Photomultiplier tube

一种光电倍增管、电子倍增的技术,应用在电子倍增管、放电管、电子倍增器倍增极等方向,能够解决耐受电压降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, preferred embodiments of the photomultiplier tube according to the present invention will be described in detail with reference to the drawings. However, in the description of the drawings, the same reference numerals are assigned to the same or corresponding parts, and overlapping descriptions are omitted.

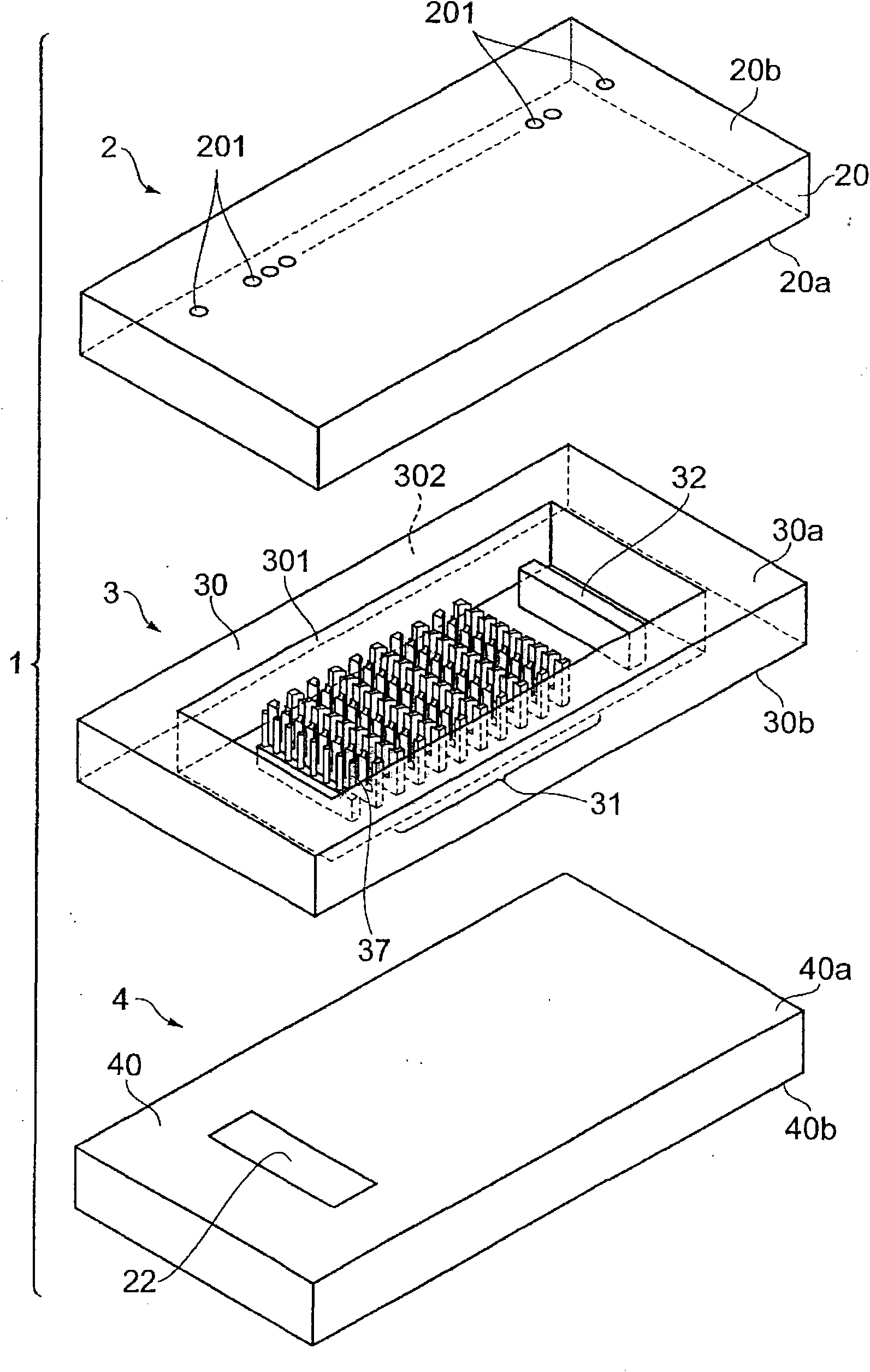

[0021] FIG. 1 is a perspective view of a photomultiplier tube 1 according to a preferred embodiment of the present invention, and FIG. 2 is an exploded perspective view of the photomultiplier tube 1 of FIG. 1 .

[0022] The photomultiplier tube 1 shown in FIG. 1 is a photomultiplier tube with a transmissive photoelectric surface, and has an upper frame 2 (second substrate), a side wall frame 3 (side wall portion), and an upper frame 2. The lower side frame 4 (first substrate) that faces the side wall frame 3 constitutes a box. This photomultiplier tube 1 is an electron tube, wherein, the direction in which light is incident on the photoelectric surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com