Winding wire for SF6 gas insulated transformer

A technology of combining wires and gas insulation, applied in the field of transformers, can solve the problems of high price and achieve the effect of good mechanical strength and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific drawings and embodiments.

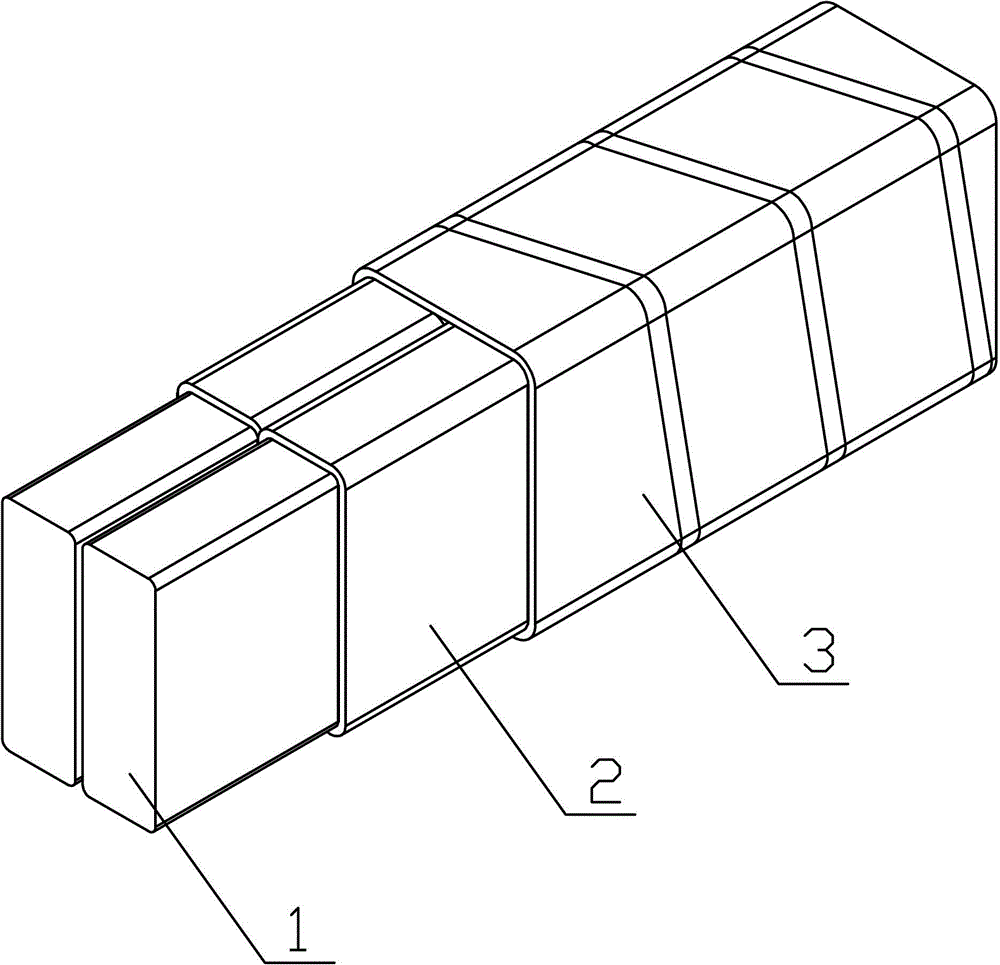

[0012] Such as figure 1 As shown, the present invention is mainly composed of parts such as aluminum flat wire conductor 1, PET film insulation layer 2 of single aluminum flat wire, PET film insulation layer 3 of aluminum combined wire.

[0013] The insulation strength of the main insulation between the high and low voltage windings and between the windings and the ground is mainly determined by the insulation strength of SF6 gas, and SF6 is highly dependent on the uniformity of the electric field, so the electric field strength in the gas must be strictly controlled. A highly airtight plastic film with high mechanical strength and insulating capacity is used as the insulating material.

[0014] During production, the aluminum flat wire conductor 1 is formed by extrusion equipment according to specifications, and the outer surface of the aluminum flat wire con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com