Water-based lubricant based on two-dimensional material nanosheets/carbon quantum dots and preparation method of water-based lubricant

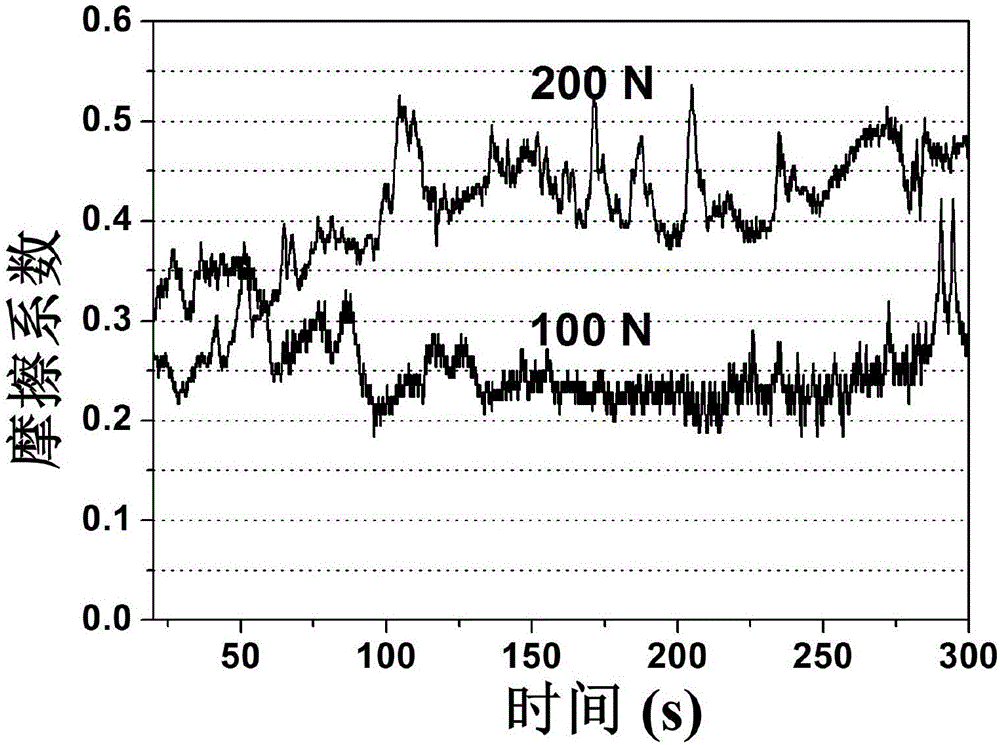

A technology of water-based lubricating fluid and carbon quantum dots, which is applied in lubricating compositions, petroleum industry, etc., to achieve the effects of good adaptability, simple and controllable preparation process, and low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

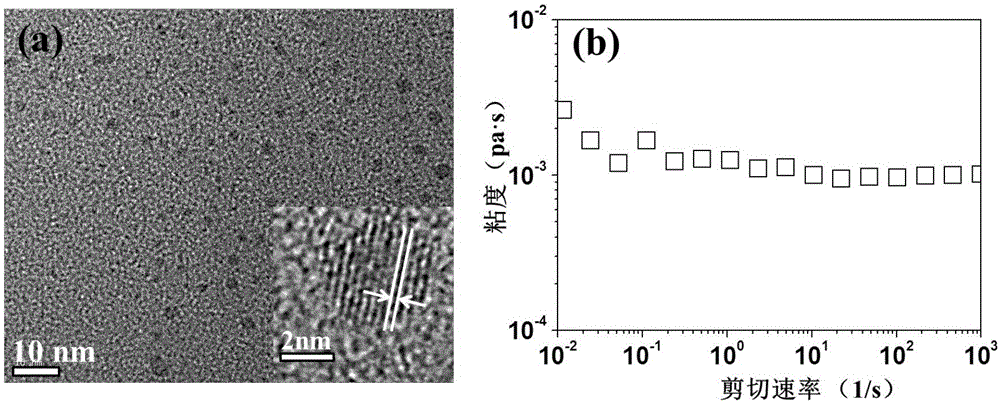

[0026] In this example, graphite, citric acid, and urea are used as raw materials to prepare graphene nanosheet / carbon quantum dot water-based lubricating fluid. The specific preparation process is as follows:

[0027] (1) prepare carbon quantum dots with existing microwave method;

[0028] (2) Disperse 300mg of carbon quantum dots in 200mL of ultrapure water, and ultrasonicate for 10 minutes to prepare an aqueous solution of carbon quantum dots with a uniform dispersion concentration of 1.5g / L;

[0029] (3) Take 50mg of graphite powder and add it to the carbon quantum dot aqueous solution prepared in step (2), and obtain the dispersion in ultrasonic for 10 minutes;

[0030] (4) Pour the dispersion obtained in step (3) into a glass bottle of 250 milliliters, and perform ultrasonication. The ultrasonic power is 80 watts, the ultrasonic temperature is 60 degrees, and the ultrasonic time is 60 hours to obtain graphene nanosheets / carbon quantum Water-based lube;

[0031] (5) the...

