Propylene Homopolymer for Capacitors

A homopolymer and capacitor technology, applied in circuits, electrical components, insulators, etc., can solve the problem of not meeting the withstand voltage, and achieve the effect of excellent withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

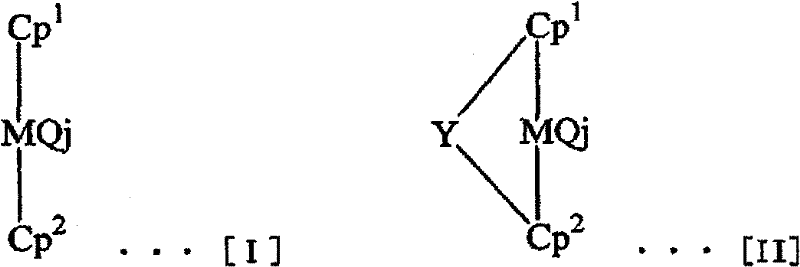

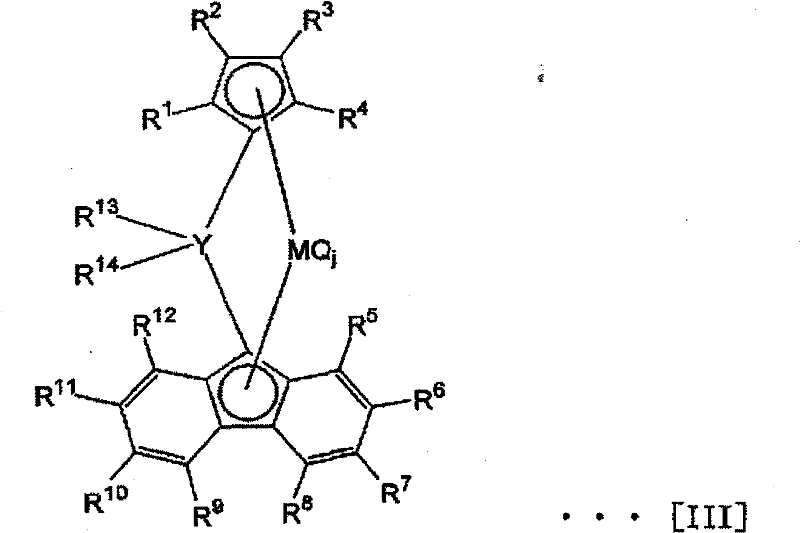

Method used

Image

Examples

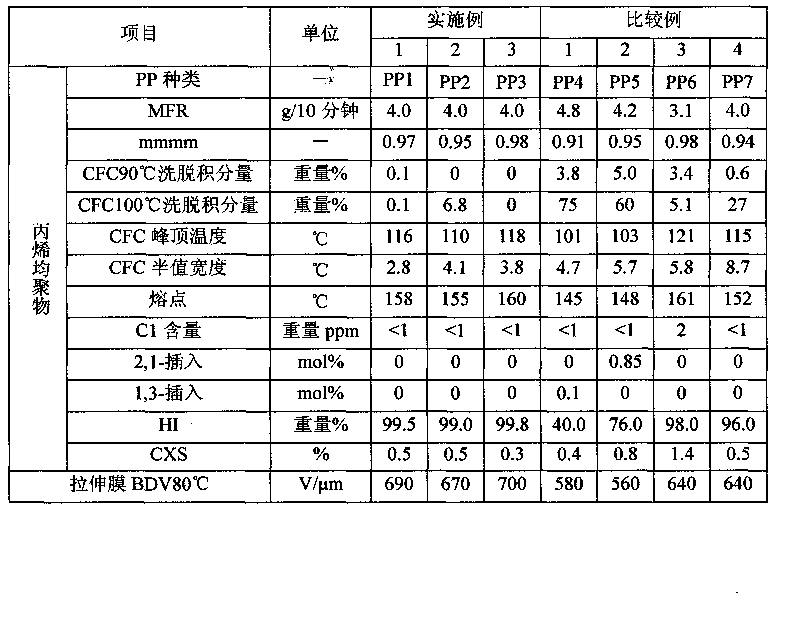

Embodiment 1

[0139] [Manufacture of propylene homopolymer (PP1)]

[0140] (1) Manufacture of solid catalyst carrier

[0141] Load SiO in a 1 L branched flask 2 (AGC Si-Tech Sunsphere H121) 300g was added to 800mL of toluene to make a slurry. Next, the liquid was transferred to a 5 L 4-neck flask, and 260 mL of toluene was added thereto. 2830 mL of a methylaluminoxane (hereinafter, MAO)-toluene solution (10 wt % solution) was introduced. Keep stirring at room temperature for 30 minutes. The temperature was raised to 110° C. over 1 hour, and the reaction was performed for 4 hours. After the reaction, cool to room temperature. After cooling, the supernatant toluene was removed and replaced with fresh toluene until the replacement rate reached 95%.

[0142] (2) Manufacture of solid catalyst (loading of metal catalytic component on carrier)

[0143] In the glove box, weigh dimethylmethylene (3-tert-butyl-5-methylcyclopentadienyl) (3,6-di-tert-butylfluorenyl) di Zirconium chloride 1.0g. ...

Embodiment 2

[0166] Polymerization was carried out as follows, except that the obtained propylene homopolymer (PP2) was used, and a stretched film was obtained in the same manner as in Example 1. The withstand voltage of the obtained stretched film was measured by the method described above. The results are shown in Table 1.

[0167] [Manufacture of propylene homopolymer (PP2)]

[0168] (1) Manufacture of solid catalyst carrier

[0169] Load SiO in a 1 L branched flask 2 (AGC Si-Tech Sunsphere H121) 300g was added to 800mL of toluene to make a slurry. Next, the liquid was transferred to a 5 L 4-neck flask, and 260 mL of toluene was added thereto. 2830 mL of a methylaluminoxane (hereinafter, MAO)-toluene solution (10 wt % solution) was introduced. Keep stirring at room temperature for 30 minutes. The temperature was raised to 110° C. over 1 hour, and the reaction was performed for 4 hours. After the reaction, cool to room temperature. After cooling, the supernatant toluene was remov...

Embodiment 3

[0183] Polymerization was carried out as follows, except that the obtained propylene homopolymer (PP3) was used, and a stretched film was obtained in the same manner as in Example 1. The withstand voltage of the obtained stretched film was measured by the method described above. The results are shown in Table 1.

[0184] [Manufacture of propylene homopolymer (PP3)]

[0185] (1) Manufacture of solid catalyst carrier

[0186] Load SiO in a 1 L branched flask 2 (AGC Si-Tech Sunsphere H121) 300g was added to 800mL of toluene to make a slurry. Next, the liquid was transferred to a 5 L 4-neck flask, and 260 mL of toluene was added thereto. 2830 mL of a methylaluminoxane (hereinafter, MAO)-toluene solution (10 wt % solution) was introduced. Keep stirring at room temperature for 30 minutes. The temperature was raised to 110° C. over 1 hour, and the reaction was performed for 4 hours. After the reaction, cool to room temperature. After cooling, the supernatant toluene was remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| ash containing ratio | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com