Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Uniform processing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

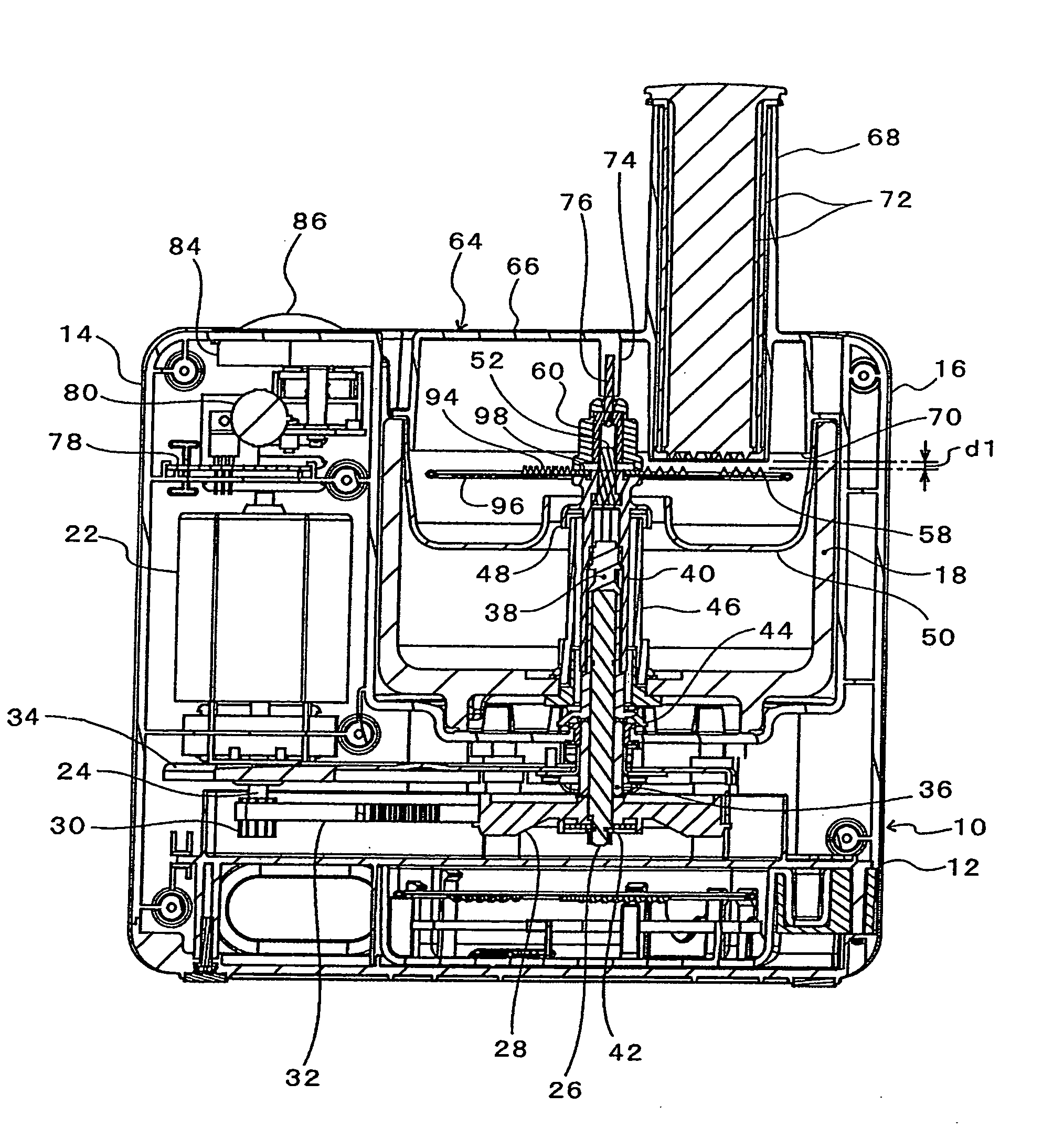

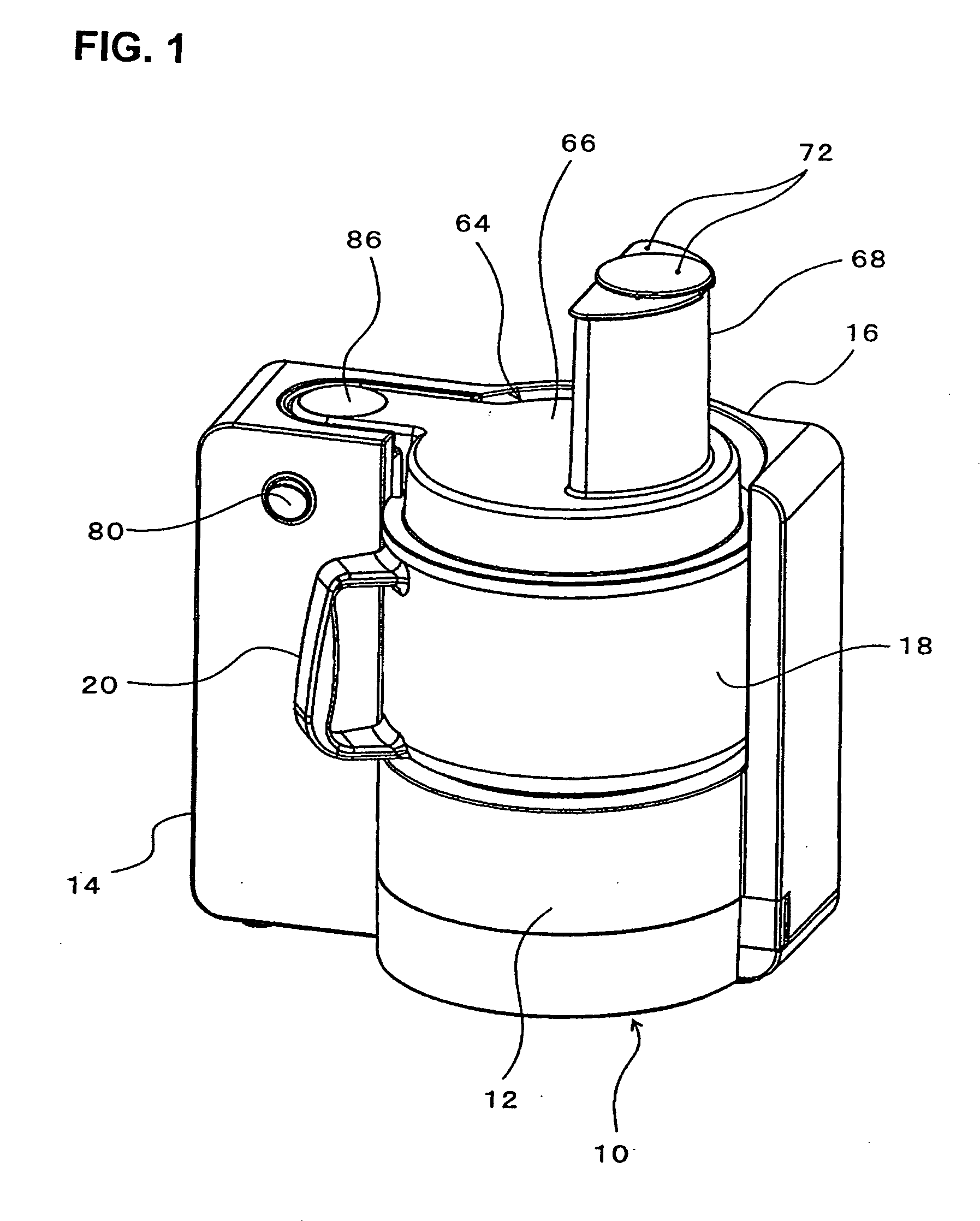

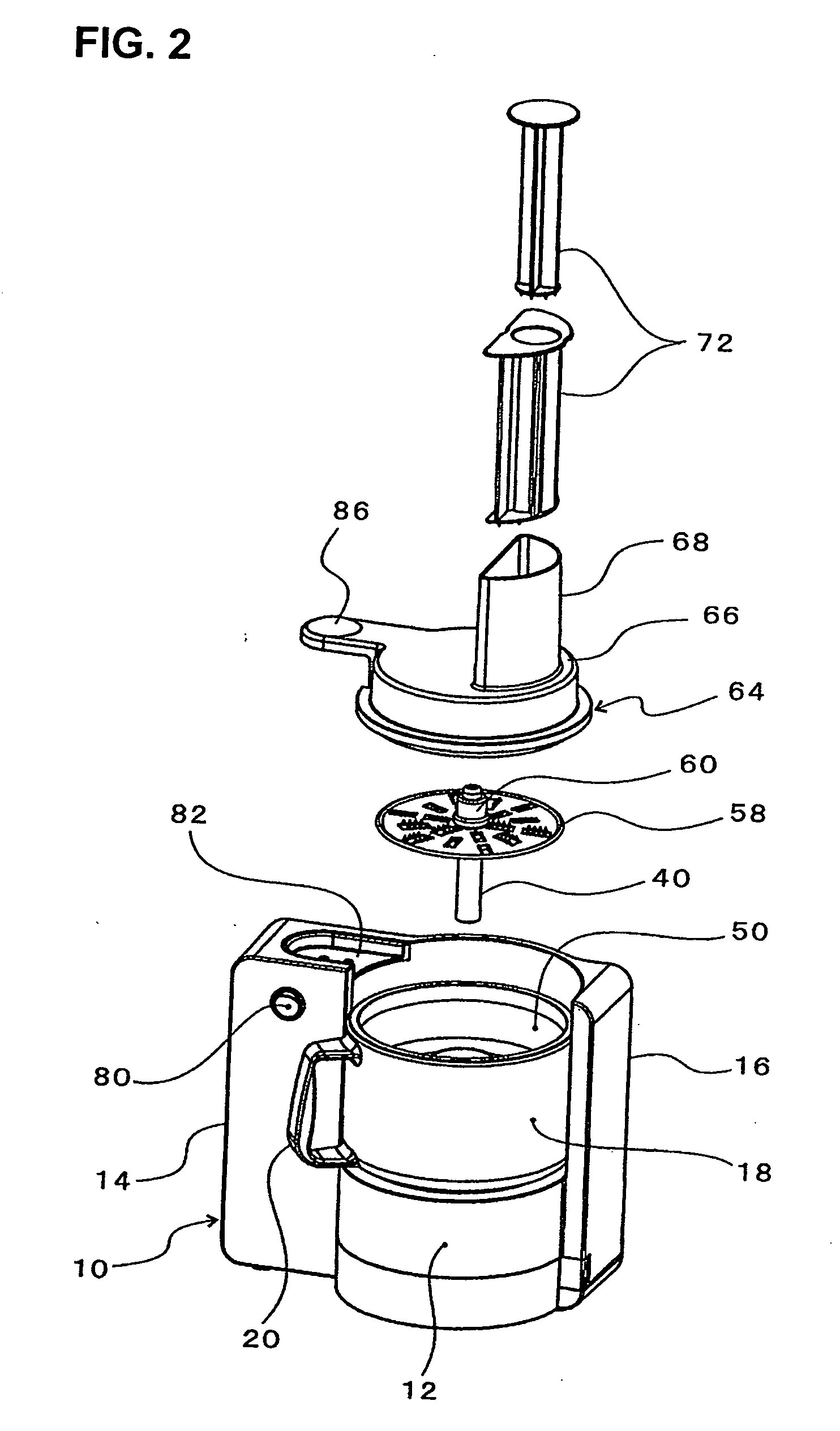

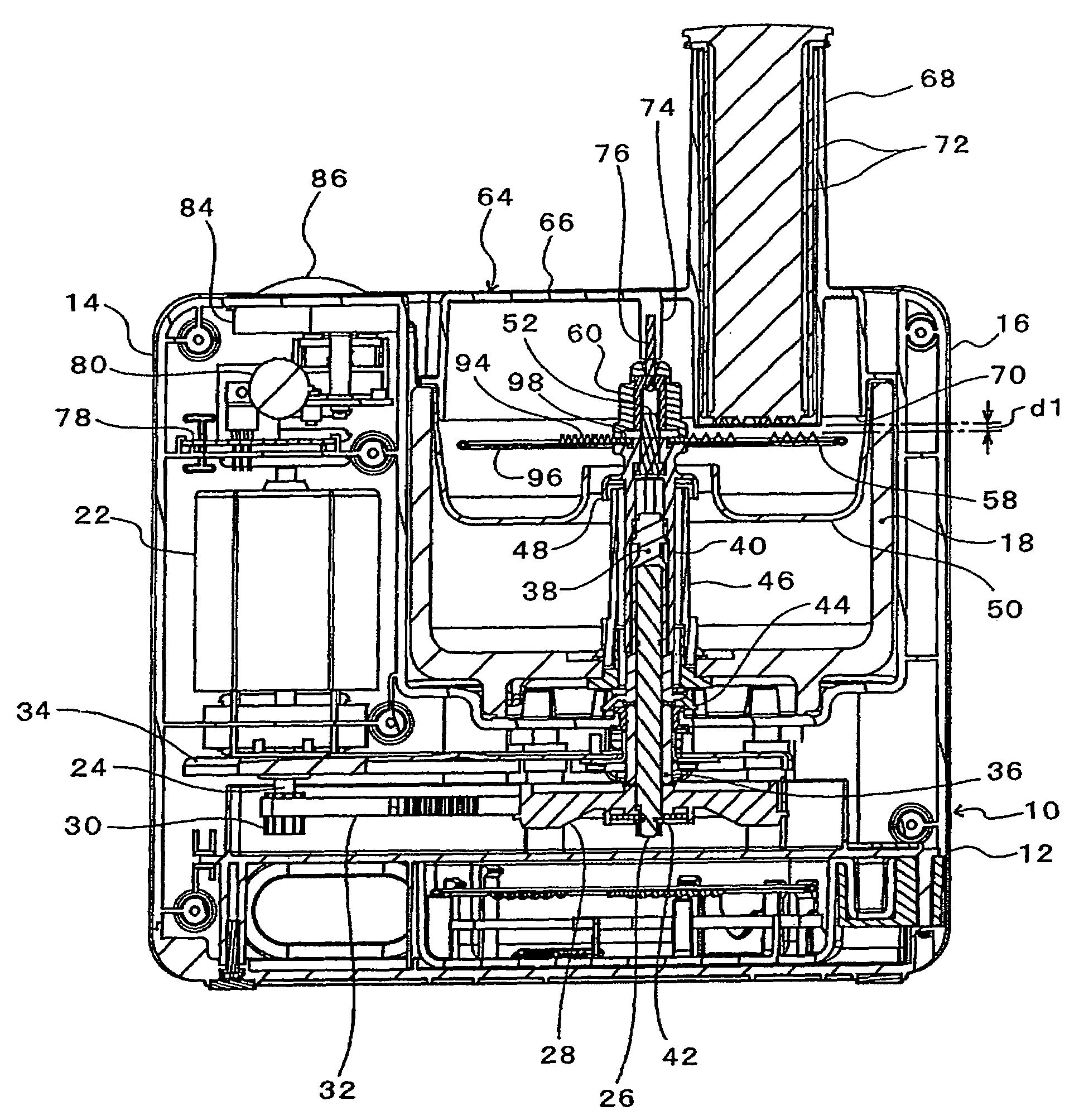

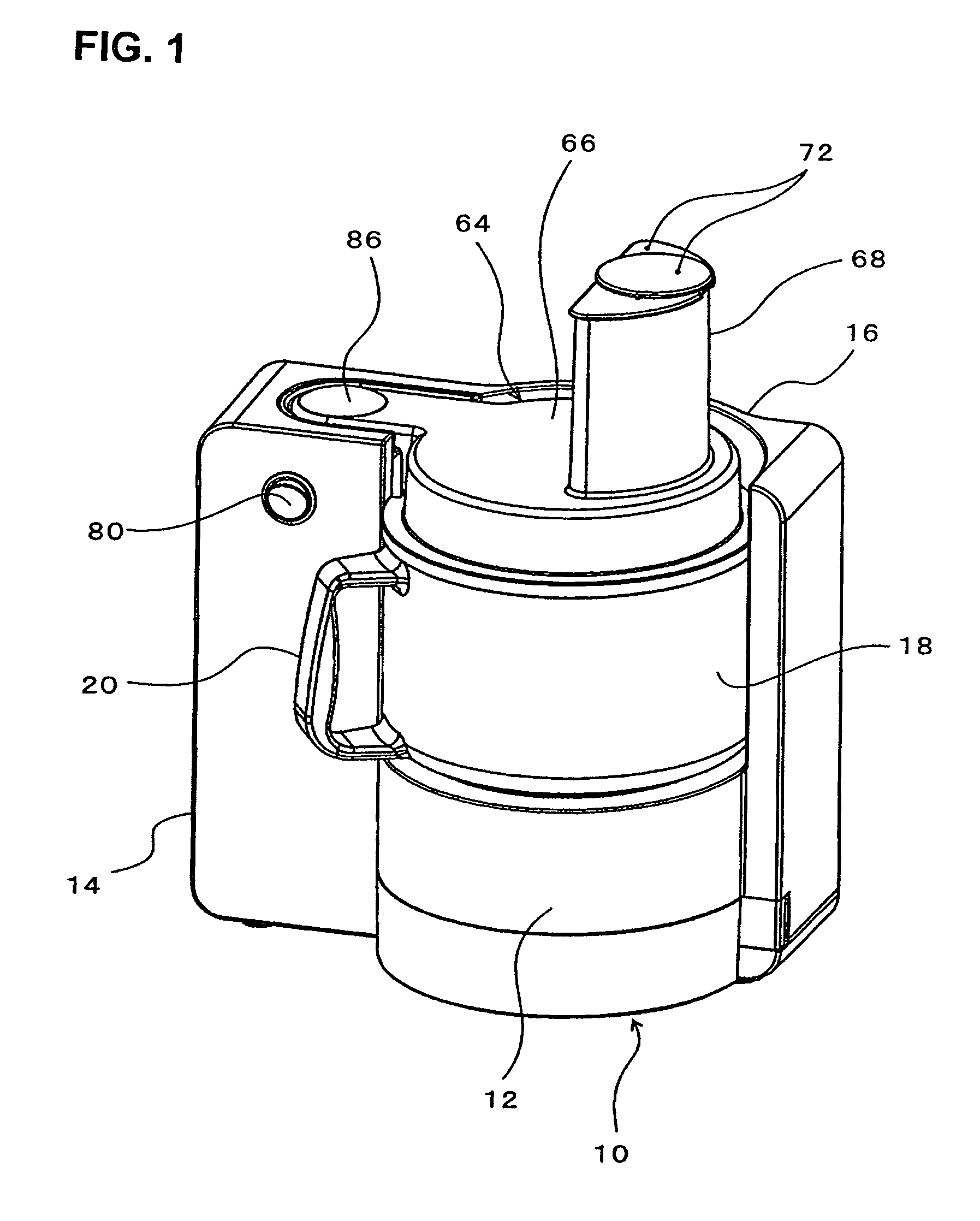

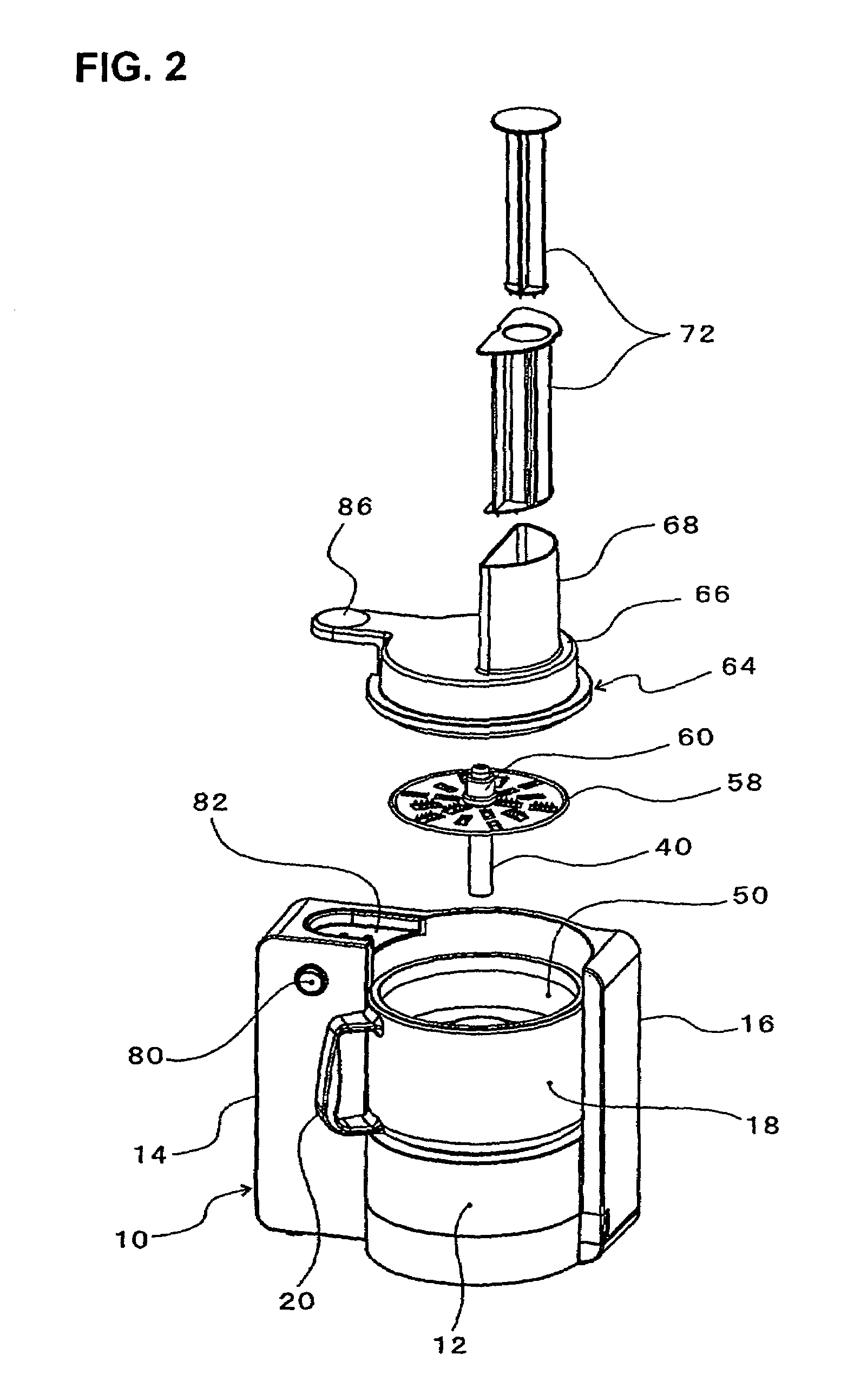

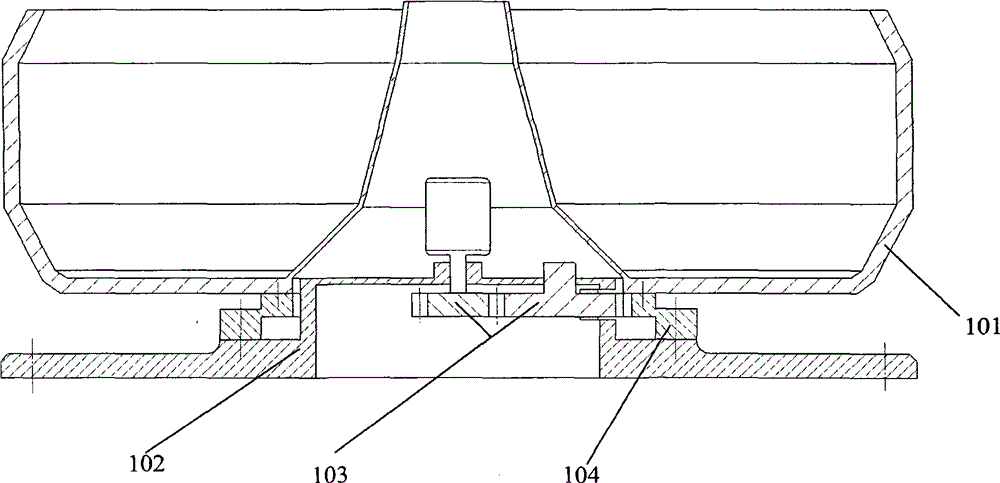

Electric grating food processor and grater plate

InactiveUS20070095959A1Uniform processing qualityUniform qualityKitchen equipmentGrain treatmentsGratingReciprocating motion

An electric grating food processor including a food material receiving section 18 that has an opening in its upper part and receives processed food materials therein, a cylindrical food material charging section 68 that has a lower end opening at its lower end, a grater plate 58 that is rotated or linearly reciprocated under the lower end opening of the food material charging section, and a drive unit for operating (rotating or linearly reciprocating) the grater plate; and the grater plate is formed with larger grating blades on one surface side thereof and lower grating blades on another surface side thereof, and the grater plate is further provided thereon with a gap adjuster 98 that adjusts the gap between the tip ends of the grating blades and the lower end opening of the food material charging section.

Owner:IZUMI PROD CO

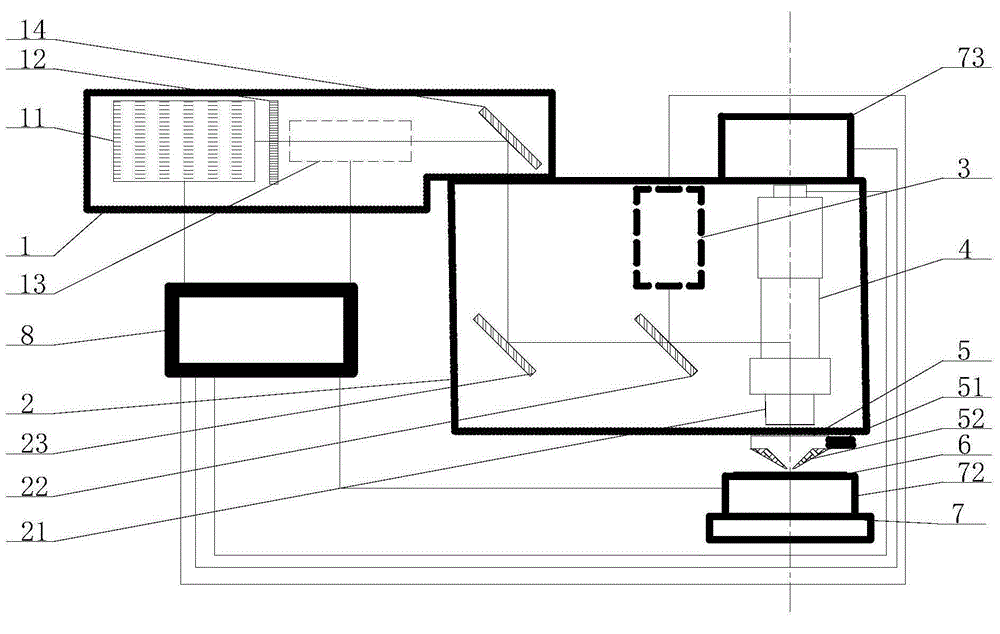

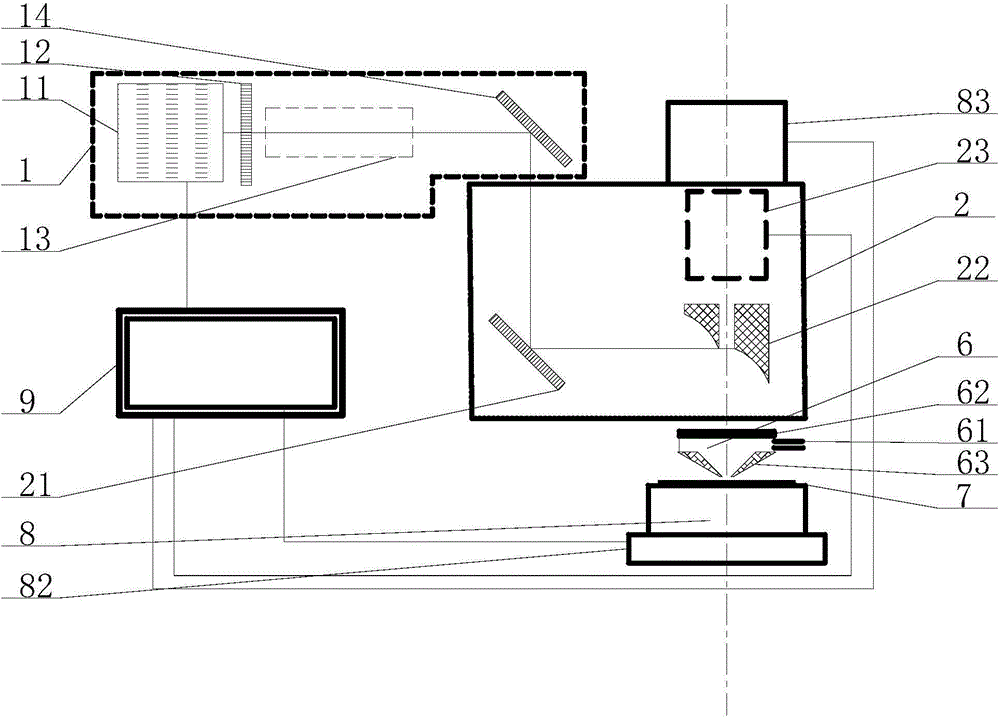

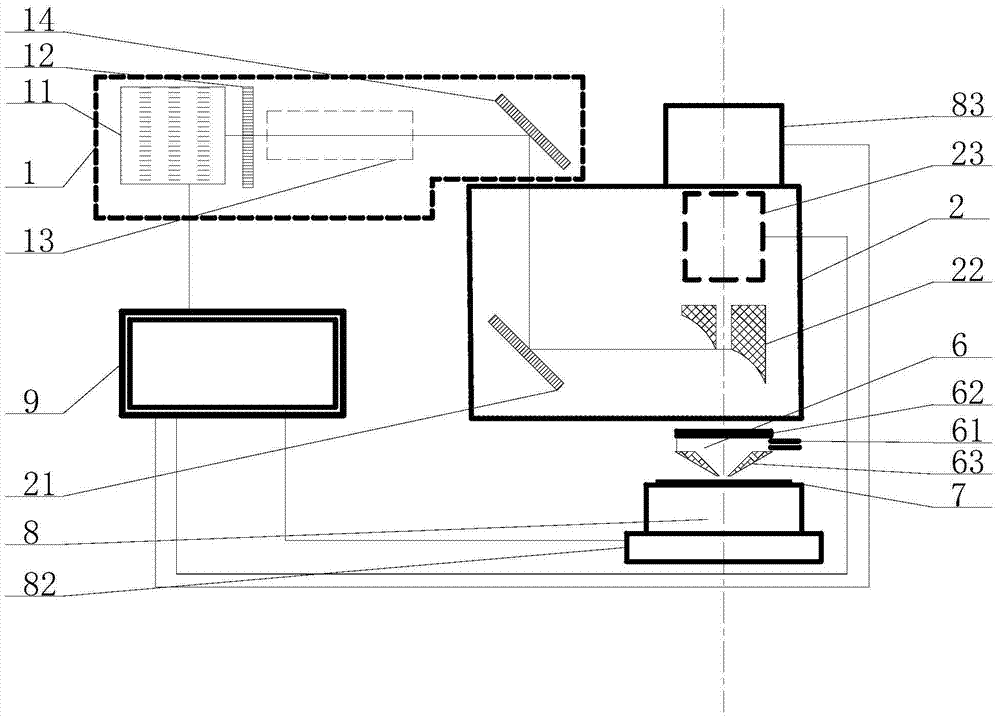

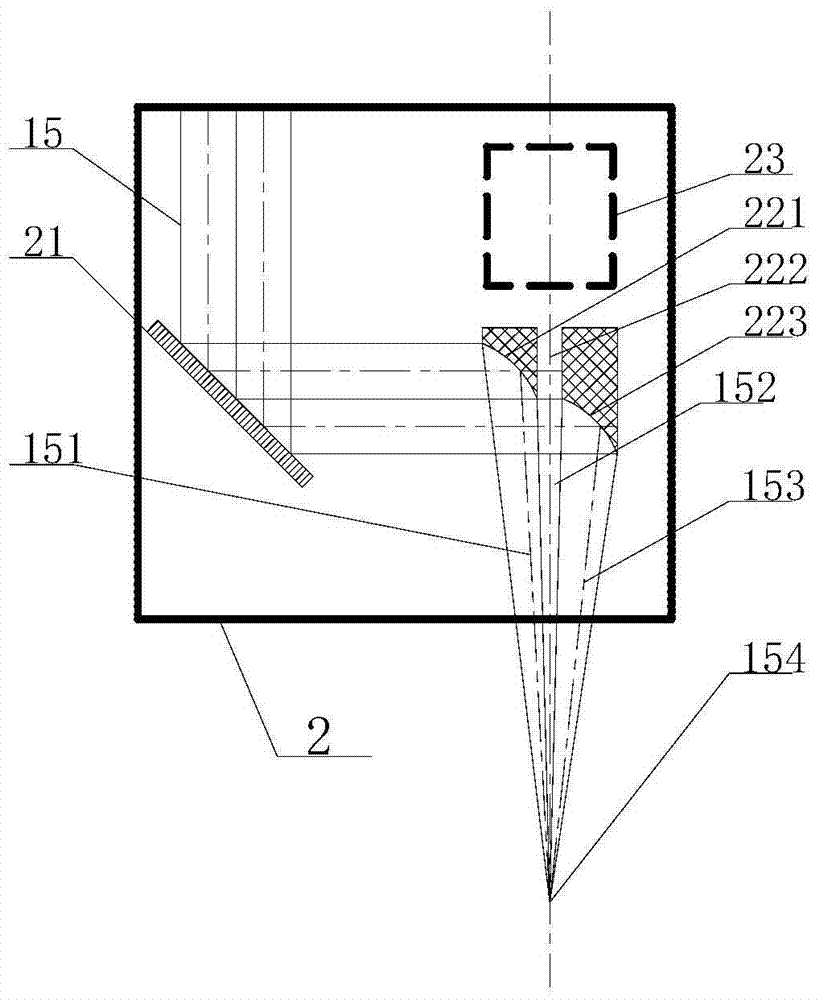

Precise laser cutting system

ActiveCN105643110AEasy to operateGuaranteed laser processing effectLaser beam welding apparatusOptical ModuleLaser cutting

