Apparatus and method for extending shelf-life and prevention of discoloration of meat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

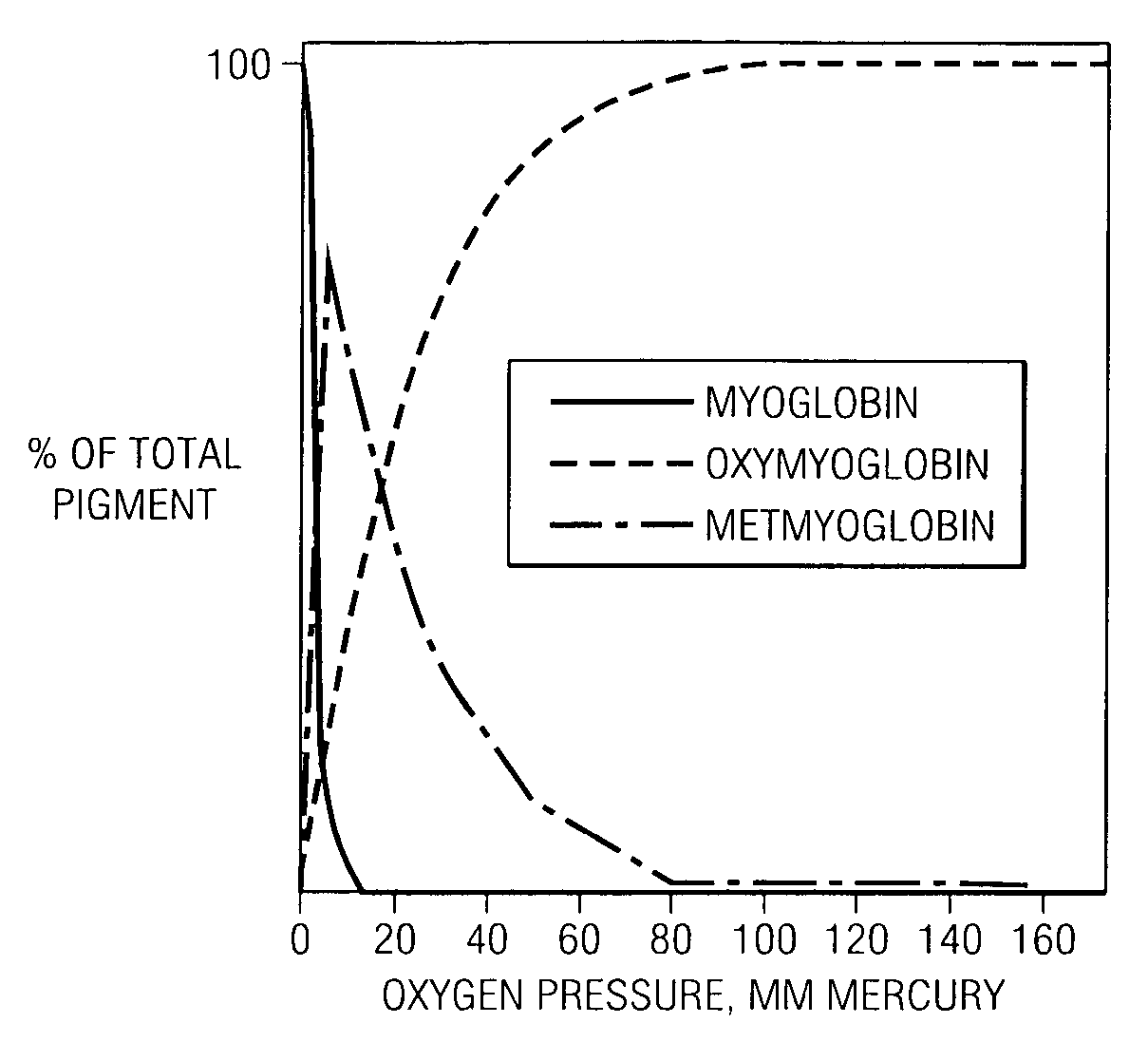

Image

Examples

experiment 1

[0144] a. Oxygen Concentration

[0145] The O2 concentration in every fifth bag at initial packaging was 150-200 ppm. After being stored for one week at 2° C. the O2 concentration in most bags with O2 scavengers was 0 ppm, except for bags with treatments H, G, and G1 with beef (Table 2b). Bags without O2 scavengers contained small amounts of O2, occasionally up to 1150 ppm.

[0146] b. Visual Properties

[0147] Pork color scores in all treatments ranged from 2.4 to 3.3, and would be considered normal except in treatment D1, where the chops were slightly pale. (Table 2c) Chops in all treatments could be considered to be without discoloration, except in treatments A and B, where the chops were slightly discolored. Chops in all treatments were rated desirable to extremely desirable except in treatments A, B, and D1. Chops in treatment A were rated slightly undesirable and chops in treatments B and D1 were rated slightly desirable. (Table 2c) Beef steaks in all treatments were perceived to b...

experiment 2

[0151] a. Oxygen Concentration

[0152] The initial O2 concentration in every fifth bag was about 120 ppm.

