Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Downsizing and thinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

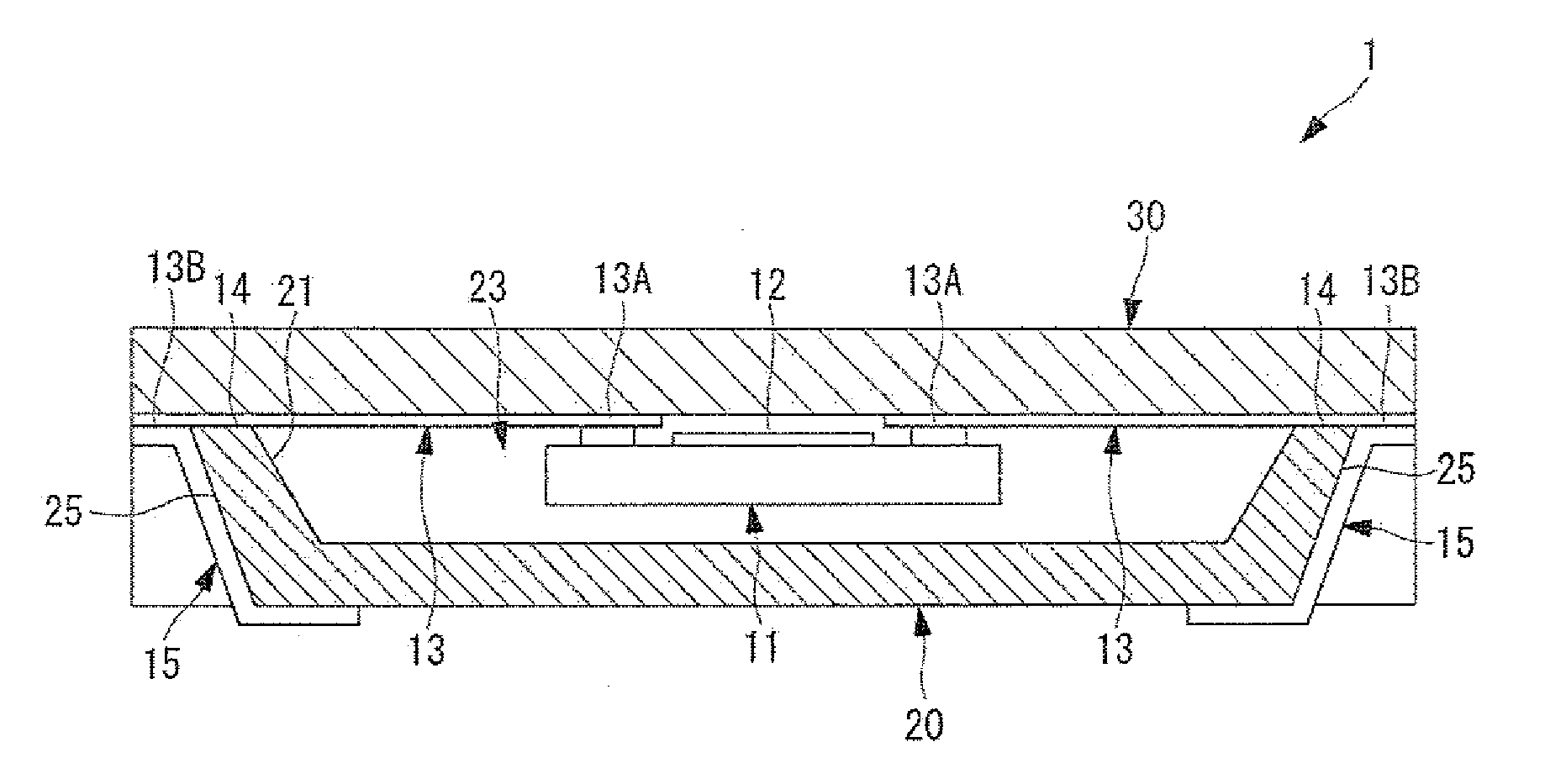

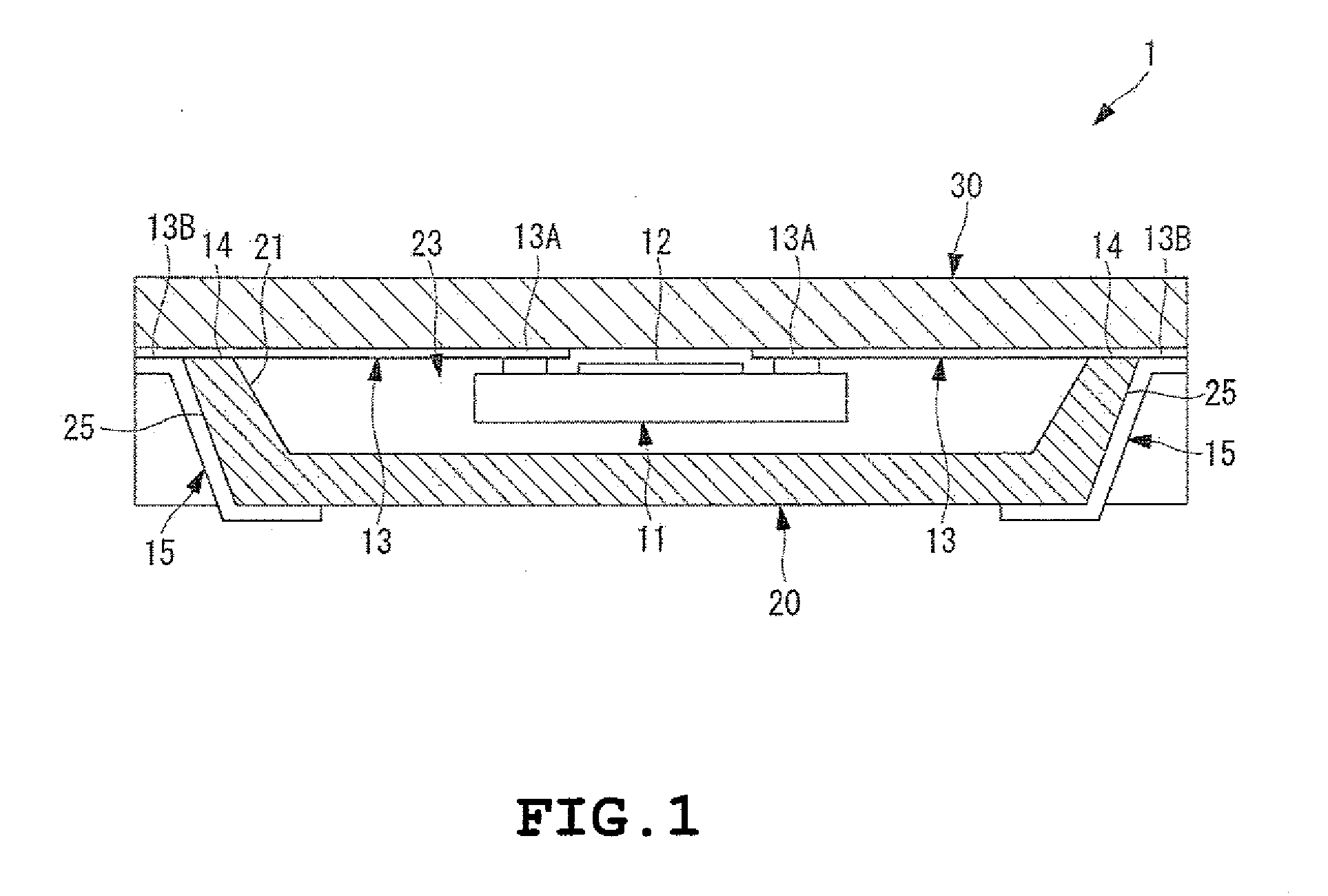

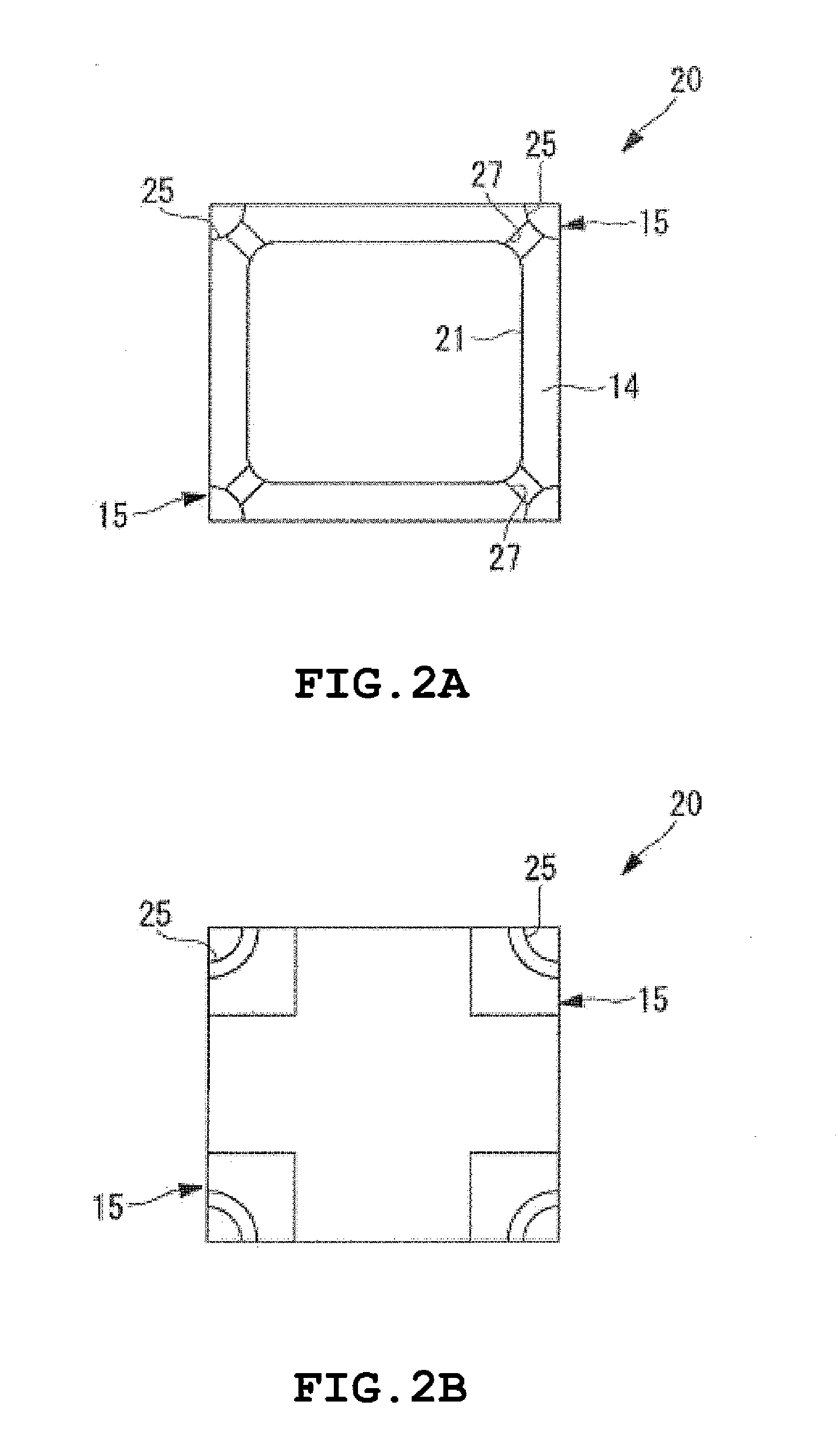

Semiconductor device

ActiveUS20160343640A1Reduce loadEffectively coolSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor device

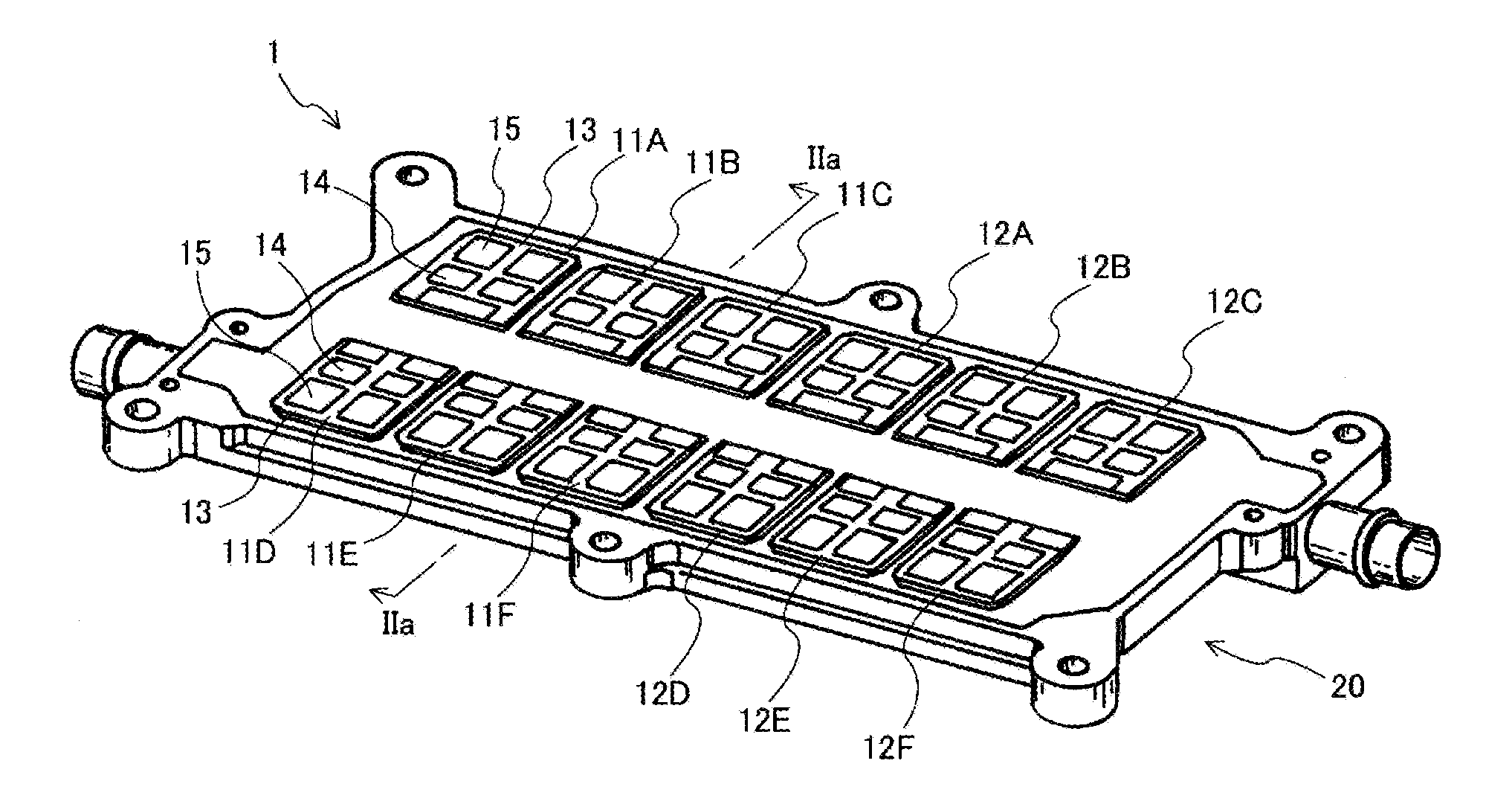

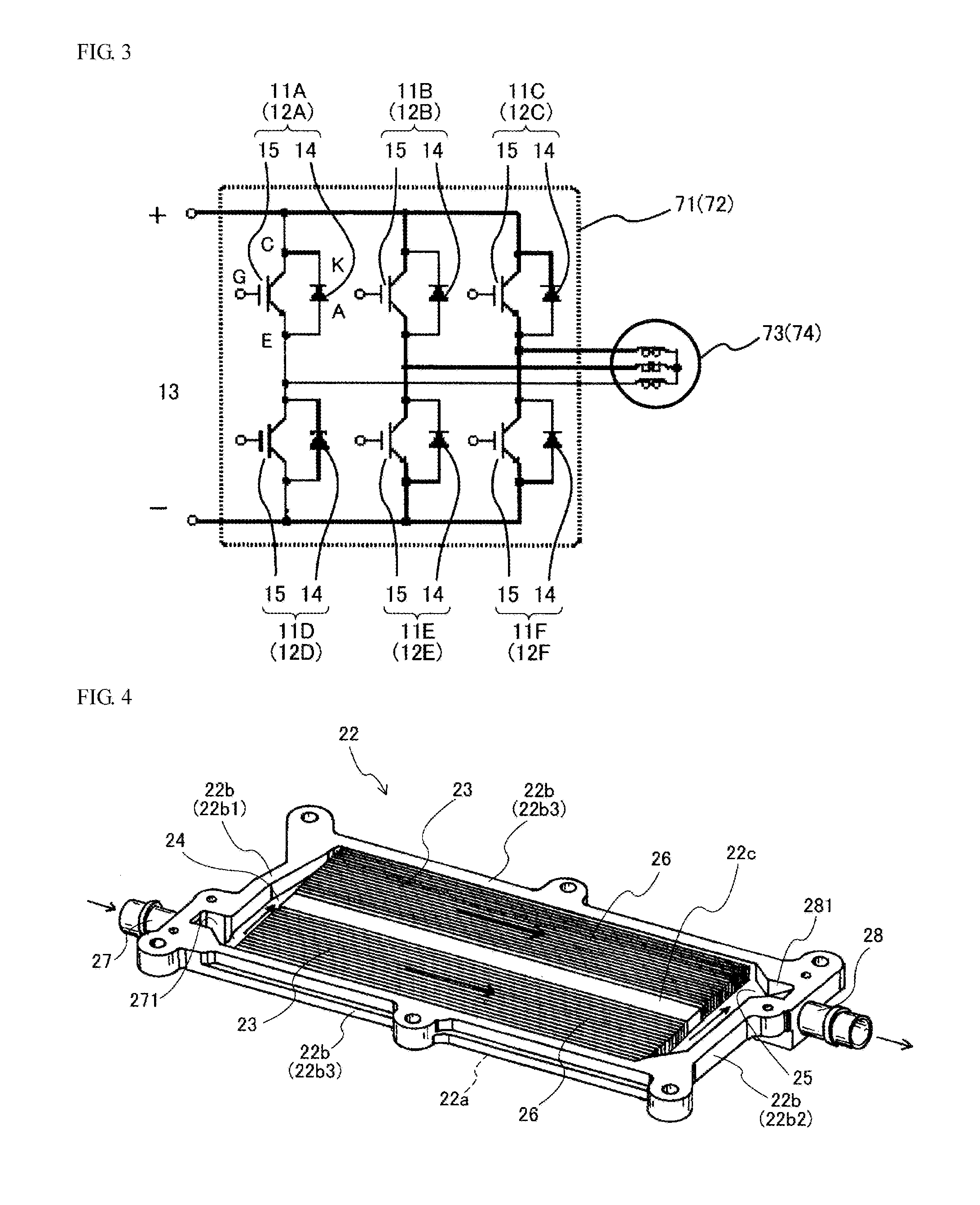

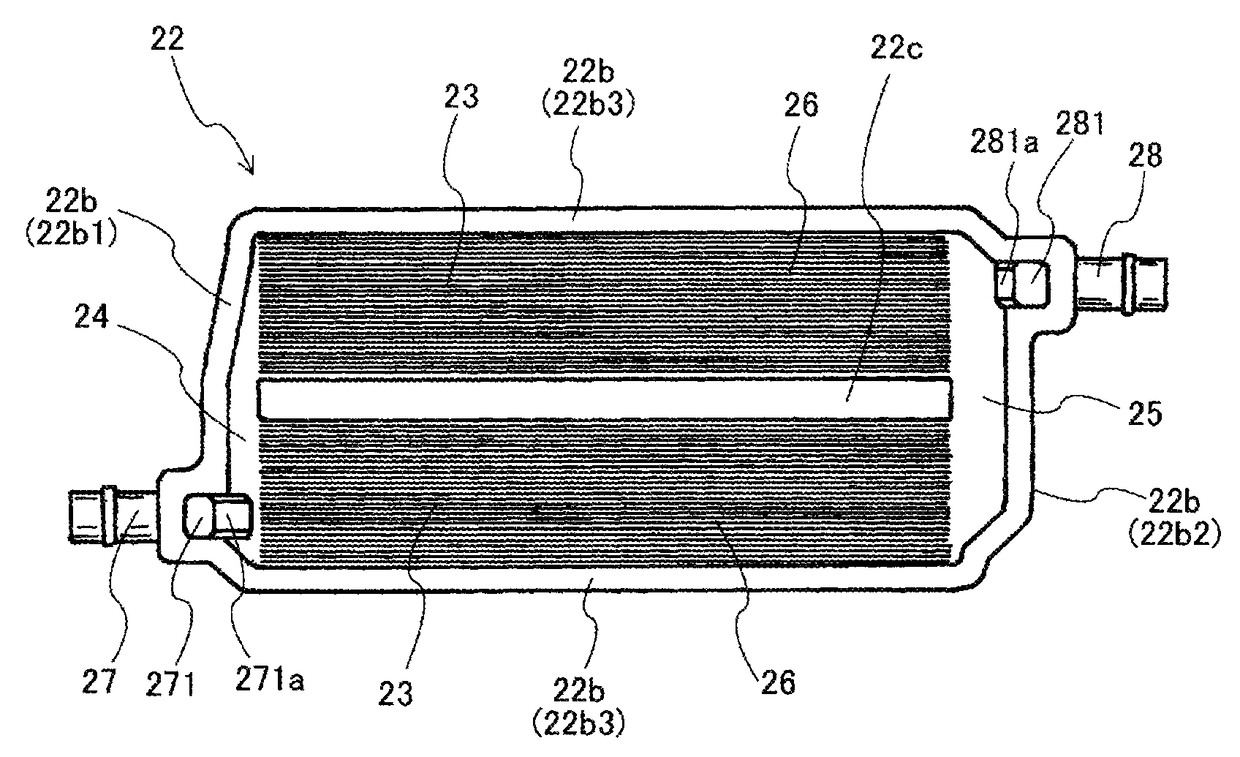

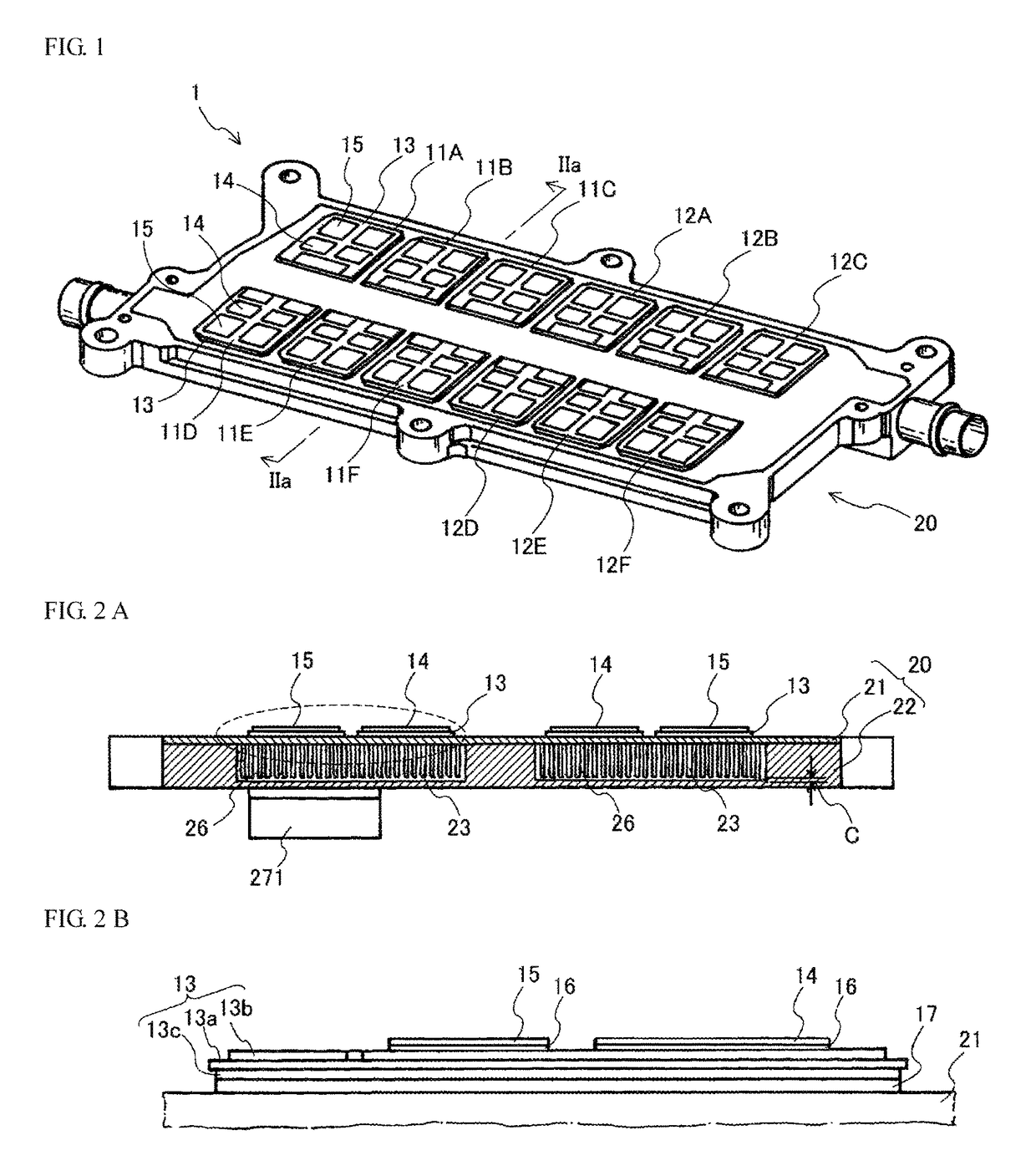

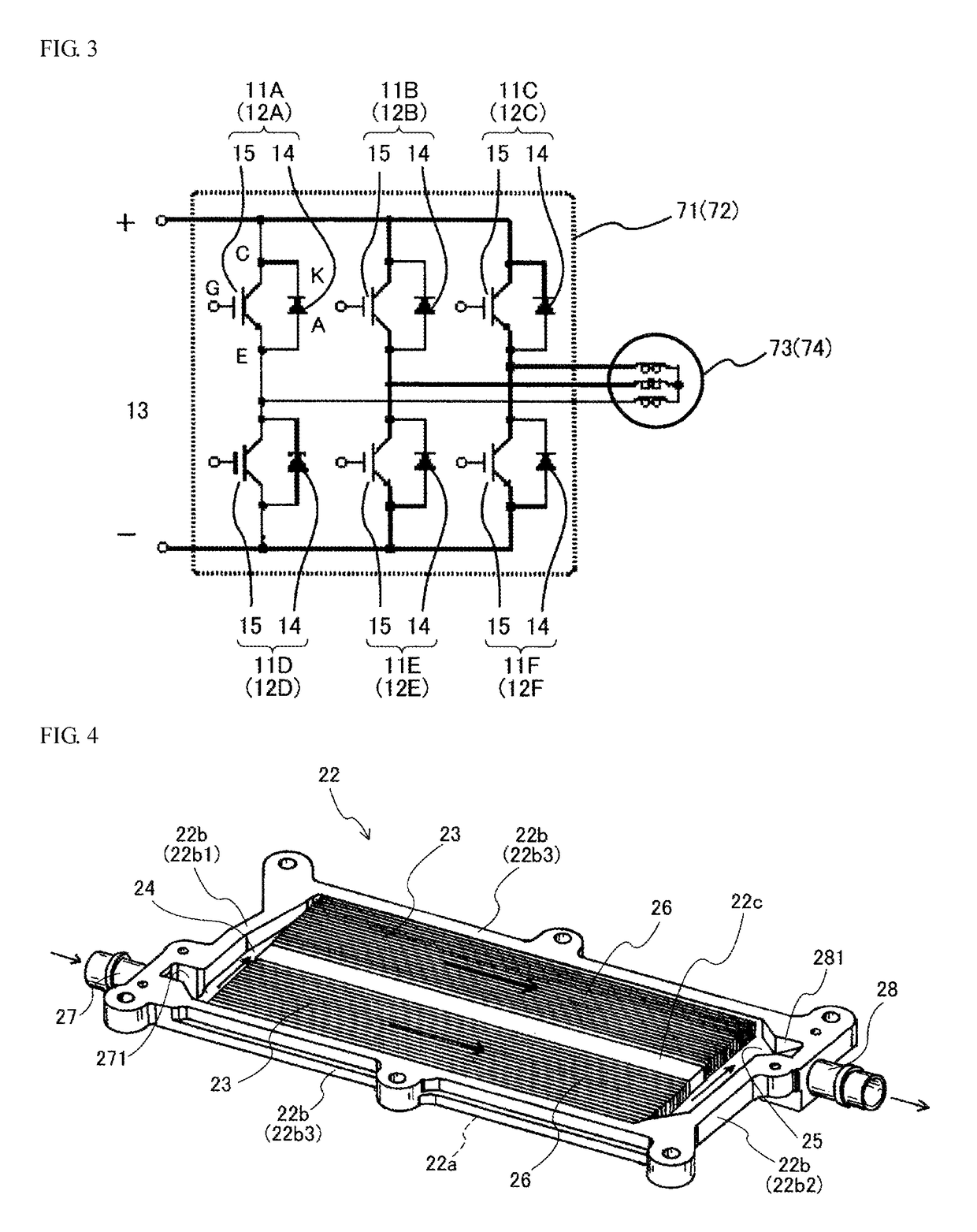

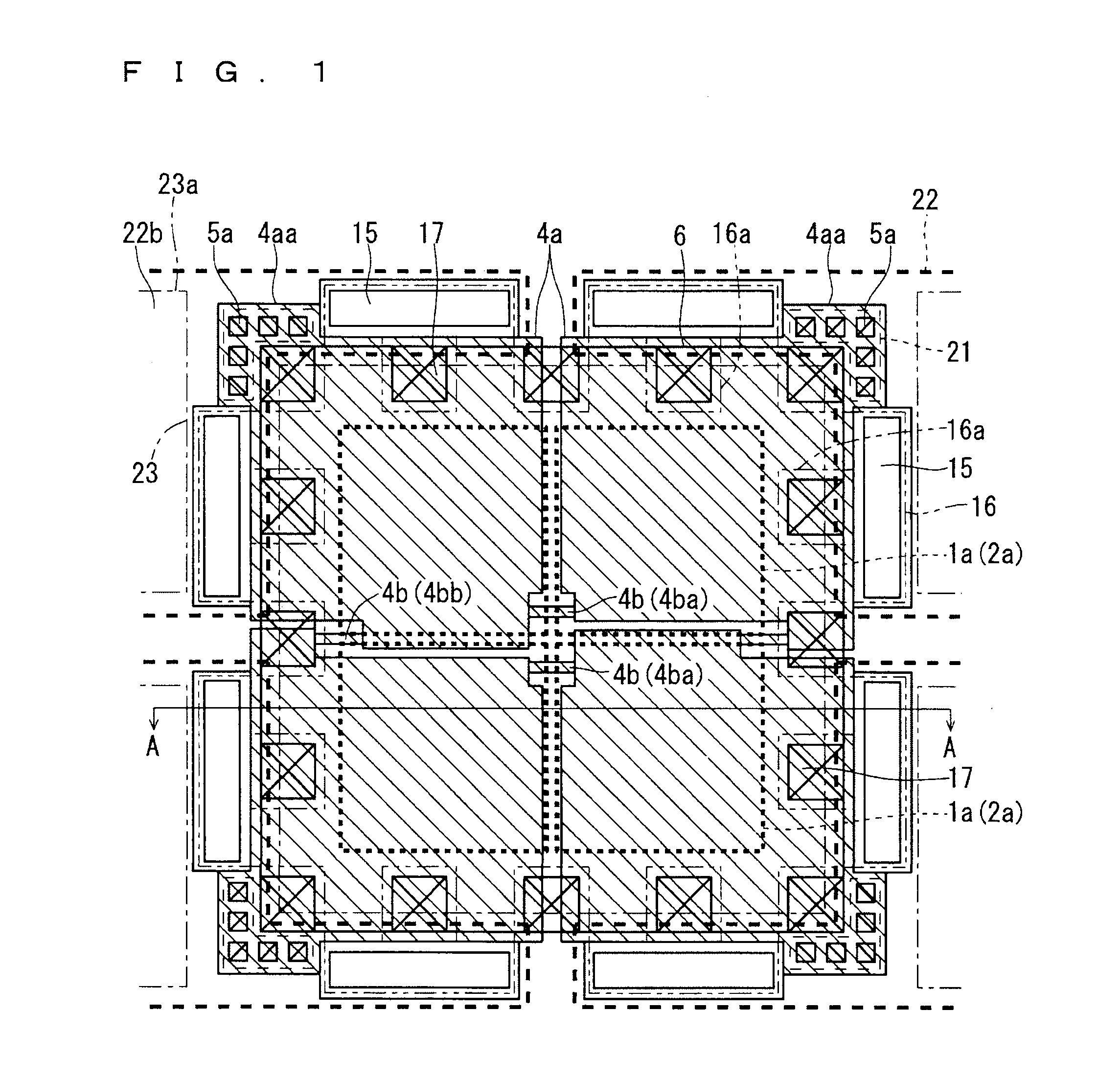

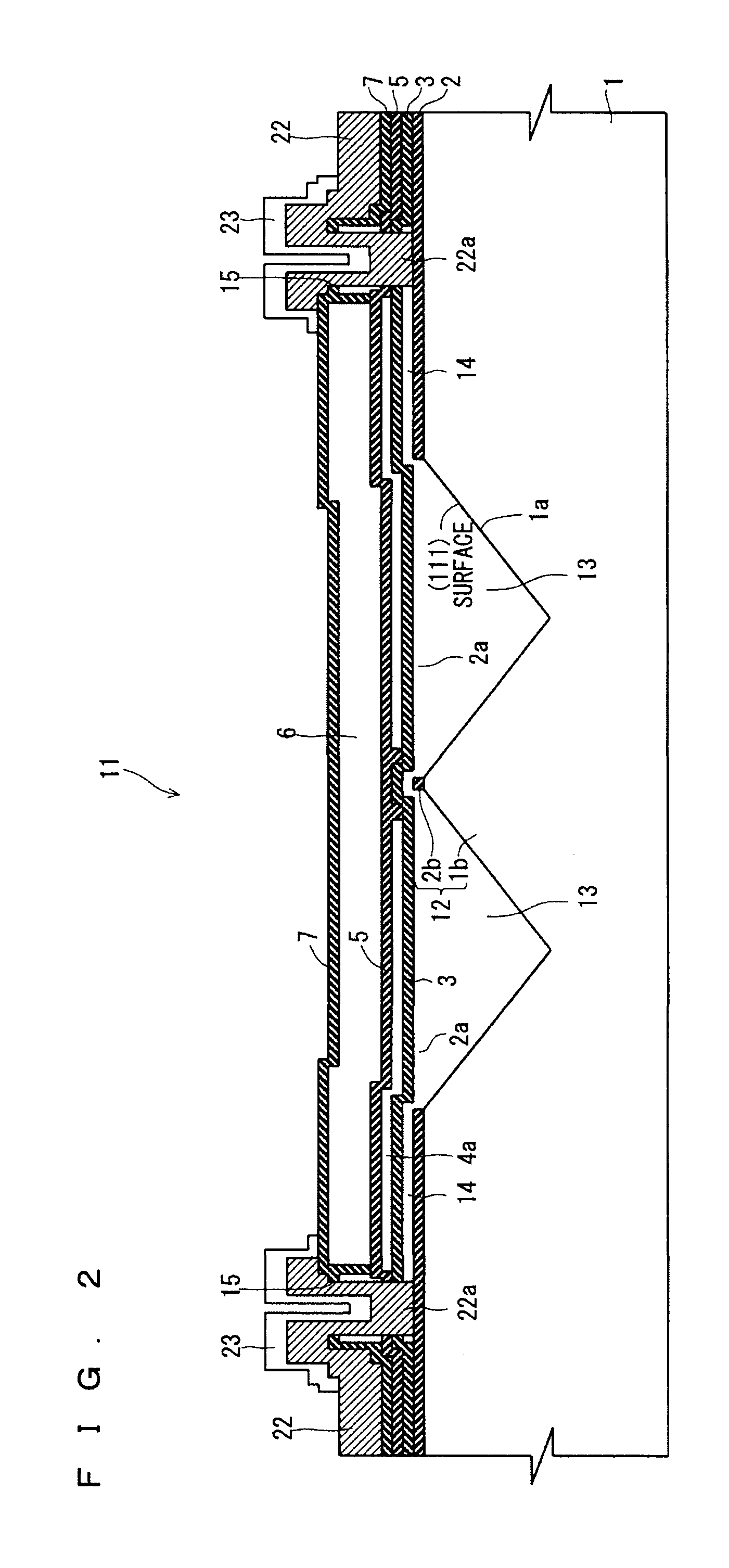

A cooler 20 of a semiconductor device includes an inlet portion 27 and an outlet portion 28 for a cooling liquid, an inlet path 24, an outlet path 25, and a cooling flow path 26. The inlet path 24 and the outlet path 25 have asymmetrical planar shapes. A connection portion 271 between the inlet path 24 and the inlet portion 27 is opposed to the cooling flow path 26 of a part immediately below plural circuit substrates 13 arranged on the cooler 20. A connection portion 281 between the outlet path 25 and the outlet portion 28 is opposed to the cooling flow path 26 of a part immediately below plural circuit substrates 13 arranged on the cooler 20.

