Method of producing composite magnetic material and composite magnetic material

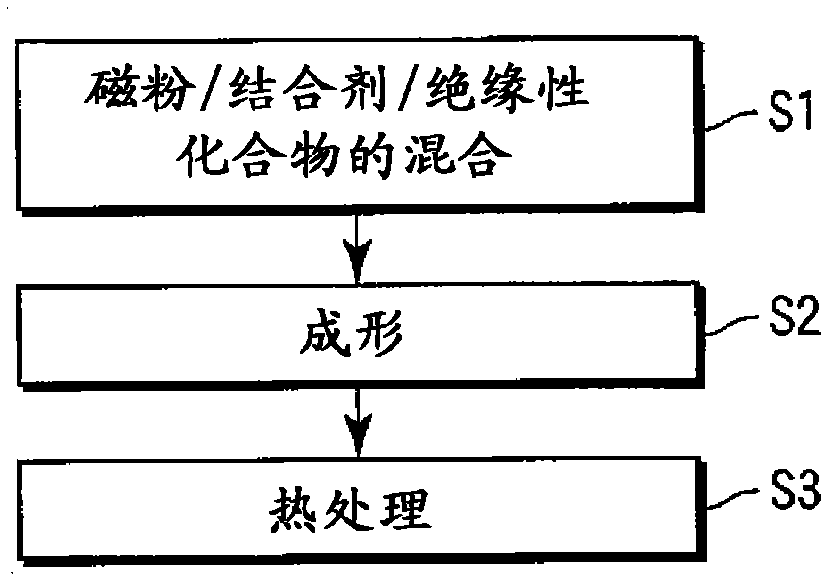

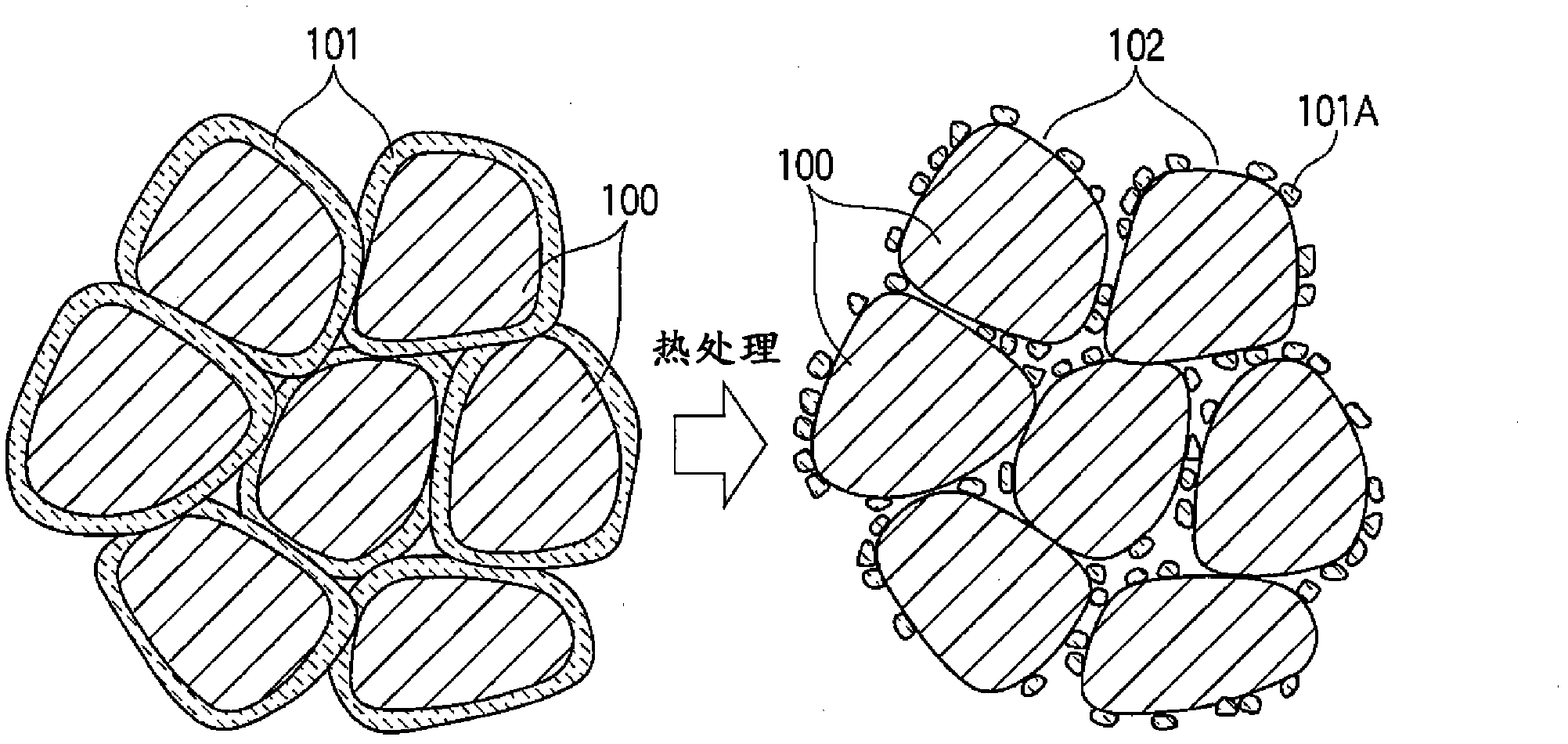

A composite magnetic material and a manufacturing method technology, applied in the field of inductors, can solve the problems of iron powder processing deformation, magnetic property deterioration, magnetic permeability and loss of magnetic properties of iron cores, etc., and achieve high reliability and excellent withstand voltage. , the effect of improving the magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A so-called aluminum-silicon-iron alloy having a composition of Fe-9.5% by mass Si-5.5% by mass Al was produced by a vacuum dissolution method, and an alloy powder having an average particle size of about 80 μm was obtained by a mechanical pulverization method. Add 0.5% by mass of an insulating layered compound and 1.0% by mass of a non-magnetic bonding material to the alloy powder, perform wet mixing with methyl ethyl ketone, and granulate while heating and drying to obtain a mixed powder . In addition, the insulating layered compound is talc, and the binder is silicone resin. The obtained mixed powder was extruded at a molding pressure of 1.8GPa to produce a ring-shaped iron core with an outer diameter of 13.4mm, an inner diameter of 7.7mm, and a thickness of 5.5mm, and then heat-treated in air at 750°C for 1 hour to produce a sample No. 8, which is used as Example 1. For this sample, the magnetic permeability was measured with an LCR tester at a frequency of 100kHz...

Embodiment 2

