Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

212results about How to "Increased longitudinal stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microsurgical balloon with protective reinforcement

ActiveUS7270673B2Increase stiffnessIncreased longitudinal stiffnessStentsBalloon catheterSurgical department

Owner:BOSTON SCI SCIMED INC

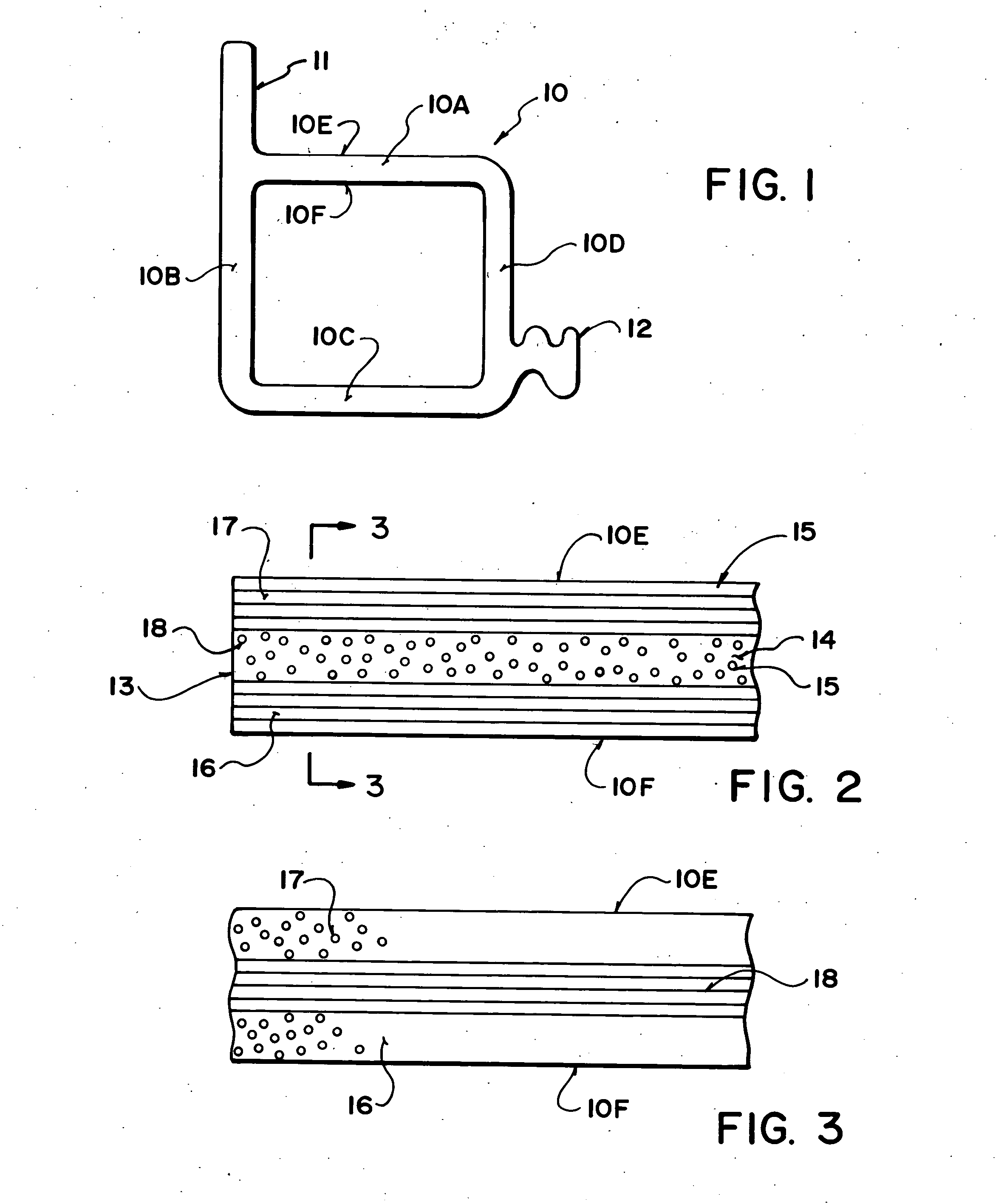

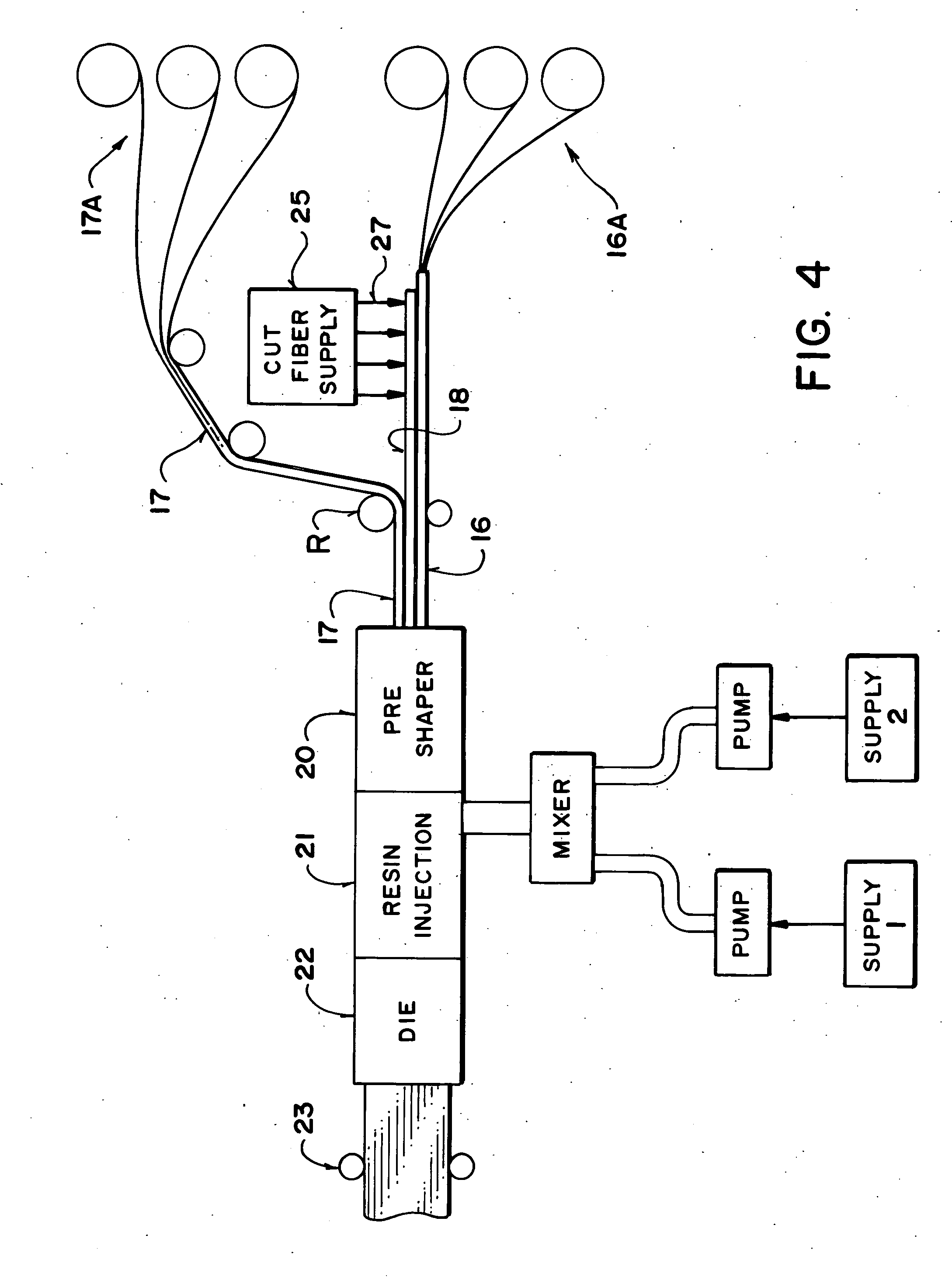

Pultruded part reinforced by longitudinal and transverse fibers and a method of manufacturing thereof

InactiveUS20050008804A1Excessive degradationSuitablePedestrian/occupant safety arrangementSynthetic resin layered productsCross-linkEngineering

A method for forming a pultruded part includes collating reinforcing fibers by providing a first layer of reinforcing rovings extending in the longitudinal pultrusion direction, applying onto the first layer an intermediate layer of reinforcing fibers at least some of which include at least portions thereof which extend in the transverse direction and covering the intermediate layer with a second layer of rovings extending in the longitudinal direction. Alternatively the transverse fiber layer is formed on the inside surface of a hollow part. To the collated fibers is applied a urethane resin so as to permeate through the layers and the materials are passed through a die to form a thermo-set cross-linked poly-urethane. The transverse layer or layers are relatively thin having a weight less than or equal to 0.5 ounces per square foot and more preferably as low as 0.25 ounces or 0.1 ounces.

