Sterilization fabric softener and preparation method thereof

A softener and fabric technology, applied in the field of daily chemicals, can solve the problems of yellowing, poor biodegradability, etc., and achieve the effects of simple preparation method, environmental friendliness, excellent softness and antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A bactericidal fabric softener, comprising the following components in parts by weight: 15 parts of tetramethylene-bis(lauroyloxyethyl dimethyl ammonium bromide), 15 parts of bistallowyl ethyl carboxyl hydroxyethyl 8 parts of methyl ammonium methyl sulfate, 2 parts of lavender, 5 parts of ginkgo biloba, 0.1 part of hydroxypropyl methylcellulose, 0.2~2 parts of chitosan quaternary ammonium salt, 80 parts of deionized water.

[0016] The preparation method of the bactericidal fabric softener of the present embodiment comprises the steps:

[0017] Step (1), crush lavender and ginkgo leaves to 150-200 meshes, use deionized water as the leaching solvent to extract by diafiltration, leave the extract for 12 hours, and take the supernatant;

[0018] Step (2), heat the supernatant of step (1) to 40°C, add tetramethylene-bis(lauroyloxyethyl dimethyl ammonium bromide), Ammonium methyl methylsulfate and chitosan quaternary ammonium salt were stirred until they were evenly mixed, ...

Embodiment 2

[0020] A bactericidal fabric softener, comprising the following components in parts by weight: 20 parts of tetramethylene-bis(lauroyloxyethyl dimethyl ammonium bromide), 20 parts of bistallow ethyl carboxyl hydroxyethyl 10 parts of ammonium methyl sulfate, 4 parts of lavender, 10 parts of ginkgo biloba, 0.5 parts of hydroxypropyl methylcellulose, 2 parts of chitosan quaternary ammonium salt, and 100 parts of deionized water.

[0021] The preparation method of the bactericidal fabric softener of the present embodiment comprises the steps:

[0022] Step (1), crush lavender and ginkgo leaves together to 150-200 mesh, use deionized water as the leaching solvent for diafiltration extraction, let the extract stand for 48 hours, and take the supernatant;

[0023] Step (2), heat the supernatant of step (1) to 30°C, add tetramethylene-bis(lauroyloxyethyl dimethyl ammonium bromide), Ammonium methyl methylsulfate and chitosan quaternary ammonium salt were stirred until they were evenly ...

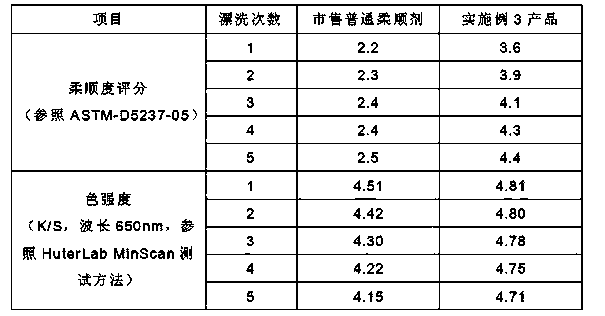

Embodiment 3

[0025] A bactericidal fabric softener, comprising the following components in parts by weight: 17 parts of tetramethylene-bis(lauroyloxyethyl dimethyl ammonium bromide), 17 parts of bistallowyl ethyl carboxyl hydroxyethyl 9 parts of ammonium methyl methyl sulfate, 3 parts of lavender, 8 parts of ginkgo biloba, 0.3 parts of hydroxypropyl methylcellulose, 1.1 parts of chitosan quaternary ammonium salt, 90 parts of deionized water.

[0026] The preparation method of the bactericidal fabric softener of the present embodiment comprises the steps:

[0027] Step (1), crush lavender and ginkgo leaves to 150-200 meshes, use deionized water as the leaching solvent to extract by diafiltration, leave the extract for 30 hours, and take the supernatant;

[0028] Step (2), heat the supernatant of step (1) to 35°C, add tetramethylene-bis(dodecanoyloxyethyl dimethyl ammonium bromide), bistallowyl ethyl carboxyl hydroxyethyl Ammonium methyl methylsulfate and chitosan quaternary ammonium salt w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com