Owner:FUJI ELECTRIC CO LTD

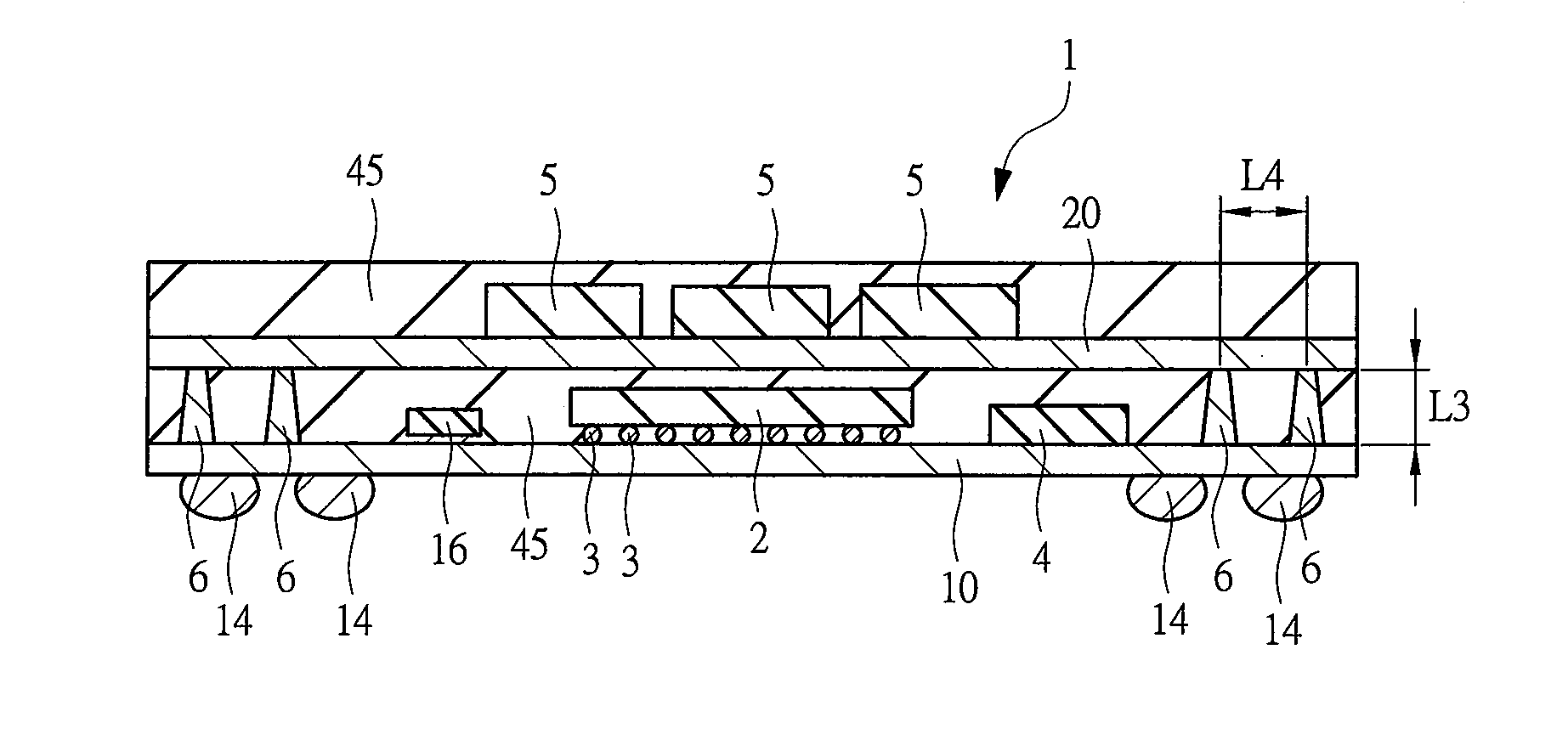

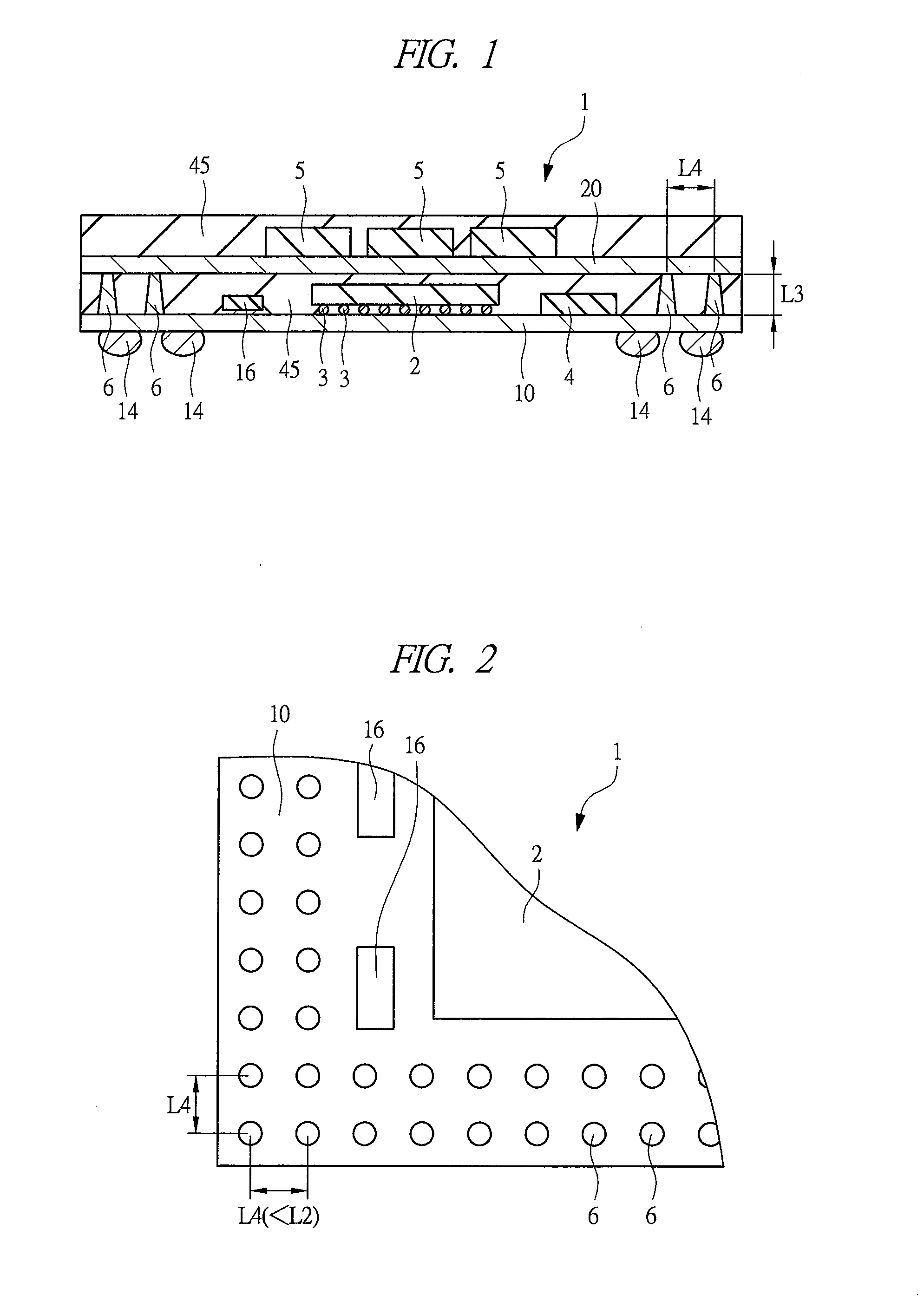

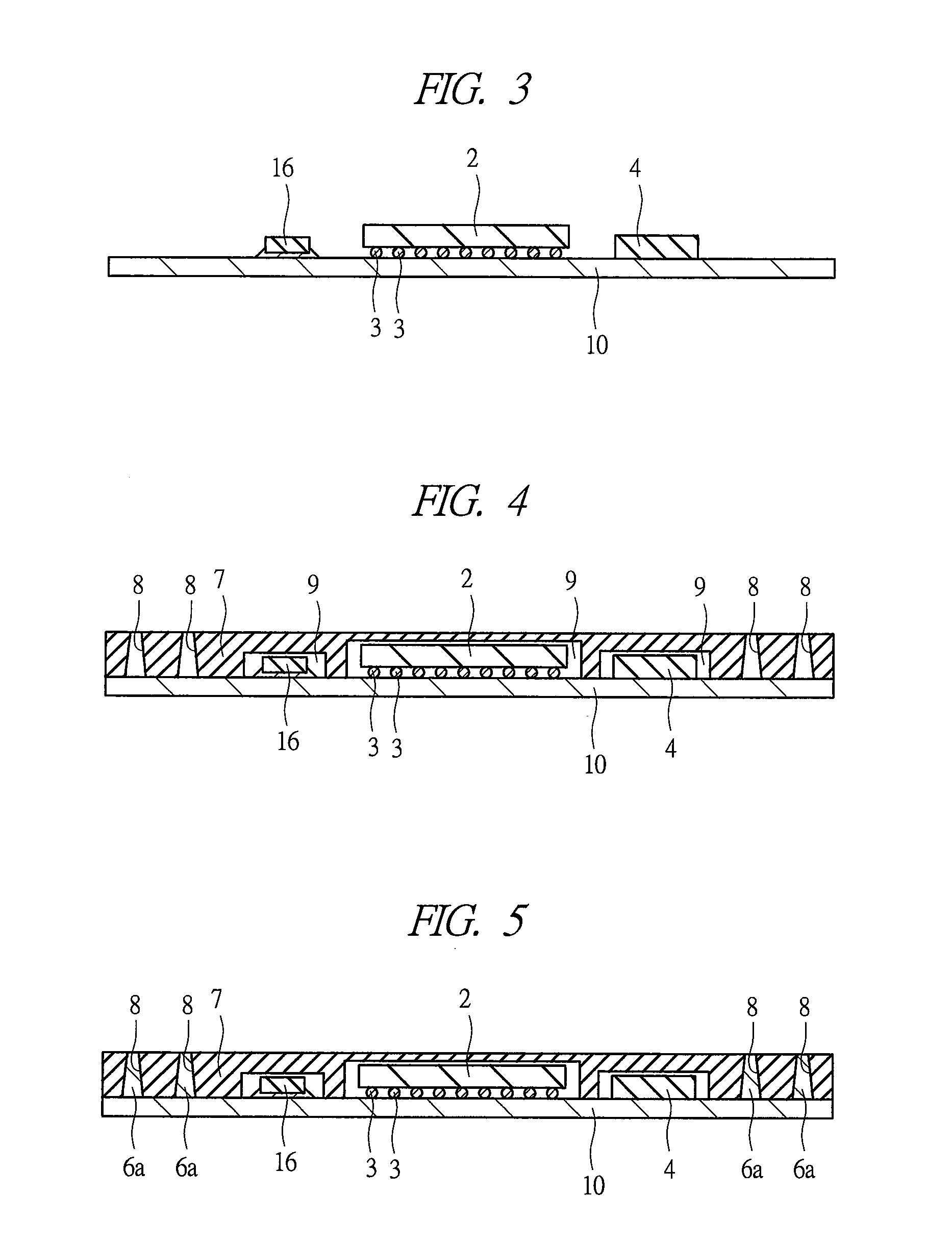

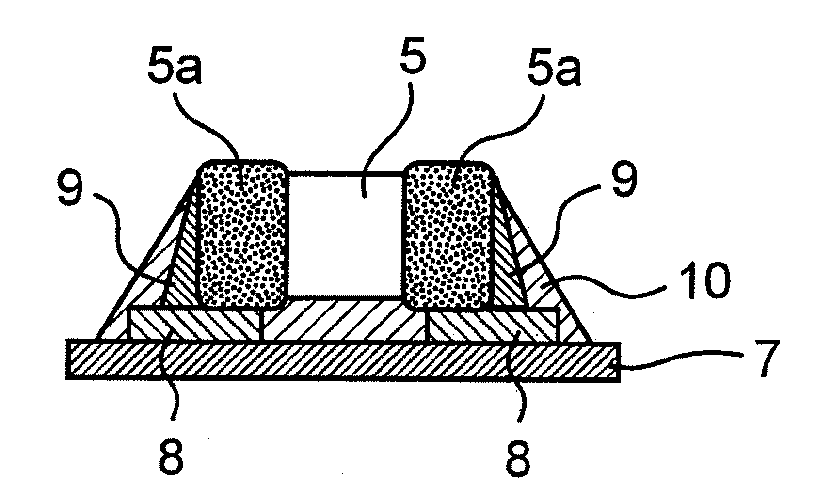

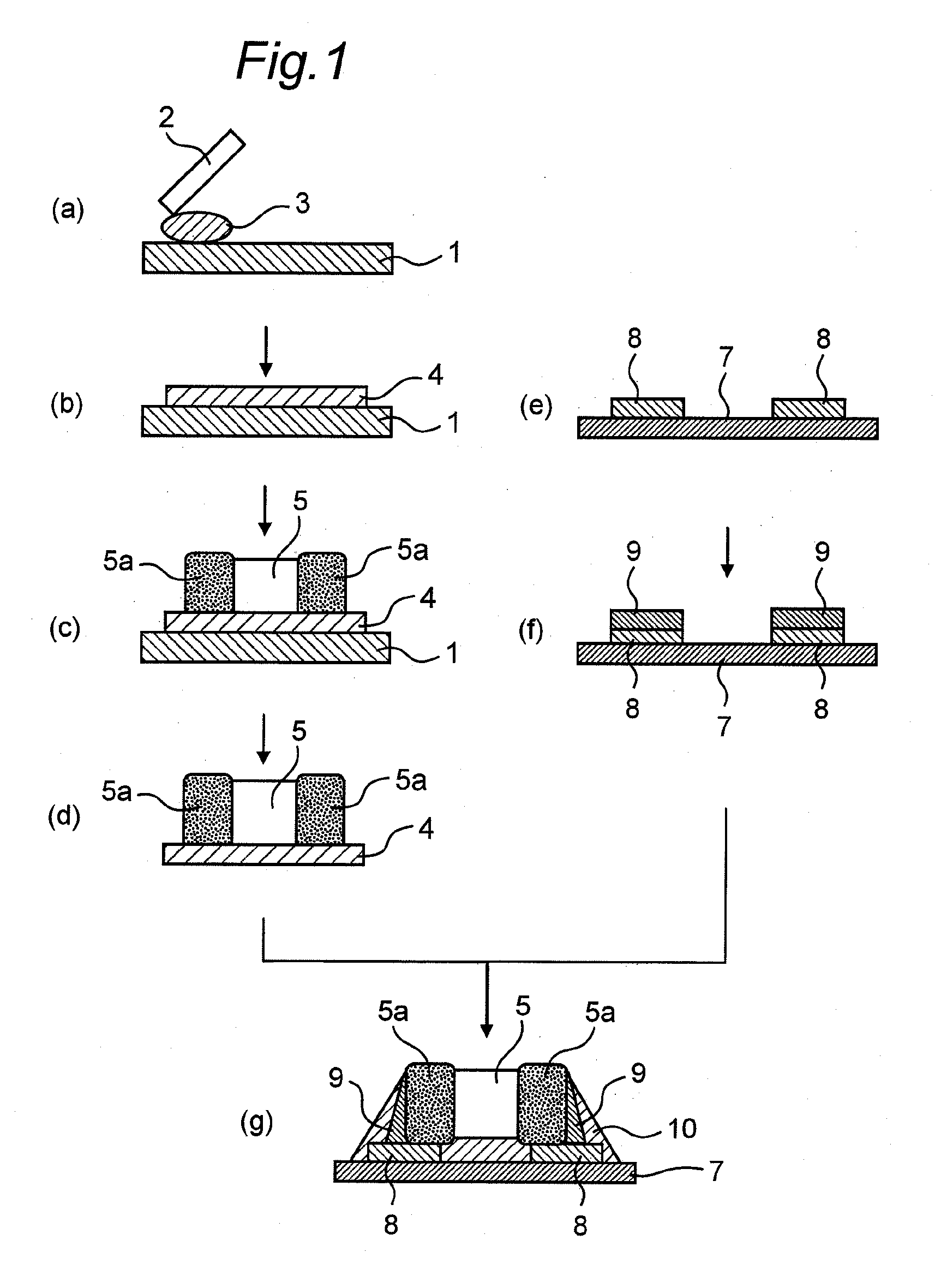

Semiconductor device and method of manufacturing the same

ActiveUS20110128713A1Downsizing and thinningLower Reliability RequirementsSemiconductor/solid-state device detailsPrinted circuit aspectsElectrical connectionSolder ball

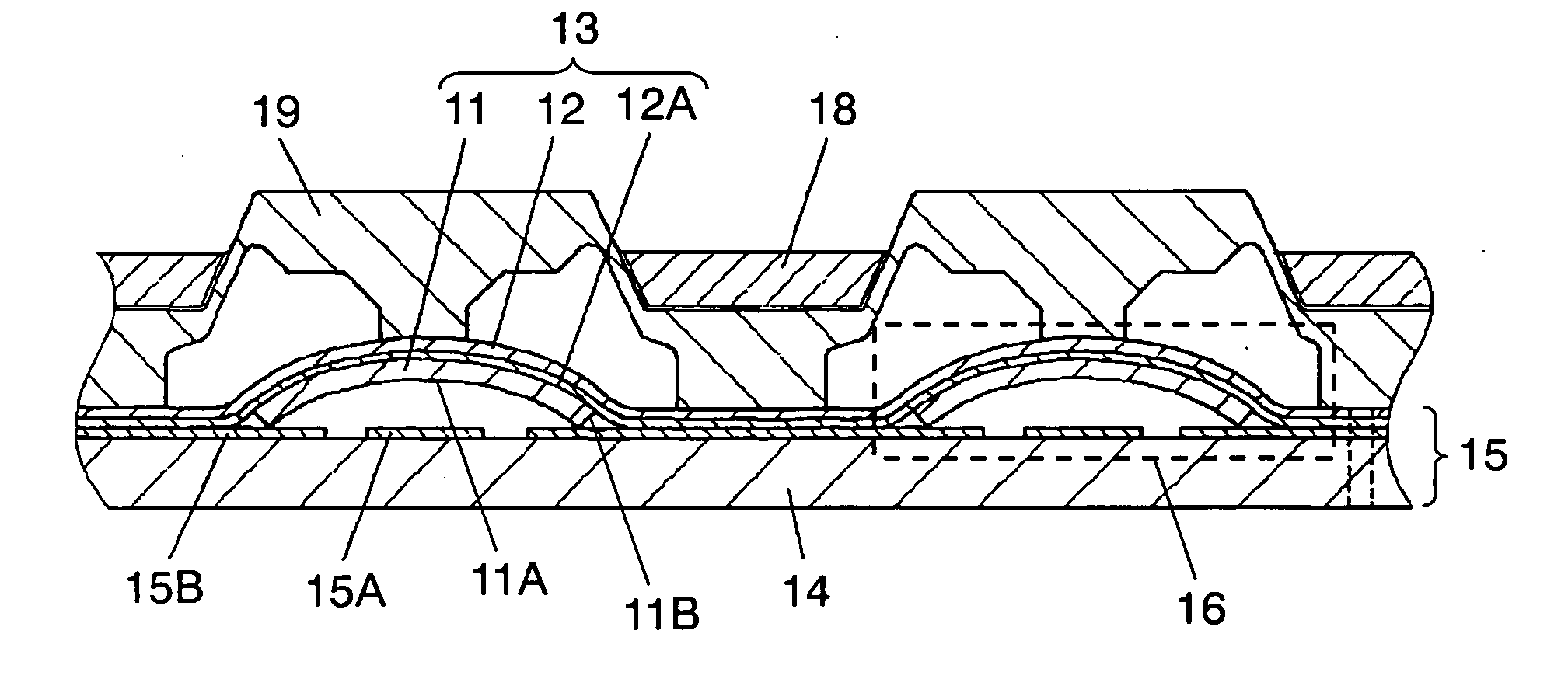

In a semiconductor device in which a plurality of wiring substrates each mounting an electronic component are stacked and sealed by a resin, the semiconductor device can be downsized, thinned, and highly reliable, and its manufacturing cost can be reduced. By using a metal paste for electrical connection between the stacked lower-layer side wiring substrate and upper-layer side wiring substrate, a connecting pitch can be smaller than that in a connecting method of using a solder ball including Cu core, and the connection at low temperature can be achieved. Also, by coating a metal paste by a print-coating method or a dispense-coating method, manufacturing steps are simplified, so that the manufacturing cost is reduced.