[0153] After one week of storage, the O2 concentration in all bags was 0 ppm, except for one bag (Bag 2, treatment H) which contained 2650 ppm O2 and was a “leaker” and was consequently eliminated from further evaluation.

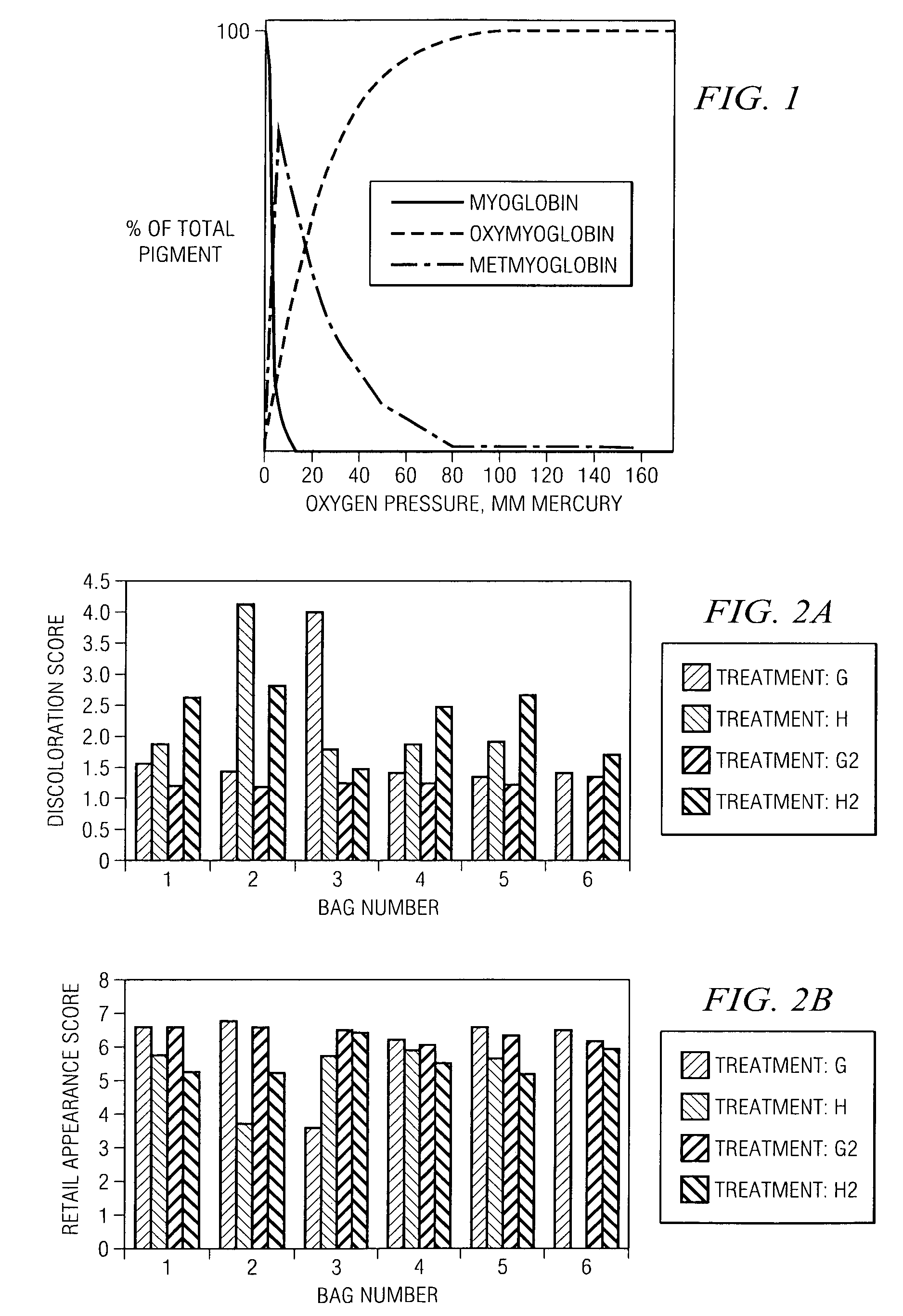

[0154] b. Visual and Reflectance Properties

[0155] Although significant (p<0.05) differences existed between treatments in visual color ratings, all steaks were perceived to be bright cherry red and no differences of practical importance existed. Retail trays containing grids resulted in steaks with greater amounts of surface discoloration. However, no differences in surface discoloration attributable to lidding or over-wrapping were detected. (Table 2c) Consequently, steaks in retail trays containing grids were rated less desirable in retail appearance (p<0.05). However, the magnitudes of these differences in retail appearance were approximately 0.8 of a panel ...

experiment 3

[0157] a. Oxygen Concentration

[0158] The O2 concentration at packaging was approximately 80 ppm. After 7 days of storage at −1.5° C., the O2 concentration in all bags was 0 ppm.