The invention relates to the technical field of precise laser cutting and discloses a precise laser cutting system. The precise laser cutting system comprises a laser source assembly, an optical module, a three-dimensional movement assembly and a computer. The three-dimensional movement assembly comprises an x-axis and y-axis movement platform and a z-axis movement platform. The x-axis and y-axis movement platform is used for driving a material to be machined to move in the x direction and the y direction. The z-axis movement platform is used for driving the optical module to move in the z direction. The laser source assembly emits a machining laser beam. The machining laser beam is focused on the material to be machined under the action of the optical module so as to machine the material to be machined. The computer is connected with the laser source assembly, the optical module, the x-axis and y-axis movement platform and the z-axis movement platform. According to the precise laser cutting system, the image of the surface of the material to be machined can be observed and detected, and the focal point of the machining laser beam can be adjusted automatically.

Owner:HANS LASER TECH IND GRP CO LTD

Electric grating food processor and grater plate

InactiveUS7328864B2Uniform processing qualityUniform qualityKitchen equipmentGrain treatmentsGratingReciprocating motion

An electric grating food processor including a food material receiving section 18 that has an opening in its upper part and receives processed food materials therein, a cylindrical food material charging section 68 that has a lower end opening at its lower end, a grater plate 58 that is rotated or linearly reciprocated under the lower end opening of the food material charging section, and a drive unit for operating (rotating or linearly reciprocating) the grater plate; and the grater plate is formed with larger grating blades on one surface side thereof and lower grating blades on another surface side thereof, and the grater plate is further provided thereon with a gap adjuster 98 that adjusts the gap between the tip ends of the grating blades and the lower end opening of the food material charging section.

Owner:IZUMI PROD CO

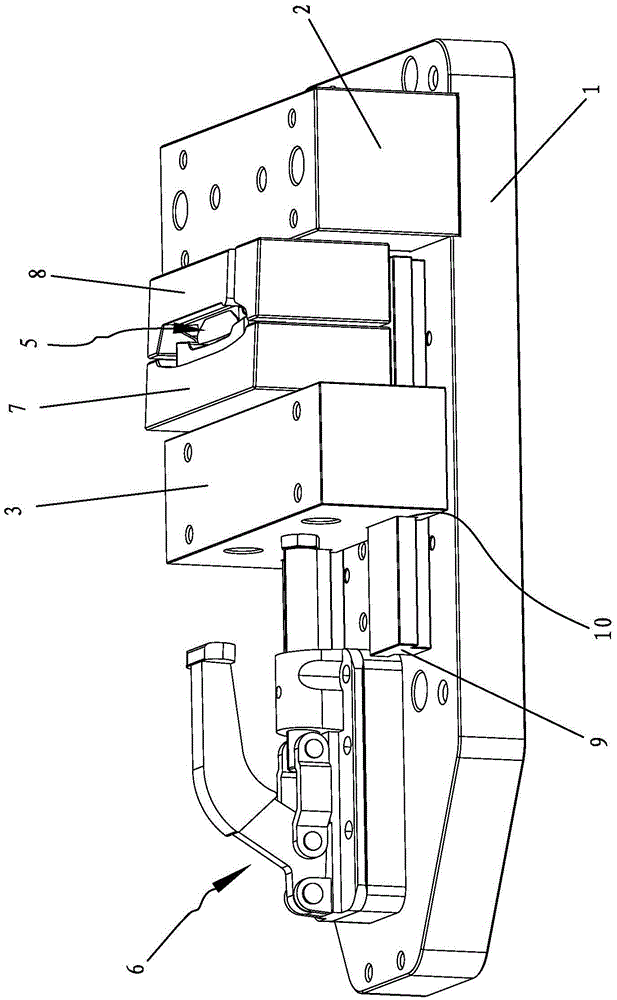

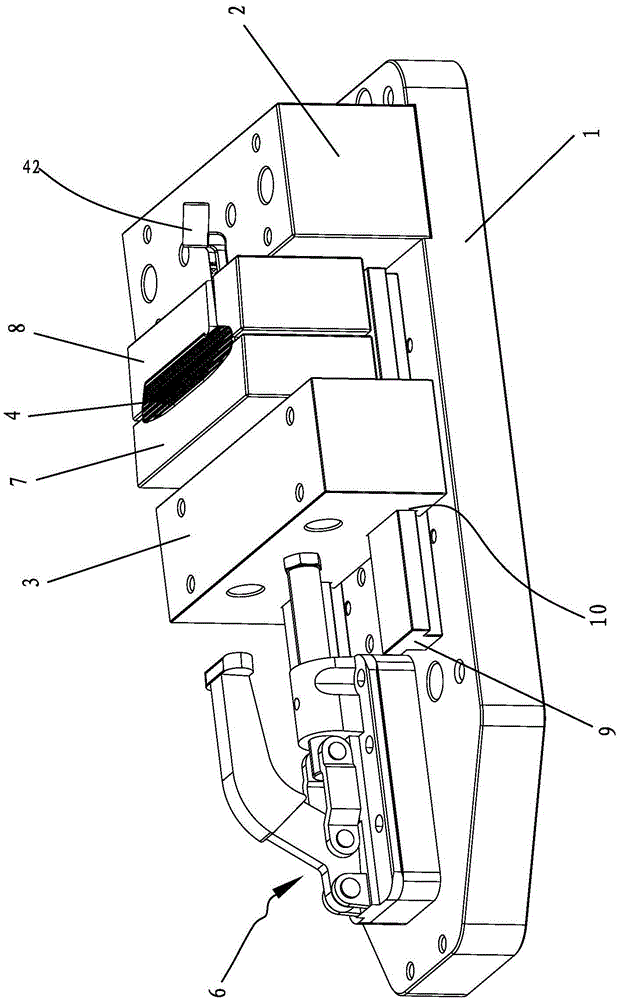

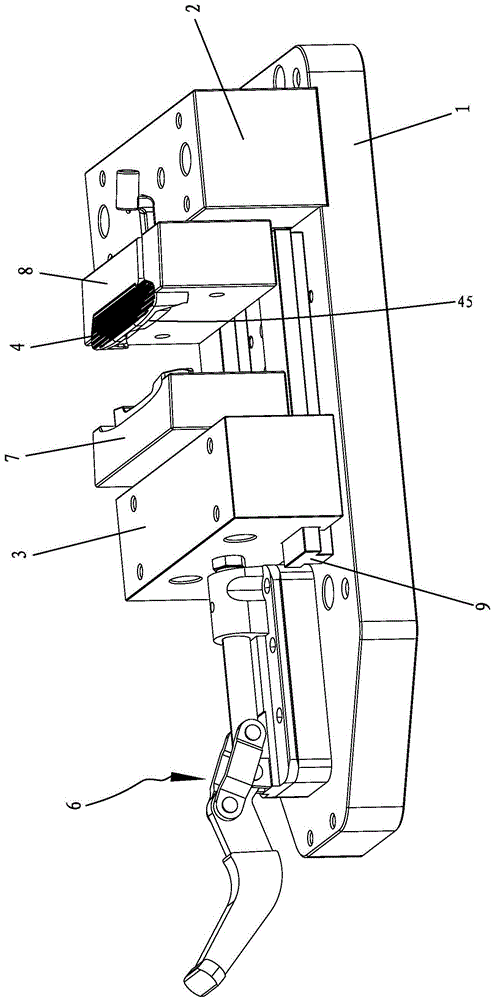

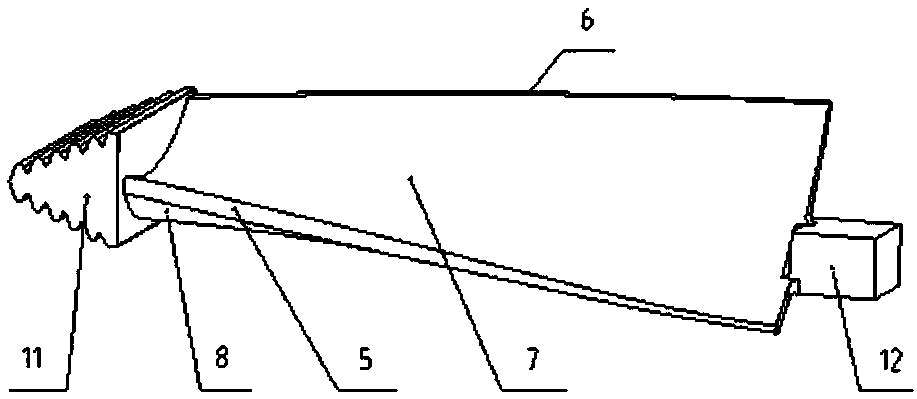

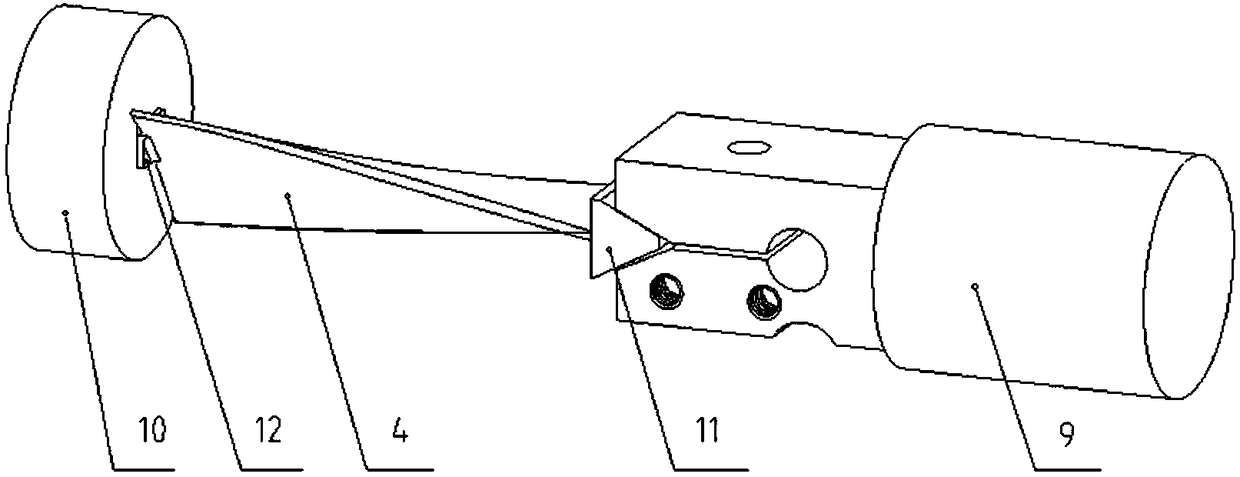

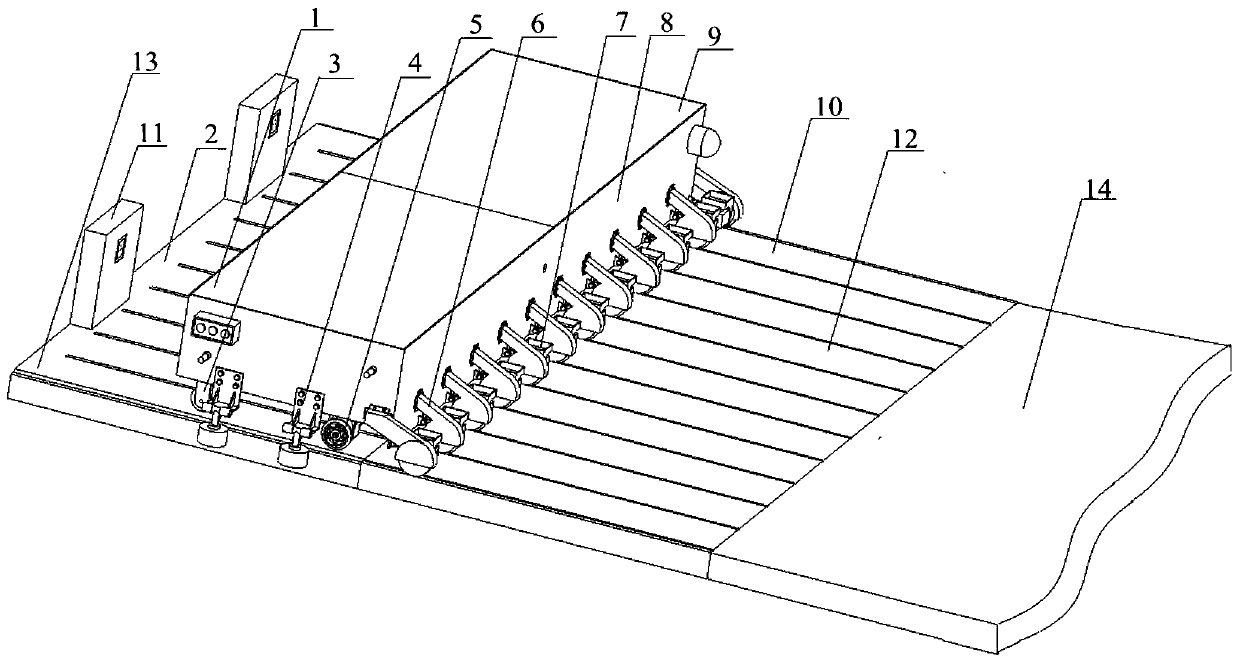

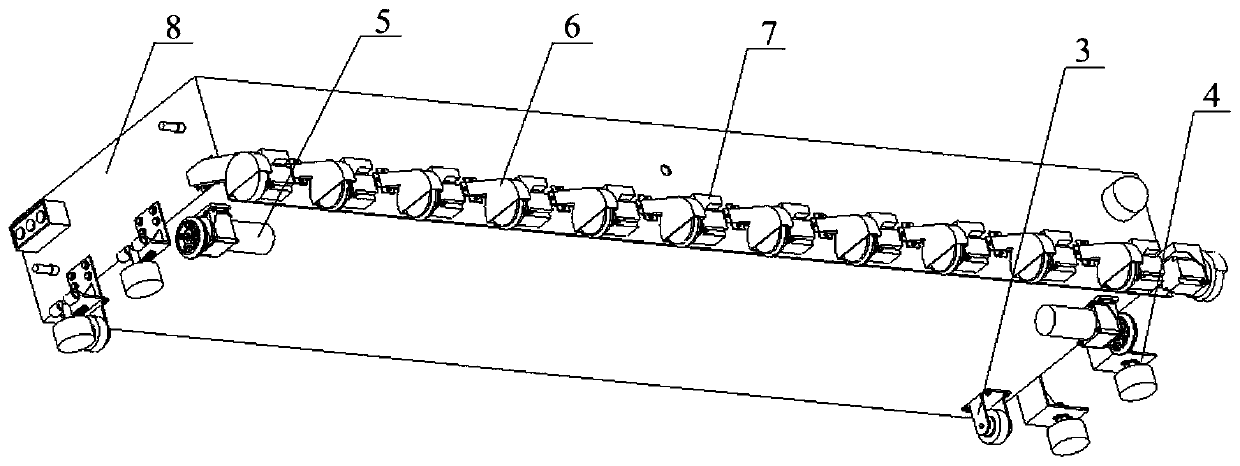

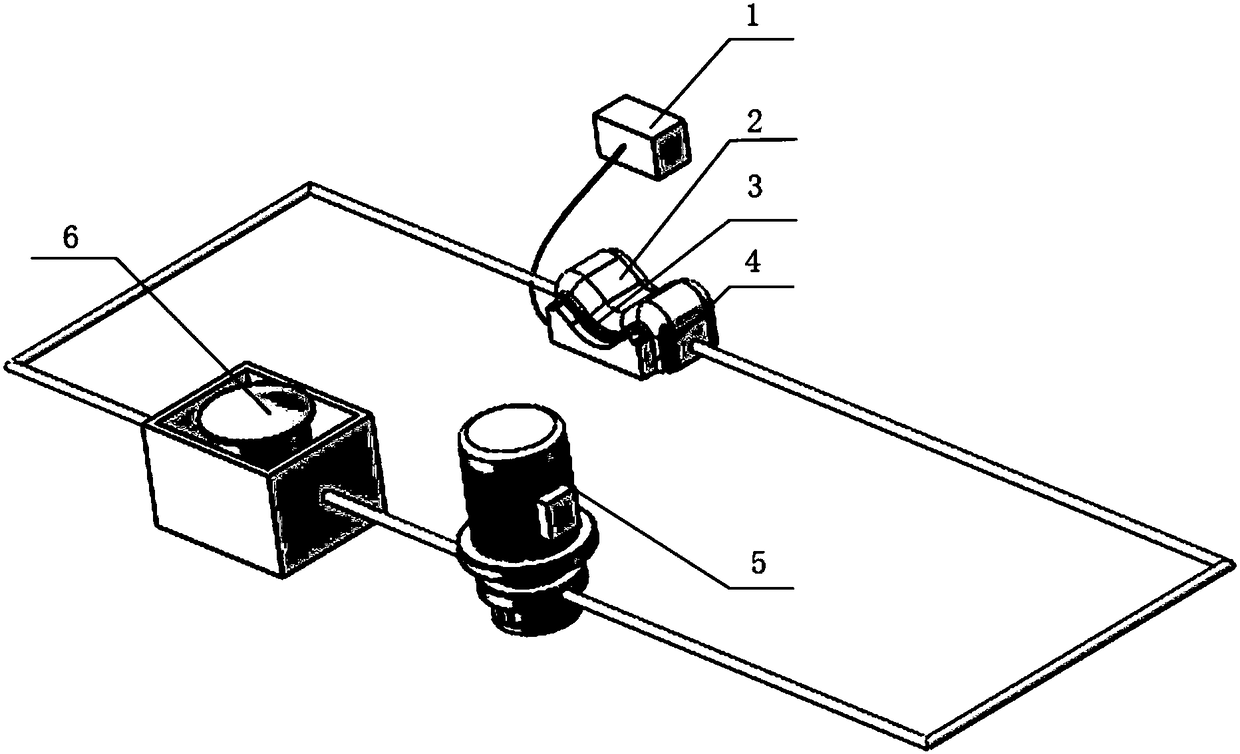

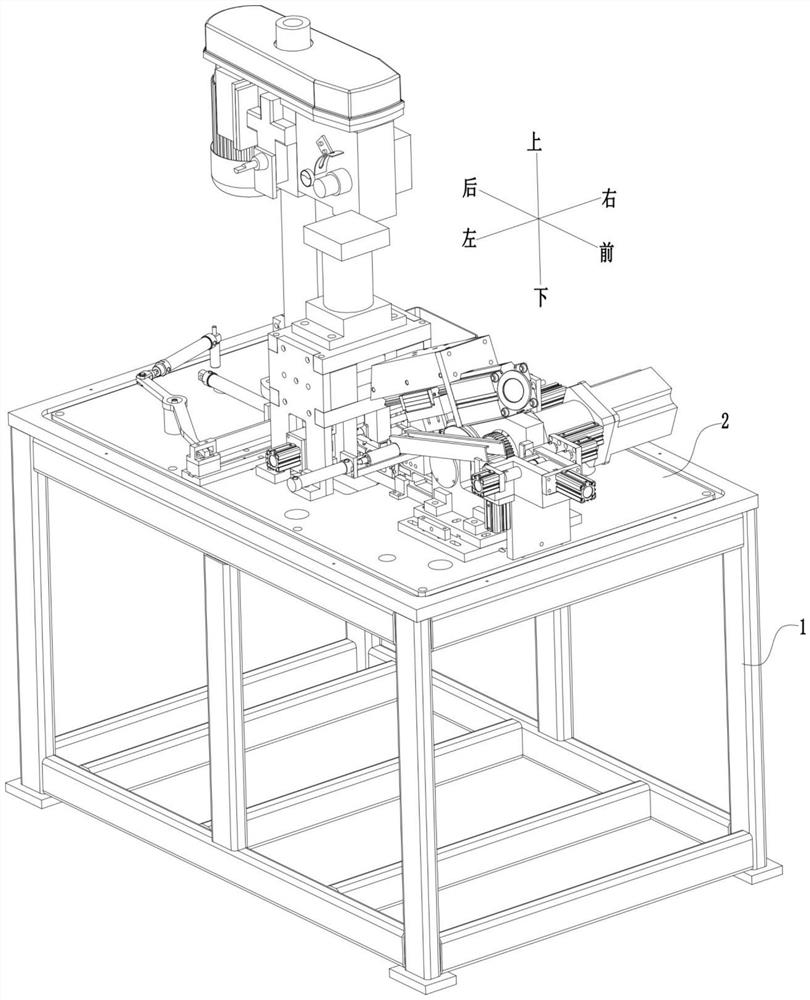

Automatic riveting device

The invention discloses an automatic riveting device which comprises a rack (1), a material belt placing disk (2), a rivet loading device, a riveting and pressing device, a material dragging device and a cutting device. The material belt placing disk (2), the rivet loading device, the riveting and pressing device, the material dragging device and the cutting device are sequentially arranged on the rack (1), the material belt placing disk (2) is installed on the rack (1) through a rotating shaft, the rivet loading device comprises a rivet feeding device and a rivet installing device, a material storing groove (42) is further arranged on the rack (1) at a discharging end of the cutting device, and a discharging guide rail (43) is arranged between the cutting device and a discharging groove and fixedly installed on the rack (1). The automatic riveting device has the advantages of being simple in structure, convenient to use and capable of saving labor costs, reducing labor intensities of operators, achieving full automatic production of loading, installing, riveting and cutting, greatly improving production and processing efficiencies and guaranteeing uniform processing qualities.

