of chlorine are controlled, so that low-carbon-chain constituents maintain low chlorine content, high-carbon-chain constituents have high chlorine content, chlorine elements are uniformly distributed on the heavy liquid wax, the distribution mode is beneficial to foam hole balance of the polyurethane foam crack filler, in addition, foam holes can emerge to be of a netted structure, and untoward effects such as enlarged foam holes and messy foam cannot be caused.

Owner:SHIJIAZHUANG DONGXIANG CHEM CO LTD

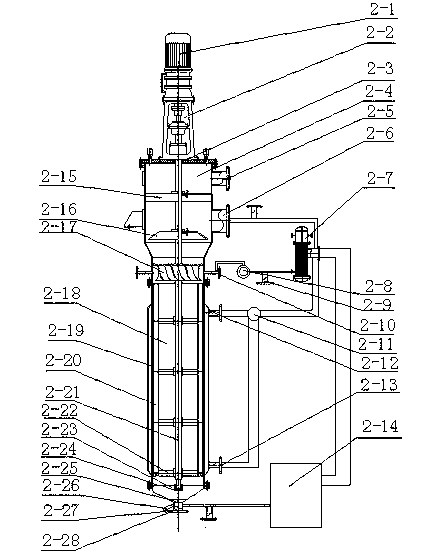

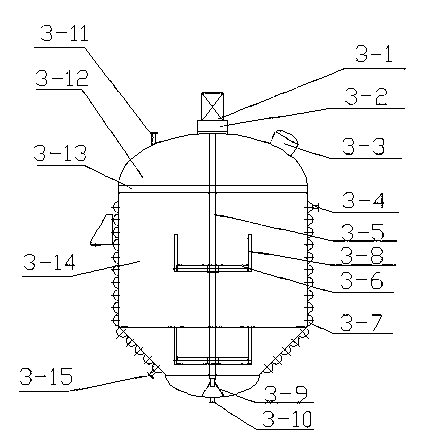

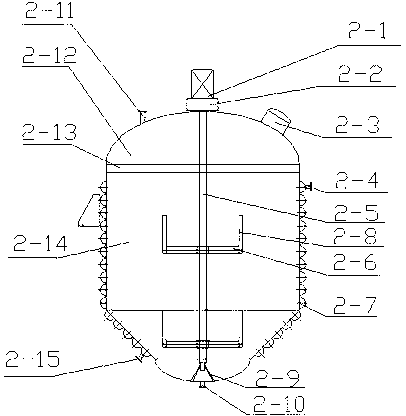

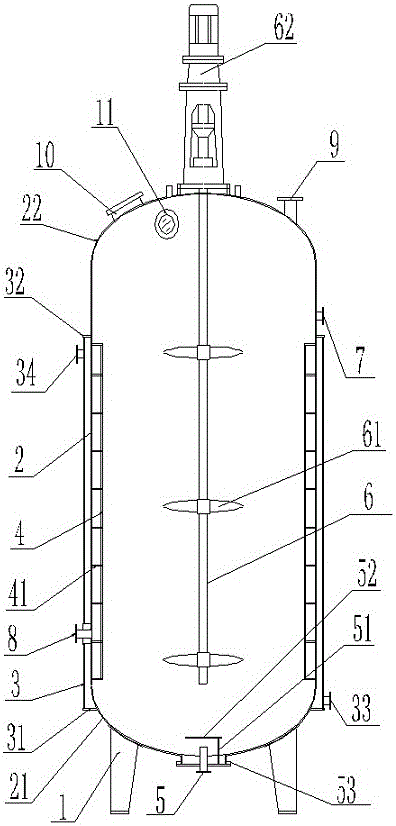

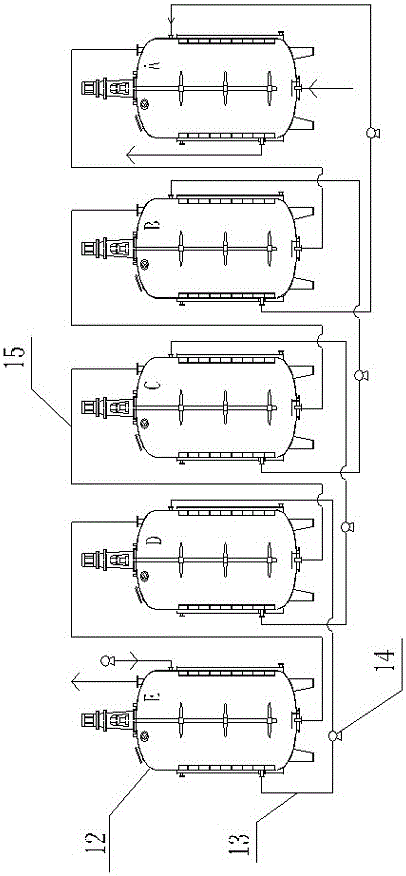

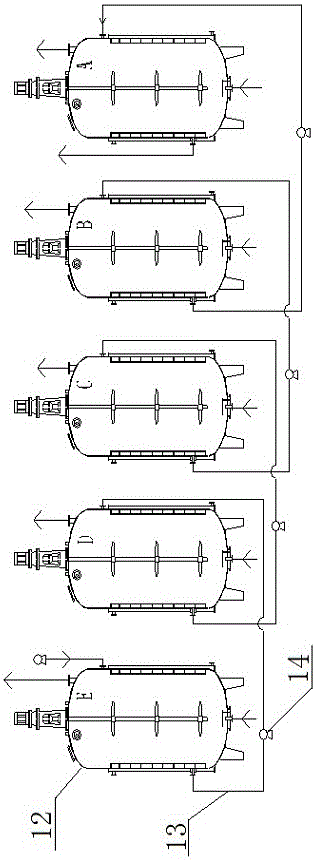

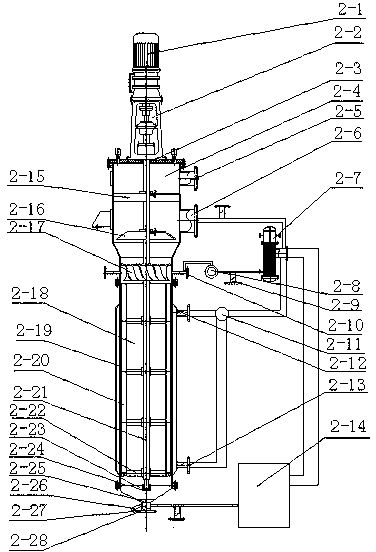

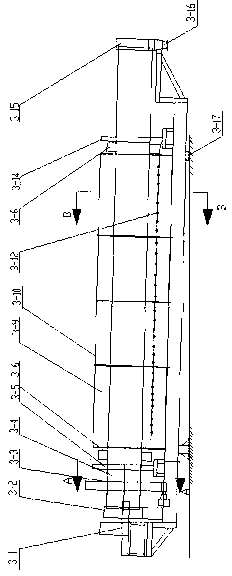

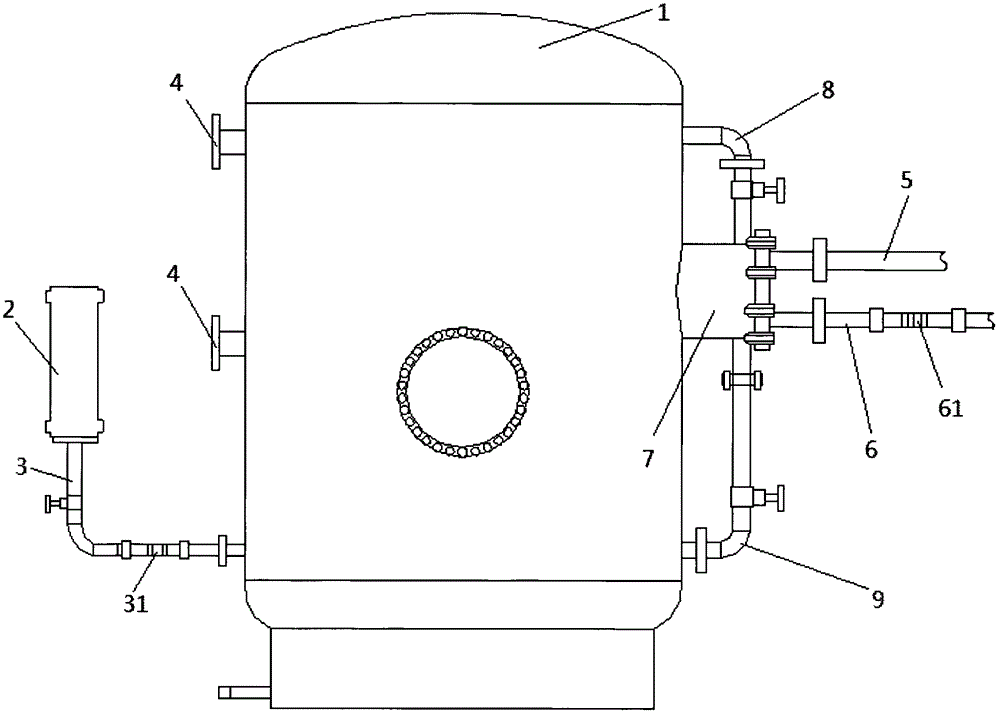

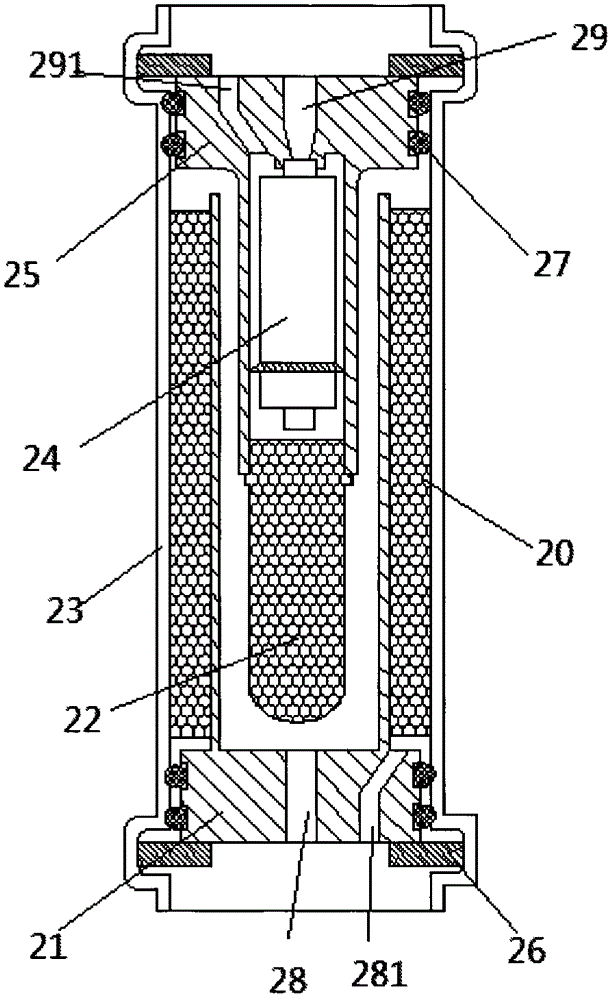

Carbonating tower, carbonating system and method

InactiveCN105731500AImprove mass transfer conditionsPromote absorptionAlkali metal carbonatesTowerCarbonation

The invention relates to a carbonation tower, a carbonation system and a method, comprising a tower shell, a cooling water tank, an air inlet, an air outlet, a feed port and a discharge port arranged on the tower shell, and a The stirring shaft, the motor connected to the stirring shaft, the stirring blades fixed on the stirring shaft, the inner side of the tower shell is fixed with a baffle, the carbonation system consists of a plurality of carbonation towers connected; the gas outlet of the carbonation tower is connected with a single Or the inlets of multiple carbonation towers are connected through gas connecting pipes, or the inlets of the carbonation towers are fed separately, and the gas outlets of the carbonation towers are directly exhausted. The above two connection methods are freely combined; The discharge port communicates with the feed ports of one or more carbonation towers through feed-liquid connecting pipes. The structure in the carbonation tower of the present invention is simple, no fouling and blockage, simple control, and the prepared product has coarse crystal particles, containing Chlorine is low.

