Epoxy resin pouring sealant

A technology of epoxy resin and potting glue, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., and can solve problems such as weak voltage resistance, low hardness, and easy fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

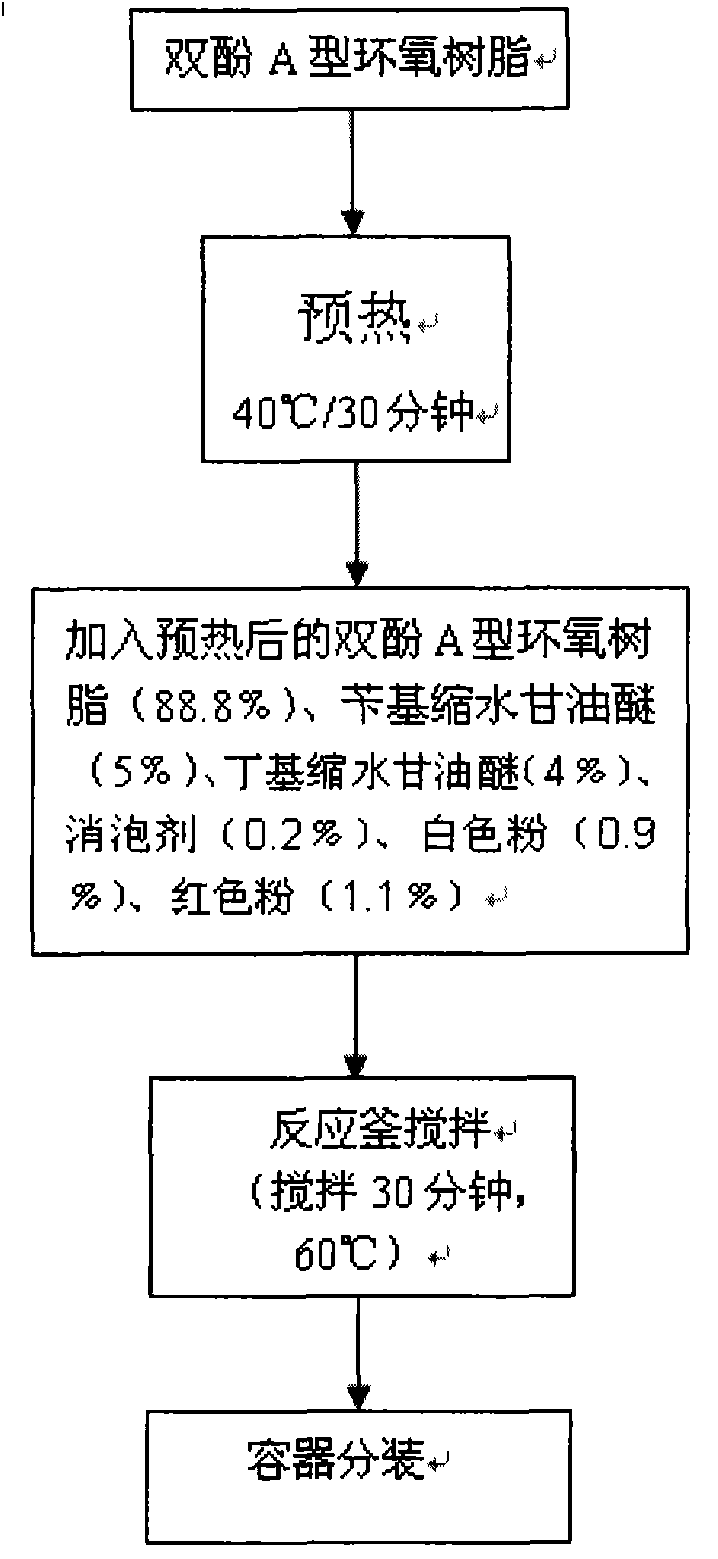

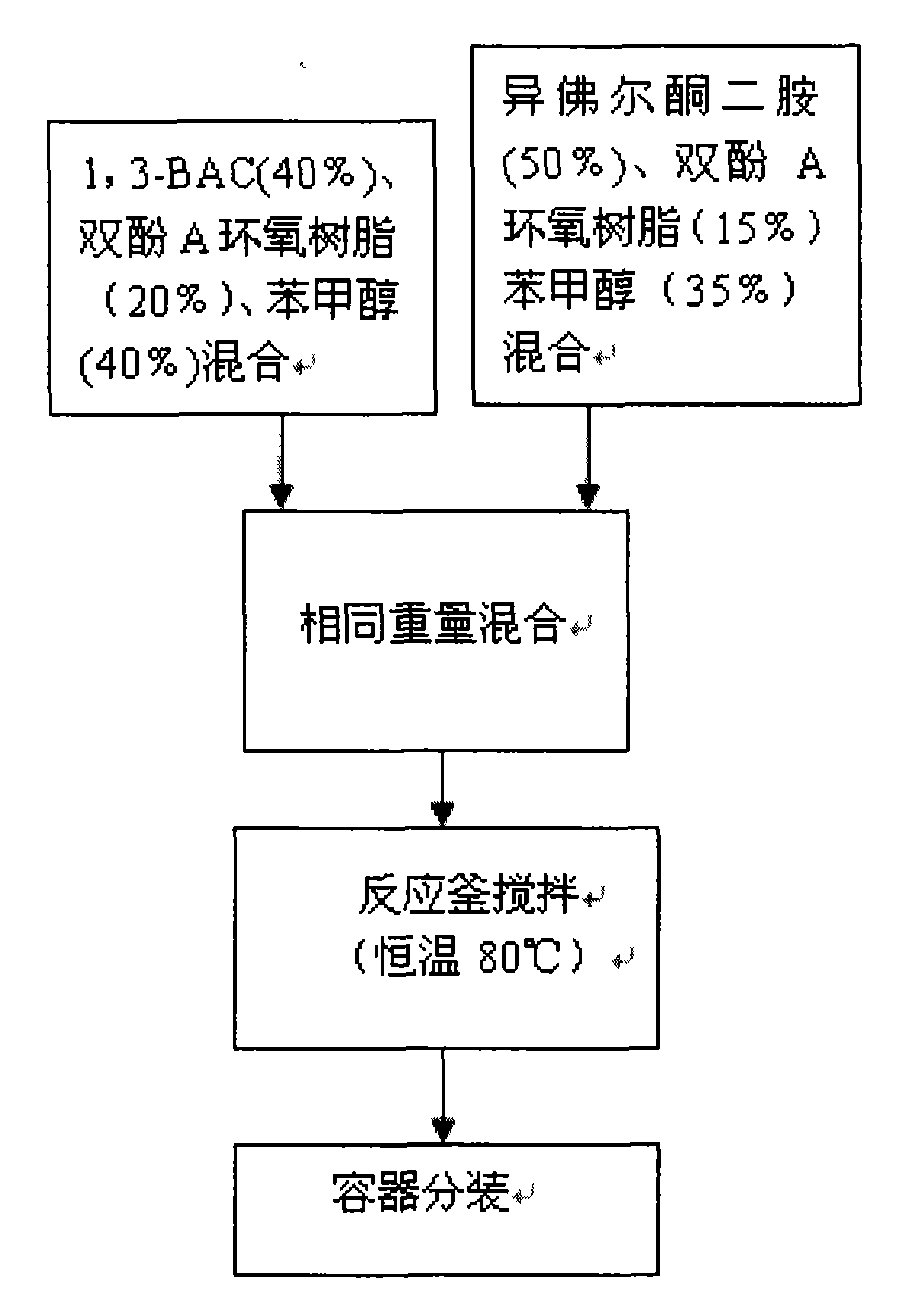

Embodiment 1

[0026] Such as figure 1 As shown, a kind of epoxy resin potting compound KRX300A / B of the present invention (KRX300 is the product model, A represents A component epoxy resin, B represents B component curing agent), when preparing A component epoxy resin KRX300A , calculated according to the weight ratio in the A component, first take the bisphenol A type epoxy resin whose weight ratio accounts for 88.8% of the A component weight (the following percentage figures have the same meaning unless otherwise specified), in Preheat at 40°C for 30 minutes, then place the bisphenol A type epoxy resin in the reaction kettle used to prepare component A, and then add 5% benzyl glycidyl ether and 4% butyl glycidyl ether to the reaction kettle A reactive diluent composed of glycidyl ether, and 0.2% defoamer is added. The defoamer is used to eliminate bubbles that may be contained in the preparation process to ensure product quality. The defoamer can be polysiloxane. According to the needs o...

Embodiment 2

[0039] The constituent components, stirring speed, stirring time, heating temperature and time, various detection procedures, and steps of use are all the same as those in Example 1, except for the specific content of each constituent component. When preparing A component epoxy resin, according to the weight ratio in A component, the weight of bisphenol A type epoxy resin accounts for 86.8% of A component weight (if no special instructions, the following percentage figures are all The same meaning as this), accounting for 6% of the weight of component A benzyl glycidyl ether and 5.05% of butyl glycidyl ether to form a reactive diluent, the defoamer accounts for 0.15% of the weight of component A, and 0.9% of white Powder, 1.1% blue powder, the weight ratio sum of the components of the above-mentioned component A epoxy resin is exactly 100%.

[0040] The preparation method of component B in this example, each component and its content, heating temperature and time are the same ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com