Owner:RENESAS ELECTRONICS CORP

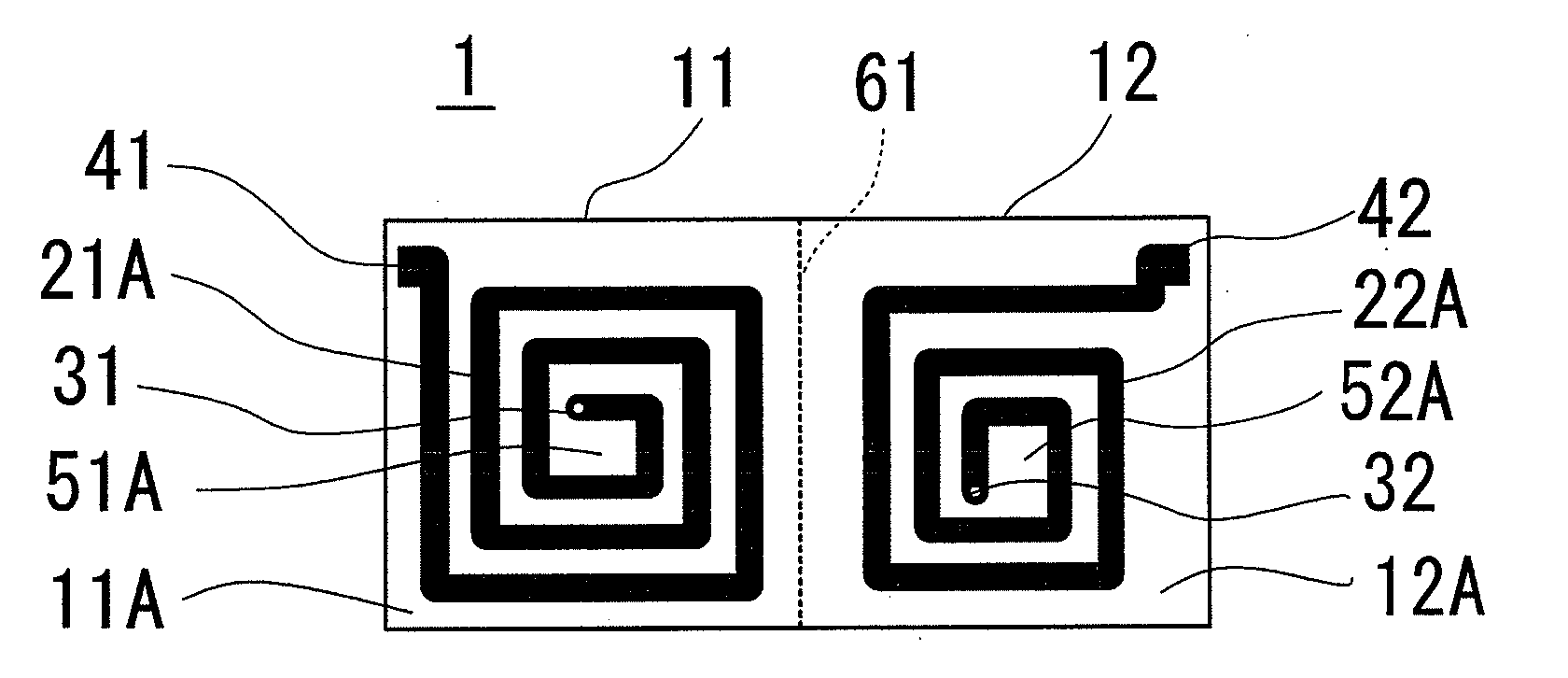

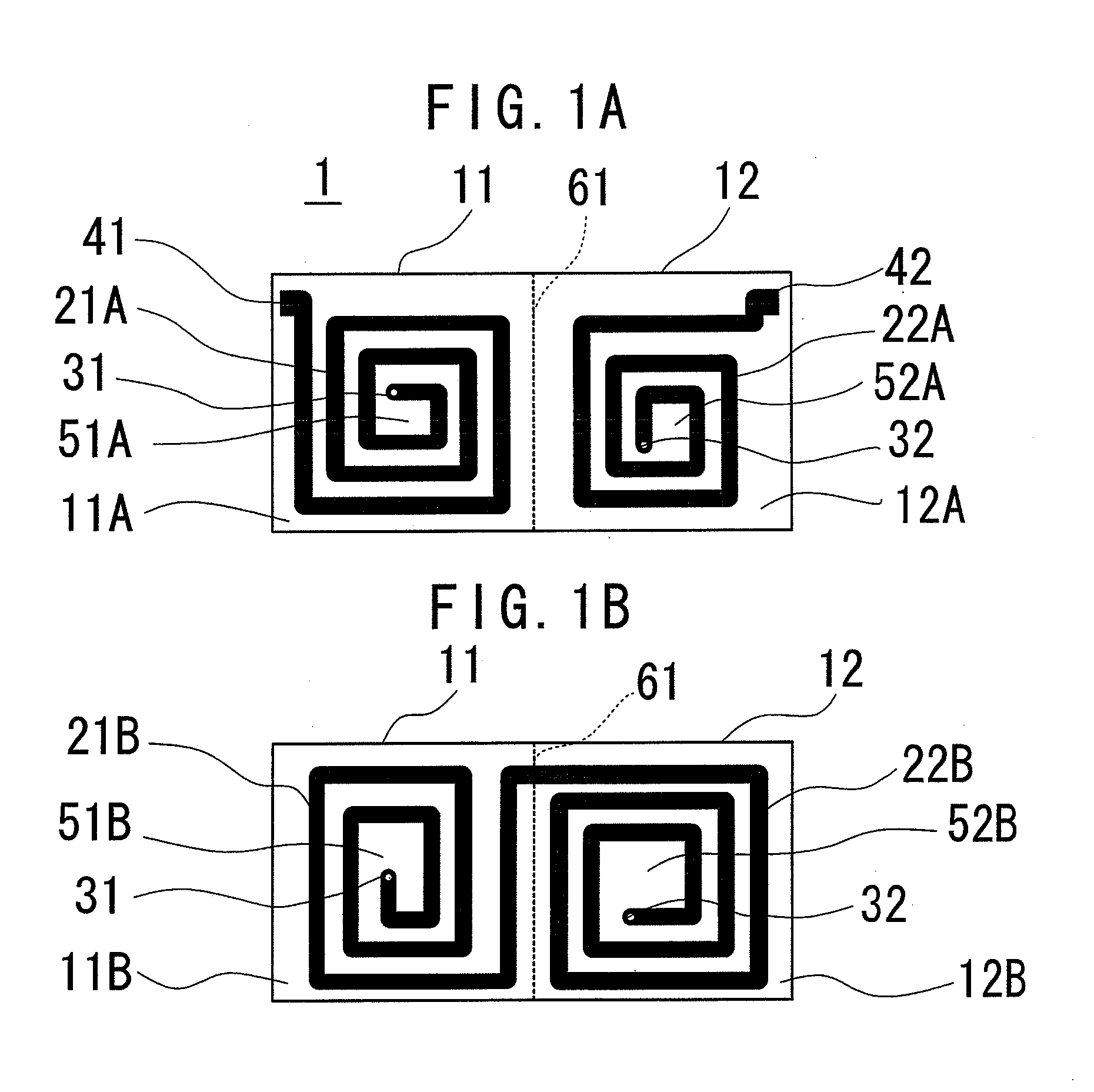

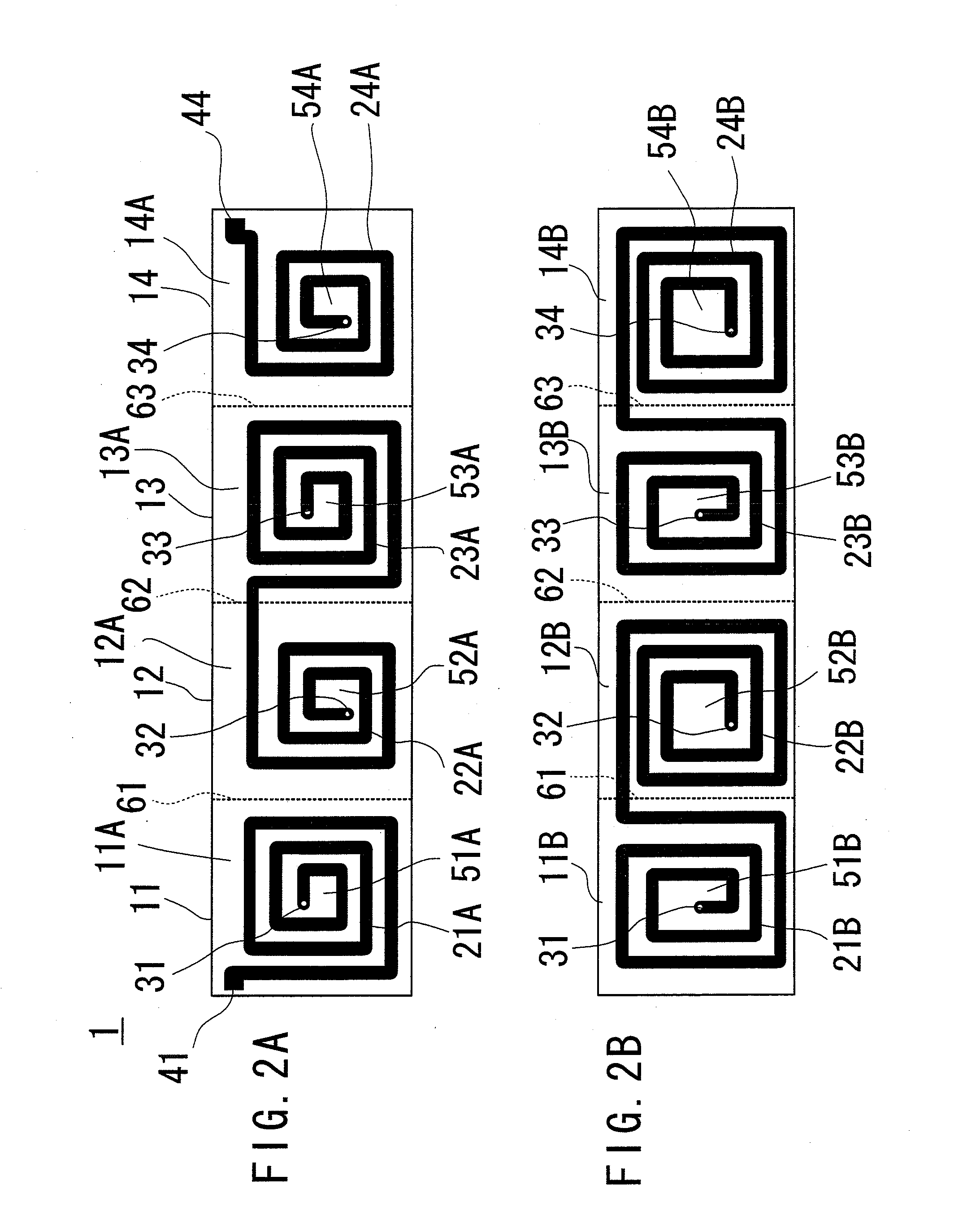

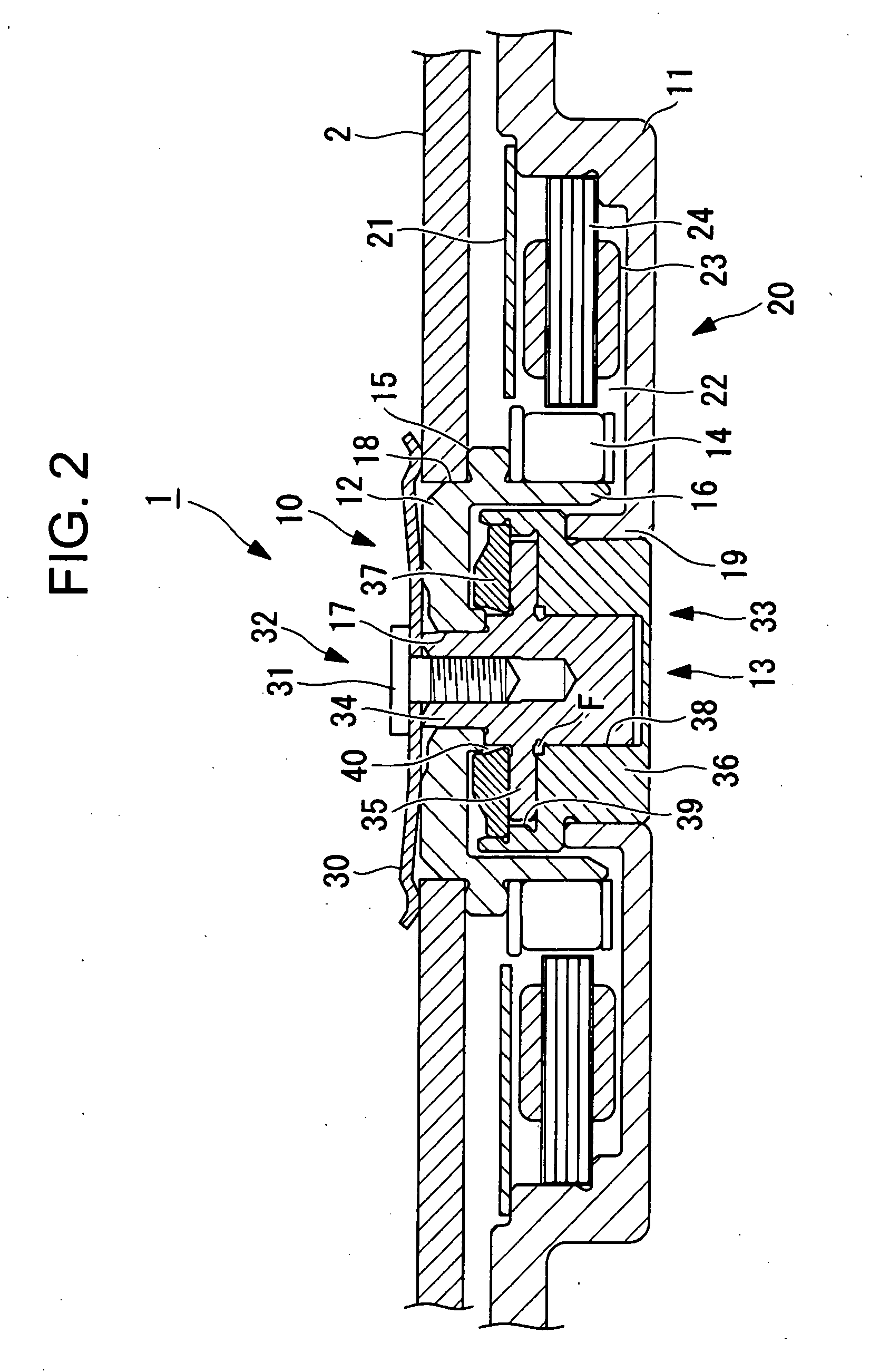

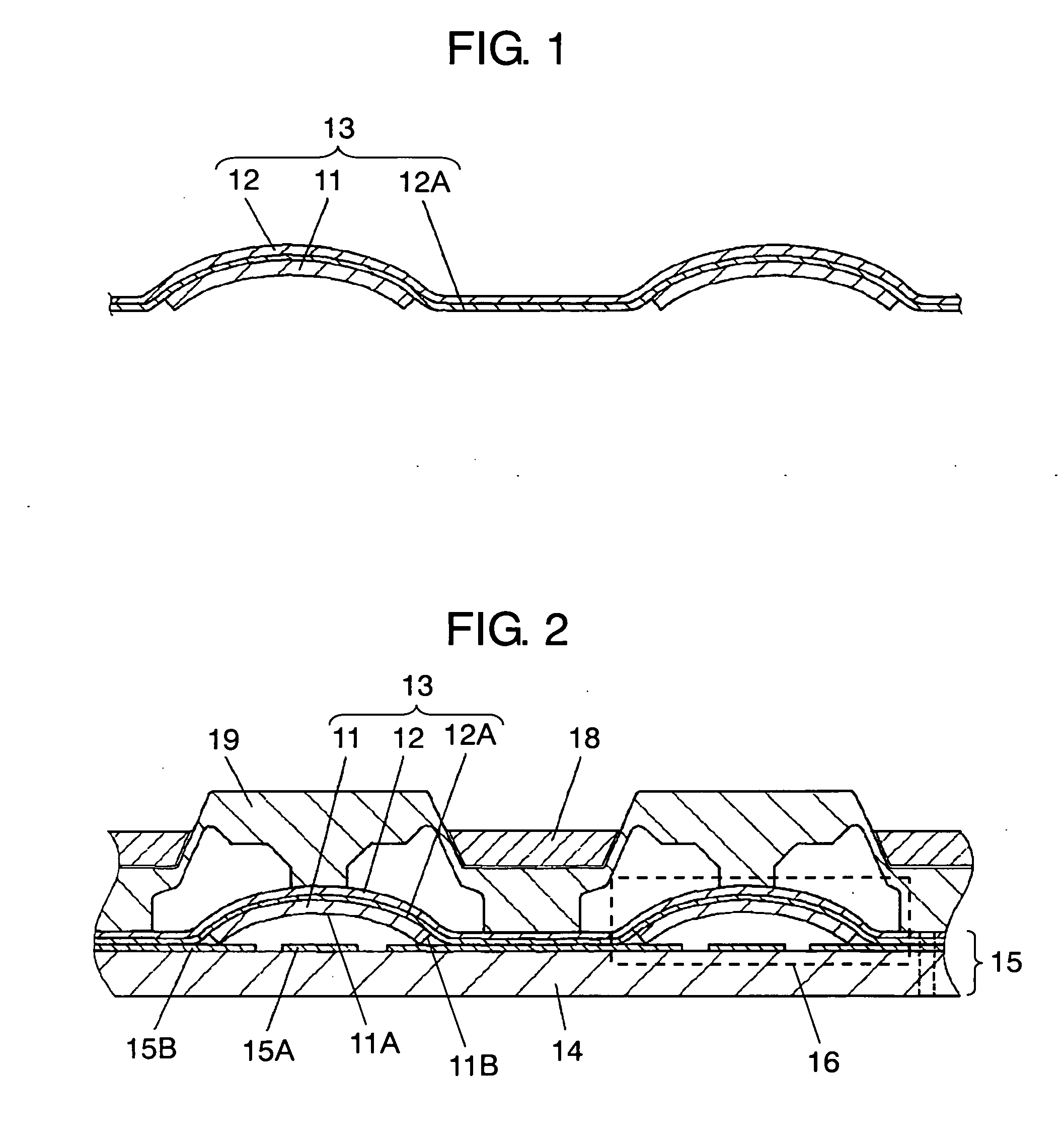

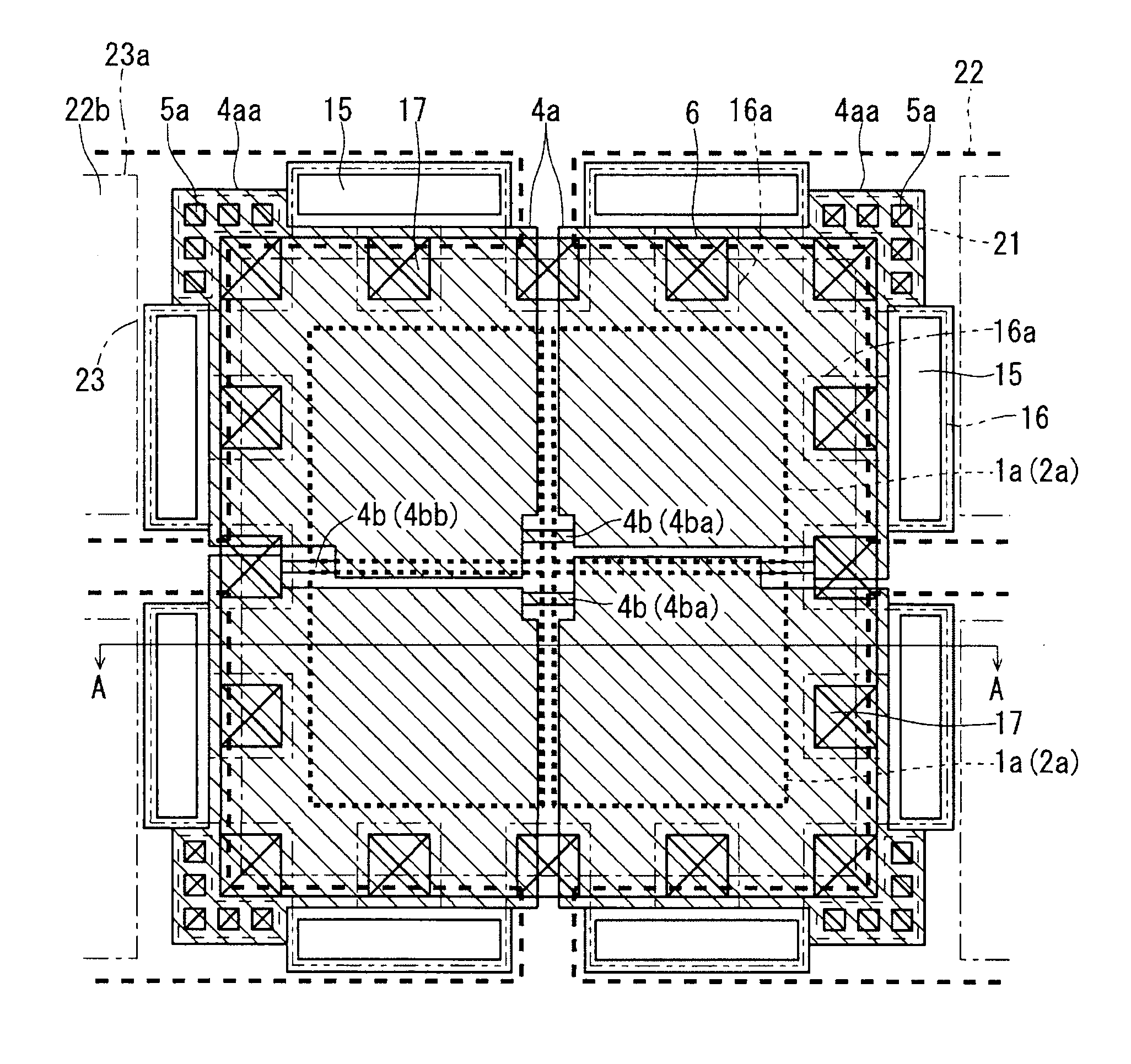

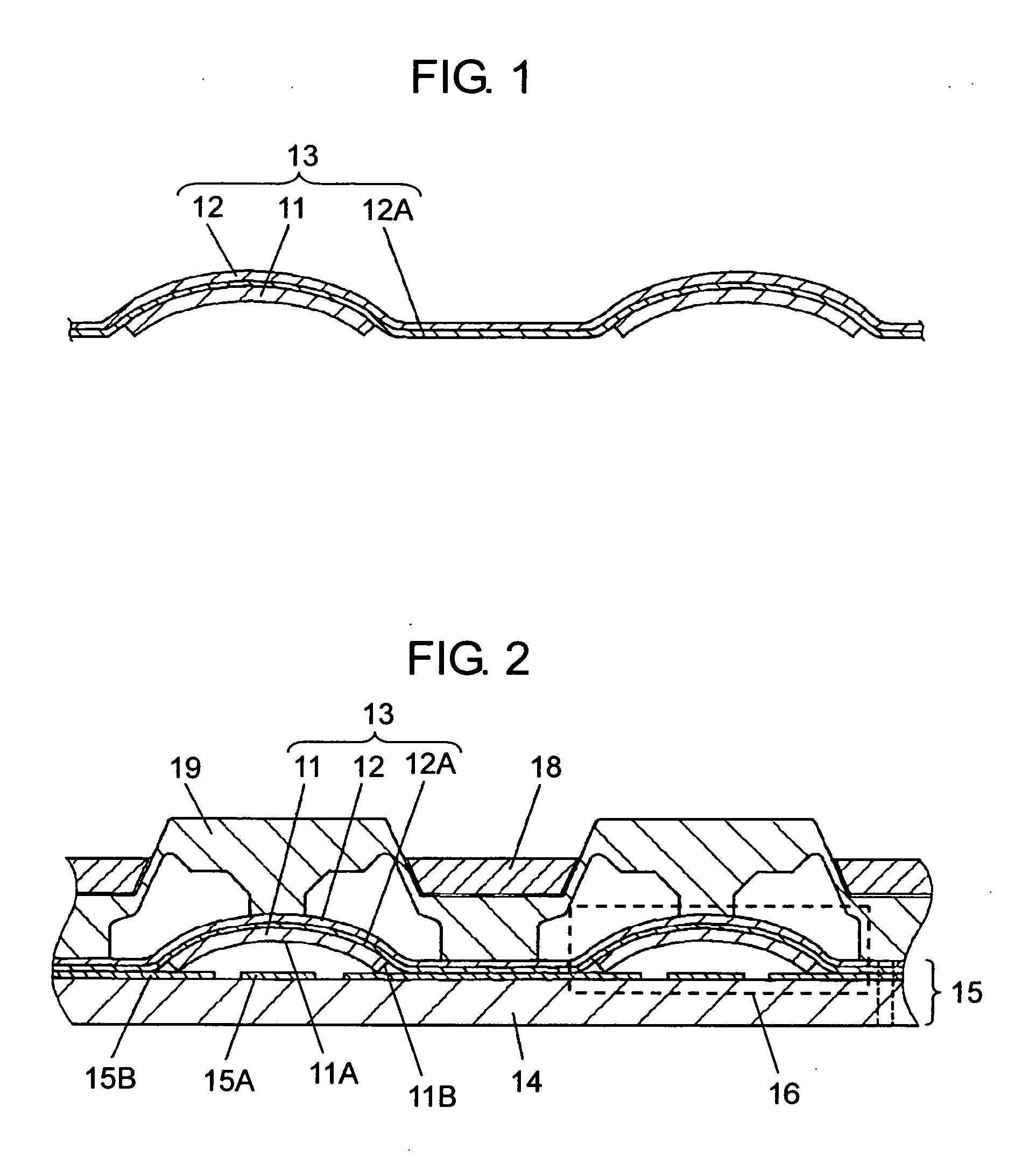

Multi-layered device

InactiveUS20100079232A1Thinner deviceDownsizing and thinningTransformers/inductances coils/windings/connectionsPrinted inductancesElectrical conductorInductor

A multilayered device comprises an insulation sheet 1 having at least two foldable areas 11, 12 which are multilayered by being folded; and a first conductor 21A, 22A which is formed on a first face 11A, 12A and constitutes a first coil 51A, 52A having one turn or more, and a second conductor 21B, 22B which is formed on a second face 11B, 12B and constitutes a second coil 51B, 52B having one turn or more in the same winding direction as that of the first coil in each of the foldable areas, at least four conductors are disposed in parallel with each other by folding the insulation sheet so as to constitute an inductor, and thus, it enables to thin the thickness of the multilayer, to downsize and to lightweight even when it constitutes a coil device having a larger winding number.