Owner:OMNIGLASS

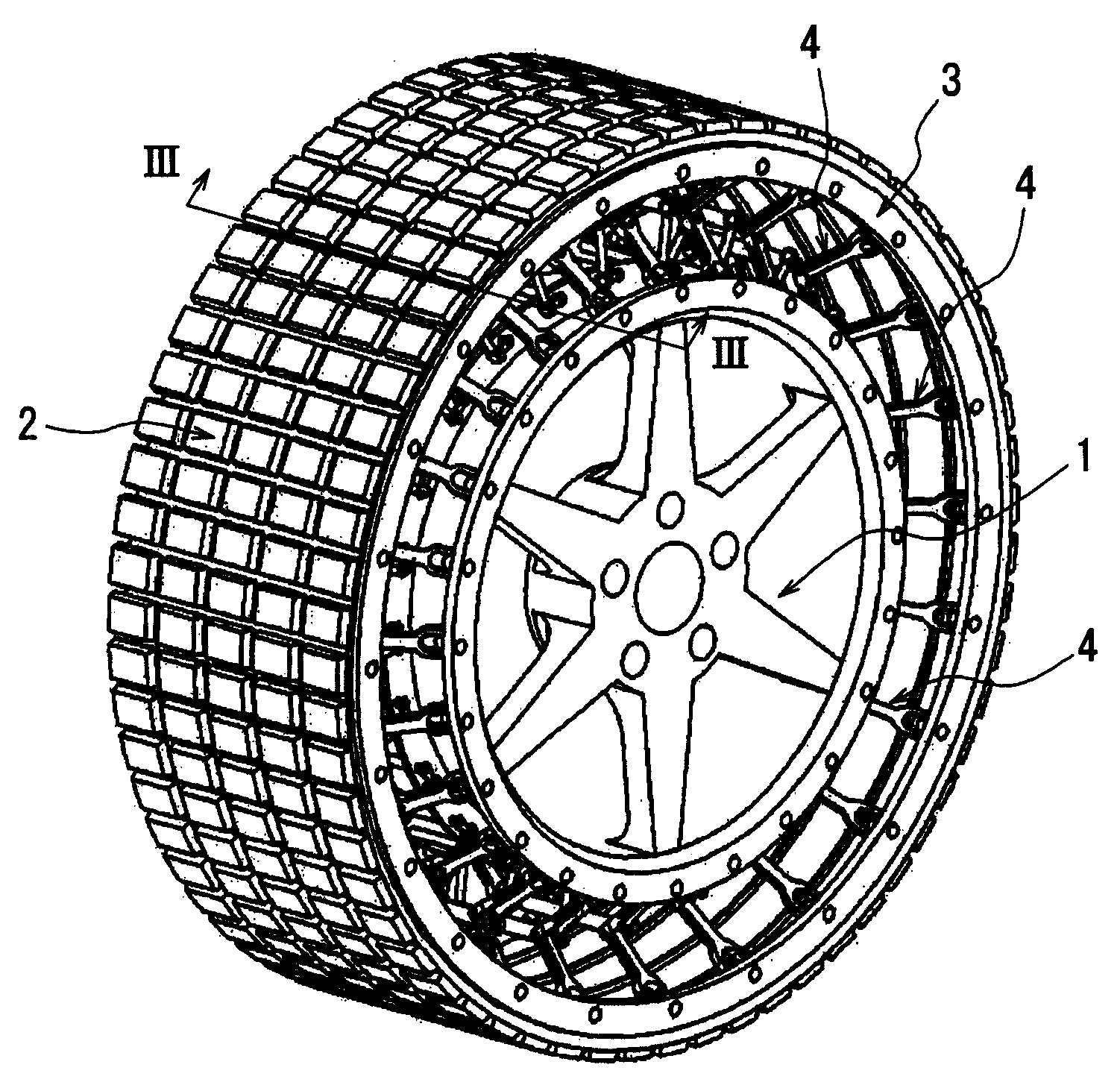

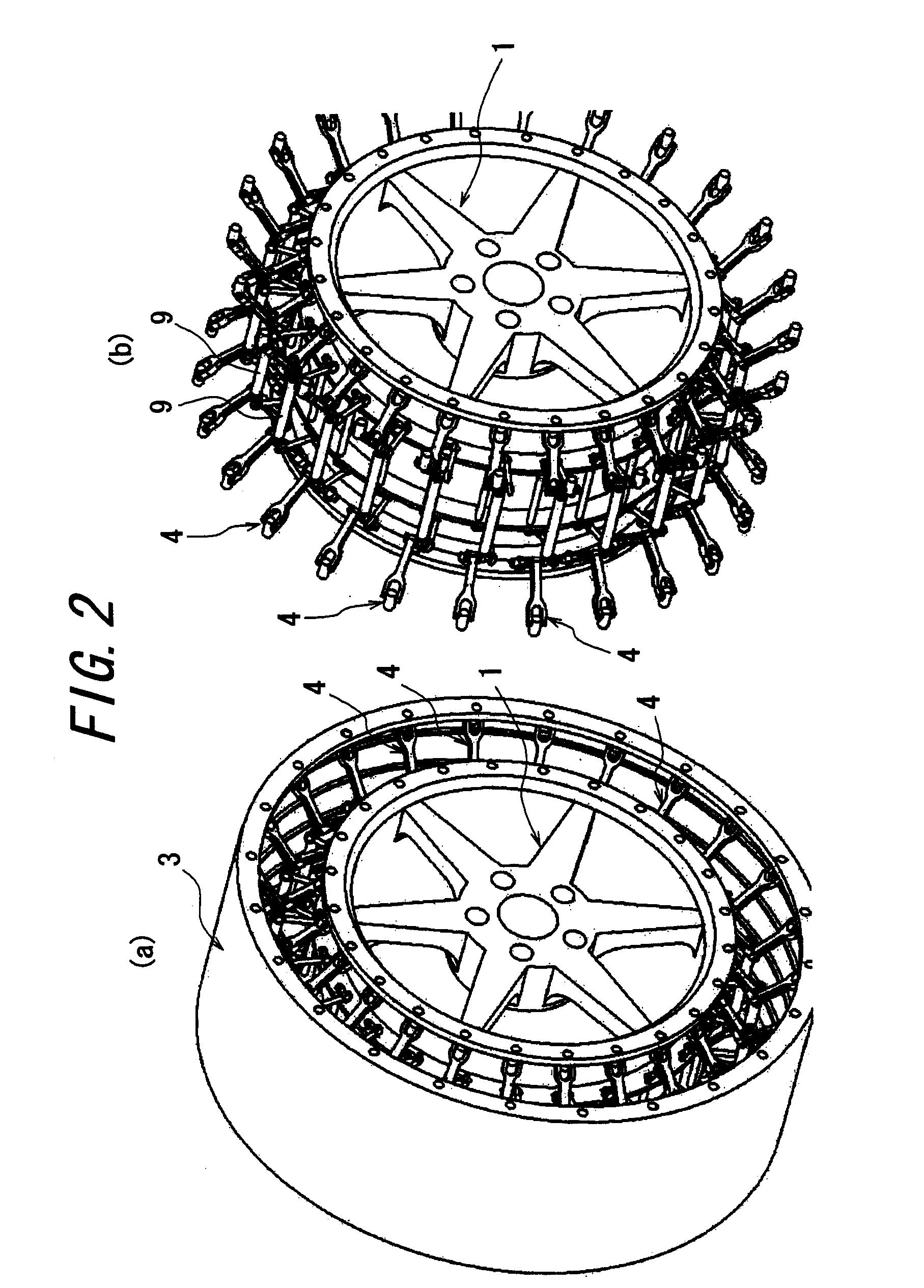

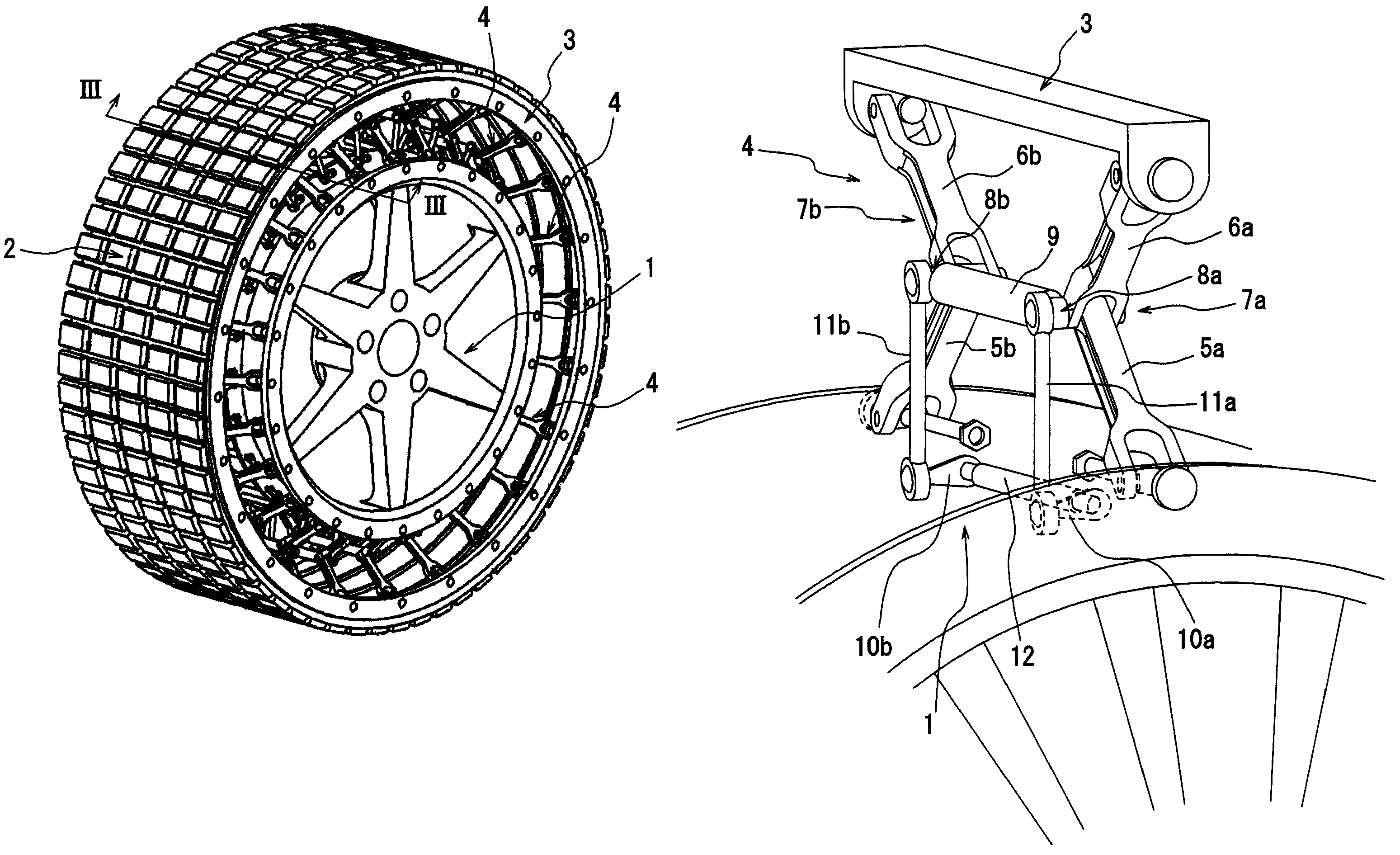

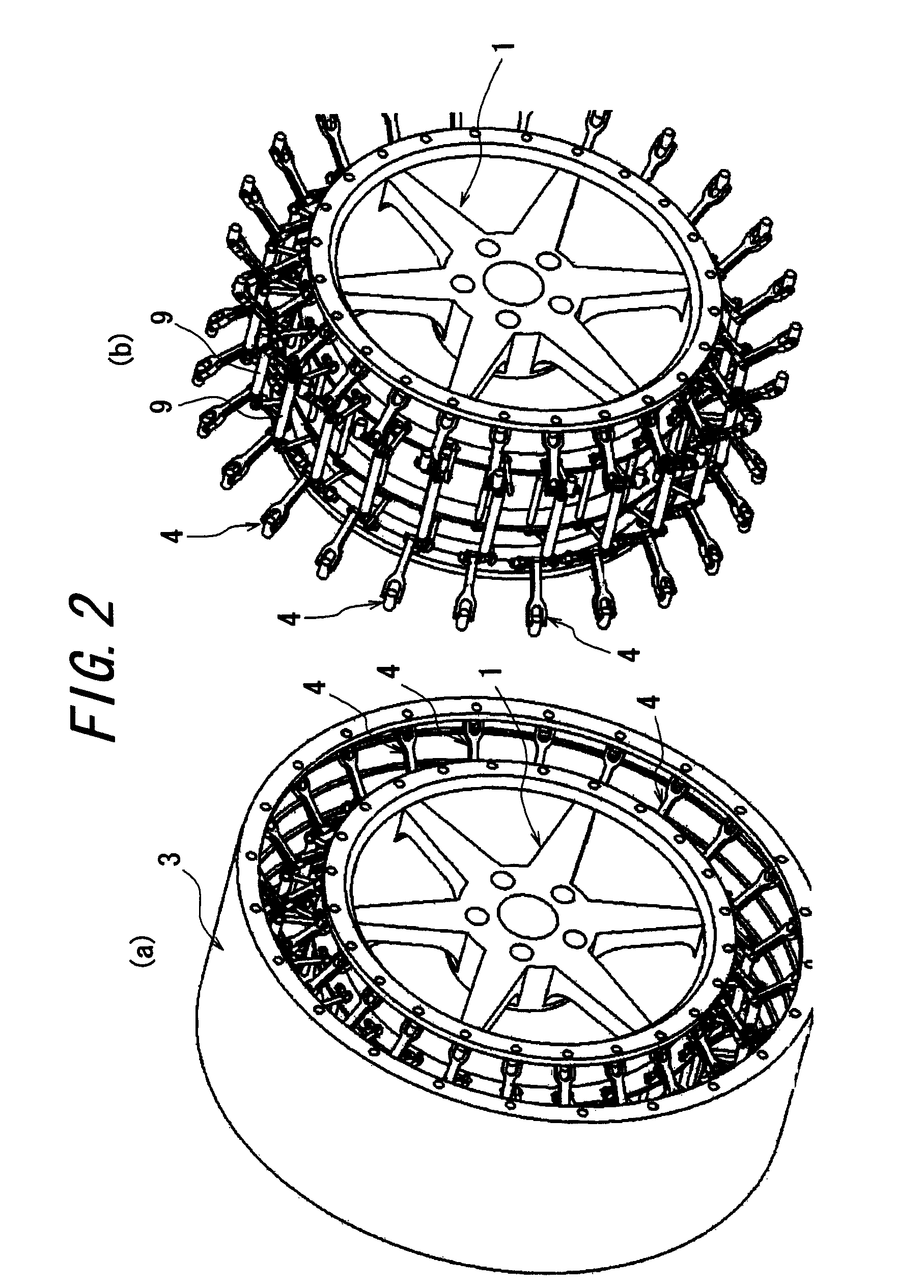

Non-pneumatic tire

InactiveUS20080073014A1Easy to provideReduce necessityRimsMetal-working apparatusRelative displacementInternal pressure

There is provided a non-pneumatic tire which can eliminate a necessity of filling a pressurized air or other gases to obviate a possibility of decrease or loss of the internal pressure of the tire and which can easily provide desired vertical, longitudinal and lateral stiffnesses in a mutually independent state.The non-pneumatic tire has a rim member 1, a ring member 3 disposed at an outer circumferential side of the rim member 1 and provided with a tread 2 on a circumferential face, and a plurality of link mechanisms 4 coupling the rim member with the ring member. Each of the link mechanisms 4 consists of a pair of link members 7a, 7b consisting of a link 5a, 5b which is connected at a first end with a side portion of the rim member 1 and which is swingable in the circumferential and meridian directions and another link 6a, 6b which is connected at a first end with a side portion of the ring member and 3 which is swingable in the circumferential and meridian directions with second ends of the links being hingedly connected one another to make the links swingable in the meridian direction. A spring member 9 imparting a stiffness against relative displacements in the radian, circumferential and width directions with respect to the rim and ring members 1, 3 is provided on the link mechanisms 4.

Owner:BRIDGESTONE CORP

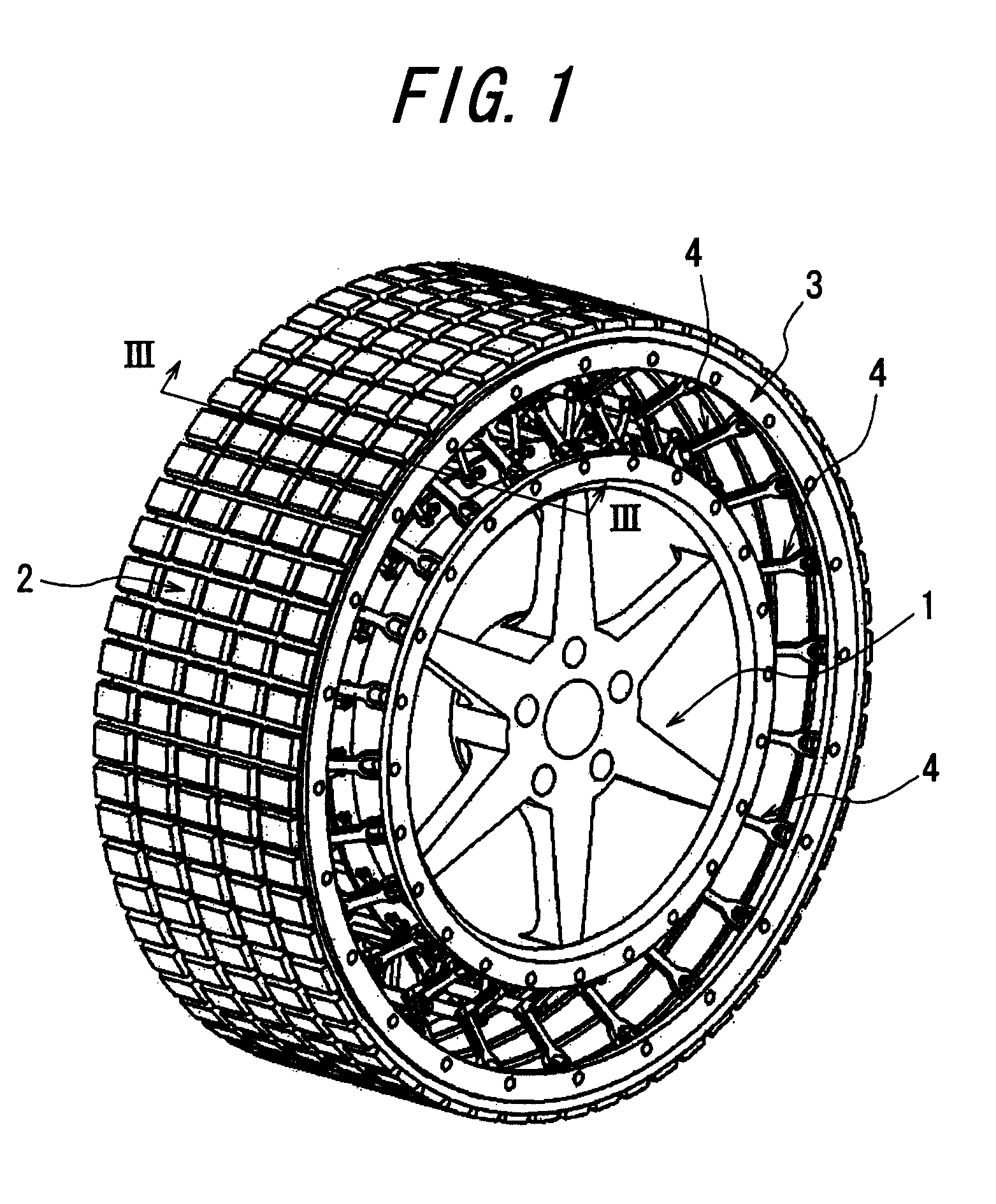

Non-pneumatic tire

InactiveUS7743806B2Easy to provideReduce necessityNon-inflatable tyresHigh resiliency wheelsRelative displacementEngineering

A non-pneumatic tire having a rim member 1, a ring member 3 disposed at an outer circumferential side of the rim member 1 and provided with a tread 2 on a circumferential face, and a plurality of link mechanisms 4 coupling the rim member with the ring member. Each of the link mechanisms 4 contains a pair of link members 7a, 7b formed of a link 5a, 5b which is connected at a first end with a side portion of the rim member 1 and which is swingable in the circumferential and meridian directions and another link 6a, 6b which is connected at a first end with a side portion of the ring member and 3 which is swingable in the circumferential and meridian directions with second ends of the links being hingedly connected one another to make the links swingable in the meridian direction. A spring member 9 imparting a stiffness against relative displacements in the radian, circumferential and width directions with respect to the rim and ring members 1, 3 is provided on the link mechanisms 4.

Owner:BRIDGESTONE CORP

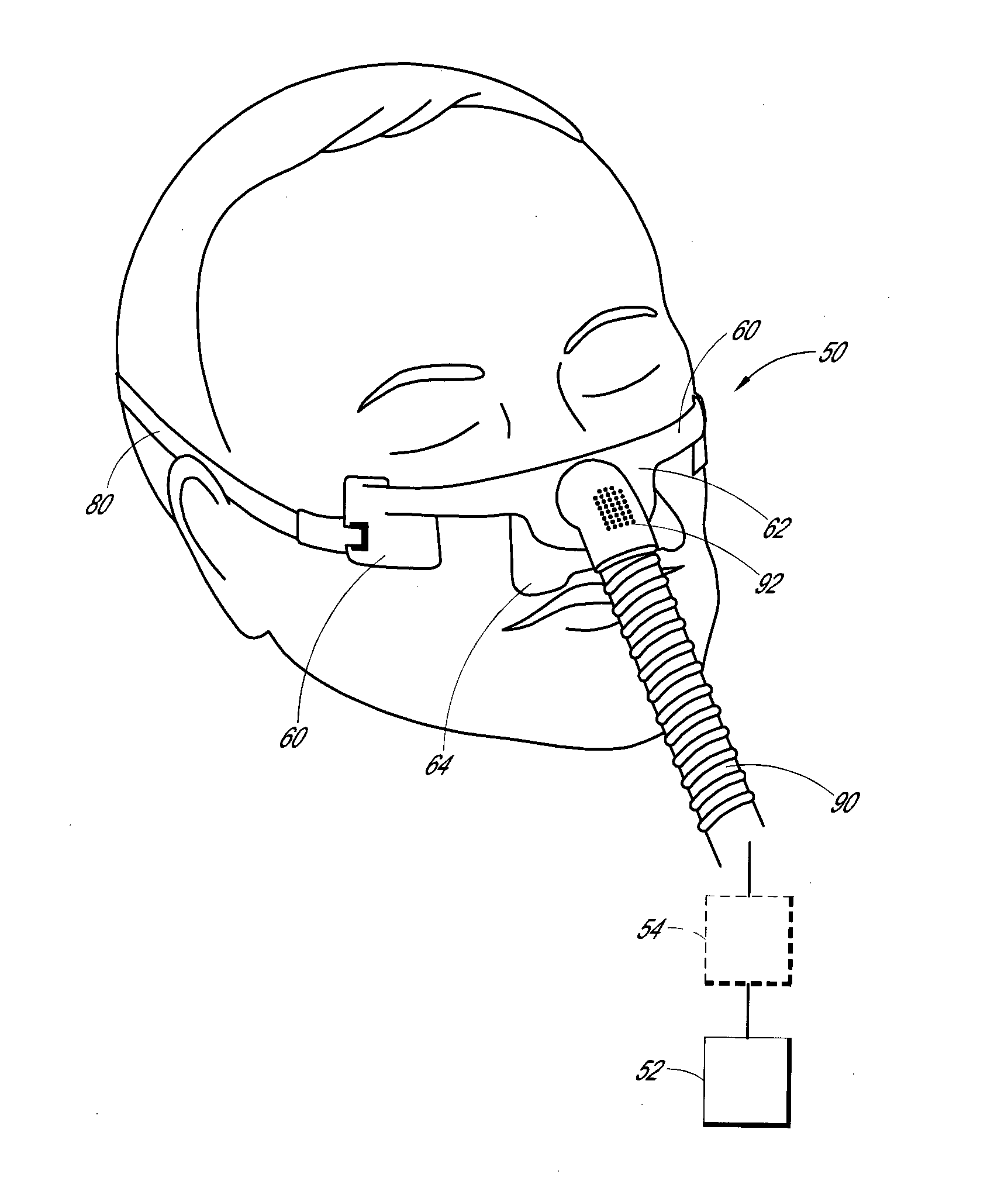

Nasal interfaces for respiratory therapy

ActiveUS20150209541A1Reduce draftReduce noiseRespiratory masksBreathing masksNasal cavityNasal prongs

Patient interfaces for respiratory therapy in the form of nasal interfaces or nasal masks include features that enhance or provide lateral stability of the interface. At least some of the embodiments provide multiple facial contact points or areas located in the general areas of the user's cheeks and / or upper lip. Some embodiments of the nasal interfaces provide advantageous sealing characteristics. The nasal interfaces may provide a controlled expiratory flow to reduce noise. Some embodiments include nasal pillows instead of or in addition to nasal prongs. The nasal pillows can have exhaust vents or can change in length in response to a pressure level within the nasal pillow.