Owner:湖南海联三一小苏打有限公司

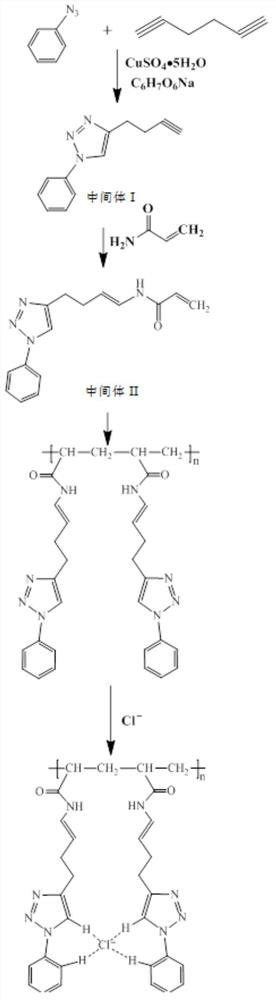

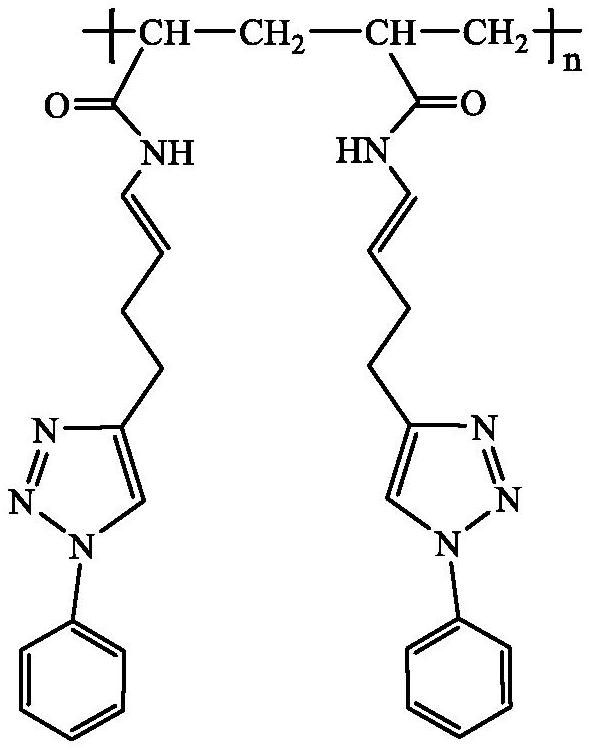

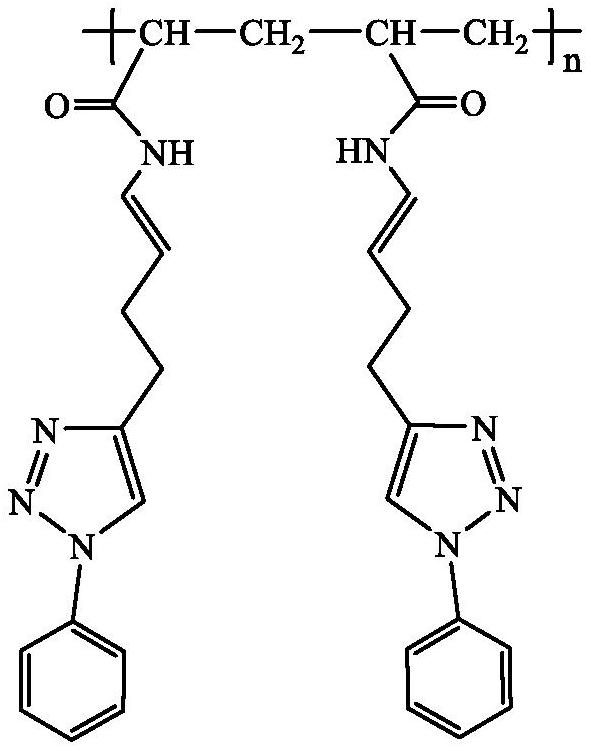

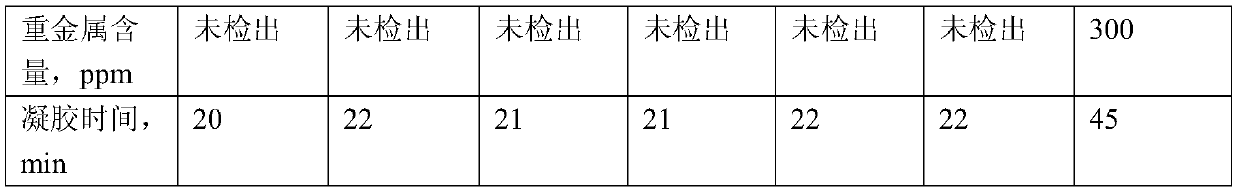

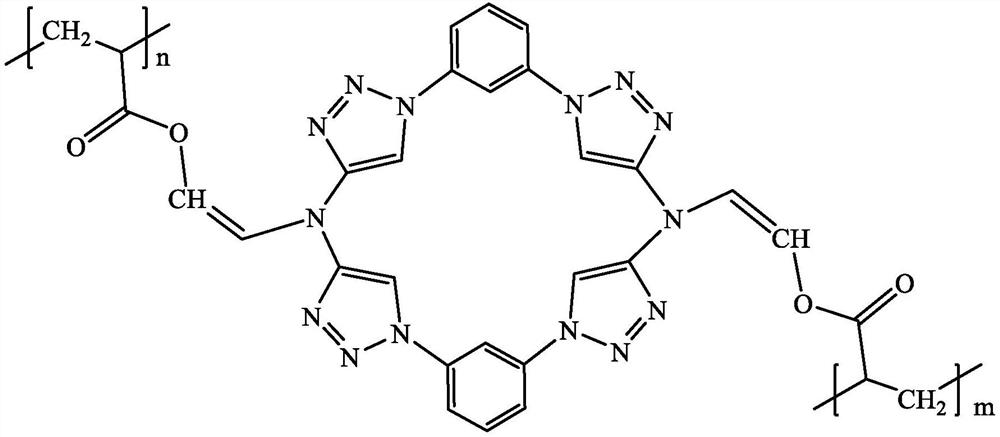

Epoxy resin dechlorinating agent as well as preparation method and application thereof

The invention provides an epoxy resin dechlorinating agent as well as a preparation method and application thereof. According to the epoxy resin dechlorinating agent, 1, 5-hexadiyne and azidobenzene serve as raw materials, copper sulfate pentahydrate and sodium ascorbate serve as catalysts, an intermediate I is obtained through the click reaction of azide and alkyne, then an intermediate II is obtained through the addition reaction of alkyne and amino, and finally the epoxy resin dechlorinating agent is obtained through the polymerization reaction of end-group double bonds. The epoxy resin dechlorinating agent has a cyclic structure and has high affinity and selectivity to chloride ions, four polarized C-H bonds exist on a 1, 2, 3-triazole ring and a benzene ring, the chloride ions in epoxy resin can be stably captured, and the epoxy resin dechlorinating agent can be recycled while the chlorine content of the epoxy resin is reduced.

Owner:智仑超纯环氧树脂(西安)有限公司

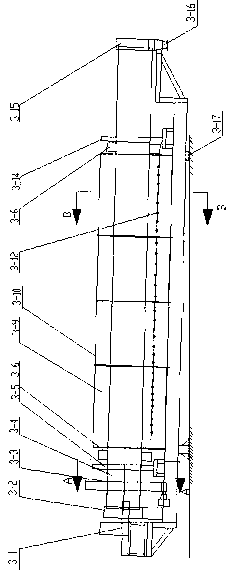

Rotary electric furnace and method thereof for preparing high-activity electro-plated copper oxide

InactiveCN103101959AGuaranteed purityOvercoming the disadvantages of static calcinationProductsReagentsHigh energyBasic copper carbonate

The invention discloses a rotary electric furnace and a method for preparing high-activity electro-plated copper oxide by using the rotary electric furnace. At least one percussion device is arranged on the outer wall of the furnace barrel of the rotary electric furnace, wherein the furnace barrel percussion device comprises a hollow cavity and a sphere; one end of the hollow cavity is open and the other end of the hollow cavity is closed, wherein the opening end is fixed on the outer wall of the furnace barrel; the sphere is movably arranged in the hollow cavity; the sphere moves up and down in the hollow cavity to form a clearance percussion status with the outer wall of the furnace barrel during the rotary process of the furnace barrel; the method for preparing the high-activity electro-plated copper oxide comprises the following steps of: preparing high-purity alkali type copper carbonate by adopting pure copper, liquid ammonia and high-purity carbon dioxide as materials; and obtaining the high-activity electro-plated copper oxide through roasting in the rotary electric furnace. According to the rotary electric furnace and the method for preparing the high-activity electro-plated copper oxide by using the rotary electric furnace, the defect that the low-temperature part is insufficient due to insufficient burning and the high-temperature part is burnt through during a static roasting process of the pushed slab kiln is overcome; moreover, the defects such as inactivity, a plurality of impurities, discontinuous production, long period, high energy consumption, high cost and the like are overcome, so that the activity of the product is ensured. Besides, the product quality is high, the energy consumption is less, the cost is low and the environment-friendliness is better.

Owner:TAIXING SMELTING PLANT

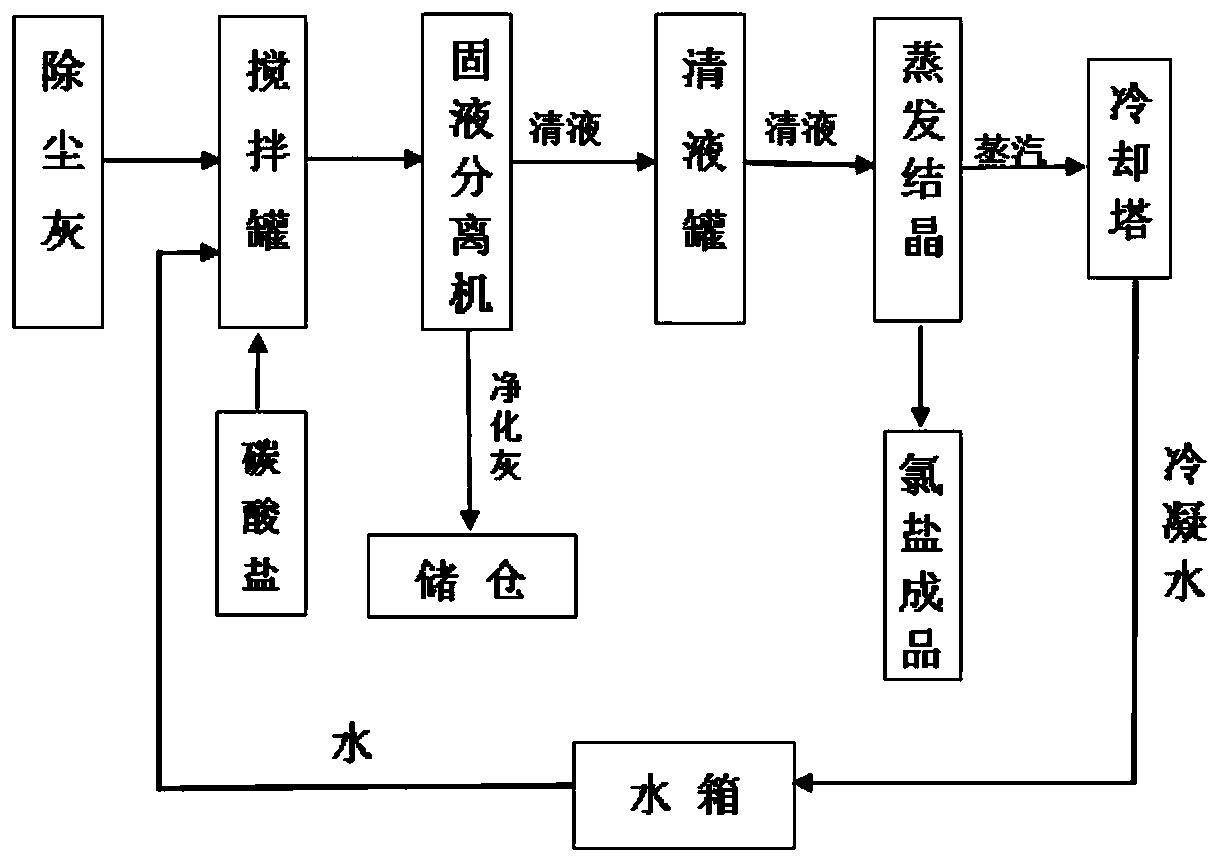

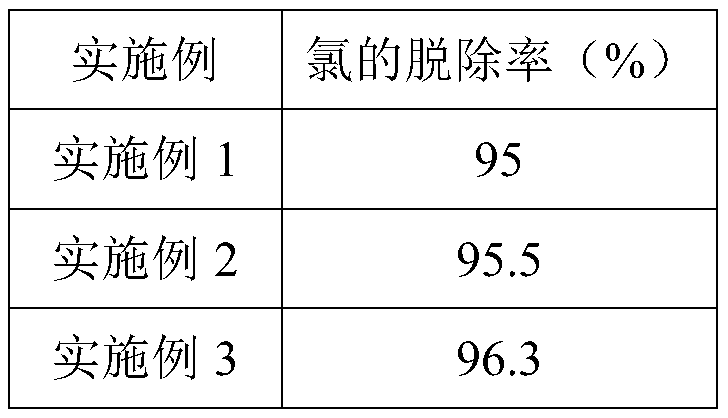

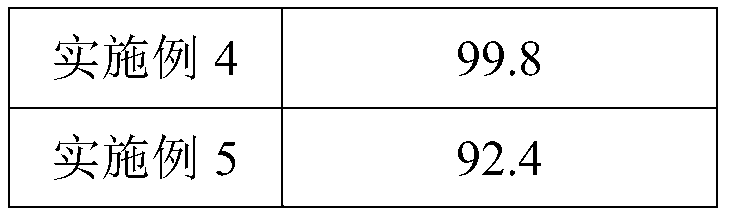

Method for removing chlorine from fly ash

PendingCN111375623ALow chlorine contentRealize added valueSolid waste disposalTransportation and packagingChlorideFilter press

The invention belongs to the technical field of fly ash, and particularly relates to a method for removing chlorine from fly ash. The invention provides a method for removing chlorine from fly ash. The method comprises the following steps of 1) adding fly ash, water and alkali carbonate into a stirring tank; stirring for 1-10 minutes at the temperature of 20-80 DEG C to obtain a mixture; 2) carrying out solid-liquid separation on the mixture obtained in the step 1); and 3) sending the solid obtained in the step 2) back to an original fly ash recovery system of an enterprise for recycling; andcarrying out post-treatment on the liquid obtained in the step 2). According to the method, water and alkali metal carbonate are added into the fly ash, and then solid-liquid separation is carried outthrough a filter press to obtain the dechlorinated purified ash, so that the chlorine content is greatly reduced, and the recovered alkali metal chloride can be used as industrial salt; and the resource comprehensive utilization of the fly ash without secondary pollution is realized.

