Carbonating tower, carbonating system and method

A carbonation tower and carbonation technology, applied in chemical instruments and methods, alkali metal carbonates, inorganic chemistry, etc., can solve problems such as difficult growth of crystal particles, low production efficiency, increased material and energy consumption, and achieve operational The effect of simple and convenient control, long equipment service life and high volume utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

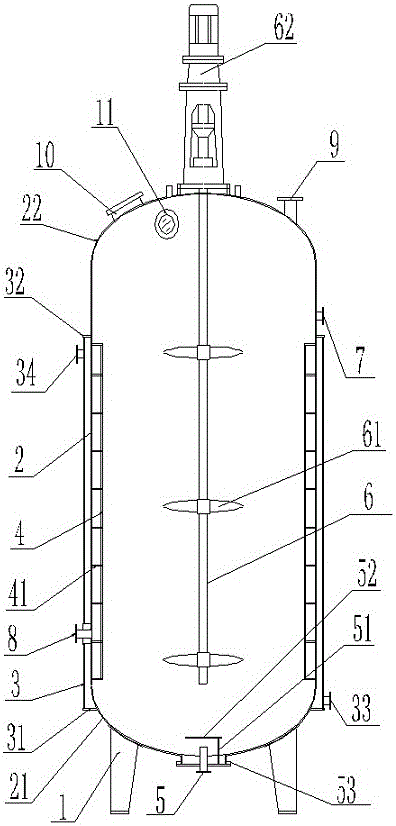

[0035] Such as figure 1 As shown, the carbonation tower of the present invention includes a tower shell, a cooling water tank, an air inlet 5 arranged on the tower shell, an air outlet 9, a feed port 7 and a discharge port 8, and the stirring shaft 6 arranged inside the tower shell , a motor 62 connected to the stirring shaft 6, a stirring blade 61 fixed on the stirring shaft 6, and a baffle plate 4 is fixed inside the tower shell.

[0036] The carbonation tower is a set of equipment used for gas-liquid mixing. In order to obtain larger crystals, it is necessary to strike a balance between grain growth and reaction rate. Reducing supersaturation and slowing down the stirring speed of the solution is to slow down the crystallization. Efficient measure of nucleation speed. Therefore, in the actual production, the mushroom cap carbonation tower has been used, which can meet the needs of production. Solvay carbonation tower is the most common tower type, and other carbonation to...

Embodiment 2

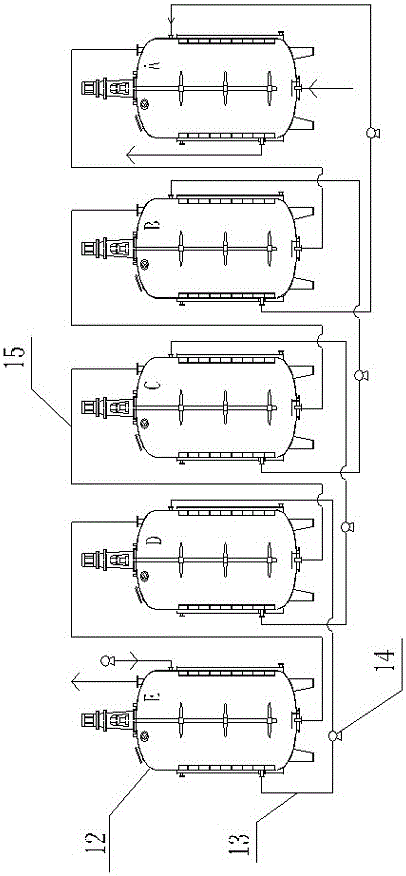

[0048] The carbonation system of the present invention comprises a plurality of carbonation towers connected; the gas outlet 9 of the carbonation tower 12 communicates with the gas inlet 5 of a single or multiple carbonation towers 12 through a gas connecting pipe 15, or the carbonation tower 12 The air inlet 5 of the carbonation tower is inhaled separately, and the gas outlet 9 of the carbonation tower 12 is directly exhausted, and the above two connection modes are combined freely; Connected through the material-liquid connecting pipe 13.

[0049] Such as figure 2 As shown, the carbonation system of the present invention comprises a plurality of carbonation towers 12 connected, and the gas outlet 9 of each carbonation tower is communicated with the gas inlet 5 of the adjacent carbonation tower through a gas connecting pipe 15, and each carbonation tower The discharge port 8 of the carbonation tower communicates with the feed port 7 of the adjacent carbonation tower through...

Embodiment 3

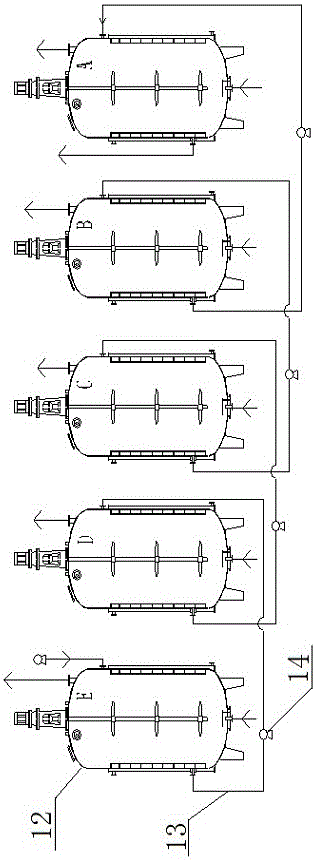

[0051] Such as image 3 As shown, the carbonation system of the present invention comprises a plurality of carbonation towers 12 connected to form, the air inlet 5 of the carbonation tower 12 is independently air-intake, the gas outlet 9 of the carbonation tower 12 is exhausted directly, each carbonation tower The discharge port 8 of the carbonation tower is communicated with the feed port 7 of the adjacent carbonation tower through the feed-liquid connection pipe 13, and a pump 14 is installed on the feed-liquid connection pipe 13, and the feed port 7 is located at the top of the carbonation tower 12.

[0052] The gas inlet 5 of the carbonation tower 12 takes in air separately, that is, the carbon dioxide gas entering the gas inlet 5 of the carbonation tower 12 is exogenous carbon dioxide, rather than the carbon dioxide gas discharged from the gas outlet 9 of the gas carbonation tower 12 . The gas outlet 9 of the carbonation tower 12 is directly exhausted, which means that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com