Embodiment 2

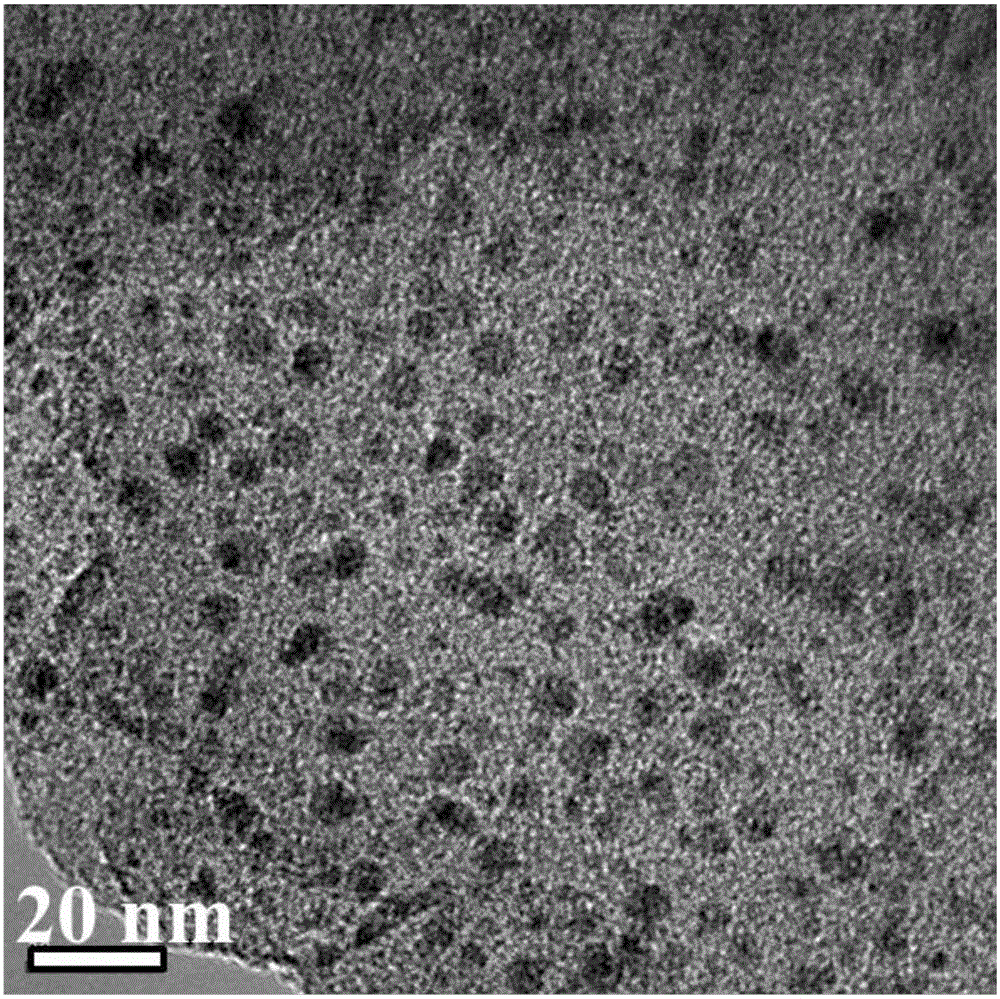

[0033] In this example, molybdenum disulfide, citric acid, and urea are used as raw materials to prepare molybdenum disulfide / carbon quantum dot water-based lubricating fluid. The specific preparation process is as follows:

[0034] (1) prepare carbon quantum dots with existing microwave method;

[0035] (2) Place 300mg of carbon quantum dots in 200mL of ultrapure water, and ultrasonicate for 10 minutes to obtain a uniformly dispersed carbon quantum dot aqueous solution with a concentration of 1.5g / L;

[0036] (3) Weighing 50 mg of molybdenum disulfide powder and adding it to the carbon quantum dot aqueous solution, and ultrasonicating for 10 minutes to obtain the dispersion;

[0037] (4) Pour the dispersion obtained in step (3) into a 250 ml glass bottle, and perform ultrasonication. The ultrasonic power is 80 watts, the ultrasonic temperature is 60 degrees, and the ultrasonic time is 60 hours to obtain the aqueous dispersion, which is Molybdenum disulfide / carbon quantum dot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com