Owner:上海宝叶冶金技术有限公司 +1

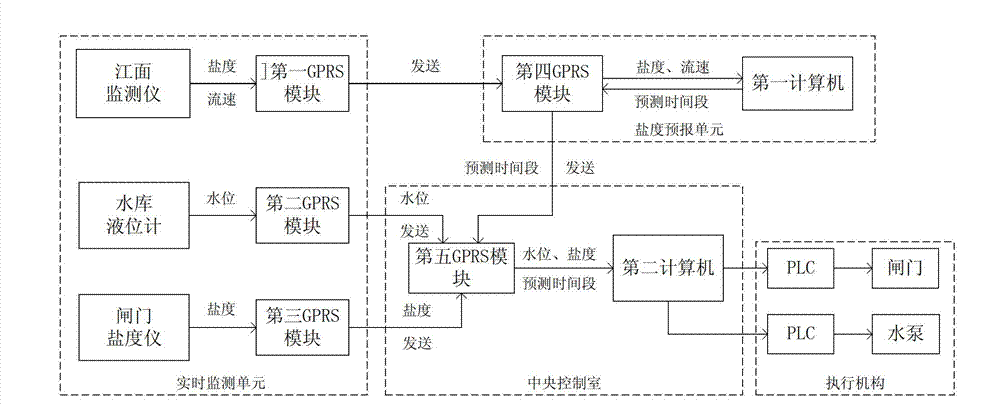

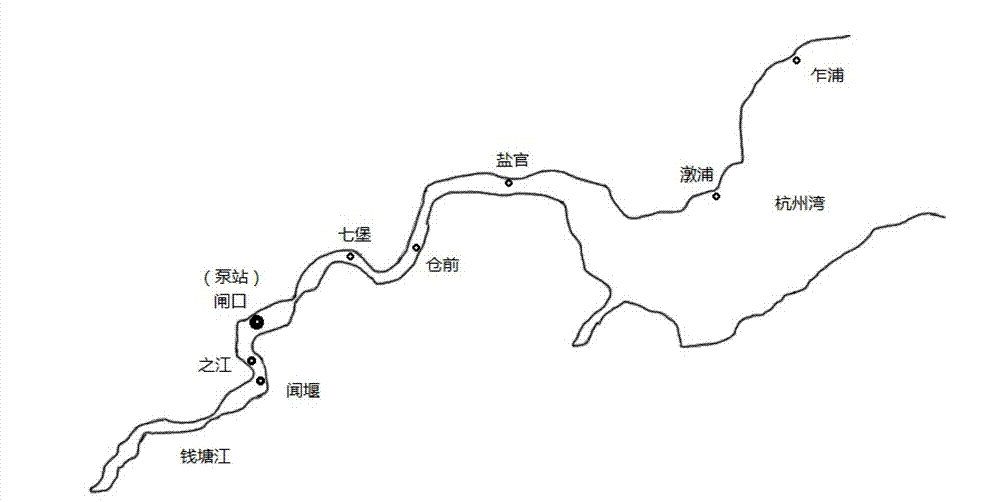

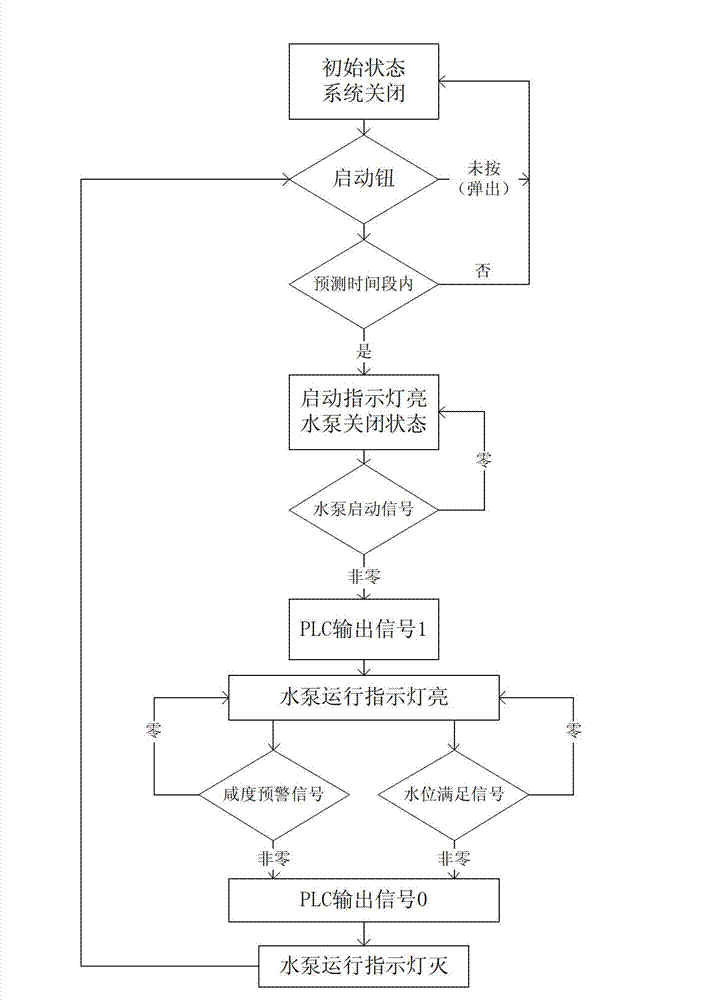

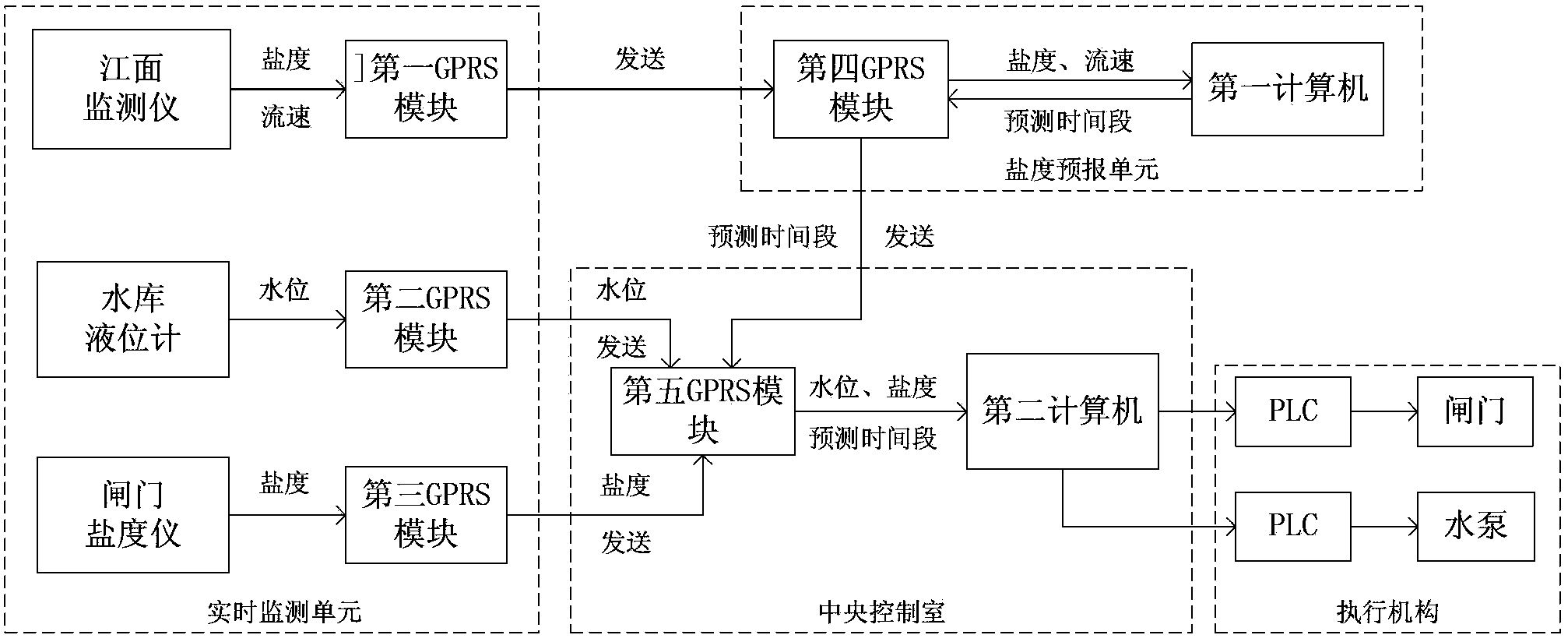

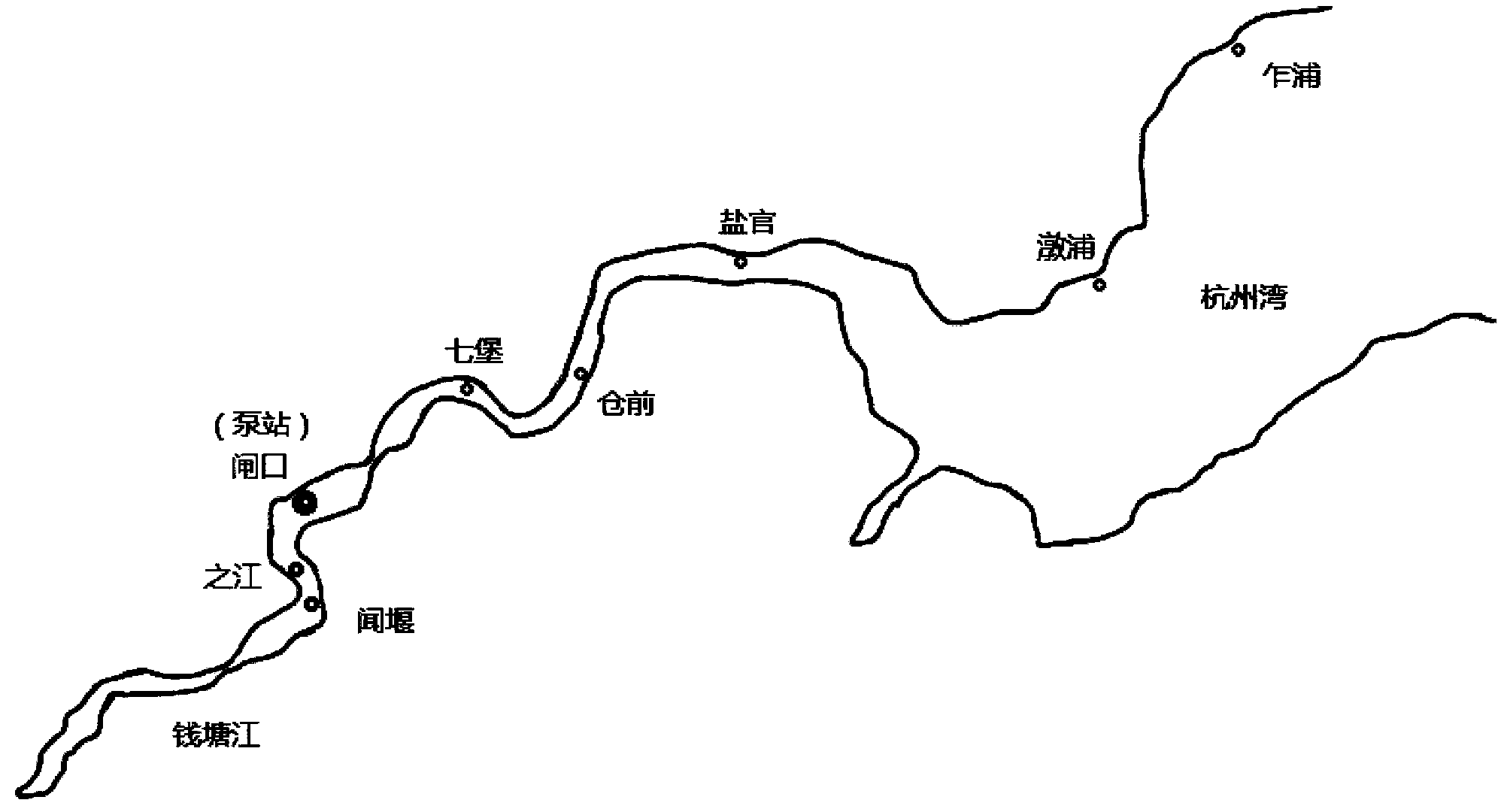

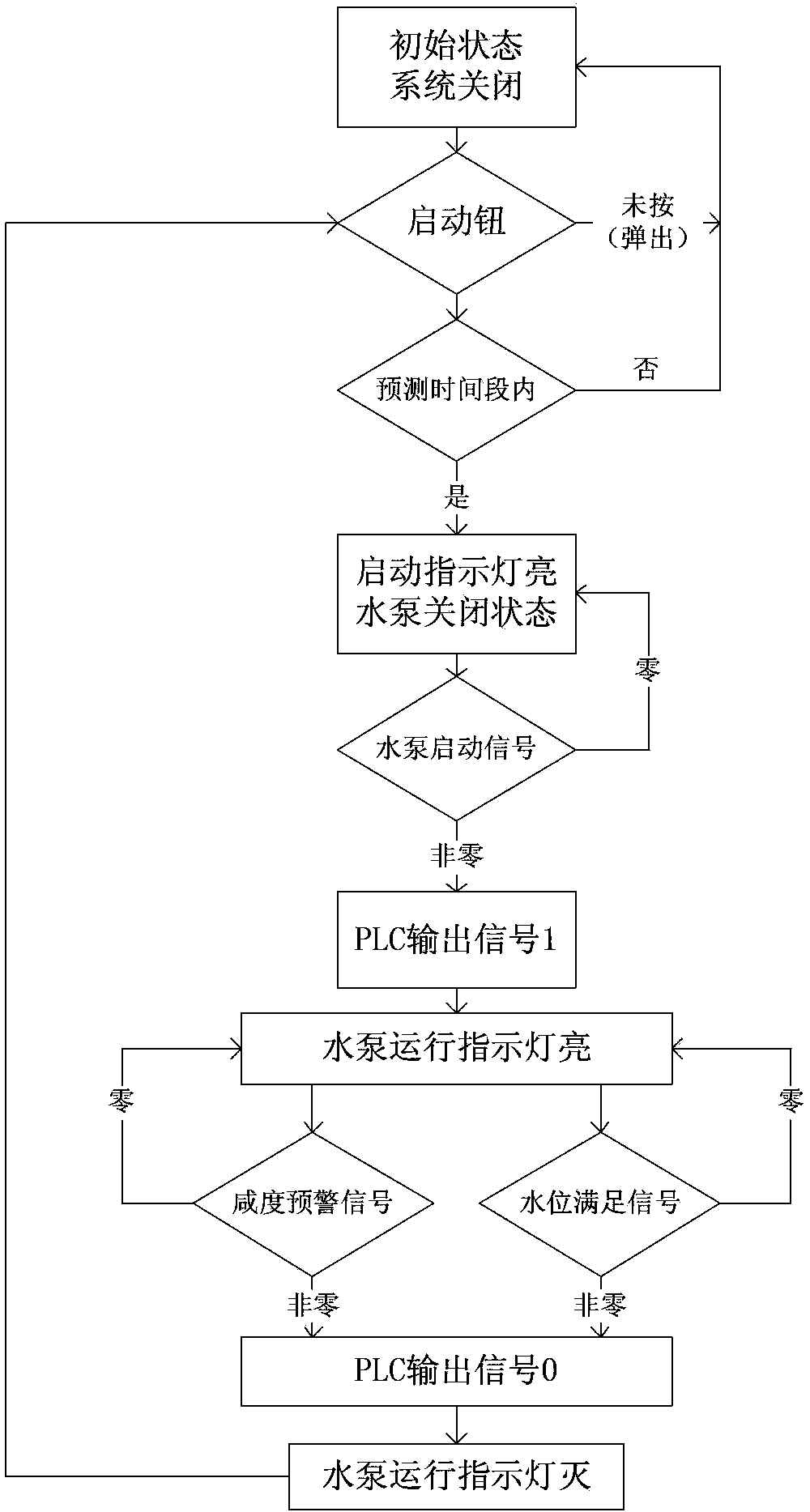

Automatic dispatch control system and method of salty prevention pumping station

ActiveCN102900124AReduce wasteLow chlorine contentPumping plantsDrinking water installationProgrammable logic controllerSalt water

The invention discloses an automatic dispatch control system and a method of a salty prevention pumping station, wherein the system is composed of a real-time monitoring unit, a salinity forecasting unit, a central control chamber and an actuating mechanism and the like; the real-time monitoring unit is composed of a plurality of groups of river surface monitors, a reservoir liquidometer, a gate salinity meter and a plurality of GPRS (General Packet Radio Service) modules; the salinity forecasting unit is composed of a first computer and a fourth GPRS module, which are connected through an RS232 serial port bus, the central control chamber is composed of a second computer and a fifth GPRS module, which are connected through an RS232 serial port bus, and the actuating mechanism is composed of a gate, a plurality of water pumps and a plurality of PLCs (Programmable Logic Controller); and the automatic dispatch control system disclosed by the invention can be used for effectively avoiding the salt water from entering water works and guaranteeing the chlorosity of the water of the water works to be minimum under the harsh condition of low water combined with spring tide.