Owner:MATSUSHITA ELECTRIC WORKS LTD

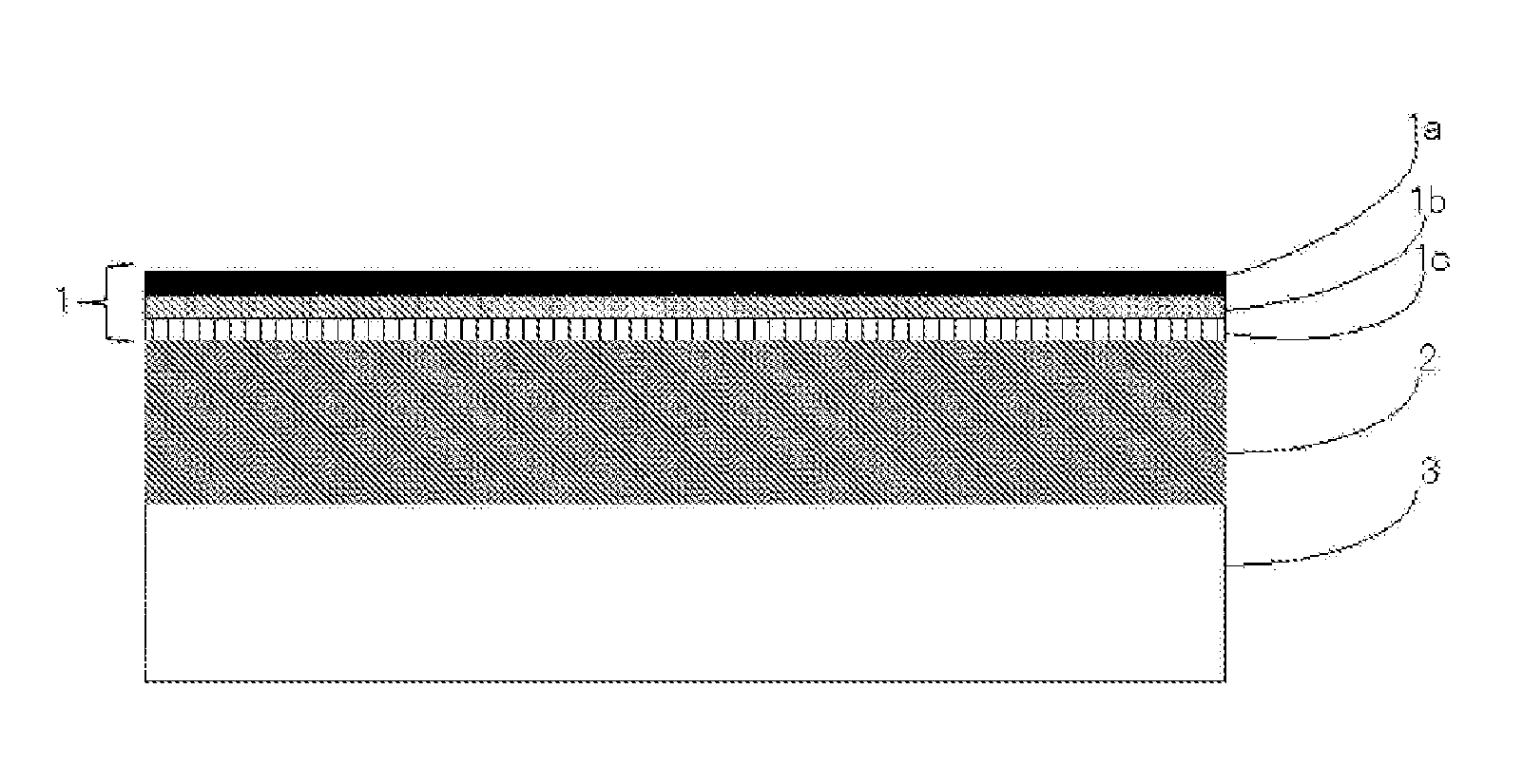

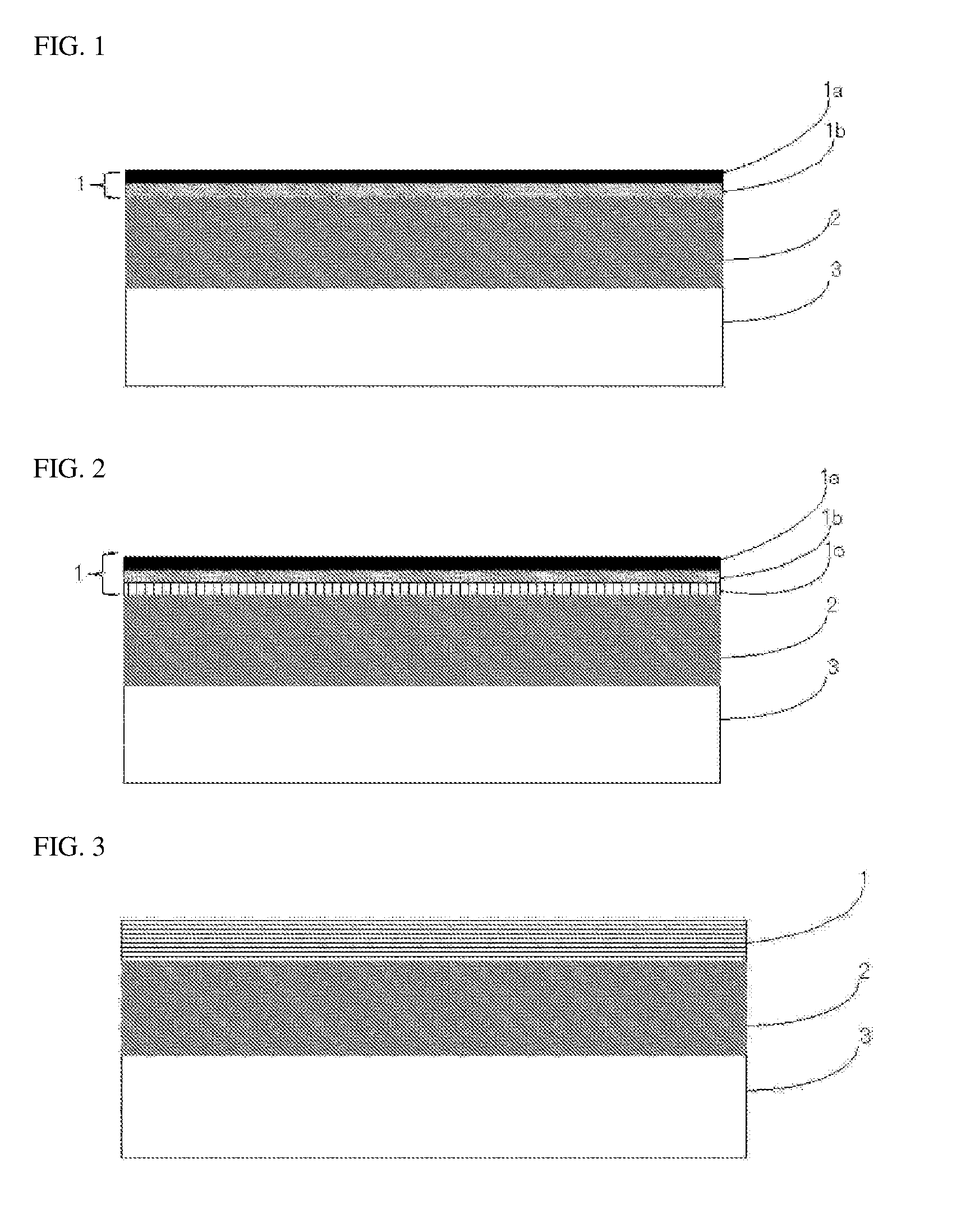

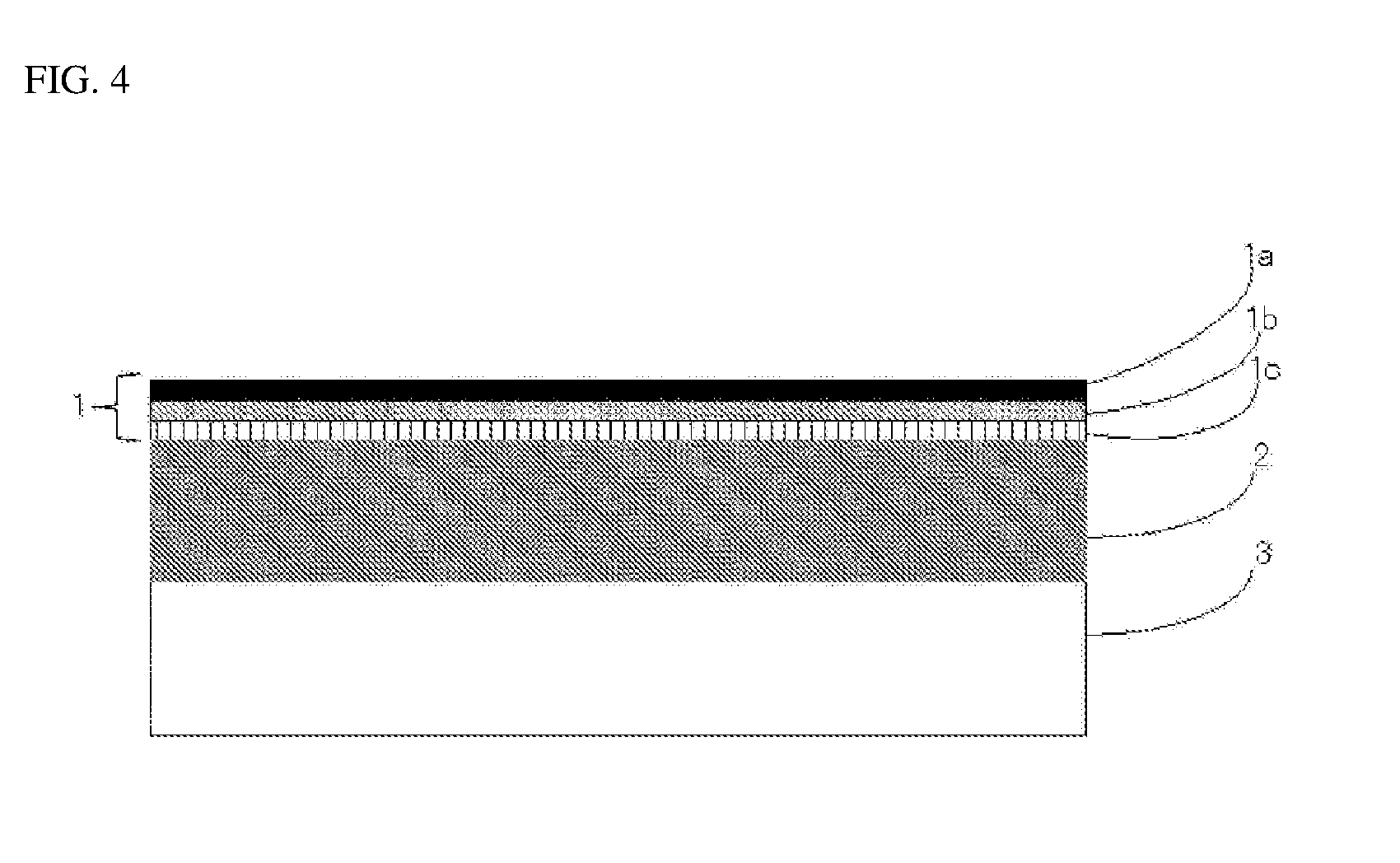

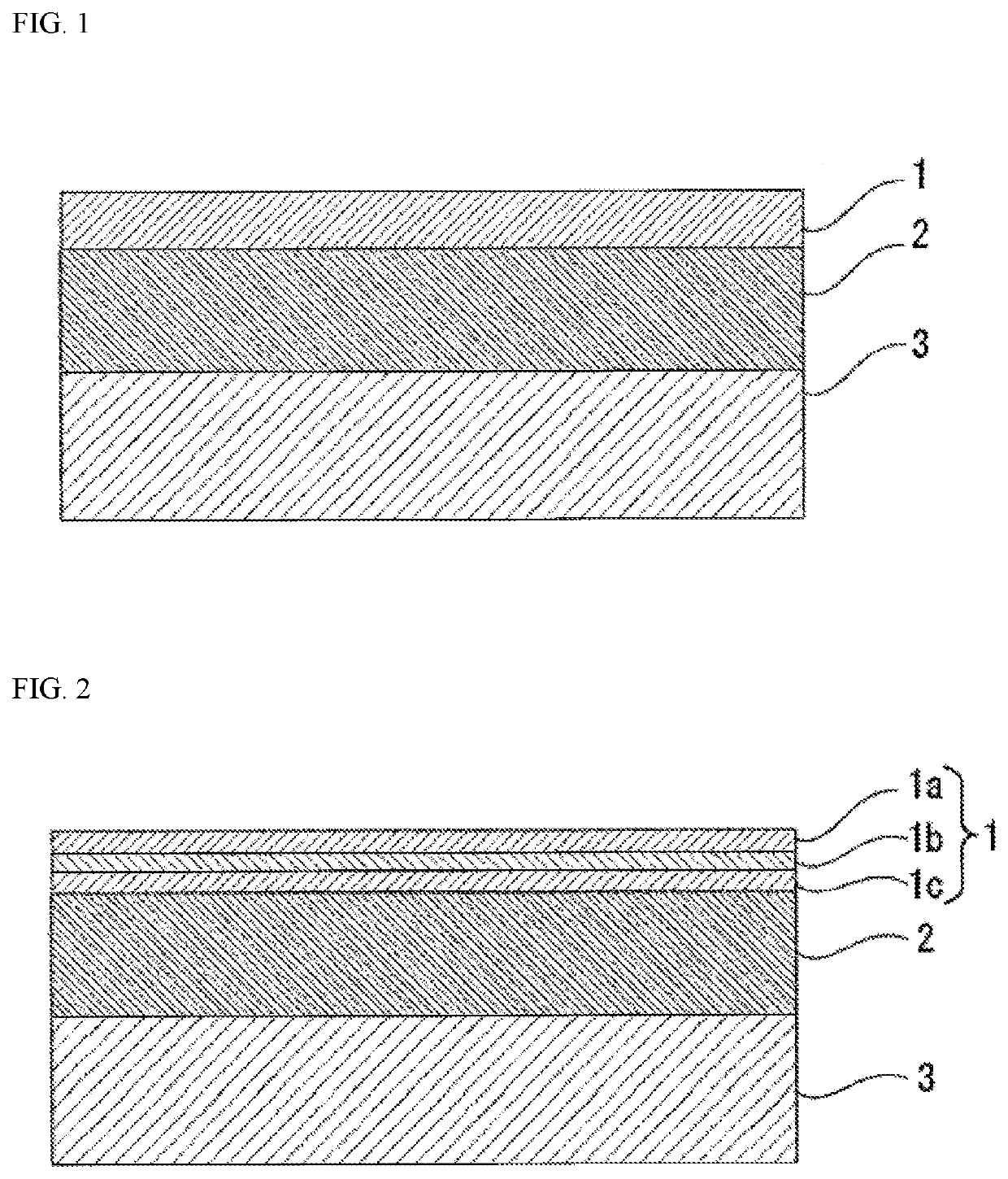

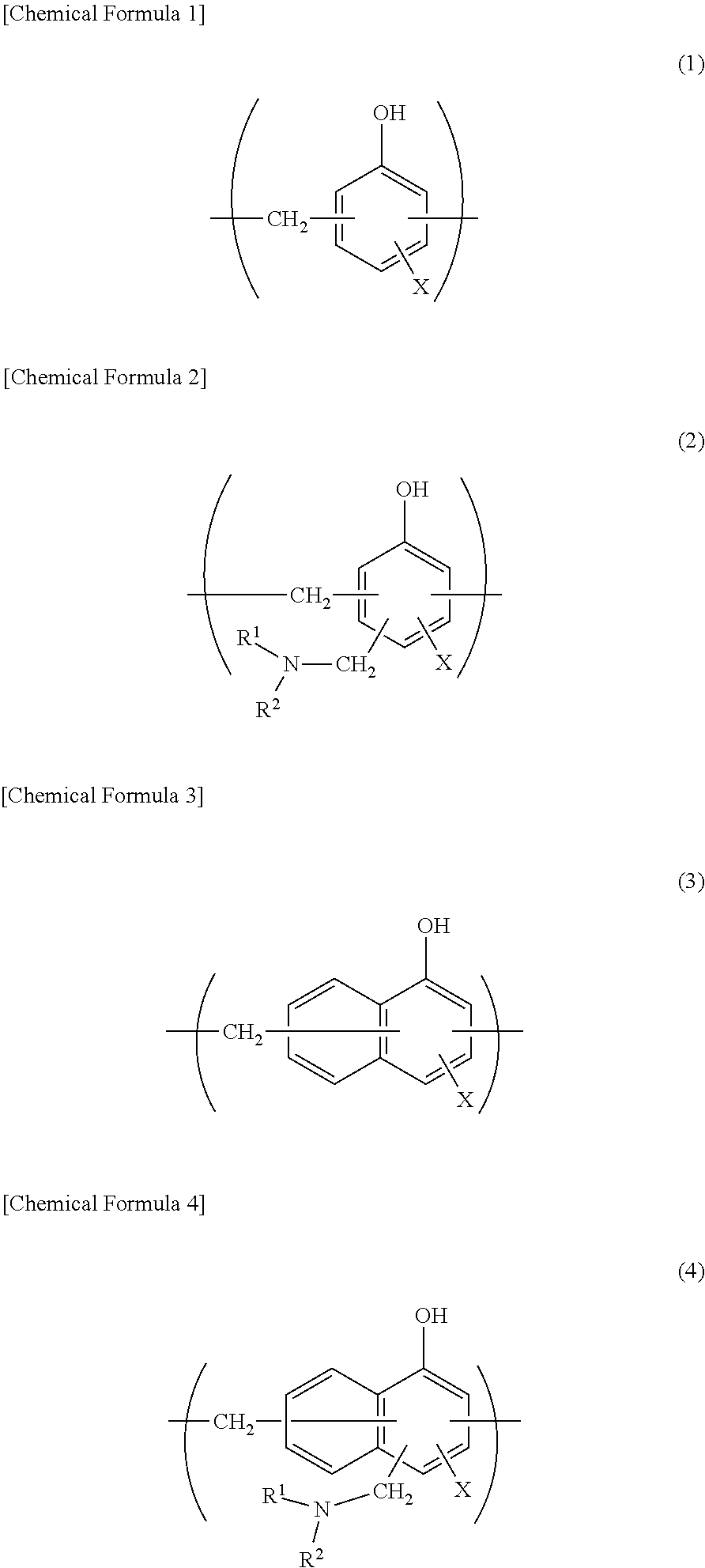

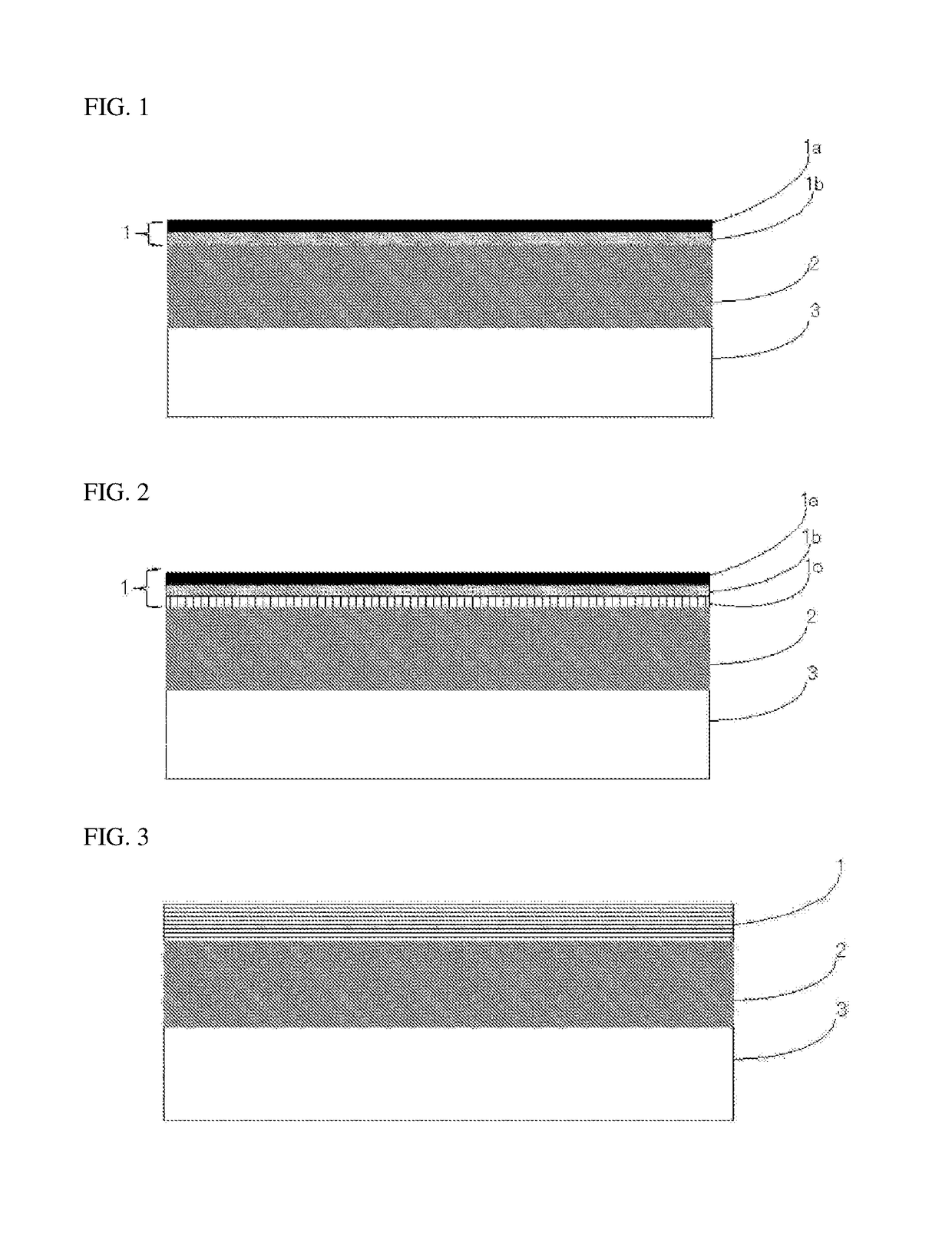

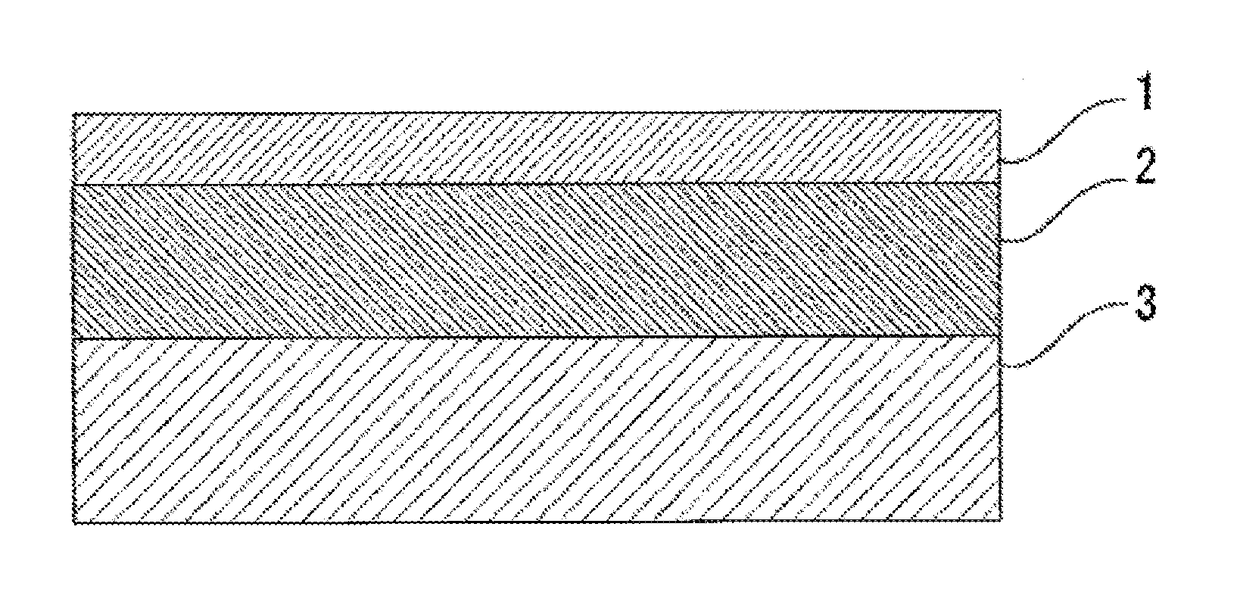

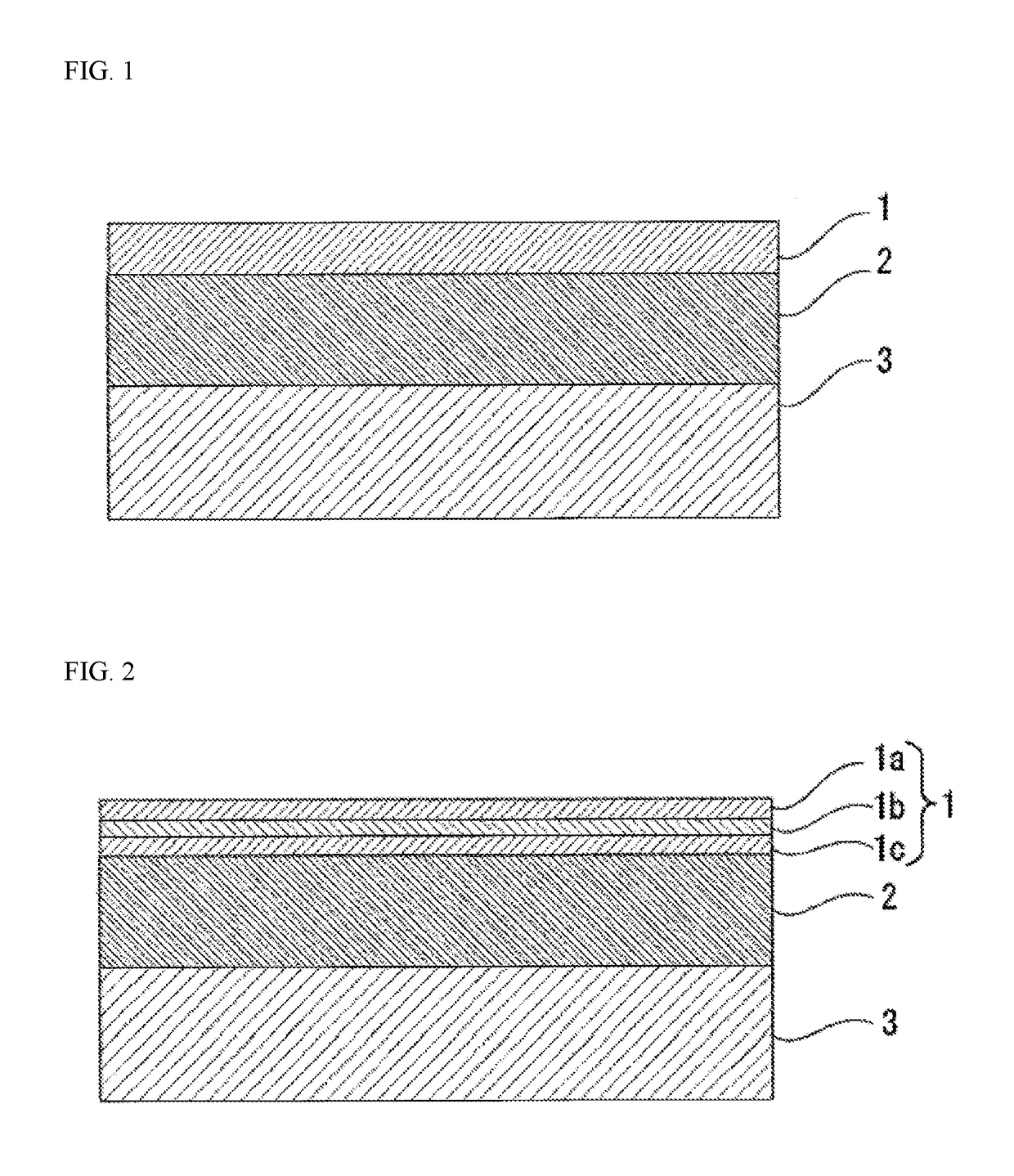

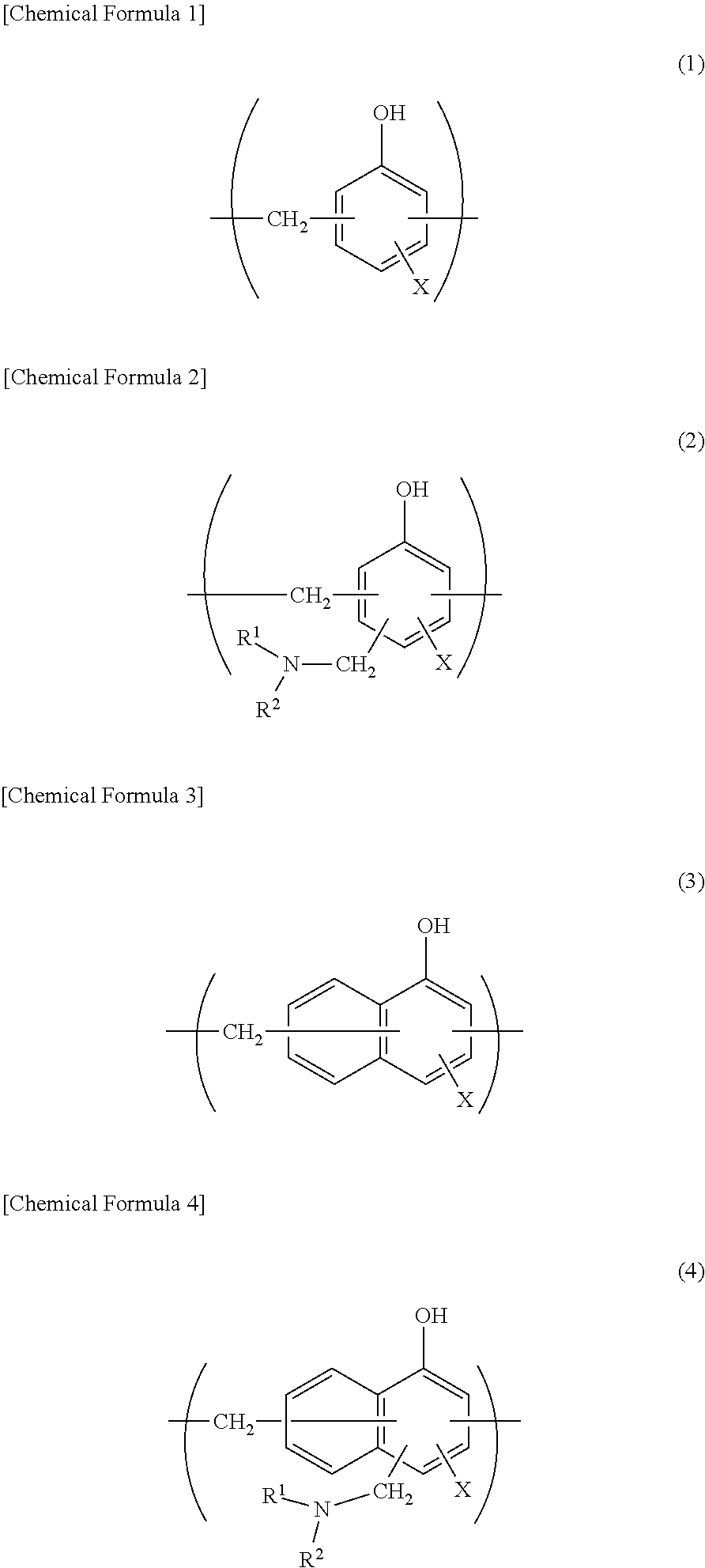

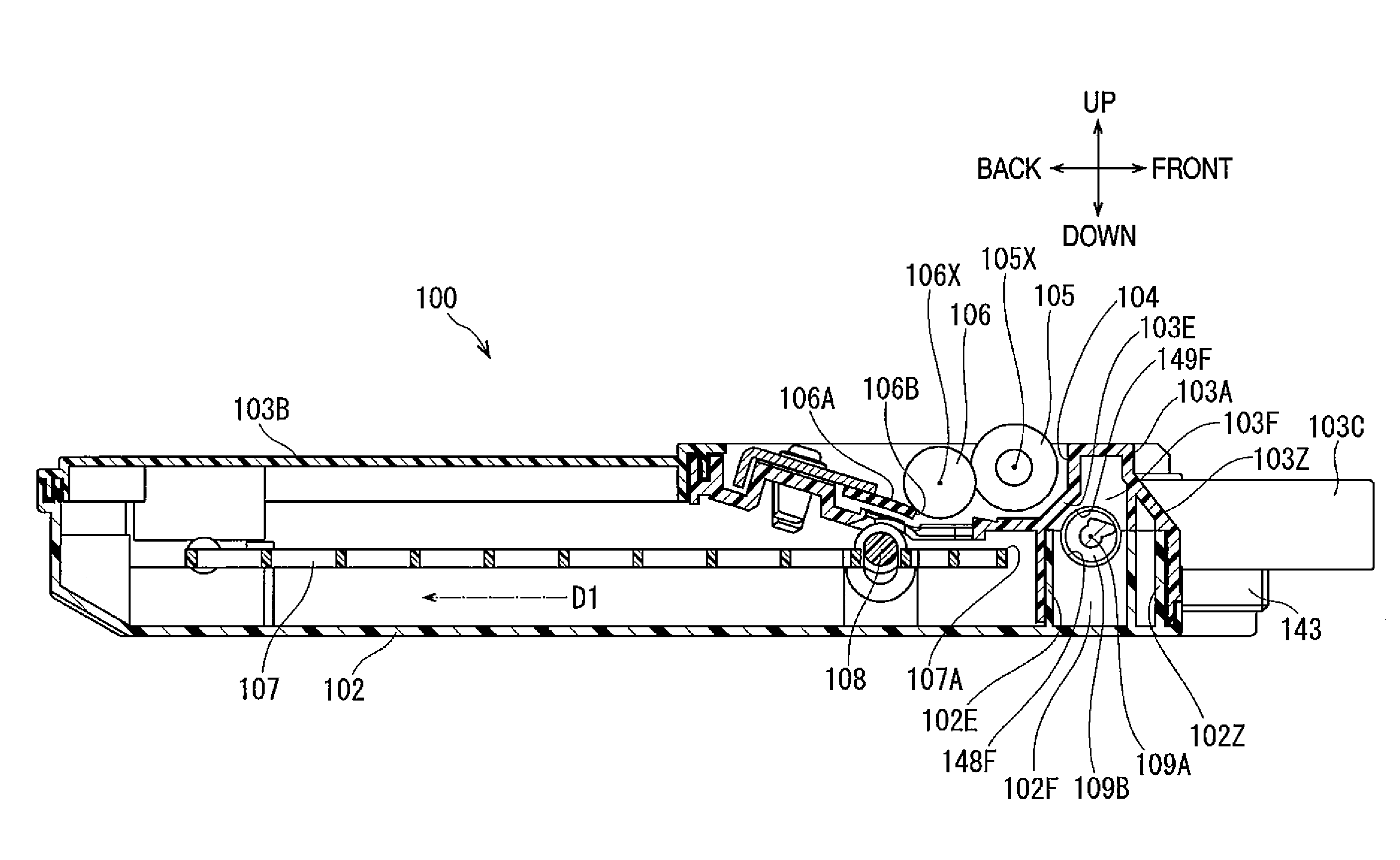

Packaging material for cell

ActiveUS20160211490A1Downsizing and thinningShorten the timeSynthetic resin layered productsLaminationInter layerHardness

A packaging material for a cell including a laminated article having at least a coating layer, a barrier layer, and a sealant layer in the stated order, wherein: the coating layer has at least three layers including a first, second and third coating layer, and is disposed so that the first coating layer is positioned as the outermost layer and the third coating layer is positioned on the barrier-layer-side; and the first coating layer, the second coating layer, and the third coating layer are formed from a cured product of a resin composition containing a heat-curing resin and a curing accelerator so as to sufficiently exhibit a specific hardness, whereby the thickness can be reduced, exceptional chemical resistance, moldability, and inter-layer adhesion between the barrier layer and the coating layer can be obtained, and the lead time can be reduced to enable an improvement in production efficiency.

Owner:DAI NIPPON PRINTING CO LTD

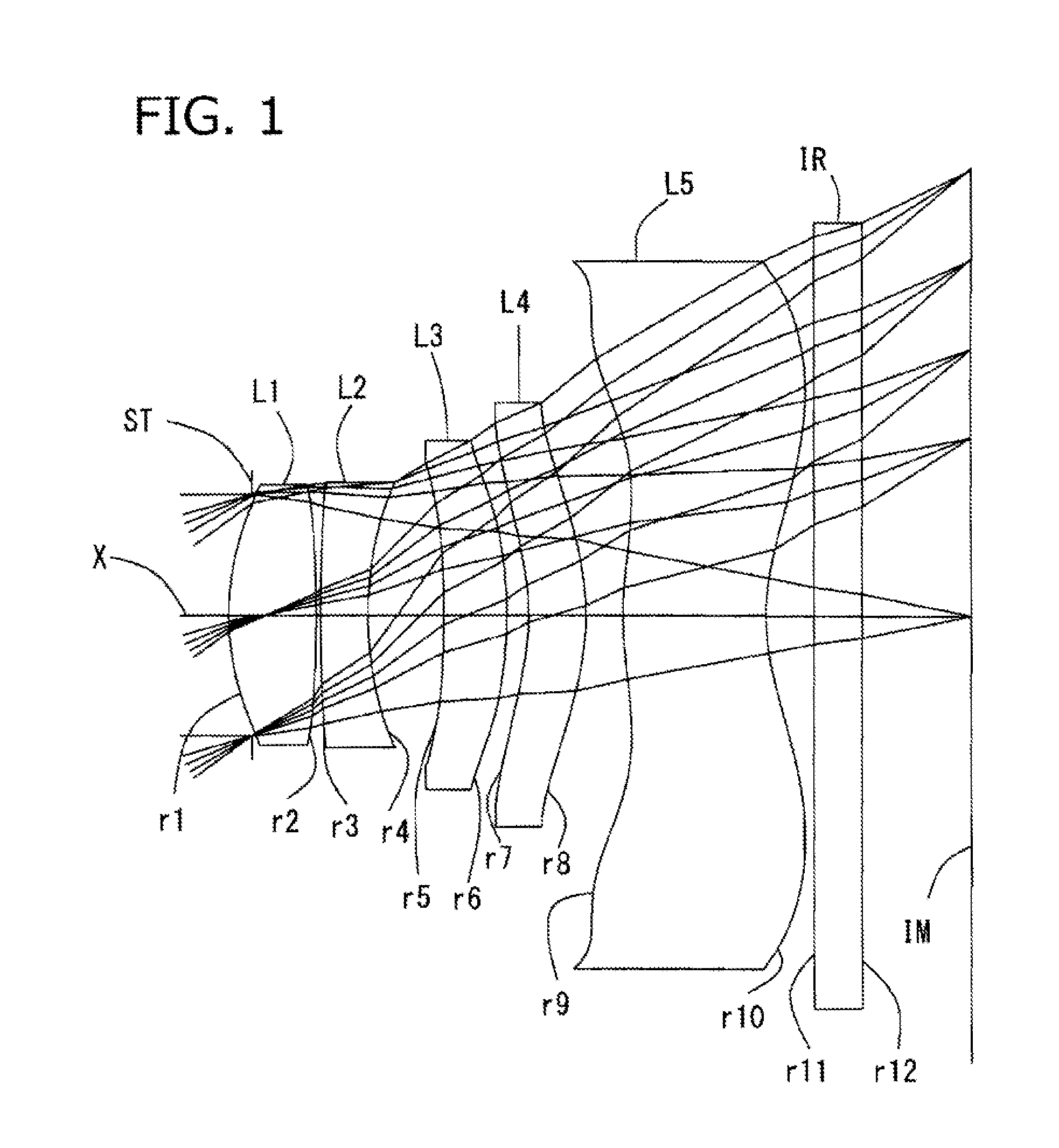

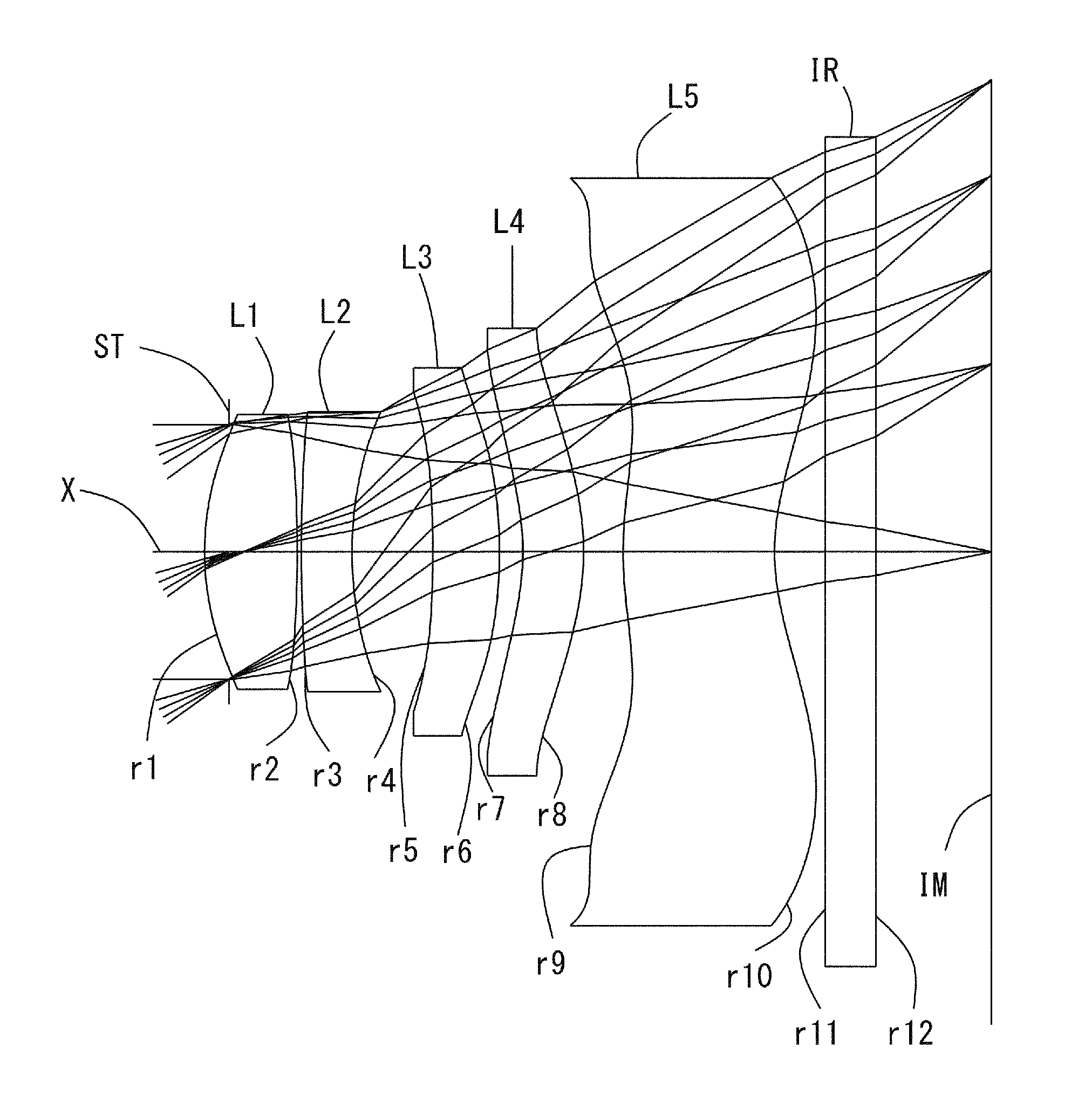

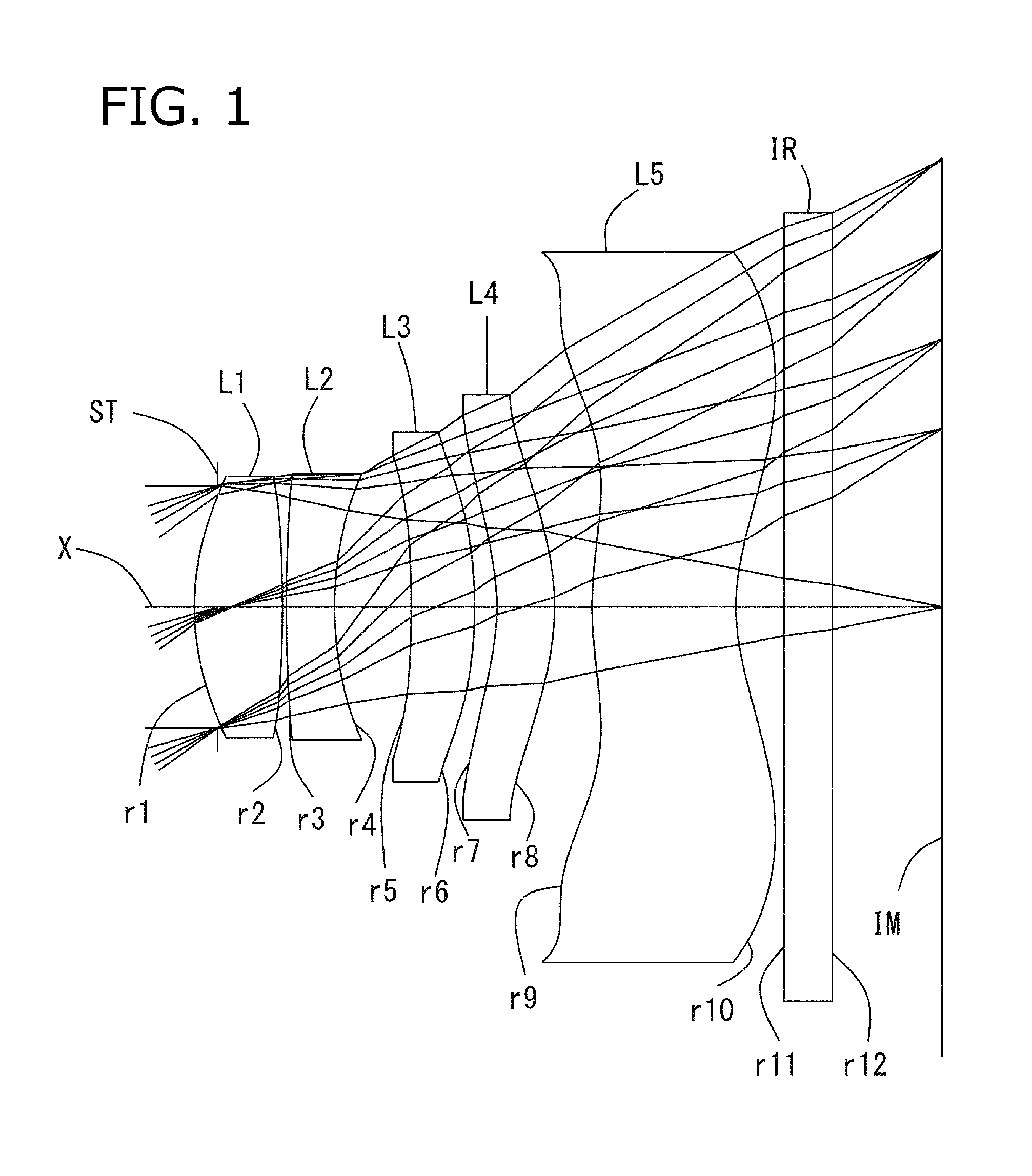

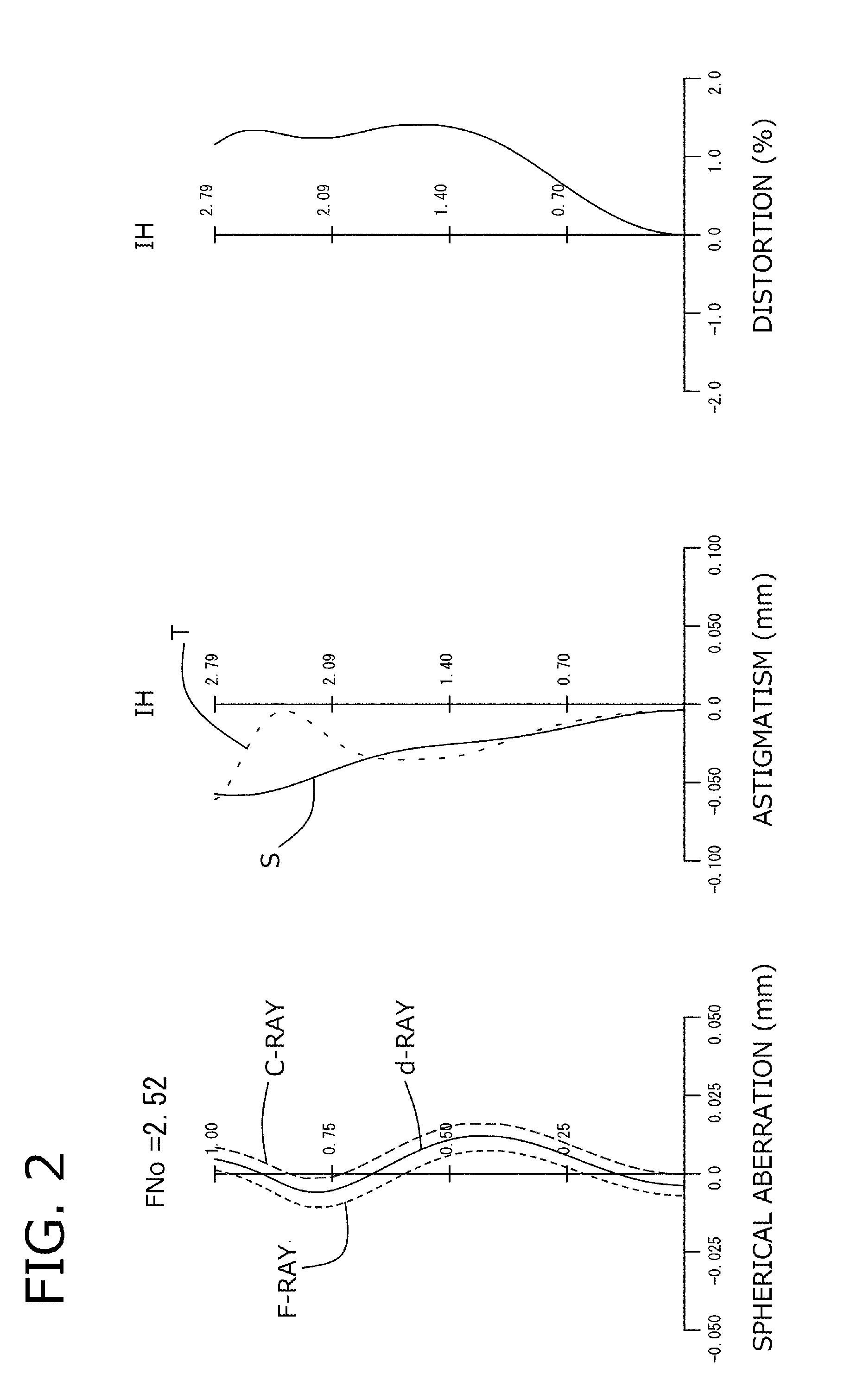

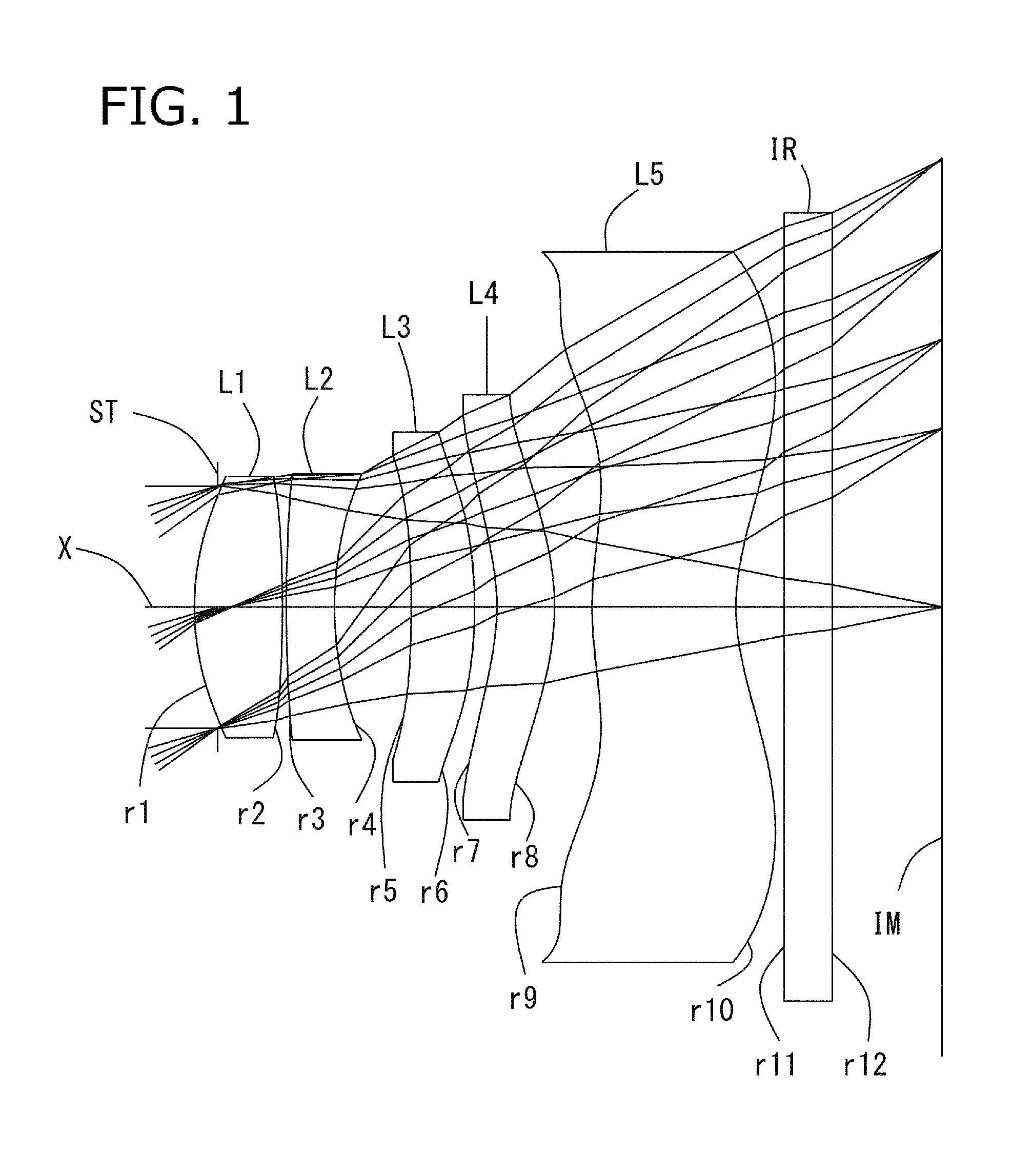

Image pickup lens

An image pickup lens includes an aperture stop, a first lens with positive refractive power having a convex object-side surface, a second lens with negative refractive power having a concave image-side surface, a third lens with positive refractive power having a convex image-side surface, a fourth lens with negative refractive power as a double-sided aspheric lens having a concave object-side surface, and a fifth lens with negative refractive power of a meniscus shape as a double-sided aspheric lens having a concave image-side surface, wherein the fifth lens is designed so that the negative refractive power weakens as the distance from the optical axis increases, and wherein the following conditional expression (1) is satisfied:0.55<f1 / f<1.0 (1)where f represents a focal length of an overall image pickup lens, and f1 represents a focal length of the first lens.

