High-efficiency composite hydrate inhibitor as well as preparation method and application thereof

A hydrate inhibitor and composite technology, which is applied in mechanical equipment, gas/liquid distribution and storage, pipeline systems, etc., can solve the problems of energy consumption, time consumption, uneconomical and other problems, and achieve long suppression time, cost reduction, chemical Good stability and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

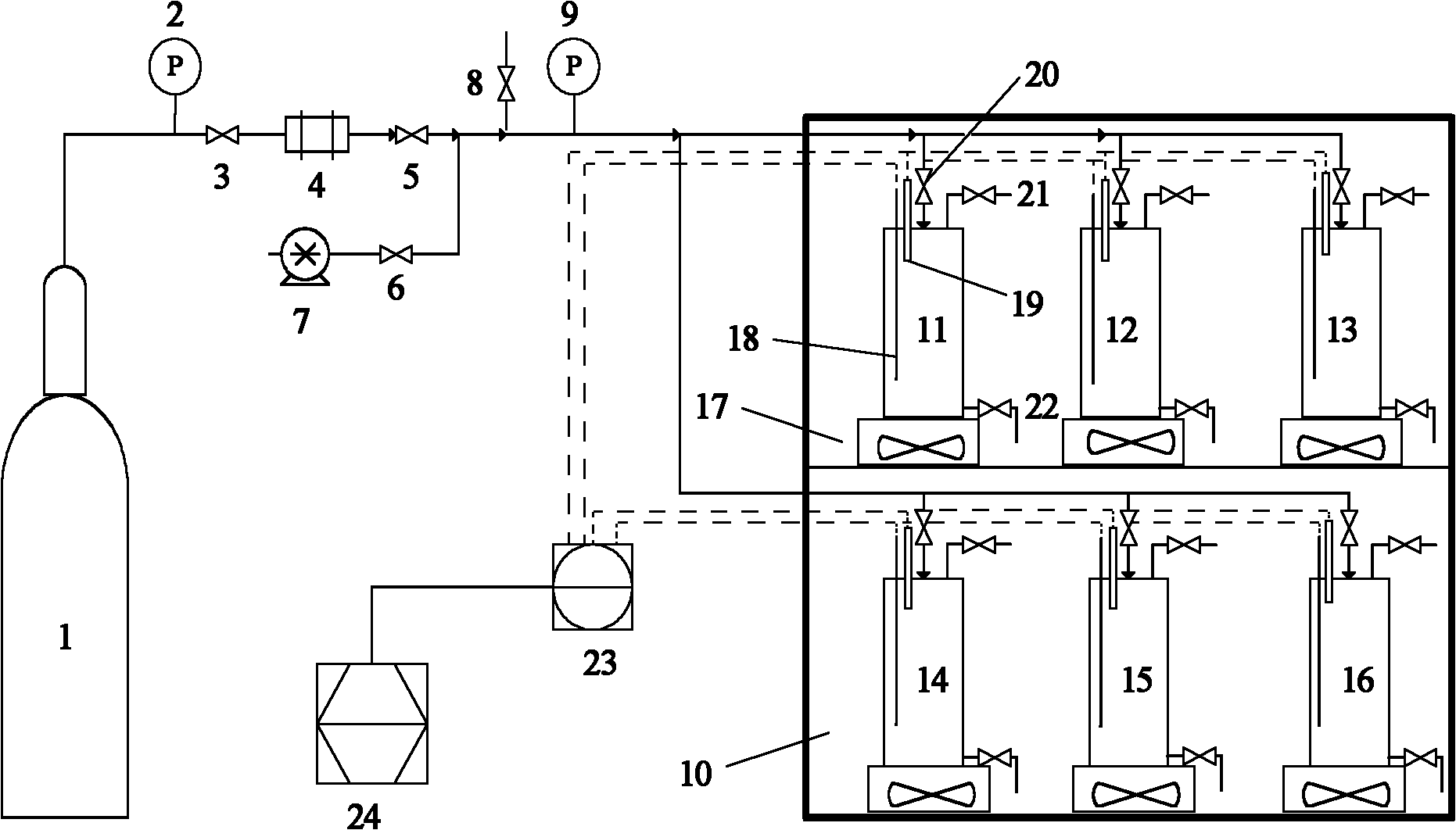

Method used

Image

Examples

Embodiment 1

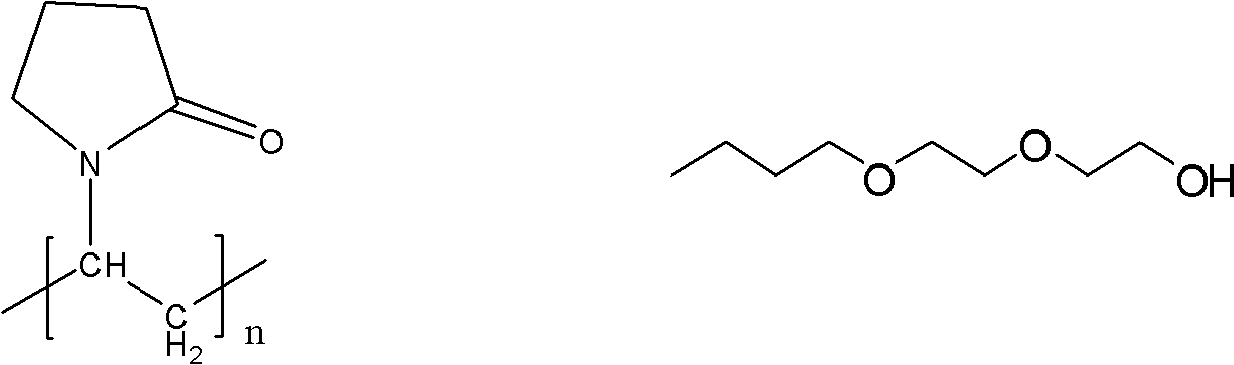

[0041] 1. Preparation of compound hydrate inhibitor

[0042] By N-vinylpyrrolidone (NVP) and diethylene glycol monobutyl ether according to the volume ratio of 1:2, the amount of initiator is 1.5% of the mass of NVP, carry out free radical solution polymerization reaction at 60 ° C, and react for 6 hours to obtain a composite Type hydrate inhibitor, wherein, the mass content of PVP is about 35%, the mass content of the synergistic solvent is about 65%, the initiator is completely decomposed, and there is no initiator in the product; it is proved by infrared spectroscopy that the pyrrolidone -C=O stretching vibration at 1660cm -1 , the C-H stretching vibration appears at 2950cm -1 , it can be determined as the target PVP.

[0043] 2. Add the composite hydrate inhibitor prepared above to a 19 wt% THF solution at a mass concentration of 2%, to prepare a reaction solution with a total mass of 40 g. Under normal pressure, the reaction temperature was maintained at -4.0°C, and hy...

Embodiment 2

[0045] 1. Preparation of compound hydrate inhibitor