Owner:ZHEJIANG UNIV

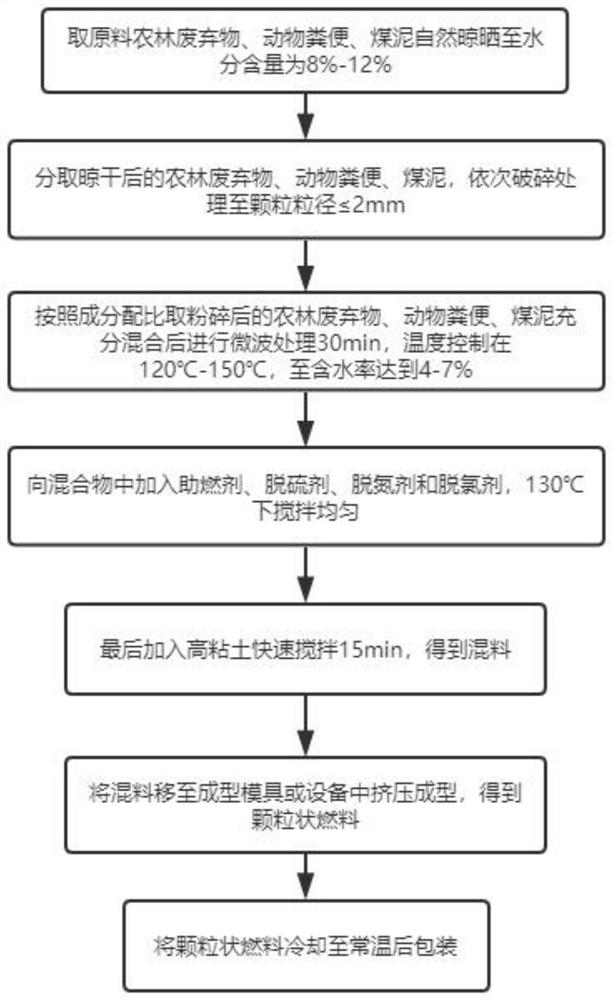

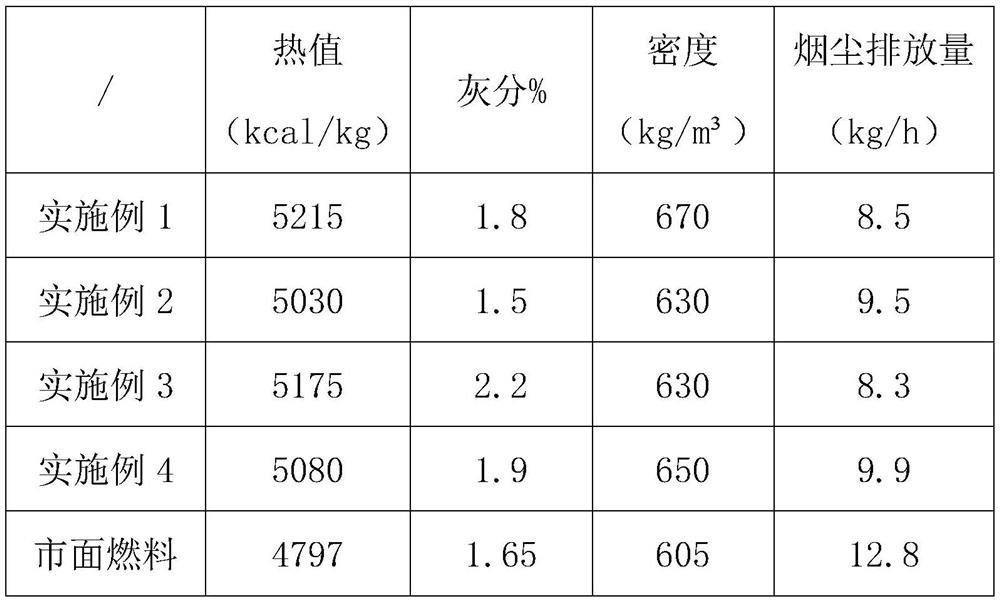

Energy-saving and environment-friendly biomass fuel and preparation method thereof

PendingCN113234507AReduce sulfur contentReduce nitrogen contentBiofuelsSolid fuelsNitrogen dioxideAgricultural residue

The invention discloses an energy-saving and environment-friendly biomass fuel and a preparation method thereof, and relates to the technical field of biomass fuels. The problem of environmental pollution is solved. The biomass fuel comprises,s by weight, 80 parts of forestry and agricultural residues, 45 parts of animal waste, 35 parts of coal slime, 7 parts of a combustion improver, 5 parts of a desulfurizer, 6 parts of a denitrification agent, 4 parts of a dechlorinating agent and 8 parts of high clay. The preparation method of the biomass fuel comprises the following steps: taking the forestry and agricultural residues, the animal waste and the coal slime as raw materials, and naturally airing until the moisture content is 8-12%; taking and sequentially crushing the aired agricultural and forestry waste, animal waste and coal slime until the particle size is smaller than or equal to 2 mm; and taking the crushed agricultural and forestry waste and animal waste according to the component proportion. The sulfur content, the nitrogen content and the chlorine content of the fuel are effectively reduced, release of harmful substances such as nitrogen dioxide and carbon dioxide is reduced, potassium ions and chloride ions are removed, pollution to the environment is prevented, and energy conservation and environmental protection are achieved.

Owner:曾淑云

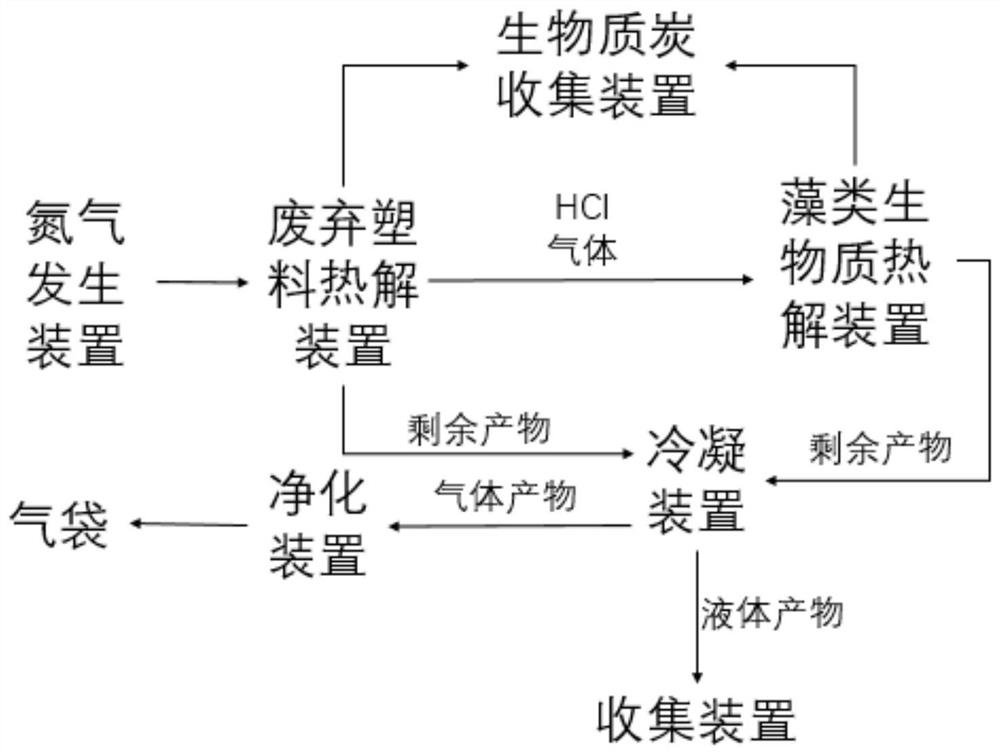

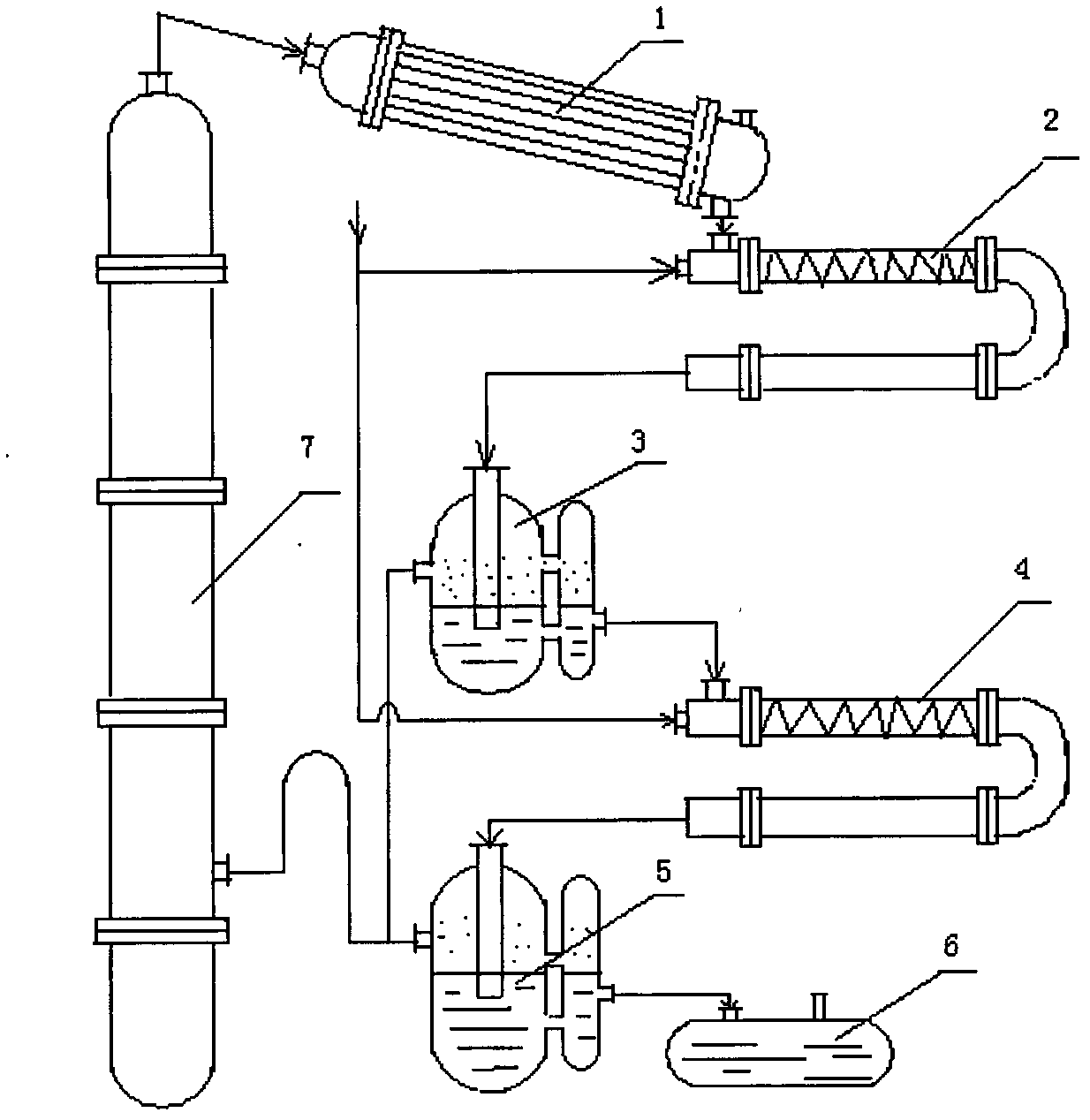

A method of pyrolyzing high-protein algae and waste plastics to produce carbon by gas-solid two-phase mixed chlorine removal

ActiveCN109609152BEfficient removalImprove qualityProductsReagentsEnvironmental engineeringHydrolysis

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Industrial bromine refining method

The invention discloses an industrial bromine refining method, where distilled bromine vapor is condensed into liquid bromine by a crude bromine condenser and free chlorine in the liquid bromine is absorbed so as to refine the crude bromine. The method is characterized in that procedures of two-step mixed absorption and two-step separation are adopted to absorb the free chlorine in the liquid bromine; and in the two-step mixed absorption procedure, the crude liquid bromine and material solution are simultaneously introduced into a static mixer and are mixed fully, so as to absorb the free chlorine in the liquid bromine by the material solution. Due to the adoption of the static mixer, the free chlorine in the crude liquid bromine can thoroughly contact the absorption solution to improve dissolution effect and achieve the purpose of high-efficiency chlorine removal. The method has the advantages of simple process, less investment, easy operation, high safety and good bromine refining effect.

Owner:天津长芦汉沽盐场有限责任公司

Environment-friendly flame-retardant plastic and preparation method thereof

The invention discloses a preparation method of environment-friendly flame-retardant plastic. The preparation method comprises the following steps: step S1, modification of octamethylcyclotetrasilazane with vinyl nitrile; step S2, preparation of an allyl benzophenone ionomer; and S3, plastic forming. The invention also provides the environment-friendly flame-retardant plastic prepared according to the preparation method of the environment-friendly flame-retardant plastic. The environment-friendly flame-retardant plastic provided by the invention is remarkable in flame-retardant effect, good in environment-friendly performance and performance stability, and excellent in comprehensive performance, aging resistance and mechanical properties.