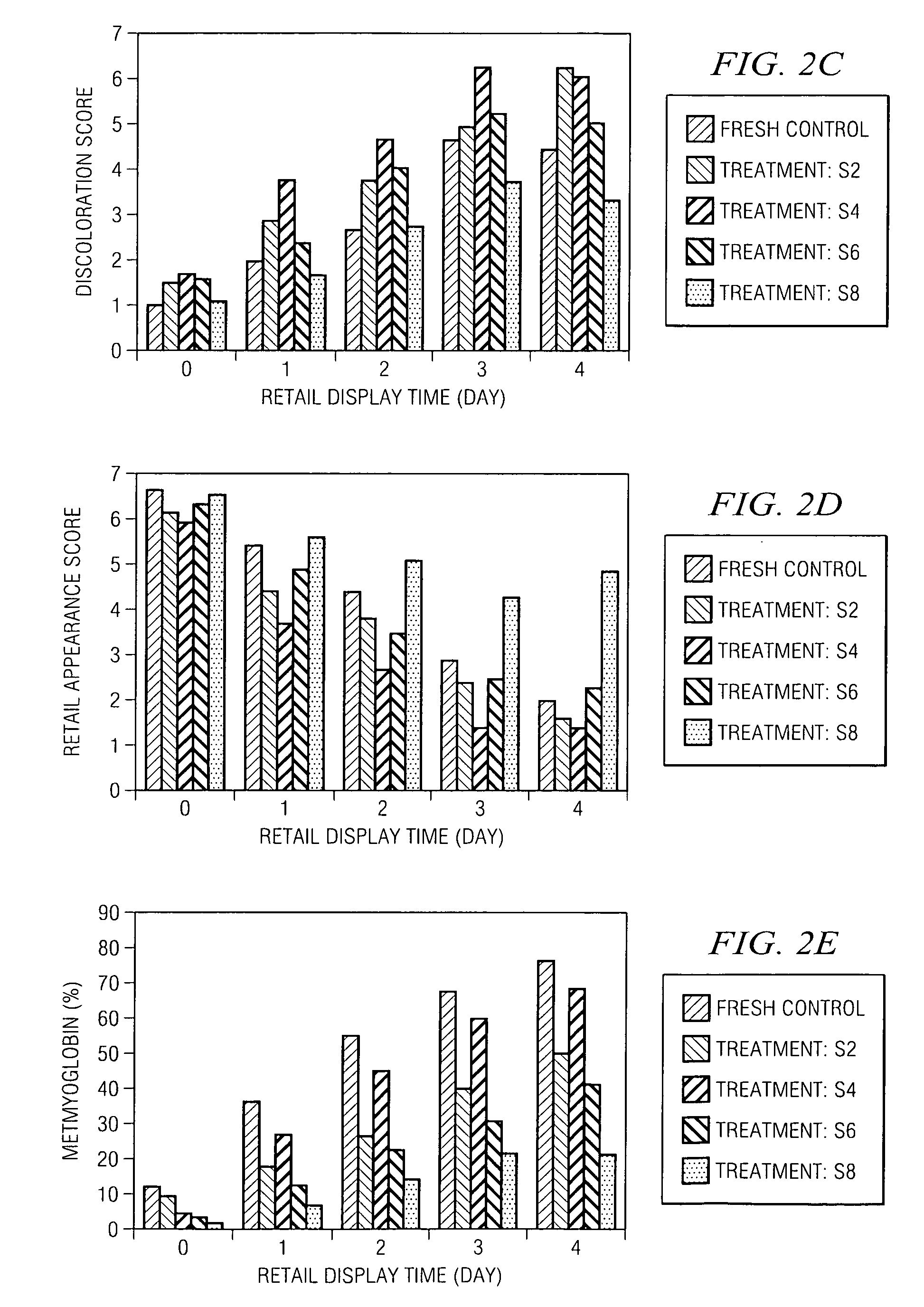

[0159] b. Visual and Reflectance Properties

[0160] Steaks in retail trays containing O2 scavengers with absorbing capacity of 2 scavengers with 800 mL of absorbing capacity also discolored at essentially the same rate as the un-stored controls, but did not discolor as extensively. Un-stored controls deteriorated rapidly in retail appearance and had a retail case-life of 2.5 days. (FIG. 2D) Steaks stored with less than or equal to six O2 scavengers resulting in O2 absorbing capacity of less than 600 mL also deteriorated rapidly in retail appearance and had shorter retail-case lives than un-stored controls. Steaks stored with O2 scavengers having absorbing capacity of >600 mL deteriorated more slowly in retail appearance and had retail-case lives in excess of 4 days. (FIG. 2D) The rate of metmyoglobin and oxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com