Owner:FISHER & PAYKEL HEALTHCARE LTD

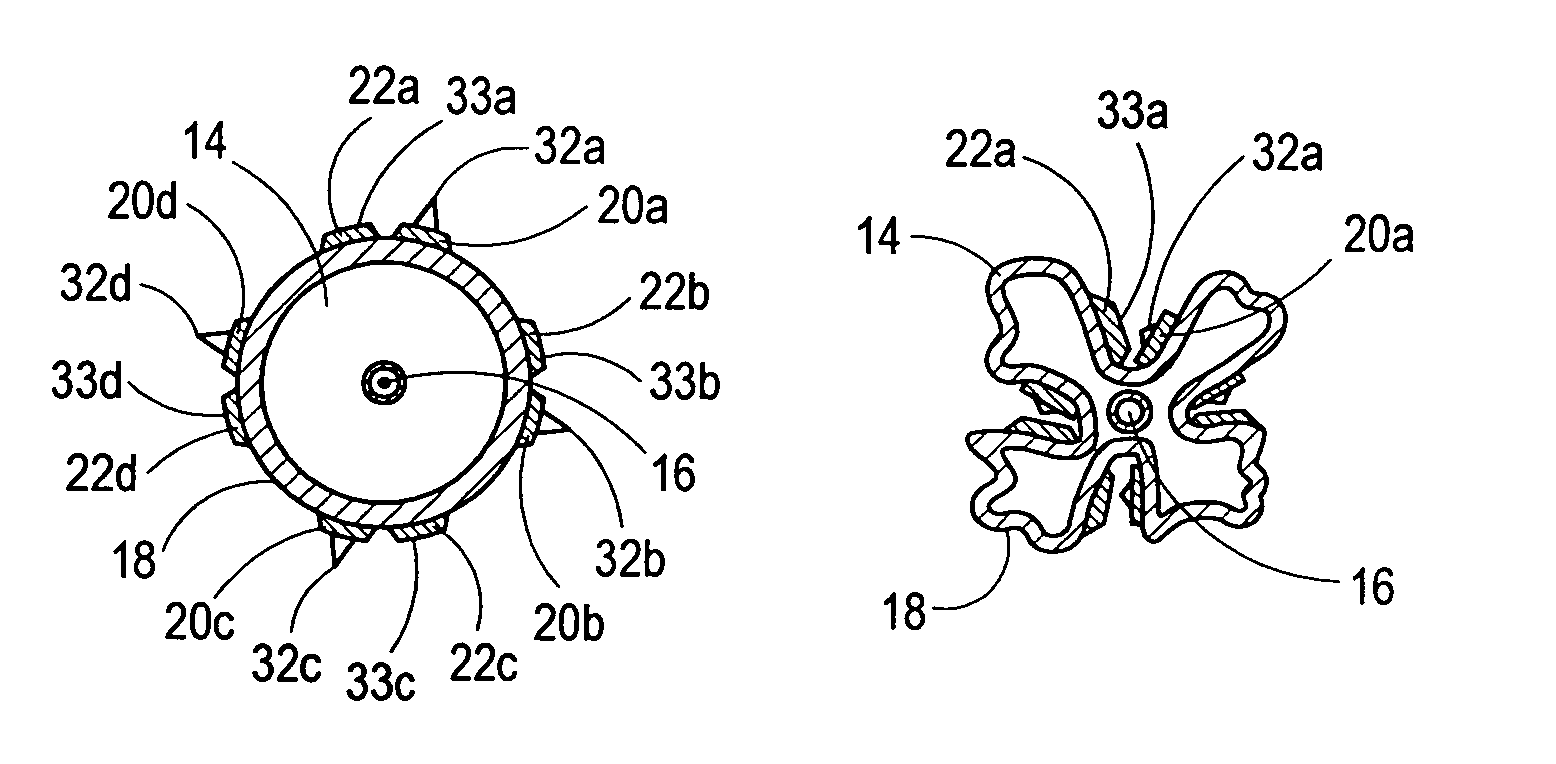

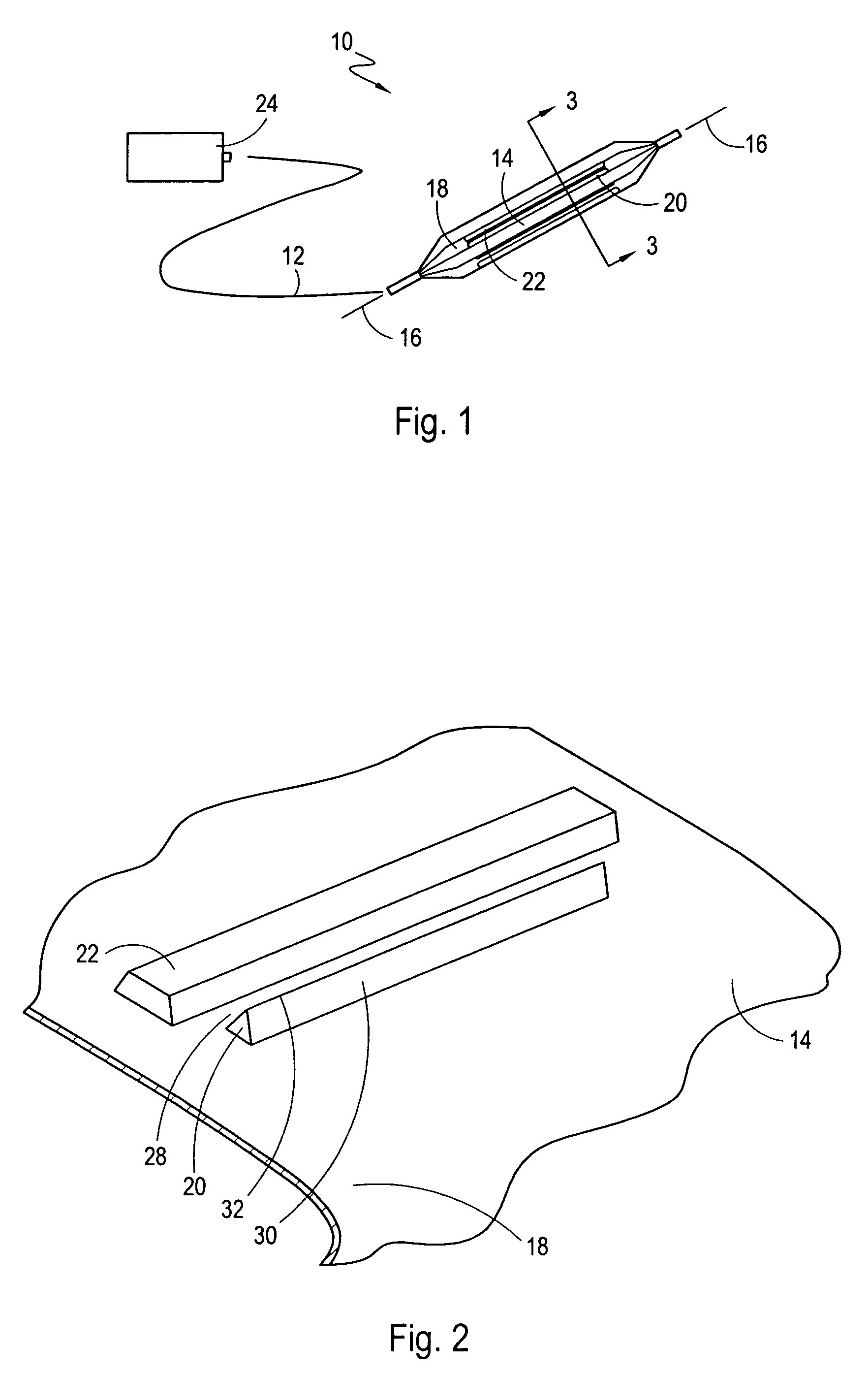

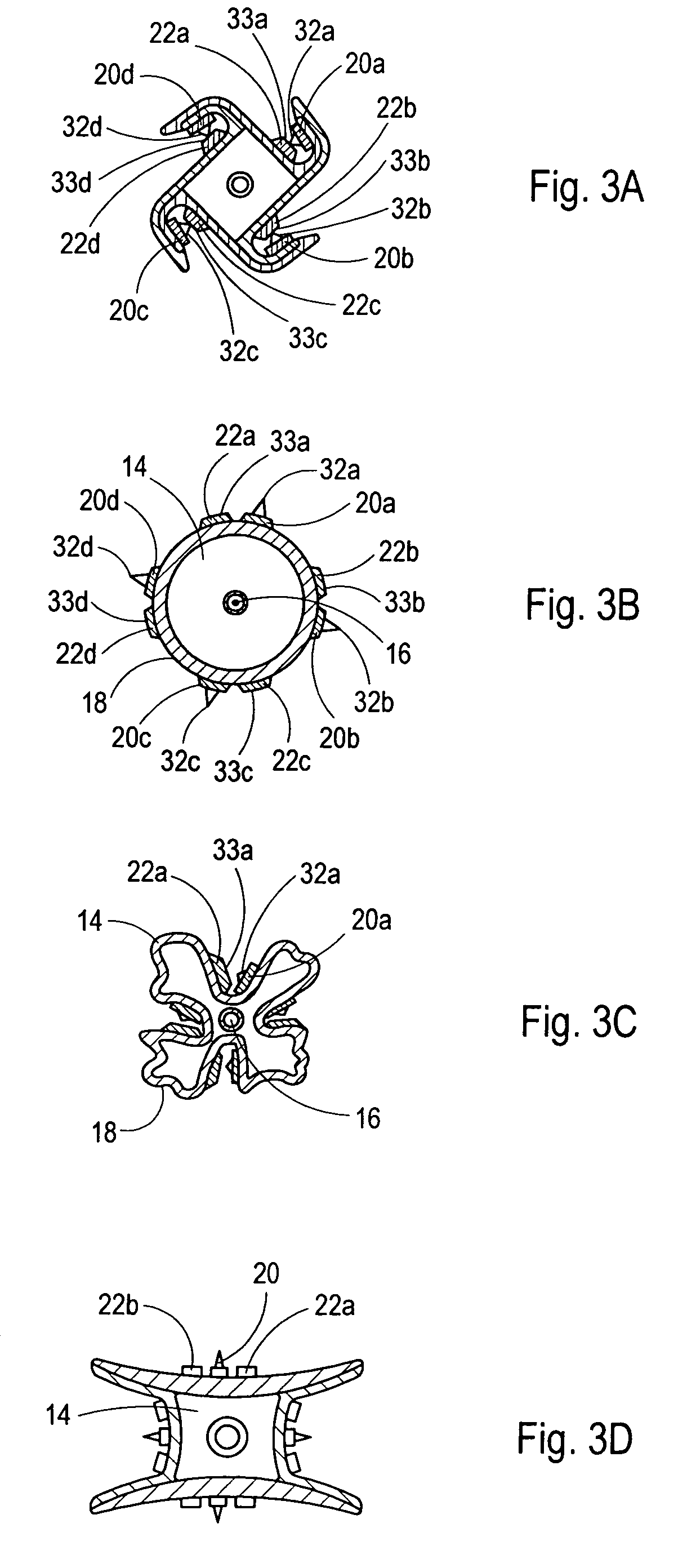

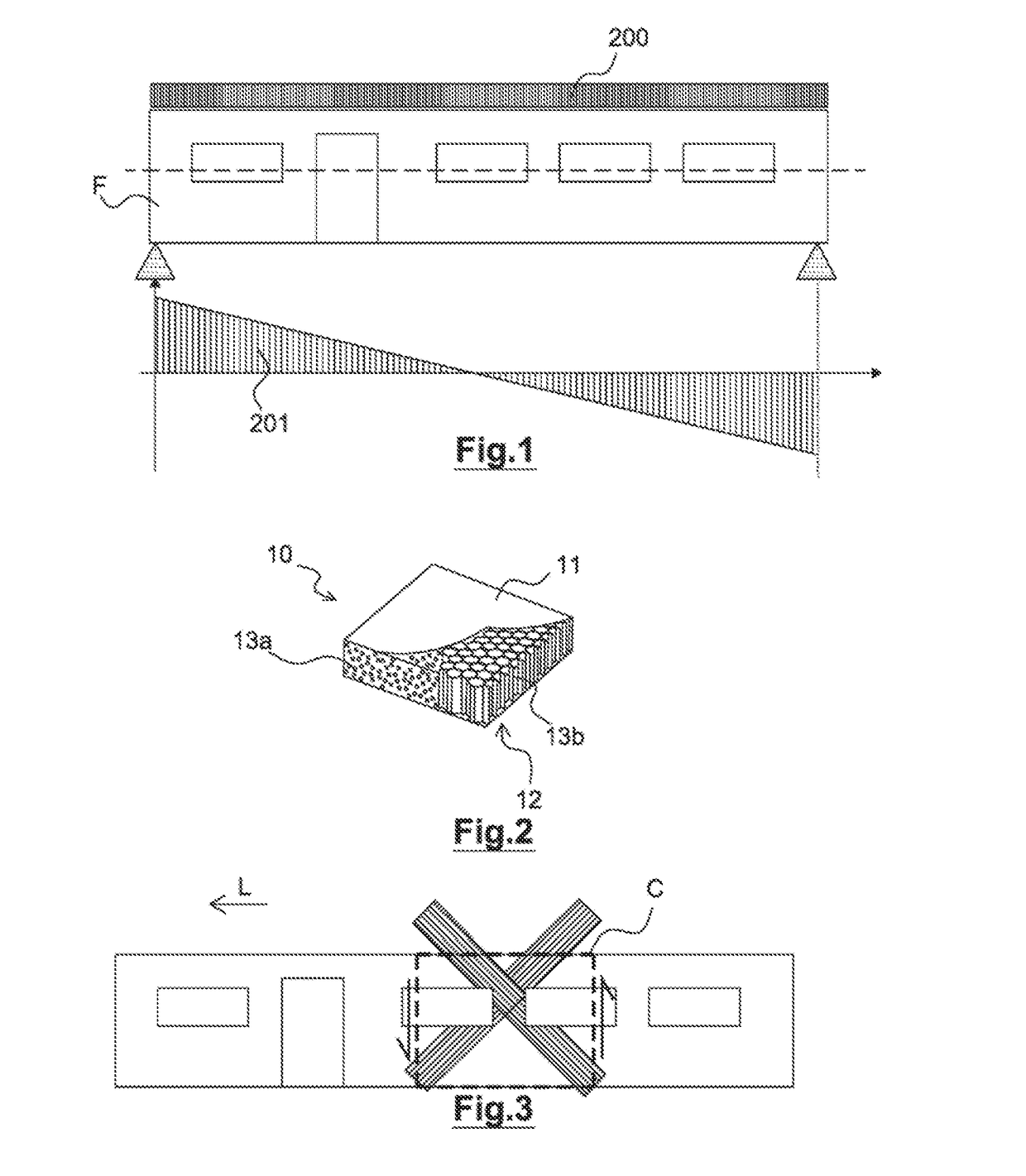

Board for gliding

Board for gliding (1) having an underfoot zone (2), intended to receive the foot or feet of the user, extending toward the front via a front zone (4) and to the rear via a rear zone (3), and the structure of which includes: a lower assembly (10) comprising the gliding sole (11), the edges (12) and an optional lower reinforcement (13); an upper assembly (6) comprising the protective upper layer (7) and an upper reinforcement (8); an intermediate core (15) placed between the lower (10) and upper (6) assemblies; characterized in that it includes a plate (25) located in the region of the underfoot zone and capable of being displaced in the direction of the lower assembly (10) through the effect of a pressure exerted by the user's foot and at least one longitudinal rigid arm (20-23), housed inside the structure of the board, traversing at least most of the thickness of the core (15), the end (40-43) of the arm furthermost from the underfoot zone bearing on the lower face of the core (15), on the lower assembly (10) of the board, the end (30-33) of the arm closest to the underfoot zone bearing under the plate (25), in the vicinity of the user's feet, so that the forces exerted by the user on the upper surface (9) of the board in the region of the underfoot zone (2) of the board are transmitted directly toward the lower surface of the board via the end of the arm (20-23) oriented in the direction of the lower assembly (10) of the board.