Owner:李明杰

Environment-friendly polyvinyl chloride ultraviolet-resistant sheath material and preparation method thereof

InactiveCN112210185ASimple manufacturing methodImprove production efficiencyPlastic/resin/waxes insulatorsEpoxyPolymer science

The invention discloses an environment-friendly polyvinyl chloride uvioresistant sheath material which is characterized by comprising the following components in parts by weight: 20-30 parts of polyvinyl chloride resin, 5-10 parts of hydroxyl-terminated functionalized hyperbranched polyethylene, 6-12 parts of 2-trimethylsiloxy-4-allyloxydiphenyl ketone / phenyl 2,3,4,5,6-pentafluoro-1-vinylsulfonate / prop-2-en-1-yl 3,5-diamino-1H-pyrazole-4-carboxylate / 1-allyl benzotrizole 96 copolymer, 30-40 parts of epoxy SBS resin, 0.2-0.8 part of carbazolyl modified graphene quantum dots, 0.3-0.6 part of benzophenone hydrazone, 3-6 parts of filler and 1-2 parts of coupling agent. The invention also provides a preparation method of the environment-friendly polyvinyl chloride uvioresistant sheath material.The environment-friendly polyvinyl chloride anti-ultraviolet sheath material disclosed by the invention is good in environment-friendly performance, good in weather resistance, ultraviolet aging resistance, flame retardance and high and low temperature resistance, and long in service life.

Owner:姚雪侠

Automatic dispatch control system and method of salty prevention pumping station

ActiveCN102900124BReduce wasteAvoid enteringElectric digital data processingAdaptive controlGeneral Packet Radio ServiceControl system

The invention discloses an automatic dispatch control system and a method of a salty prevention pumping station, wherein the system is composed of a real-time monitoring unit, a salinity forecasting unit, a central control chamber and an actuating mechanism and the like; the real-time monitoring unit is composed of a plurality of groups of river surface monitors, a reservoir liquidometer, a gate salinity meter and a plurality of GPRS (General Packet Radio Service) modules; the salinity forecasting unit is composed of a first computer and a fourth GPRS module, which are connected through an RS232 serial port bus, the central control chamber is composed of a second computer and a fifth GPRS module, which are connected through an RS232 serial port bus, and the actuating mechanism is composed of a gate, a plurality of water pumps and a plurality of PLCs (Programmable Logic Controller); and the automatic dispatch control system disclosed by the invention can be used for effectively avoiding the salt water from entering water works and guaranteeing the chlorosity of the water of the water works to be minimum under the harsh condition of low water combined with spring tide.

Owner:ZHEJIANG UNIV

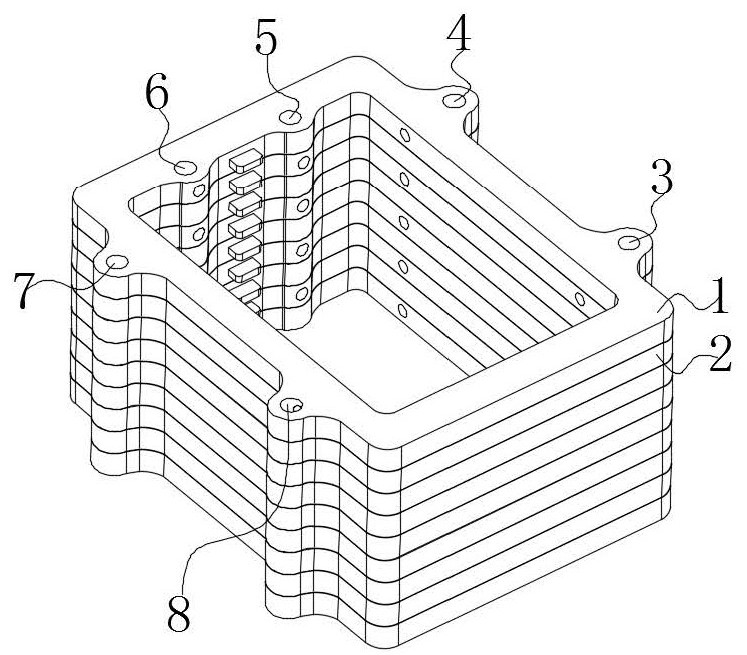

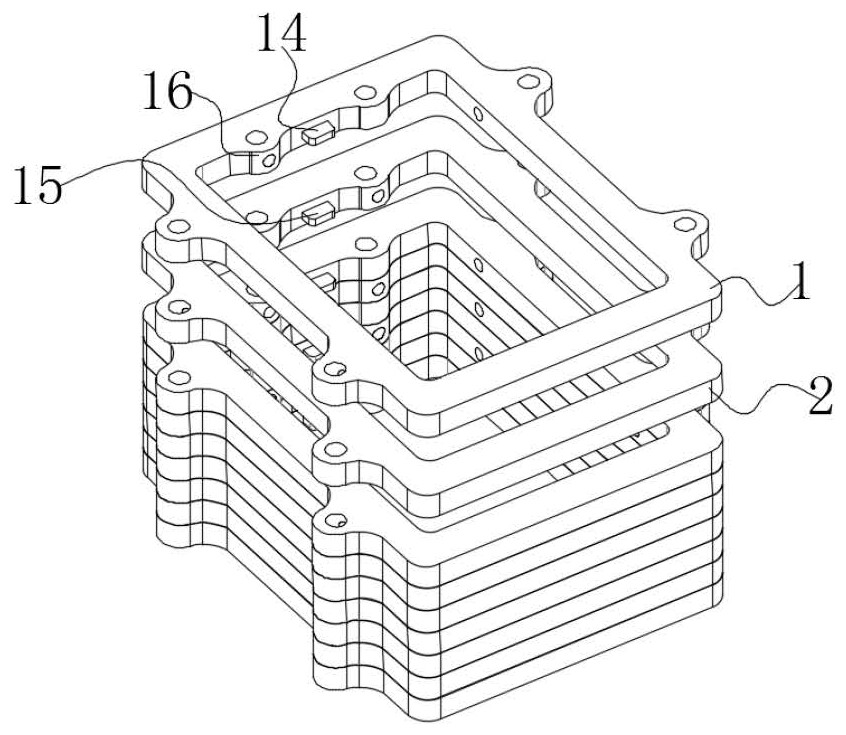

Method for treating hydrochloric acid wastewater by electrolytic process and electrolytic tank for electrolyzing hydrochloric acid wastewater

PendingCN112759036ALow chlorine contentReduce processing costsWater treatment parameter controlElectrolysis componentsIndustrial wastewater treatmentElectrolytic cell

The invention discloses a method for treating hydrochloric acid wastewater by an electrolytic method and an electrolytic tank for electrolyzing the hydrochloric acid wastewater, and relates to the technical field of industrial wastewater treatment. The electrolytic tank for hydrochloric acid wastewater electrolysis comprises anode tanks and cathode tanks, the anode tanks and the cathode tanks are alternately arranged side by side in the vertical direction, and first fixing protrusions are integrally formed at the two ends of the two symmetrical outer side walls of the anode tanks and the cathode tanks correspondingly; a conductive liquid inlet, an electrolyte outlet, a conductive liquid outlet and an electrolyte inlet are respectively formed in the four first fixed bulges; the conductive liquid inlet and the electrolyte outlet are formed in the anode tank and the cathode tank, and the conductive liquid outlet and the electrolyte inlet are respectively aligned up and down. Through the arrangement of the anode tank, the cathode tank, the hydrogen outlet, the chlorine outlet, the first through groove, the second through groove, the third through groove and the fourth through groove, and the chlorine content in discharged water can be effectively reduced; meanwhile, hydrogen and chlorine after electrolysis can be recycled, and the cost is effectively saved.

Owner:云南驰宏国际锗业有限公司

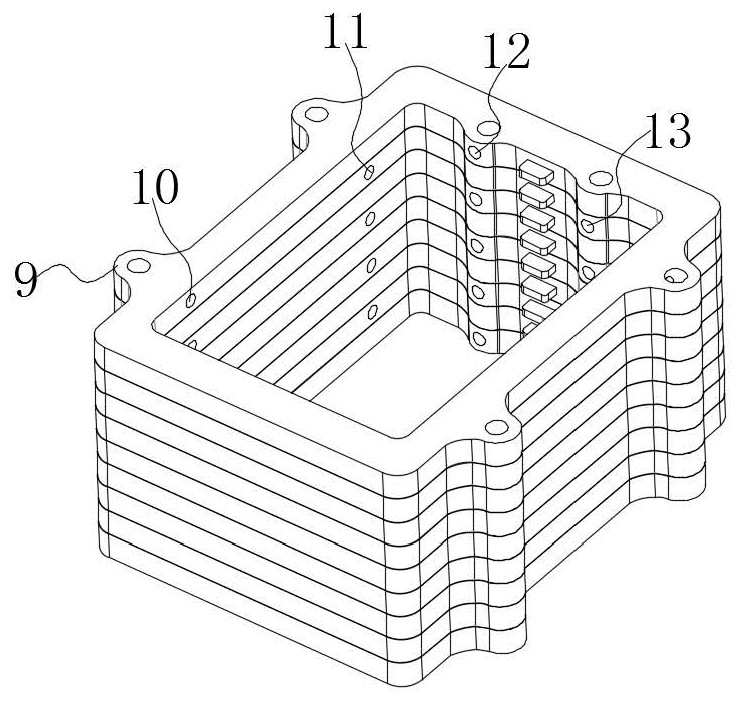

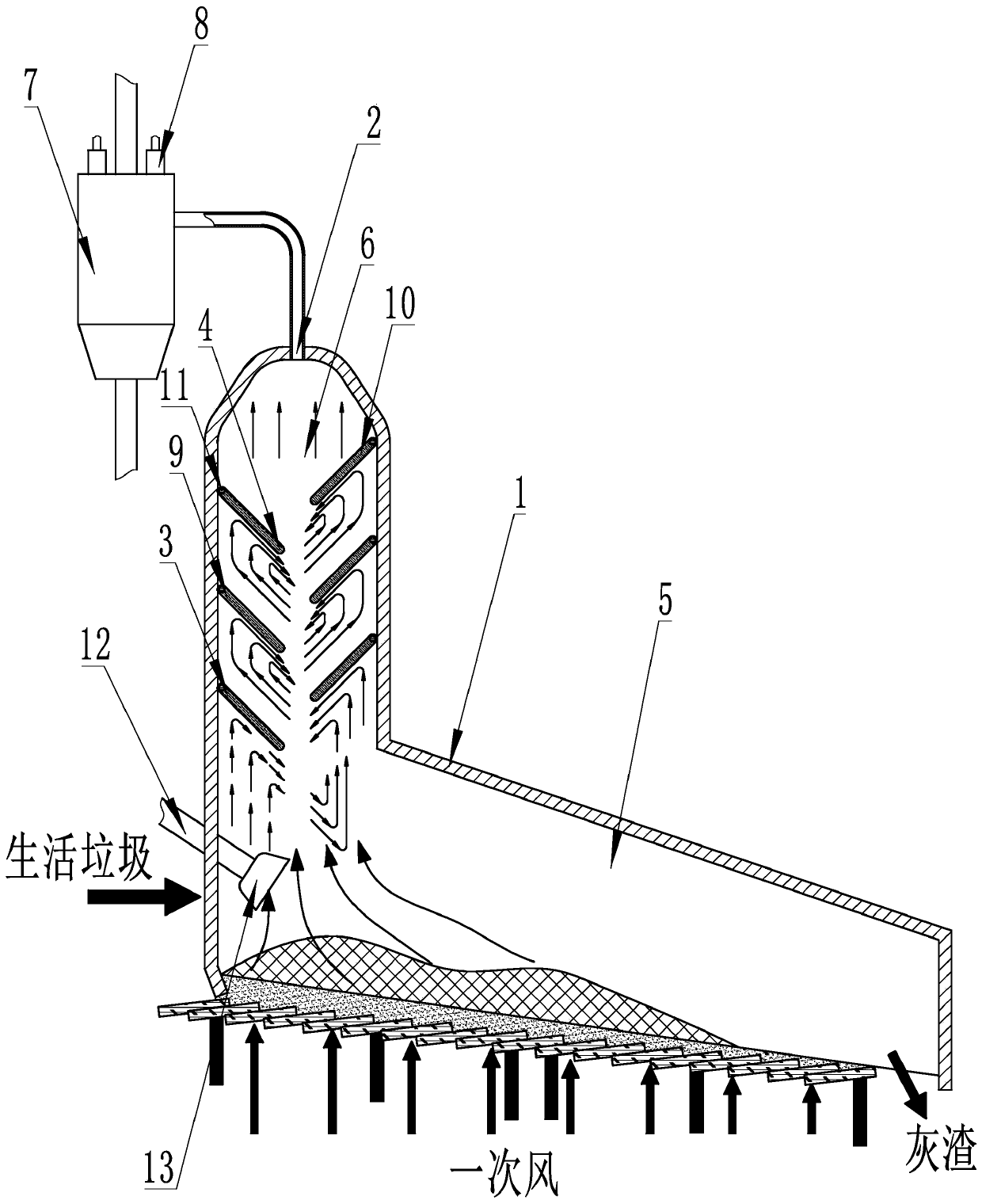

Household garbage gasification treatment system with composite dechlorination function

PendingCN111088081AReasonable structureReduce usageGranular/pulverulent flues gasificationFiltrationCombustible gas

The invention relates to a household garbage gasification treatment system with a composite dechlorination function. The system comprises a gasification furnace and a composite dechlorination system,wherein the composite dechlorination system comprises a coarse chlorine filtration device and a cyclone separator dechlorination device, the coarse chlorine filtration device comprises a plurality offiltering plates arranged in the gasification furnace from top to bottom and a calcium spraying port formed in the gasification furnace, one end of the filtering plate is connected with the gasification furnace, the filtering plate inclines downwards from the fixed end to the free end, the gasification furnace comprises a gasification reaction layer and a filter layer for placing the coarse chlorine filtration device, the filter layer is arranged at the top of the gasification reaction layer, and the calcium spraying port is arranged at the gasification reaction layer. According to the invention, after combustible gas is generated in a gasification furnace, the combustible gas can be directly subjected to deep dechlorination, so that high-temperature corrosion of the combustible gas to subsequent equipment is avoided so as to improve the steam parameters and the power generation efficiency and easily reduce the low-temperature heterogeneous catalytic synthesis of dioxin in the flue gascooling process.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