Owner:CHENGDU HOMIN TECH

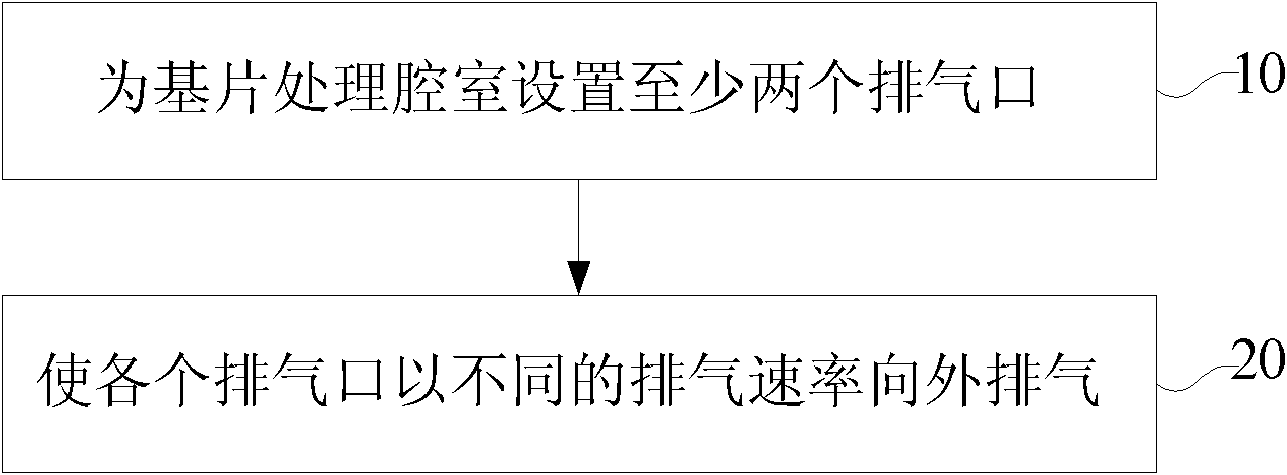

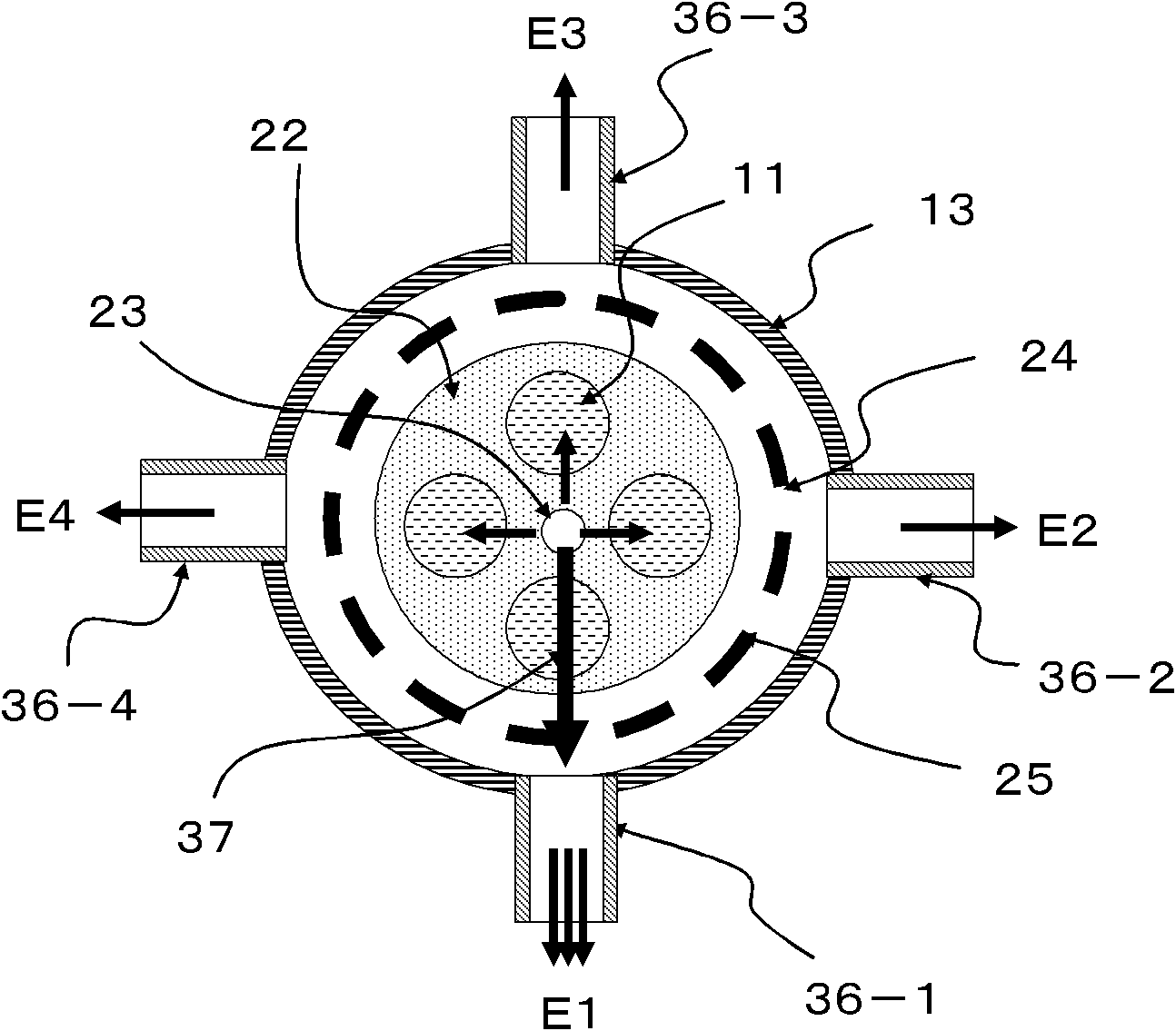

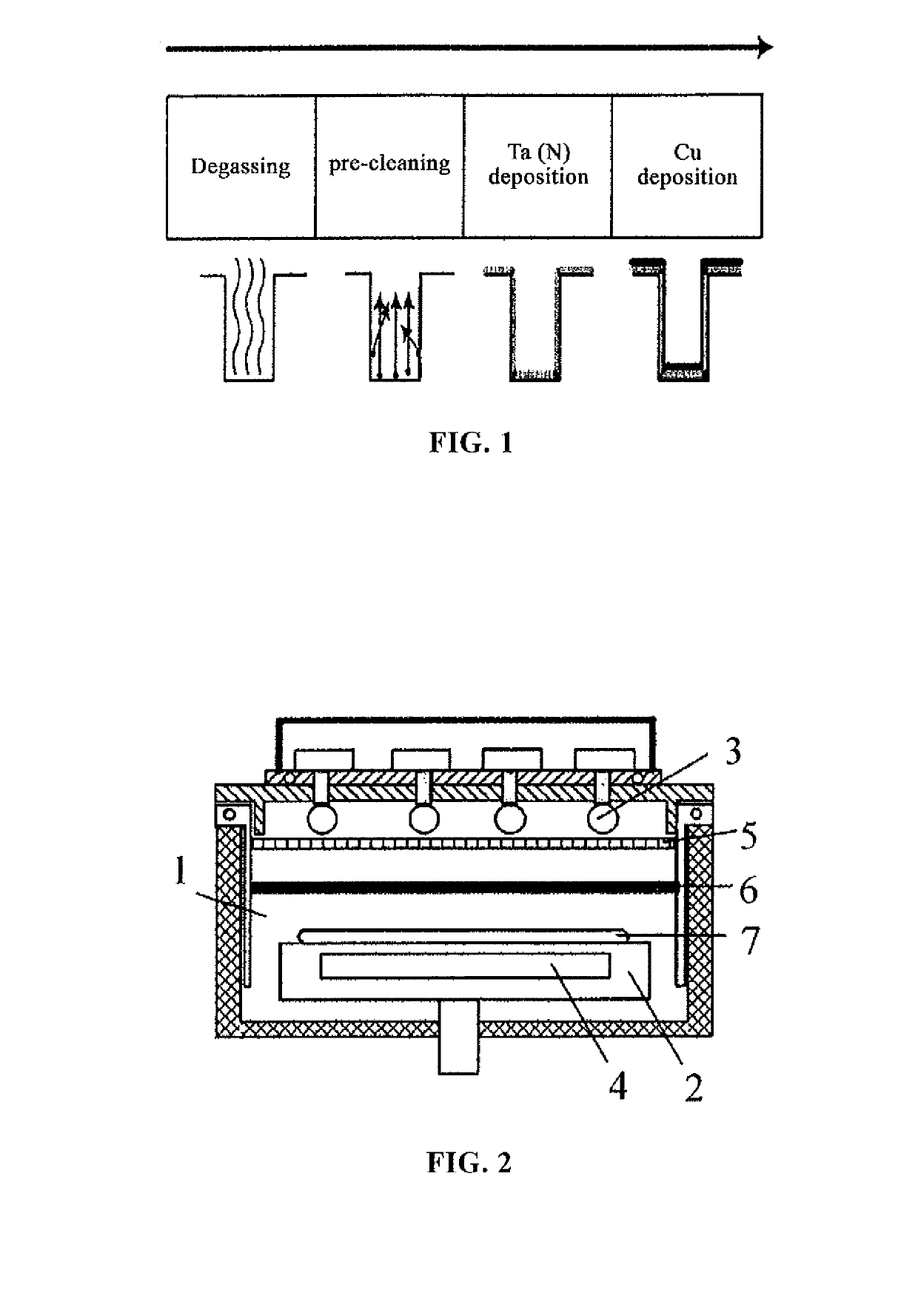

Exhaust method, exhaust apparatus and substrate treatment equipment

ActiveCN102828167AEvenly distributedImprove uniformityChemical vapor deposition coatingAirflowProcess quality

The invention provides an exhaust method, an exhaust apparatus and substrate treatment equipment, wherein the exhaust method comprises the following steps of 10) arranging at least two exhaust ports for a substrate treatment chamber, and enabling exhaust rate of each exhaust port to controlled individually, and 20) making each exhaust port exhaust outward at different exhaust rate; the exhaust apparatus comprises at least two exhaust ports connected to the substrate treatment chamber, with exhaust rate of each exhaust port capable of being controlled individually; and the substrate treatment equipment comprises the substrate treatment chamber and is provided with the exhaust apparatus provided by the invention. All the exhaust method, the exhaust apparatus and the substrate treatment equipment can effectively increase uniformity of air flow distribution in the substrate treatment chamber during a substrate treatment process, thereby improving the uniformity of the process quality.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

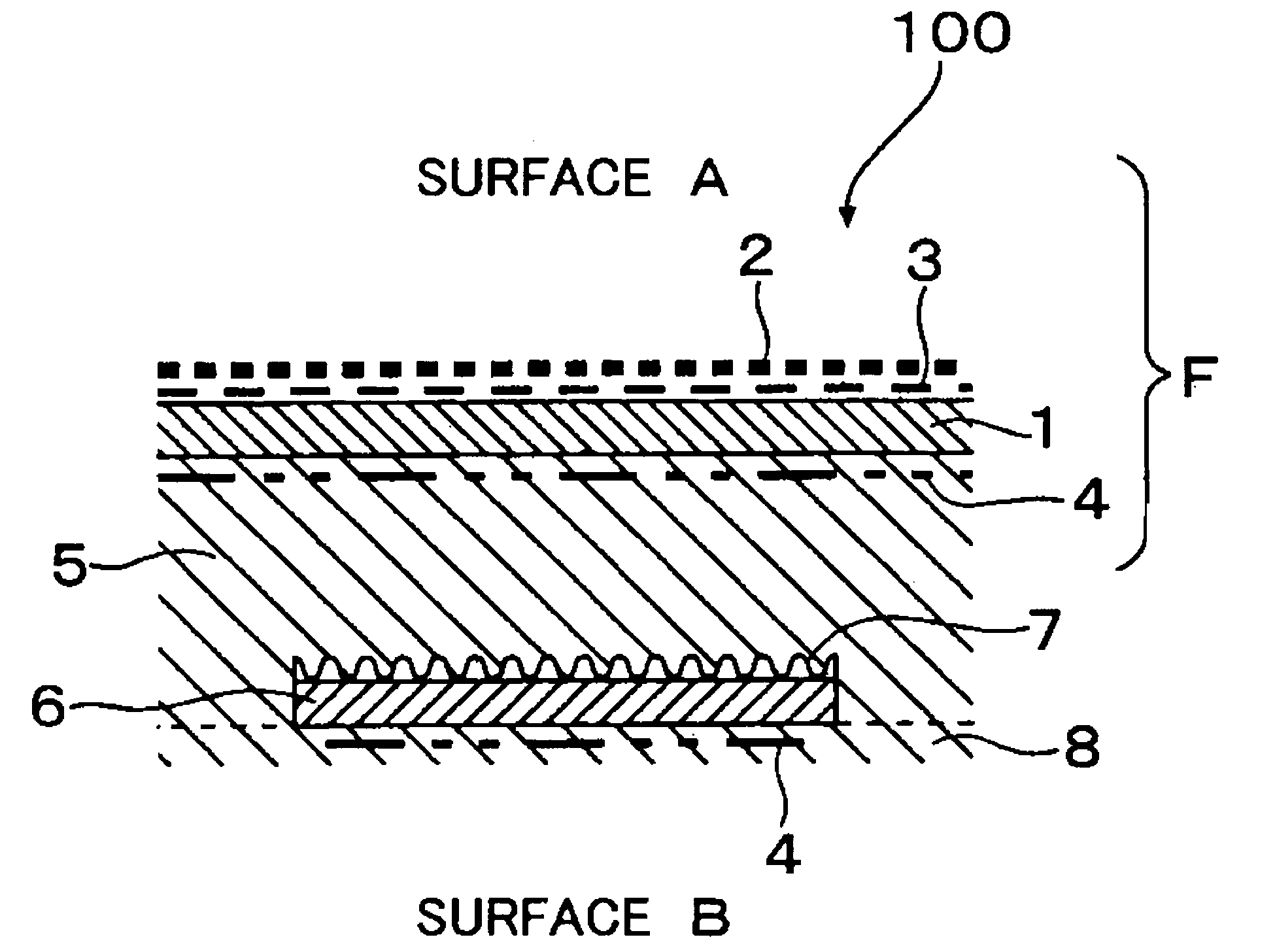

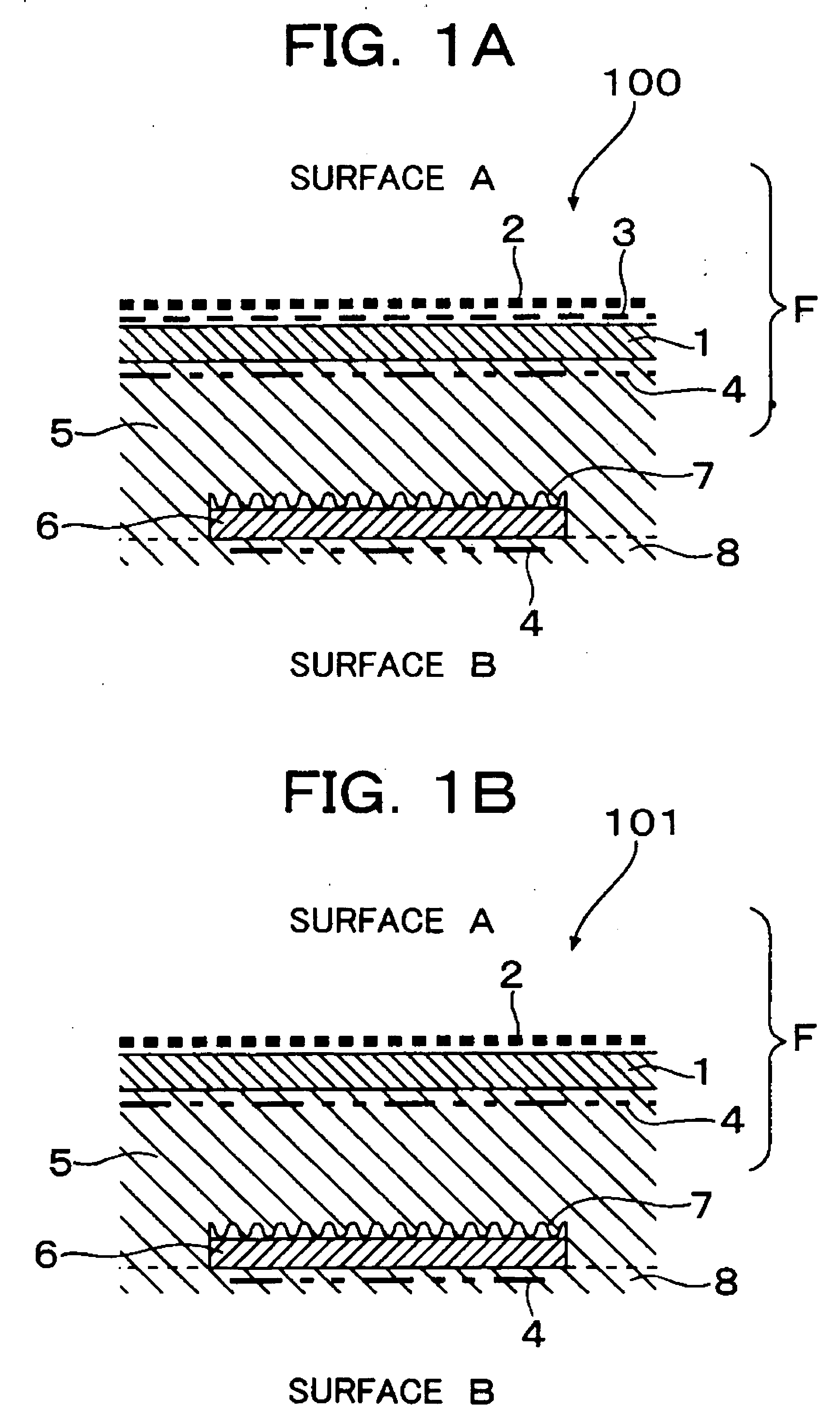

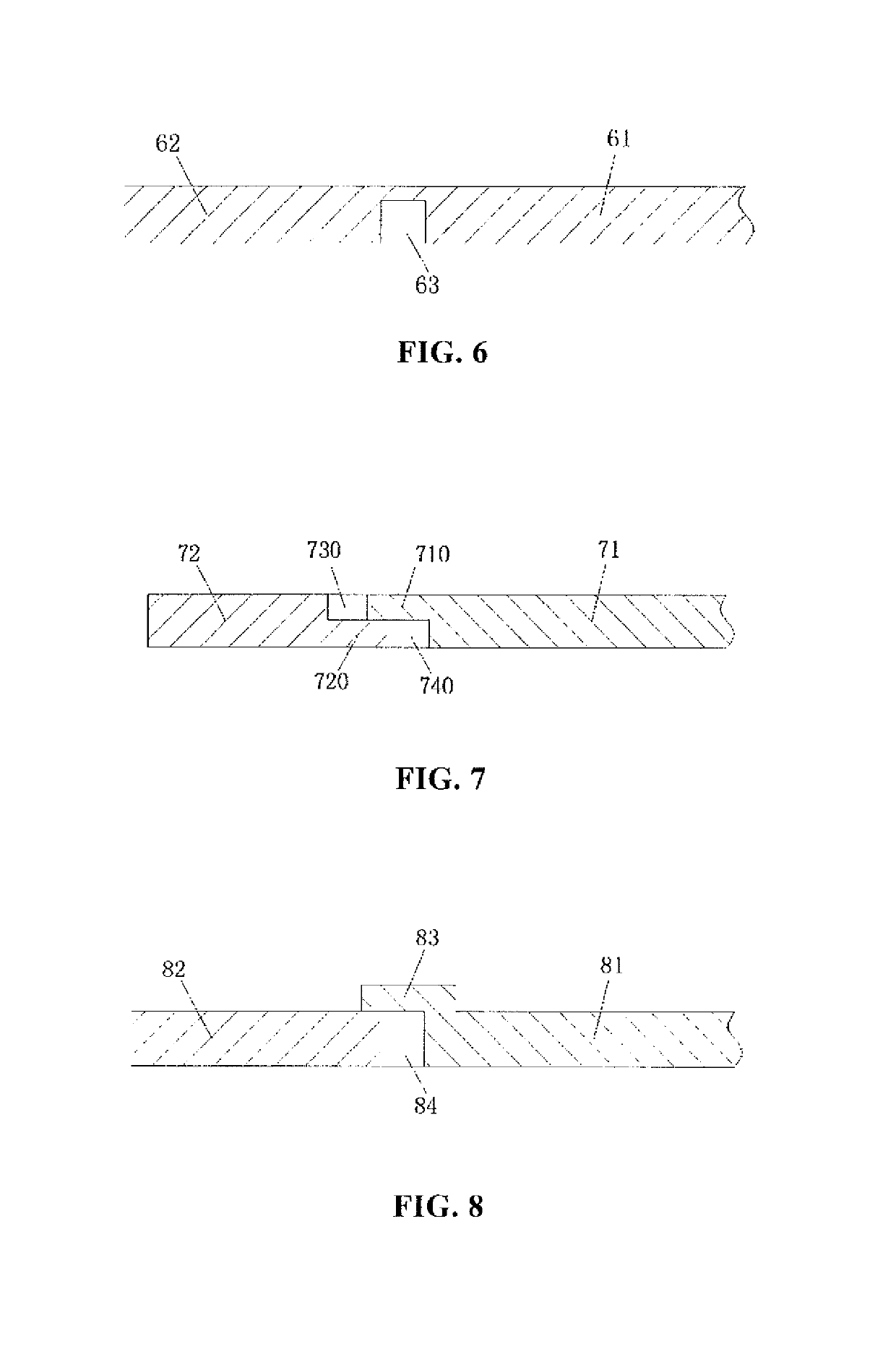

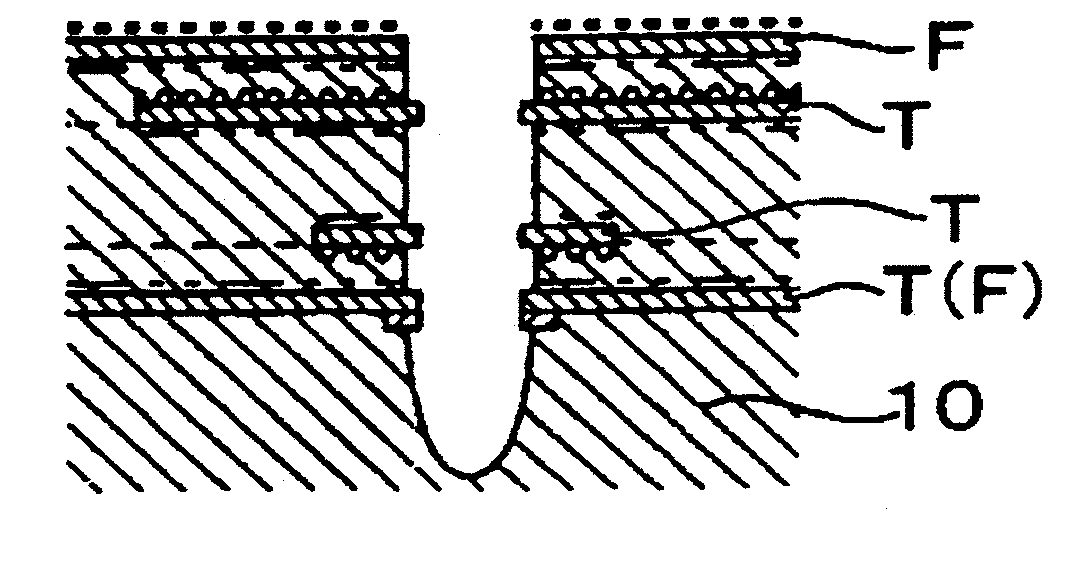

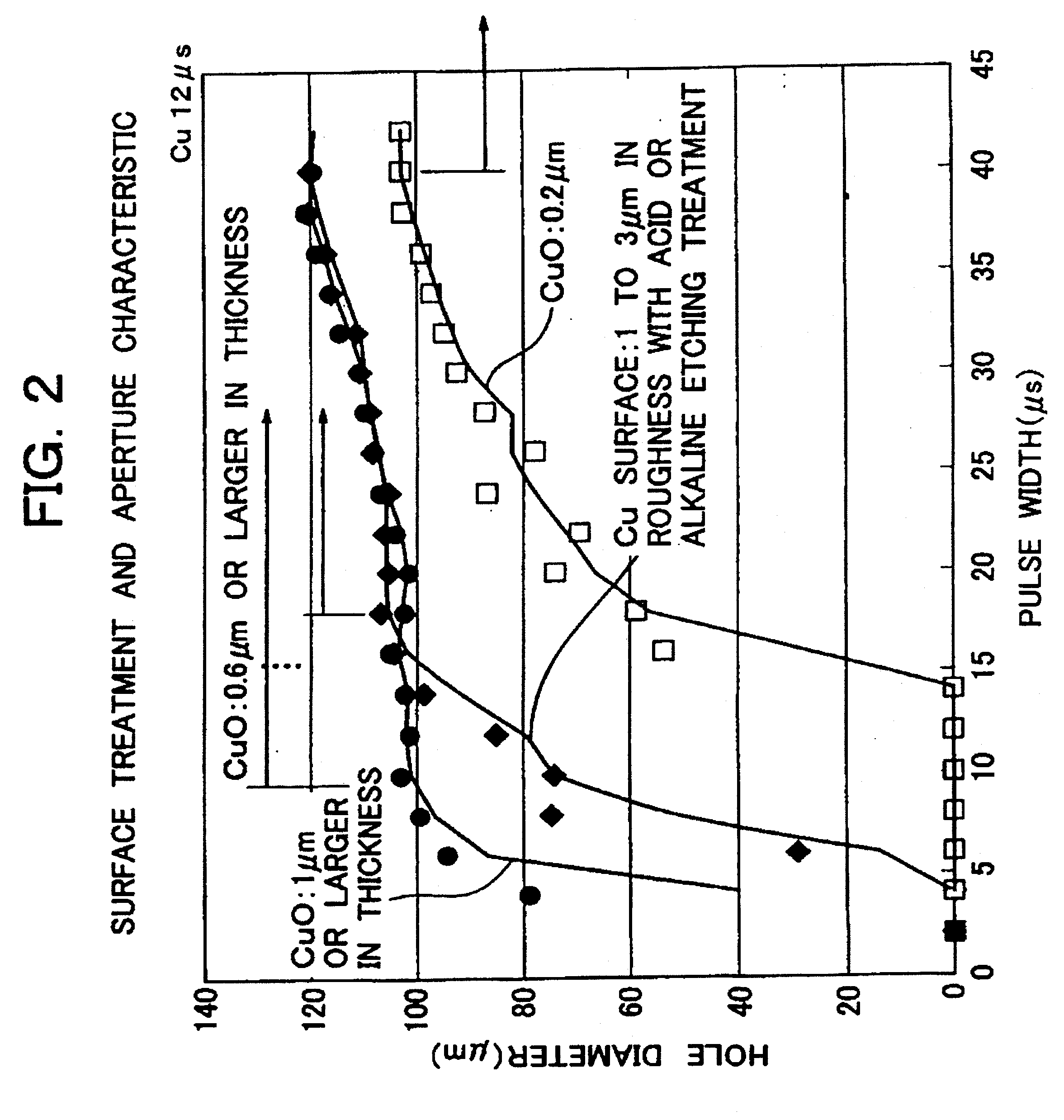

Printed circuit board and method for processing printed circuit board

InactiveUS20050244621A1Low production costUniform processing qualityLight absorption dielectricsCircuit board tools positioningLaser lightPrinted circuit board

The invention is to provide a printed circuit board in which advance of packaging density of the printed circuit board and reduction in production cost can be attained while processing quality can be made uniform, a method for processing the printed circuit board and a method for producing the printed circuit board. There is provided a printed circuit board including an alternate laminate of electric conductor layers and electrically insulating layers, wherein a coating layer capable of absorbing laser light but insoluble in an etching solution dissolving the electric conductor layers is provided on a front surface of a first one of the electric conductor layers. In this case, the coating layer may be provided on a front surface of a rear one of the electric conductor layers. Each of the electric conductor layers may contain Cu as a main component while the coating layer may contain CuO as a main component. The coating layer may have a thickness not thinner than 0.6 μm.

Owner:HITACHI SEIKO LTD

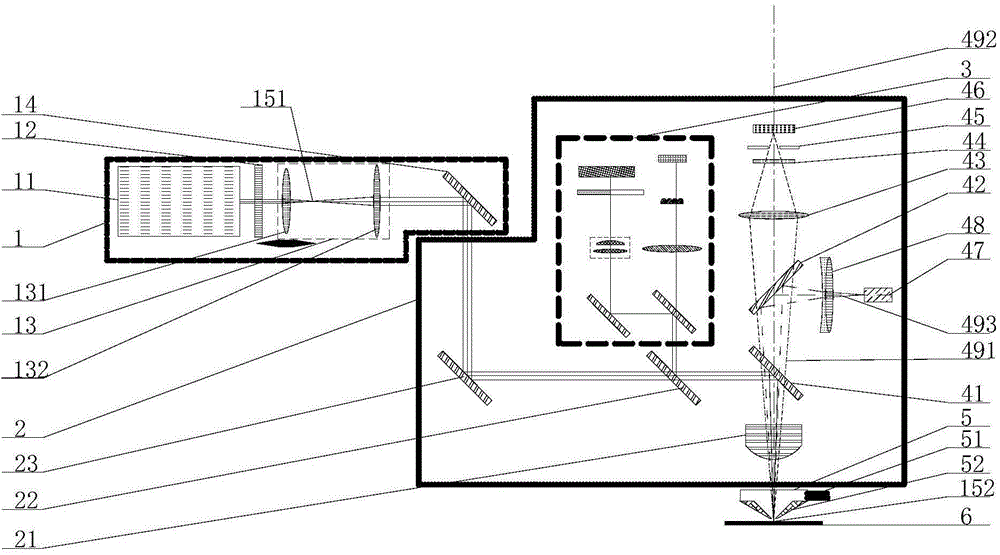

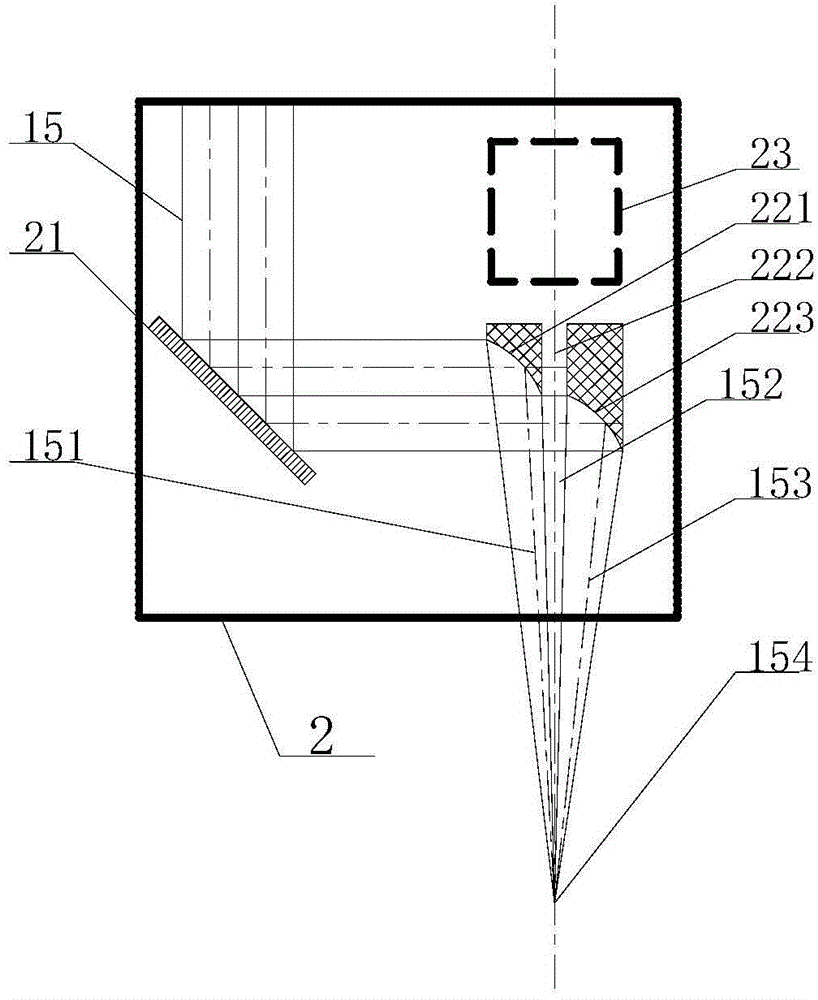

Laser cutting system

ActiveCN105710539AEasy to operateGuaranteed laser processing effectLaser beam welding apparatusLight beamLaser cutting

The invention relates to the technical field of laser cutting and discloses a laser cutting system. The laser cutting system comprises a laser light source assembly, an optical assembly, a three-dimensional motion assembly and a computer, wherein the three-dimensional motion assembly comprises an x-y-axis moving platform and a z-axis moving platform, the x-y-axis moving platform drives materials to be machined to move in the x direction and in the y direction, and the z-axis moving platform drives the optical assembly to move in the z direction. The laser light source assembly emits machining laser beams, second laser beams and third laser beams are formed by the machining laser beams under the action of the optical assembly and are focused on the materials to be machined to machine the materials. A first zone without laser beams is formed between the second machining beams and the third machining beams. The computer is connected with the laser light source assembly, the optical assembly, the x-y-axis moving platform and the z-axis moving platform. According to the laser cutting system, images of the surfaces of the materials to be machined can be observed and detected, and focuses of the machining light beams can be automatically adjusted.