Owner:SKIS ROSSIGNOL

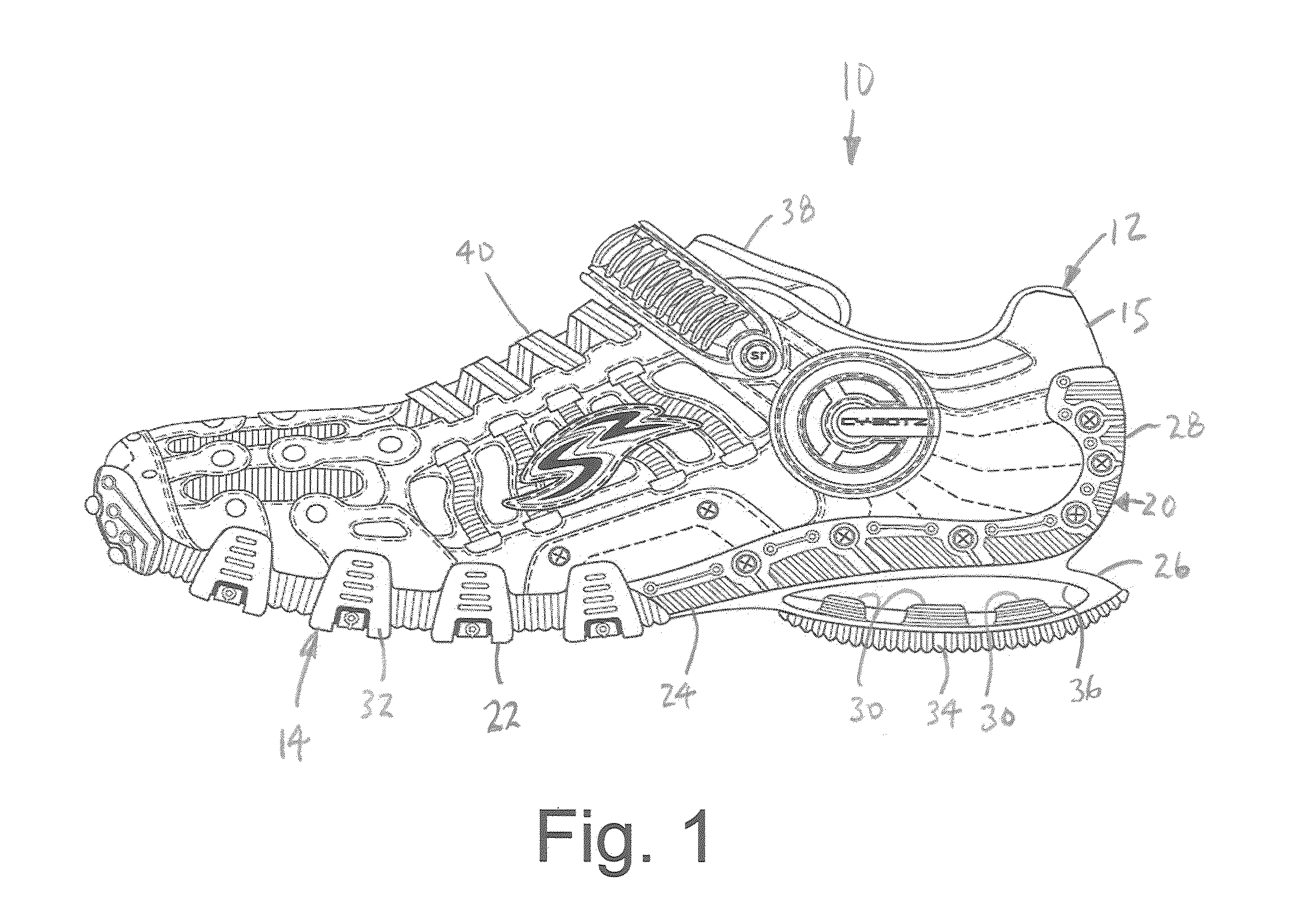

Sole assembly for article of footwear

InactiveUS20140290098A1Resists separationEnhance longitudinal stiffnessSolesMechanical engineeringHeel

A sole assembly generally including a flex plate, a heel spring and a heel cup. The flex plate may extend from the rear of the sole through the arch into the forefoot. The heel spring may be an elliptical spring and may have internal resilient stoppers that prevent the spring from bottoming out. The height of the stoppers may increase toward the rear of the sole. The stoppers may be extensions of the outsole fitted up through apertures in the elliptical spring. The heel spring may be disposed beneath the flex plate in the heel region. The heel cup may be disposed above the flex plate in the heel region. The heel cup may have an extension that extends upwardly a sufficient distance to cradle the wearer's heel to provide an enhanced forefoot lever. The flex plate, heel spring and heel cup may be a single unitary component.

Owner:WOLVERINE WORLD WIDE

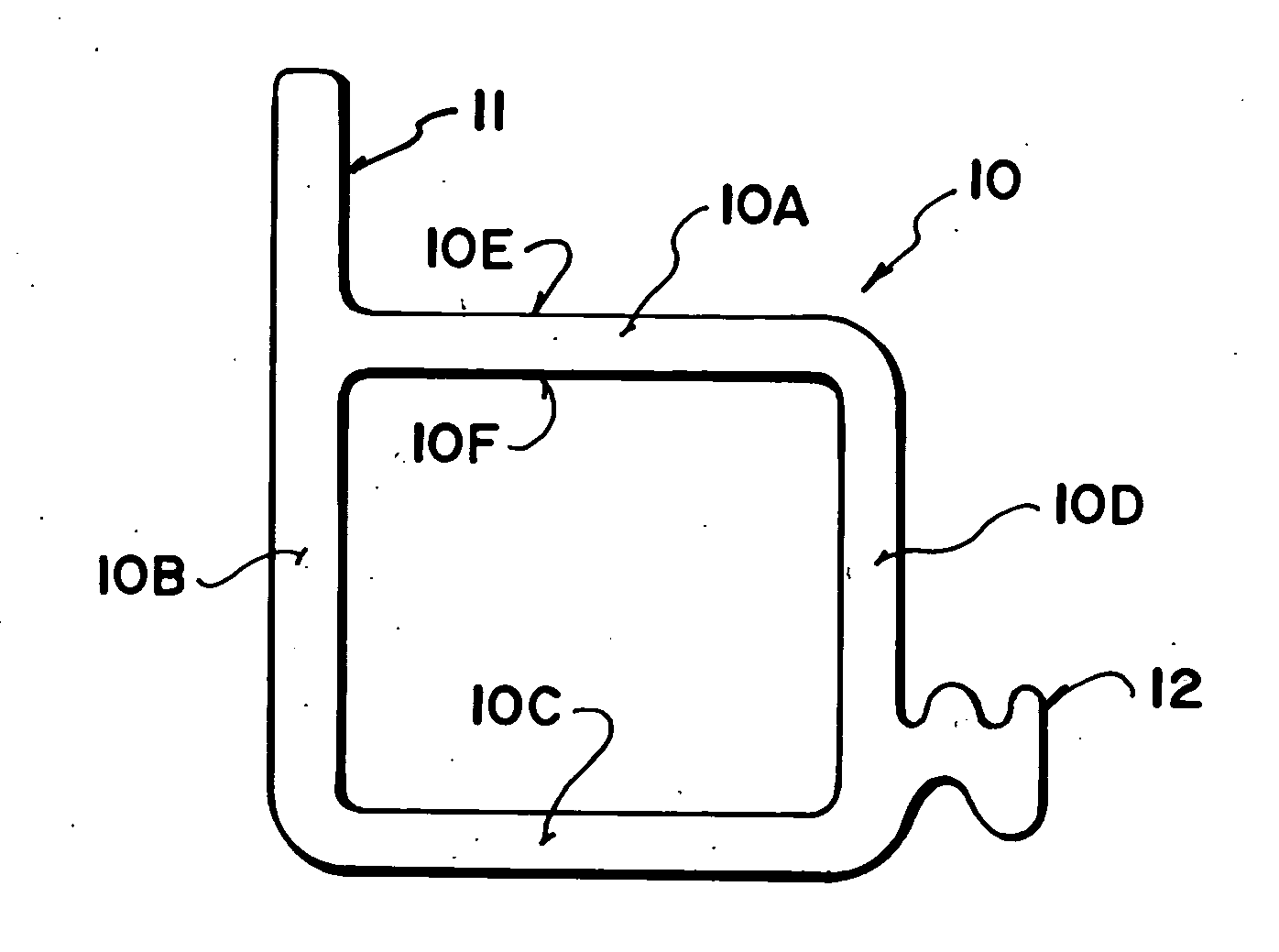

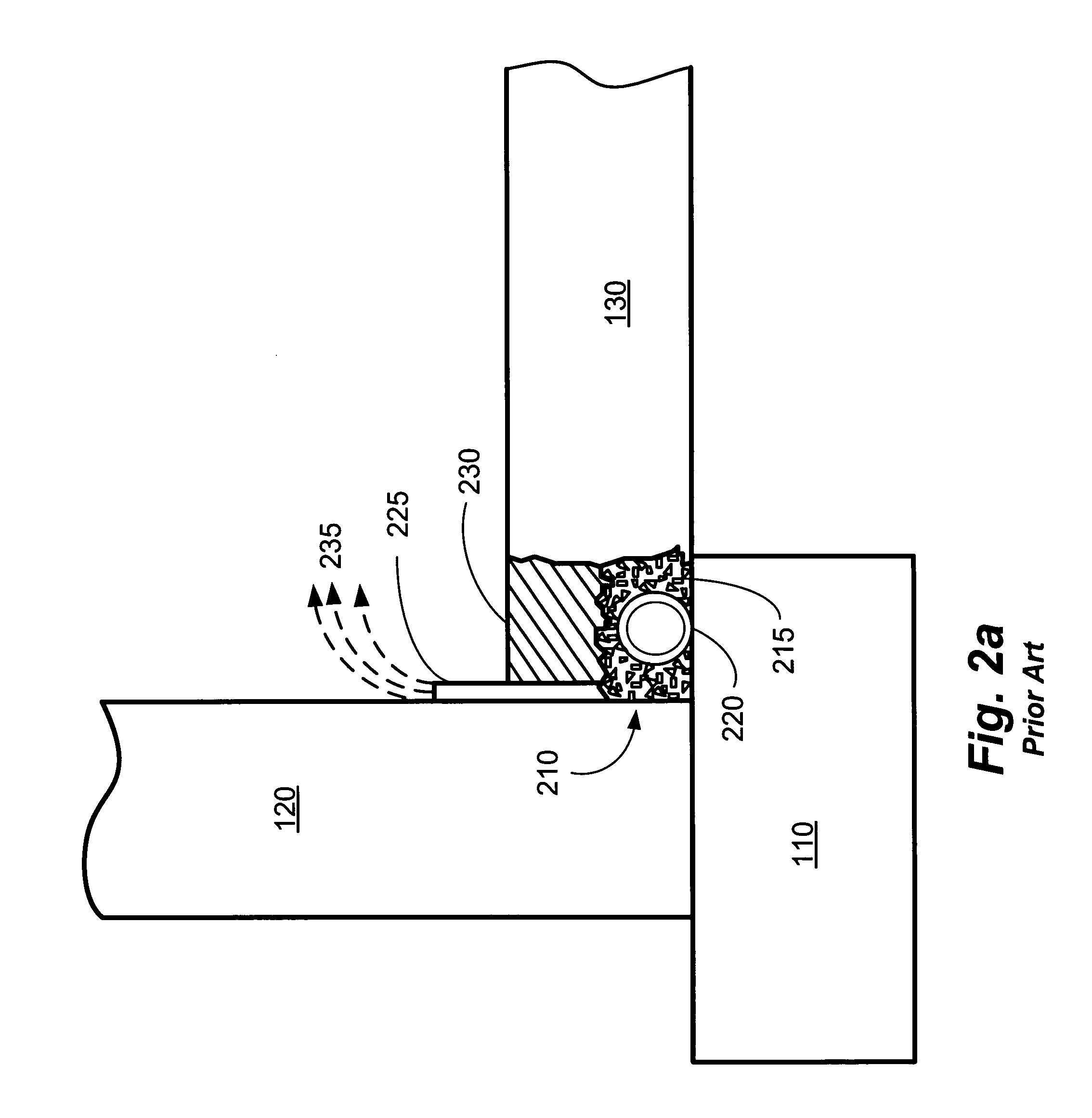

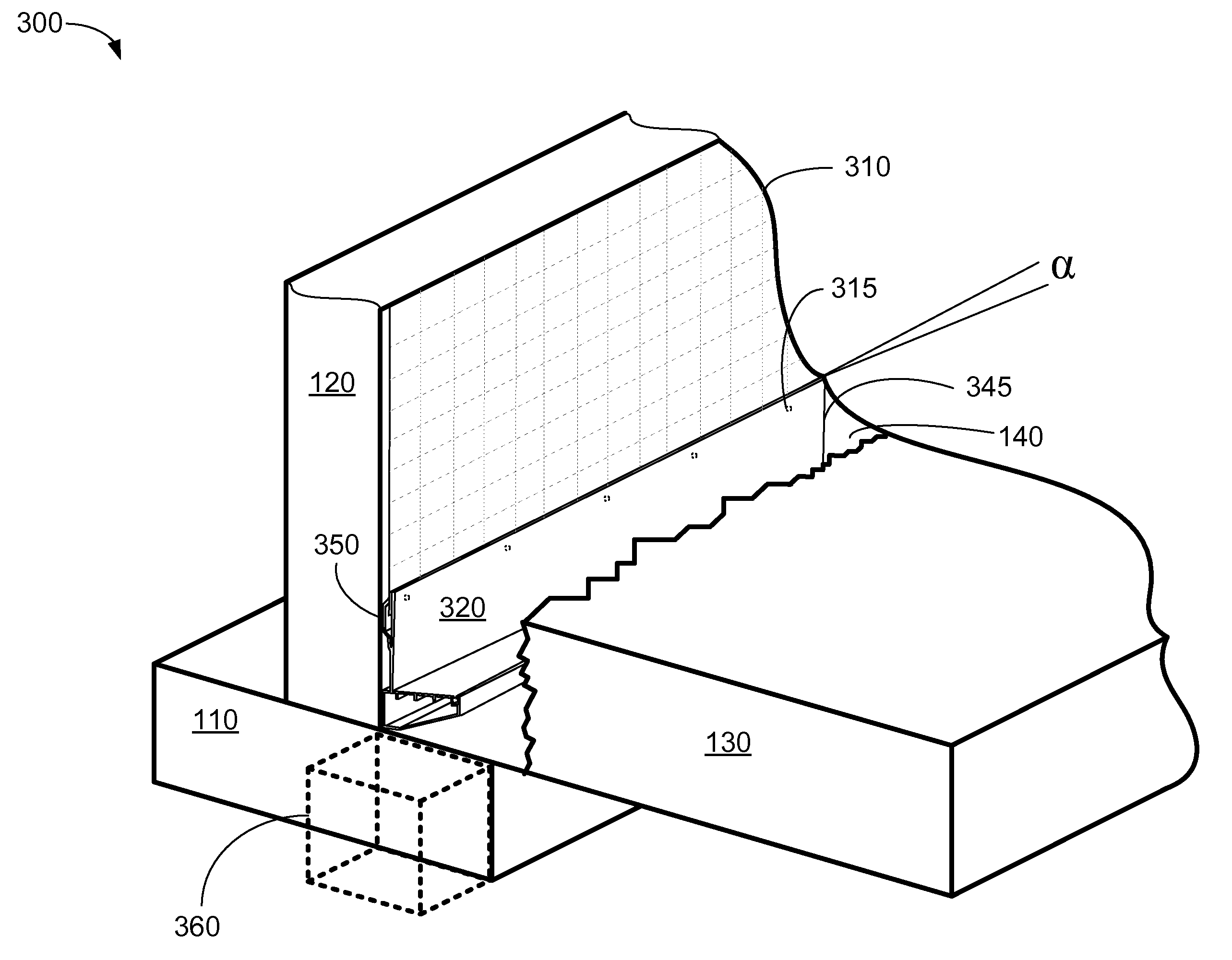

System and methods for providing a waterproofing form for structural waterproofing

ActiveUS20110041426A1Prevent evaporationIncreased longitudinal stiffnessRoof coveringFloorsVapor barrierEvaporation

The present system and method enables water entering a dwelling or structure to be contained and removed, while preventing evaporation of the water into the interior of the dwelling. Embodiments of the present invention can comprise a waterproofing system comprising a waterproofing form, affixable to a first surface of a wall at a mounting angle, and comprising a vapor barrier retainer for detachably affixing a vapor barrier to the waterproofing form, and a gutter channel, disposed at a pitch angle, and in fluid communication with the first surface of the wall, the vapor barrier, and a collection area, where the pitch angle and the mounting angle are the same angle, and where the pitch angle causes the water to flow through the gutter channel to the collection area for removal.