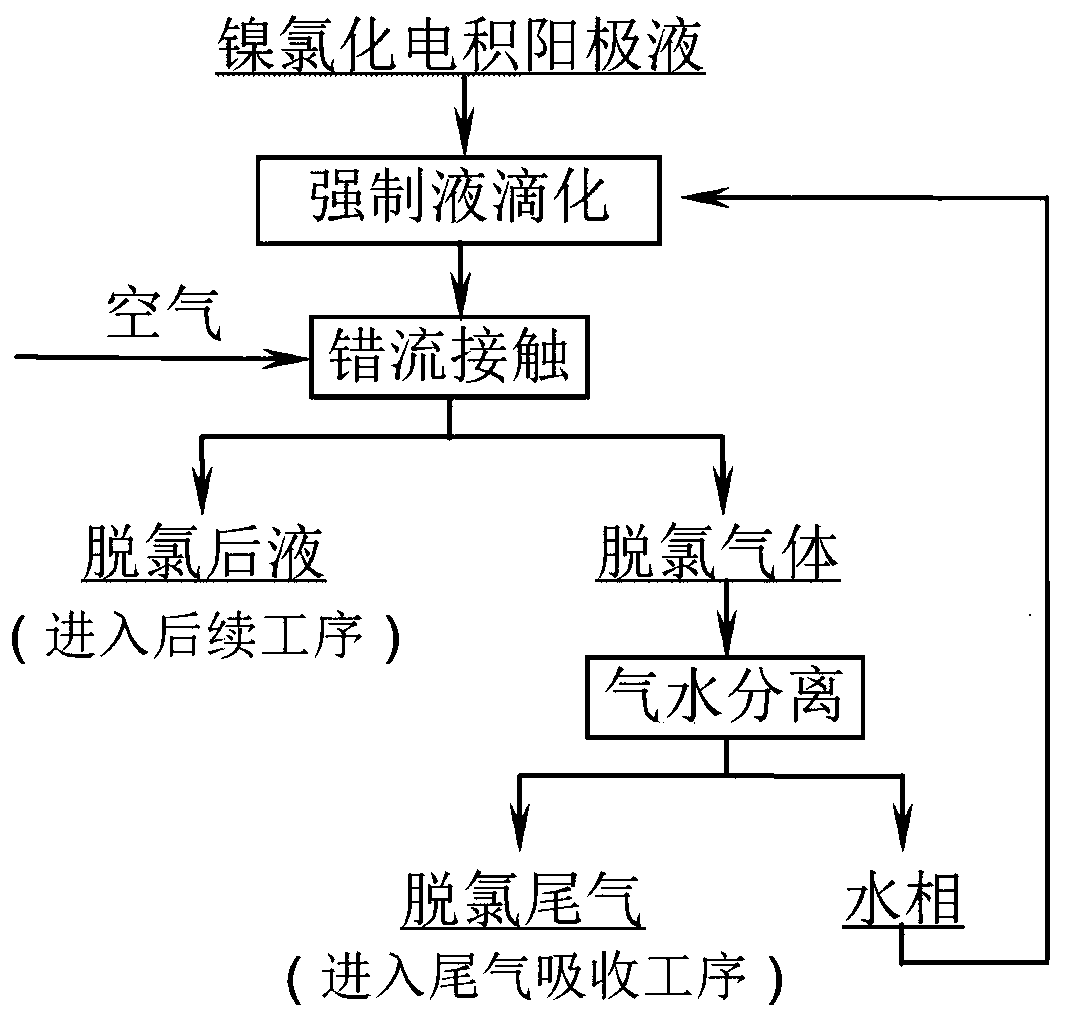

Method for removing free chlorine from nickel chloride electrodeposition anolyte

InactiveCN110921787ALow chlorine contentNo Chlorine OdorWater contaminantsWater/sewage treatmentPhysical chemistryWater chlorination

The invention discloses a method for removing free chlorine from nickel chloride electrodeposition anolyte. The method comprises the following steps of: under the action of a forced force field, allowing nickel chloride electrodeposition anolyte to perform sufficient droplet to form droplets with the radius of 1-3 mm, and performing cross-flow contact with a certain amount of air; and according toa gas-liquid interface equilibrium concentration principle, performing the balanced reaction of free chlorine in a solution towards an analysis direction, so that the concentration of the free chlorine in the nickel chloride electrodeposition anolyte is reduced, and the purpose of removing the free chlorine from the nickel chloride electrodeposition anolyte is achieved. The concentration of the chlorine in the anolyte after the chlorine is removed is below 6ppm, the whole technological process is good in dechlorination effect, the removal rate of the free chlorine is 98.5% or above, the removal rate of the free chlorine in the anolyte is increased, the chlorine content of the anolyte is low, no chlorine smell exists, the requirement for cyclic utilization of the anolyte is met, the dechlorinated anolyte reaches the ideal state of cyclic utilization, and the purposes that the field operation environment is clean and friendly are achieved.

Owner:JINCHUAN GROUP LIMITED

A plasma fly ash melting treatment and metal recycling system

ActiveCN108704926BIncrease relative volatilityHelps restore recoveryElectrostatic separationTransportation and packagingActivated carbonBottom ash

The invention discloses a plasma bottom ash, fly ash melting treatment and metal recycling system, which includes a feeding device, a two-stage ash melting device, a combustion chamber, a wet-type temperature reduction washing device, a mist eliminator, an activated carbon material layer and induced draft fan; the feeding device is connected to the two-stage ash melting device; the two-stage ash melting device is connected to the combustion chamber; the combustion chamber is connected to the wet desuperheating washing device; the wet desuperheating washing device is connected to the demister, The demister is connected with the activated carbon material layer; the activated carbon material layer is connected with the induced draft fan. The invention adopts a two-stage ash melting device to realize the harmless treatment of bottom ash and fly ash, and at the same time recover the basic metals, heavy metals and other metals reduced in the melting furnace respectively in the bottom ash and fly ash; the combustion chamber It ensures the full removal of pollutants such as combustible components in the flue gas; the wet desuperheating scrubber realizes the capture and recovery of volatile salts such as alkaline metals and heavy metals and the deep purification of the flue gas.

Owner:加拿大艾浦莱斯有限公司 +1

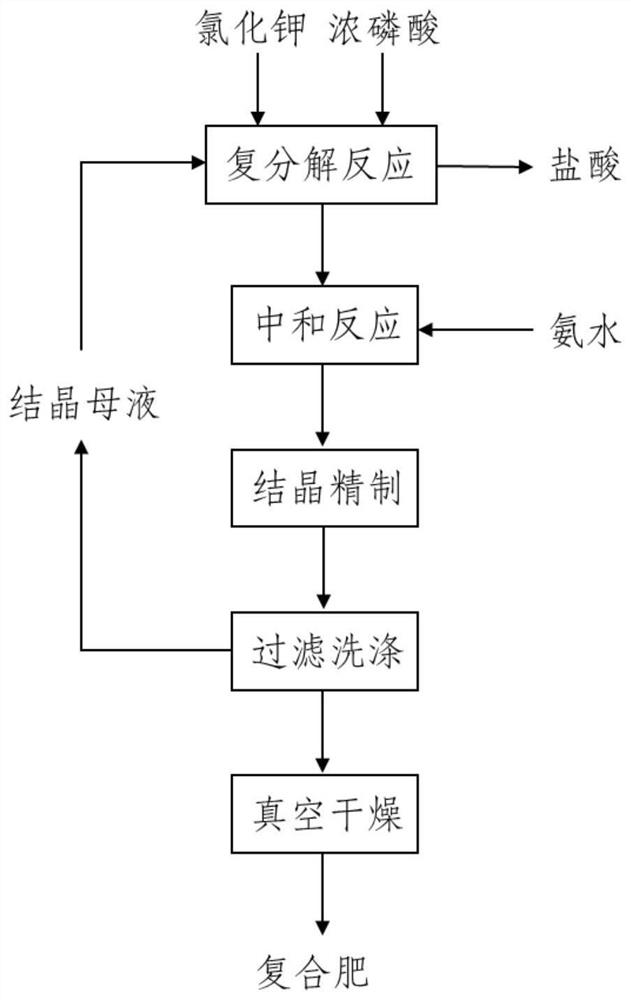

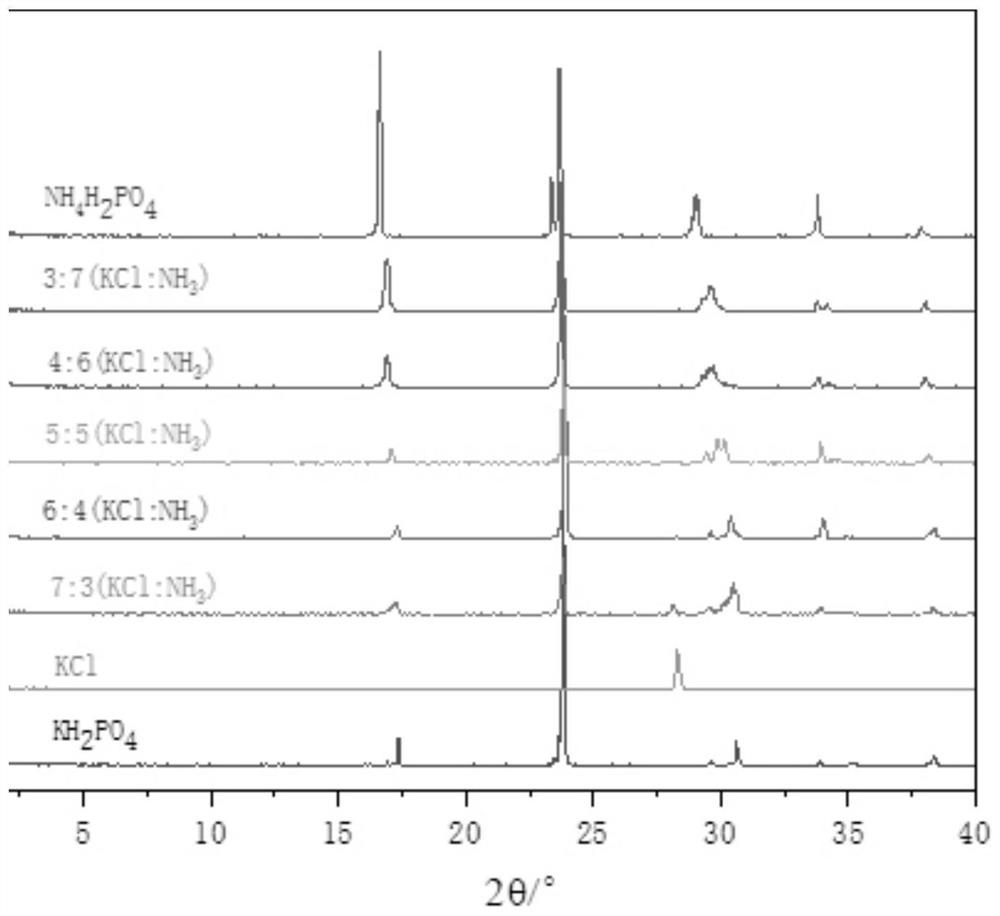

Method for preparing nitrogen-phosphorus-potassium compound fertilizer from fertilizer-grade phosphoric acid eutectic

The invention provides a method for preparing a compound fertilizer with an adjustable nitrogen-phosphorus-potassium ratio from a fertilizer-grade phosphoric acid eutectic. The method comprises the steps of (1) conducting double decomposition reaction; (2) conducting a neutralization reaction; (3) crystallizing and refining; and (4) filtering and drying. The method has the beneficial effects that the cost of raw materials is low, zero emission of the whole process is also realized through reutilization of crystallization mother liquor and recovery of a reaction byproduct hydrogen chloride, and efficient utilization of the raw materials is realized; the reaction is segmented, so that the conversion rate of potassium chloride in the reversible reaction is improved, and the problem of crop leaf burn caused by overhigh chlorine ion content of the fertilizer is solved; and the content of nitrogen, phosphorus and potassium in the product is regulated and controlled by simply regulating and controlling the feeding ratio of the reaction raw materials, the controllable range is large, and different requirements of actual agricultural production on the fertilizer can be met.

Owner:TIANJIN UNIV

Method for making open-cell paraffin for polyurethane foam caulk

ActiveCN105733273BLow chlorine contentImprove balancePetroleum chemical modificationParaffin waxHigh carbon

The invention discloses a method for producing tapping paraffin serving as polyurethane foam crack filler.The method comprises the following steps of adding heavy liquid wax into a reaction kettle; introducing chlorine into the reaction kettle, and controlling the reaction temperature; after the heavy liquid wax reacts with the chlorine for a while, detecting the density of chlorinated paraffin, and then blowing off hydrogen chloride gas; after the hydrogen chloride gas is blown off, detecting the acid value, and then adding compound heat stabilizer, so that the tapping paraffin is obtained.The method for producing the tapping paraffin has the advantages that the temperature of the reaction conducted between the heavy liquid wax and chlorine and the introducing amount of chlorine are controlled, so that low-carbon-chain constituents maintain low chlorine content, high-carbon-chain constituents have high chlorine content, chlorine elements are uniformly distributed on the heavy liquid wax, the distribution mode is beneficial to foam hole balance of the polyurethane foam crack filler, in addition, foam holes can emerge to be of a netted structure, and untoward effects such as enlarged foam holes and messy foam cannot be caused.

