Aftertreatment method for Bixalomer

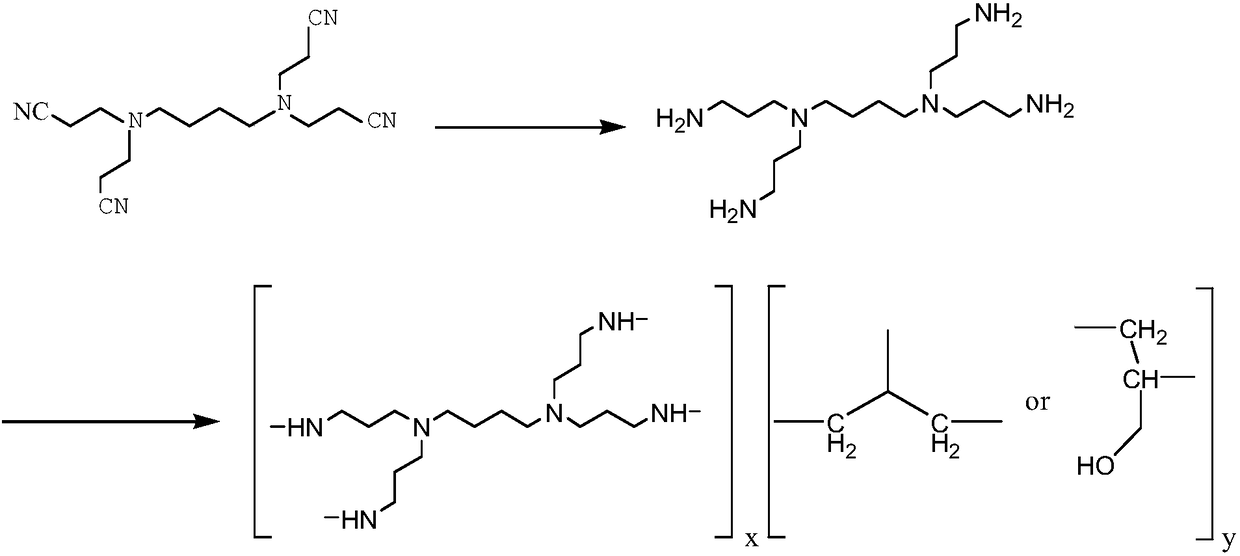

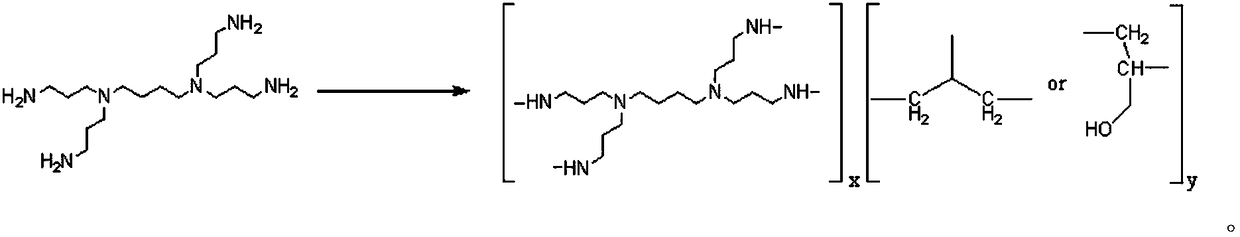

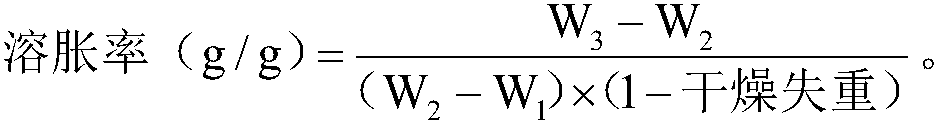

A bisalom and purified water technology, applied in the field of medicine, can solve the problems of high swelling rate, high chlorine content, and low phosphate binding amount, and achieve the effect of low swelling rate, low chlorine content, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Dissolve 15g (47.4mmol) of N,N,N',N'-tetra(3-aminopropyl)-1,4-butanediamine in 15g of purified water, lower the temperature to 15-20°C, and add epoxy chlorine dropwise Propane 9.21g (99.5mmol), temperature control does not exceed 25°C, heat up to 80°C after dropwise addition, react for 9 hours, then cool down to room temperature, add the reaction residue into 300mL of purified water, stir, pulverize, and wash with anhydrous methanol , 1wt% dilute hydrochloric acid, 5wt% sodium hydroxide aqueous solution, purified water, washed with 300mL of purified water, and dried under normal pressure at 50°C for 24 hours to obtain 15g of product with a yield of 61.9%.

Embodiment 2

[0048] Dissolve 150g (0.474mol) of N,N,N',N'-tetrakis(3-aminopropyl)-1,4-butanediamine in 150g of purified water, lower the temperature to 15-20°C, and add epoxy chloride dropwise Propane 96.46g (1.04mol), temperature control does not exceed 25°C, heat up to 80°C after dropwise addition, react for 10 hours, then cool down to room temperature, add the reaction residue into 3000mL of purified water, stir, pulverize, and wash with anhydrous methanol , 1wt% dilute hydrochloric acid, 5wt% sodium hydroxide aqueous solution, purified water, washed with 3000mL of purified water, and dried under normal pressure at 50°C for 35 hours to obtain 155g of product with a yield of 62.9%.

Embodiment 3

[0050] Dissolve 1.5kg (4.74mol) of N,N,N',N'-tetrakis(3-aminopropyl)-1,4-butanediamine in 1.5kg of purified water, cool down to 15-20°C, add ring Oxychloropropane 1.01kg (10.9mol), temperature control not exceeding 25°C, heat up to 80°C after dropwise addition, react for 9 hours, cool down to room temperature, add the reaction residue into 30L of purified water, stir, pulverize, and use Water methanol, 1wt% dilute hydrochloric acid, 5wt% sodium hydroxide aqueous solution, purified water, washed with 30L of purified water, and dried at 50°C under normal pressure for 48 hours to obtain 1.57kg of product with a yield of 62.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com