Owner:TROTTER ROBERT MIKE

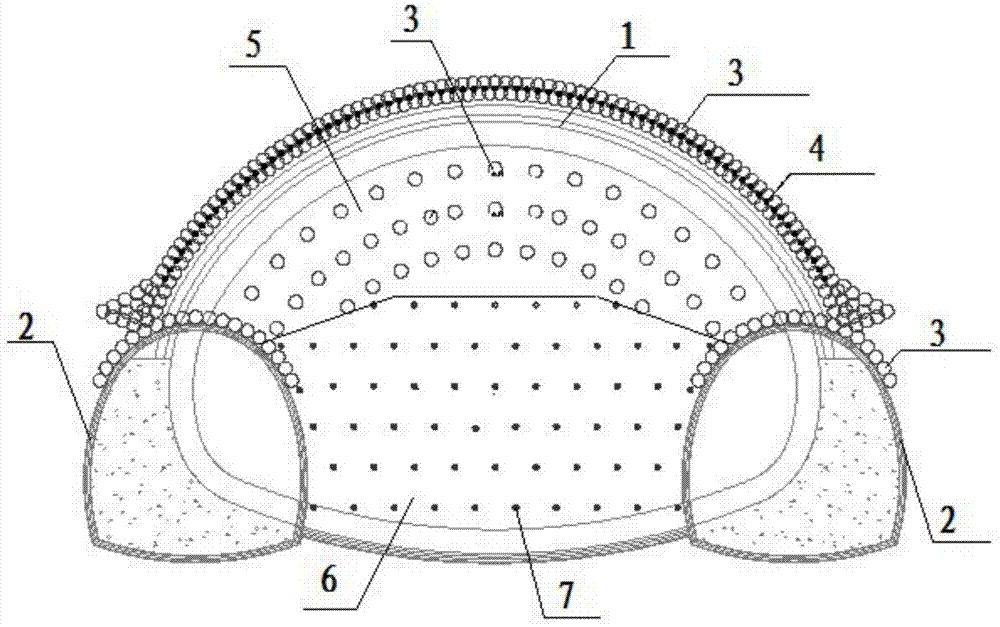

Advanced support structure for oversized variable-section tunnel

InactiveCN104500100AEasy to adaptWork well togetherUnderground chambersTunnel liningDegrees of freedomHigh pressure

The invention provides an advanced support structure for an oversized variable-section tunnel. A main hole to be excavated and side holes to be excavated form a tunnel section; the side holes to be excavated are positioned in both sides of the main hole to be excavated; two layers of high-pressure horizontal jet grouting piles are arranged outside a tunnel excavation contour line on the arch crown of the main hole to be excavated; an advanced long pipe shed is embedded between the two layers of jet grouting piles; a layer of high-pressure horizontal jet grouting piles is arranged outside the tunnel excavation contour line on the arch crowns of the side holes to be excavated; a plurality of high-pressure horizontal jet grouting piles are arranged outside the tunnel excavation contour line on an arch foot between the side holes to be excavated and the main hole to be excavated; a plurality of high-pressure horizontal jet grouting piles are arranged on the tunnel face arch of the main hole to be excavated along a tunnel excavation direction. By adopting the advanced support structure, safety during excavation of the oversized variable-section tunnel in particularly-weak surrounding rock is ensured, the use of temporary supports is reduced, the degree of freedom in operation is increased, and the construction progress is accelerated.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

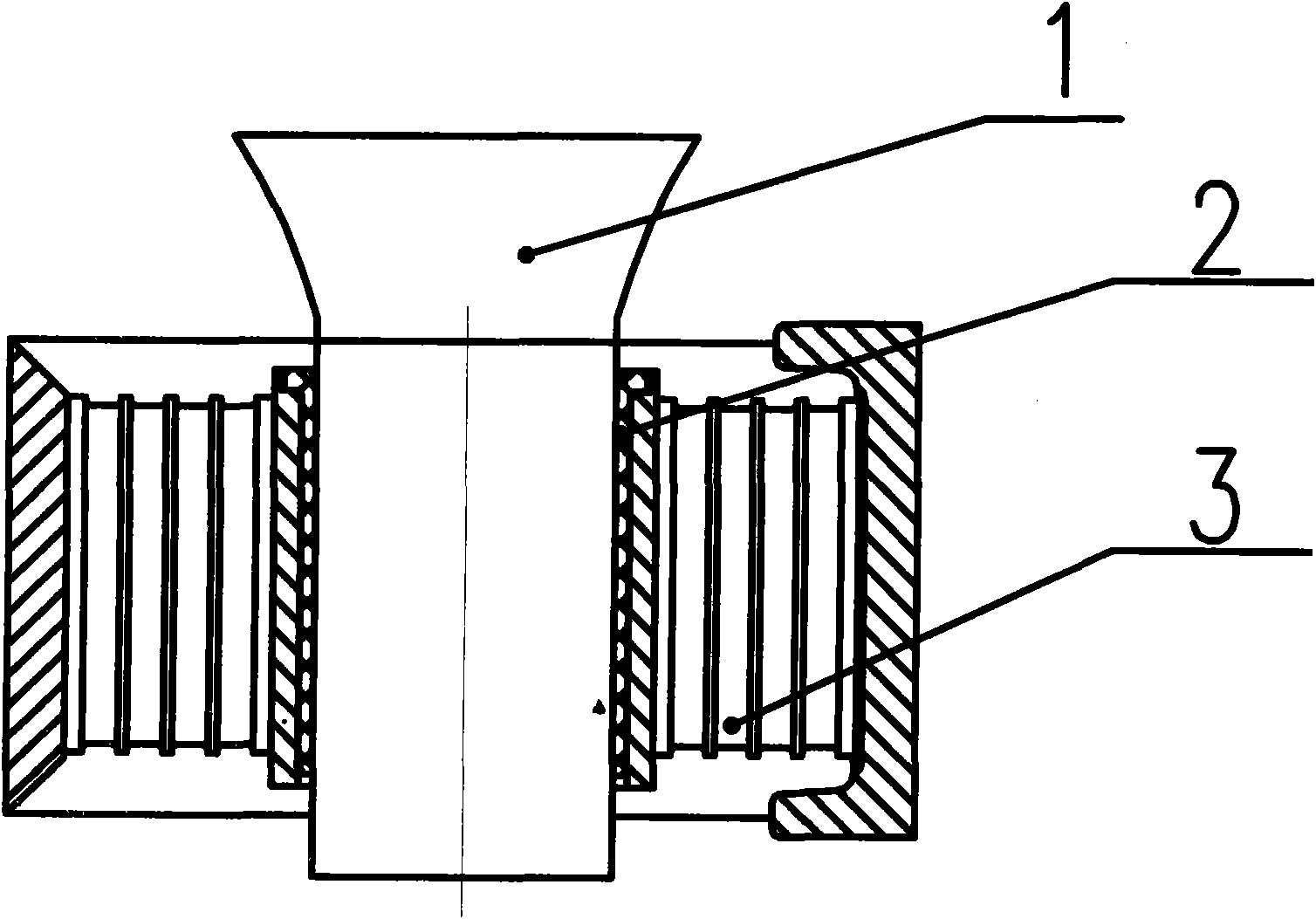

Method of manufacturing an ink-jet recording head

InactiveUS7305764B2Forming accuratelyCost advantageRecording apparatusPiezoelectric/electrostrictive device manufacture/assemblyNozzleRecording head

An ink-jet recording head has a plate-shaped member including a first layer with a partition wall formed by a first etching process and defining a pressure chamber, an ink inlet passage and a common ink storage chamber, a second layer with a land formed by a second etching process so as to correspond to the pressure chamber, and an intermediate layer sandwiched between the first and the second layers. The recording head also has a pressure producing device disposed with its extremity in contact with the land, and a nozzle plate with a nozzle hole bonded to the front surface of the plate-shaped member. An ink particle is jetted through the nozzle hole when the pressure in the pressure chamber is changed by the pressure producing device.

Owner:SEIKO EPSON CORP

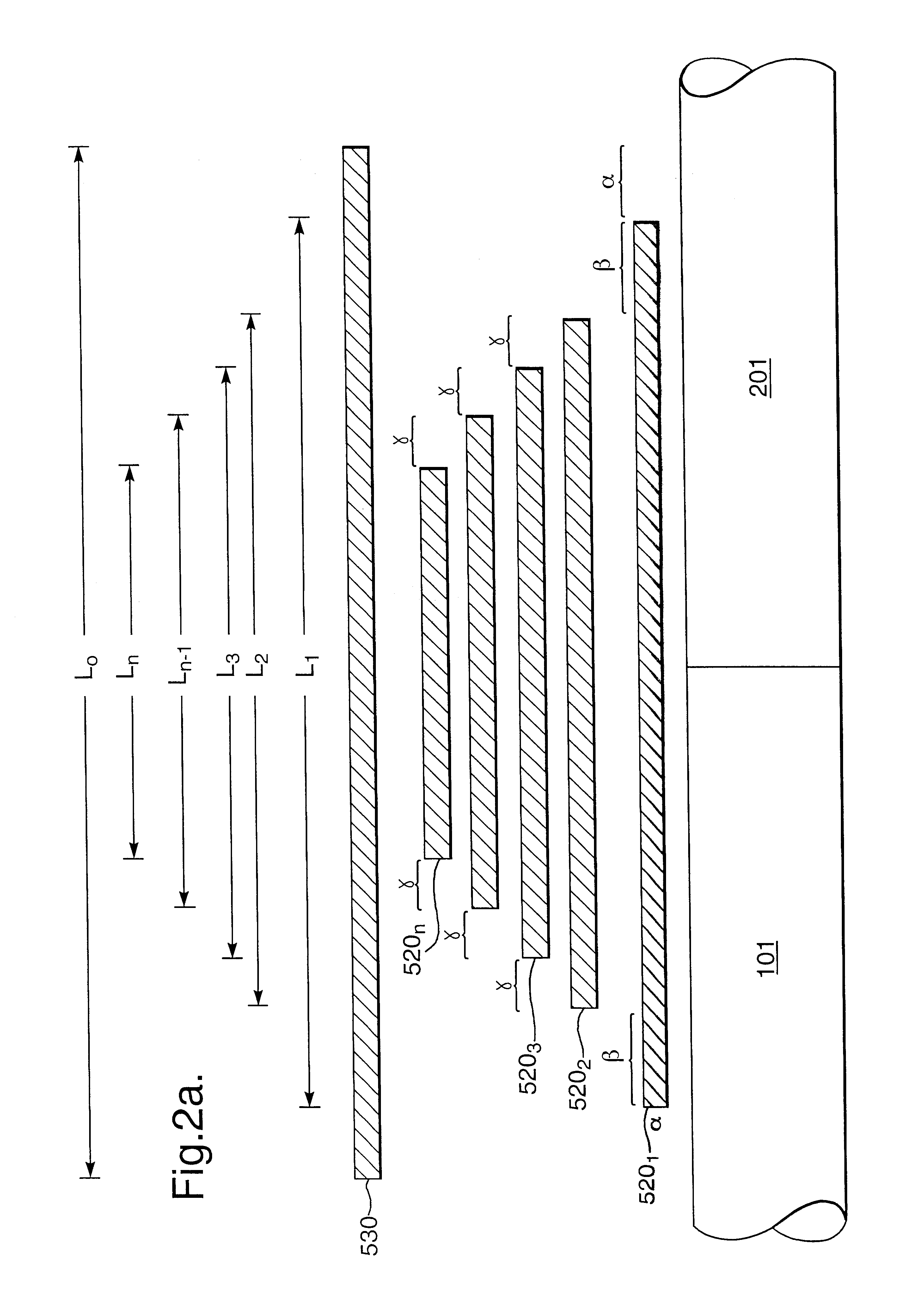

High-strength butt-wrap joint for reinforced plastic pipes

InactiveUS6585298B2Increased longitudinal stiffnessControl stressSleeve/socket jointsFluid pressure sealed jointsButt jointEngineering

A butt-wrap joint includes a plurality of wraps 5201-520n of material wetted with a thermosetting resin and wrapped circumferentially about two abutting pipe ends 101, 201. The first wrap is disposed relative to the respective pipes and the second through n-th wrap is deposed successively outwardly, relative of the respective preceding wrap. The wraps are covered by a chopped strand mat 530 wetted with the thermosetting resin.

Owner:FLOWTITE TECH

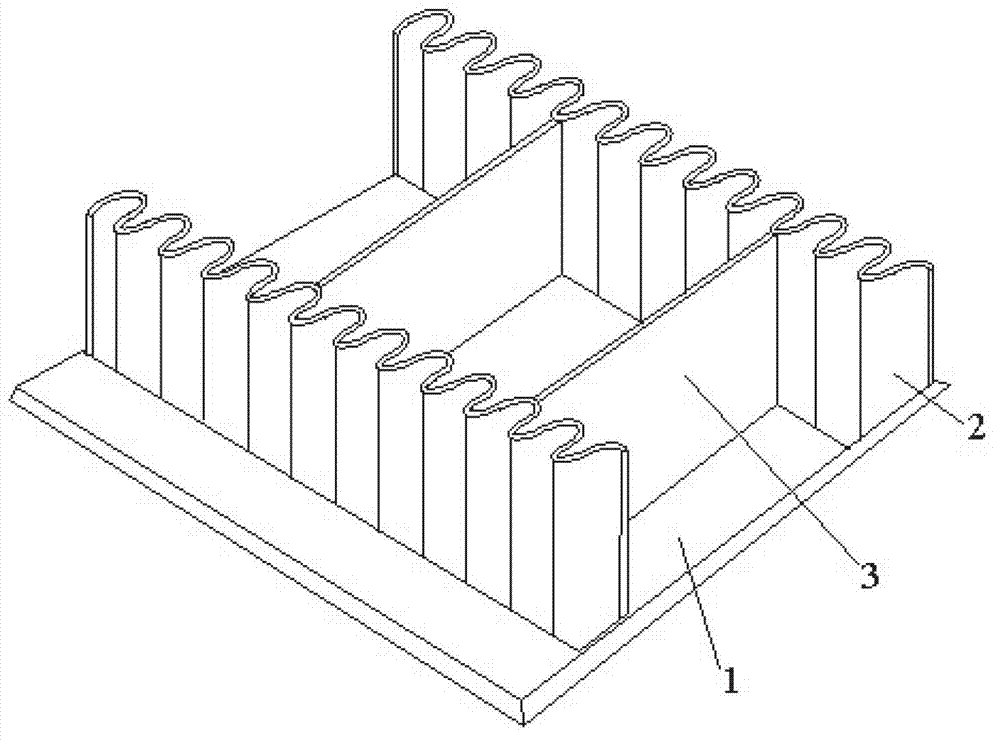

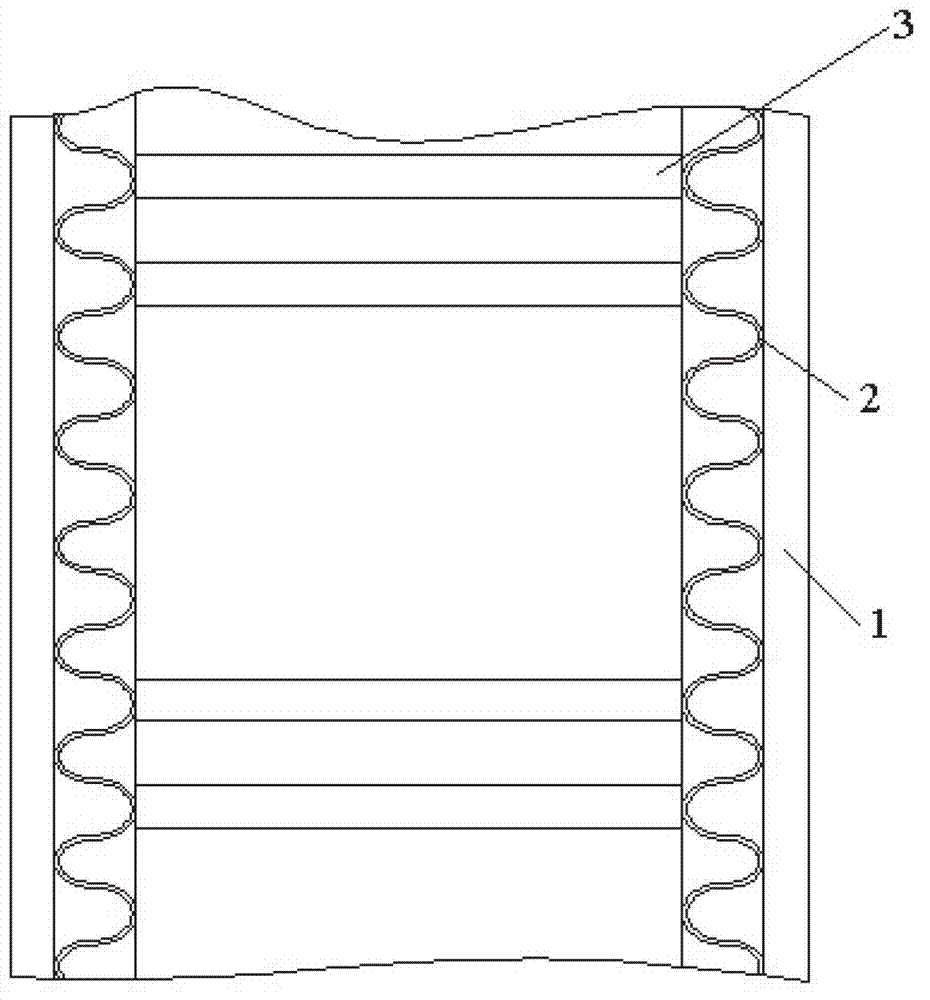

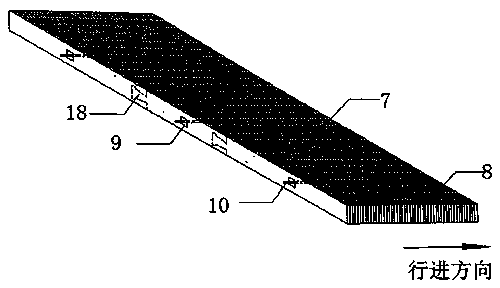

Large-inclination wavy-retaining-edge conveying belt and processing method thereof

InactiveCN102826330AImprove tear resistanceNot easy to tearConveyorsMetal layered productsVulcanizationMechanical engineering

The invention relates to a large-inclination wavy-retaining-edge conveying belt, which comprises a base belt, retaining edges and transverse baffles. The base belt is a composite rubber layer consisting of an upper covering rubber layer, a latitudinal steel cord anti-tearing layer, a steel chord skeleton layer, a side rubber layer and a lower covering rubber layer which are sequentially arranged from top to bottom, are bonded primarily and are vulcanized secondarily. A plurality of transversely and evenly arranged steel wires are embedded into the steel chord skeleton layer. The steel wires are embedded in the steel chord skeleton layer and are arranged in the same plane. The side rubber layer is arranged on the side of the steel chord skeleton layer. Wavy retaining edges which are fixedly arranged through a secondary vulcanization bonding method are symmetrically arranged on the two sides of the base belt. The number of the transverse baffles is multiple. The transverse baffles are vertically and fixedly arranged on the base belt at intervals through the secondary vulcanization bonding method and are arranged corresponding to the valleys of the wavy retaining edges. The large-inclination wavy-retaining-edge conveying belt has the advantages that the anti-tearing performance of the existing retaining edge conveying belt is mainly improved, the conveying belt is prevented from being longitudinally drawn, the requirement on large-inclination conveying is satisfied and the service life of the conveying belt is prolonged.