Owner:SHIJIAZHUANG DONGXIANG CHEM CO LTD

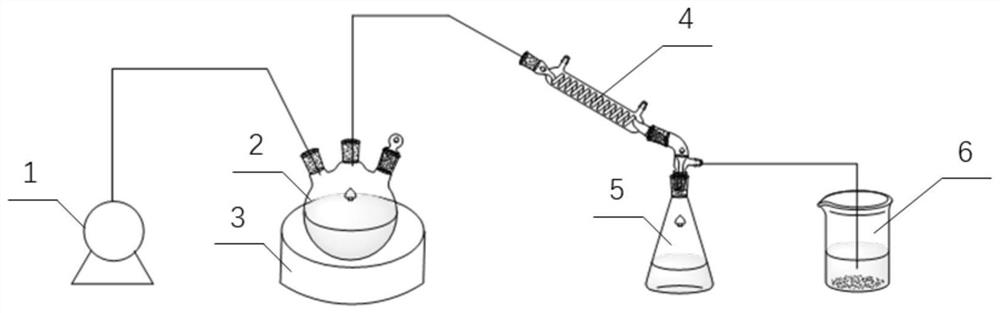

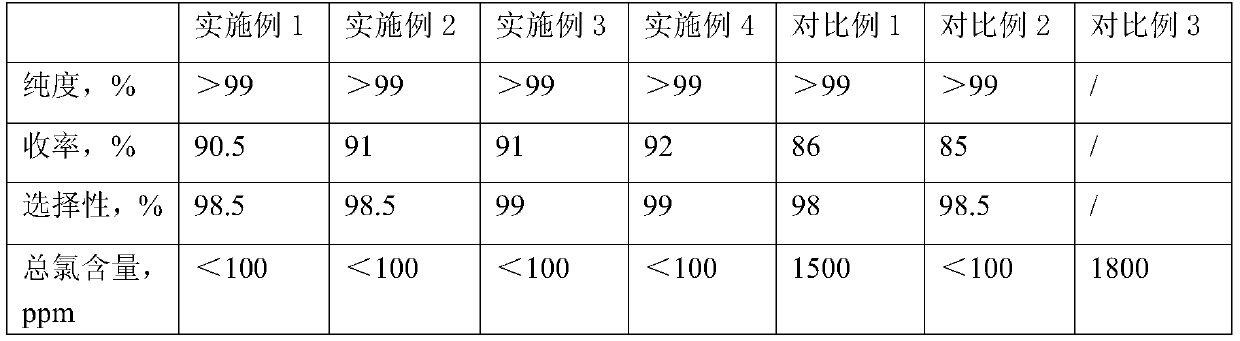

A kind of 4-vinyl epoxycyclohexane and preparation method thereof

The invention relates to 1,2-epoxy-4-vinylcyclohexane. 1,2-epoxy-4-vinylcyclohexane is prepared from the following raw materials in percentage by mass: 12%-14% of 4-vinyl-1-cyclohexene, 40%-45% of toluene, 17%-19% of acetic anhydride, 2%-4% of sodium acetate and 21%-23% of 35% hydrogen peroxide. The invention further relates to a preparation method of 1,2-epoxy-4-vinylcyclohexane. Prepared 1,2-epoxy-4-vinylcyclohexane has high yield and selectivity, and purity of a reaction product is improved; besides, 1,2-epoxy-4-vinylcyclohexane has low chlorine content and has no heavy metal residues, andgelation time of the product is short.

Owner:JIANGSU TETRA NEW MATERIAL TECH

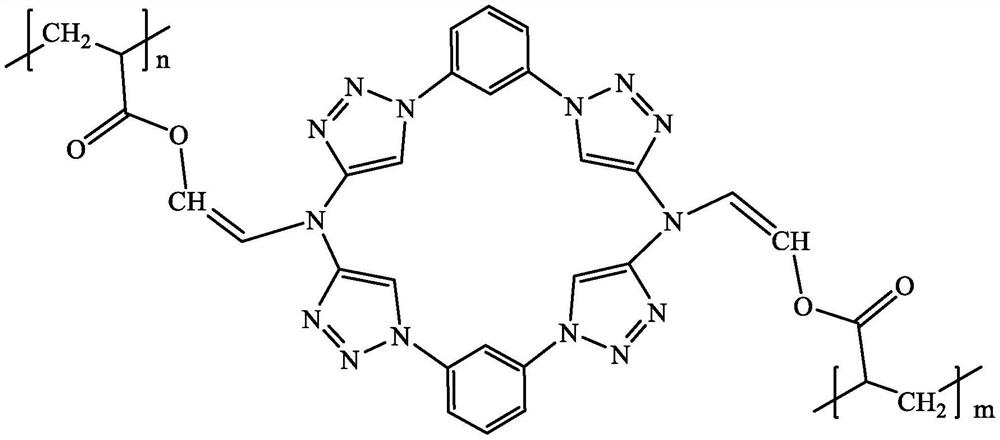

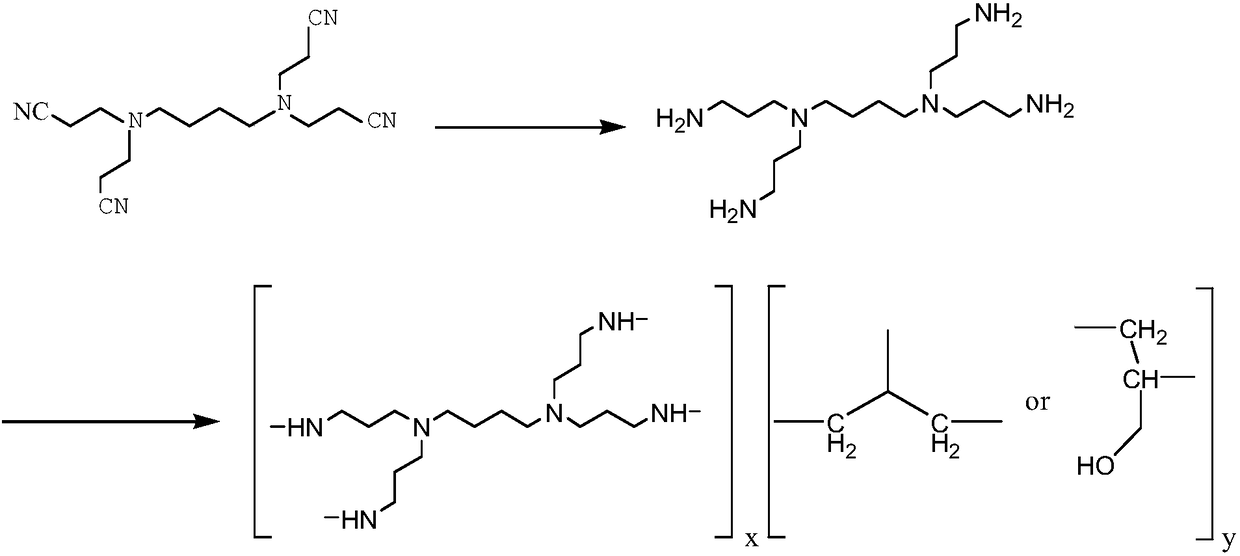

Dechlorinating agent as well as preparation method and application thereof

ActiveCN114395061ALow chlorine contentReduced risk of corrosionOther chemical processesPlastic recyclingEpoxyPtru catalyst

The invention provides a dechlorinating agent and a preparation method and application thereof.The preparation method comprises the steps that firstly, in a first organic solvent, in the atmosphere that copper sulfate pentahydrate and sodium ascorbate serve as catalysts and first protective gas, a mixed solution of triacetylene amine and m-azidobenzene is dropwise added into the first organic solvent, a first contact reaction is carried out, and a second contact reaction is carried out; a first product is obtained; then, extracting and separating the first product to obtain an organic phase of the first product; drying the organic phase, filtering, and performing rotary evaporation to obtain an intermediate I; further, in a second organic solvent, under the action of sodium hydroxide as a catalyst, performing a second contact reaction on a mixed solution of the intermediate I and acrylic acid, and performing rotary evaporation to obtain an intermediate II; and further, by taking water as a solvent, controlling the intermediate II and an ammonium persulfate aqueous solution to carry out a third contact reaction in the atmosphere of a second protective gas, and carrying out rotary evaporation to obtain the dechlorinating agent. The dechlorinating agent is applied to synthesis of epoxy resin.

Owner:智仑超纯环氧树脂(西安)有限公司

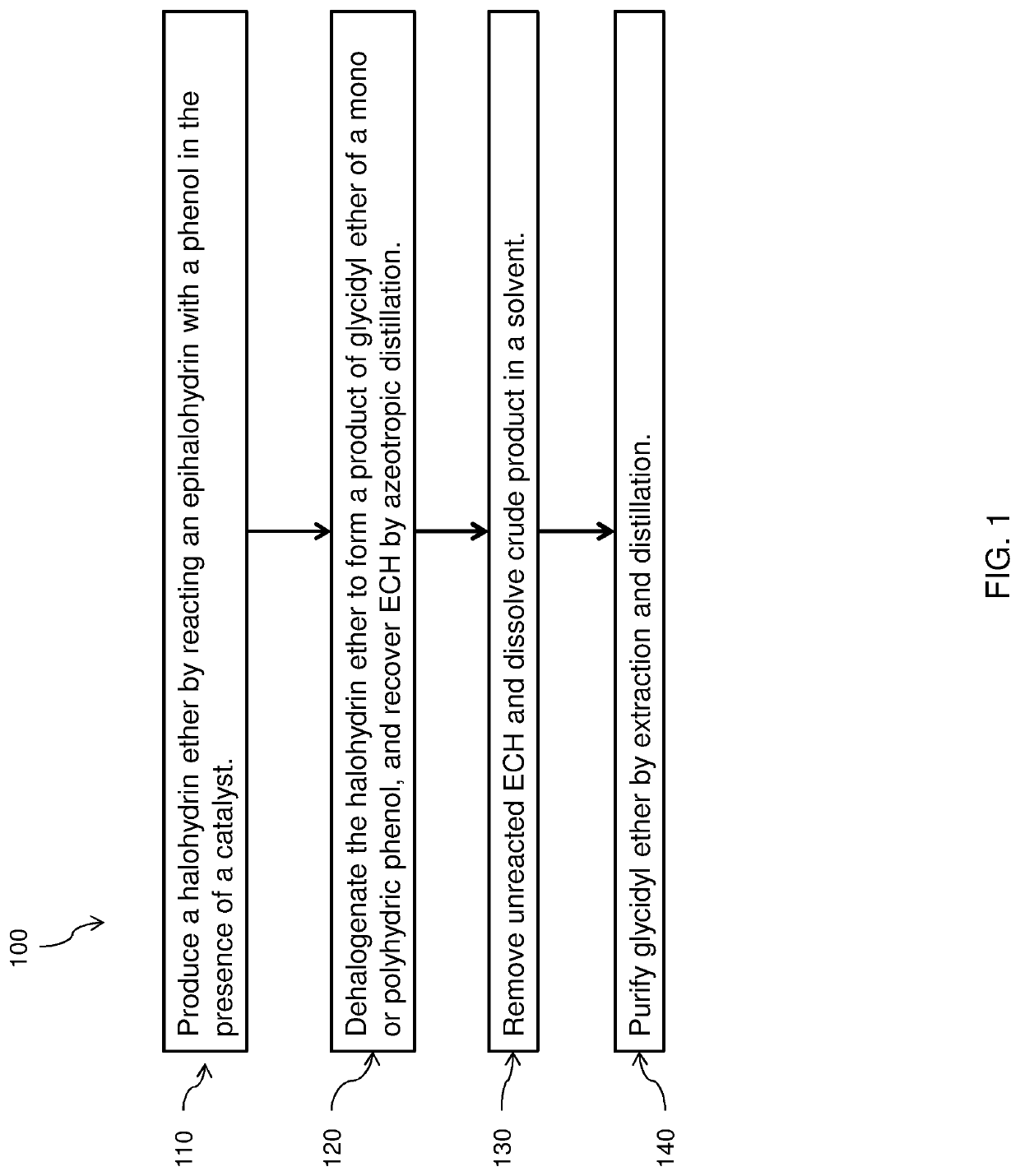

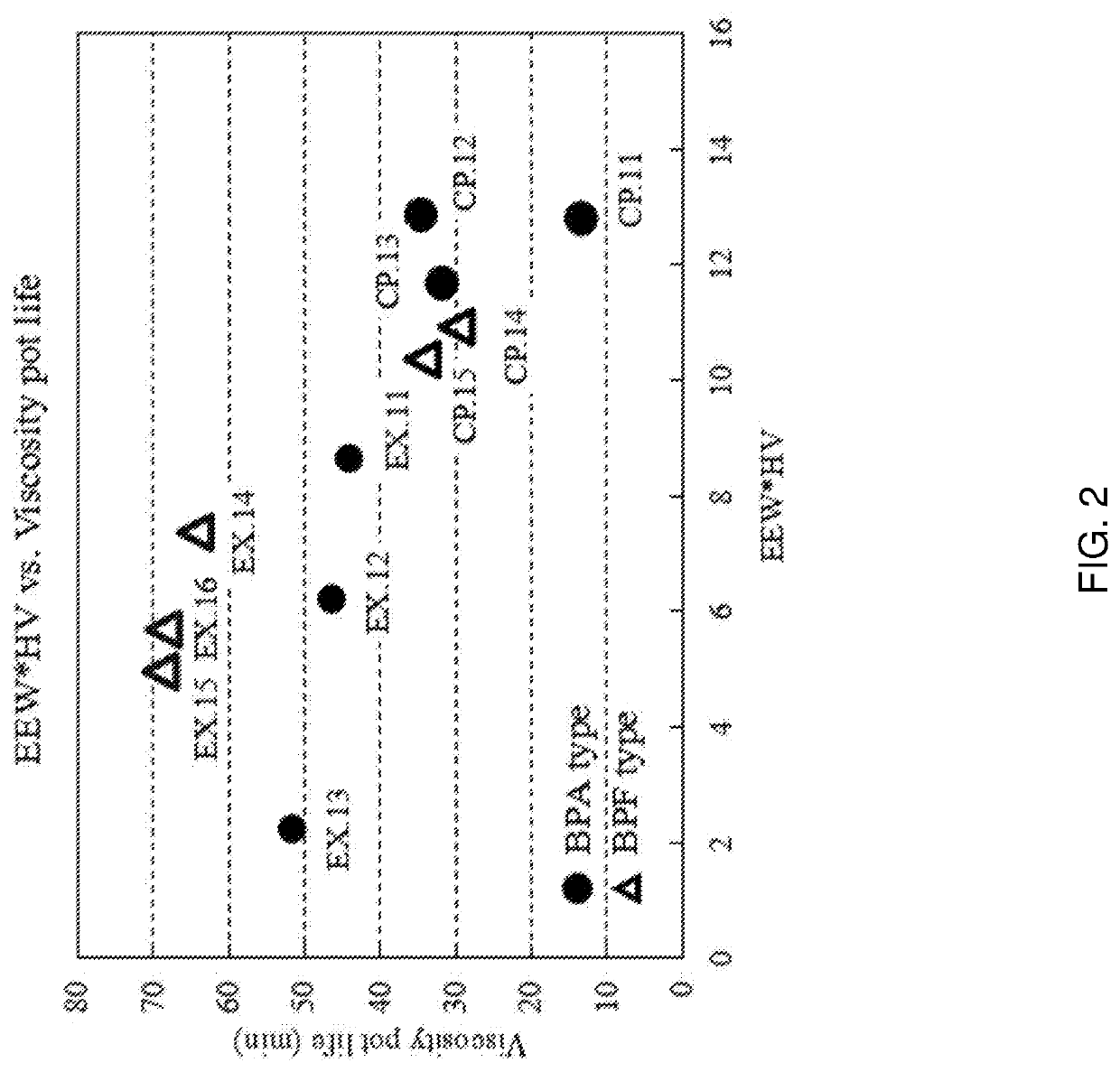

Product of glycidyl ether of a mono or polyhydric phenol

ActiveUS10961208B1Low chlorine contentHigh dimensional stabilityOrganic chemistryComposite materialBis epoxide

