Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

228results about How to "Difficult to dissolve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

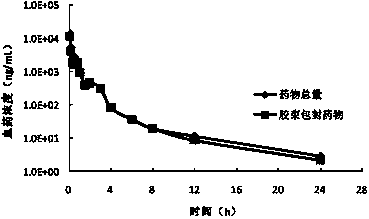

Amphiphilic block copolymer and preparation method thereof, micelle drug delivery system formed by copolymer and anti-tumor drug

ActiveCN103772686AGood compatibilityIncrease forcePowder deliveryEther/acetal active ingredientsPolyesterPolyethylene glycol

The invention relates to an amphiphilic block copolymer and a preparation method thereof, and a micelle drug delivery system formed by the copolymer and an anti-tumor drug. The amphiphilic block copolymer comprises a hydrophilic chain segment and a hydrophobic chain segment, and the end of the hydrophobic chain segment is sealed by hydrophobic radicals. According to the amphiphilic block copolymer disclosed by the invention, methoxy polyethylene glycol (or polyethylene glycol)-polyester segmented copolymer with generally recognized safety is taken as a base material, and terminated hydroxyl hydrophobic radicals of the polyester chain segment are modified, thus the compatibility of hydrophobic chain segments in drug molecules and segmented copolymers is improved, and mutual acting force is increased; through a self-assembling method, the drug can be solubilized in micelle hydrophobic cores of the amphiphilic block copolymer, and the drug molecules are limited in the micelle cores so as not to be likely to be dissolved out, thus drug delivery micelle with high stability is obtained.