Owner:HANS LASER TECH IND GRP CO LTD

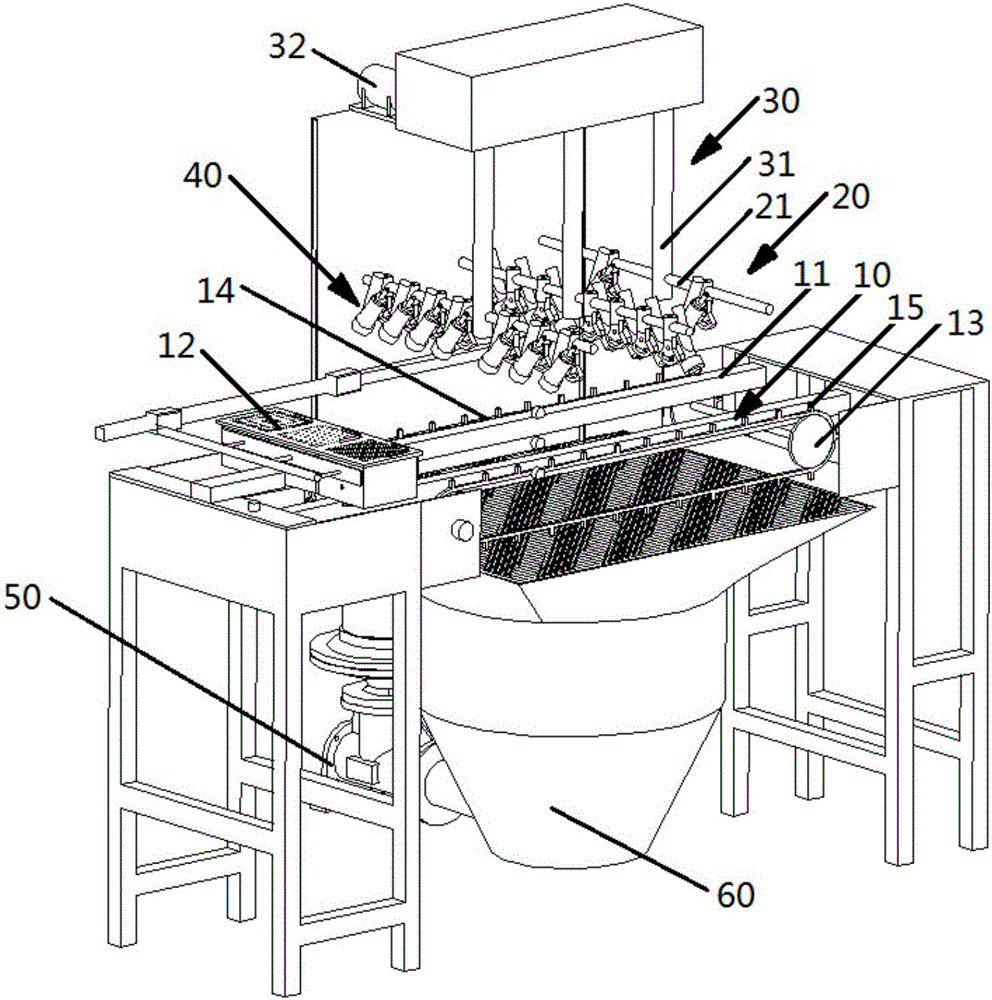

Three-axis-linkage automatic sand blasting device for diamond wire polycrystalline silicon slices

ActiveCN106003446AChange the surface morphologySimple structureWorking accessoriesGrinding machinesNumerical controlSand blasting

The invention discloses a three-axis-linkage automatic sand blasting device for diamond wire polycrystalline silicon slices. The three-axis-linkage automatic sand blasting device comprises a longitudinal transmission mechanism, a transverse transmission mechanism, a vertical transmission mechanism, a spray gun module, a sand pump and a sand vat. The longitudinal transmission mechanism is used for driving the diamond wire polycrystalline silicon slices to enter and exit from a sand blasting area. The transverse transmission mechanism is arranged above the longitudinal transmission mechanism and used for fixing the spray gun module. The transverse transmission mechanism can perform reciprocating motion in the X-axis direction. The output end of the vertical transmission mechanism is connected with the transverse transmission mechanism, and the vertical transmission mechanism is used for driving the transverse transmission mechanism to move in the Z-axis direction. By means of three-axis-linkage of the longitudinal transmission mechanism, the transverse transmission mechanism and the vertical transmission mechanism, multi-freedom-degree numerical control adjustment is achieved; the processing requirement of the multiple types of diamond wire polycrystalline silicon slices can be met; in addition, the cutting depth and the surface microstructure of each diamond wire polycrystalline silicon piece can be strictly controlled; machining quality is uniform; and consistency is good.

Owner:BEIJING HEDEFENG MATERIAL TECH

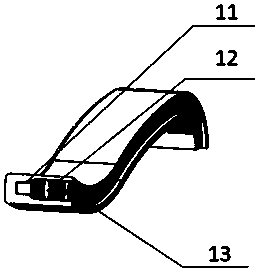

Processing technique for golf club push rod and clamp for technique

ActiveCN105598654AScientific and reasonable arrangementReduce processing timePositioning apparatusGolf clubsEngineeringGolf Ball

The invention discloses a processing technique for a golf club push rod. The processing technique comprises the following steps: milling a positioning pin and a push rod pipe handle; tapping a drill hole; milling a push rod cavity; milling an aiming line; milling a rod surface; milling a push rod pipe handle; processing a push rod thread hole; checking products. The processing technique has the characteristics that the arrangement is scientific and reasonable, the processing time is efficiently shortened, the processing efficiency is increased and the processing quality is stable and uniform. The invention also discloses a clamp for processing a rod surface. A cavity is arranged between a moveable mold plate and a fixed mold plate; the golf club push rod can be accurately positioned through the cavity; when the workpieces in different size are processed, only the corresponding moveable mold plate and fixed mold plate are required to be replaced; the manufacturing cost of the jig can be effectively saved; the clamp has the characteristics of use flexibility and quick positioning and clamping; the processing efficiency is increased; the stable and uniform processing quality can be ensured.

Owner:ZHONGSHAN XINHUI PRECISION TECH CO LTD

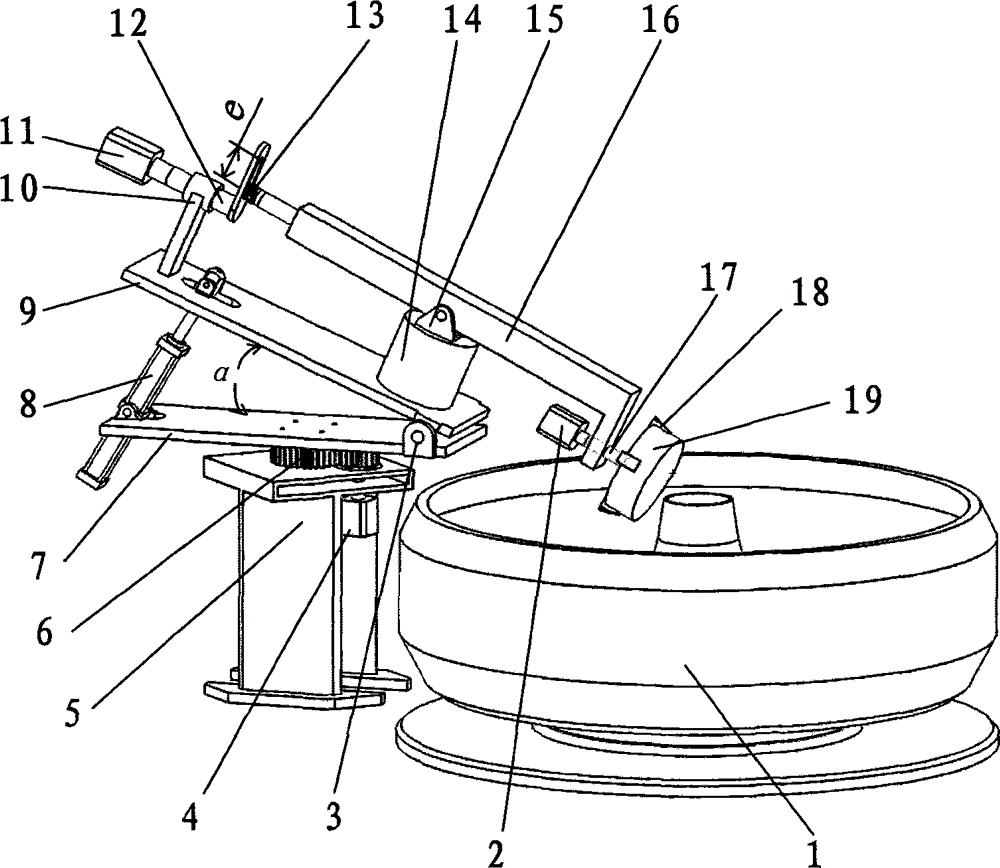

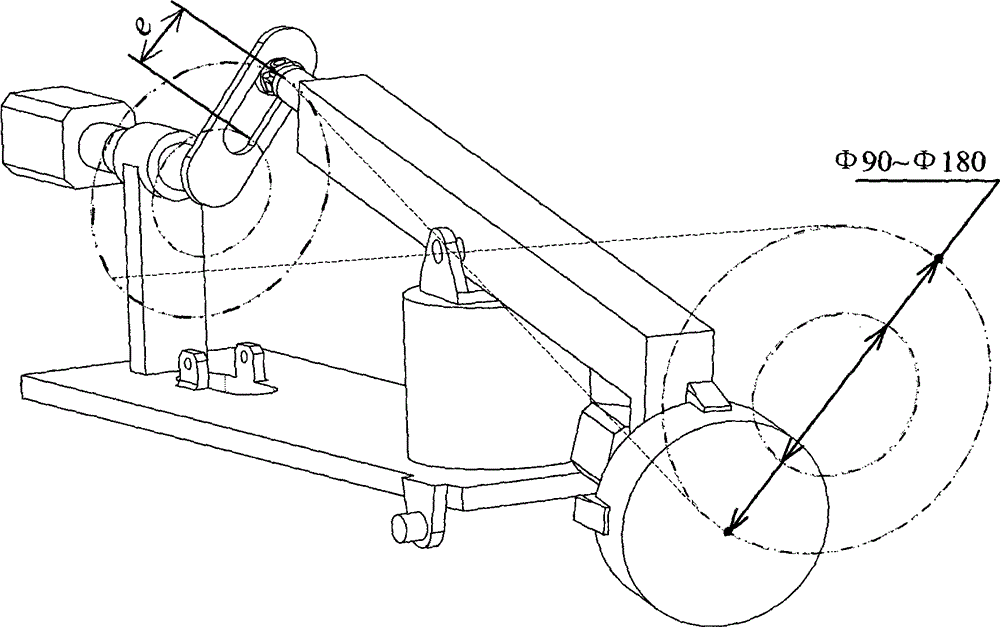

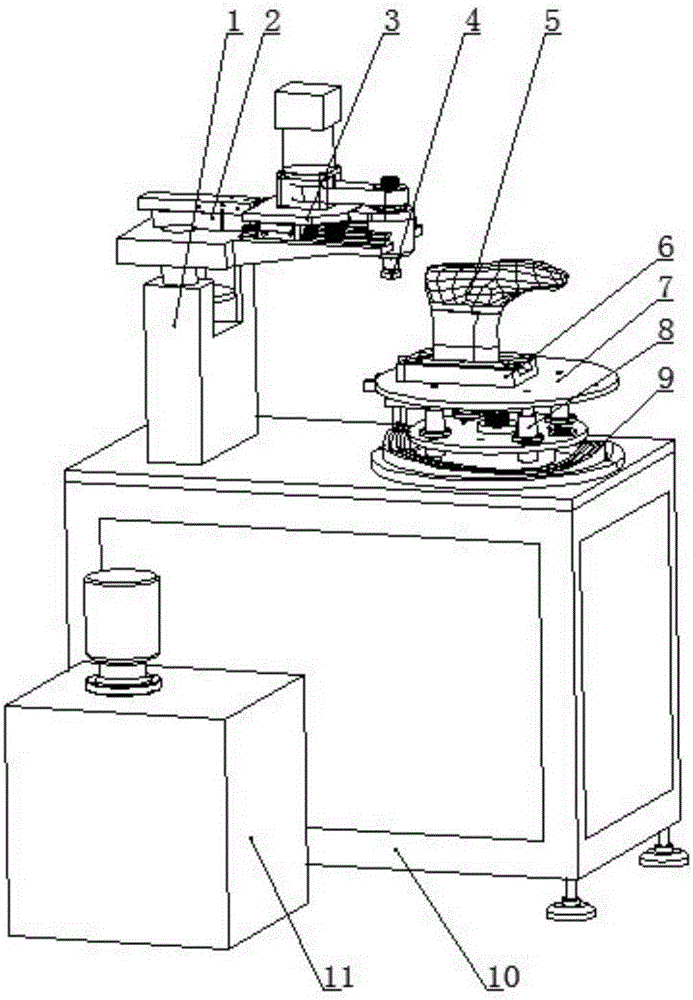

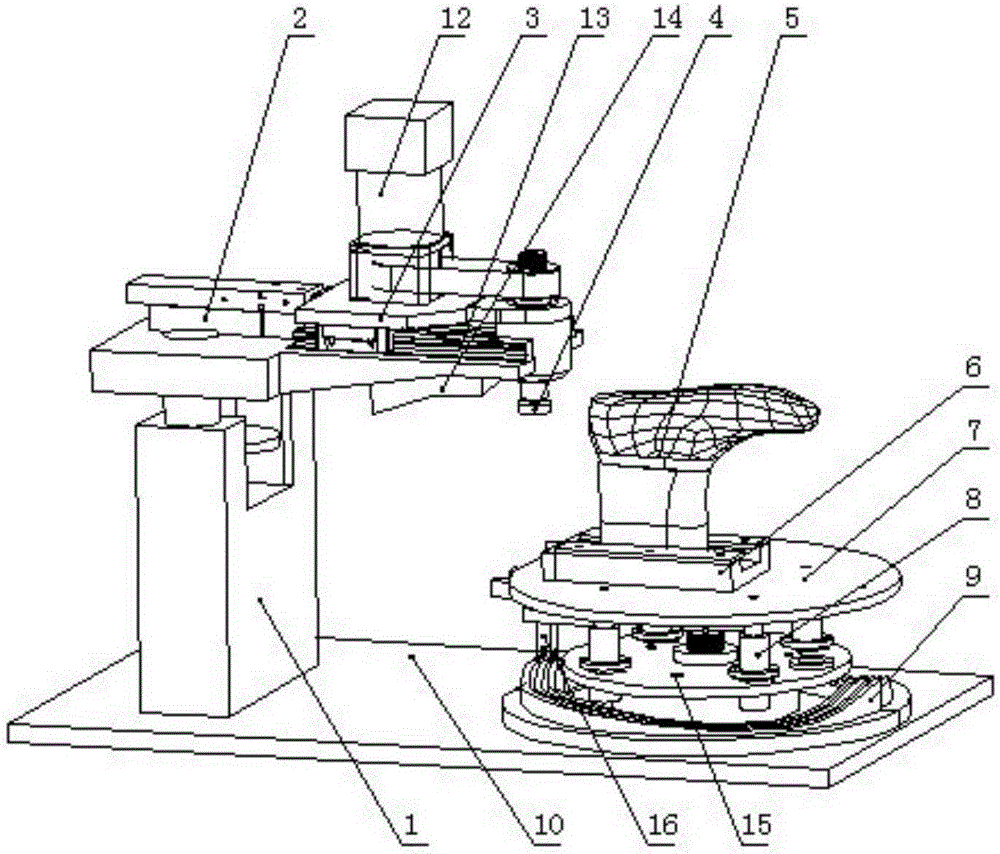

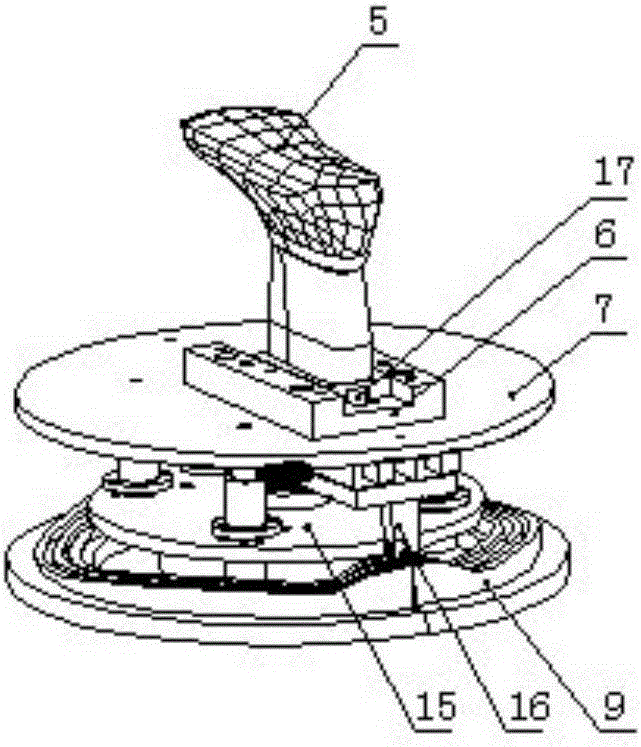

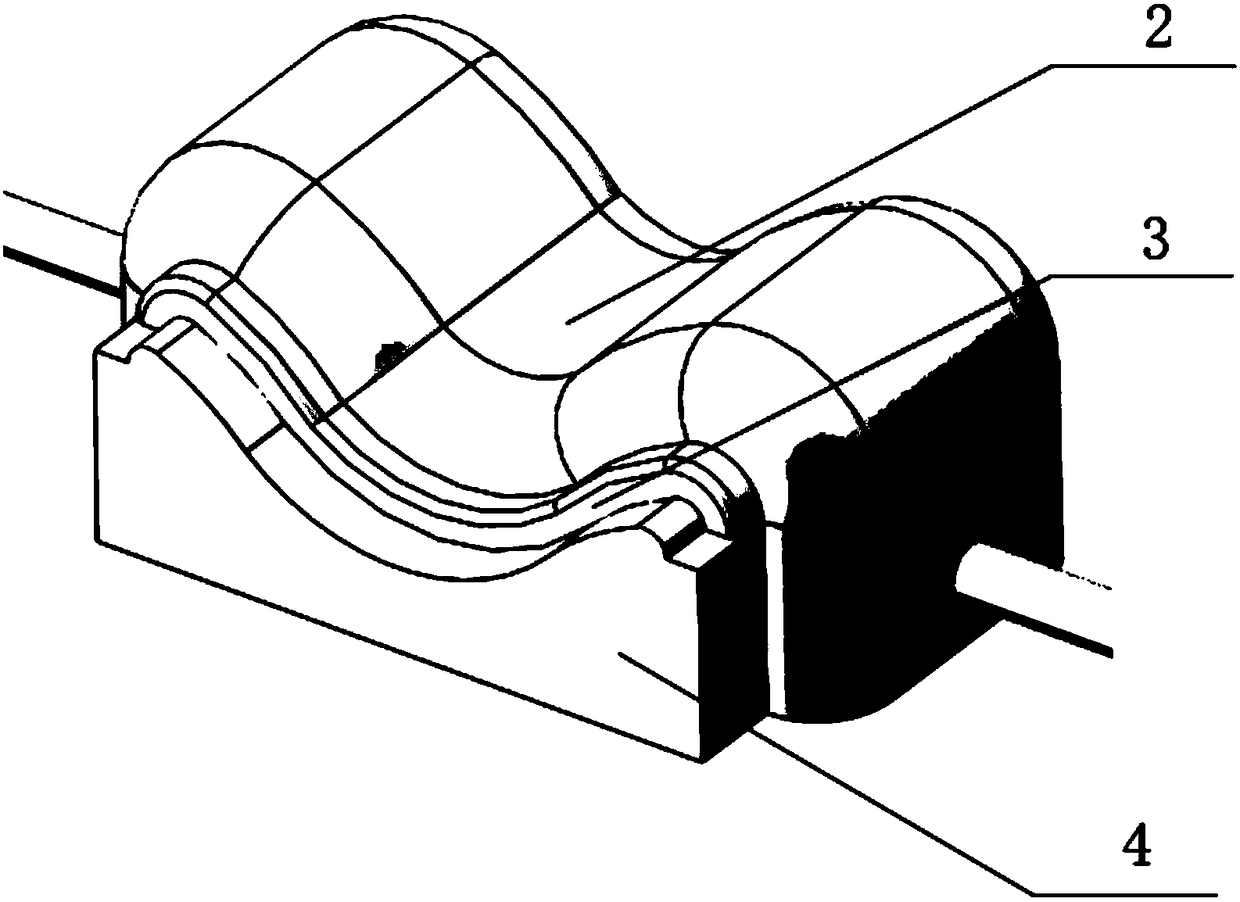

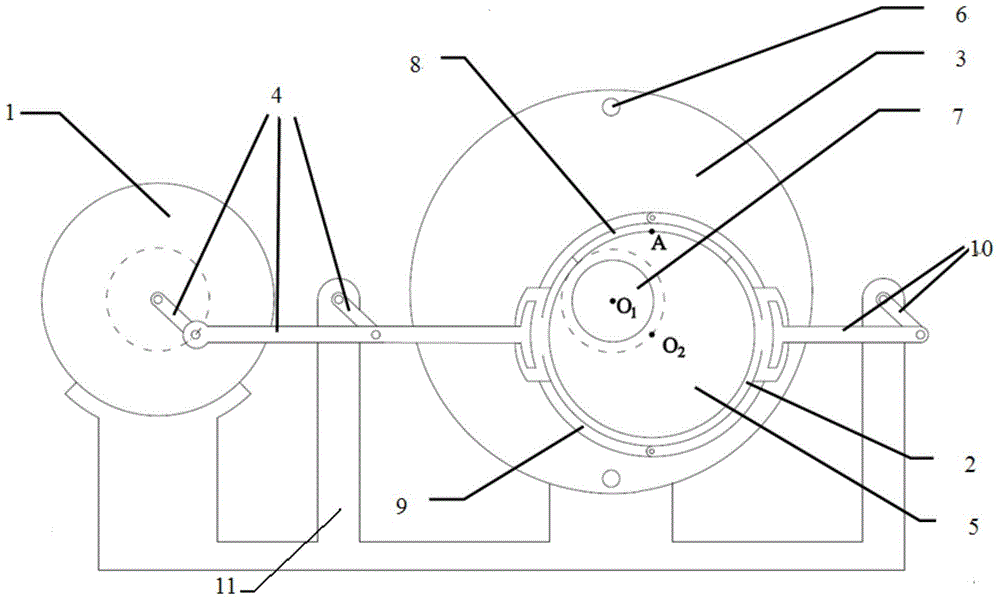

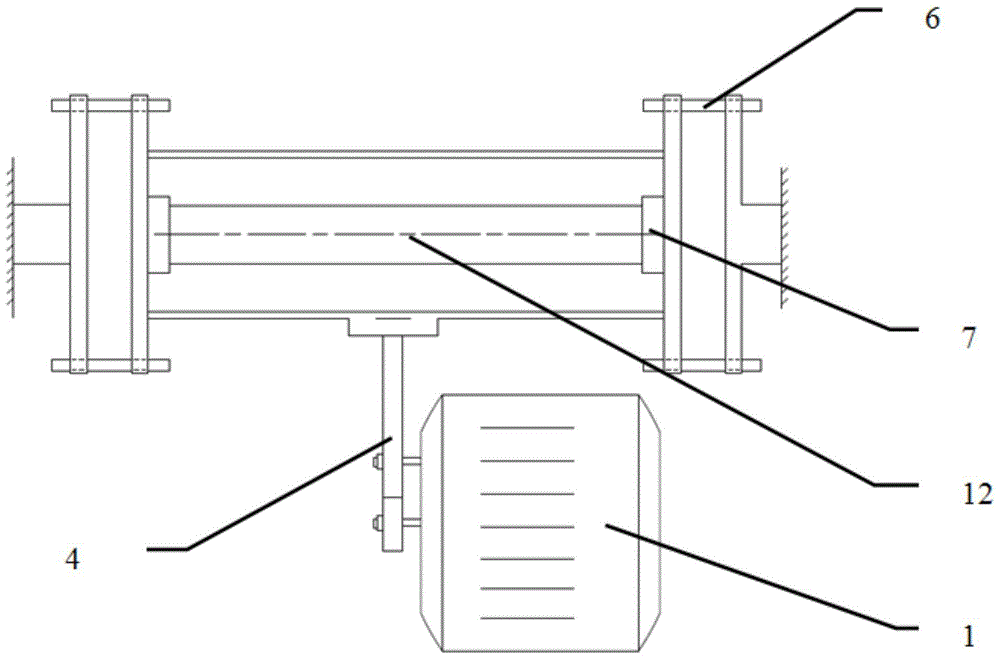

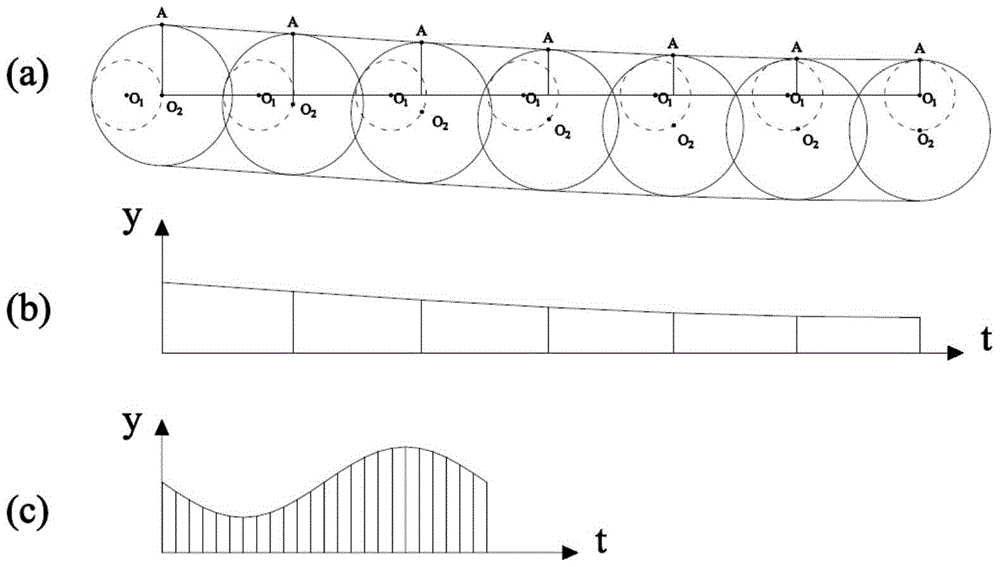

Coning movement type finishing device suitable for wheel disc type parts and method thereof

InactiveCN104889878AUniform finishing effectOvercome the problem of differences in finishing qualityEdge grinding machinesPolishing machinesEngineeringMechanical engineering

The invention discloses a coning movement type finishing device suitable for wheel disc type parts and a method thereof, and is mainly used for finishing such large-medium wheel disc type parts as automobile hubs. The device consists of a main engine device and an abrasive container device, wherein the main engine device consists of such parts as a coning arm, a coning driving device, an inclined plate, a rotating plate and a lifting device; and the lifting device lifts one end of the inclined plate to drive the inclined plate, the coning arm and the coning driving device thereon so as to push workpieces into the abrasive container device for finishing. In working, the workpieces rotate by surrounding self axes, and perform the coning movement with a certain radius and speed through the coning driving device. The device and the method can effectively solve the difficulty of difference between the center and edge finishing qualities of the wheel disc type parts, are uniform and consistent in finishing quality, and have such advantages as simple device, high finishing efficiency and low finishing cost.