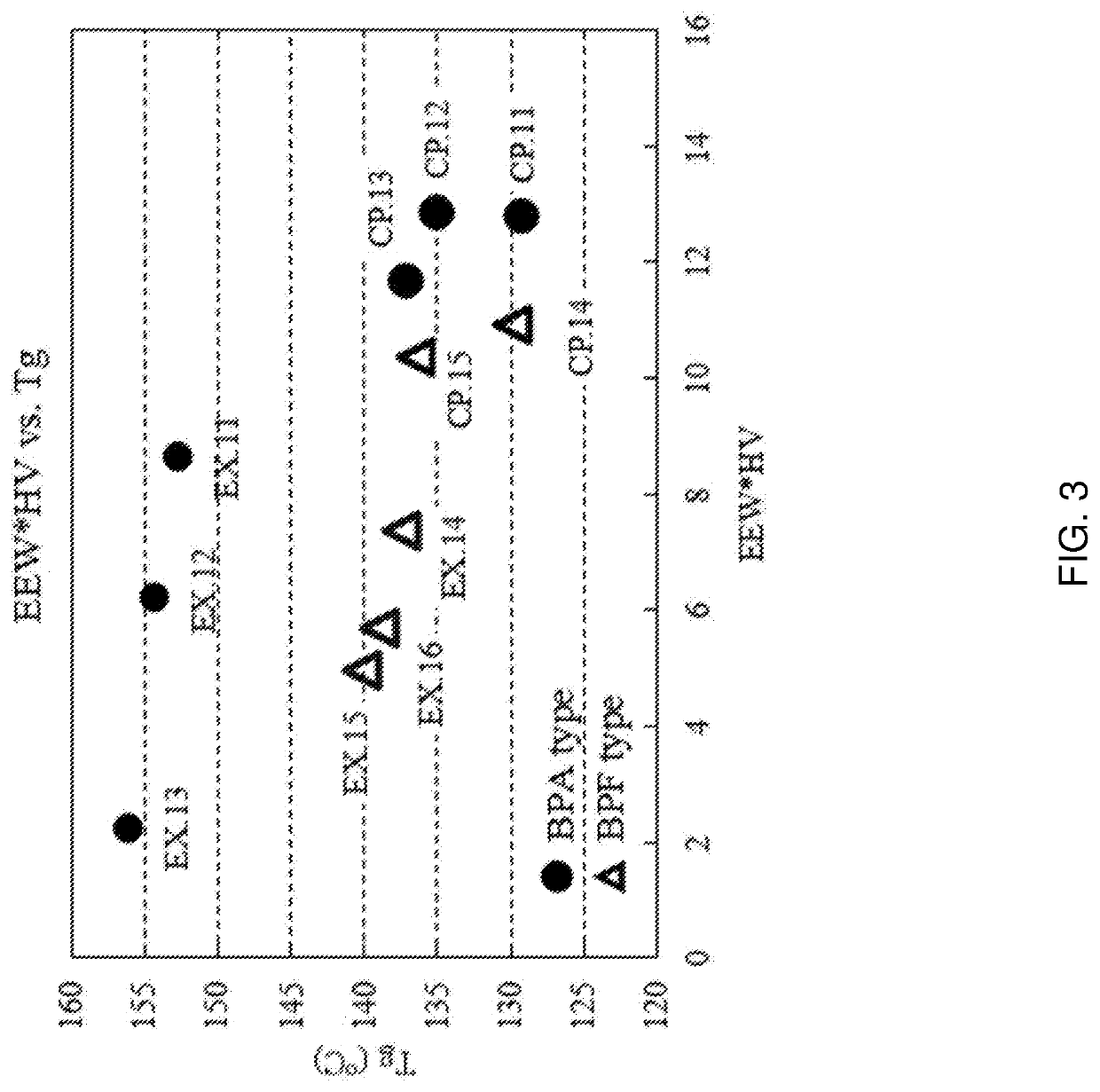

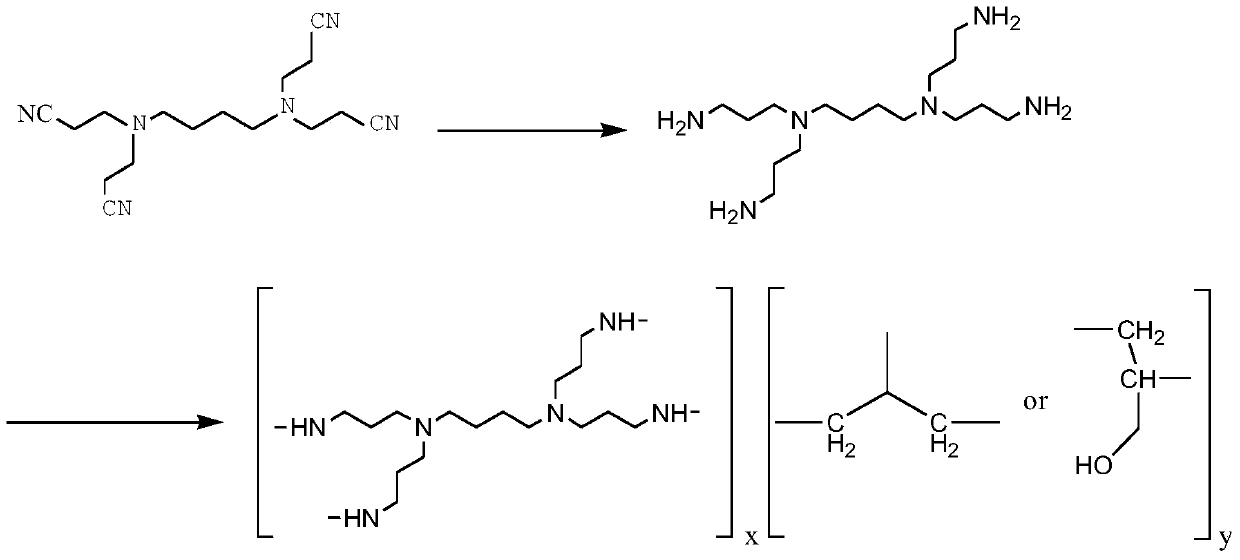

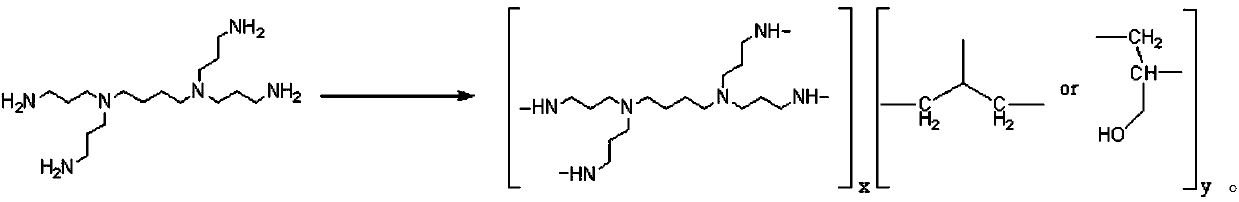

Products of glycidyl ether of a mono or polyhydric phenol as well as methods to manufacture the same. In some instances, the product of glycidyl ether of a mono or polyhydric phenol has an epoxy equivalent weight (“EEW”) and a hydroxyl value (“HV”), wherein the epoxy equivalent weight multiplied by the hydroxyl value (EEWxHV) is a value from 1 to 10. A process for producing the product of glycidyl ether of a mono or polyhydric phenol typically includes reacting an epihalohydrin with a mono or polyhydric phenol in the presence of a catalyst to produce a halohydrin ether; and dehalogenating the halohydrin ether to form the product of glycidyl ether of a mono or polyhydric phenol.

Owner:CHANG CHUN PLASTICS

A kind of preparation method of bishalom

Owner:SHANDONG CHENGCHUANG BLUE OCEAN PHARM TECH CO LTD

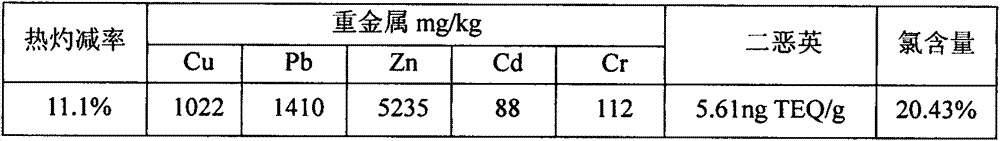

Step-by-step flotation detoxification method for fly ash of medical waste incineration

ActiveCN104275245BAchieve recyclingReduce secondary synthesisFlotationDecompositionResource utilization

The invention discloses a sub-step flotation and detoxification method for incineration fly ash of medical garbage. The sub-step flotation and detoxification method is characterized in that coseparation of dioxin and a carbon component is realized by first-step flotation, so that the toxicity of organic pollutants including the dioxin and the like in the fly ash is reduced; meanwhile, soluble heavy metal is eluted; second-step flotation of tail slurry is subjected to a sulfide precipitation flotation method and heavy metal including Pb, Zn and the like is removed and recycled, so that the harms of the heavy metal are eliminated. Separated final products mainly comprise enriched carbon, residual ash, heavy metal sediment salt and the like, wherein the enriched carbon rich in the dioxin is conveyed into a garbage incinerator secondary incineration chamber to be incinerated, so that the high-temperature decomposition of the dioxin is realized by a low cost; the volume and the toxicity of the residual ash are greatly reduced and the residual ash is directly conveyed into a municipal solid waste landfill to be safely treated or reutilized, so that the subsequent treatment cost is greatly reduced; the heavy metal in the fly ash is leached with an acid and vulcanized and then is precipitated, floated and recycled, so that a plurality of purposes are realized. The method can realize harmless treatment and resource utilization of the incineration fly ash of the medical garbage under environment-friendly and low-cost conditions.

Owner:TIANJIN CHENGJIAN UNIV

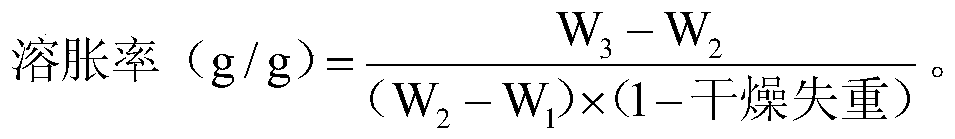

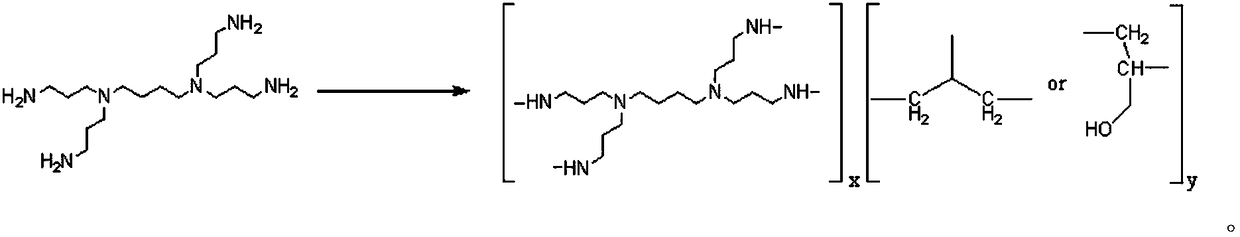

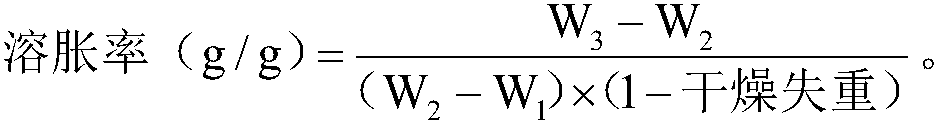

Aftertreatment method for Bixalomer

The invention discloses an aftertreatment method for Bixalomer. The method is simple to operate, a product has low chlorine content and low swelling rate, and the phosphate binding amount is equivalent to that of Japanese listed preparations. The method comprises the following specific steps: after the reaction is completed, reaction residues are added to purified water, and the mixture is stirred, crushed, washed and dried, wherein in the washing step, anhydrous methanol, dilute hydrochloric acid, sodium hydroxide solution and purified water are used for washing.

Owner:SHANDONG CHENGCHUANG PHARMA R&D

Tank type heat exchanger

InactiveCN104457395AReduce corrosionPrevent scalingCorrosion preventionMultistage water/sewage treatmentWork performancePlate heat exchanger

The invention discloses a tank type heat exchanger. The tank type heat exchanger comprises a tank and a water purifier, wherein the water purifier is connected with the tank through a water inlet pipeline, a first flowmeter is arranged on the water inlet pipeline, a heater is arranged on the tank and is located on the outer side of the tank, a heating medium inlet pipe and a heating medium outlet pipe are arranged on the heater, a second flowmeter is arranged on the heating medium outlet pipe, a hot water inlet is formed in the tank and is connected with the water inlet pipeline through a pipeline, and the heater is connected to the upper portion of the pipeline. According to the tank type heat exchanger, the flowmeters are arranged on the water inlet pipeline and the heating medium outlet pipe, in this way, adjustment can be conducted according to requirements during production, waste of raw materials is avoided, and the working performance of a machine can be maintained easily; the water purifier is arranged in front of the water inlet pipeline, in this way, the chlorine content of tap water entering equipment is extremely low, the salt content of tap water entering the equipment is extremely low, corrosion of the pipelines is reduced to the maximum, the situation that scale formation happens in the pipelines due to high salt content of water is avoided, and the service life of the equipment is effectively prolonged.

Owner:WUXI YUDA HEAT EXCHANGER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com