Car face wall architecture for a car such as a train car made from sandwich composite material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

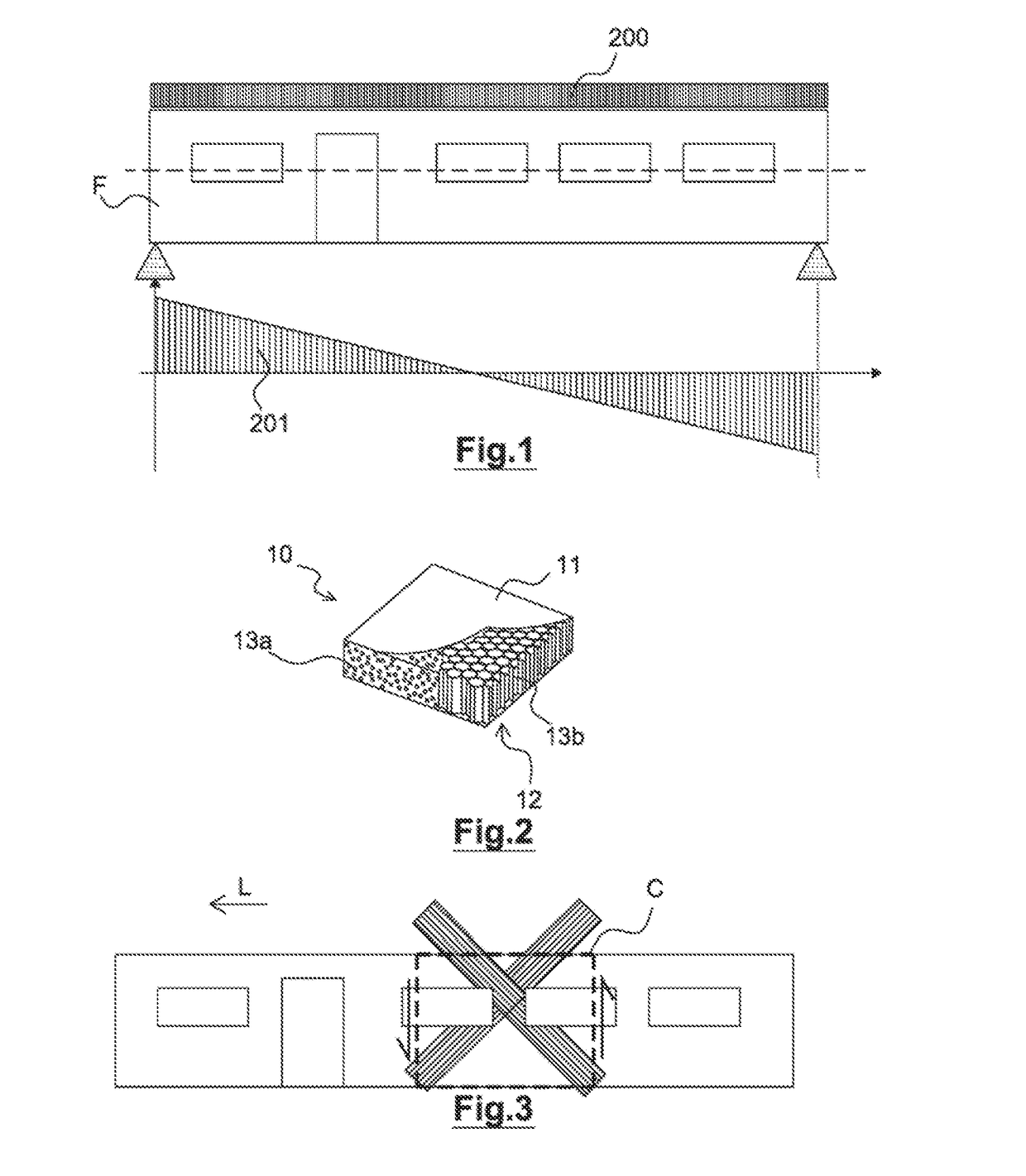

[0071]The disclosed embodiment is described mainly in FIGS. 2 and 4 to 8.

[0072]Its principle is to provide a train car 1, an example of which is given in FIG. 8, comprising lateral walls 2 in a single piece made of composite material.

[0073]The material selected has a sandwich structure 10 shown in FIG. 2, provided with a first skin 11 on the outer side of the car, a second skin 12 on the inner side of the car, and a core made of closed cells 13a or honeycomb 13b between said skins.

[0074]According to the disclosed embodiment, the walls are provided with window openings 20 formed by interruptions of drapes of longitudinal fibers, transverse fibers and crossed diagonal fibers 100 of the sandwich structure, said openings 20 as represented in FIG. 4 having a hexagonal form comprising two large horizontal sides and lateral walls 29 with a profile in the form of a convex “V” or an oval profile which reduce the surface of diagonal fibers 100 interrupted in the corners of the opening, and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com