[0046] By N-vinylpyrrolidone (NVP) and ethylene glycol butyl ether according to the volume ratio of 1:2, the amount of initiator is 1.0% of the mass of NVP, carry out free radical solution polymerization at 60 ° C, react for 8 hours, and obtain a composite hydration Inhibitors, wherein, the mass content of PVP is about 37%, the mass content of the synergistic solvent is about 63%, the initiator is completely decomposed and reacted, and there is no initiator in the product. Infrared spectroscopy proves that the -C=O stretching vibration of pyrrolidone is at 1660cm -1 , the C-H stretching vibration appears at 2950cm -1 , it can be determined as the target PVP.

[0047] 2. Add the composite hydrate inhibitor prepared above to a 19 wt% THF solution at a mass concentration of 2%, to prepare a reaction solution with a total mass of 40 g. Under normal pressure, the reaction temperature was maintained at -4.0°C, and hydrate was ...

Embodiment 3

[0049] 1. Preparation of compound hydrate inhibitor

[0050] By N-vinylpyrrolidone (NVP) and methanol according to the volume ratio of 1:4, the amount of initiator is 0.3% of the mass of NVP, carry out free radical solution polymerization at 60 ° C, and react for 10 hours to obtain a composite hydrate inhibitor. Wherein, the mass content of PVP is about 25%, the mass content of the solvent having a synergistic effect is about 75%, the initiator is completely decomposed, and there is no initiator in the product. Infrared spectroscopy proves that the -C=O stretching vibration of pyrrolidone is at 1660cm -1 , the C-H stretching vibration appears at 2950cm -1 , it can be determined as the target PVP.

[0051] 2. Add the composite hydrate inhibitor prepared above to a 19wt% THF solution at a mass concentration of 2%, and then add 4g of methanol to prepare a reaction solution with a total mass of 40g. Under normal pressure, the reaction temperature was maintained at -2.0°C, and n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com