A kind of 4-vinyl epoxycyclohexane and preparation method thereof

A technology based on epoxycyclohexane and epoxy ring, which is applied in the field of 4-vinylepoxycyclohexane and its preparation, can solve the problems of product gel time prolongation, heavy metal ion residues, and affecting production efficiency. Achieve shortened gel time, low chlorine content, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

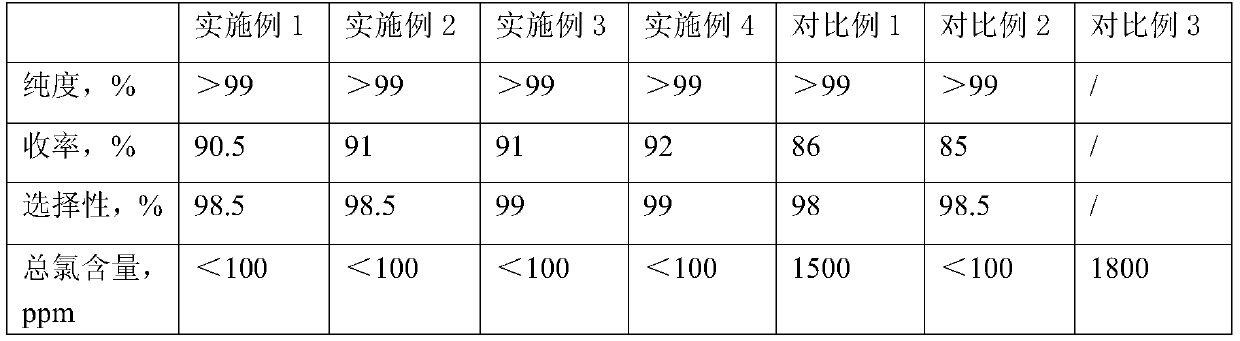

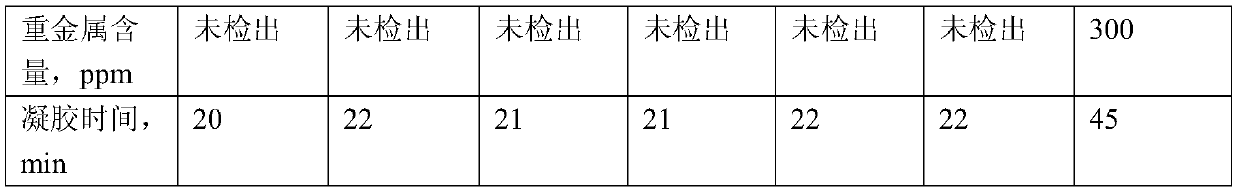

Examples

Embodiment 1

[0028] A kind of preparation method of 4-vinyl epoxycyclohexane is characterized in that comprising the steps:

[0029] (1) Add 100g of 4-vinylcyclohexene, 300g of toluene, 110g of acetic anhydride and 8g of sodium acetate into a 1000ml three-necked flask, and cool to 5°C-15°C while stirring;

[0030] (2) Then start to drop 150g 35% hydrogen peroxide, control the rate of addition to keep the temperature of the reaction system no more than 25°C, complete the dropwise addition in about 2 hours, and react for 4 hours after the addition;

[0031] (3) Slowly add 60 g of commercially available 30% liquid caustic soda to the system to adjust the pH to 10-12, stir for 10 minutes and stand for phase separation, and separate the upper organic phase;

[0032] (4) Add 50g of 10% sodium sulfite aqueous solution to the organic phase, stir for 10 minutes and leave to separate the phases, separate the upper organic phase (pH=10-12, starch potassium iodide test paper shows no peroxide residue)...

Embodiment 2

[0035] A kind of preparation method of 4-vinyl epoxycyclohexane is characterized in that comprising the steps:

[0036] (1) Add 98g of 4-vinylcyclohexene, 280g of toluene, 108g of acetic anhydride and 8.5g of sodium acetate into a 1000ml three-necked flask, and cool to 5°C-15°C while stirring;

[0037] (2) Then start to drop 155g 35% hydrogen peroxide, control the rate of addition to keep the temperature of the reaction system no more than 25° C., drop it in about 2.5 hours, and react for 5 hours after the addition;

[0038] (3) Slowly add 65 g of commercially available 32% liquid caustic soda to the system to adjust the pH to 10-12, stir for 15 minutes to stand for phase separation, and separate the upper organic phase;

[0039] (4) Add 55g of 8% sodium sulfite aqueous solution again, stir for 15 minutes and let stand to separate the phases, separate the upper organic phase (pH=10-12, starch potassium iodide test paper shows no peroxide residue), and recover toluene through p...

Embodiment 3

[0042] A kind of preparation method of 4-vinyl epoxycyclohexane is characterized in that comprising the steps:

[0043] (1) Add 99g of 4-vinylcyclohexene, 290g of toluene, 112g of acetic anhydride and 8.4g of sodium acetate into a 1000ml three-necked flask, and cool to 5°C-15°C while stirring;

[0044] (2) Then start to drop 131g of 40% hydrogen peroxide, control the rate of addition to keep the temperature of the reaction system no more than 25°C, complete the dropwise addition in about 1.8 hours, and react for 6 hours after the addition;

[0045] (3) Slowly add 64 g of commercially available 35% liquid caustic soda to the system to adjust the pH to 10-12, stir for 12 minutes and stand for phase separation, and separate the upper organic phase;

[0046] (4) Add 35g of 15% sodium sulfite aqueous solution again, stir for 12 minutes and let stand to separate the phases, separate the upper organic phase (pH=10-12, starch potassium iodide test paper shows no peroxide residue), and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com