Owner:ZHANGJIAGANG HUASHEN INDAL RUBBER PRODS

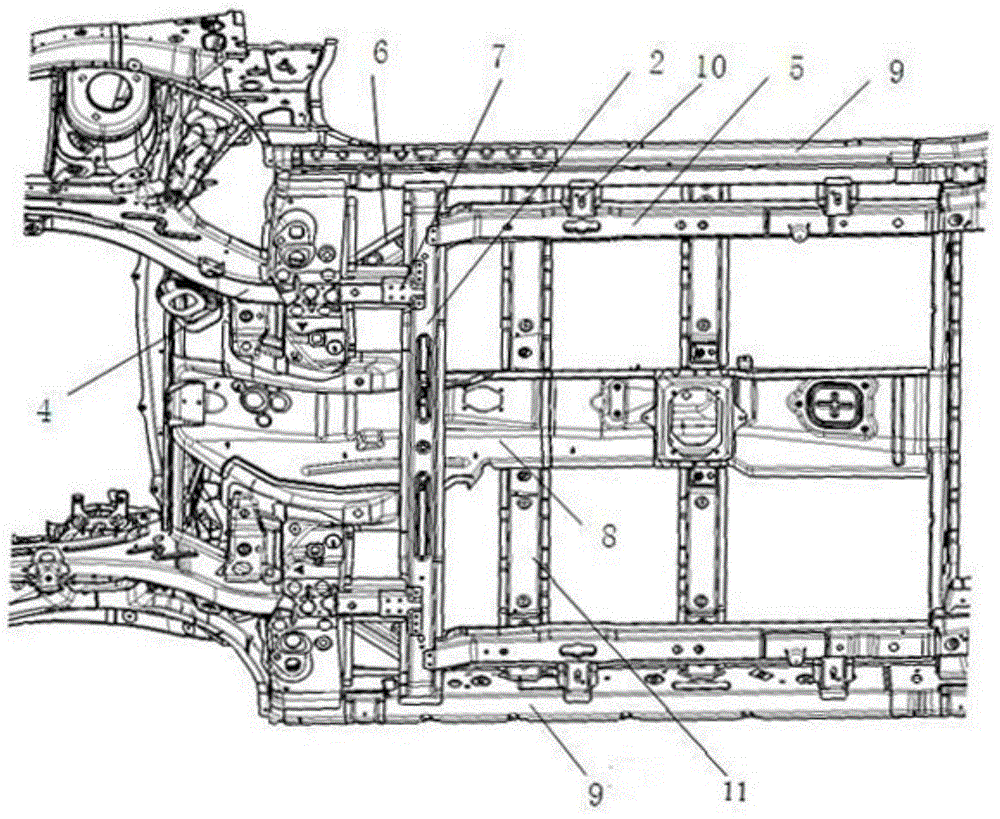

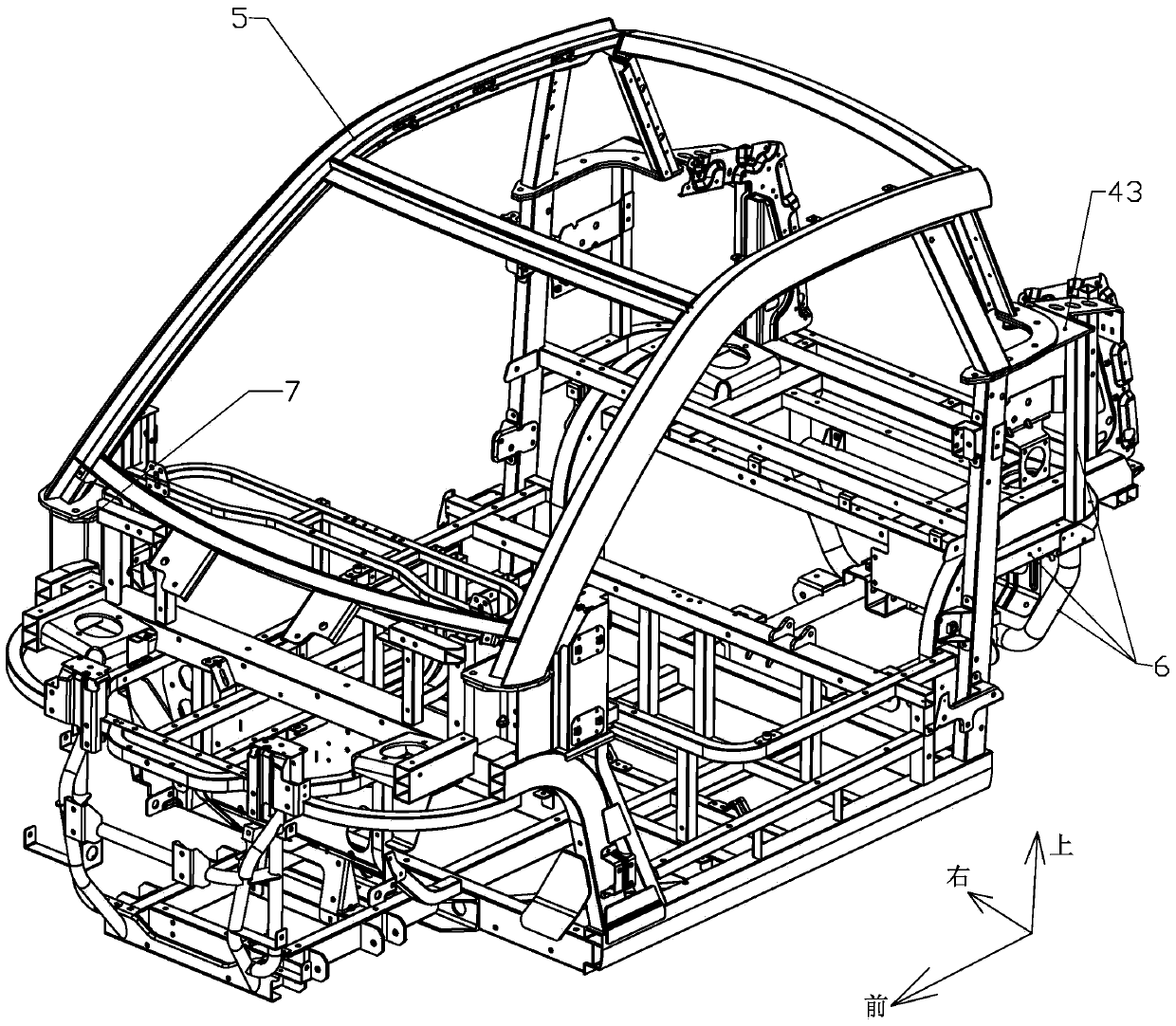

Front floor lower beam connecting structure of battery-changing type electric vehicle body

ActiveCN104787123AIncreased longitudinal stiffnessIncrease lateral stiffnessSuperstructure subunitsAutomotive batteryElectric vehicle

The invention discloses a front floor lower beam connecting structure of a battery-changing type electric vehicle body. The front floor lower beam connecting structure comprises a vehicle body front floor, a front floor lower beam is arranged in front below the vehicle body front floor, the two ends of the front floor lower beam are fixedly connected with front floor side longitudinal beams, the middle of the front floor lower beam is fixedly connected with a middle channel, the rear ends of vehicle body front longitudinal beams are fixedly connected with the front floor lower beam, and the front ends of front floor inner longitudinal beams are fixedly connected with the front floor lower beam. The front floor lower beam connecting structure is simple, convenient to assemble and reliable to use, and installs and fixes a vehicle battery pack without substantially changing a traditional vehicle body structure, meanwhile, longitudinal and transverse rigidity of the lower portion of an electric vehicle body floor is guaranteed, the performance of resisting front face and side face collision of the vehicle body is effectively improved, the safety and the stability of an electric vehicle are improved, the manufacturing cost of the electric vehicle is lowered, and the consumed tooling time for the electric vehicle is shortened.

Owner:DONGFENG MOTOR CORP HUBEI

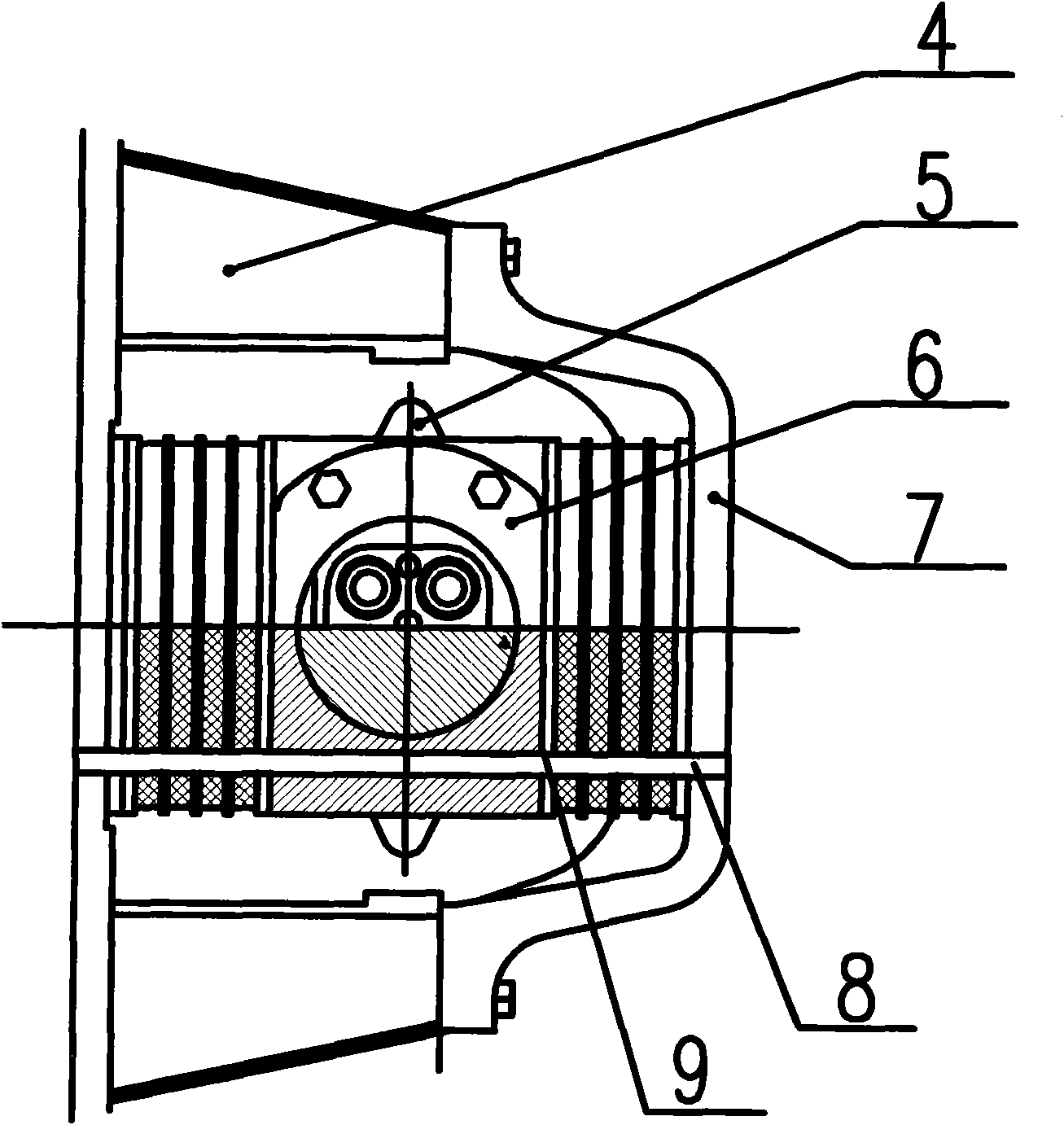

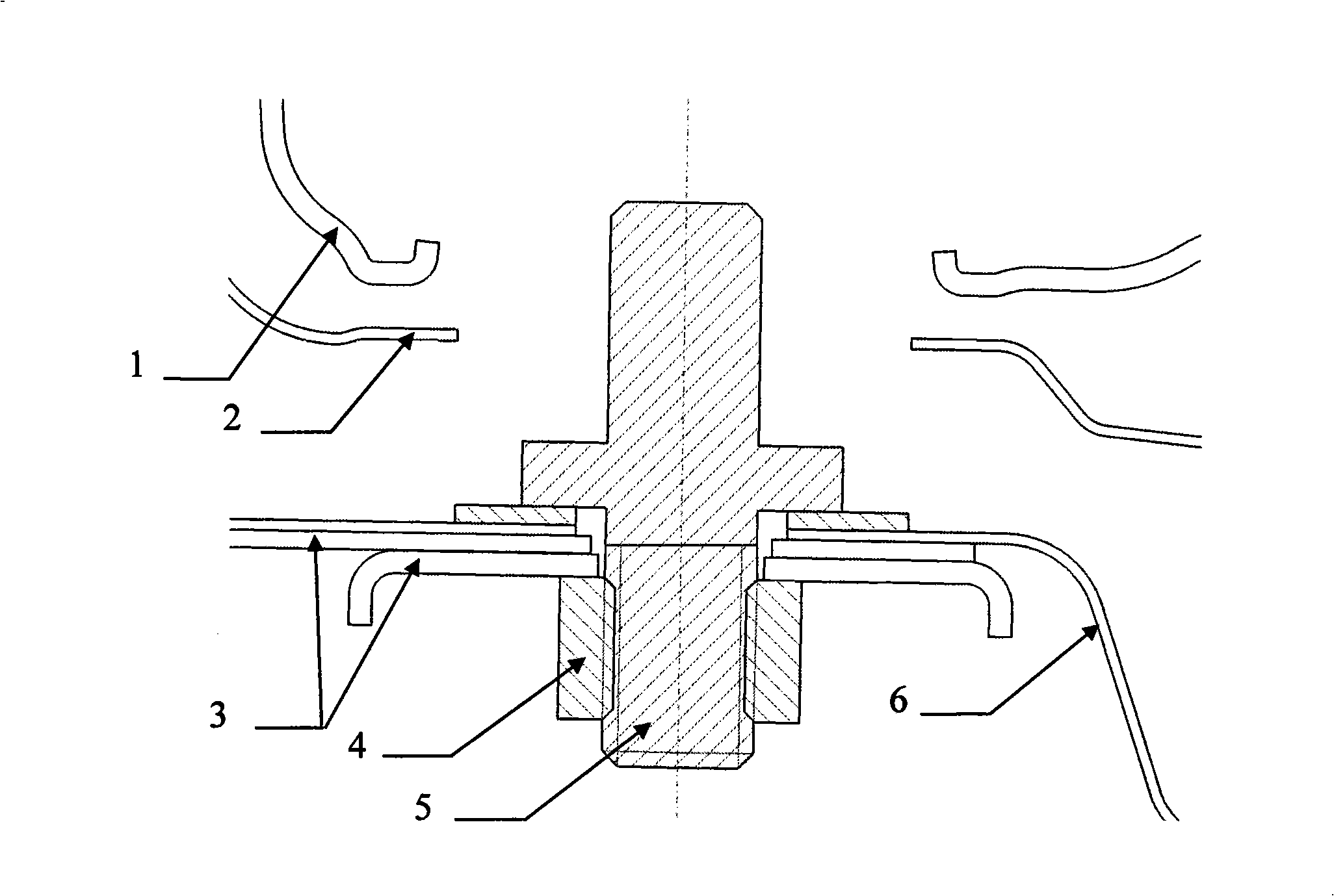

Composite axle box positioning device and processing and assembling method thereof

The invention provides a composite axle box positioning device and a processing and assembling method thereof. The device is characterized in that a composite positioning structure of combining a steel spring with a rubber spring is adopted, so that zero clearance and zero wear limit and assembling for positioning of an axle box is realized so as to improve the horizontal and longitudinal rigidities and proper vertical rigidity of the axle body positioning device synchronously. The composite axle box positioning device comprises a positioning guide column which is vertically connected with a structural frame through positioning bolts, a lower clamping plate and an upper clamping plate which are arranged on a mounting seat of the axle box body, and a steel spring is clamped between the lower clamping plate and the upper clamping plate. A groove around the positioning guiding column is arranged at the lower clamp plate; and a rubber spring is sleeved in the groove and the on the positioning guiding column; the rubber spring is formed by vulcanization of rubber and steel plates and is pressed in the lower clamp plate; the rubber spring is matched with the lower clamp plate for use, longitudinal and horizontal rigidities and flexibilities of the axle box positioning device are provided for a suspending system of a steering frame, thereby ensuring stability when the steering frame runs at a high speed.