Owner:LANGFANG NORTH TIANYU ELECTROMECHANICAL TECH +1

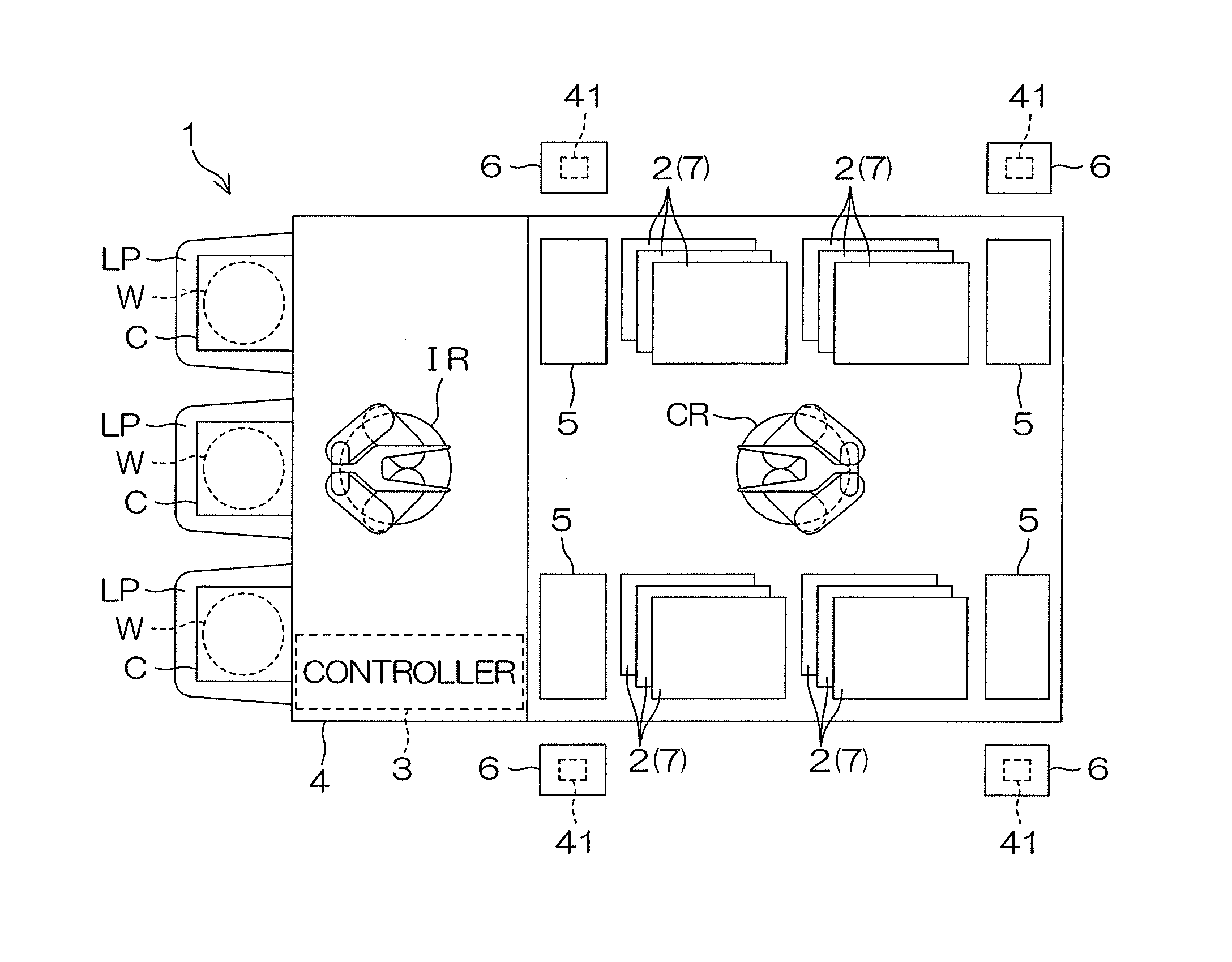

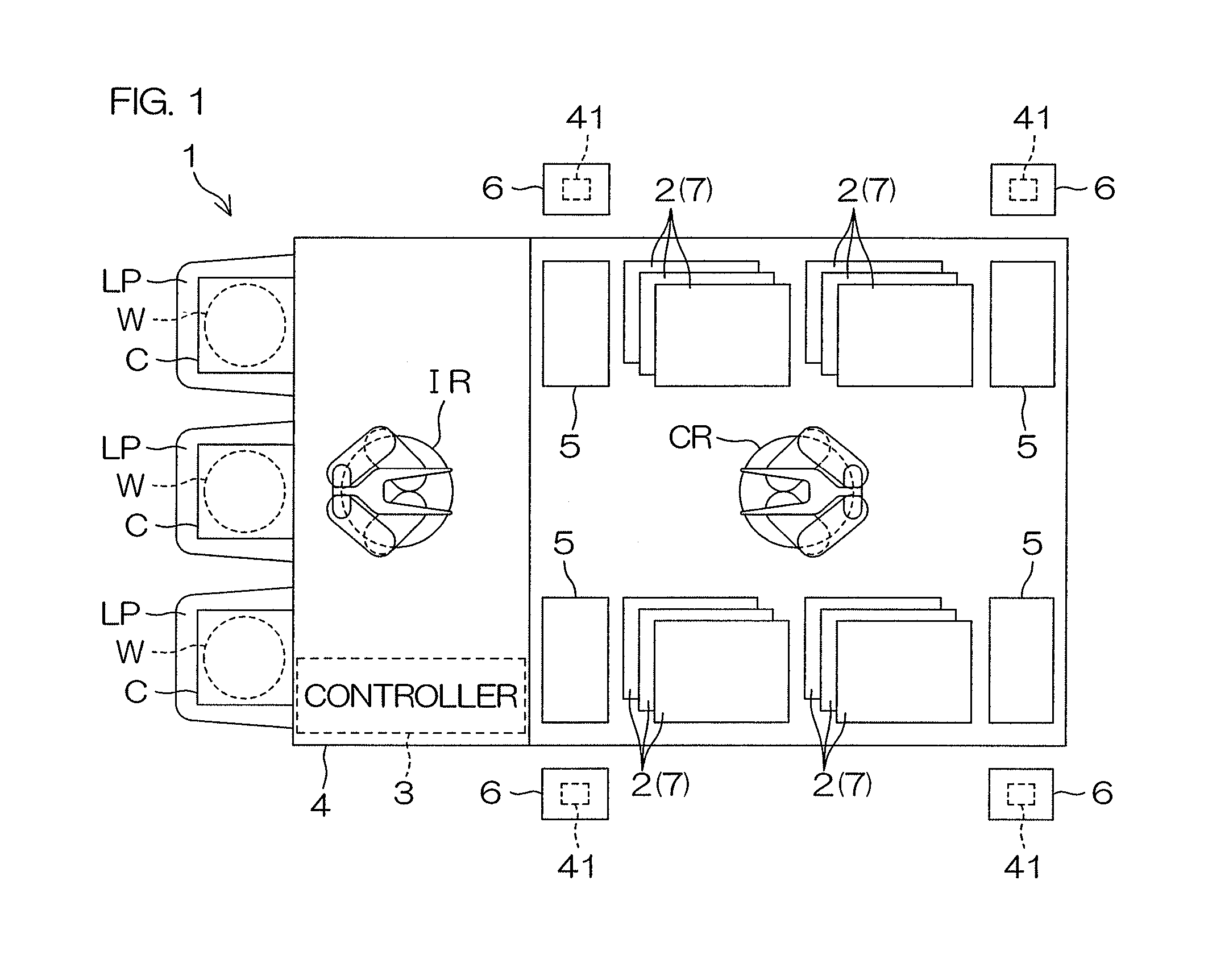

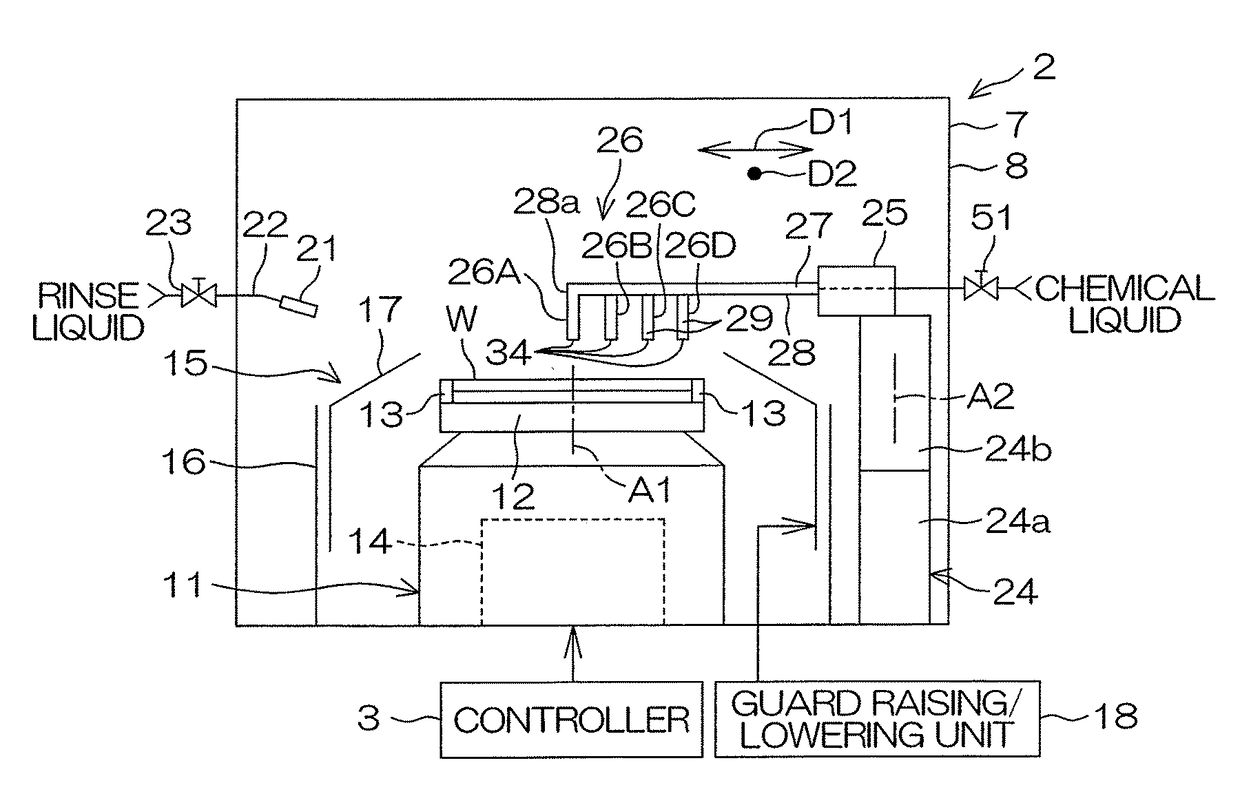

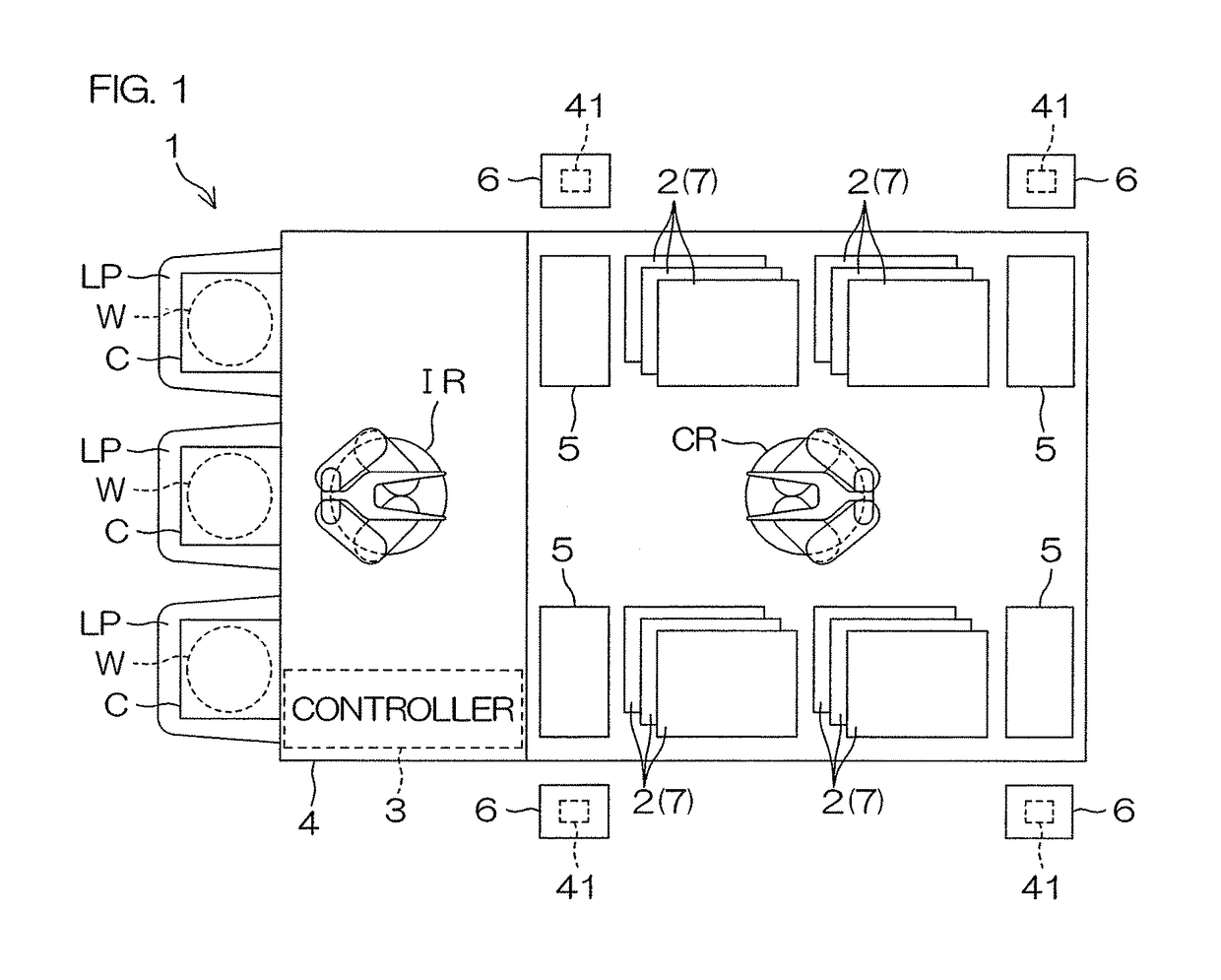

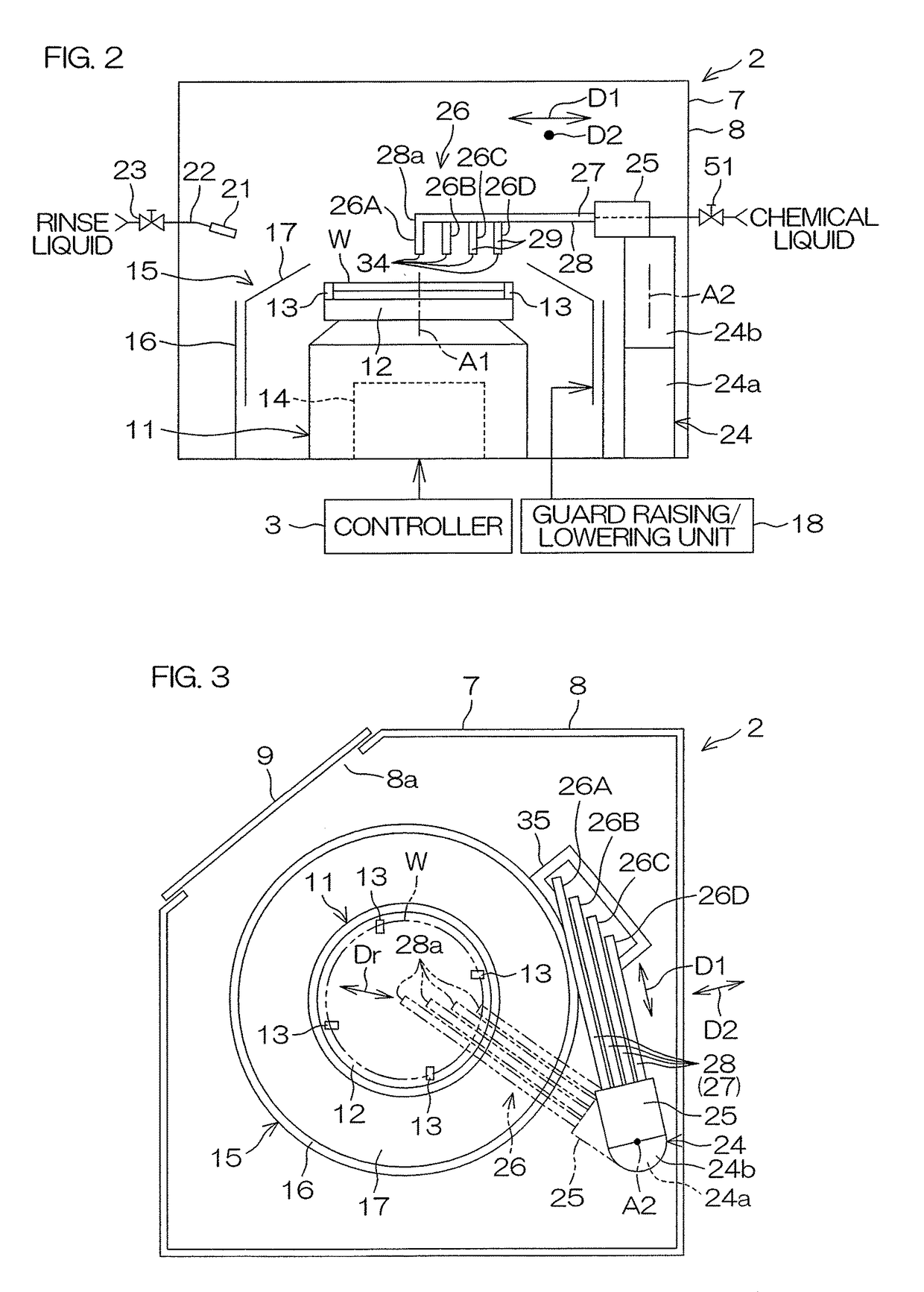

Substrate processing apparatus and substrate processing method

ActiveUS20160372341A1Easy dischargeShorten the time periodSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingPhysical chemistryAnalytical chemistry

The temperature of a chemical liquid supplied to a pot is detected while allowing a processing liquid discharge port to discharge the chemical liquid toward the pot at a pre-dispensing position. The temperature of the chemical liquid rises in response to the lapse of time. When the temperature of the chemical liquid supplied to the pot reaches a second target temperature, the processing liquid discharge port is allowed to stop the discharge of the chemical liquid. Thereafter, a positional relationship between the processing liquid discharge port and the pot is changed, and the processing liquid discharge port is allowed to discharge the chemical liquid toward the substrate at the processing position.

