MEMS sensing device for electric field measurement based on piezoelectric-magnetic anisotropy coupling structure

A technology of magnetic anisotropy and coupling structure, which can be used in measuring devices, electromagnetic field characteristics, measuring electrical variables, etc. It can solve the problems of poor temperature stability and serious temperature drift of photoelectric sensors, and achieve adjustable electric field sensing range, frequency response The effect of good characteristics and fast dynamic response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]In the electric field measurement MEMS sensor device based on the piezoelectric-magnetic anisotropic coupling structure proposed by the present invention, the material selection basis of the bottom metal and the four metal electrodes is good conductivity, such as commonly used aluminum, copper, platinum, gold And other metals, the thickness of the material can range from tens of nanometers to several microns, and the processing method of the material can be a metal thin film micromachining process such as magnetron sputtering coating and chemical vapor deposition. Among them, the piezoelectric material can be a cylinder or a block piezoelectric material with a positive side prism, such as a relaxor ferroelectric crystal lead magnesium niobate titanate (PMN-PT) with a perovskite structure, lead titanium niobate zincate, etc. Lead zirconate titanate (PZN-PT), lead zirconate titanate (PZT) crystals, etc.; piezoelectric materials can also choose piezoelectric films, such as P...

Embodiment 2

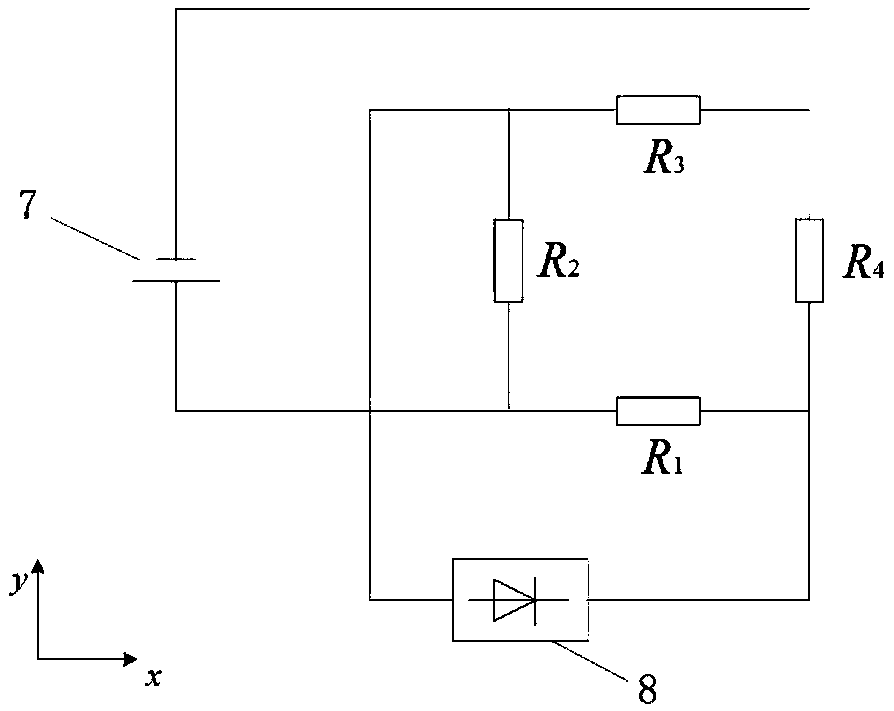

[0034] Such as figure 1 As shown, the length of the four ferromagnetic thin films is I, and the width is W. Assume that the electric field to be measured is along the thickness direction, which is consistent with the prepolarization direction of the piezoelectric material. Assuming that the piezoelectric effect is linear, it can be characterized by a piezoelectric constant coefficient, and the shear strain is neglected, then under the action of an external electric field E, the resistance value of the ferromagnetic film and the output voltage U o can be expressed as

[0035]

[0036]

[0037]

[0038] Among them, d 31 and d 32 are the piezoelectric constant coefficients of the piezoelectric material in the 1 direction (x direction in the coordinate system) and the 2 direction (y direction in the coordinate system), which can be found in the material parameter manual; the amplitude of the Wheatstone bridge DC power supply voltage source The value is U s ; ρ(θ) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com