Owner:CRRC QINGDAO SIFANG CO LTD

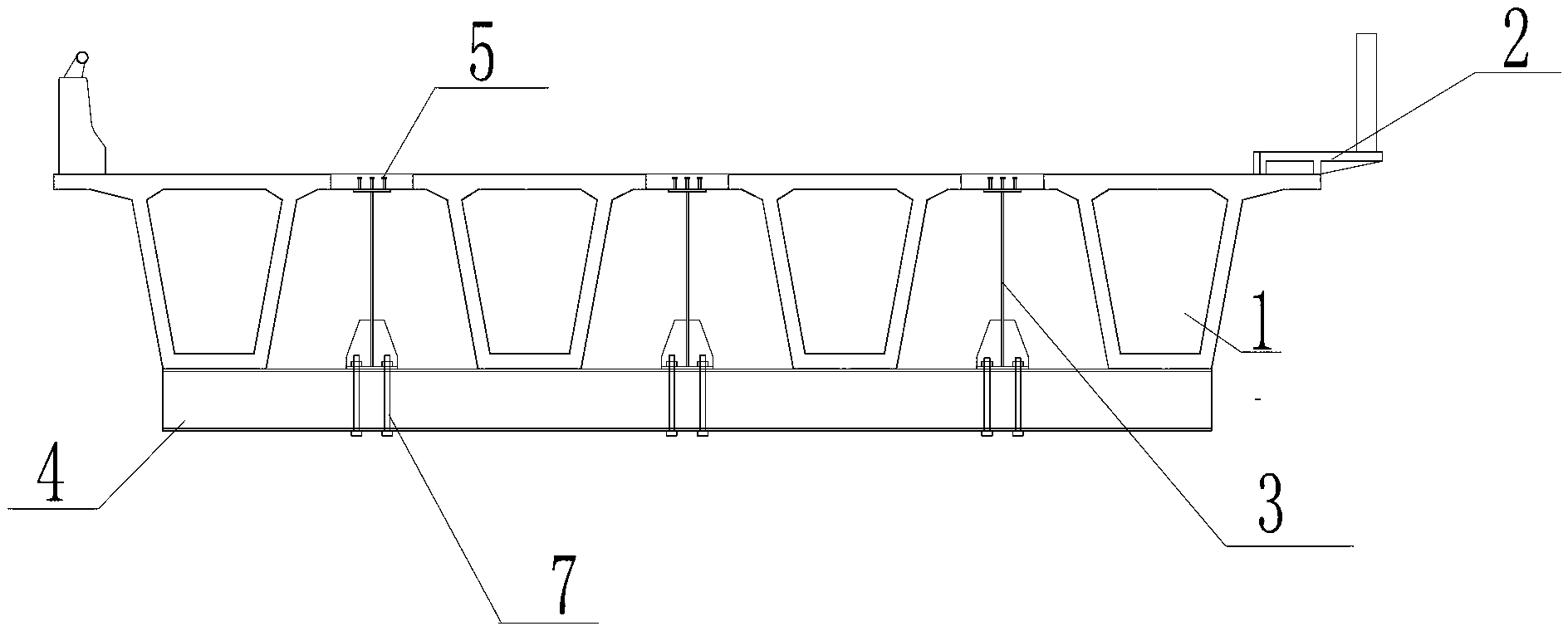

I-section steel girder reinforcement small box girder structure

InactiveCN103015329AReduce implementation riskAdd structural strengthBridge erection/assemblyBridge strengtheningHorizontal forceRoad surface

The invention discloses an I-section steel girder reinforcement small box girder structure. The structure comprises a road surface layer and small box girders arranged side by side on a pier, wherein an I-section steel girder is arranged between every two small box girders; the lower ends of the I-section steel girders are fixed at the lower end of the pier; and the upper ends of the I-section steel girders are fixed on flange plates fixed between every two adjacent small box girders. In the invention, the I-section steel girder reinforcement small box girder structure is adopted for the first time, and the new structure is added to bear forces; for inherent weaknesses that the horizontal force is weaker, the integrity is strengthened, so that the force condition becomes better, longitudinal stiffness is enlarged, and the horizontal force is improved; and the structure has the outstanding advantages of reliable technology, and small implementation risk.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

System and methods for providing a waterproofing form for structural waterproofing

ActiveUS8312682B2Prevent evaporationIncreased longitudinal stiffnessRoof coveringFloorsVapor barrierEvaporation

Owner:TROTTER ROBERT MIKE

Traction method and system for rail transportation

The invention relates to a traction method and a system for rail transportation. A soft elastic composite material is used as an elastic vibration-damping structure; a center pivot block is connected with a traction pin by an elastic nylon center pin sleeve, and the nylon sleeve with certain elasticity avoids the rigid shock between the center pivot block and the traction pin and simultaneously realizes the unconstrained rotation between the traction pin and the center pivot block when a vehicle makes a turning; two traction pads are respectively arranged in the front and at the back between the center pivot block and a bogie frame in the traction direction, the traction pads are rubber-metal compound elastic elements, two end plates of the traction pads are respectively provided with a connecting pin, and the connecting pin on the traction pad is directly inserted into a connecting hole for the center pivot block and the bogie frame; and the two traction pads connect the center pivotblock and the bogie frame, transfer traction force and brake force and buffer the shock load in transverse direction, vertical direction and other directions, so that the vehicle has better dynamicalperformance in operation.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Crashworthy plate of vehicle door

InactiveCN1958346AReduce distortionEnhance static pressure resistanceDoors/windowsBumpersMarine engineeringCar door

Owner:CHERY AUTOMOBILE CO LTD

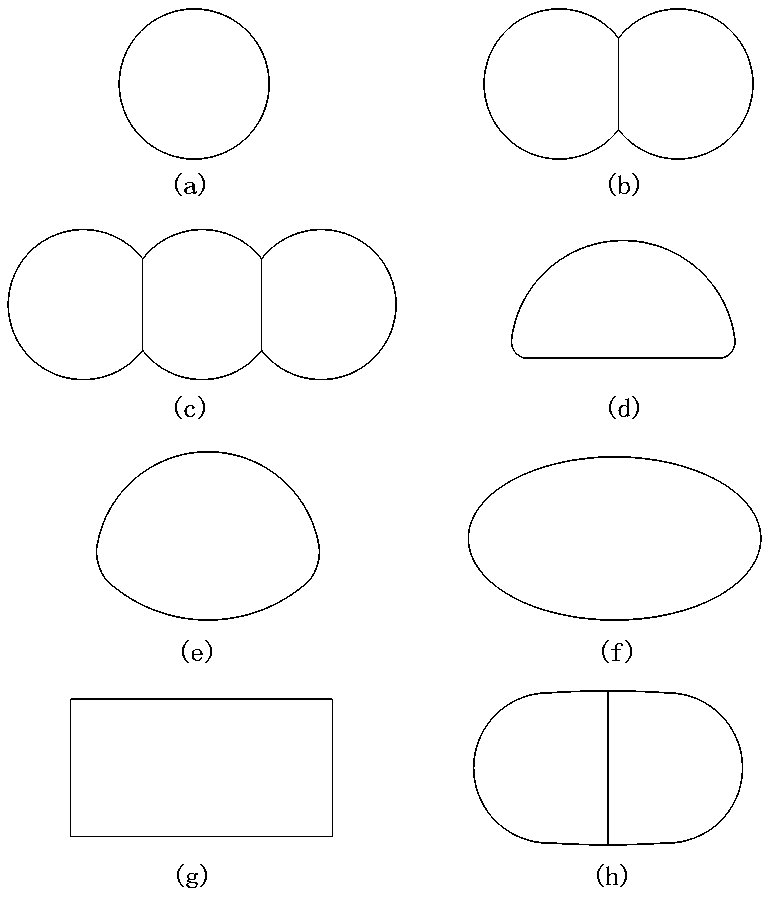

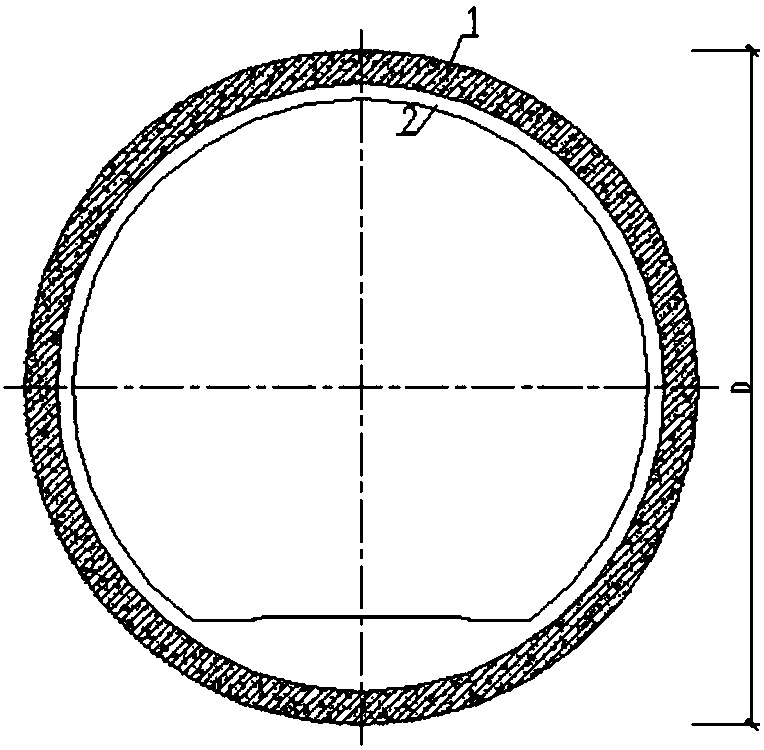

Design and calculation method of zero bending moment shield tunnel cross section

ActiveCN107247851AReduce bending momentReduce lateral deformationGeometric CADDesign optimisation/simulationWater tableWater level

The invention discloses a design and calculation method of a zero bending moment shield tunnel cross section. In the method, overall buried depth conditions, surrounding water and soil mechanical properties, underground water level conditions and the like of the top of a shield tunnel are analyzed according to formation conditions of the shield tunnel, the designed water and soil pressure mode of the shield tunnel is determined after comprehensive analysis, in this way, the rational axis and key parameters of shield tunnel cross section are designed, the cross section of the shield tunnel is of an egg-shaped structure which is small in the top and big in bottom, and the cross section theoretical bending moment of the shield tunnel cross section is zero under the effect of the designed water and soil pressure. The design and calculation method of the zero bending moment shield tunnel cross section has the advantages that the design and calculation method is simple and easy to operate, compared with a traditional shield tunnel, on the condition that the project cost is not basically increased, the bending moment of the designed zero bending moment shield tunnel is reduced to the greatest extent, therefore the cross section deformation of the shield tunnel and the expansion deformation of a pipe sheet longitudinal joint connector are avoided, breakage and water seepage of the pipe sheet longitudinal joint connector are prevented, and the using quantity of steel bars in a pipe sheet is reduced.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Vehicle battery case

ActiveUS10741809B2Reduce weightIncrease lateral stiffnessArc welding apparatusVehicle sub-unit featuresIn vehicleMechanical engineering

Owner:HYUNDAI MOTOR CO LTD +1

Light alloy wheel

InactiveUS20120286562A1Longitudinal rigidity be improveLateral rigidity be improveRimsPassengers carsFlangeMaterials science

A light alloy wheel having excellent longitudinal and lateral rigidities is provided.The present invention is a light alloy wheel 10 for a vehicle provided with a disk portion 6 and an inner rim portion 8 erected along a circumferential edge of the disk portion 6, wherein the inner rim portion 8 includes a well portion 11 erected vertically along the circumferential edge of the disk portion 6, a rim middle portion 12 continuous with the well portion 11, and an inner rim flange portion 13 connected to a junction portion 15 at a distal end of the rim middle portion 12, the inner rim flange portion 13 includes an outer circumferential flange 13a extending outward from the junction portion 15, and an inner circumferential flange 13b extending inward from the junction portion 15, and a circumferential edge of the outer circumferential flange 13a is bent in an axial direction of the light alloy wheel.

Owner:WASHI KOSAN

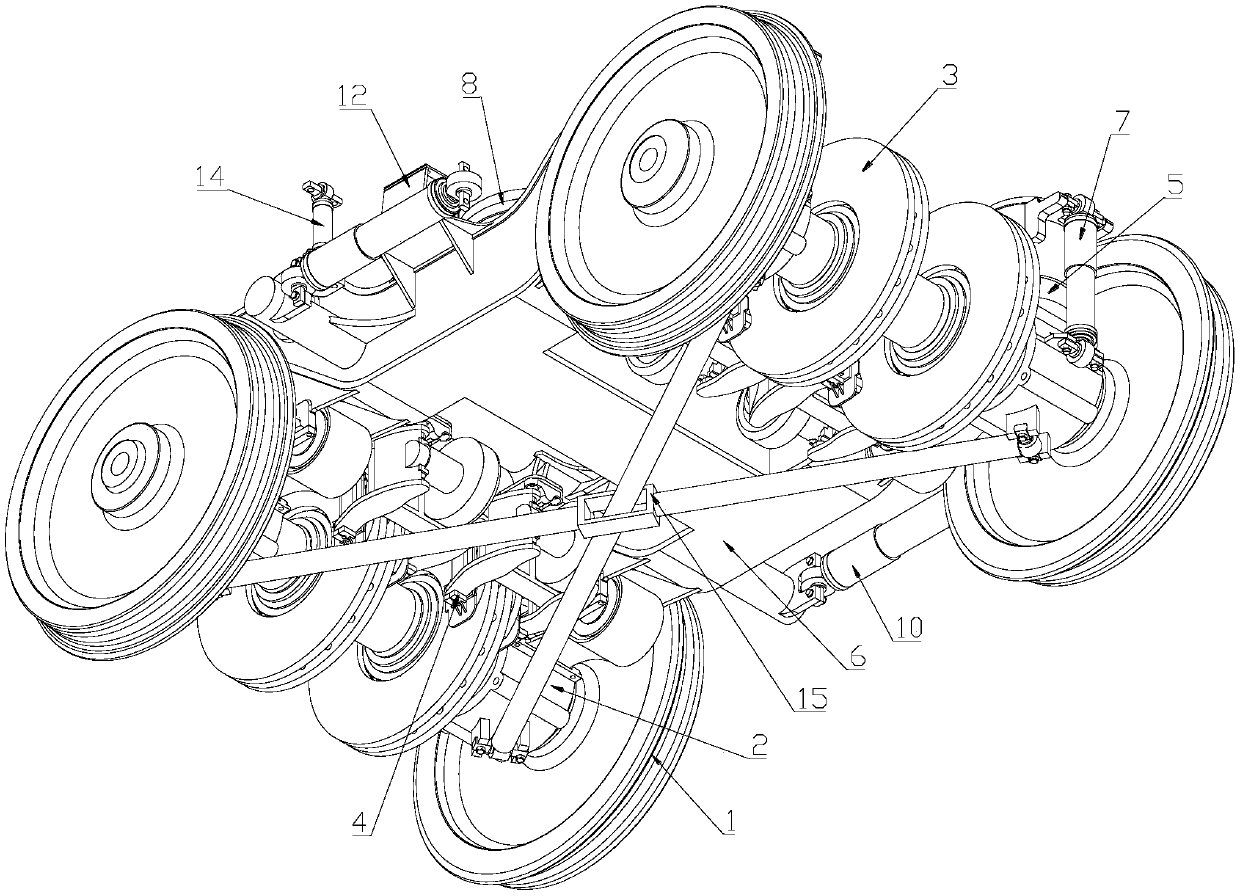

Axle box embedded bogie for high speed railway wagon

The invention discloses an axle box embedded bogie for a high speed railway wagon. An H-shaped integral truss and an embedded axle box are adopted; an anti-snake vibration absorber and a secondary transverse vibration absorber are arranged on the truss; the anti-snake vibration absorber is longitudinally connected to the two sides of a truss side frame; and the secondary transverse vibration absorber is transversely connected to the end part of a truss small cross beam. A primary suspension of the axle box embedded bogie for the high speed railway wagon is located by using an axle box rotatingarm; and under coordination of a wheel pair crossed supporting device, the vehicle stability is enhanced. Compared with a traditional truck, the axle box embedded bogie for the high speed railway wagon has the advantage that a problem of insufficient anti-roll ability provided by a secondary suspension is solved because an anti-roll torsion bar device is additionally mounted. According to the axle box embedded bogie for the high speed railway wagon, a high speed railway wagon bogie overall scheme satisfying a cargo transporting realistic demand is designed for a problem that an operation speed of an existing truck bogie cannot satisfy a demand. According to the axle box embedded bogie for the high speed railway wagon, on the basis of an axle box embedded type integral truss structure bogie, the critical value of velocity is increased by improving the anti-snake motion performance and the motion stability during operation.

Owner:SOUTHWEST JIAOTONG UNIV

Anti-collision structure of vehicle door

InactiveCN101270628AHigh strengthImprove crash resistanceDoorsDoor leavesStructure basedImpact energy

The invention relates to an anti-collision structure of the car door. The invention has an additional anti-collision bolt structure based on the traditional car door structure. Bolt gears with a welding nut on the internal plate of the car door to connect with the car door. A matching hole is arranged on the corresponding position of side wall. When collision happens, the anti-collision bolt will balance out the bore brink on the side wall. According to structural mechanics principle, the structure can compensate for the deficiency of an anti-collision plate or an anti-collision rod during the collision, thus effectively improving the anti-collision ability of the car door. In addition, impact energy can be led to the bottom of the car door and to the side wall to possibly reduce the deformation of the door, thus keeping the integrity of the car body and giving maximum possible protection to an occupant to prevent an occupant from getting hurt.

