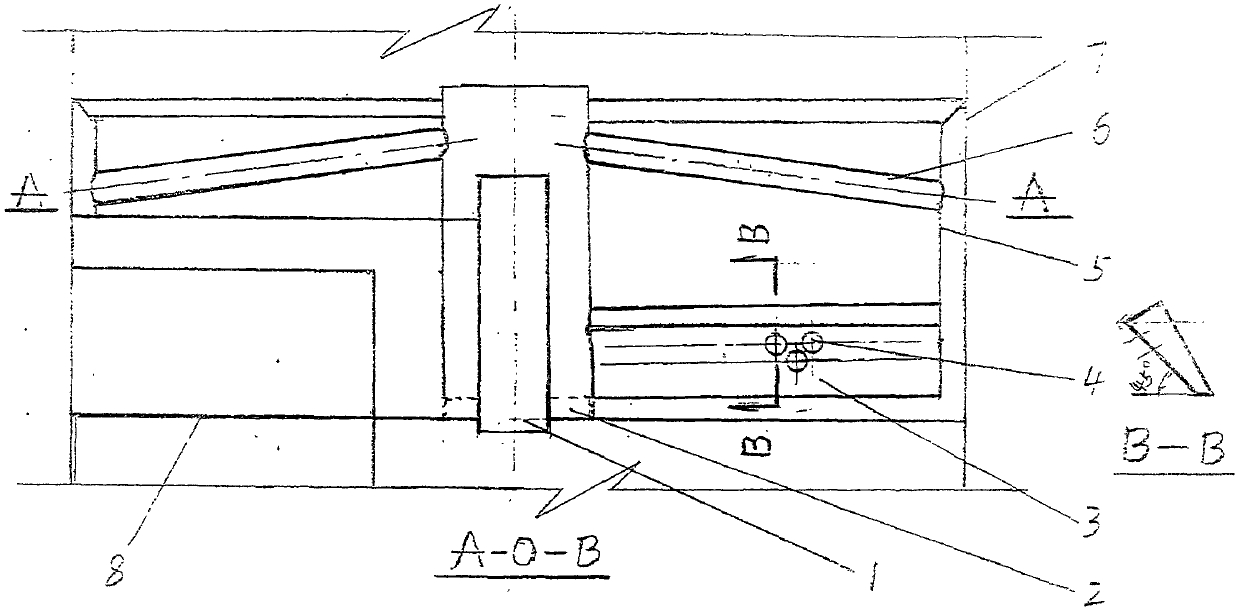

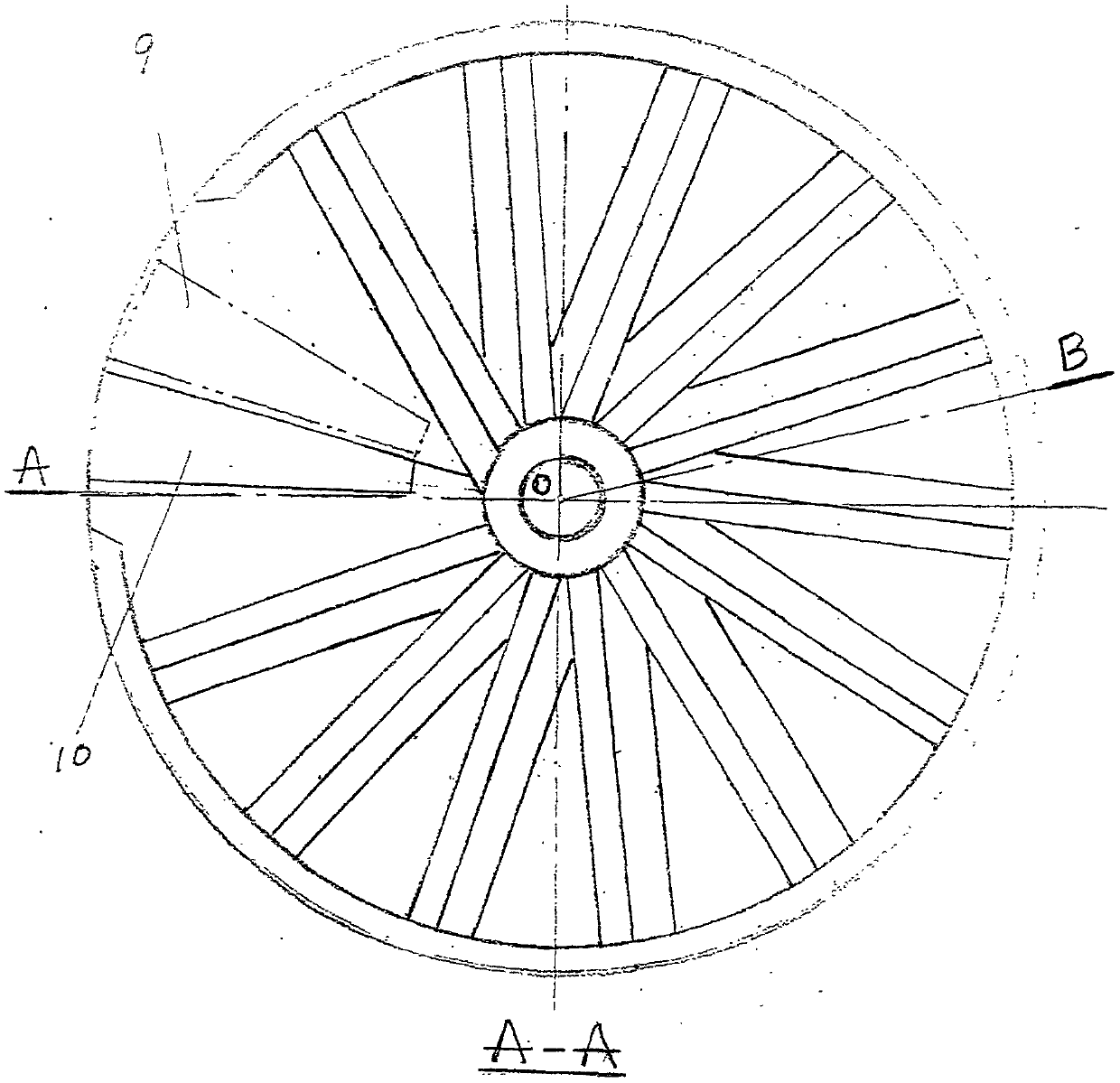

Rotary vortex jetting tray

A technology of tray and jet tube, applied in the field of rotating vortex jet tray, can solve the problems of high operating conditions, low gas-liquid two-phase turbulence, low operating elasticity, etc., and achieve the effect of strengthening mass transfer conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] 1. One-time sale.

[0038] 2. Cooperative development.

[0039] 【Note 1】

[0040] About the gas flow resistance of the rectification column. The resistances that need to be overcome for gas flow in this tower include: the resistance of the two-way liquid layer above the nozzle hole, the resistance of the vortex flow pressure, the resistance of the dry plate, and the resistance caused by the surface tension, viscosity and gravity of the liquid. Among them, the first three items are larger than the existing tray tower.

[0041] On the same tray, the concentration of volatile components gradually decreases in the direction of liquid flow. As a result, the concentration of the gas under the plate is always constant, and the low-volatile components and the volatile components in the liquid phase are continuously provided for mass exchange. With the lengthening of the liquid flow path, the liquid that should have overflowed like a conventional column continues to contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com