[0059] Using Fe-9.5 mass % Si-5.5 mass % Al alloy powder of the same composition as in Example 1, an insulating layered compound and water glass as a binder were added to the alloy powder, wet mixed with water, and produced while heating and drying. Granules were prepared as mixed powder, and an annular iron core was produced in the same manner as in Example 1. Three types of bentonite, talc, and mica were used as the insulating layered compound. For each of these three kinds of insulating layered compounds, two samples were produced, respectively, sample Nos. 11 to 16, and these samples were used as Examples 2-1, 2-2, 2-3, 2-4, and 2- 5. 2-6. In addition, bentonite contains montmorillonite. In addition, as for mica, what was pulverized into a fine powder with a mortar was used. The obtained ring was subjected to heat treatment at temperatures of 400° C. and 750° C. in air for 1 hour, respectively, and the same test as in Example 1 was carried out.

reference example 2、3

[0061] Sample Nos. 9 and 10 in which an insulating layered compound was not added were produced as Reference Examples 2 and 3, and were evaluated by the same test as in Example 1. The above results are shown in Table 2.

[0062] Table 2

[0063]

[0064] It can be seen from Table 2 that only in the case of water glass, the resistance is low and the withstand voltage cannot be obtained; by adding an insulating layered compound, the required insulation and withstand voltage can be ensured, and the magnetic permeability and core loss are also low. excellent.

[0065]That is, the resistance (insulation) and withstand voltage of each of Examples 2-1 to 2-6 exceeded the above-mentioned judgment level; and the magnetic permeability and core loss were not inferior or superior to Reference Examples 2 and 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com