Owner:DAINIPPON SCREEN MTG CO LTD

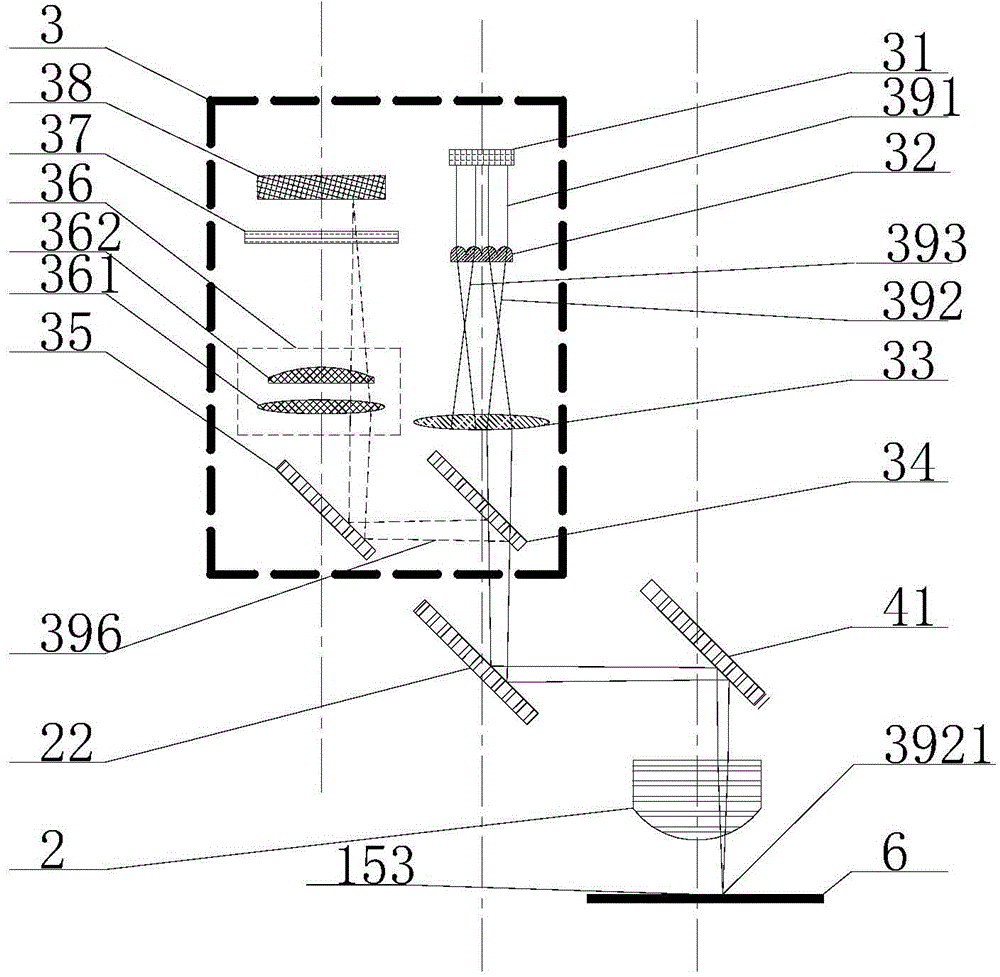

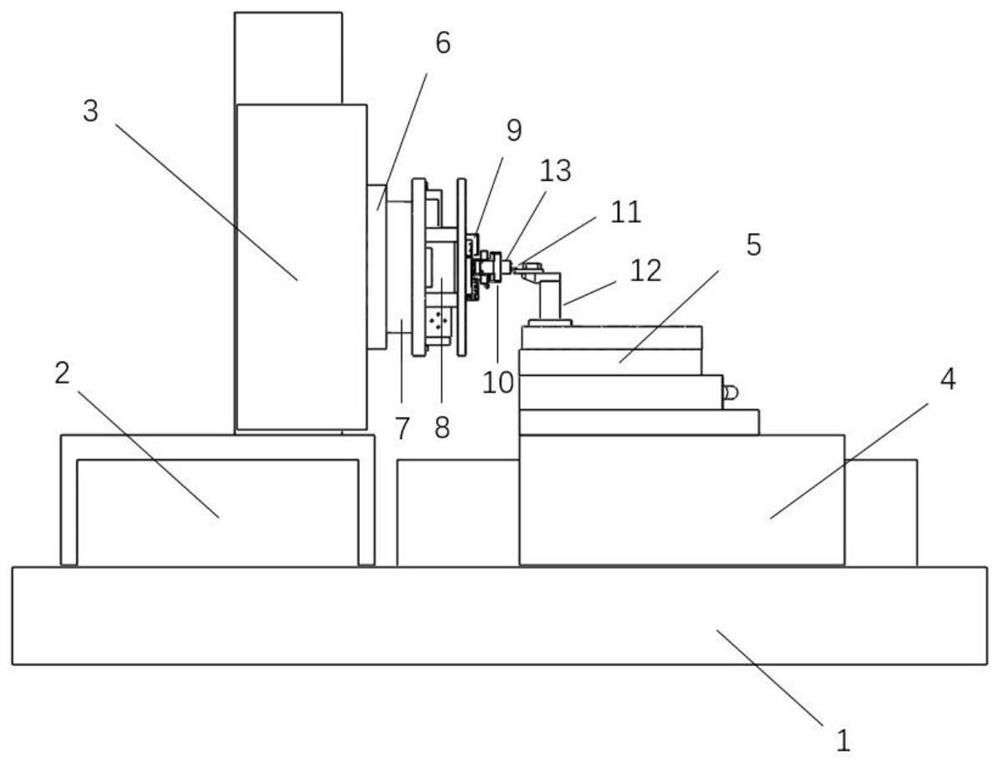

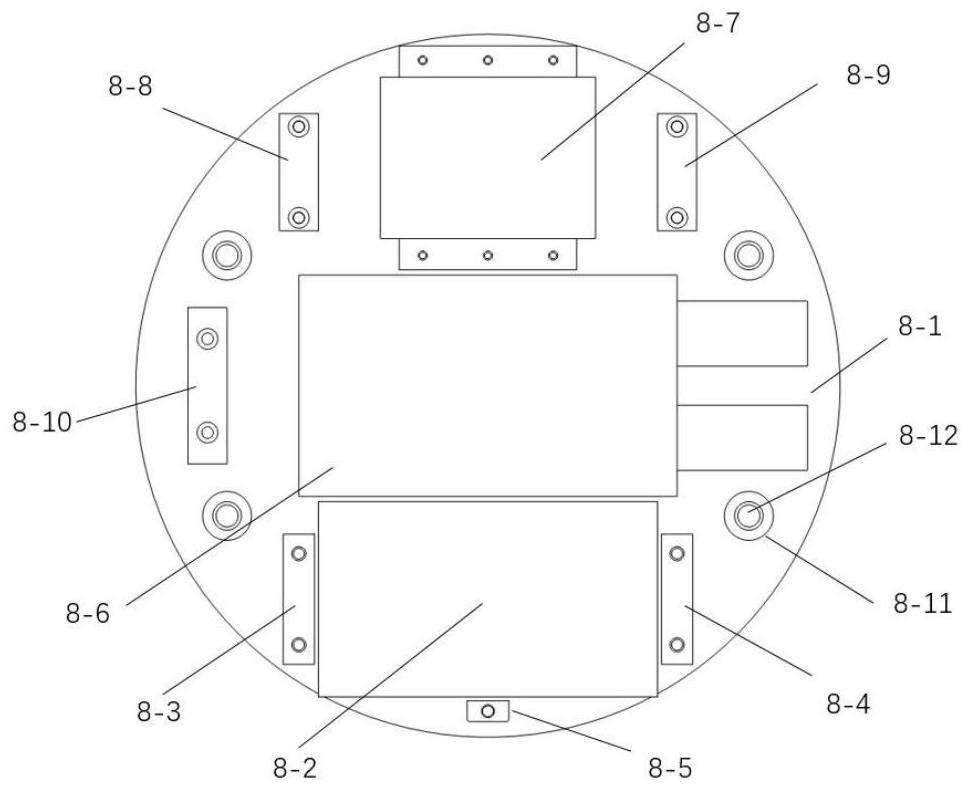

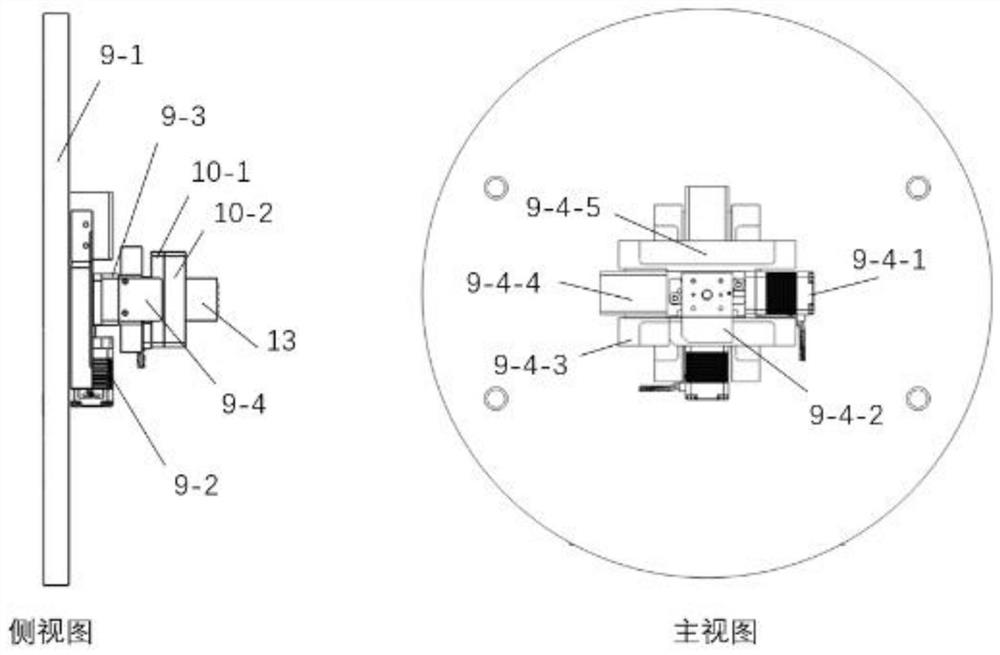

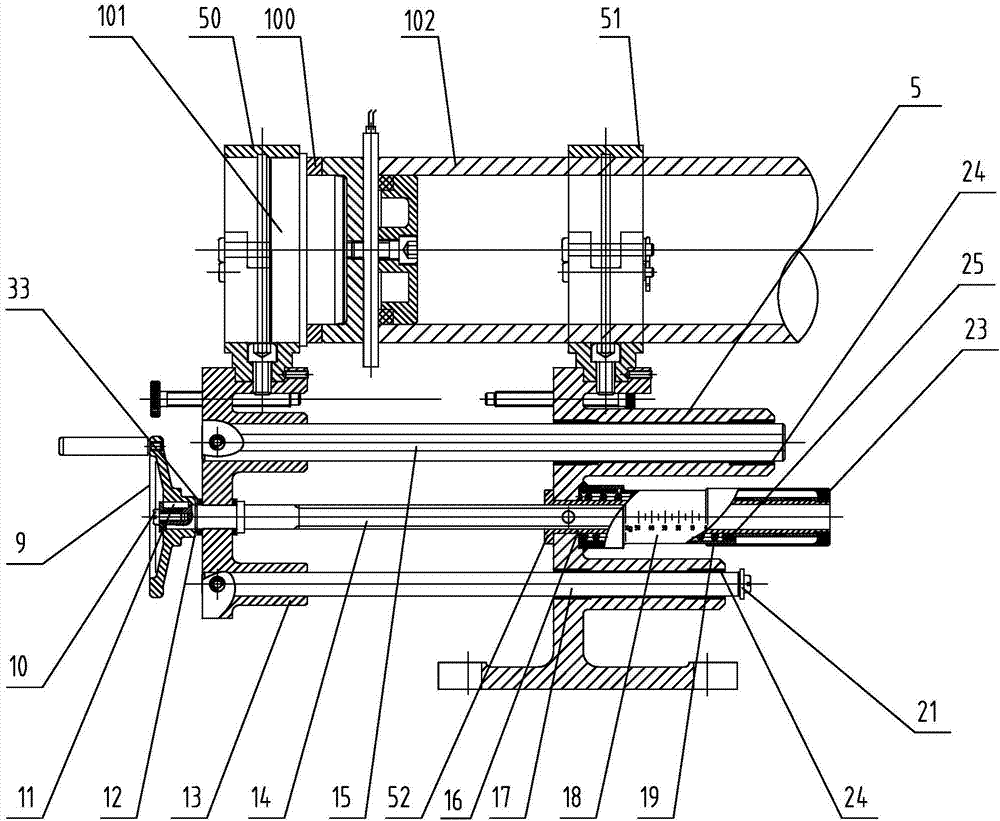

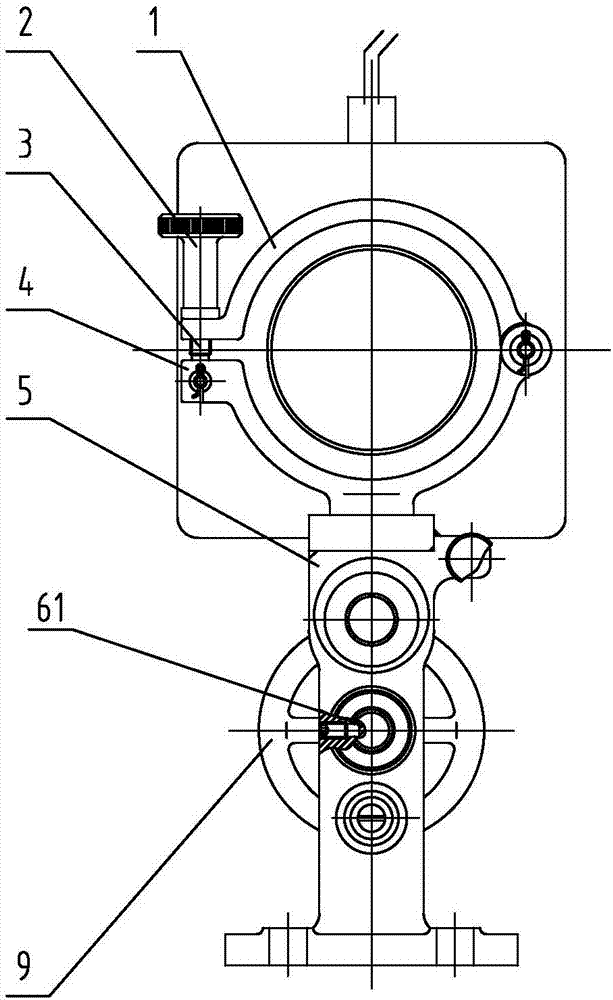

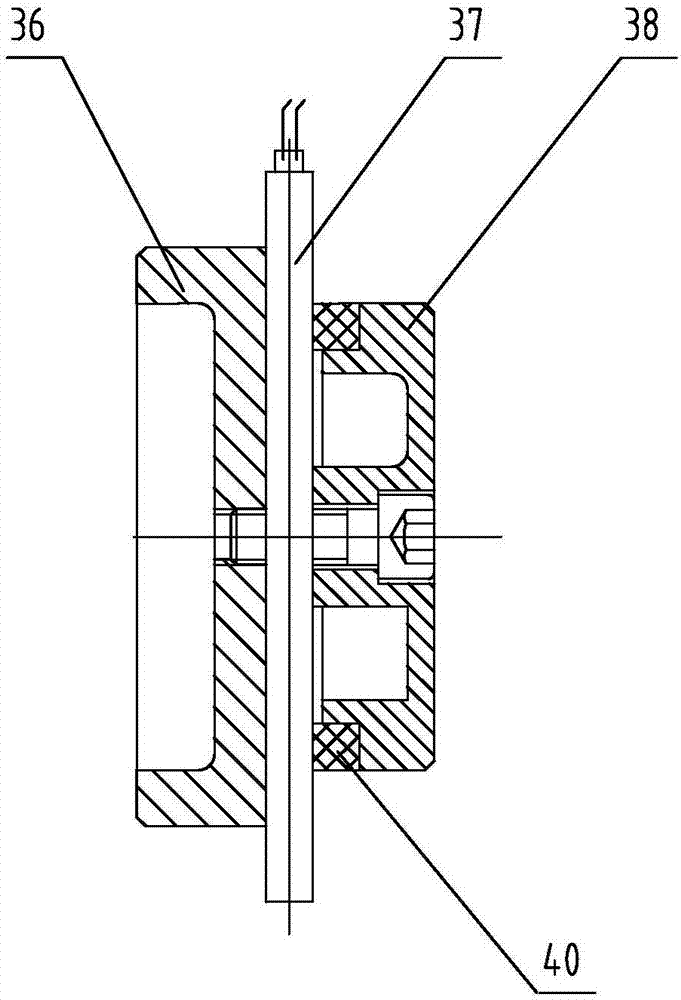

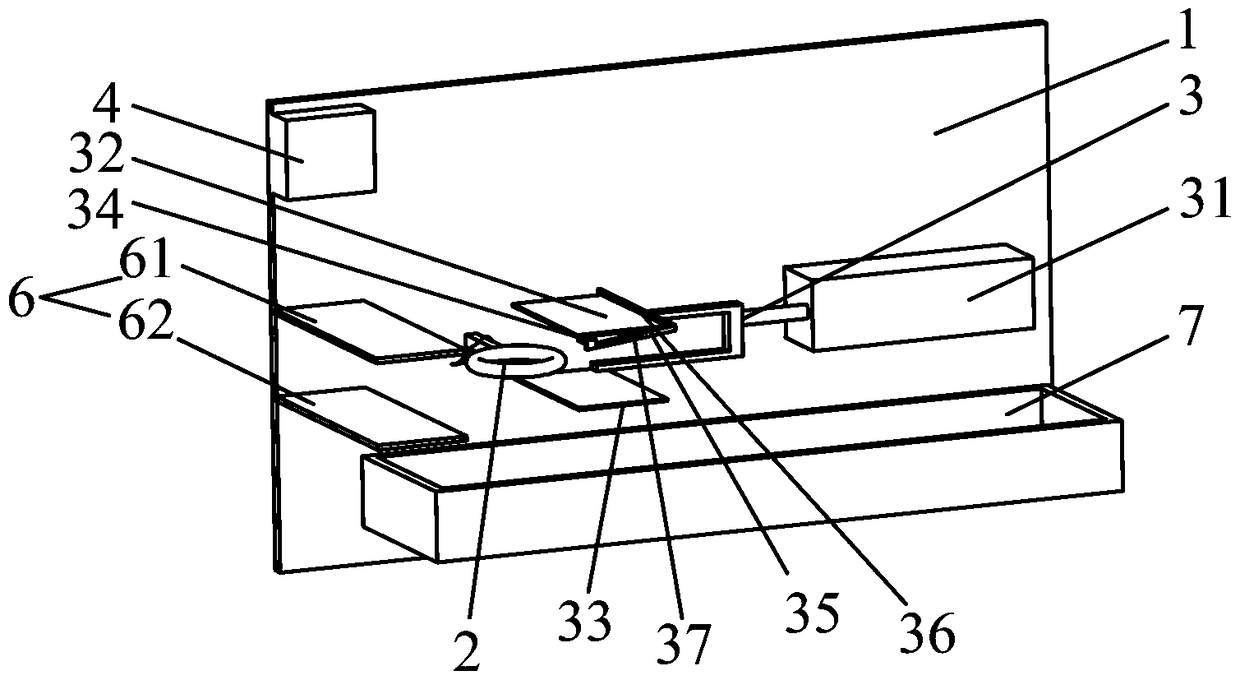

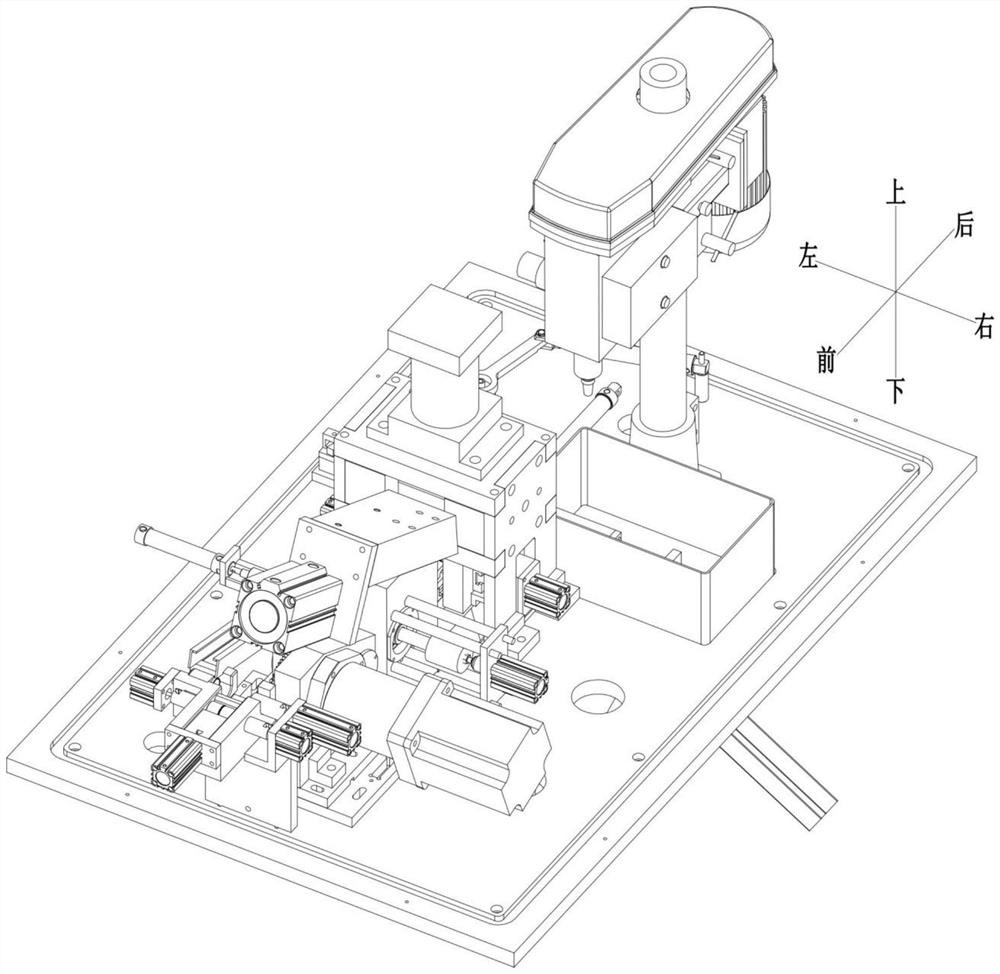

Shifting centering type micro-lens array machining device and method

ActiveCN113210636AReduce volumeHigh positioning accuracyAuxillary equipmentFine working devicesEngineeringMicro lens array

The invention relates to a shifting centering type micro-lens array machining device and method. The device comprises a base, a machine tool X shaft and a machine tool Y shaft are installed on the base, the moving directions of the machine tool X shaft and the machine tool Y shaft are perpendicular to each other, a machine tool Z shaft is arranged on a sliding table of the machine tool X shaft, the moving direction of the machine tool Z shaft is perpendicular to the machine tool X shaft and the machine tool Y shaft, a machine tool B shaft is arranged on the machine tool Z shaft, and a machine tool C shaft is arranged on the machine tool Y shaft. The machining device is characterized in that a machining tool is fixed to the surface of the machine tool B shaft; a vacuum suction cup is fixed to the surface of the machine tool C shaft, a control module is fixed to the surface of the vacuum suction cup, a two-dimensional positioning module is installed on the control module, and a workpiece clamp is installed on the two-dimensional positioning module; and the two-dimensional positioning module is used for adjusting the relative position of the workpiece to be machined on the workpiece clamp and the machine tool C shaft. According to the shifting centering type micro-lens array machining device and method, the machining efficiency of the micro-lens array can be improved, and the machining quality of each micro-lens unit is unified.

Owner:霖鼎光学(上海)有限公司

Automatic polishing and grinding robot

InactiveCN105538092ALabor savingUniform processing qualityGrinding machinesGrinding feedersMotor shaftManipulator

The invention discloses an automatic polishing and grinding robot. The automatic polishing and grinding robot comprises a conveying belt used for conveying materials horizontally, a grinding wheel arranged on one side of the conveying belt, and a manipulator used for clamping the materials on the conveying belt, then approaching the grinding wheel and polishing the materials. The grinding wheel comprises a grinding wheel frame, a grinding wheel motor and a grinding wheel body, wherein the grinding wheel motor is fixedly arranged on the grinding wheel frame, and the grinding wheel body is fixedly connected with a motor shaft of the grinding wheel motor. The automatic polishing and grinding robot has the beneficial effects that material taking, polishing and grinding are completed through the conveying belt of the robot, and labor is saved; in addition, the machining quality is uniform, and the qualified rate of products is high.

Owner:DONGGUAN FULI ENVIRONMENTAL PROTECTION

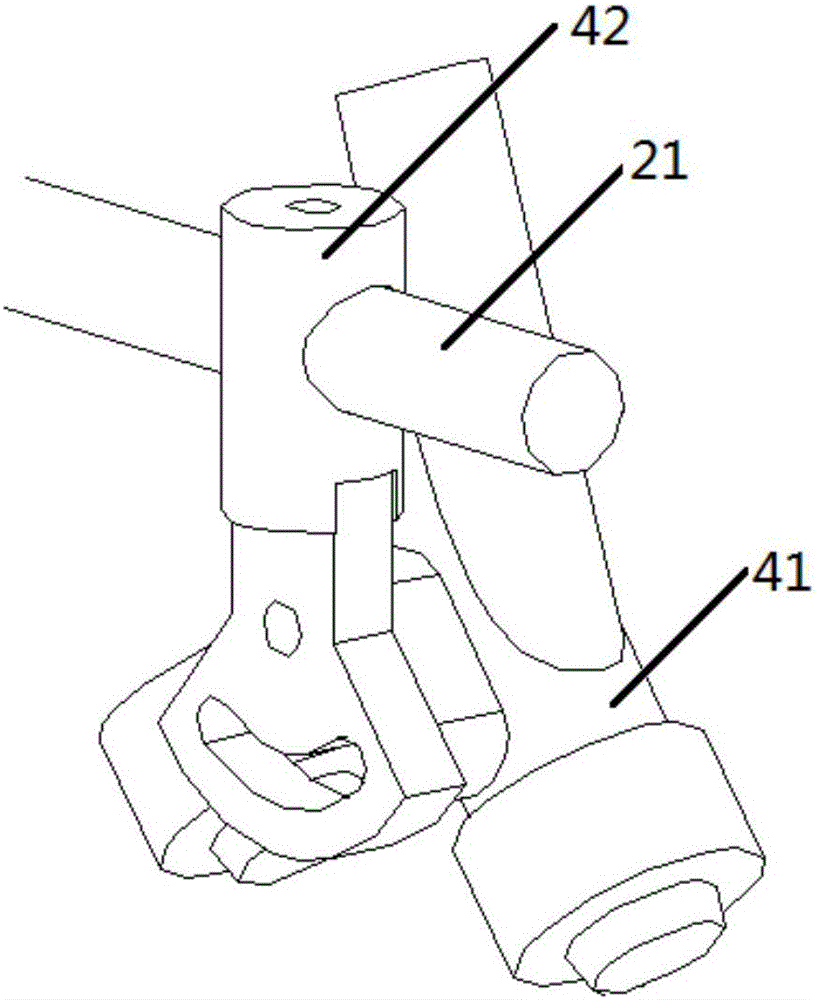

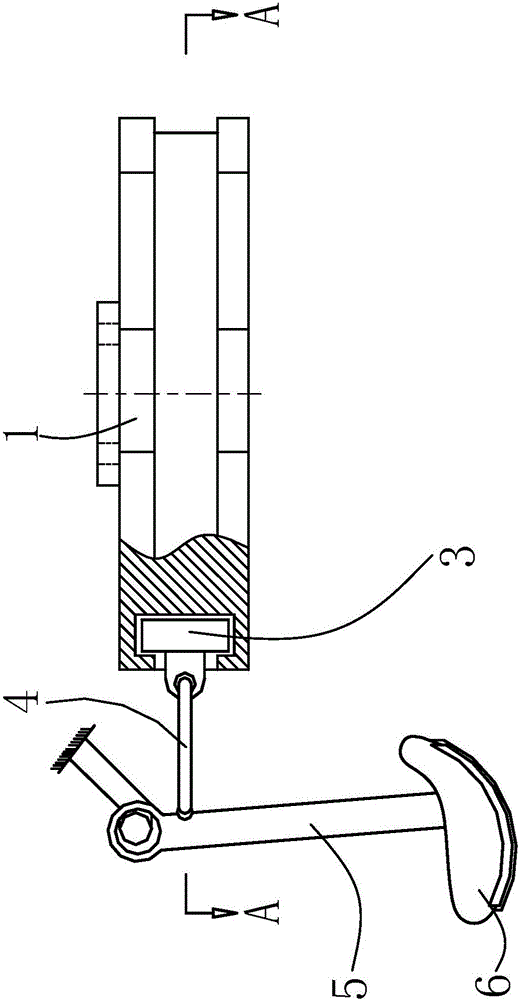

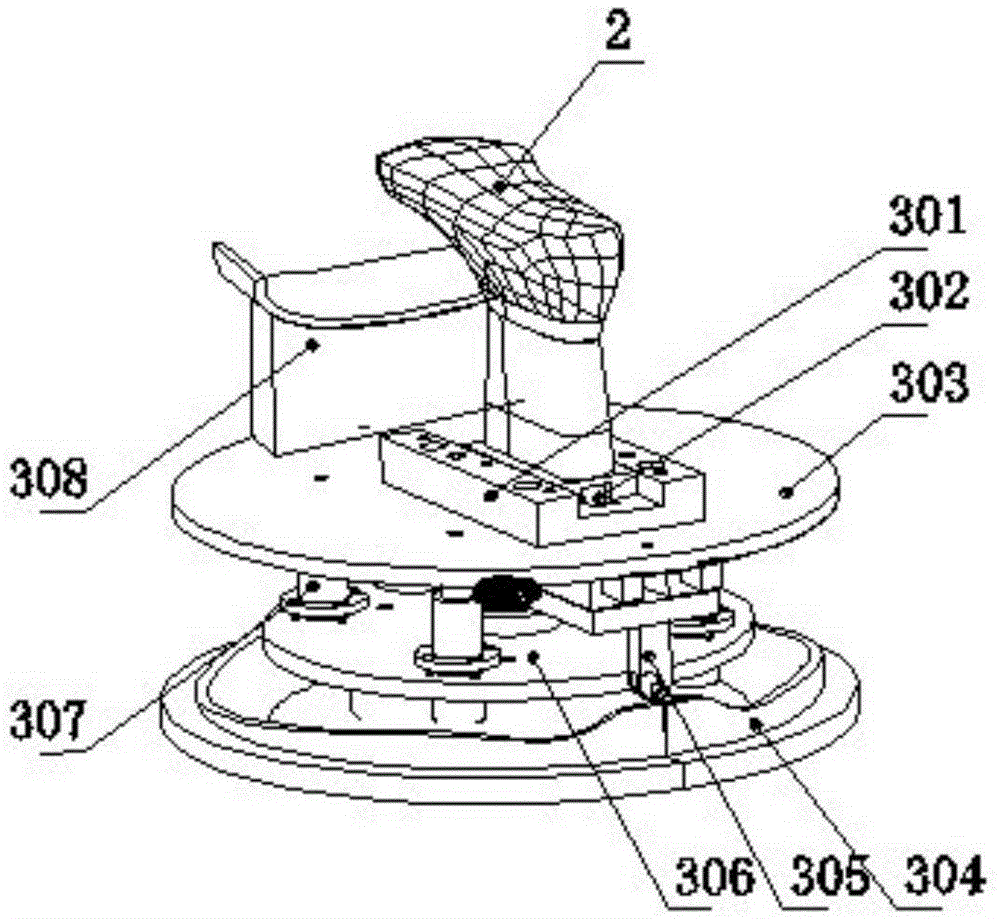

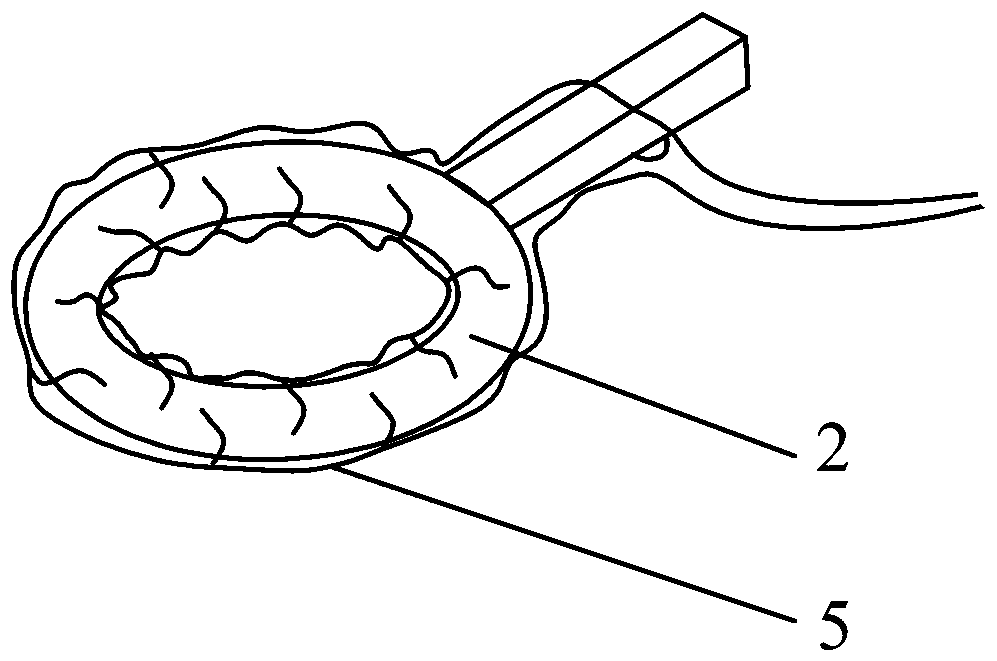

Upper rotary type raising machine and processing method thereof

ActiveCN105286215AReduced strength requirementsLow technical requirementsSolesEngineeringMechanical engineering

The invention relates to an upper rotary type raising machine. A tray rotating mechanism and a raising mechanism are installed in the middle of the upper end of a working platform transversely in a spaced mode. An upper to be processed is limited, installed and rotated through the tray mechanism assembly. Raising is conducted on the outer circumference of the bottom of the upper through the raising mechanism. The tray mechanism assembly comprises a tray, a first up-down template, a shoe tree clamping groove and a second up-down template. The tray is installed on the working platform in a driving module. One radial side of the upper end of the tray is fixedly provided with the shoe tree clamping groove. A rotating support is installed at the lower portion, corresponding to the shoe tree clamping groove, of the tray. The second up-down template is installed at the portion, below the tray, of the working platform, and the shape of the second up-down template is consistent with the up-down shape of the upper. The rotating support is limited to move through the annular up-down template. Automatic raising is conducted by rotating the tray, a raising wheel conducts raising on the upper through the annular up-down template, the shape positioning accuracy is high, the processing quality standard is uniform, and labor intensity and technological requirements are lowered for operators.

Owner:马士通安全设备(天津)有限公司

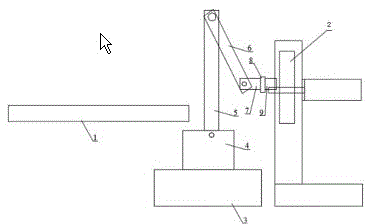

Cam for engraving redwood furniture

InactiveCN105774355AImprove processing efficiencyUniform processing qualityOther artistic work equipmentsModel makingEngravingEngineering

The invention relates to a cam for engraving redwood furniture. The cam comprises a cam body arranged horizontally. A ring groove with a T-shaped section is formed in the side face of the cam body. A pin roller is movably arranged in the ring groove in a clamping manner. A swing rod capable of swinging vertically relative to the pin roller is connected to the side portion of the pin roller in a hinged manner. When the cam rotates, rotation of the cam is utilized for driving the pin roller to rotate, when the pin roller rotates, along with left and right fluctuating rotation of the cam, a push rod is pushed circularly, an engraving knife at the lower end of the push rod swings from left to right in a reciprocating mode, and the engraving knife engraves marks on wood below. Manual engraving is replaced for engraving texture of patterns, the processing efficiency is improved, the processing quality is uniform, and the production cost of equipment is reduced.

Owner:ANHUI KUNCHANG FURNITURE CO LTD

Hot plate and substrate processing equipment using the same

ActiveUS10287686B2Uniform speedPrevent and reduce heat conductionVacuum evaporation coatingSemiconductor/solid-state device manufacturingThermal insulationHeat losses

The present invention provides a hot plate and substrate processing equipment using the same, wherein the hot plate comprises a central sub hot plate and at least one outer ring sub hot plate located around the central sub hot plate; thermal insulation parts are provided between the central sub hot plate and the outer ring sub hot plate and between two adjacent outer ring sub hot plates, so that the heat conduction between the adjacent sub hot plates can be effectively prevented or reduced by means of the thermal insulation parts. The hot plate and the substrate processing equipment using the same provided in the present invention can effectively compensate for the heat losses in the edge region of the substrate, so as to keep the heating rate the same in each region of the substrate.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