Owner:CHERY AUTOMOBILE CO LTD

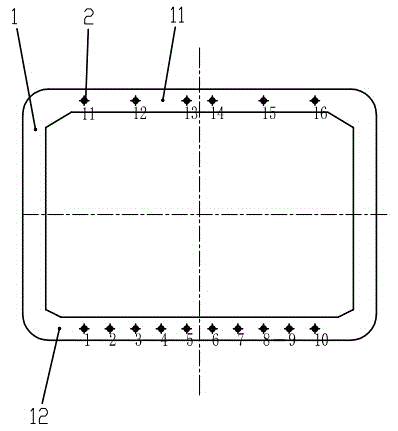

Assembly type bamboo bridge with variable expansion coefficients

ActiveCN103452035AHigh tensile strengthNo possibility of crackingSynthetic resin layered productsBridge structural detailsPolymer sciencePolymer chemistry

The invention provides an assembly type bamboo bridge. The assembly type bamboo bridge comprises bamboo longitudinal beams (1), bamboo transverse beams (2), bamboo panels (3), transverse pre-stressing tendons (4) and longitudinal pre-stressing tendons (16), the outer surface of a bamboo is sequentially and uniformly coated with a layer of waterborne polyurethane resin, a layer of polyurethane resin, a layer of waterborne polyurethane resin and a layer of resorcinol formaldehyde resin, and the expansion coefficients of the four coating layers are sequentially lessened from the outer surface of the bamboo to outside. The assembly type bamboo bridge provided by the invention has the advantages that the structural strength is large, the ductility is good, a selected material is environment-friendly, standardization degree and assembling degree of structural members are high, the structural integrity is good, the advantages of the material can be fully expressed, and the requirements on normal use and durability of a bridge structure can be met.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

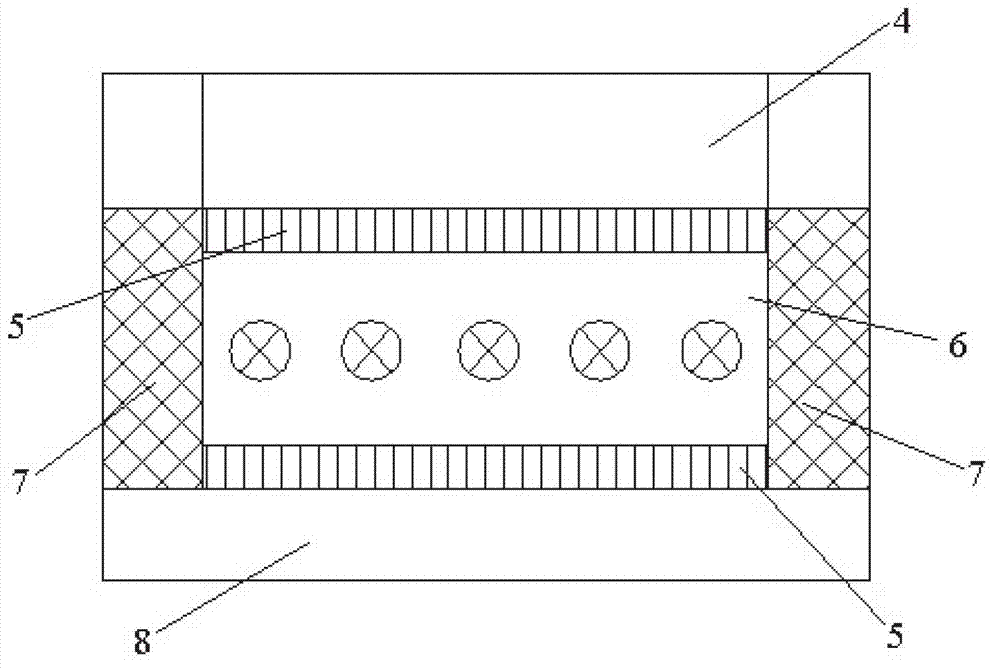

High-speed railway nose-shaped metal sound barrier unit board

InactiveCN102261045AImprove sound absorptionImprove sound insulationNoise reduction constructionNoseBarrier effect

The invention discloses a nose-shaped metal sound barrier unit plate for a high-speed railway. The unit plate comprises an aluminium alloy face plate (1), an aluminium alloy back plate (9), a fiber cement plate (13) between the aluminium alloy face plate (1) and the aluminium alloy back plate (9), sound absorbing materials (14) and sound absorbing material fixing devices (16), wherein a nose-shaped bulge (2) protruding outwards is arranged in the middle-upper part of the aluminium alloy face plate (1); the slant part of the nose-shaped bulge (2) is arc-shaped; a transverse bottom (3) is provided with sound absorbing materials (15); and sound holes (4) are arranged on the bottom (3) of the nose-shaped bulge (2) and on the parts except the nose-shaped bulge (2), on the aluminium alloy face plate (1). The unit plate has a strong barrier effect on sounds and has a good noise reduction effect.

Owner:常州西南交大金路轨道交通科技发展有限公司 +1

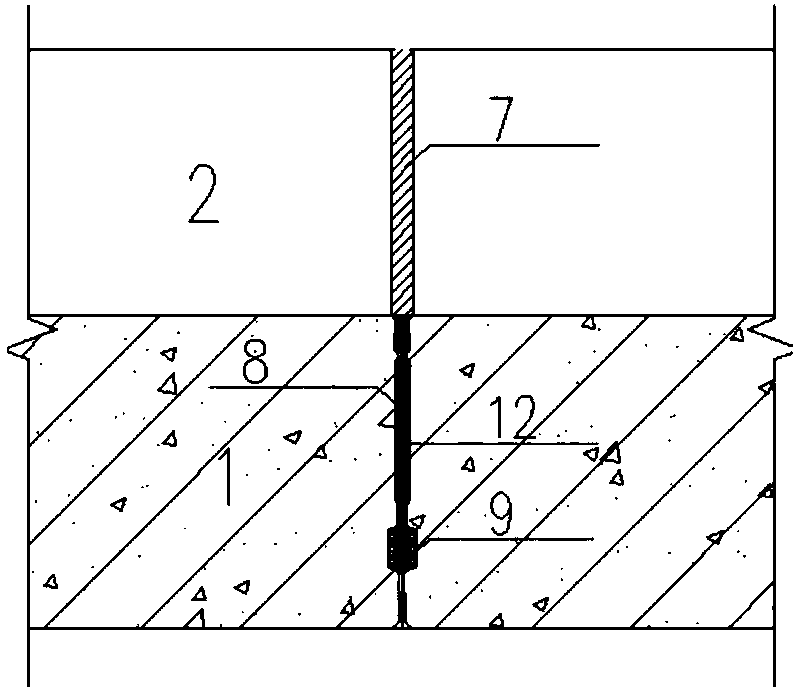

Double-layer lining shield tunnel deformation joint structure and shield tunnel

PendingCN108150192AReduce the amount of openingImprove waterproof effectUnderground chambersTunnel liningTransverse shearEngineering

The invention discloses a semi-flexible and semi-rigid double-layer liner shield tunnel deformation joint structure. The structure comprises segments and linings, and laminated structural connection is formed between the segments and the linings in a non-deformation joint section; in a deformation joint section, the segments is continuously provided with N segment deformation joints at a predetermined length L at each interval, and N is an integer greater than or equal to 1; in positions corresponding to deformation joints of the segments, the linings are provided with lining small sections, lining deformation joints are arranged at the junction of the lining small sections and adjacent non-deformation joint sections, and the lining deformation joints and the segment deformation joints arearranged longitudinally in a staggered mode; and the invention further discloses a shield tunnel. According to the semi-flexible and semi-rigid double-layer liner shield tunnel deformation joint structure and the shield tunnel, the longitudinal rigidity of the deformation joints is higher than that of conventional flexible deformation joints, the opening amount of the segment joints can be reduced effectively, and the waterproof effect of a double-layer lining structure is improved; N segment deformation joints are arranged at the deformation joint sections to jointly share the opening amountof the segment joints; and the segments and the lining deformation joints are staggered in space, and the transverse shear can be resisted effectively to prevent slab staggering.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

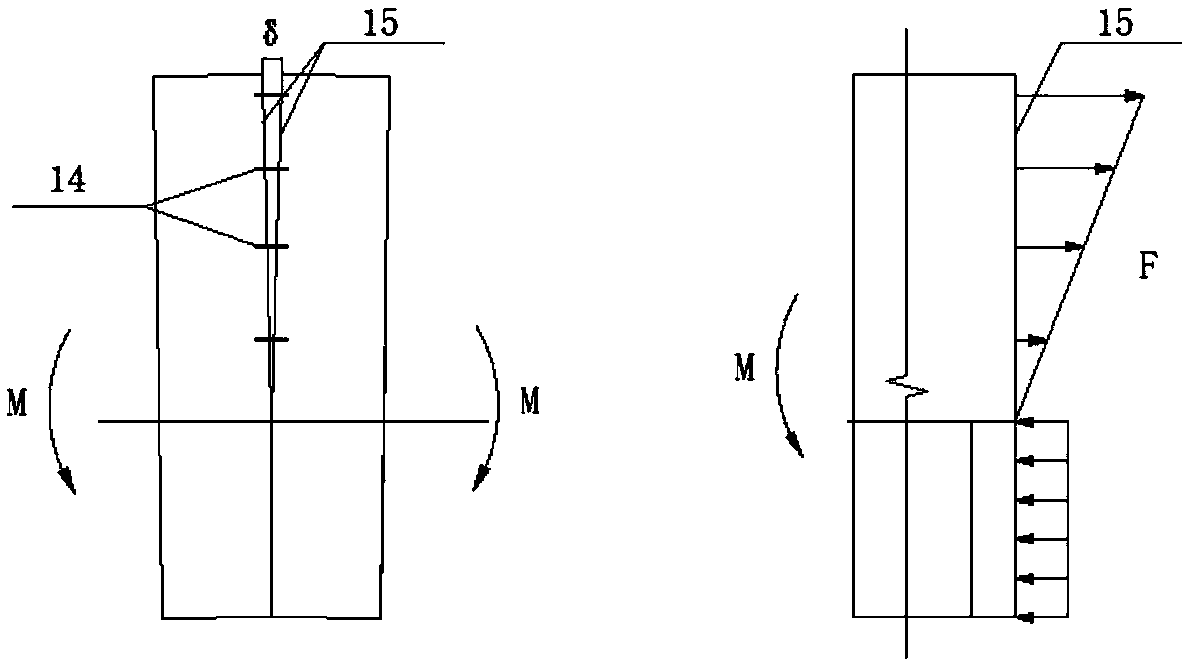

Anchor cable construction method for rectangular top pipe joint connecting and strengthening

ActiveCN104976424AIncreased longitudinal stiffnessImprove stabilityPipe laying and repairPre stressArchitectural engineering

The invention discloses a top pipe construction technology. An anchor cable construction method for rectangular top pipe joint connecting and strengthening comprises the steps of construction preparing, hole forming position measuring, anchor cable placing, anchorage device installing, steel strand tensioning, steel strand locking, primary grouting and secondary grouting. According to the construction method, prestress through holes are punched in the end faces of rectangular top pipes in the axial directions of the top pipes, an anchor cable penetrates through the prestress through holes to connect the multiple rectangular top pipes from a starting well to a receiving well, the anchor cable is tensioned and locked, grouting fixing is conducted, and therefore pipe joints are connected integrally in the longitudinal direction through the prestress steel strand, the longitudinal rigidity of a whole top pipe channel is improved, the stability of the top pipe channel is improved effectively, the construction technology is simple, the influences on the top pipe channel during later-period construction of buildings or structures on the periphery of the top pipe channel are reduced, the later maintenance cost is reduced, and the comprehensive construction cost is low.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

Light electric automobile body structure

InactiveCN104192215AExtend your lifeSmall load factorUnderstructuresSuperstructuresVehicle frameRoad surface

A light electric automobile body structure comprises a frame, an automobile body, an electric motor, suspensions, front wheels and rear wheels. The frame is of an integrated frame structure welded by aluminum alloy profiles and plates, the electric motor, the suspensions and the automobile body are arranged on the frame, the frame is connected with the wheels through a front suspension and a rear suspension, screw holes for fixing the automobile body are formed in the frame, and a base for fixing springs is arranged on the frame. The automobile body is good in comfort, and therefore, riding comfort is improved. The electric motor is not fixed on the automobile body directly, so that noise is unlikely to be transmitted into an automobile. The finished automobile is large in longitudinal rigidness, various impacts transmitted to the automobile body from the road surface can be relieved, and the service life of the automobile body is prolonged. When automobile collision happens, the frame can absorb part of impact energy, and therefore, safety performance is improved. The bearing factor of the automobile body is small, so that development of variants is facilitated. A chassis and the automobile body which serve as assemblies are assembled in advance respectively, so that the assembly process of the finished automobile is simplified.

Owner:山东宝雅新能源汽车有限公司

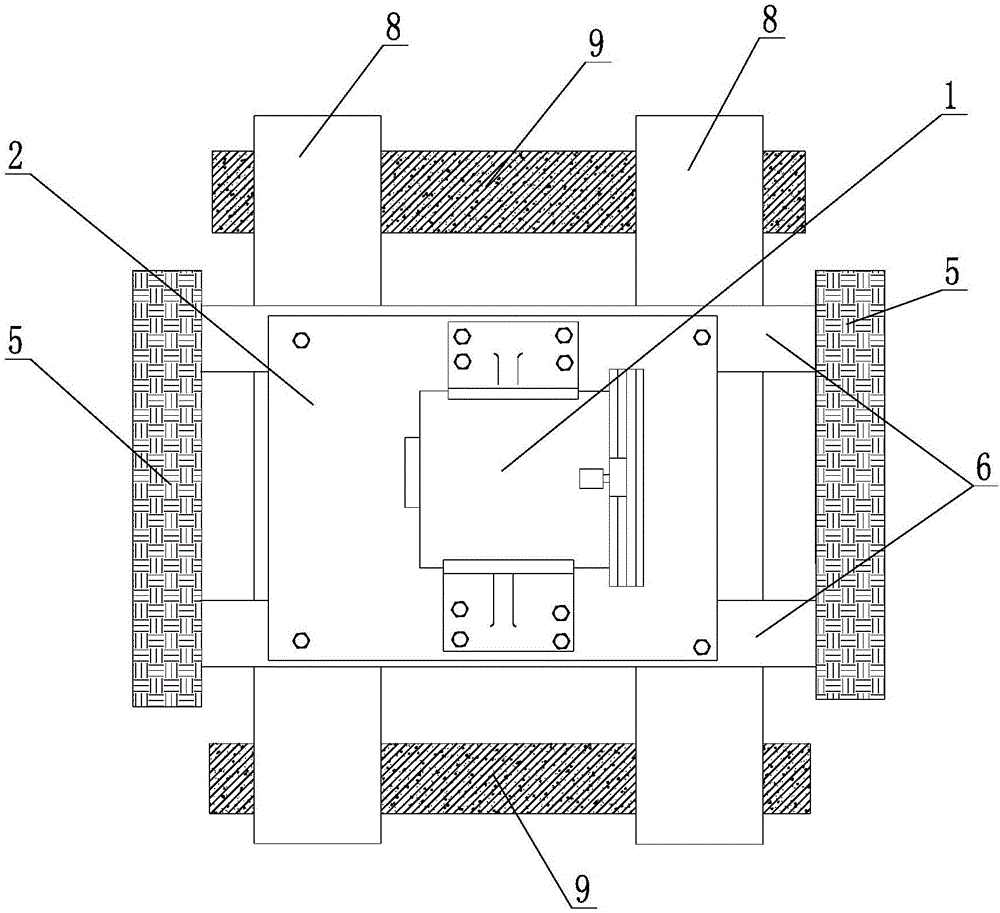

Novel elevator tractor belt swing-resistant damping device

ActiveCN106365020AEasy to installEasy loading and unloadingNon-rotating vibration suppressionBuilding liftsSteel frameNoise reduction

The invention relates to novel elevator tractor belt swing-resistant damping device. The device is provided with an elevator tractor, wherein the lower end of the elevator tractor is fixed on a base and the lower end of the base is provided with parallel joint steel strutting pieces; vibration isolation swing resistance assemblies are arranged between the base and the joist steel strutting pieces; each vibration isolation swing-resistant assembly comprises a telescopic standing column, a vibration isolation counter weight, a vibration isolation steel frame, a vibration isolation damping layer and a vibration isolation cushion layer. The novel elevator tractor belt swing-resistant vibration damping device is simple in structure, traverse rigidity and longitudinal rigidity of the strutting pieces are improved by the arrangement of the vibration isolation swing-resistant assemblies on the lower end of the tractor, traverse swing-resistant performance is greatly improved while vibration isolation in the vertical direction is guaranteed, and thus noise reduction performance, vibration isolation performance and swing-resistant performance of an elevator are wholly improved.

Owner:江苏工邦振控科技有限公司 +2

Car face wall architecture for a car such as a train car made from sandwich composite material

InactiveUS20170240188A1Reduce weightImprove mechanical stressRailway transportAxle-box lubricationFiberHoneycomb

A car belonging to a rolling vehicle, characterized in that it includes sidewalls in the form of a single piece made from composite material including a sandwich structure provided with a first skin on the outside of the car, a second skin on the inside of the car and a closed-cell foam or honeycomb core between the skins, the walls being provided with window openings formed by interruptions in the drapes of longitudinal fibres, transverse fibres and intersecting diagonal fibres, the openings having a polygonal shape that reduces the surface area of interrupted diagonal fibres in the corners of the openings.

Owner:EJRBAS SAFRAN LONCHERZ SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com