Method for treating hydrochloric acid wastewater by electrolytic process and electrolytic tank for electrolyzing hydrochloric acid wastewater

A technology of electrolytic cell and electrolysis method, which is applied in the field of electrolytic treatment of hydrochloric acid wastewater, electrolytic cell for electrolysis of hydrochloric acid wastewater, and treatment of hydrochloric acid in wastewater. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

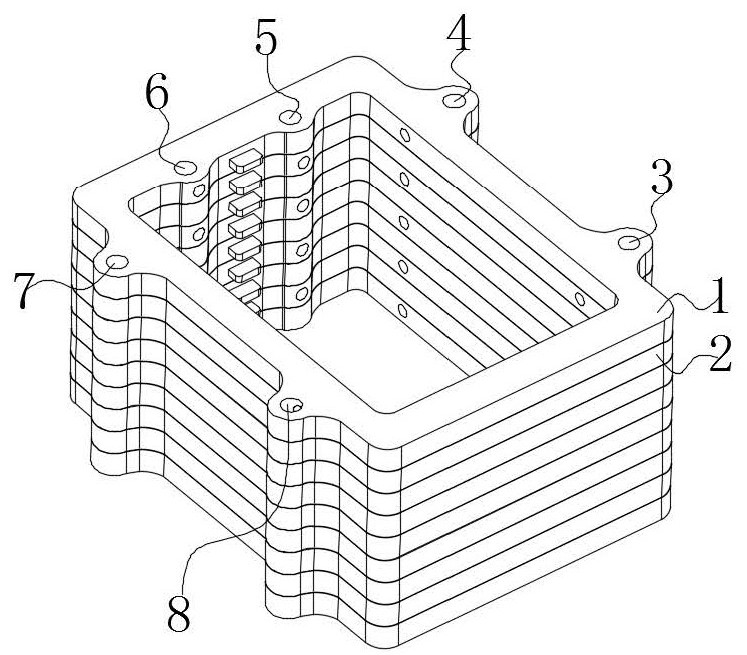

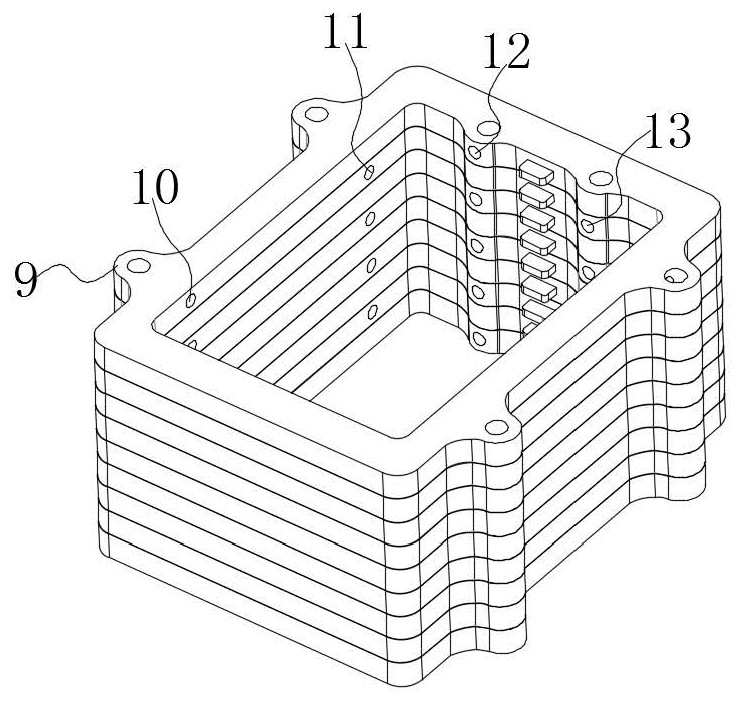

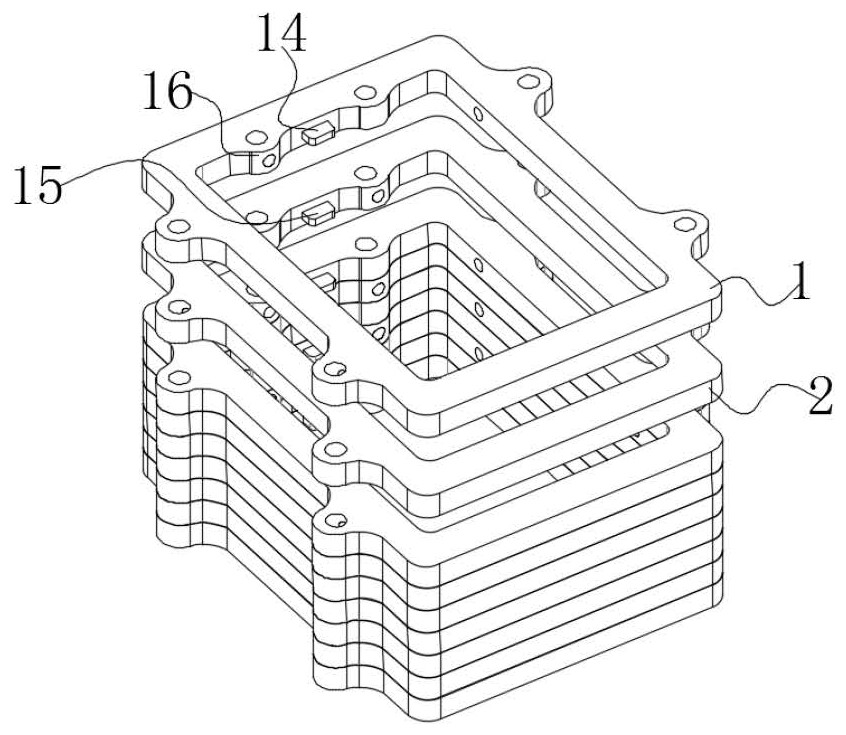

Image

Examples

Embodiment 1

[0036] The present invention is the method for treating hydrochloric acid wastewater by electrolysis, specifically comprising the following steps:

[0037] S1: dilute the hydrochloric acid wastewater with industrial water to obtain the electrolyte solution, the concentration of HCL in the electrolyte solution is 3%;

[0038] S2: The electrolyte to be injected into the anode tank through the electrolyte inlet on the electrolytic cell, and the injected electrolyte to be injected gradually fills each anode chamber through the dark hole inside the anode tank;

[0039] S3: The conductive liquid is injected into the cathode tank through the conductive liquid inlet on the electrolytic cell, and the injected conductive liquid gradually fills each cathode chamber through the dark hole inside the cathode tank; the conductive liquid is preferably NaCl brine, and the NaCl content in the conductive liquid is 5 %;

[0040] S4: Power on to electrolyze the electrolyte solution in the electro...

Embodiment 2

[0044] The present invention is the method for treating hydrochloric acid wastewater by electrolysis, specifically comprising the following steps:

[0045] S1: dilute the hydrochloric acid wastewater with industrial water to obtain the electrolyte solution, the concentration of HCL in the electrolyte solution is 5%;

[0046] S2: The electrolyte to be injected into the anode tank through the electrolyte inlet on the electrolytic cell, and the injected electrolyte to be injected gradually fills each anode chamber through the dark hole inside the anode tank;

[0047] S3: The conductive liquid is injected into the cathode tank through the conductive liquid inlet on the electrolytic cell, and the injected conductive liquid gradually fills each cathode chamber through the dark hole inside the cathode tank; the conductive liquid is preferably NaCl brine, and the NaCl content in the conductive liquid is 5 %;

[0048] S4: Power on to electrolyze the electrolyte solution in the electro...

Embodiment 3

[0052] The present invention is the method for treating hydrochloric acid wastewater by electrolysis, specifically comprising the following steps:

[0053] S1: dilute the hydrochloric acid wastewater with industrial water to obtain the electrolyte solution, the concentration of HCL in the electrolyte solution is 10%;

[0054] S2: The electrolyte to be injected into the anode tank through the electrolyte inlet on the electrolytic cell, and the injected electrolyte to be injected gradually fills each anode chamber through the dark hole inside the anode tank;

[0055]S3: The conductive liquid is injected into the cathode tank through the conductive liquid inlet on the electrolytic cell, and the injected conductive liquid gradually fills each cathode chamber through the dark hole inside the cathode tank; the conductive liquid is preferably NaCl brine, and the NaCl content in the conductive liquid is 5 %;

[0056] S4: Power on to electrolyze the electrolyte solution in the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com