Owner:TOKYO VISIONARY OPTICS CO LTD

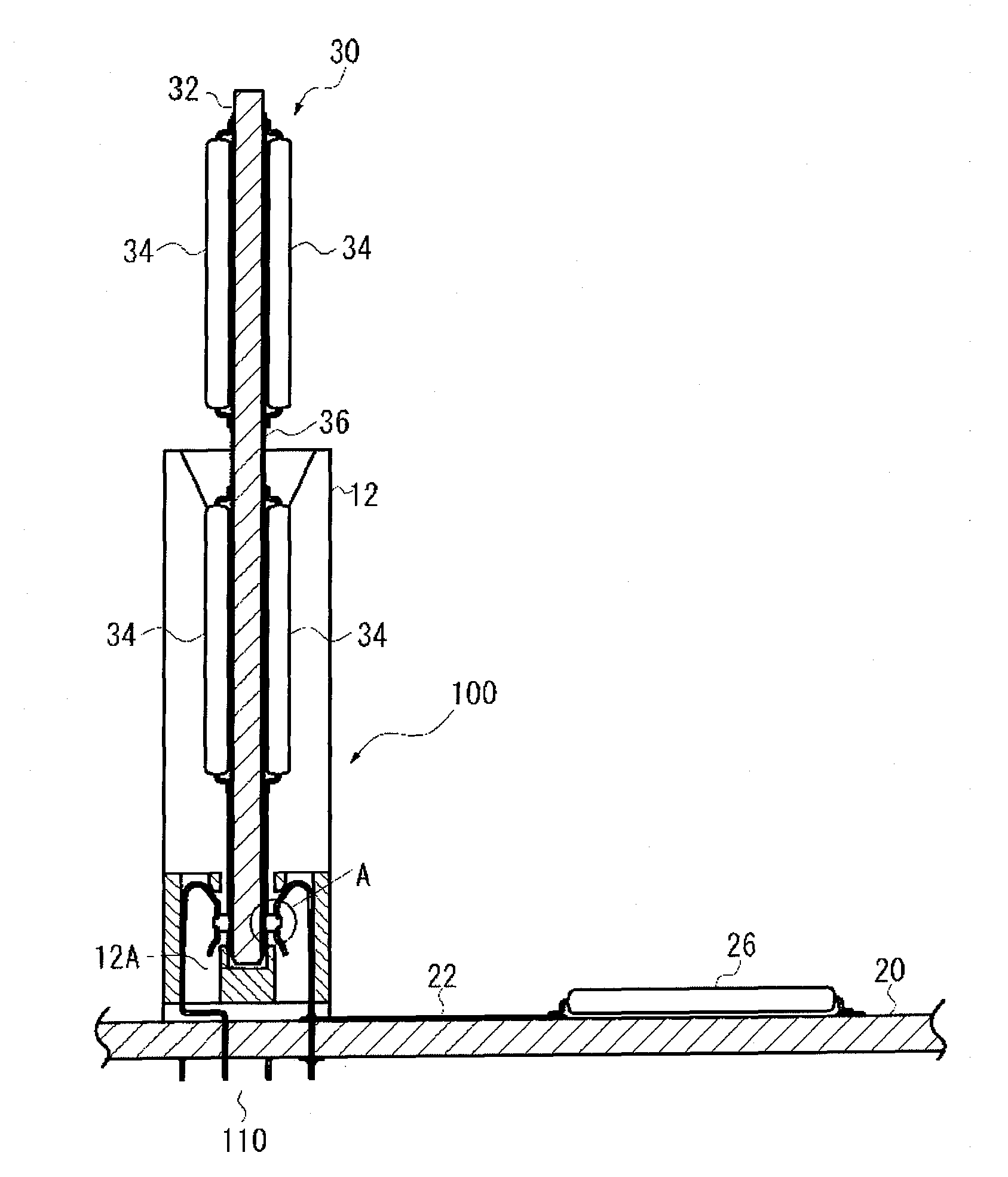

Electronic Device and Manufacturing Method for Electronic Device

InactiveUS20100101845A1Secured stablyImproved junction reliabilityPrinted circuit detailsFinal product manufactureThermal energyEngineering

An electronic device manufacturing method includes: setting a solder material on electrodes of a first circuit assembly; setting a resin having a flux action on one surface of a second circuit assembly so as to entirely cover solder bumps formed on the one surface of the second circuit assembly; setting the second circuit assembly on the first circuit assembly via the resin so that the solder material set on the electrodes of the first circuit assembly and the solder bumps of the second circuit assembly are put into contact with each other; and applying thermal energy to connecting portions between the solder material and the solder bumps and to the resin. By carrying out these processes, an electronic device in which the first circuit assembly and the second circuit assembly are joined together and in which their junction portions are sealed by the resin is manufactured. As a result, in the electronic device, junction reliability can be improved.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

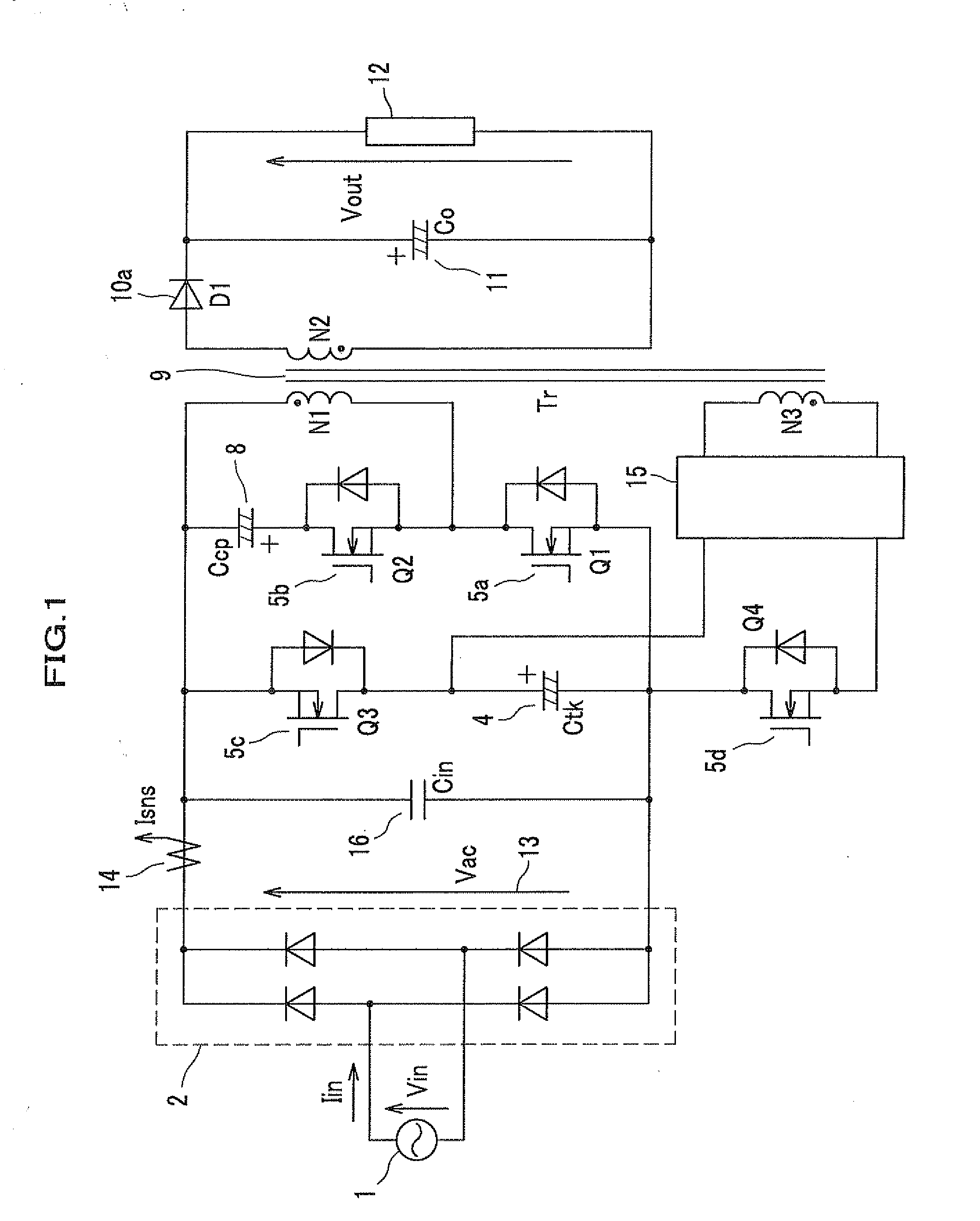

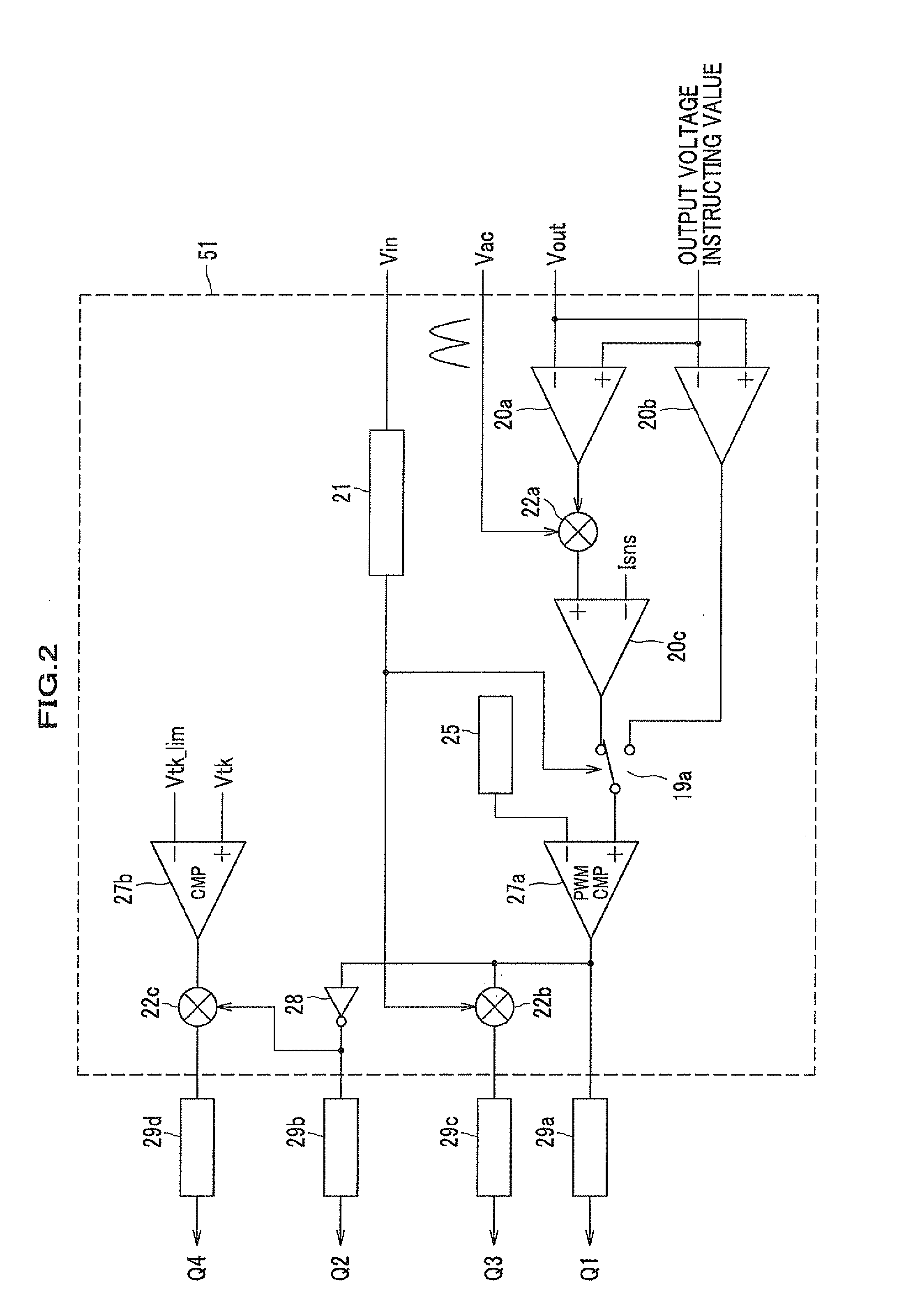

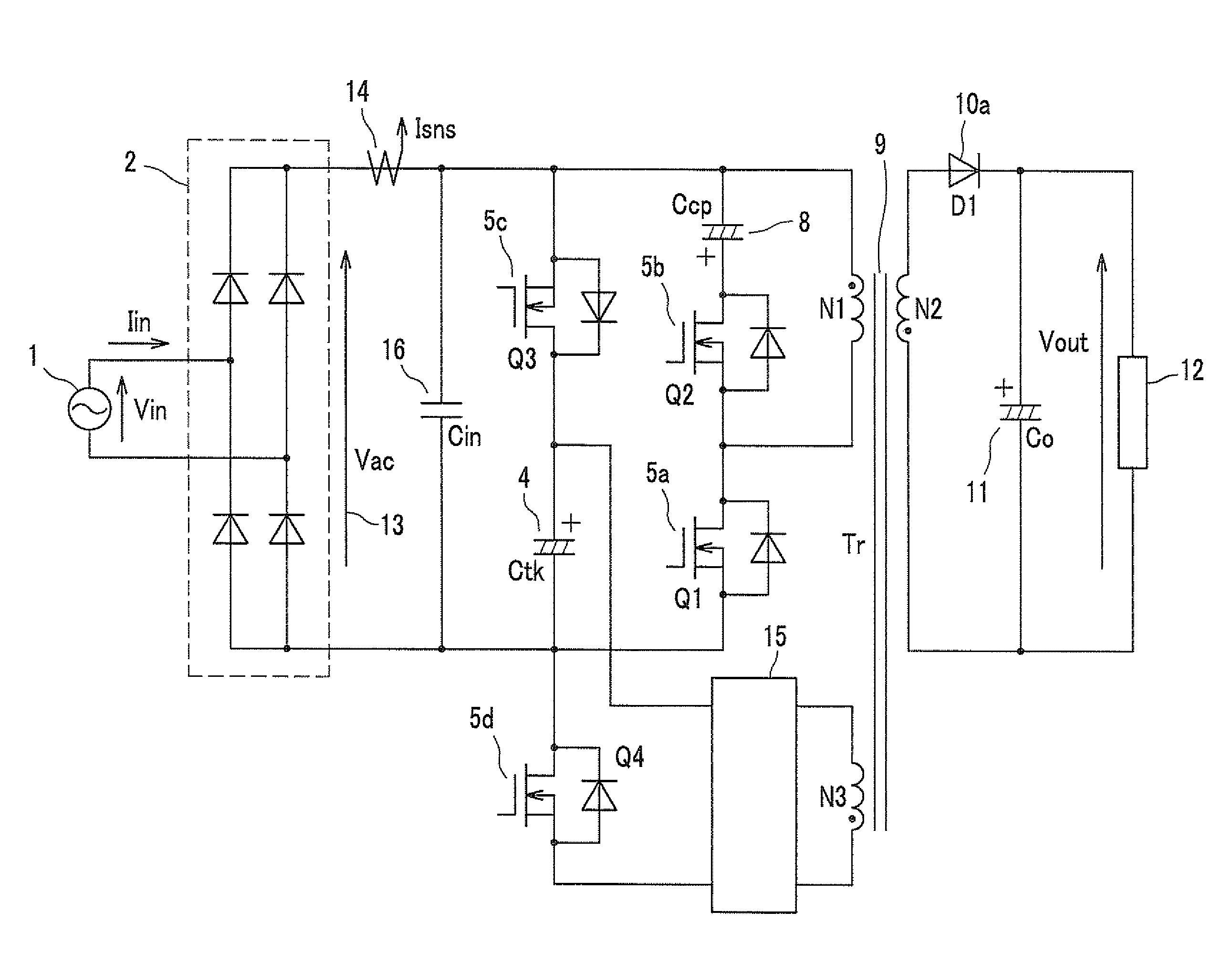

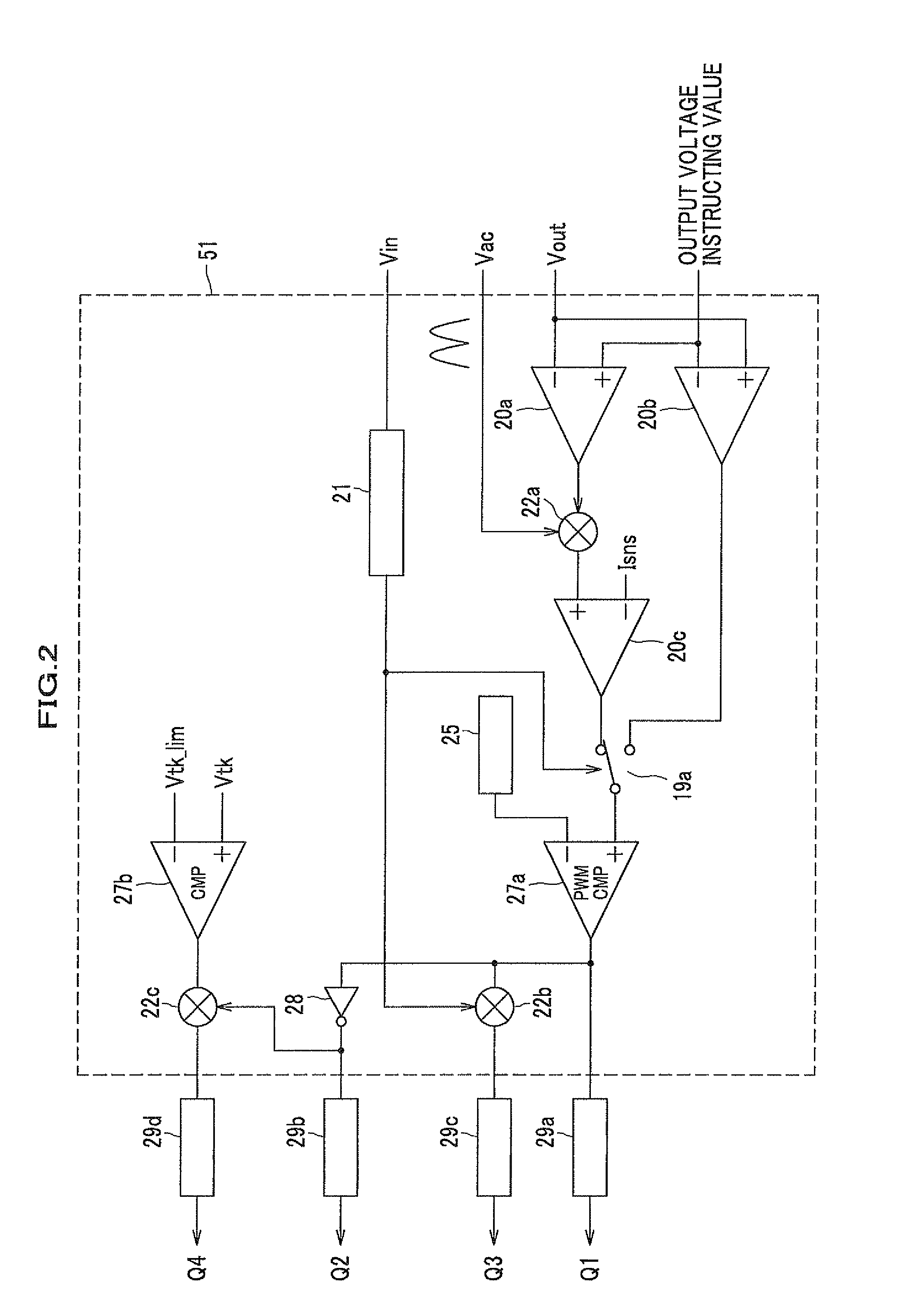

Switching power supply and display device provided with same

InactiveUS20120146986A1Downsizing and thinningSufficient characteristicEfficient power electronics conversionDc-dc conversionCharge currentPower factor

A switching power supply has a function of improving a power factor, and outputs insulated DC. The switching power supply performs two kinds of controls for switching devices exclusive to each other: controlling of a switching device provided in a direction in which the discharging of a primary-side smoothing capacitor is prohibited at the time of suspension of commercially available AC power and near the zero cross of an input voltage; and causing a switching device provided between the output side of a third winding and the primary-side smoothing capacitor to control a charging current, thereby charging a capacitor in a boosted manner.

Owner:TKR

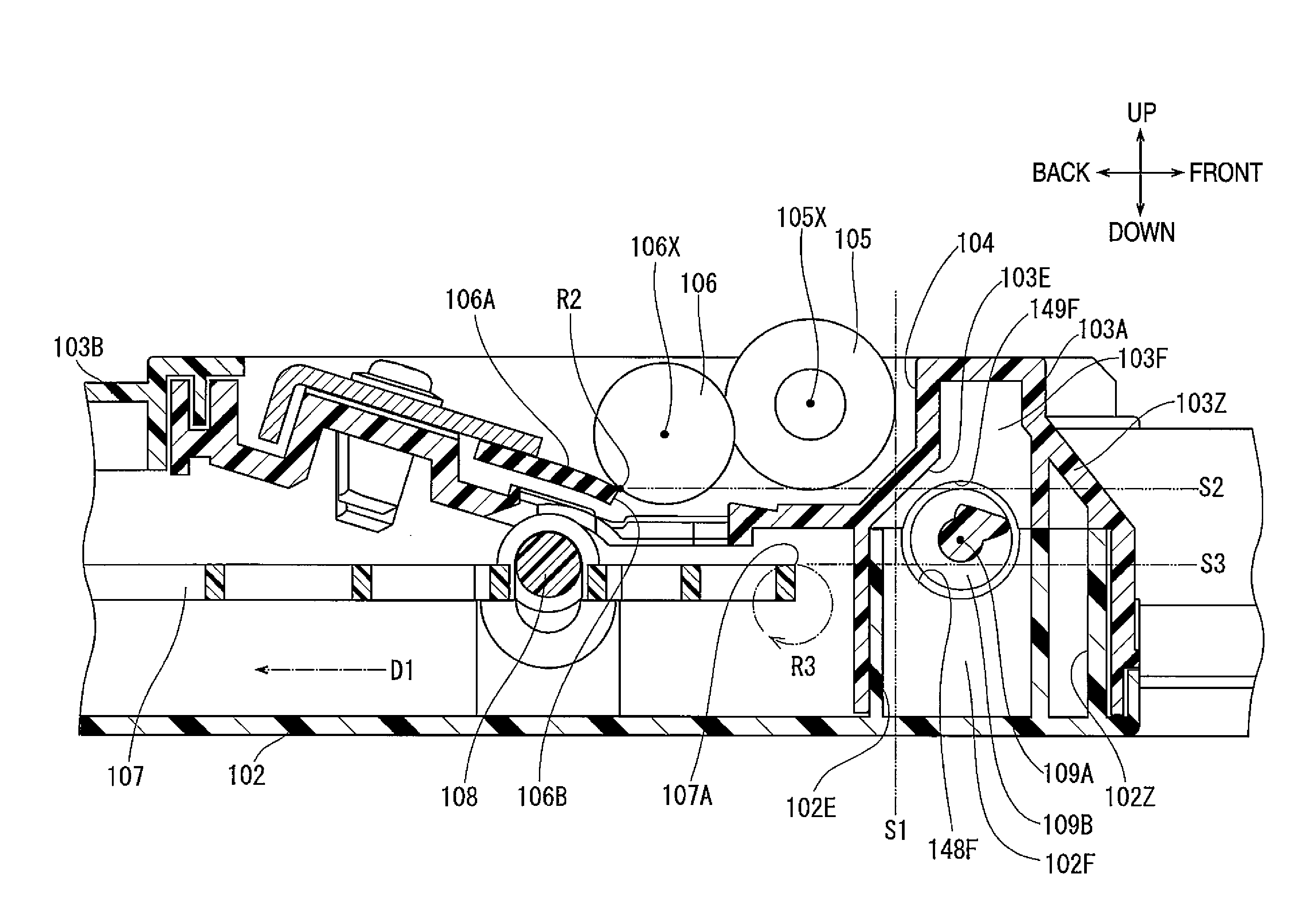

Hard disk drive

ActiveUS20080068744A1Accurately recorded/reproducedRemarkable effectRecord information storageRecording on magnetic disksHard disc driveEngineering

Owner:SEIKO INSTR INC

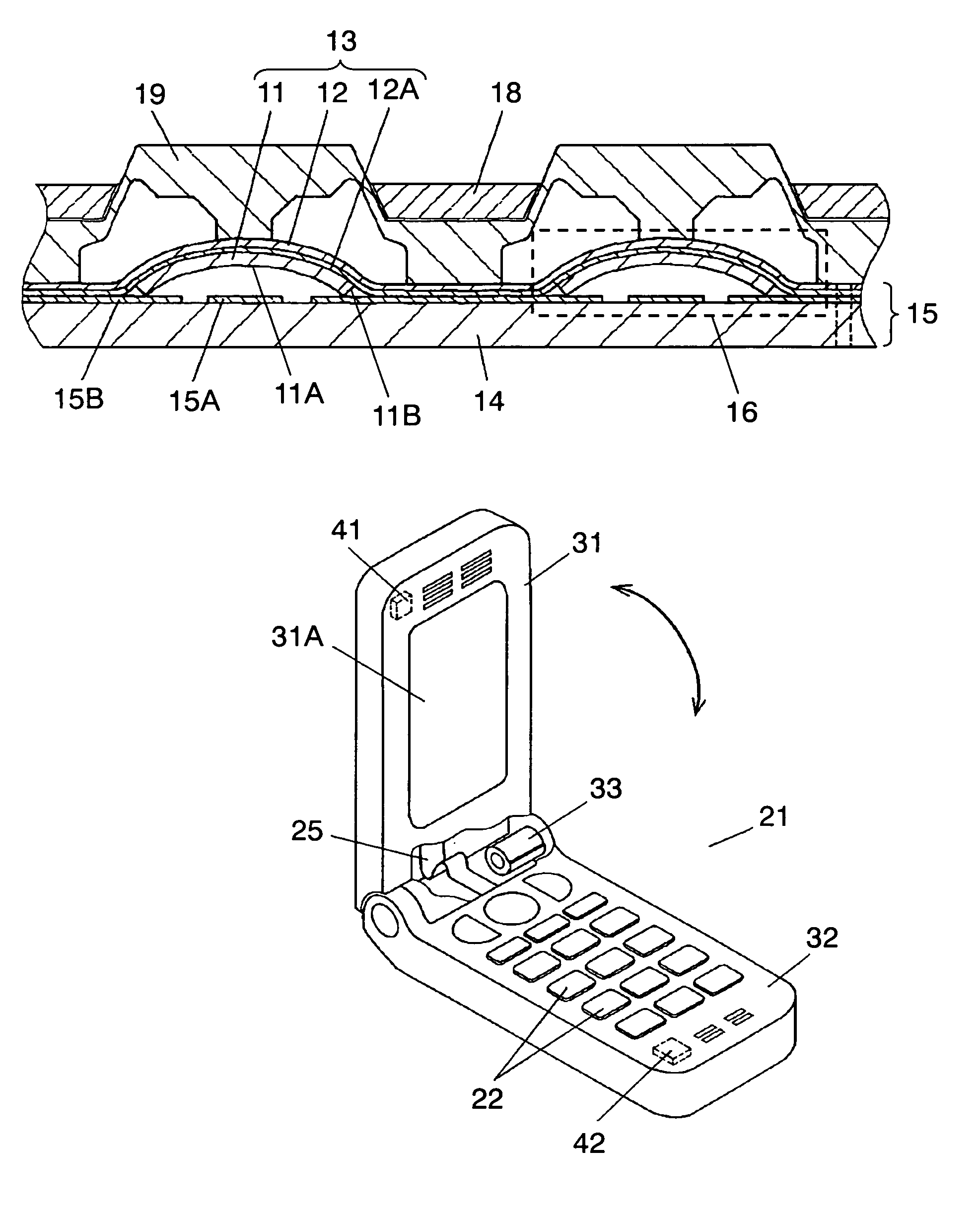

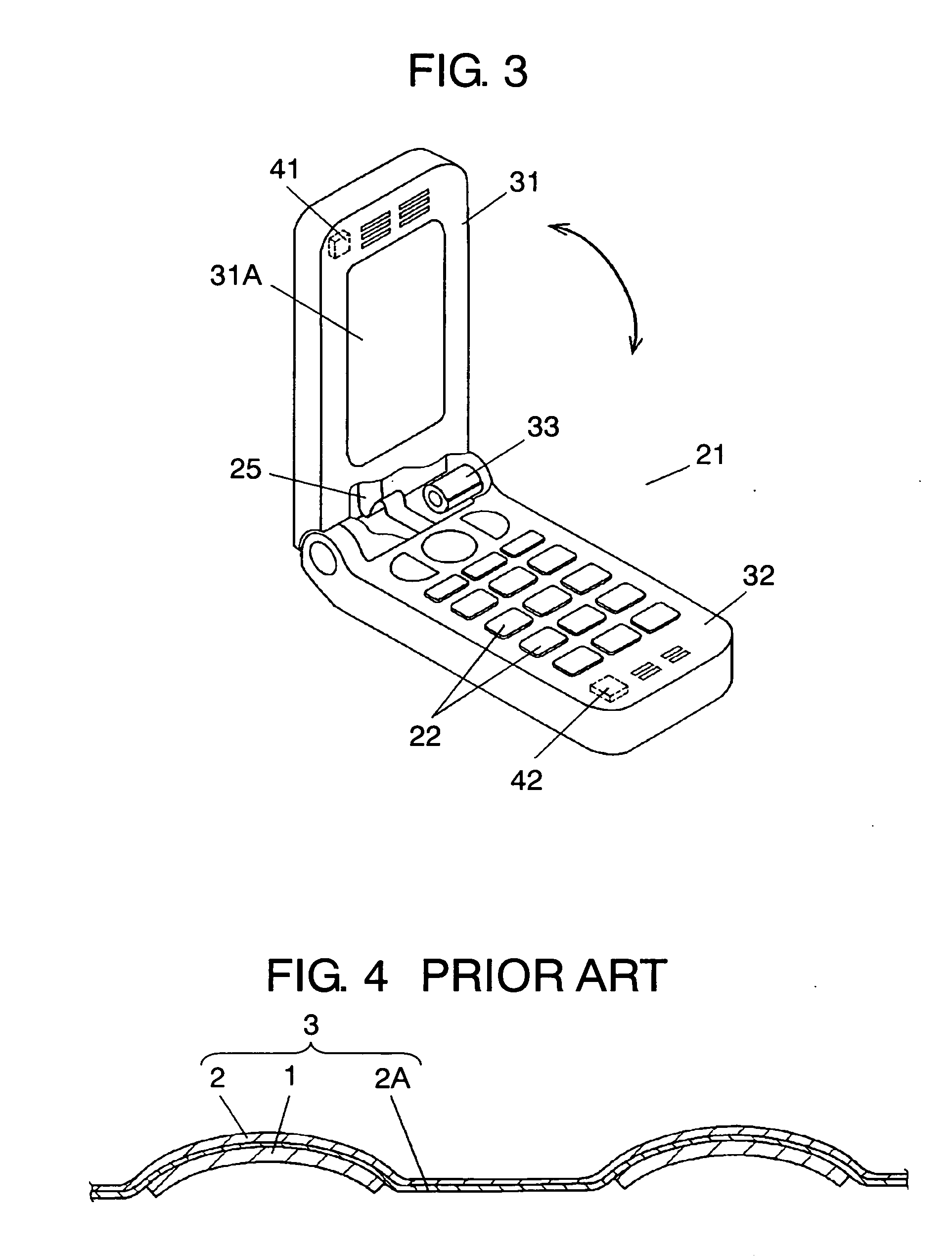

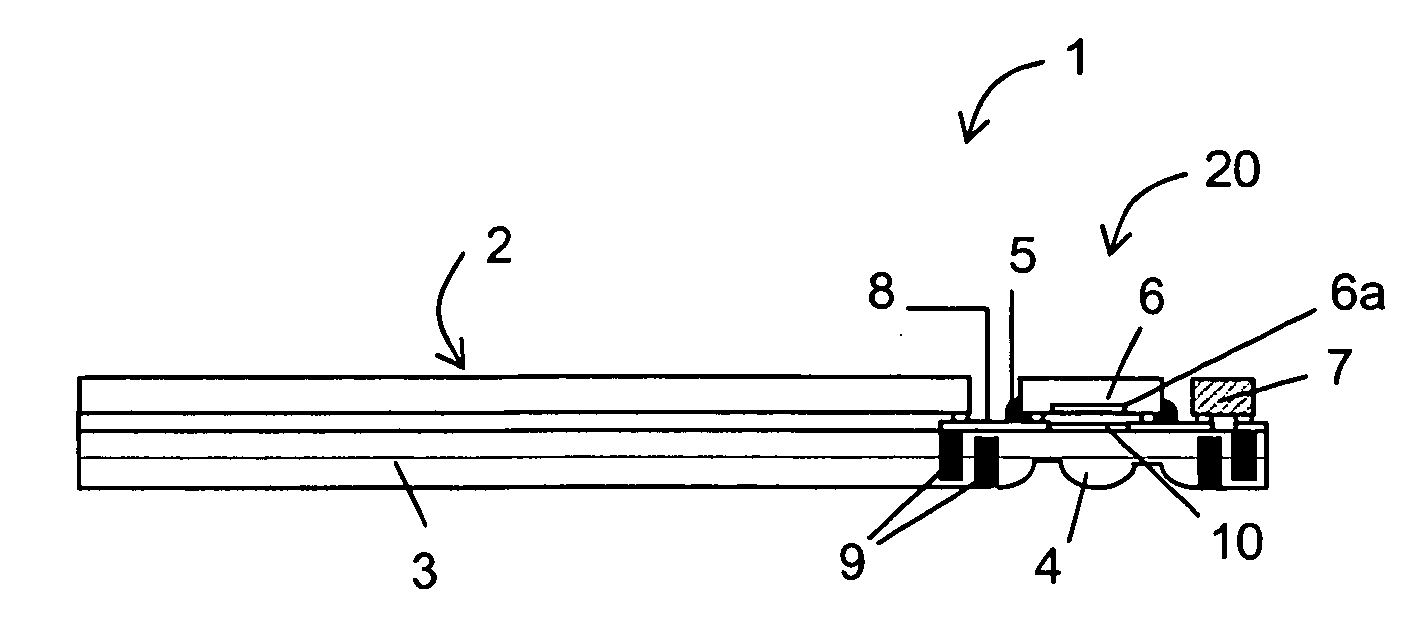

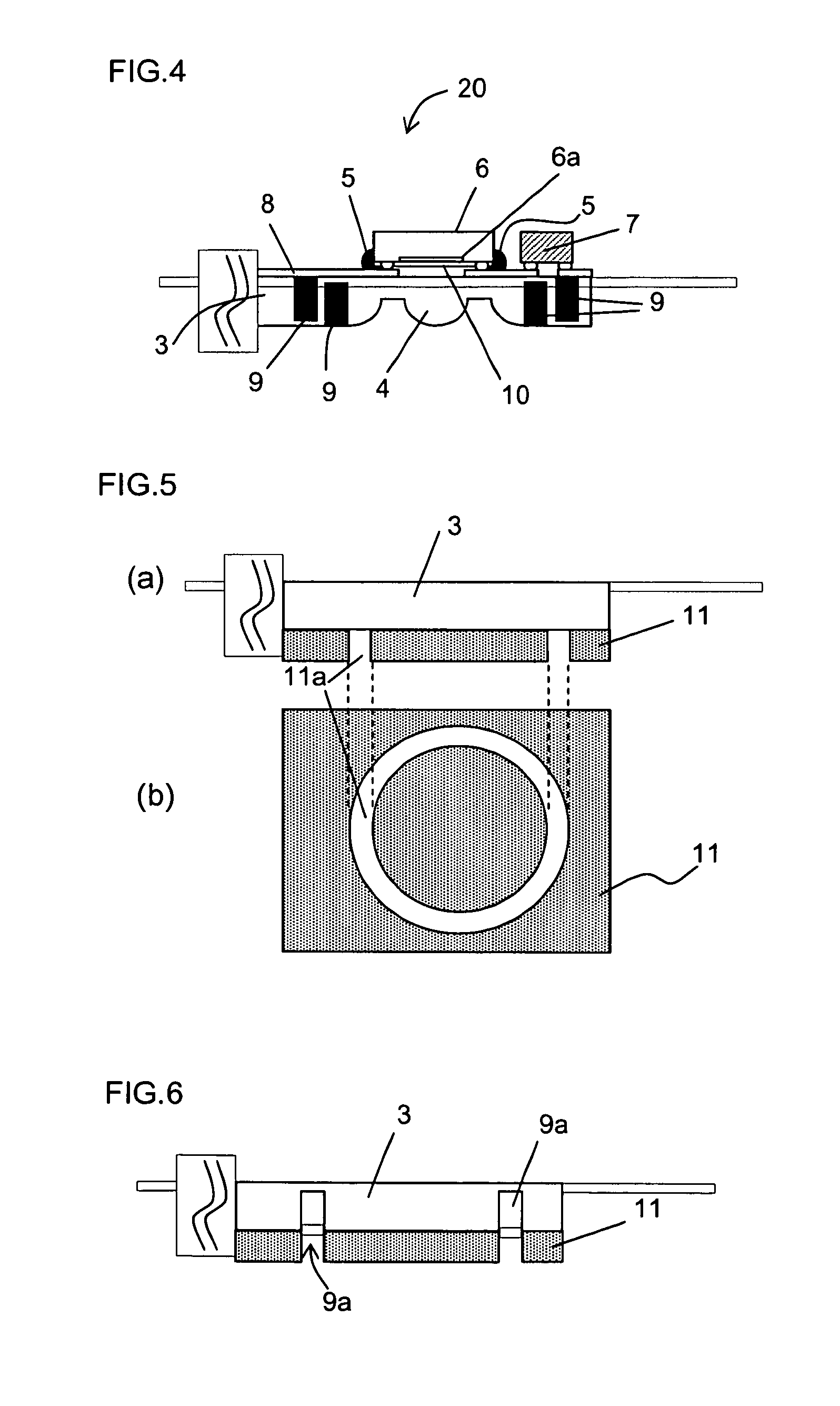

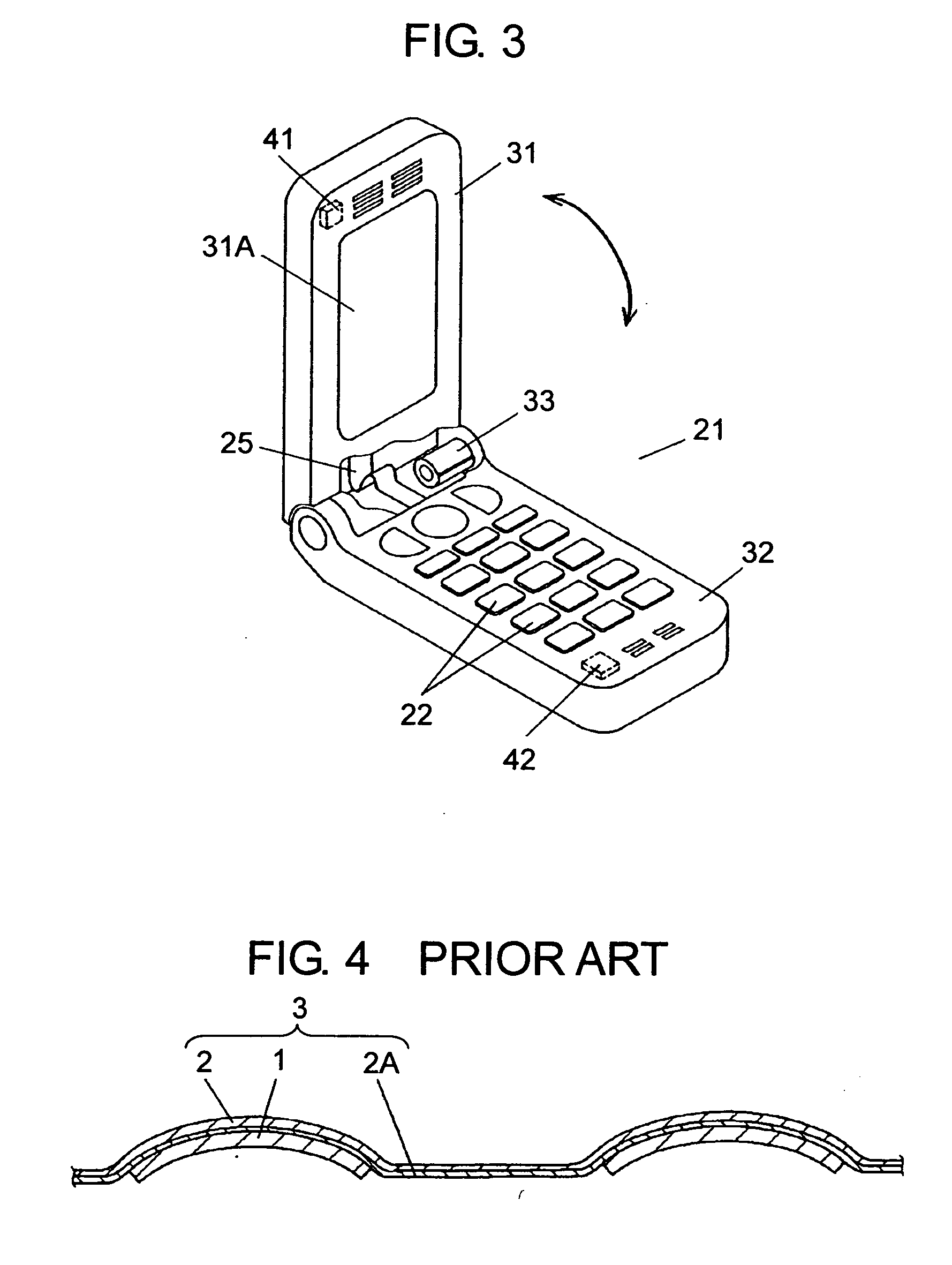

Method of manufacturing a movable contact unit to be disposed close to a magnetic sensor

InactiveUS7178223B2Downsizing and thinningInterconnection arrangementsContact surface shape/structureMagnetic fluxDome shape

A method of manufacturing a movable contact unit includes manufacturing a movable contact, sticking the movable contact to a base sheet made of insulating resin, and applying demagnetization to the movable contact so that the residual magnetic flux density is smaller than the operation magnetic flux density of the magnetic sensor. In manufacturing the movable contact, elastic metal plate material is processed into a downwardly opening dome shape to form the movable contact. In a method of manufacturing a switch panel, the movable contact unit is overlaid on a wiring board having a contact, including pair an outer fixed contact and a central fixed contact, that corresponds to the movable contact so that the lower end of the outer periphery of the movable contact is mounted on the outer fixed contact.