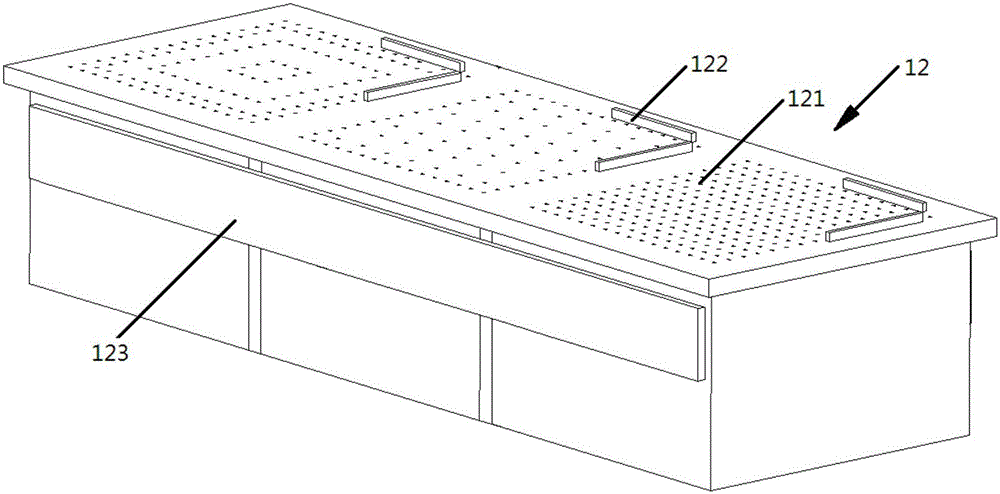

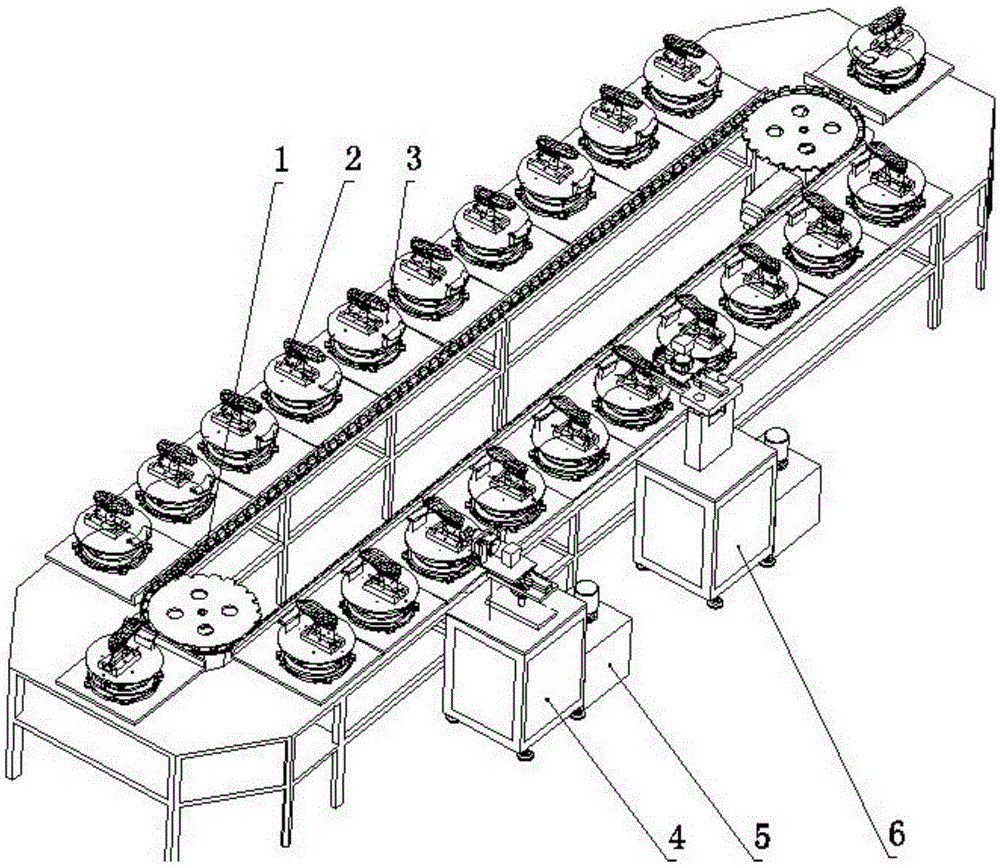

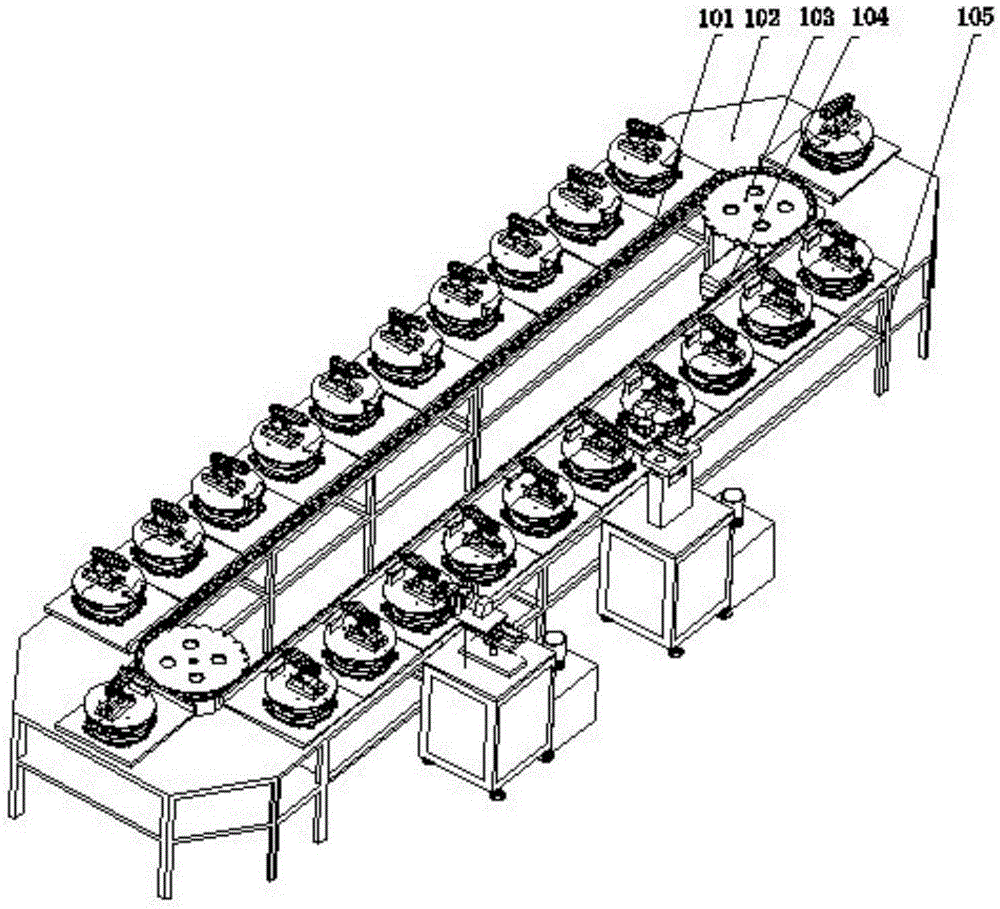

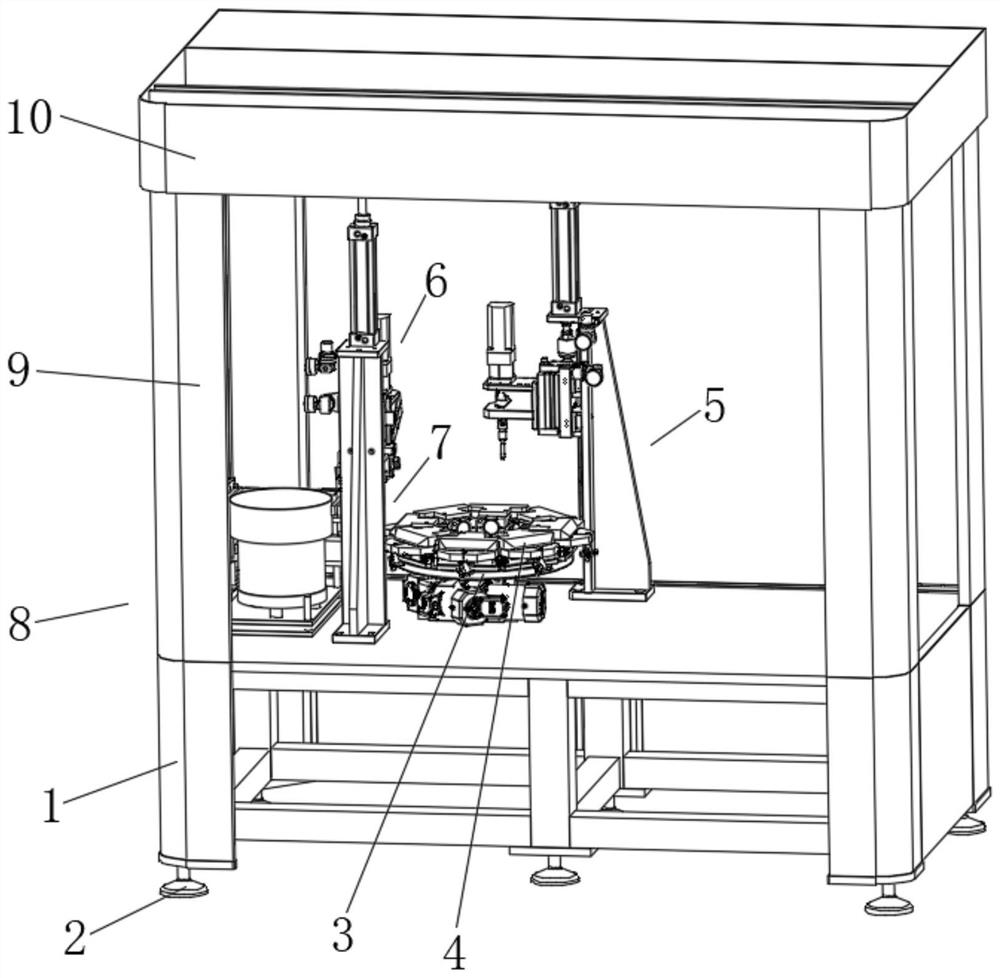

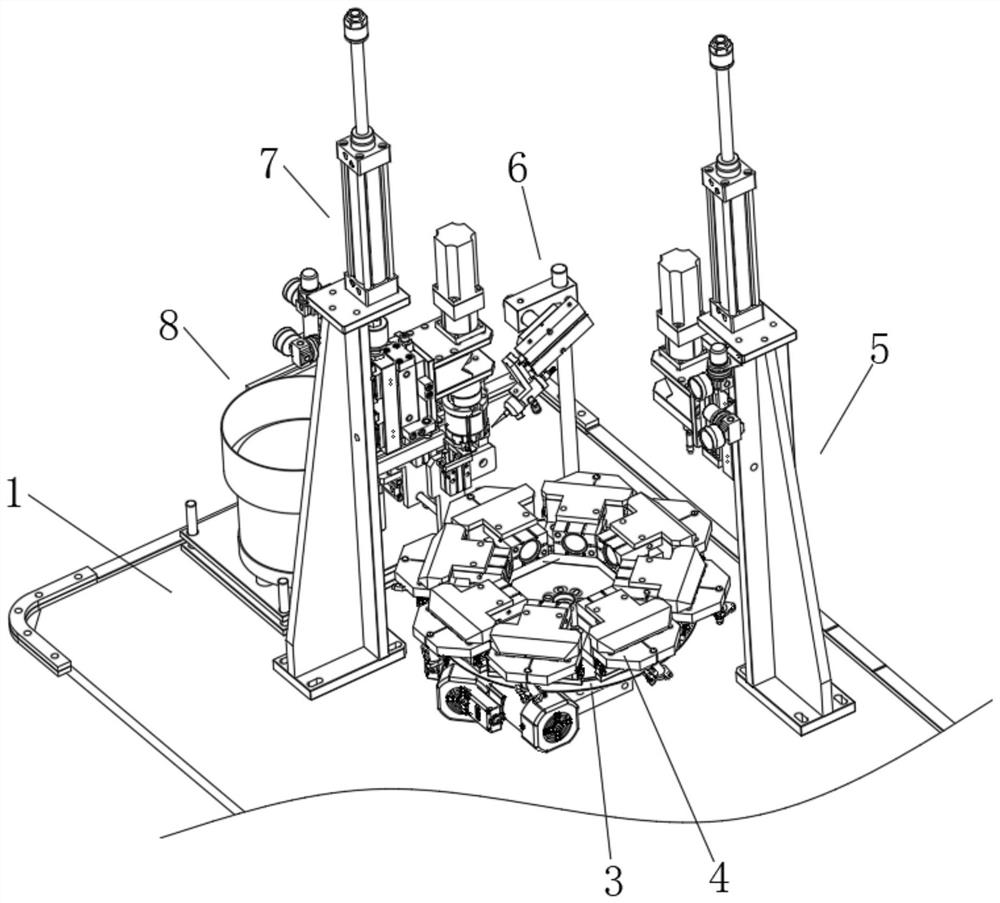

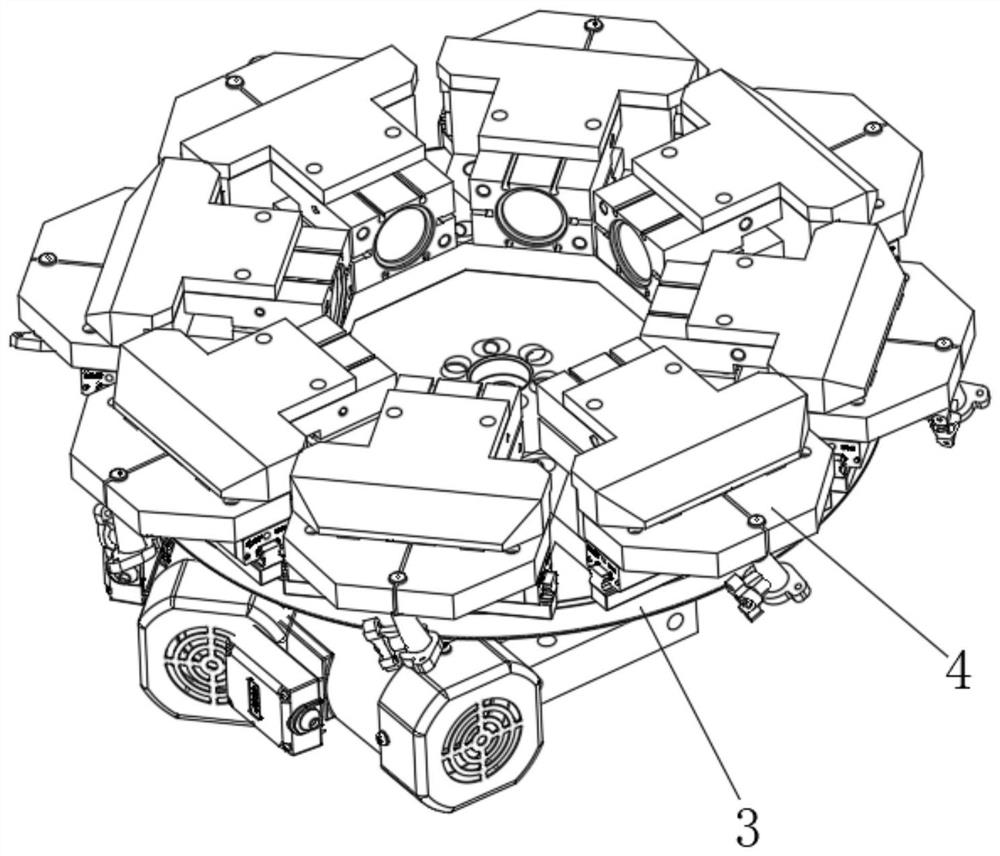

Multi-station production line type upper napping system and processing method thereof

ActiveCN105266280AReduced strength requirementsLow technical requirementsSolesProduction lineTemplate design

The invention relates to a multi-station production line type upper napping system. The multi-station production line type upper napping system comprises an annular transmission mechanism, support plate rotating mechanisms, a toe cap napping machine, dust suction devices and a rotary napping machine, wherein the plurality of support plate rotating mechanisms are radially evenly distributed on the annular transmission mechanism, the rotary napping machine and the toe cap napping machine are disposed on the outer periphery of the annular transmission mechanism at interval, a limit lifting support plate matched with the support plate rotating mechanisms is mounted at the upper end of each of the rotary napping machine and the toe cap napping machine, and each limit lifting support plate is used for lifting the corresponding support plate rotating mechanism to a processing position; each of the rotary napping machine and the toe cap napping machine is connected with one dust suction device. The multi-station production line type upper napping system is reasonable in module structure, convenient to operate, exquisite in template design, capable of achieving whole-process electric-control automatic napping, fast in processing, and capable of guaranteeing uniform quality and increasing product quality and processing efficiency.

Owner:马士通安全设备(天津)有限公司

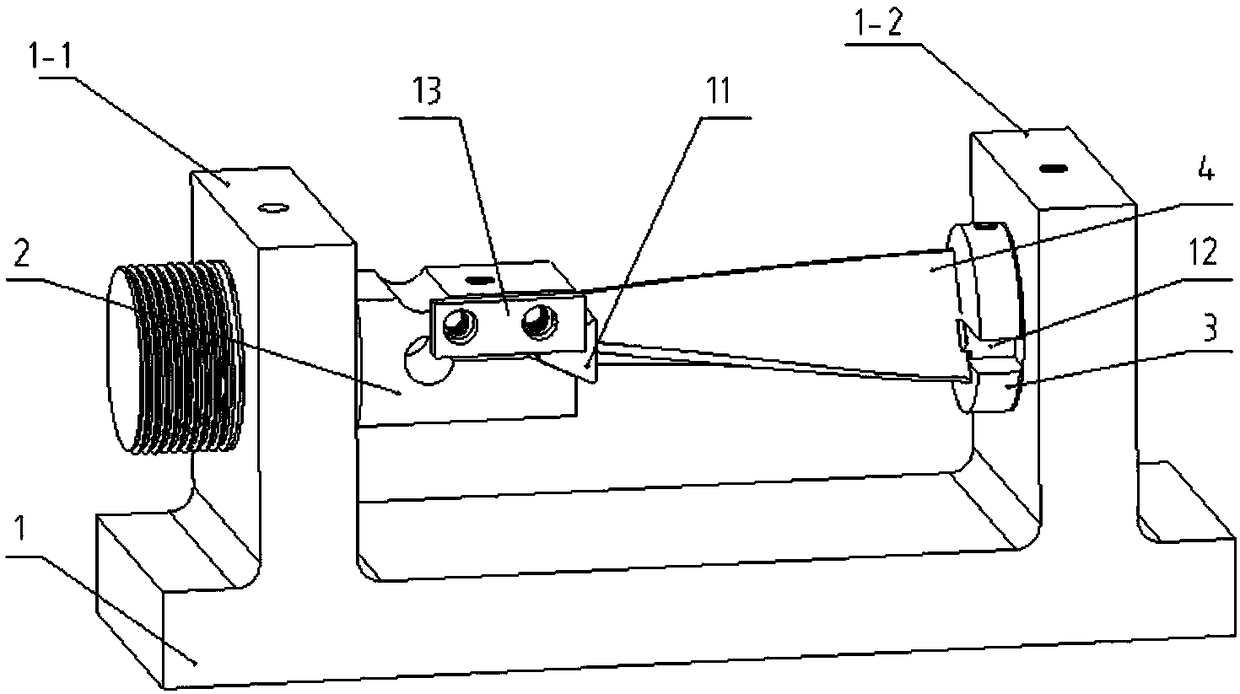

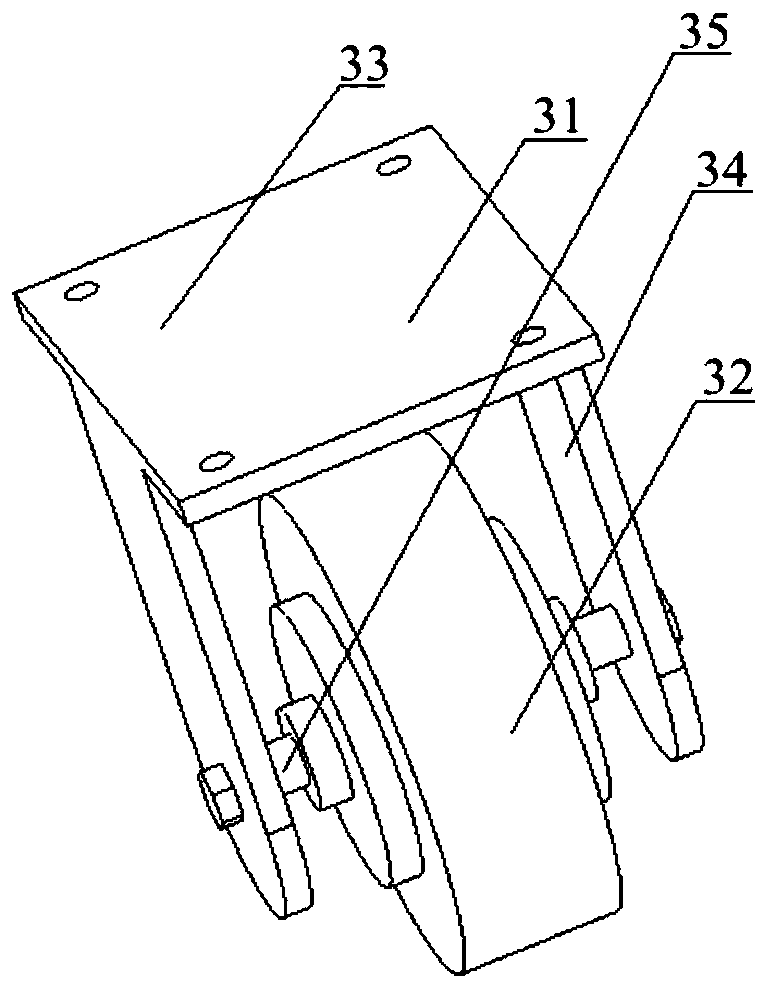

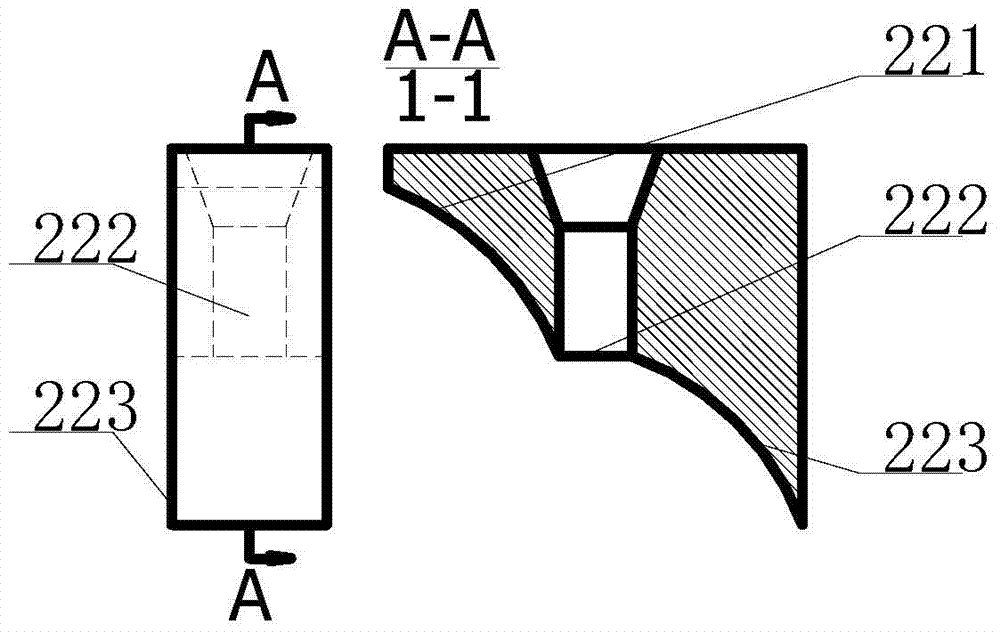

Tool for machining second-stage blade of free turbine of aero-engine

PendingCN108406374AHigh strengthFast cutting speedPositioning apparatusMetal-working holdersAviationEngineering

The invention relates to a tool for machining a second-stage blade of a free turbine of an aero-engine. The tool comprises a base, the left side and the right side of the base are provided with a vertical left supporting part and a vertical right supporting part respectively, a chuck is arranged on the left supporting part, and a V-shaped toothed surface groove is formed in the right end face of the chuck; a top sleeve is arranged on the inner side face of the right supporting part, and a rectangular groove is formed in the left end face of the top sleeve; and a workbench at the right end of the second-stage blade is fixedly matched with the rectangular groove, and the V-shaped toothed surface groove is fixedly matched with a tenon at the left end of the second-stage blade. By means of thetool, finish machining on to-be-machined surfaces of the secondary blade can be completed on a three-axis machining center, and dependence of an existing machining method on a four-axis machining center or manual machining is avoided; the efficiency of machining the secondary blade by using the tool is high, and time is saved; and on the premise of ensuring the qualified rate of the quality of the secondary blade, the machining quality of the to-be-machined surfaces of the secondary blade is uniform.

Owner:CHINA HANGFA CHANGZHOU LANXIANG MACHINERY CO LTD

Printed Circuit Board and Method for Processing Printed Circuit Board

InactiveUS20080230512A1Low production costUniform processing qualityLight absorption dielectricsLayered productsElectrical conductorEngineering

The invention is to provide a printed circuit board in which advance of packaging density of the printed circuit board and reduction in production cost can be attained while processing quality can be made uniform, a method for processing the printed circuit board and a method for producing the printed circuit board.There is provided a printed circuit board including an alternate laminate of electric conductor layers and electrically insulating layers, wherein a coating layer capable of absorbing laser light but insoluble in an etching solution dissolving the electric conductor layers is provided on a front surface of a first one of the electric conductor layers. In this case, the coating layer may be provided on a front surface of a rear one of the electric conductor layers. Each of the electric conductor layers may contain Cu as a main component while the coating layer may contain CuO as a main component. The coating layer may have a thickness not thinner than 0.6 μm.

Owner:HITACHI SEIKO LTD

Hot-melting welding device of plastic composite pipe of steel wire framework

The invention discloses a hot-melting welding device of a plastic composite pipe of a steel wire framework, and belongs to the technical field of comprehensive machining. The hot-melting welding device solves the problems that at present, in a butt welding tool adopted when manual hot-melting welding is carried out on a plastic composite pipe of a steel wire framework, in the butt welding process,the axial application pressure to the pipe is not symmetric, heating is not uniform, and the schedule during batch operation treatment is slow. A lead screw is sequentially mounted on a moving body and a screw sleeve in a penetrating manner. The lead screw is rotationally and fixedly connected to the moving body. The left ends of two guide rods are fixedly connected to the moving body. The rightends of the two guide rods are mounted in a guide body in a penetrating manner. A graduated pipe is mounted on the screw sleeve in a sleeved manner. A spring is arranged between the graduated pipe andthe screw sleeve. A pipe cover is mounted on the screw sleeve in a sleeving manner. The right end of the graduated pipe is located between the screw sleeve and the pipe cover. A jig is fixed above the moving body through a first clamp ring, and a second clamp ring provided with a pipeline in a penetrating manner is fixed above the guide body. A heating device is arranged between a pipe head and the pipeline. The hot-melting welding device is used for hot-melting welding of the plastic composite pipe of the steel wire framework.

Owner:HARBIN JIANCHENG GRP

Pear end-cutting device

ActiveCN108081330AGood for neat cuttingUniform processing qualityMetal working apparatusFood treatmentPEARPulp and paper industry

The invention relates to the technical field of fruit processing, in particular to a pear end-cutting device. The pear end-cutting device comprises a mounting frame, a fixing ring, a cutting device and a controller; the fixing ring is fixed to the mounting frame and sleeved with an annular air bag; the annular air bag communicates with an external air source; the cutting device is arranged on oneside of the fixing ring and comprises an air cylinder, an upper blade and a lower blade, wherein the upper blade and the lower blade are horizontally arranged in the up-down direction; the air cylinder is fixed to the mounting frame; the output end of the air cylinder is fixedly connected with the upper blade and the lower blade; the controller can control the external air source and the air cylinder to act; and the air cylinder can push the upper blade and the lower blade to the fixing ring, thus the upper blade skims over the upper portion of the fixing ring, and the lower blade skims over the lower portion of the fixing ring. Pears are placed on the fixing ring, under control of the controller, the annular air bag is inflated through the external air source, and thus the annular air baglocks the pears, so that the pears are fixed stably so as to facilitate neat cutting in the subsequent cutting working procedure, the uniform processing quality is guaranteed, and the cutting efficiency is improved.

Owner:连江县维佳工业设计有限公司

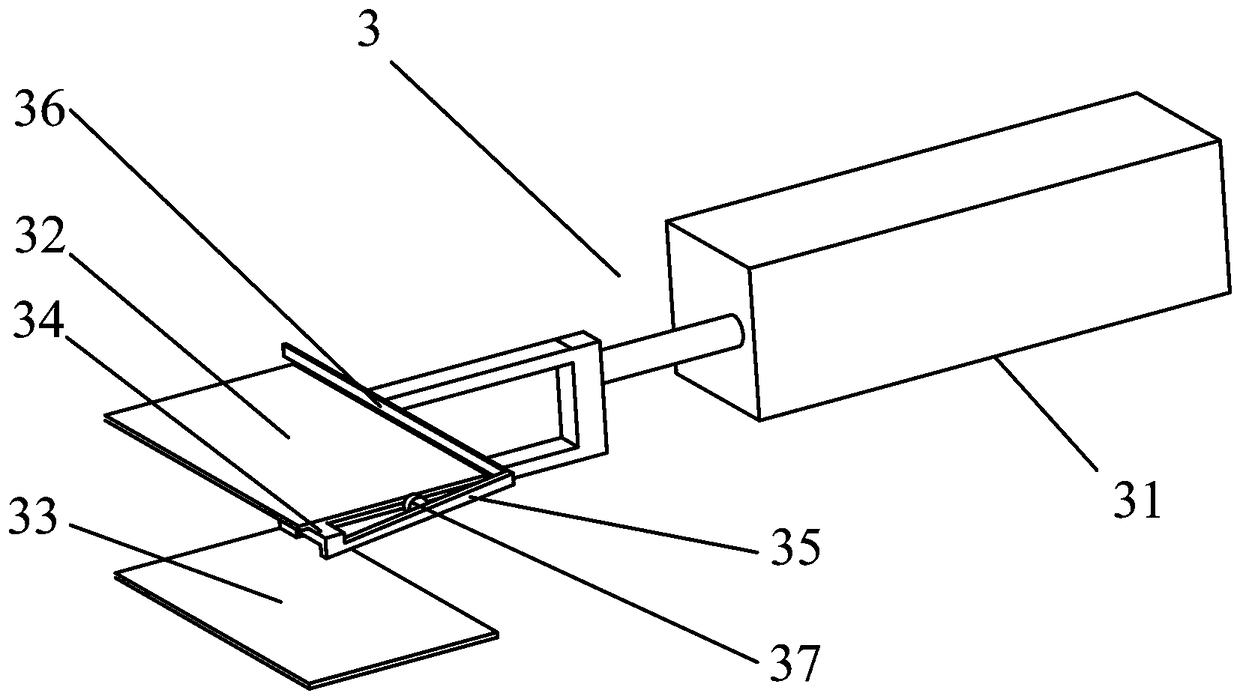

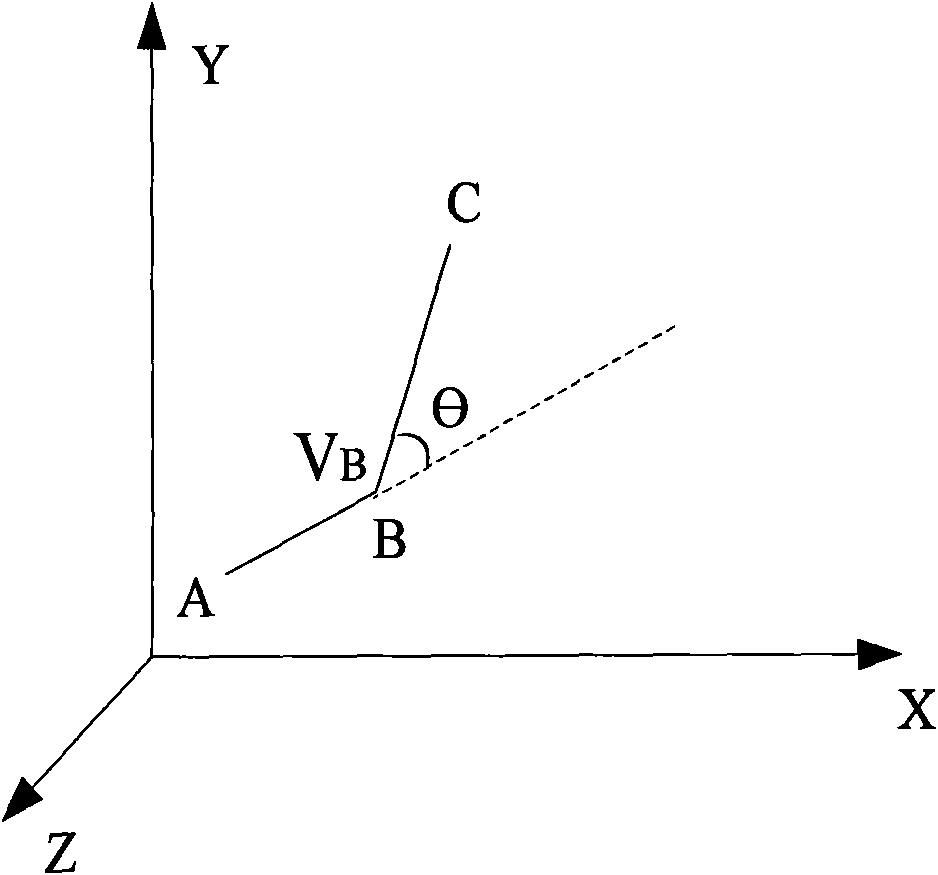

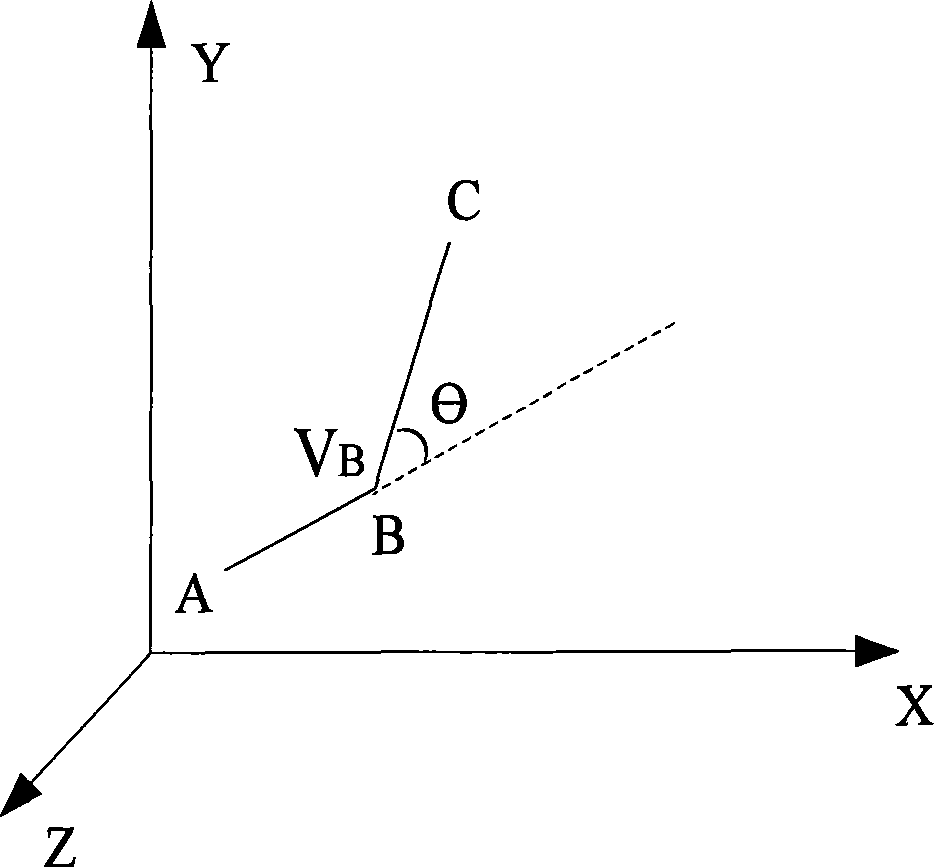

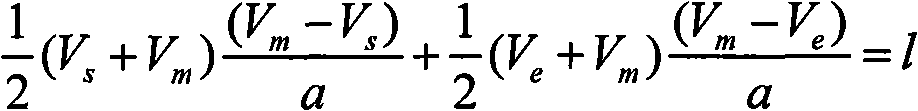

Application of acceleration linear high-speed interpolation algorithm in numerical control machine

InactiveCN101807067AImprove processing qualityImprove processing efficiencyProgramme controlComputer controlNumerical controlMachine tool

The invention provides application of an acceleration linear high-speed interpolation algorithm in a numerical control machine for calculating the connecting speed of a processing path. The application relates to two problems, one is the servo capability of the machine, which is determined by the performance of the machine per se, and the other is an included angle between two adjacent paths, wherein for the included angle between the two adjacent paths, if the included angle between the two paths is more than 90 degrees, the connecting speed must be set to zero; if the included angle is between 0 and 90 degrees, the corresponding speed is calculated by using the included angles between the two paths, the connecting speed at the moment is not zero, and the connecting speed is higher while the included angle is smaller; and if the included angle is zero, and speed is not reduced at the point, which is the maximum speed permitted by the machine. With respect to the acceleration linear algorithm without high-speed connection, the connecting speed is calculated according to the included angle without reducing to zero each time, and is hardly reduced particularly when the included angle is smaller, so that the processing efficiency is greatly improved.