Owner:SUZHOU LEINA PHARMA RES DEV

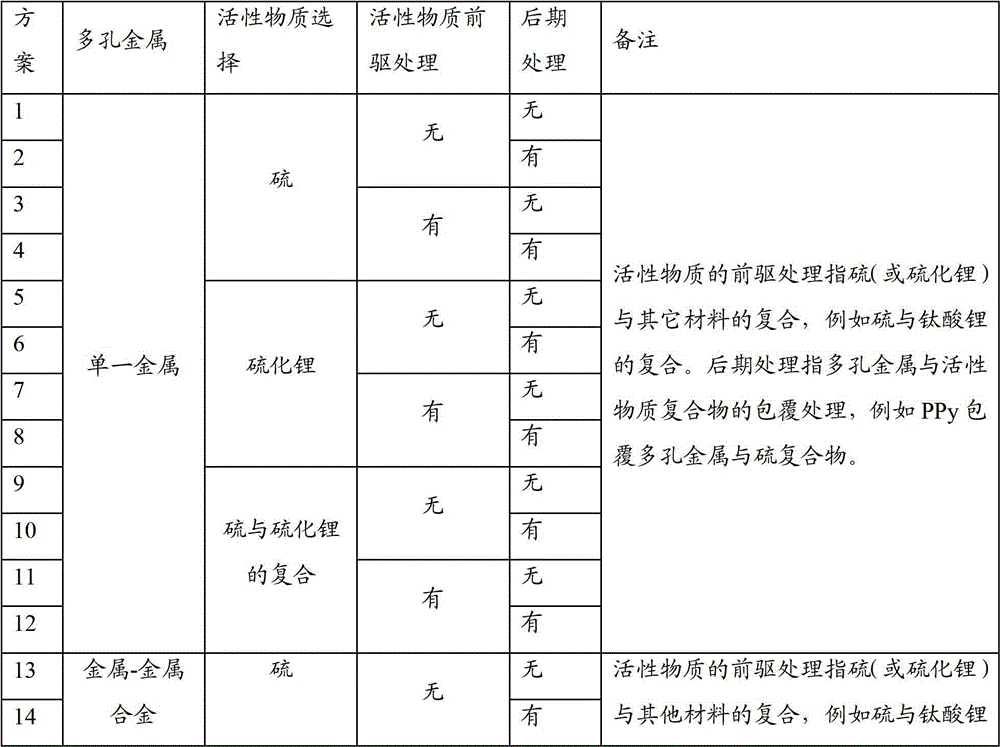

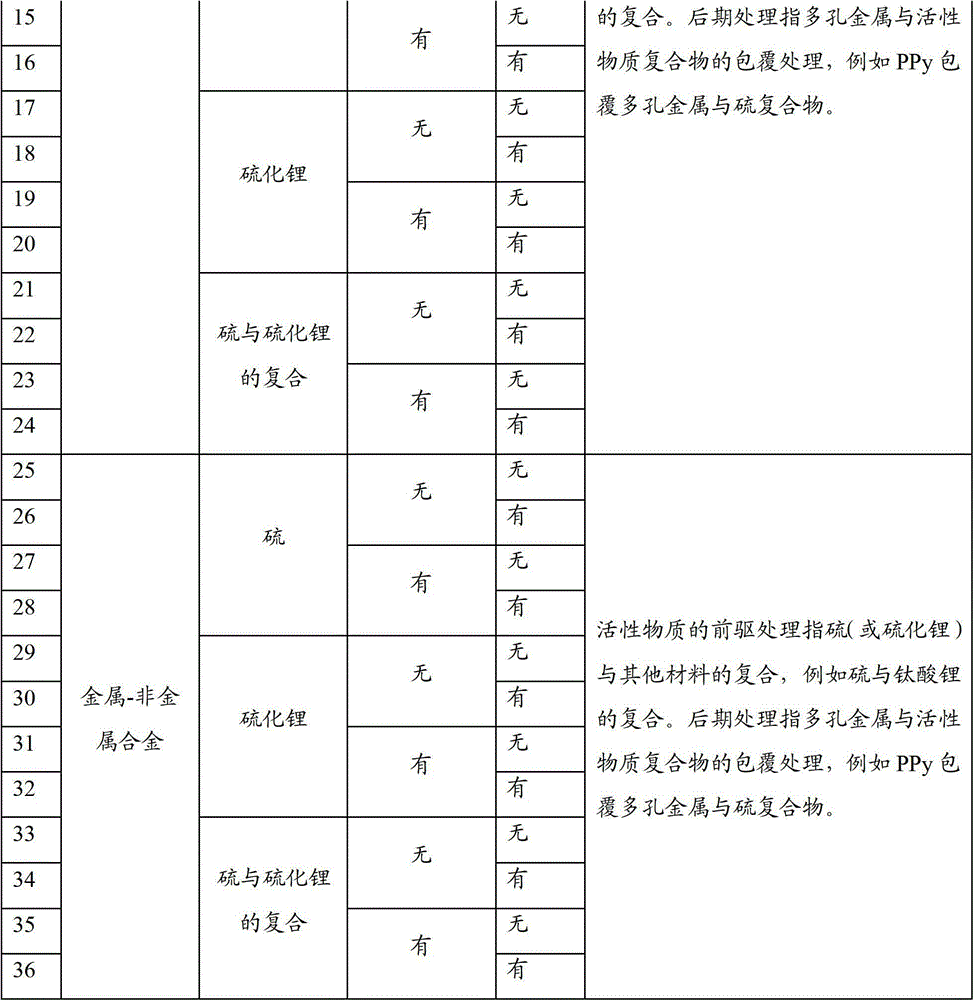

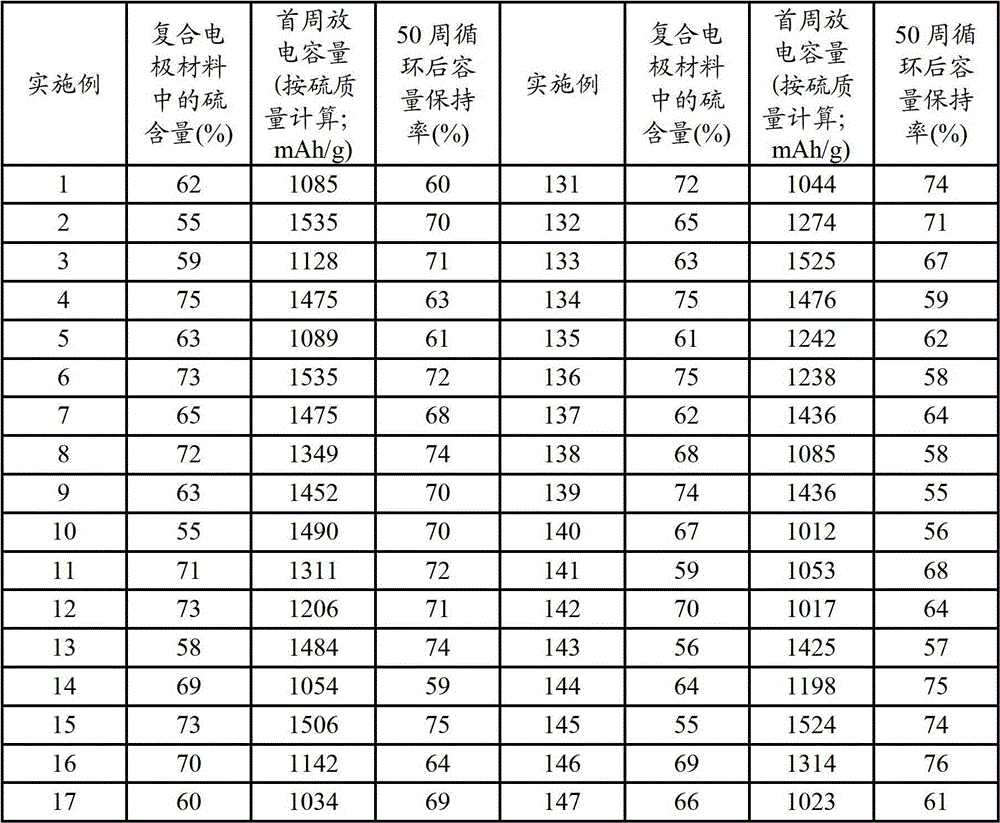

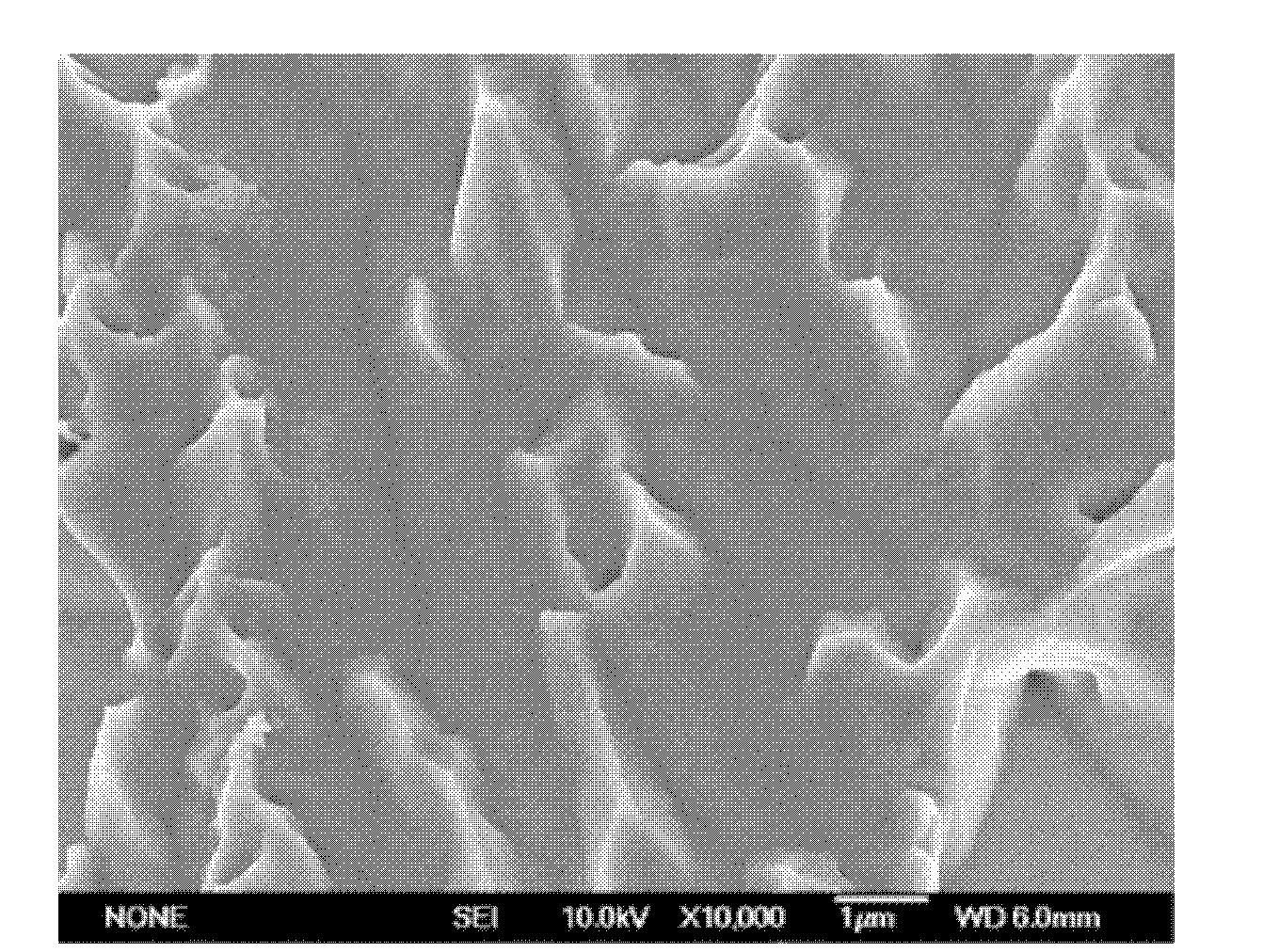

Lithium-sulfur battery anode material comprising porous metal and preparation method thereof

ActiveCN102723470ALarger than surfaceHigh porosityCell electrodesLithium sulfideLithium–sulfur battery

The invention discloses lithium-sulfur battery anode material comprising porous metal. The porous metal is compounded with lithium sulfide so as to be used as the anode material of the lithium-sulfur battery. The invention also discloses a preparation method of the lithium-sulfur battery anode material comprising the porous metal. According to the invention, by utilizing the characteristics of high electric conductivity, high porosity, high specific surface area and the like of the porous metal, elemental sulfur or the lithium sulfide is filled into pores of the porous metal, metal / sulfur composite material can be manufactured, and the utilization rate of