Owner:PANASONIC CORP

Semiconductor device having a cooler

ActiveUS9673130B2Improve cooling effectGuaranteed uptimeSemiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device

A cooler 20 of a semiconductor device includes an inlet portion 27 and an outlet portion 28 for a cooling liquid, an inlet path 24, an outlet path 25, and a cooling flow path 26. The inlet path 24 and the outlet path 25 have asymmetrical planar shapes. A connection portion 271 between the inlet path 24 and the inlet portion 27 is opposed to the cooling flow path 26 of a part immediately below plural circuit substrates 13 arranged on the cooler 20. A connection portion 281 between the outlet path 25 and the outlet portion 28 is opposed to the cooling flow path 26 of a part immediately below plural circuit substrates 13 arranged on the cooler 20.

Owner:FUJI ELECTRIC CO LTD

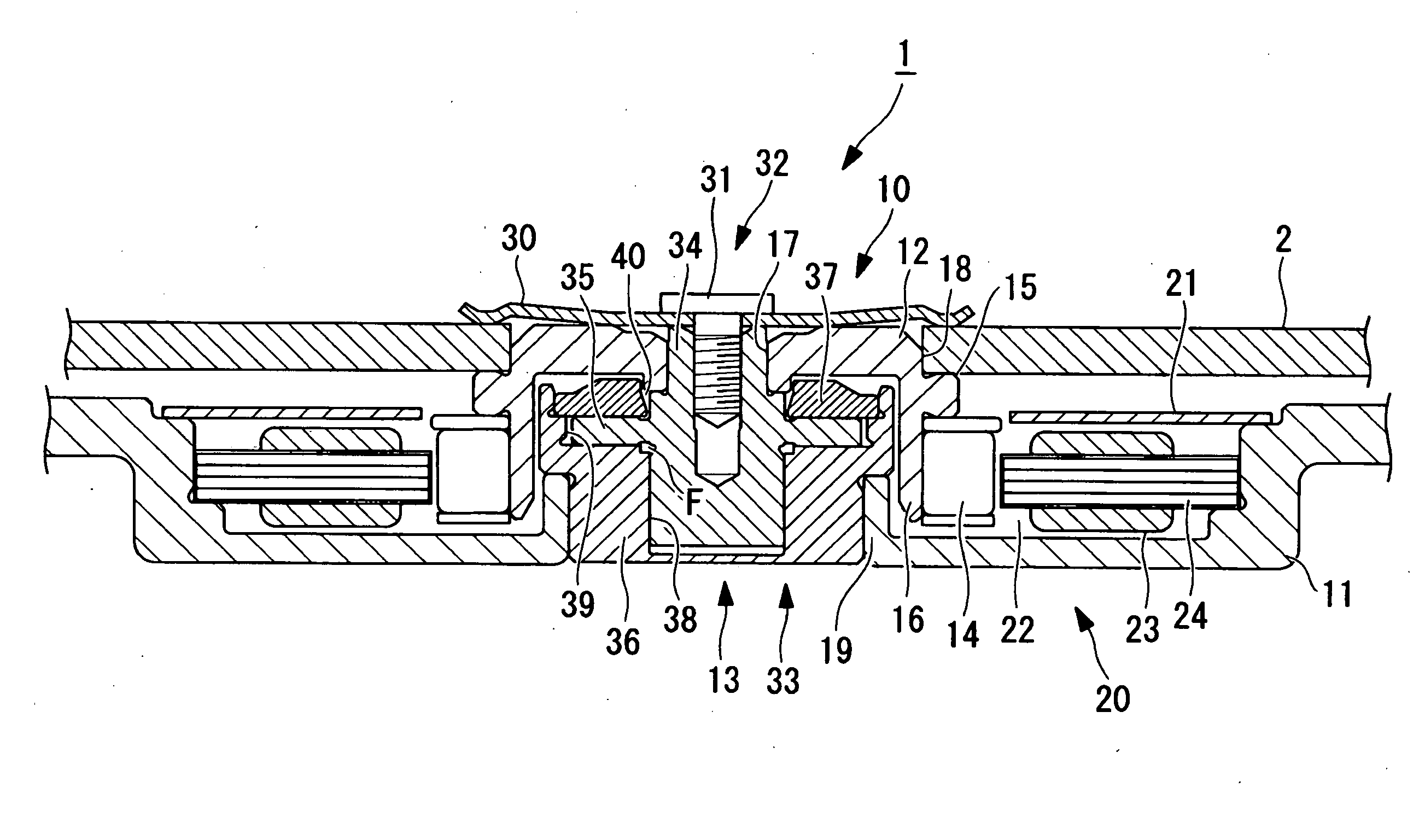

Movable contact unit, manufacturing method of the same, and manufacturing method of panel switch

InactiveUS20060081453A1Downsizing and thinningContact surface shape/structureSolid-state devicesMagnetic fluxDome shape

A manufacturing method of a movable contact unit includes the steps of (A) manufacturing a movable contact, (B) sticking the movable contact to a base sheet made of insulating resin, and (C) applying demagnetization to the movable contact so that the residual magnetic flux density is smaller than the operation magnetic flux density of the magnetic sensor. In step A, elastic metal plate material is processed into a downwardly opening dome shape to form the movable contact. In a manufacturing method of a panel switch, the movable contact unit is overlaid on a wiring board having a pair of an outer fixed contact and a central fixed contact that correspond to the movable contact so that the lower end of the outer periphery of the movable contact is mounted on the outer fixed contact.

Owner:PANASONIC CORP

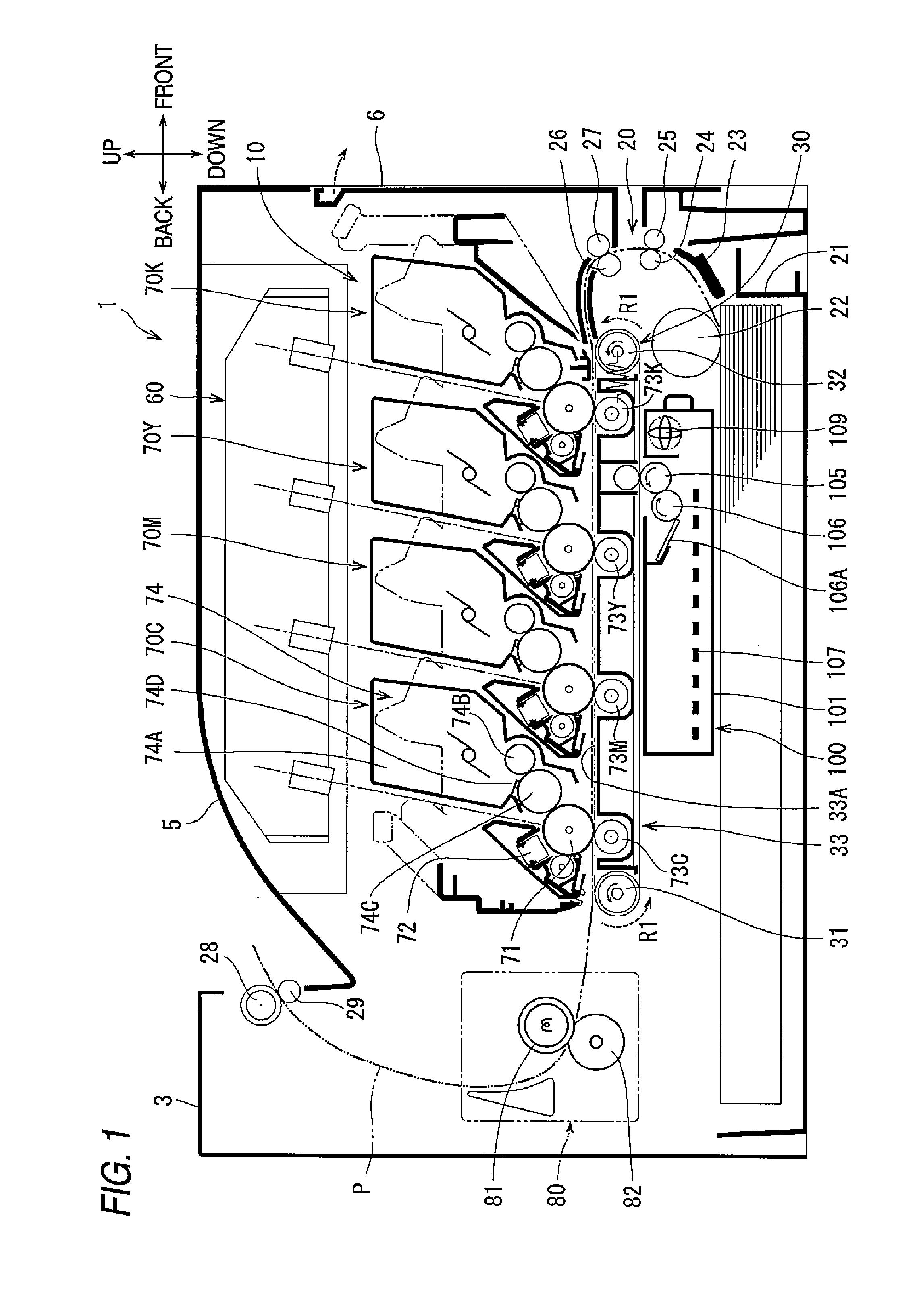

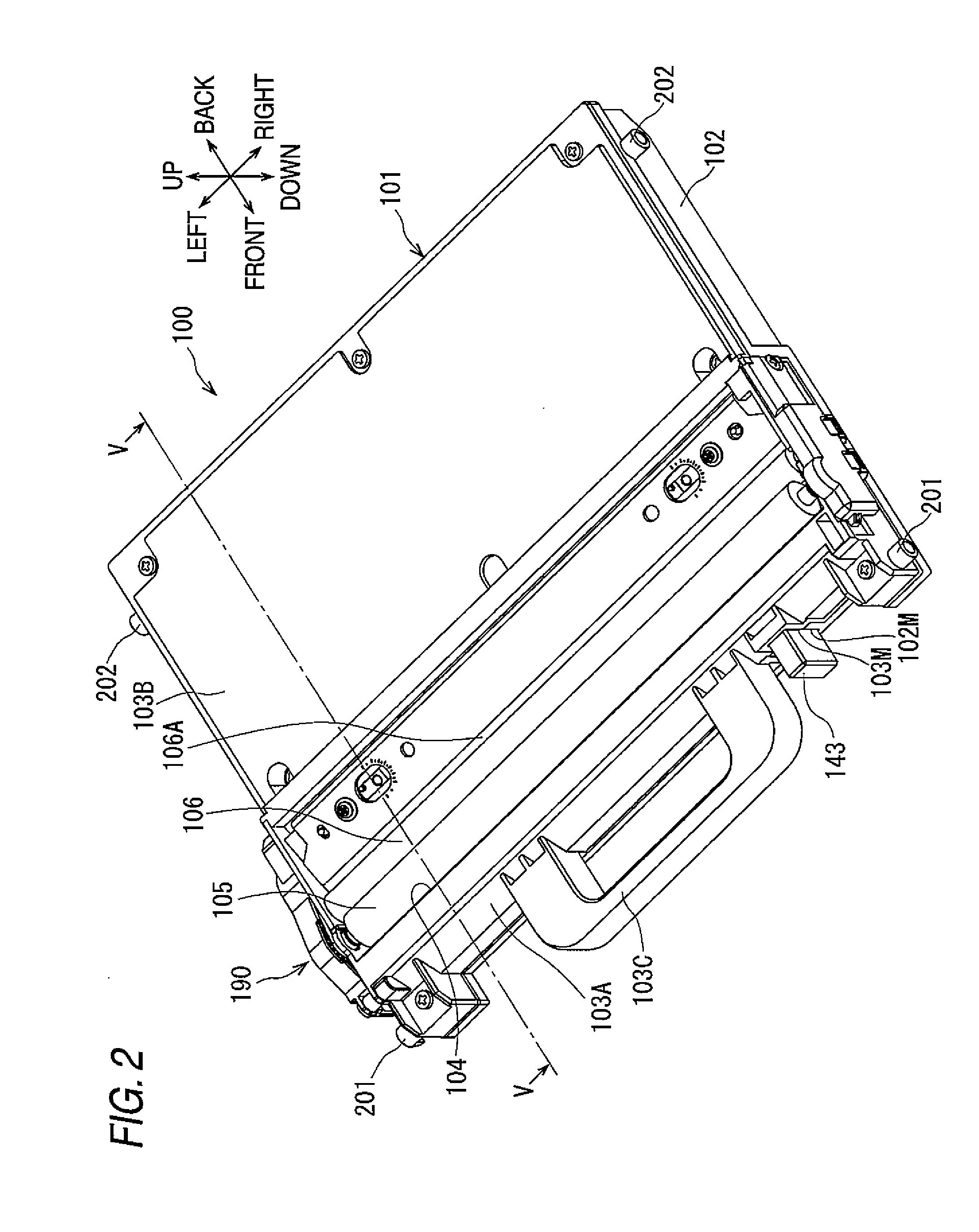

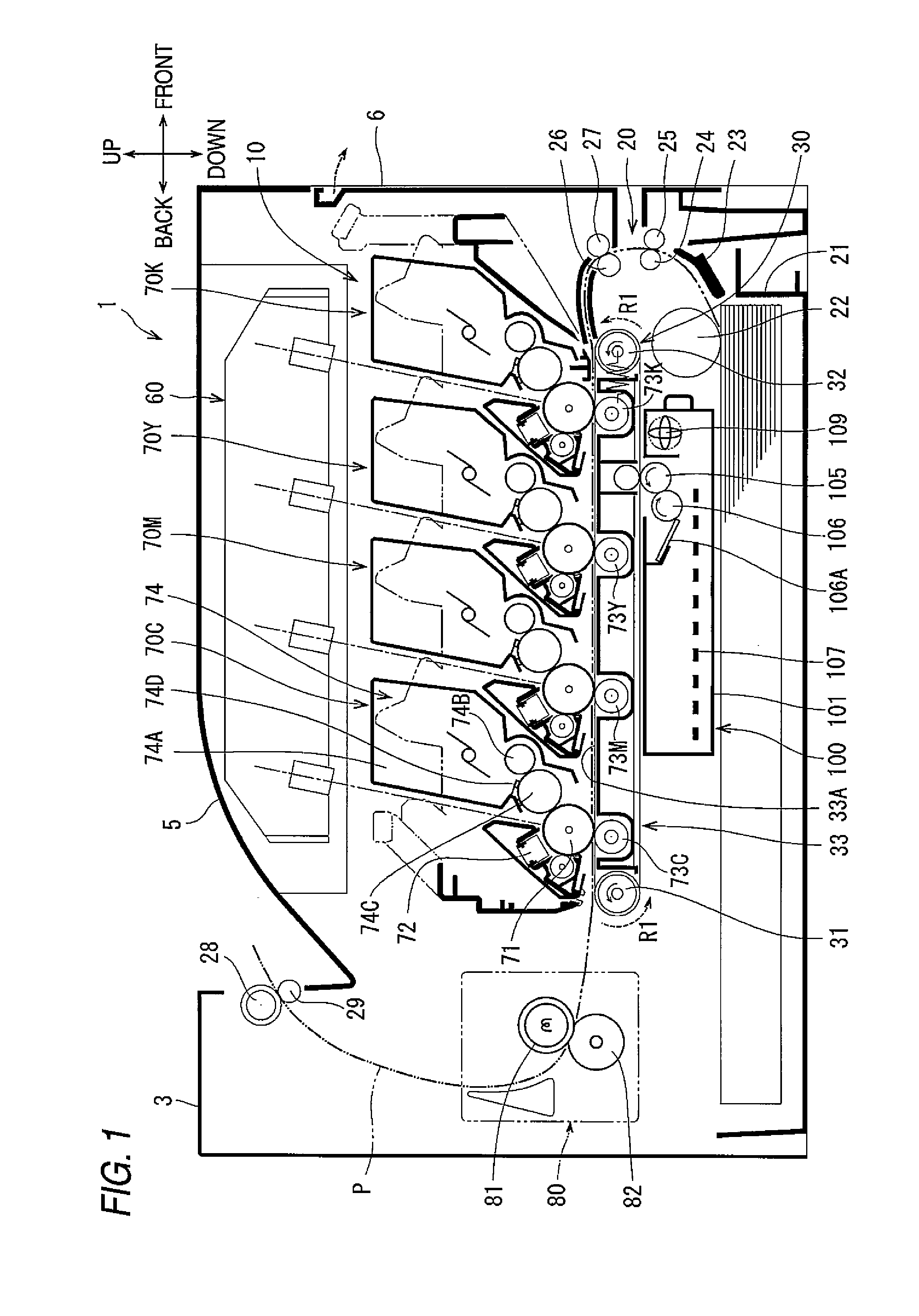

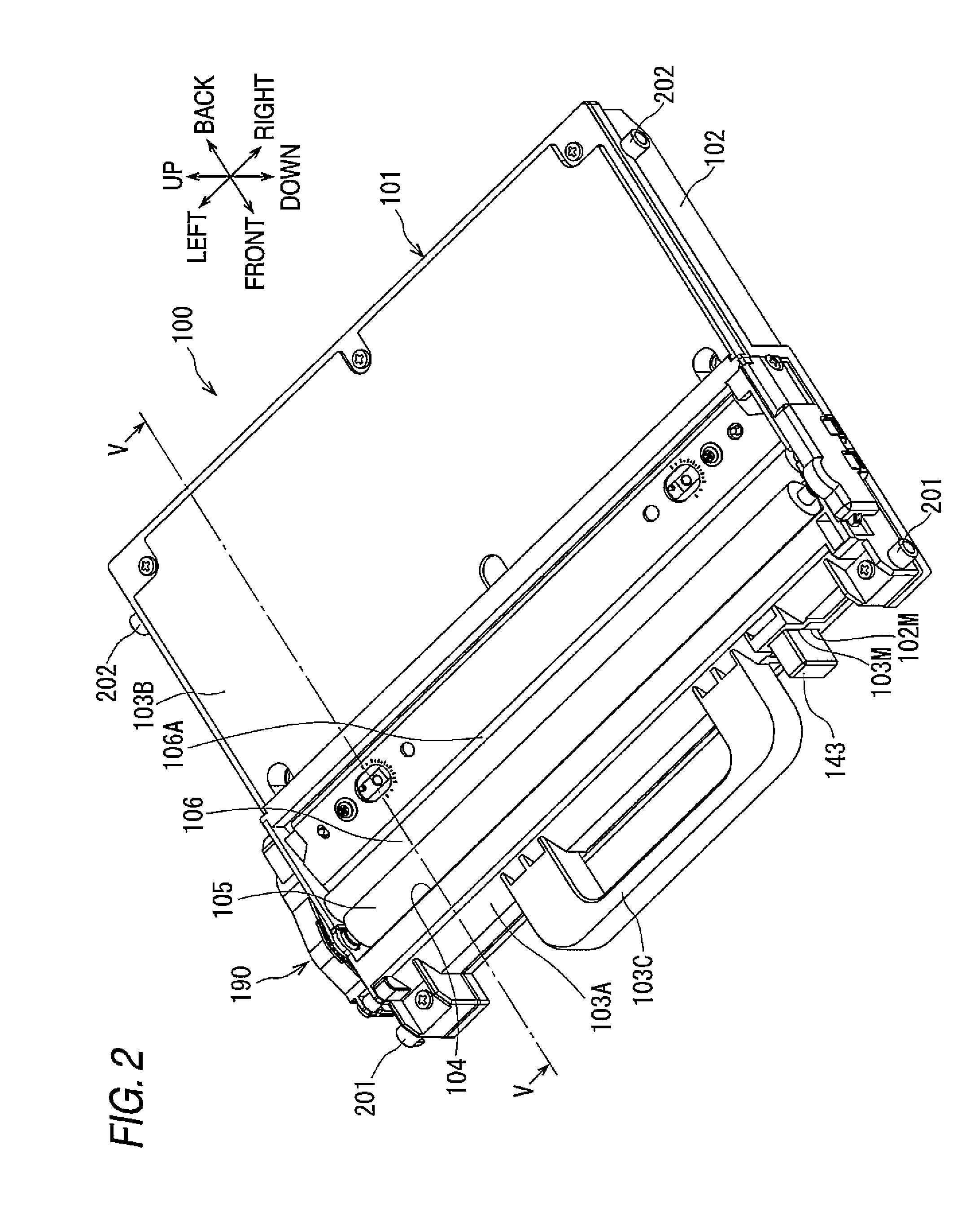

Toner Recovery Machine and Image Forming Apparatus

ActiveUS20100303497A1Improve fill rateReduce thicknessElectrographic process apparatusEngineeringMechanical engineering

A toner recovery machine comprising: a first roller having a radius and rotatable about a first axis, the first axis along a first direction; a cleaner touching the first roller; a container for accommodating toner, the container comprising: a first conveyer movable along a second direction perpendicular to the first direction; and a second conveyer rotatable about a second axis and having a radius defined by the rotation about the second axis, the second axis along the first direction, wherein the second conveyer, the first roller, and the first conveyer are positioned in this order along the second direction, wherein the sum of the radius of the first roller and the radius defined by the second conveyer is smaller than a distance in the second direction between the first axis and the second axis.

Owner:BROTHER KOGYO KK

Display element having a lens being formed as part of a translucent support substrate having a display disposed thereon

InactiveUS8704961B2Reduced installation areaDownsizing and thinningTelevision system detailsPrintersDisplay deviceEngineering

Owner:SHARP KK

Semiconductor pressure sensor and method of manufacturing the same

InactiveUS20120152029A1Suppressing the variation in the performance of a semiconductor pressure sensorAvoid performance changesFluid pressure measurement by electric/magnetic elementsSemiconductor/solid-state device manufacturingMiniaturizationEngineering

In a method of manufacturing a semiconductor pressure sensor, a multilayer structure including a polysilicon diaphragm, a polysilicon gauge resistor formed on a side of a space which is to serve as a vacuum chamber below the polysilicon diaphragm, and a group of insulating films containing the polysilicon diaphragm and the polysilicon gauge resistor and having an etching solution introduction hole in contact with a sacrificial layer is formed on the sacrificial layer. Then, an etching solution is supplied through the etching solution introduction hole and the sacrificial layer is etched with the etching solution, to thereby obtain a diaphragm body formed of the multilayer structure, which functions on the vacuum chamber, and a surface of a silicon substrate below a first opening of a first insulating film is etched to thereby form the space which is to serve as the vacuum chamber and a diaphragm stopper disposed in the space, protruding toward near the center of the diaphragm body. With this structure, it is possible to provide a technique for suppressing the variation in the performance of a semiconductor pressure sensor when the semiconductor pressure sensor is downsized.

