Plasma fly ash fusion treatment and metal recycling system

A plasma and ash melting technology, used in solid separation, electrostatic effect separation, solid waste removal, etc., can solve problems such as consumption of large acid liquid, large energy and water, consumption, etc., to improve system economy and product quality. The effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

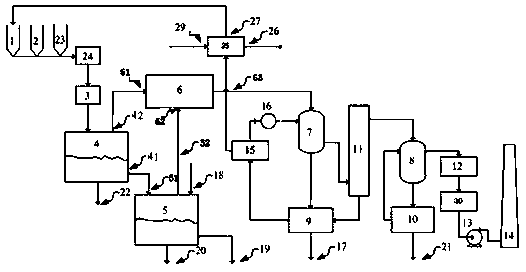

[0035] Such as figure 1Shown is the plasma bottom ash, fly ash melting treatment and metal recycling system of the present invention, including a feeding device, a two-stage ash melting device, a combustion chamber, a wet temperature reduction washing device, a mist eliminator, and an activated carbon material layer and induced draft fan.

[0036] Feeding device of the present invention comprises fly ash feeding device 1, bottom ash feeding device 2, additive feeding device 23, mixing device 24 and pelletizing device 3; Fly ash feeding device 1, bottom ash feeding device 2 and Additive feeding device 23 is connected with described mixing device 24; Described mixing device 24 is connected with described granulating device 3; Described fly ash feeding device 1, bottom ash feeding device 2 and additive feeding device The feeding device 13 is provided with a speed controller to control the feeding speed; fly ash, bottom ash and additives enter the mixing device 24 for mixing at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com