Owner:SHANGHAI WEIHONG ELECTRONICS TECH +1

Automatic mounting and dispensing structure for nozzle

InactiveCN111842017AImprove the installation effectThe installation effect is tightLiquid surface applicatorsMaterial gluingManufacturing engineeringManual handling

Owner:中山市优梦自动化设备有限公司

Substrate processing apparatus and substrate processing method

ActiveUS9793176B2Easy dischargeShorten the time periodSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineering

The temperature of a chemical liquid supplied to a pot is detected while allowing a processing liquid discharge port to discharge the chemical liquid toward the pot at a pre-dispensing position. The temperature of the chemical liquid rises in response to the lapse of time. When the temperature of the chemical liquid supplied to the pot reaches a second target temperature, the processing liquid discharge port is allowed to stop the discharge of the chemical liquid. Thereafter, a positional relationship between the processing liquid discharge port and the pot is changed, and the processing liquid discharge port is allowed to discharge the chemical liquid toward the substrate at the processing position.

Owner:DAINIPPON SCREEN MTG CO LTD

Bullet train chassis oxidization film automatic grinding system

ActiveCN109807730AAutomate operationIncrease productivityGrinding carriagesGrinding drivesDrive wheelConstant force

The invention discloses a bullet train chassis oxidization film automatic grinding system. The bullet train chassis oxidization film automatic grinding system comprises a moving device, a grinding device and a workbench; the moving device, a vehicle body supported by the moving device, and a workpiece extending out along the workbench and composed of a bullet train chassis oxidization film are arranged on the workbench; the moving device comprises a driving wheel assembly, a driven wheel assembly and an automatic guiding assembly; the grinding device comprises a plurality of steel wire steelsarranged on the moving device; and each steel wire wheel is drive by a grinding motor, constant force is loaded for the grinding device through a counter weight at a constant mass, and the grinding device is pressed of the machined surface of the workpiece, and therefore grinding on the surface of the workpiece is achieved. According to the bullet train chassis oxidization film grinding device, due to the fact that the constant force and a constant rotating speed are adopted for machining the to-be-machined surface, the machining quality of the machined surface is uniform, the surface roughness meets the grinding requirement, the whole grinding process is controlled by a PLC, and the production efficiency is effectively improved.

Owner:YANSHAN UNIV

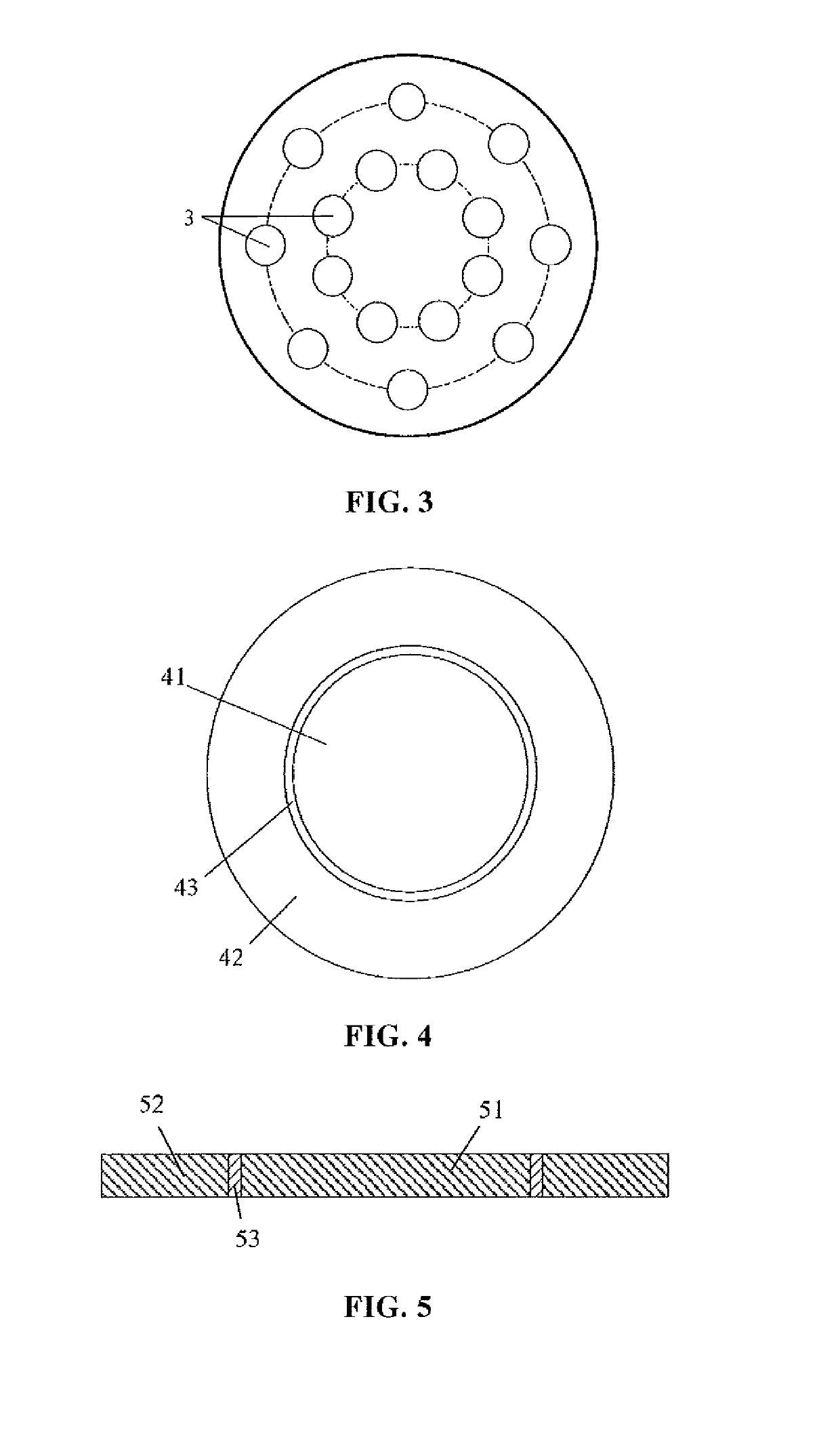

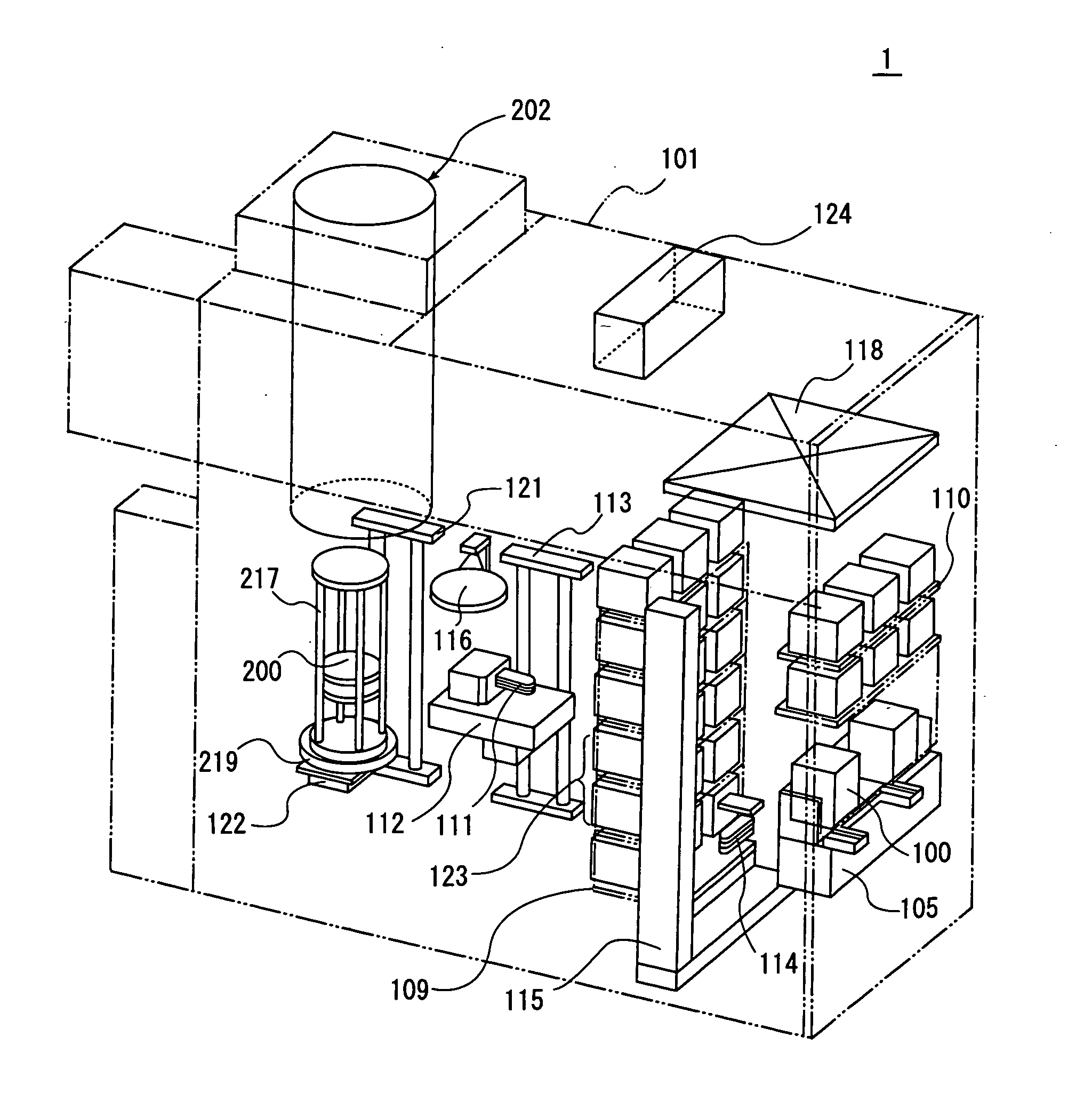

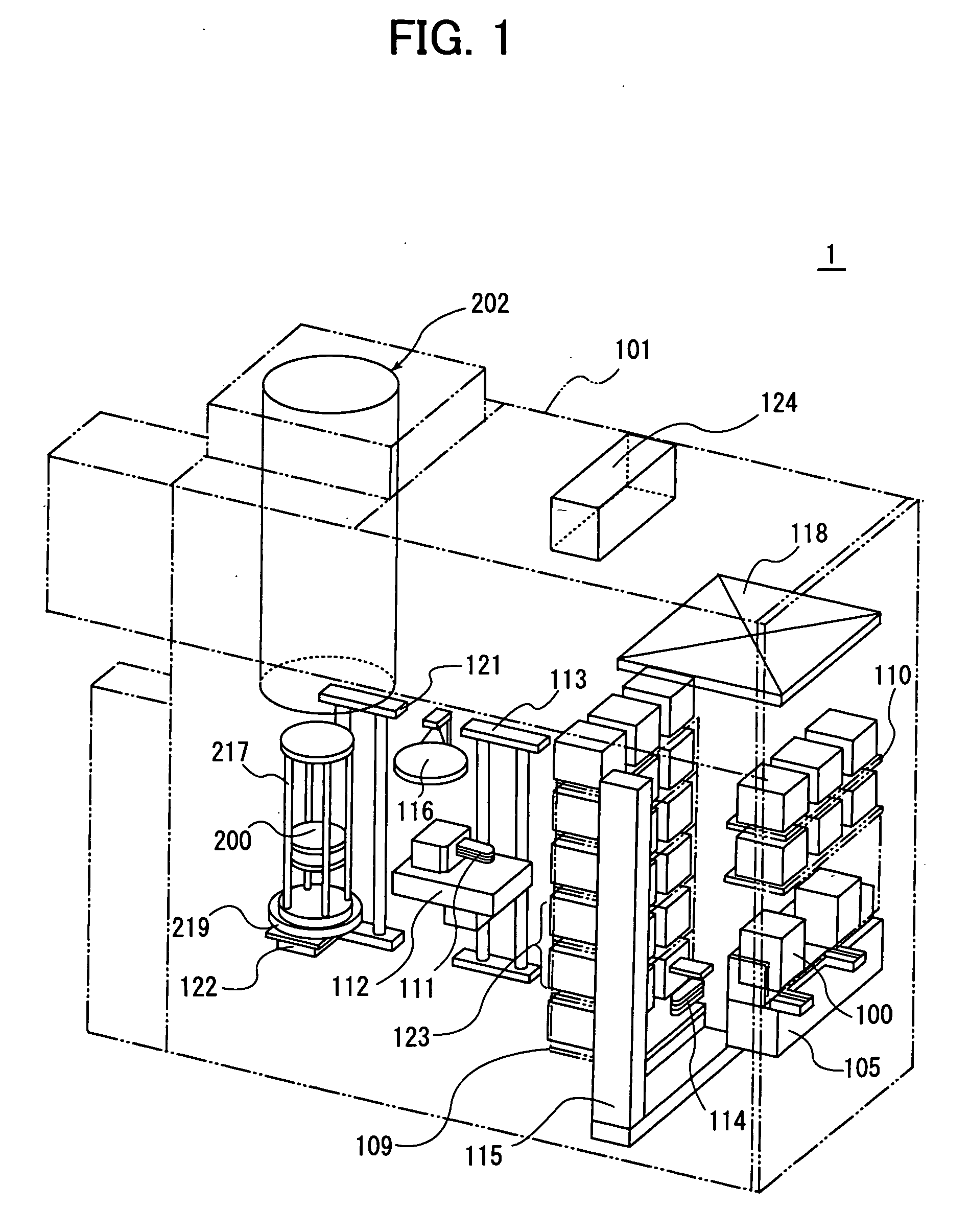

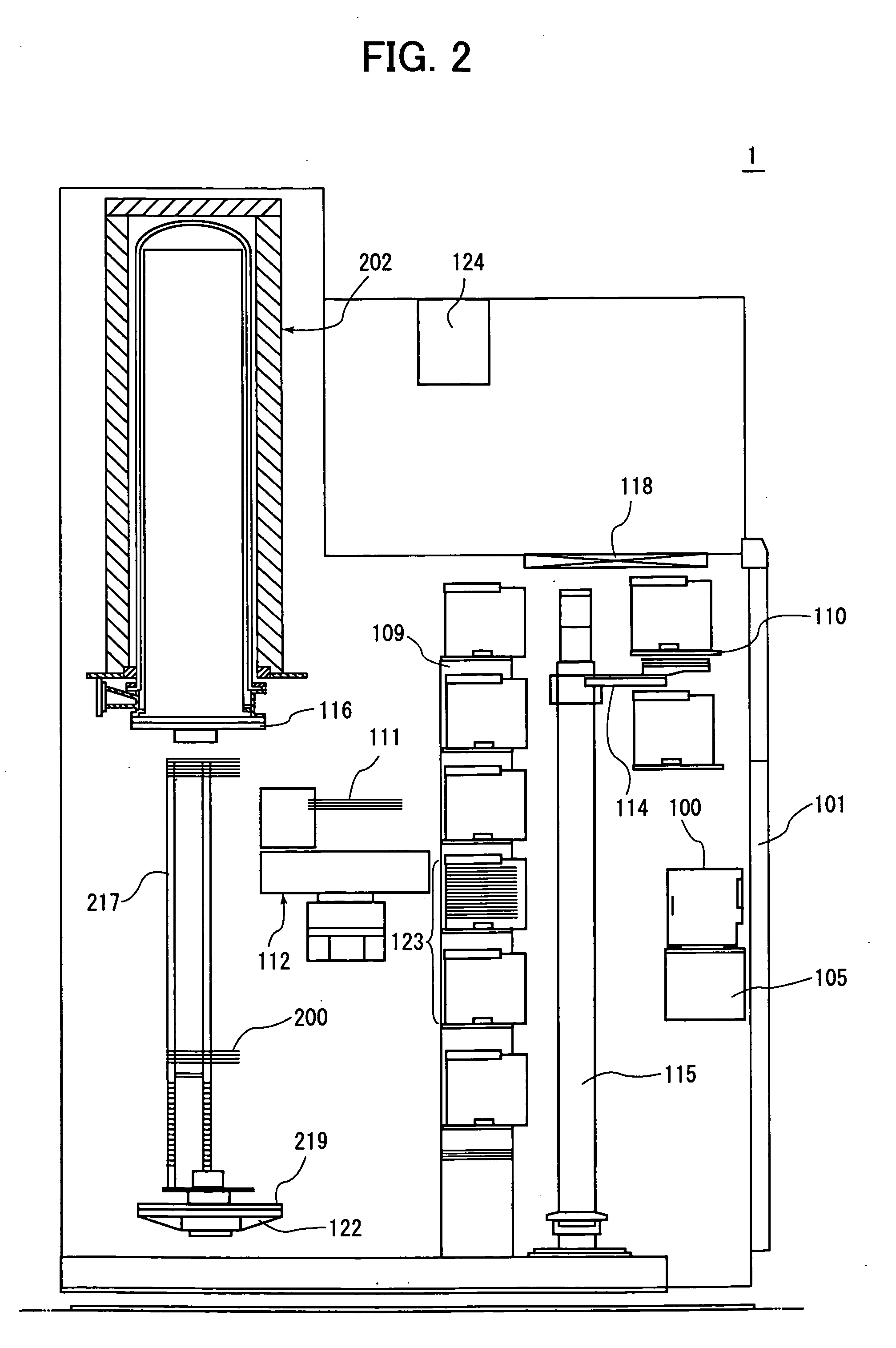

Substrate processing apparatus

ActiveUS20090241835A1Uniform processing qualityUniform qualitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh frequency powerNuclear engineering

A substrate processing apparatus includes a processing chamber in which a substrate is mounted, a gas supply unit that supplies processing gas into the processing chamber, a gas exhaust unit that exhausts atmospheric gas in the processing chamber, first and second electrodes to which high-frequency power is applied to set the processing gas to an active state. Each of the first and second electrodes includes a core wire formed of a metal and plural pipe bodies that are joined to one another through the core wire so as to be bendable, and less thermally deformed than the core wire.

Owner:KOKUSA ELECTRIC CO LTD

Turbulent flow simulation polishing device and method for artificial joint-like surface

ActiveCN106625277BHigh polishing precisionUniform processing qualityAbrasive machine appurtenancesAbrasive blasting machinesElectricityArtificial joints

The invention discloses an artificial joint-like piece curved surface turbulence simulating polishing device and a method thereof. The device comprises a glass constraint component, a profiling electromagnetic wave heater, a temperature detection device, a supporting frame and an electromagnetic wave controller, wherein the glass constraint component is arranged outside an artificial joint-like piece in a sleeving way; the inner surface of the glass constraint component and the curved surface of the artificial joint-like piece form a profiling runner with uniform thickness; the profiling electromagnetic wave heater is arranged on one side of the glass constraint component; the profiling electromagnetic wave heater comprises an outer cover, heating sources, a concave lens and a convex lens; and each heating source of the profiling electromagnetic wave heater is electrically connected with the electromagnetic wave controller and is independently controlled by the electromagnetic wave controller. One heating source is placed on the side surface of the glass constraint component, the turbulence energy and the speed of abrasive flow cutting fluid are increased, and the linear loss and the head loss of the abrasive flow in the profiling runner are compensated, so that the whole processing effect is improved and the surface processing quality of the artificial joint-like piece is more uniform.

Owner:ZHEJIANG UNIV OF TECH

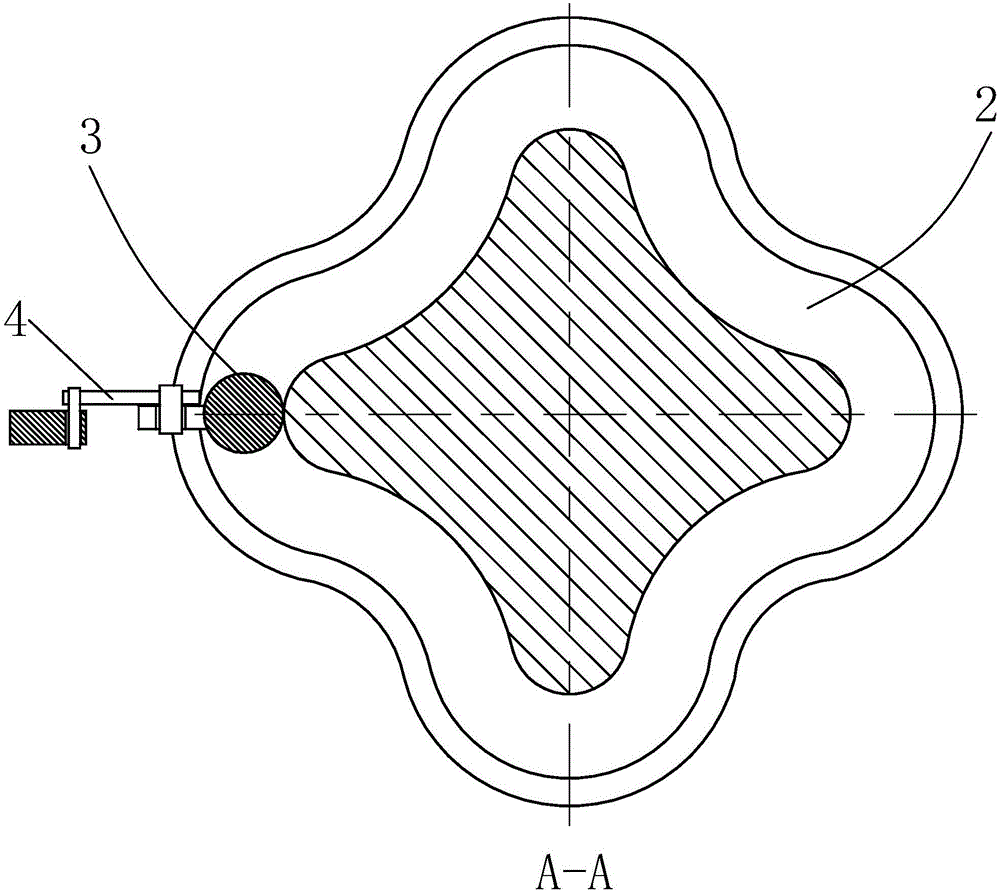

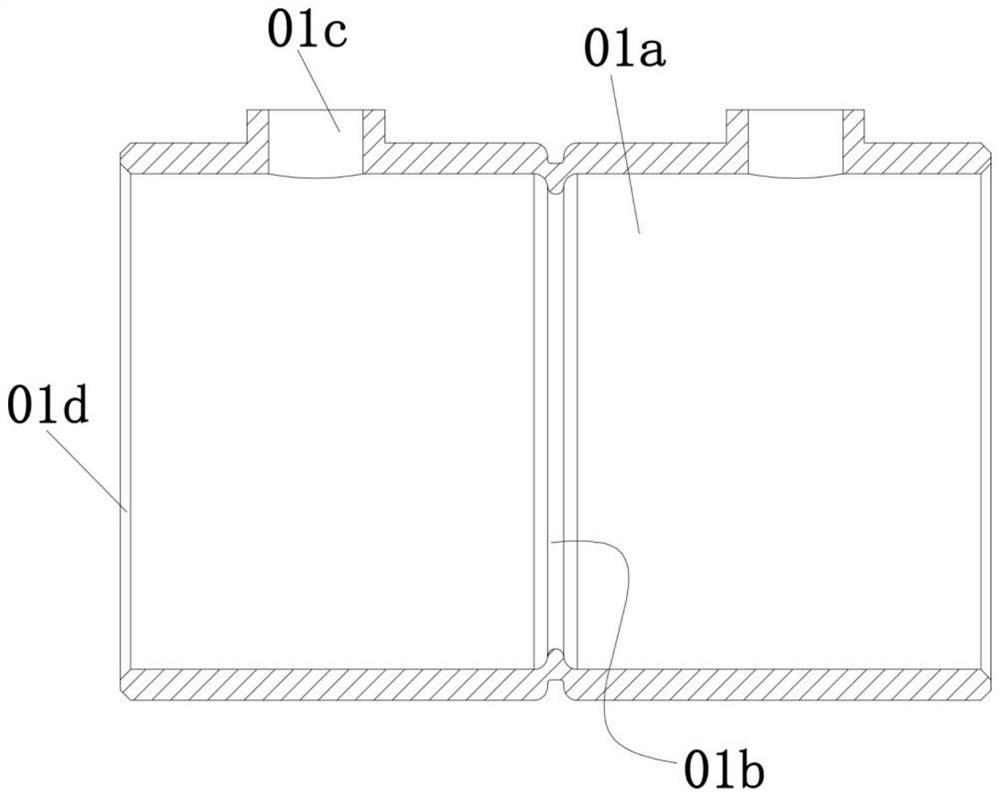

Device for self-nanometerization of the surface of rod-shaped metal materials

The invention discloses a rod-shaped metal material surface self-nanocrystallization device. The rod-shaped metal material surface self-nanocrystallization device comprises a metal cylinder, a driving device, baffles on the two sides, a baffle adjusting device, fixtures on the two sides and projectiles, wherein the whole metal cylinder is through in a ring shape, no bottom face exists, a closed space is formed between the metal cylinder and the baffles on the two sides, and a projectile loading device is arranged on the metal cylinder; the fixtures on the two sides are attached to the baffles on the two sides respectively, the driving device drives the metal cylinder to conduct high-speed revolution surrounding one point O1 deviated from the circle center in the metal cylinder, and meanwhile the O1 is also the shaft center of the rod-shaped metal to be machined. The rod-shaped metal material surface self-nanocrystallization device has the advantages that a simple mechanical device and a power device are adopted, the surface of a machined sample is uniformly impacted continuously and periodically by a plurality of spherical metal projectiles obtaining enough kinetic energy, therefore, crystalline grains in a certain depth range on the surface of the sample generate violent severe plastic deformation and are refined to a nanometer scale, a special microstructure with the crystalline grain size distributed in a gradient mode is obtained, and finally the material surface nanocrystallization modification is achieved.

Owner:南通河海大学海洋与近海工程研究院 +2

Automatic sleeve machining device and machining method thereof

ActiveCN114227268AReduce labor costsUniform processing qualityOther manufacturing equipments/toolsEmbossing decorationsStructural engineeringManufacturing engineering

The invention discloses an automatic casing pipe machining device and a machining method.The automatic casing pipe machining device comprises a table frame, a table plate is arranged on the table frame, and a detection mechanism, a casing pipe clamping mechanism, a character impressing mechanism, a rib rolling mechanism, a punching conveying mechanism and a tapping mechanism are arranged on the table plate; the detection mechanism is used for detecting whether inner chamfers exist at the two ends of the casing pipe or not and feeding the casing pipe with the inner chamfers at the two ends into the casing pipe clamping mechanism; the sleeve clamping mechanism is used for transversely fixing a sleeve; the character impressing mechanism is used for impressing characters on the outer side of the circumference of the sleeve; the rib rolling mechanism is used for rolling the inner convex ribs of the sleeve; the punching conveying mechanism is used for receiving the casing pipe in the casing pipe clamping mechanism, completing punching and then sending the punched casing pipe into the tapping mechanism, the tapping mechanism is used for tapping, the automatic casing pipe machining device can achieve casing pipe machining, then manual operation is replaced, the labor cost is reduced, and meanwhile it is guaranteed that the machining quality of the casing pipe is unified.

Owner:NINGBO SANLING ELECTRONICS

A laser cutting system

ActiveCN105710539BEasy to operateGuaranteed laser processing effectLaser beam welding apparatusLight beamLaser beam machining

Owner:HANS LASER TECH IND GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com