Owner:MITSUBISHI ELECTRIC CORP

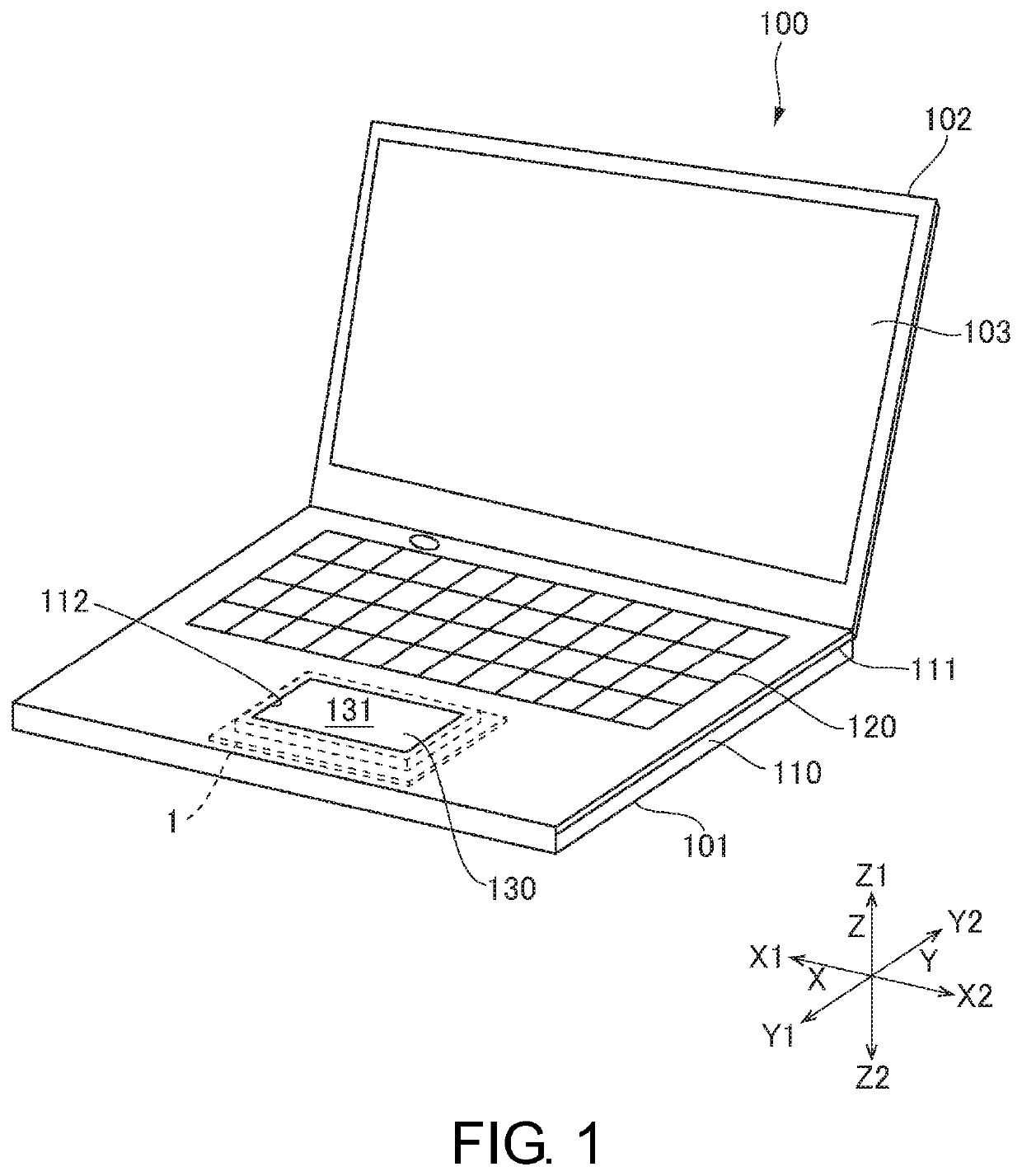

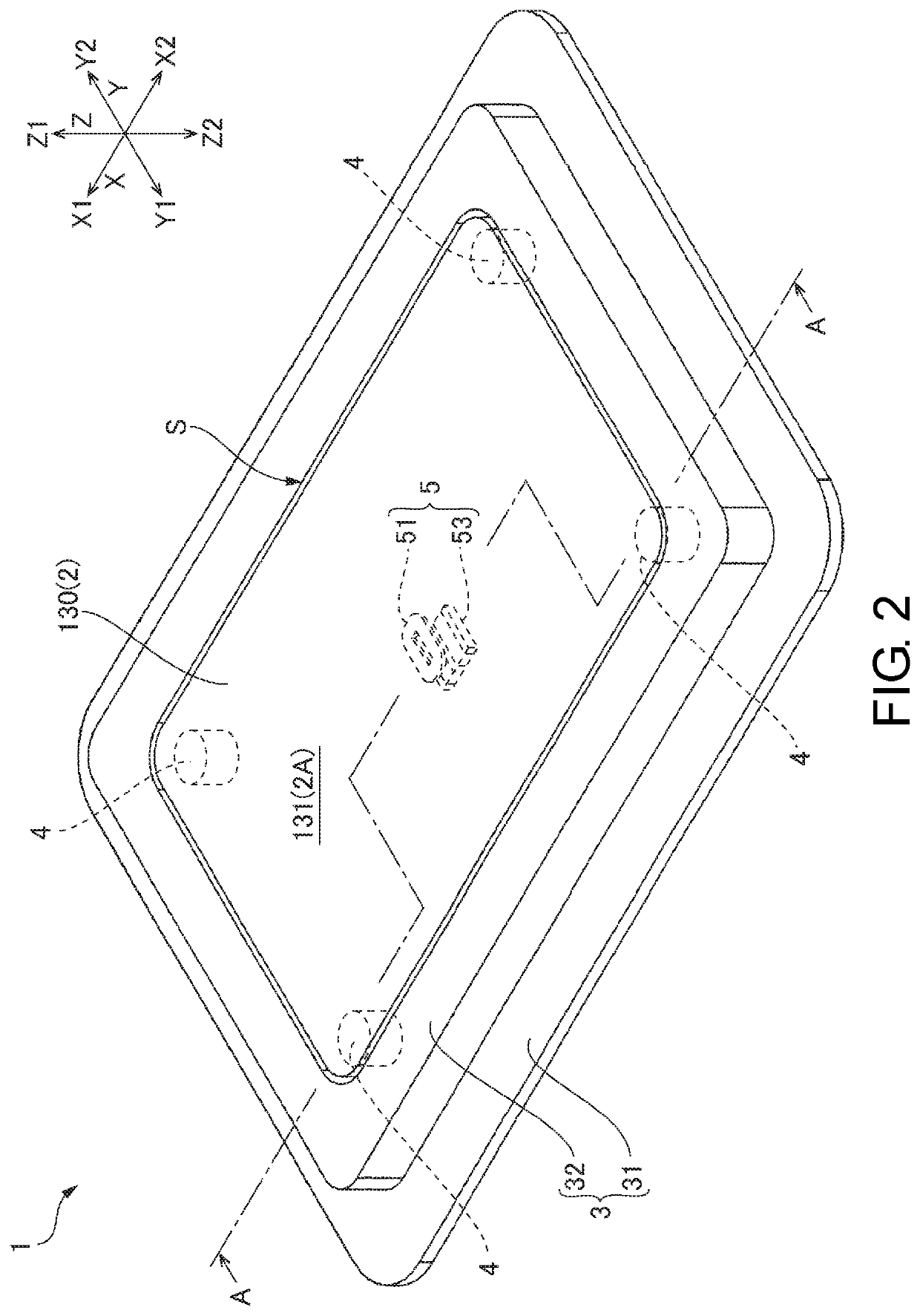

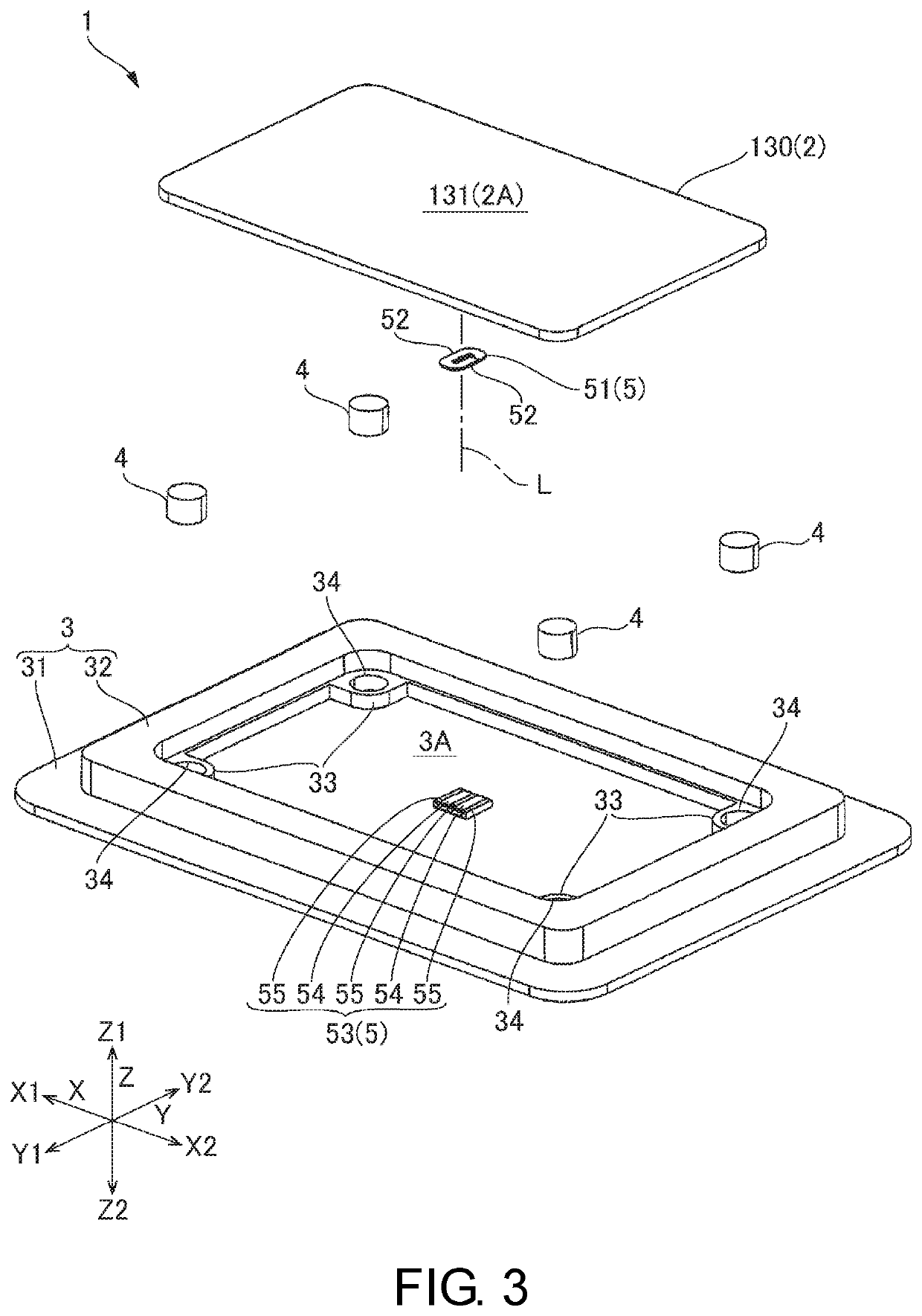

Touchpad module

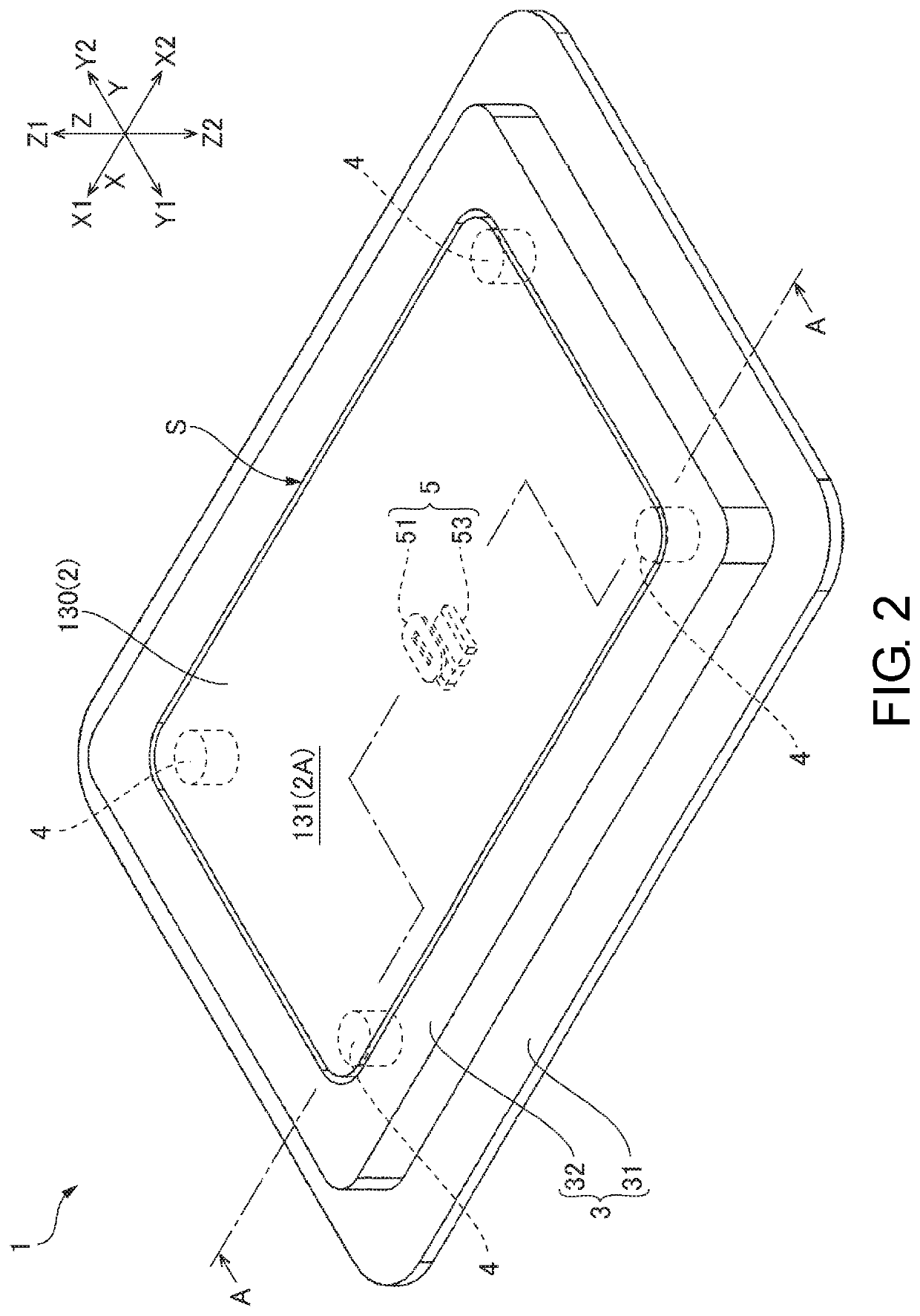

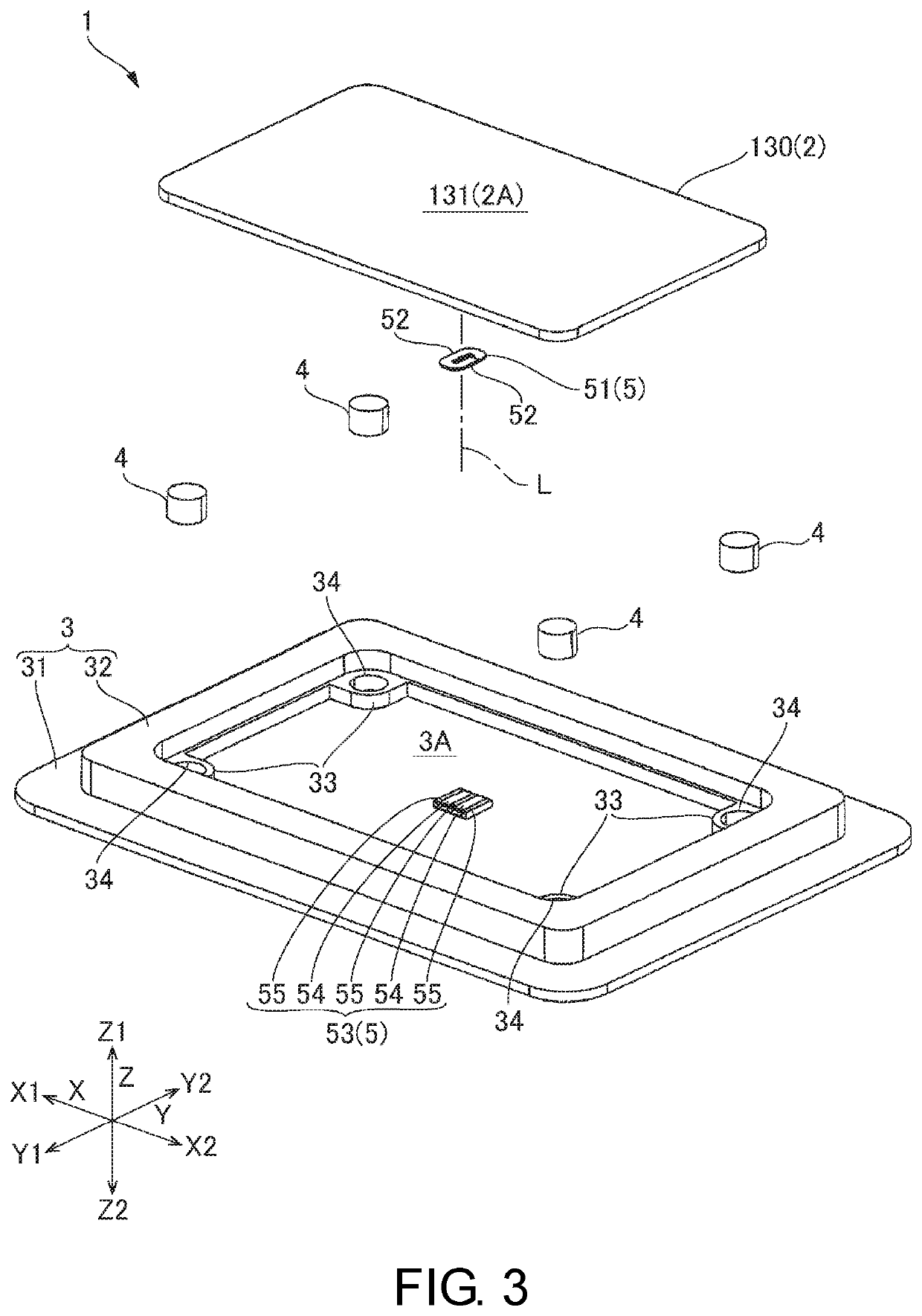

ActiveUS20200133397A1Improve responsivenessDownsizing and thinningInput/output for user-computer interactionDynamo-electric machinesClassical mechanicsTouchpad

A touchpad module includes a movable plate in which one surface is an operation surface of a touchpad, a support member including a facing portion facing the other surface of the movable plate, damper members for connecting the movable plate and the support member, and an actuator for vibrating the movable plate. The actuator includes an air-core coil and a magnet facing each other in a first direction in which the other surface faces the facing portion. The air-core coil is fixed to the other surface, and the magnet is fixed to the facing portion. The actuator vibrates the movable plate in a second direction perpendicular to the first direction by energizing the air-core coil.

Owner:COPAL CO LTD

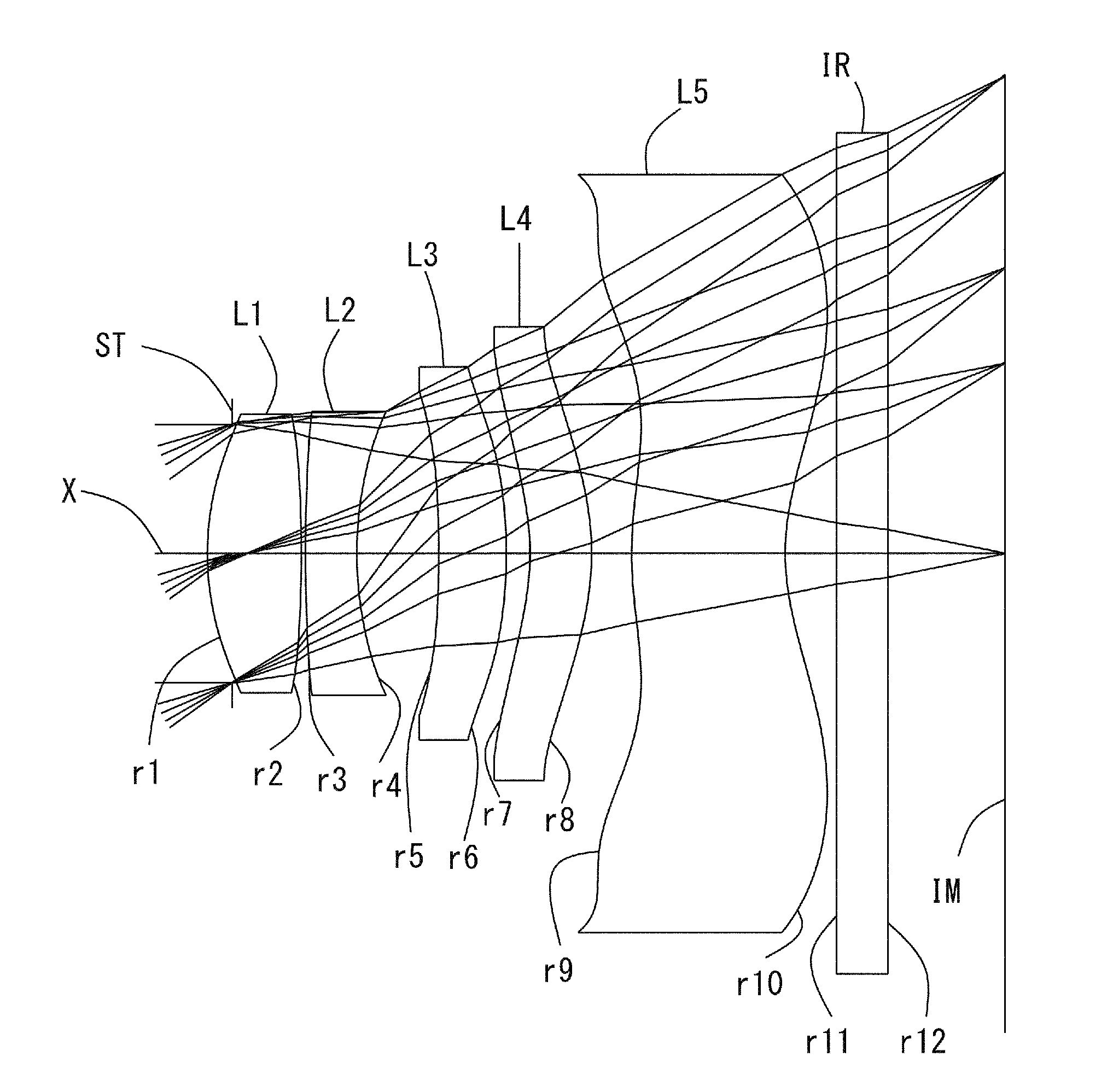

Image pickup lens

ActiveUS9494773B2High resolutionDownsizing and thinningOptical elementsOptical axisConditional expression

An image pickup lens includes an aperture stop, a first lens with positive refractive power having a convex object-side surface, a second meniscus lens having a concave image-side surface, a third meniscus lens having a convex image-side surface, a fourth meniscus lens having a concave object-side surface near an optical axis, and a fifth meniscus lens having a concave image-side surface near the optical axis, wherein the image-side surface of the fourth lens has an aspherical shape in which a positive refractive power weakens toward the periphery, and wherein the following conditional expressions (1) and (7) are satisfied:0.55<f1 / f<1.0 (1)−1.6<f2 / f<−0.7 (7)where f represents a focal length of an overall image pickup lens, f1 represents a first lens focal length, and f2 represents a second lens focal length.

Owner:TOKYO VISIONARY OPTICS CO LTD

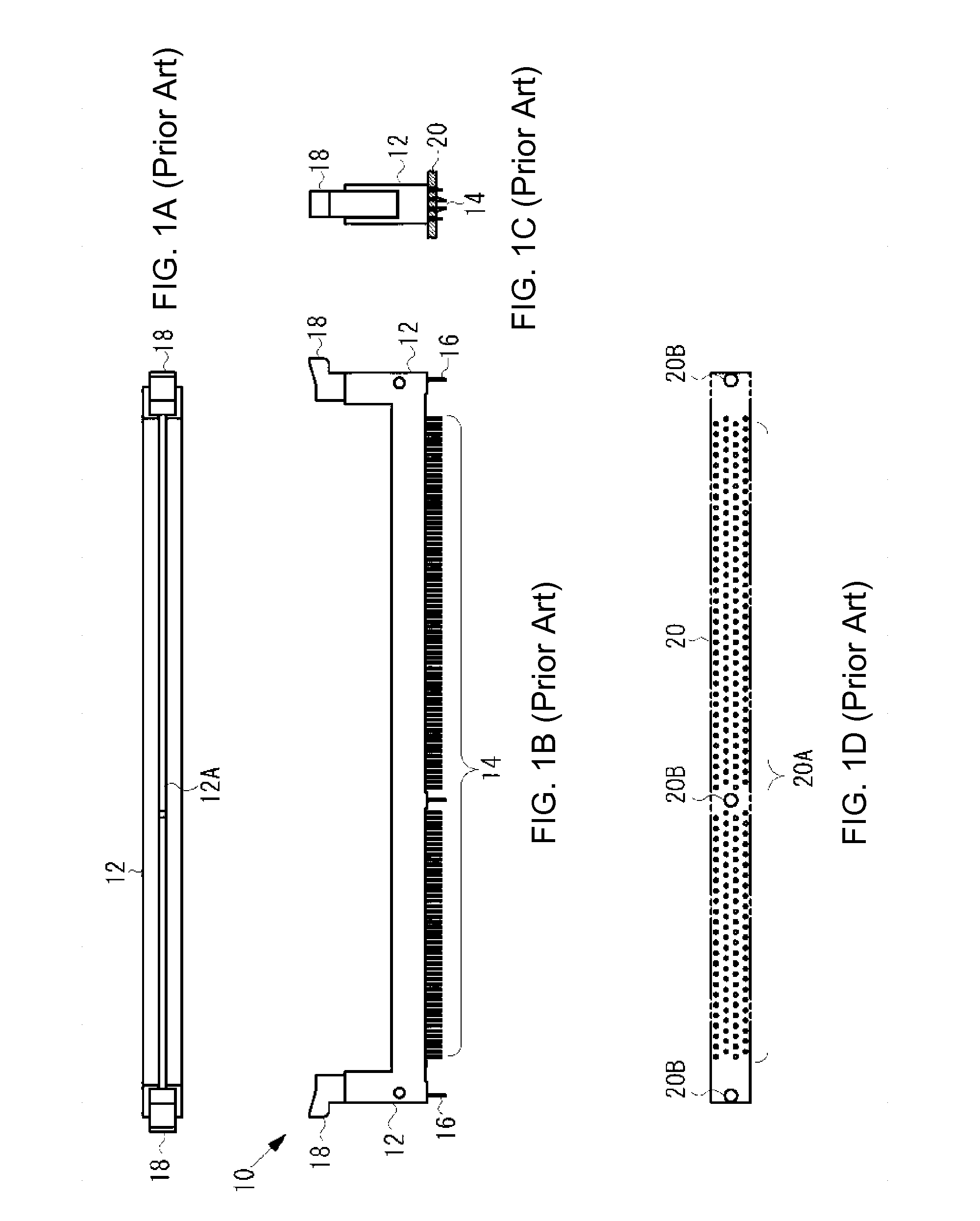

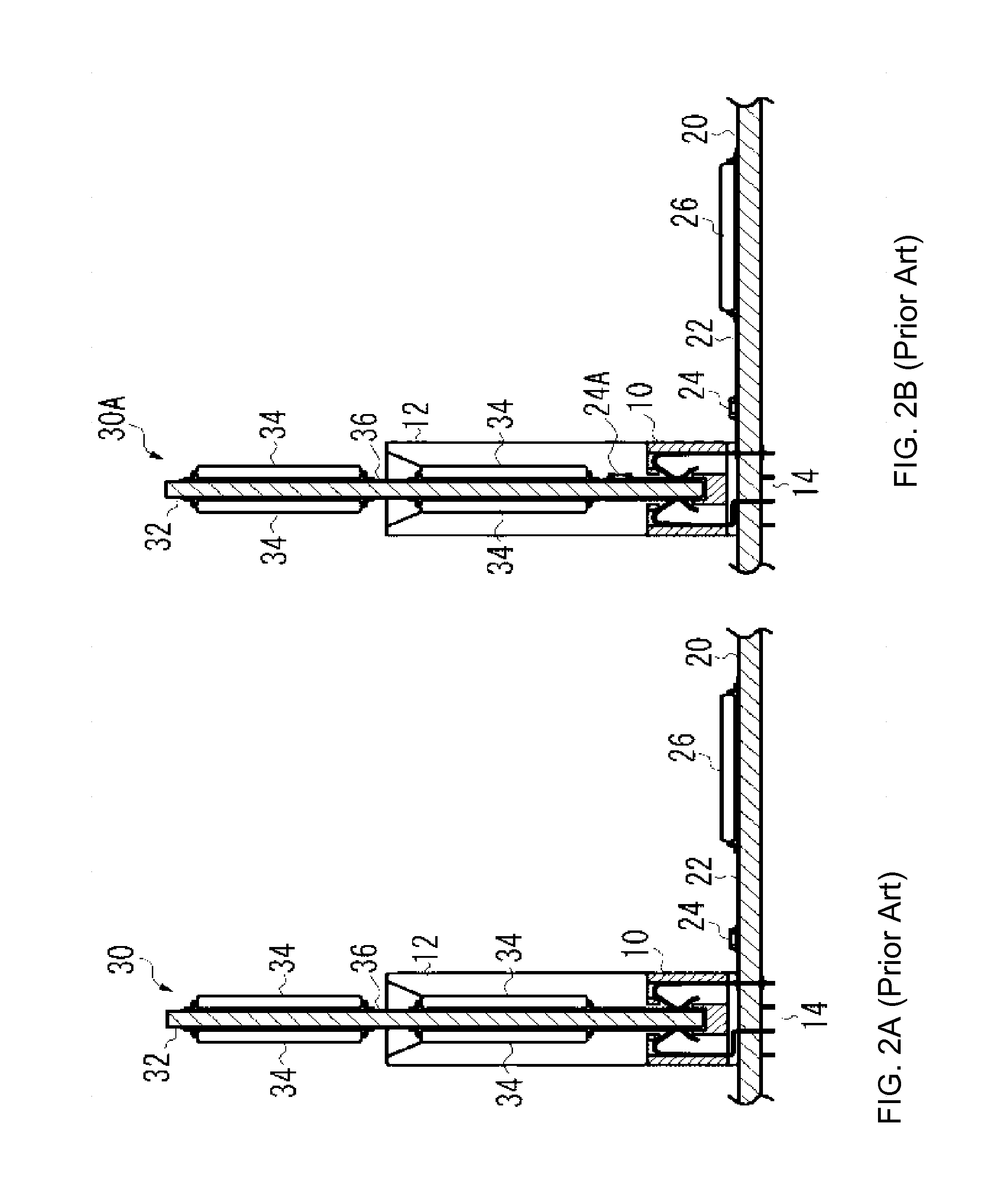

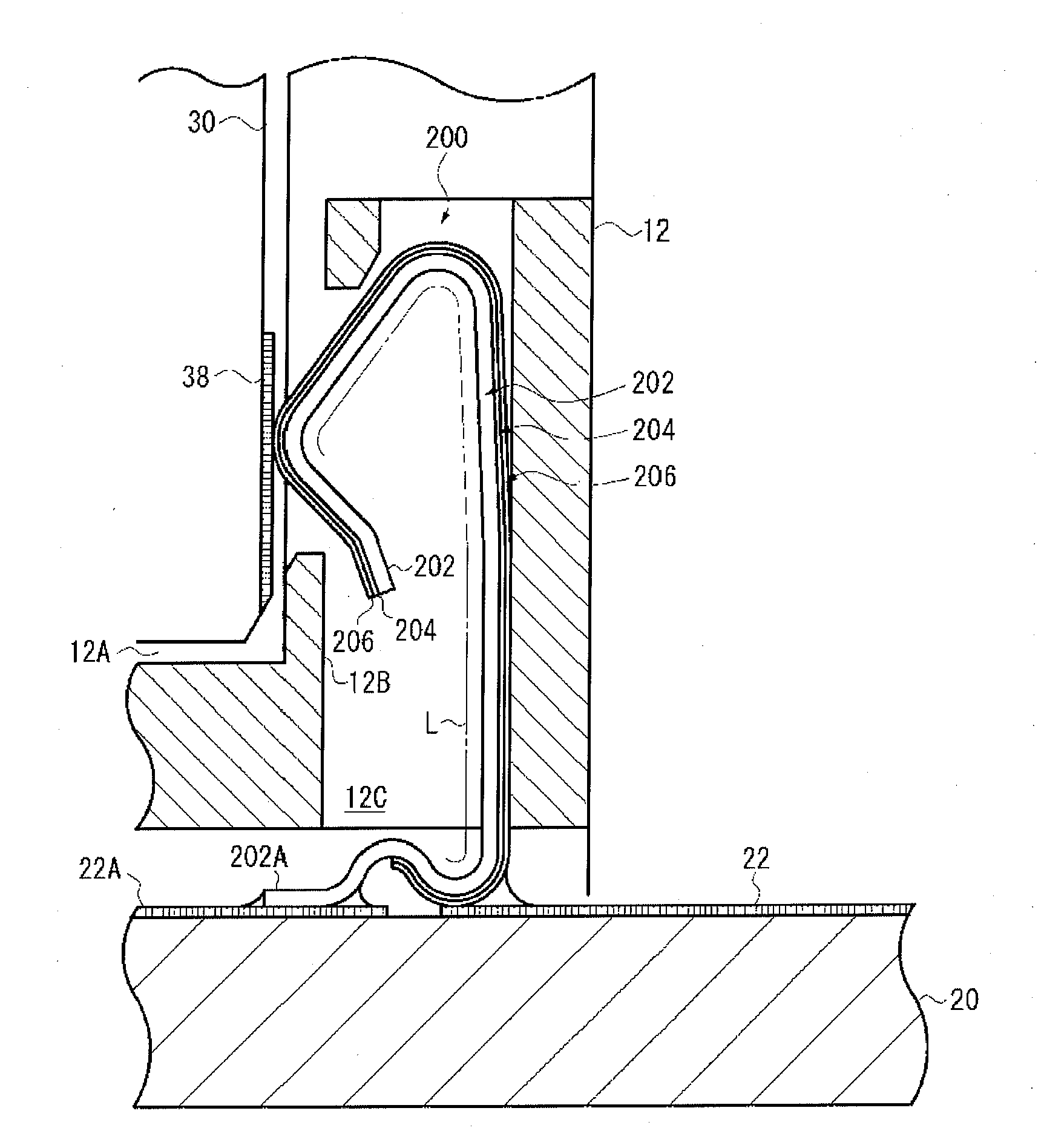

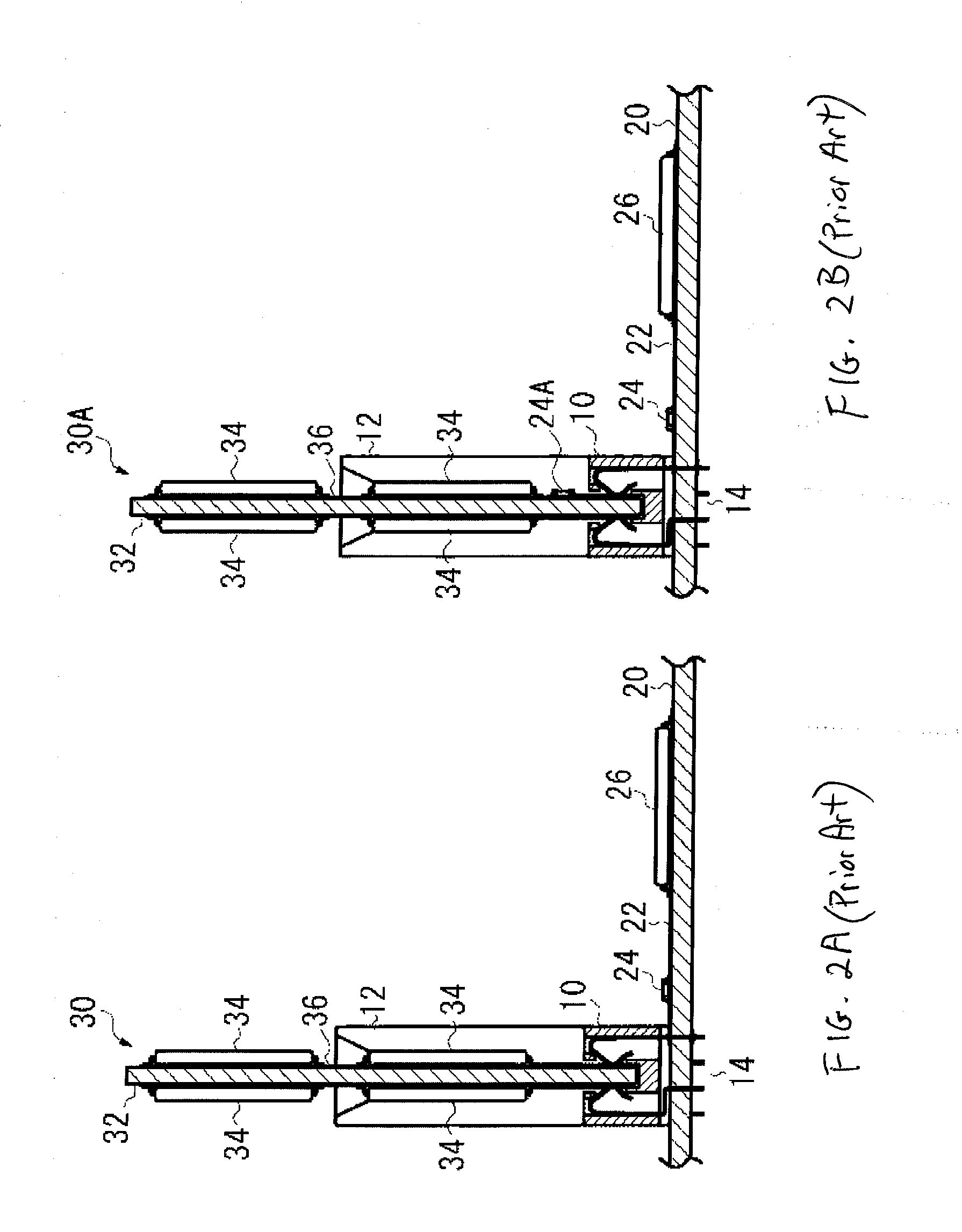

Socket with integrated damping resistor

InactiveUS8632366B2Reducing the damping resistors requiredSimplify the design processEngagement/disengagement of coupling partsTwo-part coupling devicesElectrical resistance and conductanceEngineering

This invention provides a socket for a circuit board that adds function of electrical resistive element to a contact. A socket includes a socket body extending at a longitudinal direction; and a plurality of contacts disposed in two lines along the longitudinal direction of the socket body. When a memory module is connected to the socket body, terminals formed on opposite surfaces of the memory module are electrically and elastically connected by the contacts. The contact includes a contact portion which contacts the terminal, a bent portion for generating an elastic force, and a base portion. The contact is made of a conductive metal having elastic properties, and the contact used for carrying signal is provided with a resistor of an electrical resistive material that is different from the conductive metal. The resistor is connected in a current path between the base portion and the terminal of the memory module.

Owner:SENSATA TECHNOLOGIES INC

Socket

InactiveUS20120252233A1Downsizing and thinningSimplify the design processCoupling device detailsSupport structure mountingEngineeringResistor

This invention provides a socket for a circuit board that adds function of electrical resistive element to a contact. A socket includes a socket body extending at a longitudinal direction; and a plurality of contacts disposed in two lines along the longitudinal direction of the socket body. When a memory module is connected to the socket body, terminals formed on opposite surfaces of the memory module are electrically and elastically connected by the contacts. The contact includes a contact portion which contacts the terminal, a bent portion for generating an elastic force, and a base portion. The contact is made of a conductive metal having elastic properties, and the contact used for carrying signal is provided with a resistor of an electrical resistive material that is different from the conductive metal. The resistor is connected in a current path between the base portion and the terminal of the memory module.

Owner:SENSATA TECHNOLOGIES INC

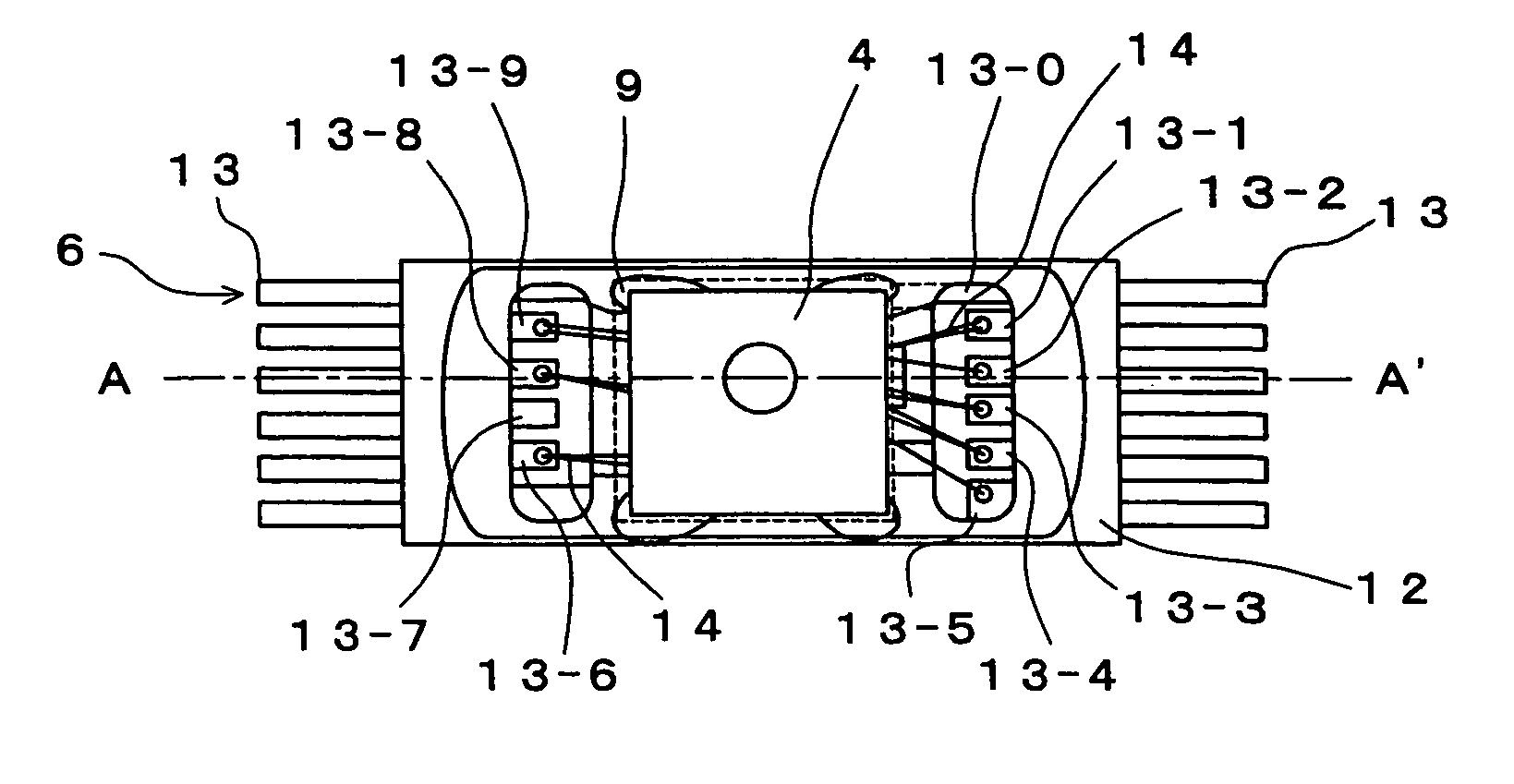

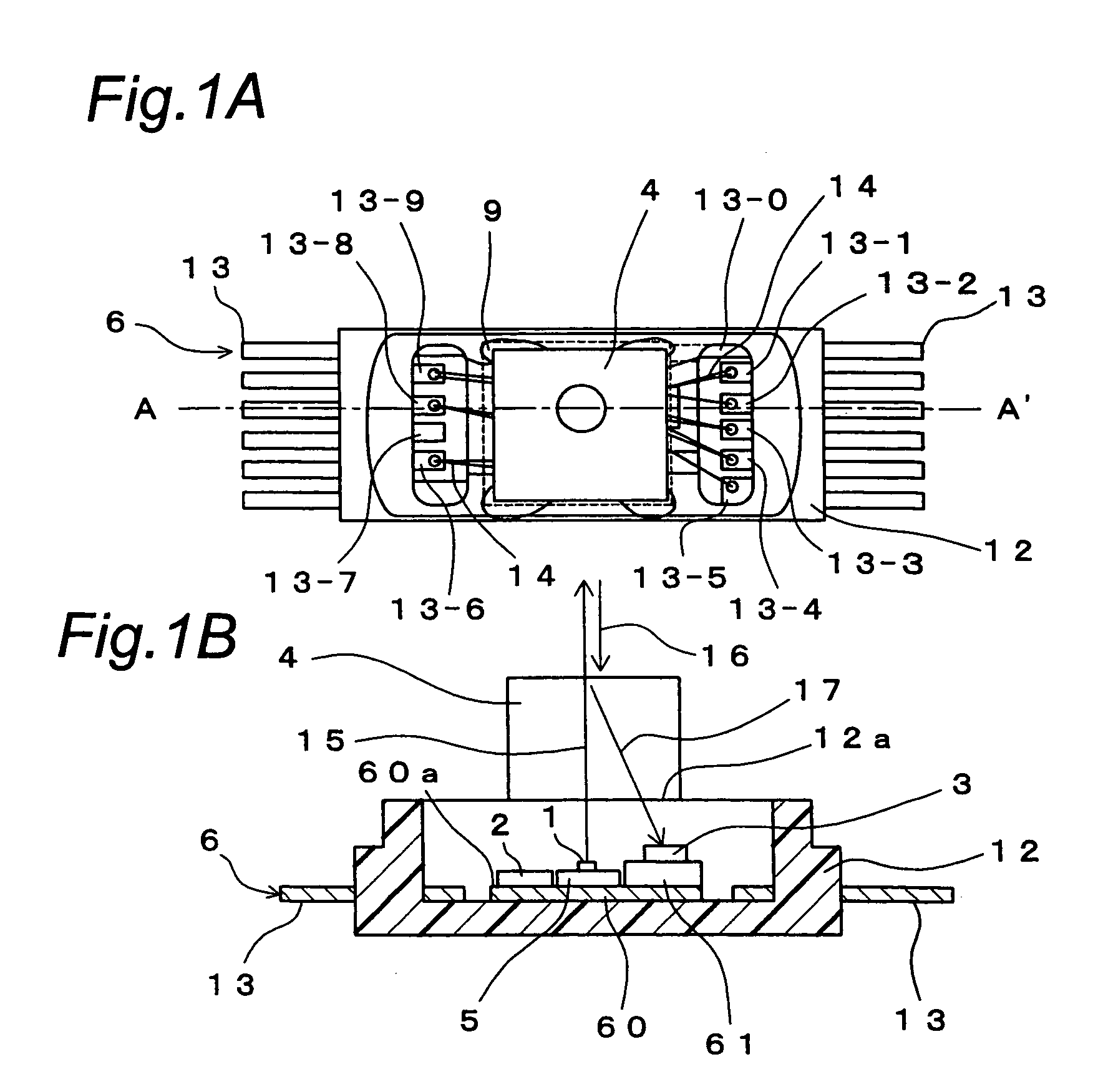

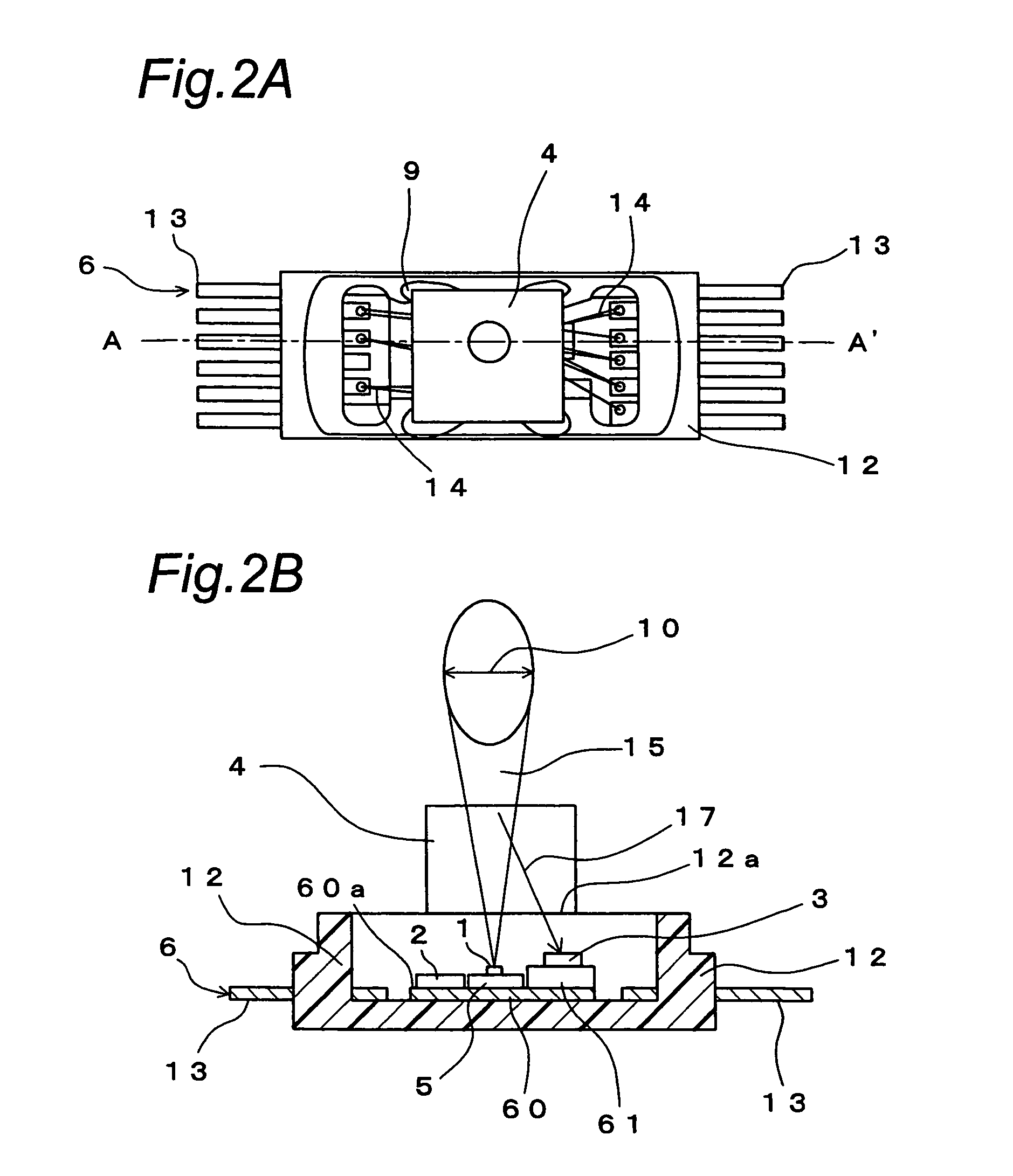

Semiconductor laser device containing laser driver and electronic equipment having the same

InactiveUS7184453B2Downsizing and thinningLow costSemiconductor laser structural detailsOptical beam sourcesOptical axisPhotoelectric conversion

There is provided a semiconductor laser device containing a laser driver capable of implementing downsizing, thinning and cost reduction of equipment using the laser device. In the semiconductor laser device containing a laser driver, a semiconductor laser element, a laser driver for driving the laser element, and a signal detection part for performing photoelectric conversion are mounted on a common mount surface of a lead frame and moreover accommodated in a common package. Upward of the semiconductor laser element is provided a hologram element for transmitting laser light emitted by the laser element toward a recording medium and then diffracting toward the signal detection part the laser light reflected by the recording medium. The laser driver and the signal detection part are disposed on both sides with respect to an optical axis of the laser element.

