Articles and methods providing liquid-impregnated scale-phobic surfaces

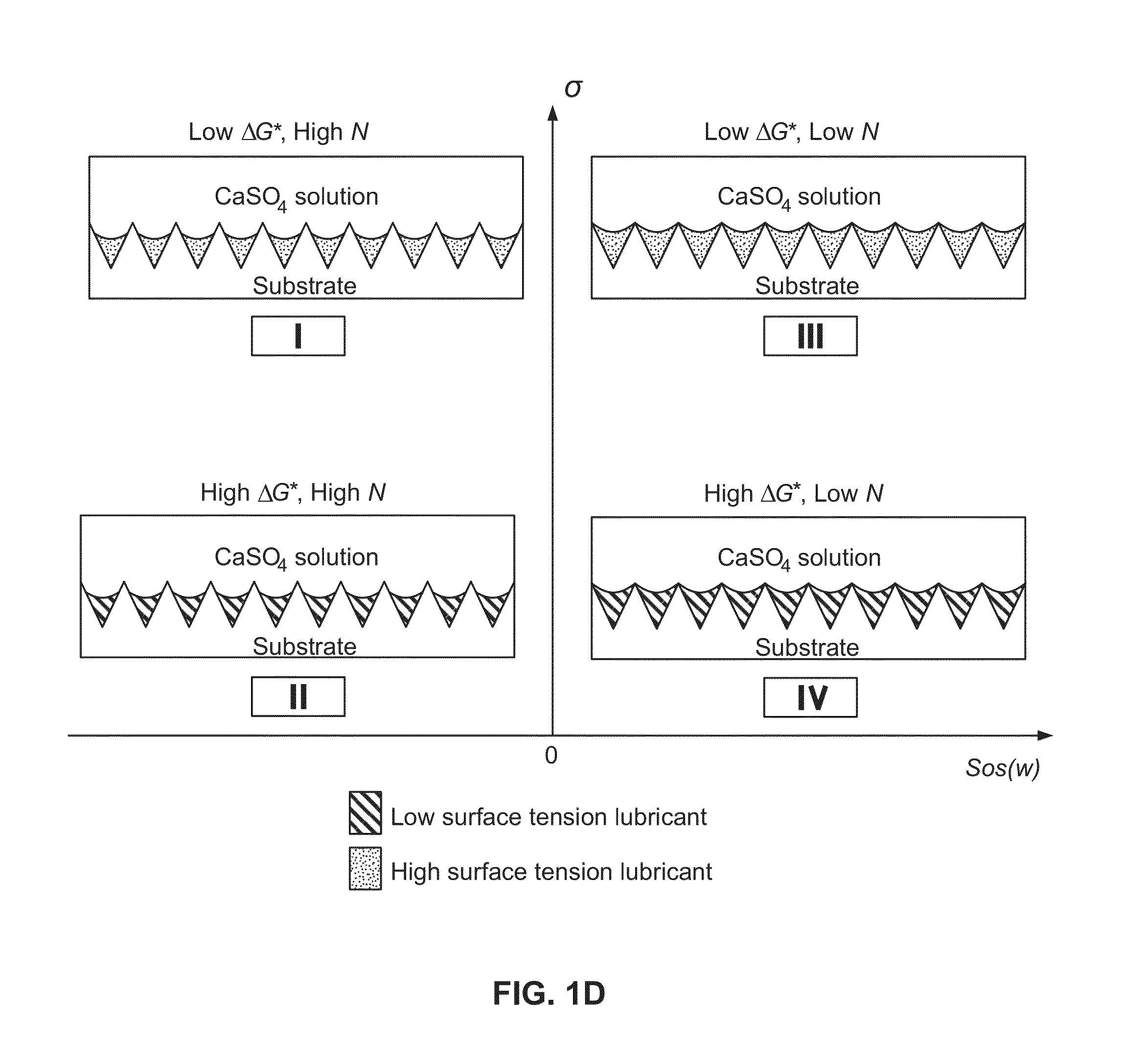

a technology of liquid impregnating and scale, applied in the direction of packaging foodstuffs, packaged goods types, lighting and heating apparatus, etc., can solve the problems of scale formation or precipitation fouling of heat exchanger surfaces and oil and gas pipelines, significant loss of efficiency and useful life of process equipment in these industries, and major impact on the capital and operating costs of most conversion processes. , to achieve the effect of reducing the number of particles, and reducing the number o

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experimental examples

Example 1

[0135]In this example, scaling experiments were conducted using calcium sulfate solution at a temperature of about 45° C. Bare smooth silicon, silanized silicon, silicon nanograss, silanized nanograss, and liquid impregnated surfaces were tested.

[0136]To systematically study scale formation on the test substrates, these substrates were immersed inside a 600 ml glass beaker. To reduce the surface energy of the dish and slides rack and prevent preferential scale formation, the substrates were coated with trichloro(1H,1H,2H,2H-perfluorooctyl)silane before the experiment. The glass beaker was filled with a saturated solution of CaSO4 in water and placed on a multi-position hotplate (Ika Works IKAMAG RT 15 position Hot Plate). Temperature was set at 45° C. and controlled within ±3° C. of the set point. The experimental set-up allows the solutions to reach supersaturation through evaporation of the aqueous phase during the course of experiment (80 h).

[0137]FIG. 4 shows a schemati...

example 2

[0149]In this Example, scaling experiments were conducted on stainless steel and carbon steel. Carbon steel is a low cost structural material whose low corrosion resistance is a serious drawback in certain industrial applications. This example demonstrates that by texturing and liquid-impregnating stainless steel and carbon steel surfaces, such surfaces can be made to become more resistant to scale formation.

[0150]The experimental setup was similar to the one described for silicon substrates in Example 1.

[0151]Stainless-steel (type 304, ASTM A240, from Mcmaster) and carbon-steel (grade 1010, ASTM A109, also from Mcmaster) were sand-blasted using silica and alumina particles of 80 grit size for ˜3 min. The feature size of the sandblasted steel is roughly 10 μm. In certain embodiments, the feature size for liquid impregnation may be less than about 100 μm.

[0152]After sand-blasting, polyethylmethacrylate (PEMA) (surface energy density 33 J / m2) was used to modify the surface energy of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flow rate | aaaaa | aaaaa |

| surface energy density | aaaaa | aaaaa |

| resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com