Owner:SHARP KK

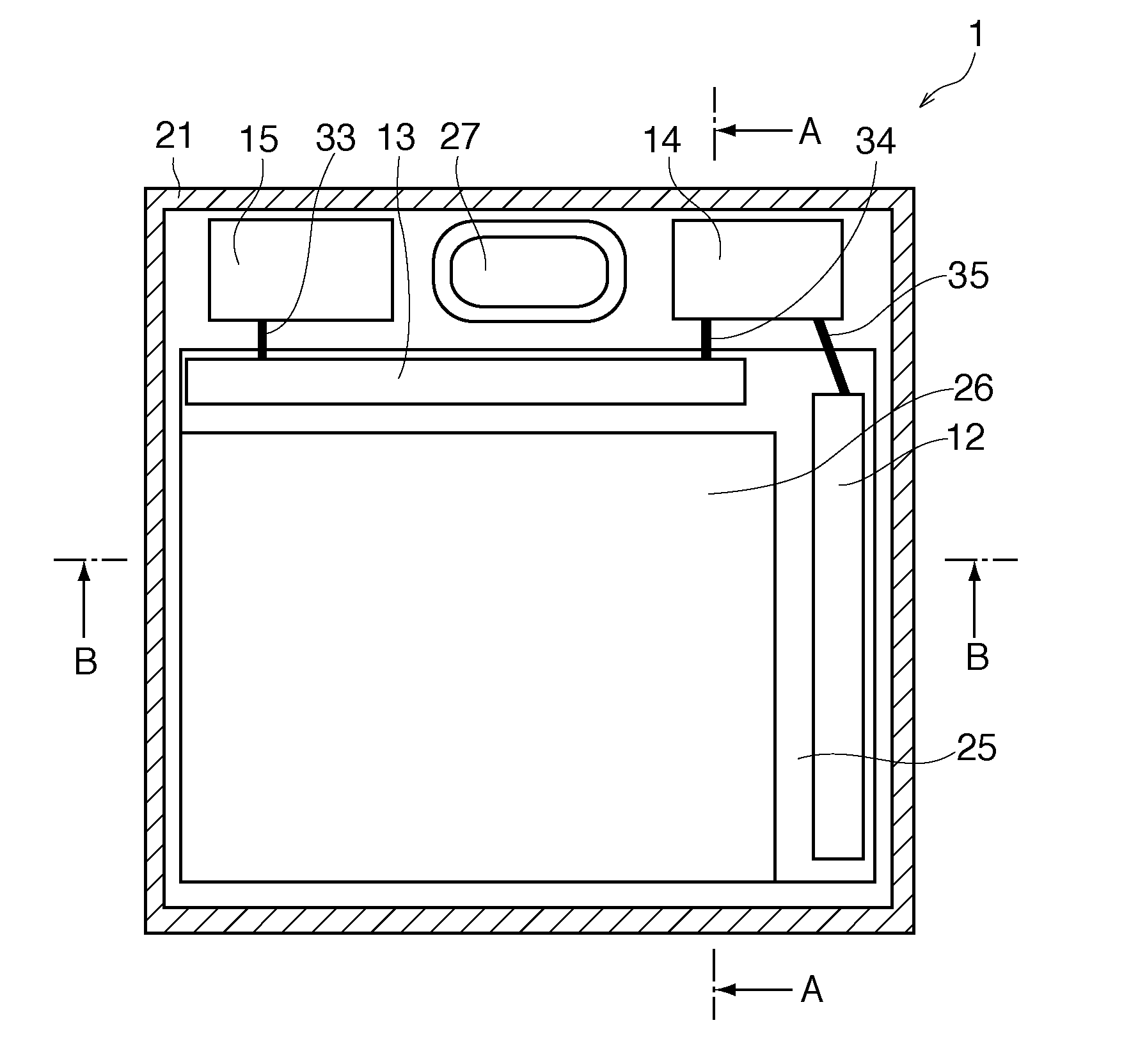

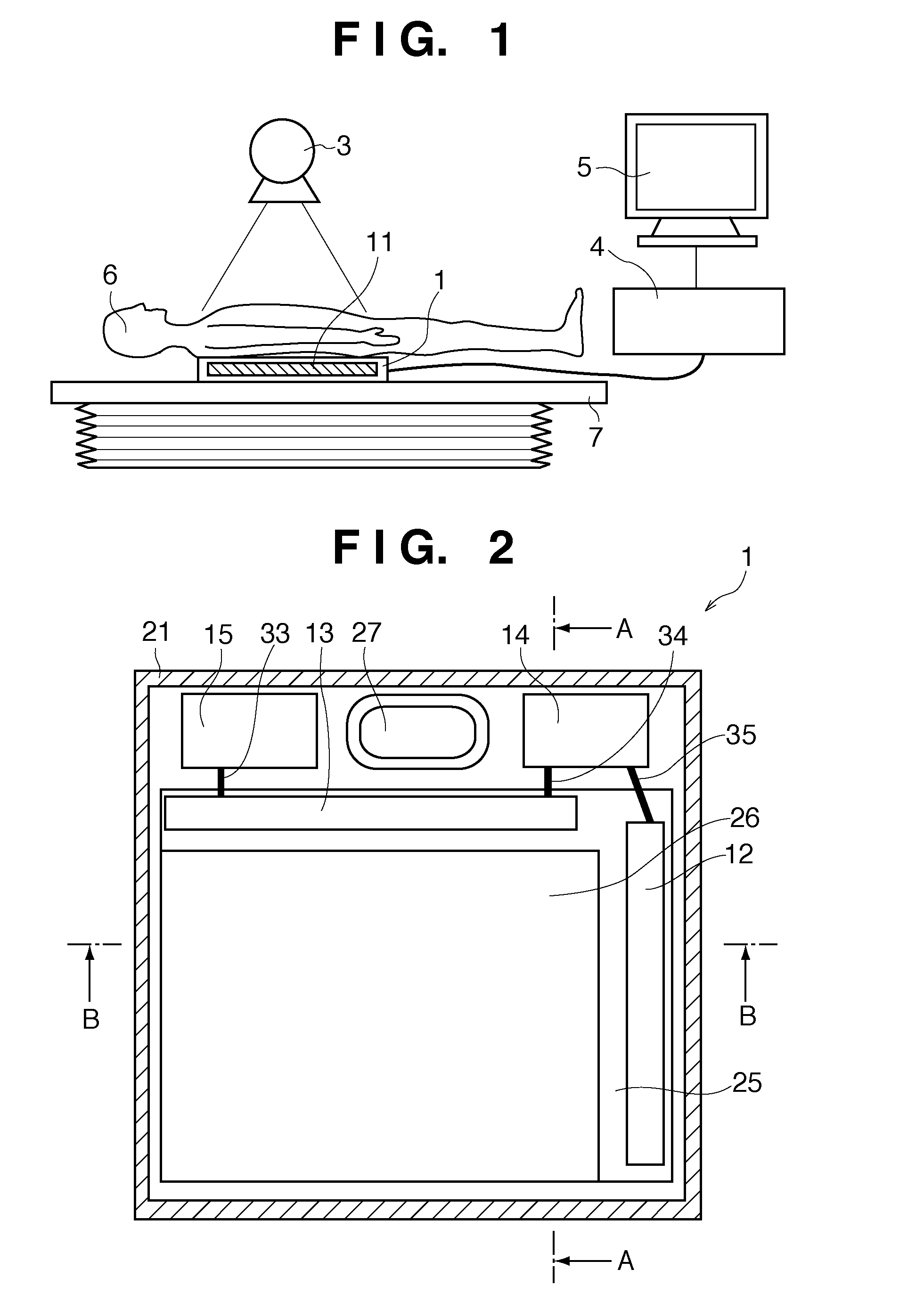

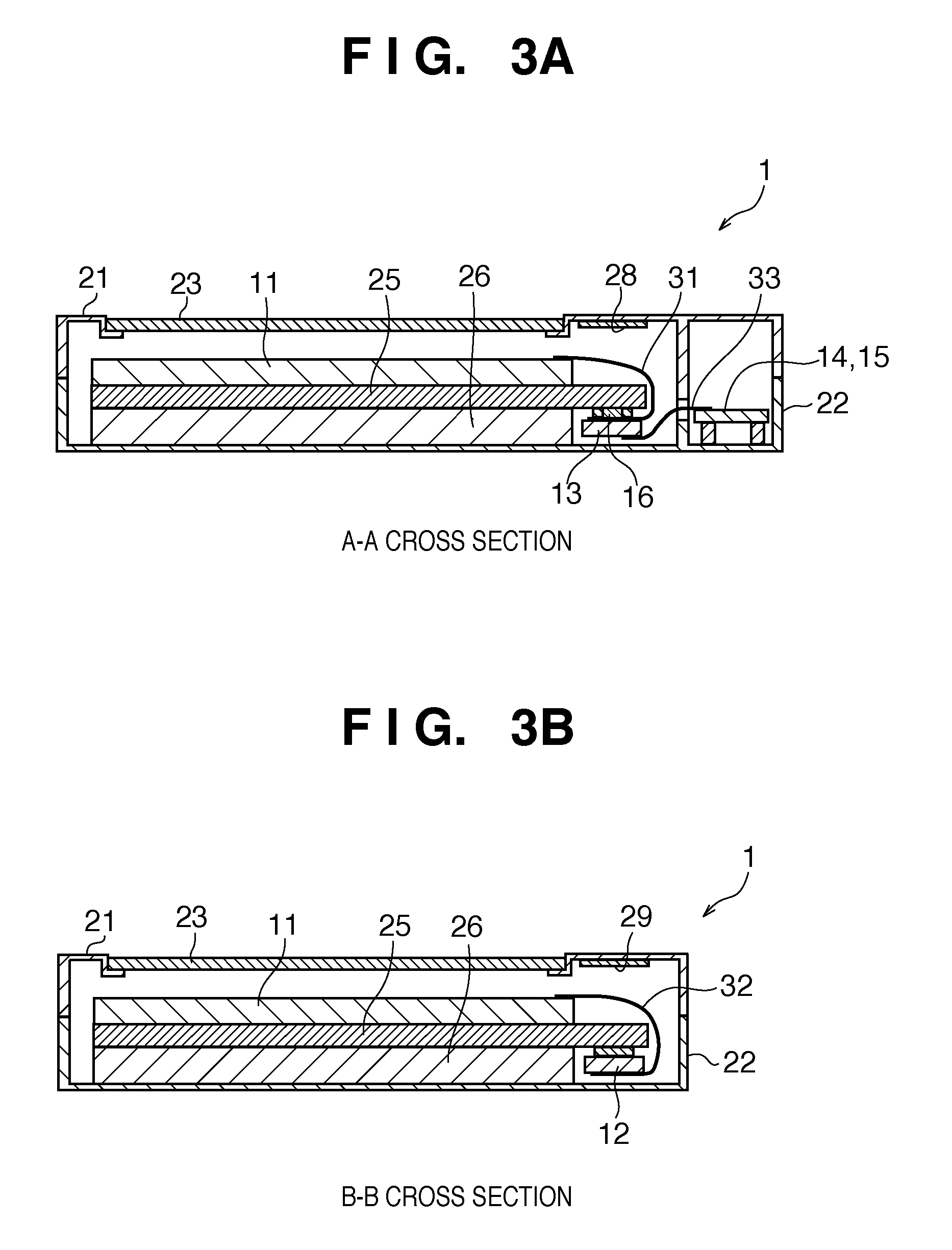

Radiographic apparatus

InactiveUS20130266121A1Reduce weightDownsizing and thinningMaterial analysis using wave/particle radiationImage-conversion/image-amplification tubesTwo dimensional detectorX-ray

A radiographic apparatus includes an X-ray detection sensor having a two-dimensional detector plane for detecting an intensity distribution of X-rays, a body internally containing the X-ray detection sensor, a supporting member having a supporting surface for supporting the X-ray detection sensor across the detector plane and which fixes the X-ray detection sensor to an inner bottom surface of the body, and a circuit board on which is mounted a circuit for reading out a detection signal from the X-ray detection sensor. Furthermore, in the radiographic apparatus, the supporting member forms a space between the supporting member and the inner bottom surface of the body in a peripheral portion of the supporting member. At least a part of the circuit board is arranged in the space.

Owner:CANON KK

Image pickup lens

An image pickup lens includes an aperture stop, a first lens with positive refractive power having a convex object-side surface, a second meniscus lens having a concave image-side surface, a third meniscus lens having a convex image-side surface, a fourth meniscus lens having a concave object-side surface near an optical axis, and a fifth meniscus lens having a concave image-side surface near the optical axis, wherein the image-side surface of the fourth lens has an aspherical shape in which a positive refractive power weakens toward the periphery, and wherein the following conditional expressions (1) and (7) are satisfied:0.55<f1 / f<1.0 (1)−1.6<f2 / f<−0.7 (7)where f represents a focal length of an overall image pickup lens, f1 represents a first lens focal length, and f2 represents a second lens focal length.

Owner:TOKYO VISIONARY OPTICS CO LTD

Optical sensor and method of manufacturing the optical sensor

InactiveUS20120248298A1Easy to manufactureImprove reliabilityRadiation pyrometryBeam/ray focussing/reflecting arrangementsEngineeringPhotoelectric conversion

An optical sensor has a glass base having a concave portion, and a glass lid is bonded to the base and overlies the concave portion to form an hermetically sealed cavity portion. A photoelectric conversion element is accommodated in the cavity portion. Internal wirings are each connected at one end to the photoelectric conversion element and extend through notches formed in a peripheral edge of the base. The other ends of the internal wirings are connected inside the notches to external wirings that extend along an outside surface of the base and terminate in external terminals.

Owner:ABLIC INC

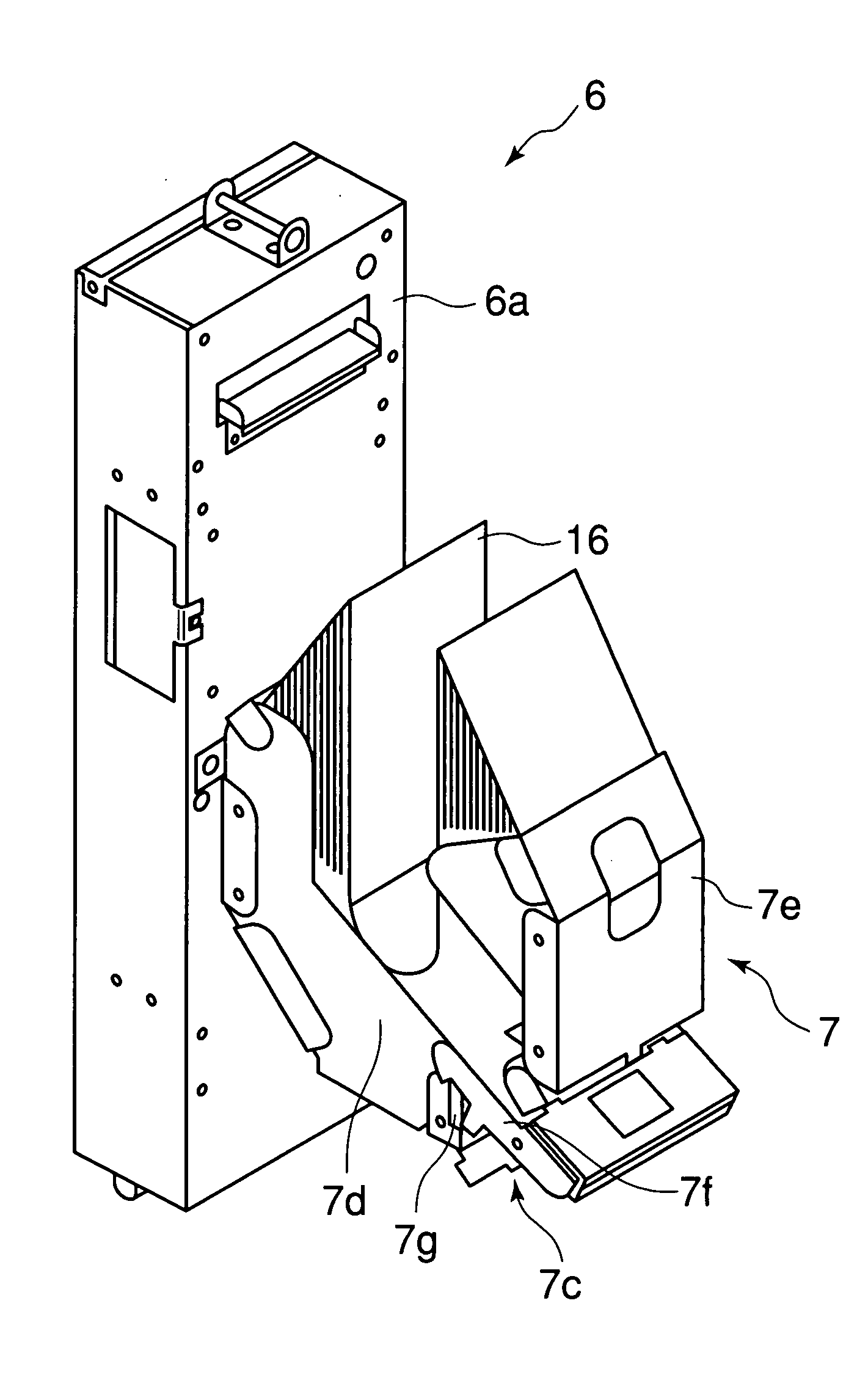

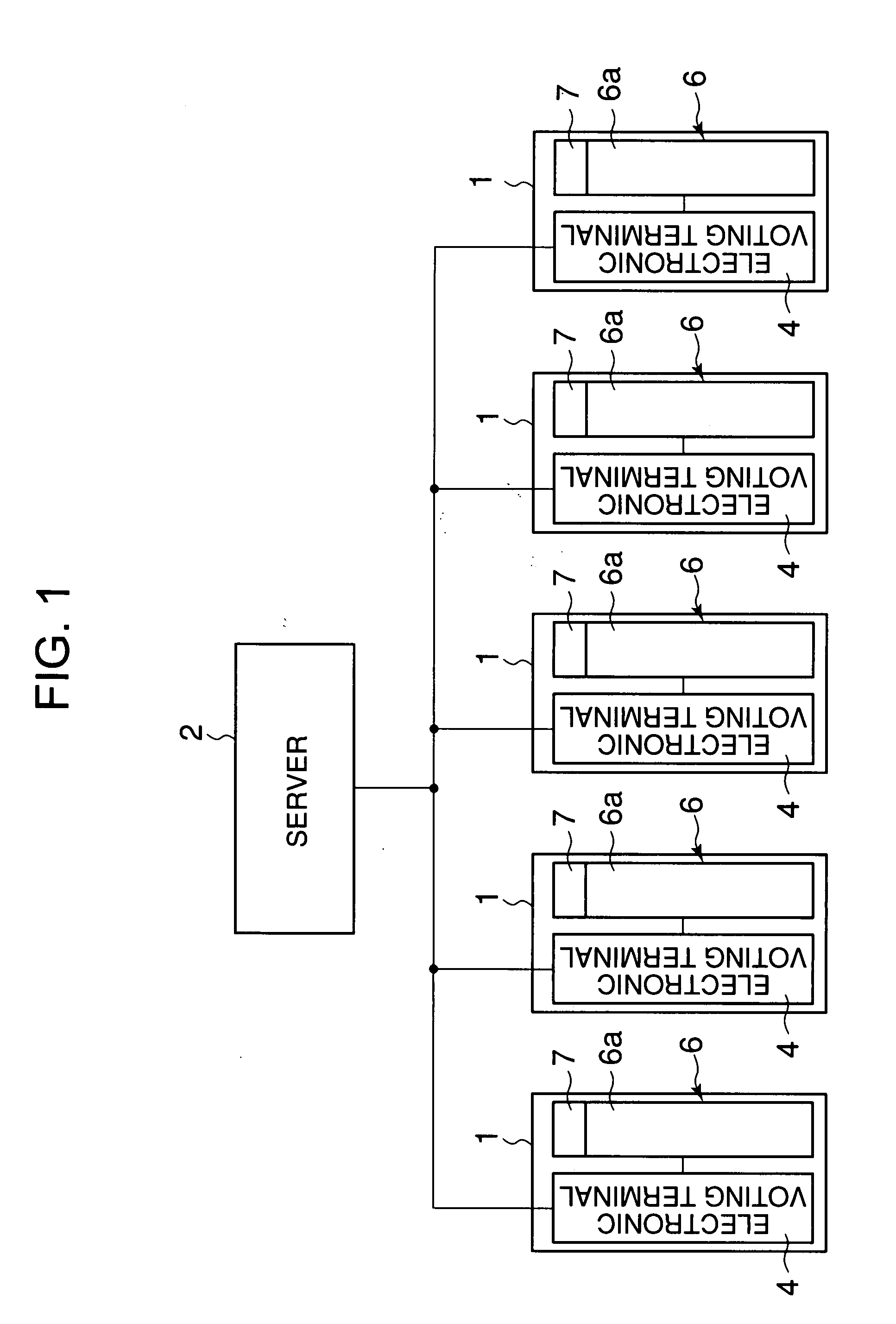

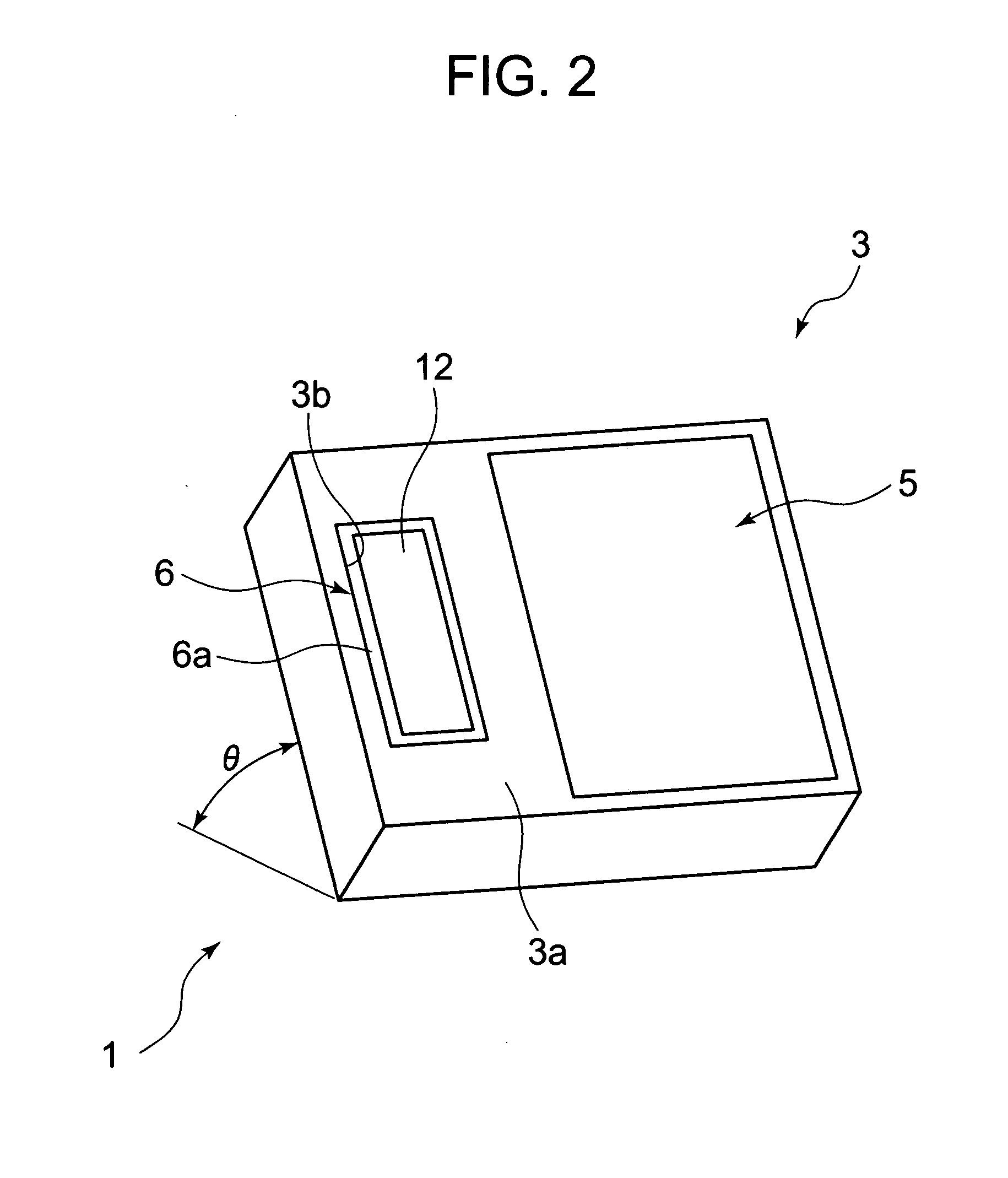

Sheet retaining structure and printer for an electronic voting device

InactiveUS20080056799A1Easy maintenance and operationEasy to implementVoting apparatusOther printing apparatusEngineeringMechanical engineering

In order to provide a printer for an electronic voting device, capable of smoothly transporting a recording sheet having a free end and capable of realizing downsizing and simplification, a container (7) includes a main body portion (7d) mounted on to a casing (6a) of a printer (6) and a movable portion (7e) attached to the main body portion (7d) so as to be capable of being opened and closed. In a state where the container (7) is opened, a fanfold sheet (16) in a state where a deflection thereof is small is inserted as it is, and the movable portion (7e) is then closed with respect to the main body portion (7d). As a result, the fanfold sheet (16) is retained in the container (7) in a state where the fanfold sheet (16) is largely deflected in a U-shape. The fanfold sheet (16) can smoothly be supplied from the container (7) into the casing (6a) The printer (6) prints electronic voting contents on the fanfold sheet (16) which is smoothly supplied. When the printed content is visually confirmed, the printer (6) prints characters indicating approval thereof. After that, a printed portion of the fanfold sheet (16) is cut off to be discharged.

Owner:SEIKO INSTR INC

Touchpad module

ActiveUS10908692B2Improve responsivenessDownsizing and thinningInput/output for user-computer interactionDynamo-electric machinesClassical mechanicsTouchpad

A touchpad module includes a movable plate in which one surface is an operation surface of a touchpad, a support member including a facing portion facing the other surface of the movable plate, damper members for connecting the movable plate and the support member, and an actuator for vibrating the movable plate. The actuator includes an air-core coil and a magnet facing each other in a first direction in which the other surface faces the facing portion. The air-core coil is fixed to the other surface, and the magnet is fixed to the facing portion. The actuator vibrates the movable plate in a second direction perpendicular to the first direction by energizing the air-core coil.

Owner:COPAL CO LTD

Movable contact unit, manufacturing method of the same, and manufacturing method of panel switch

InactiveUS20060180456A1Downsizing and thinningContact surface shape/structureContact mechanismsEngineeringMagnetic flux

A manufacturing method of a movable contact unit includes the steps of (A) manufacturing a movable contact, (B) sticking the movable contact to a base sheet made of insulating resin, and (C) applying demagnetization to the movable contact so that the residual magnetic flux density is smaller than the operation magnetic flux density of the magnetic sensor. In step A, elastic metal plate material is processed into a downwardly opening dome shape to form the movable contact. In a manufacturing method of a panel switch, the movable contact unit is overlaid on a wiring board having a pair of an outer fixed contact and a central fixed contact that correspond to the movable contact so that the lower end of the outer periphery of the movable contact is mounted on the outer fixed contact.

Owner:PANASONIC CORP

Packaging material for cell

ActiveUS11024832B2Made thinnerDownsizing and thinningFlexible coversWrappersPolymer scienceThin membrane

A film-shaped packaging material for a cell in which a coating layer is provided as the outermost layer instead of a substrate layer and an adhesive layer in a conventional film-shaped packaging material for a cell, thereby making it possible to produce a thinner film; wherein the packaging material is provided with exceptional moldability and insulation performance and enables lead time to be reduced. The packaging material is a laminate having at least a coating layer, a barrier layer, and a sealant layer in the stated order, the coating layer including a single- or multiple-layer configuration formed by a cured product of a resin composition containing a heat-curable resin and curing accelerator, the laminate having a piercing strength of at least 5 N, as measured in compliance with JIS 1707:1997, and the coating layer having a breakdown voltage of at least 1.0 kV, as measured in compliance with JIS C2110-1.

Owner:DAI NIPPON PRINTING CO LTD

Packaging material for cell

ActiveUS10033021B2Downsizing and thinningShort timeLamination ancillary operationsSynthetic resin layered productsInter layerHardness

A packaging material for a cell including a laminated article having at least a coating layer, a barrier layer, and a sealant layer in the stated order, wherein: the coating layer has at least three layers including a first, second and third coating layer, and is disposed so that the first coating layer is positioned as the outermost layer and the third coating layer is positioned on the barrier-layer-side; and the first coating layer, the second coating layer, and the third coating layer are formed from a cured product of a resin composition containing a heat-curing resin and a curing accelerator so as to sufficiently exhibit a specific hardness, whereby the thickness can be reduced, exceptional chemical resistance, moldability, and inter-layer adhesion between the barrier layer and the coating layer can be obtained, and the lead time can be reduced to enable an improvement in production efficiency.

Owner:DAI NIPPON PRINTING CO LTD

Packaging material for cell

A film-shaped packaging material for a cell in which a coating layer is provided as the outermost layer instead of a substrate layer and an adhesive layer in a conventional film-shaped packaging material for a cell, thereby making it possible to produce a thinner film; wherein the packaging material is provided with exceptional moldability and insulation performance and enables lead time to be reduced. The packaging material is a laminate having at least a coating layer, a barrier layer, and a sealant layer in the stated order, the coating layer including a single- or multiple-layer configuration formed by a cured product of a resin composition containing a heat-curable resin and curing accelerator, the laminate having a piercing strength of at least 5 N, as measured in compliance with JIS 1707:1997, and the coating layer having a breakdown voltage of at least 1.0 kV, as measured in compliance with JIS C2110-1.

Owner:DAI NIPPON PRINTING CO LTD

Toner recovery machine and image forming apparatus

ActiveUS8306450B2Improve fill rateDownsizing and thinningElectrographic process apparatusMechanical engineeringEngineering

A toner recovery machine comprising: a first roller having a radius and rotatable about a first axis, the first axis along a first direction; a cleaner touching the first roller; a container for accommodating toner, the container comprising: a first conveyer movable along a second direction perpendicular to the first direction; and a second conveyer rotatable about a second axis and having a radius defined by the rotation about the second axis, the second axis along the first direction, wherein the second conveyer, the first roller, and the first conveyer are positioned in this order along the second direction, wherein the sum of the radius of the first roller and the radius defined by the second conveyer is smaller than a distance in the second direction between the first axis and the second axis.

Owner:BROTHER KOGYO KK

Switching power supply and display device provided the same

InactiveUS8630104B2Downsizing and thinningSufficient characteristicEfficient power electronics conversionEmergency protective circuit arrangementsCharge currentPower factor

A switching power supply has a function of improving a power factor, and outputs insulated DC. The switching power supply performs two kinds of controls for switching devices exclusive to each other: controlling of a switching device provided in a direction in which the discharging of a primary-side smoothing capacitor is prohibited at the time of suspension of commercially available AC power and near the zero cross of an input voltage; and causing a switching device provided between the output side of a third winding and the primary-side smoothing capacitor to control a charging current, thereby charging a capacitor in a boosted manner.

Owner:TKR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com