the elemental sulfur and the lithium sulfide and the multiplying performance of the composite electrode can be increased; and simultaneously, by utilizing the strong interaction between the porous metal and the elemental sulfur or the lithium sulfide, the elemental sulfur, the lithium sulfide or polysulfide generated in a charge-discharge process can be more firmly attached on the surface of the porous metal, the dissolution of the polysulfide in an electrolyte, the shuttle effect caused by the dissolution of the polysulfide in the electrolyte and the deactivation on an anode and a cathode by redox product of the polysulfide can be restrained, and the circulation stability of a metal / sulfur composite electrode and the lithium-sulfur battery can be increased.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Curing agent for treating heavy metal pollution and heavy metal curing method

The invention relates to a curing agent for treating heavy metal pollution and a heavy metal curing method. The curing agent is prepared from following raw materials, by mass, 30-70 parts of a curing framework material, 20-60 parts of a curing cementing material and 5-10 parts of a curing promoter. The curing framework material is at least one of fly ash, blast furnace slag, carbide slag and calcined coal gangue powder; the curing cementing material is at least one of ordinary Portland cement and lime; and the curing promoter is at least one of potassium hydrogen phosphate, sodium hydrogen phosphate and aluminum sulfate. The heavy metal curing method includes following steps: mixing the curing agent, solid waste and water with stirring into paste to form a curing body, wherein a usage amount of the curing agent accounts for 30-50% of the dry weight of the solid waste; and maintaining the mixed curing body at normal temperature under a relative humidity of 90% for at least seven days, thereby finishing the heavy metal curing process. By means of the curing agent and the heavy metal curing method, a heavy metal curing efficiency is high and a treatment cost is low.

Owner:SHENZHEN TECHAND ECOLOGY & ENVIRONMENT CO LTD

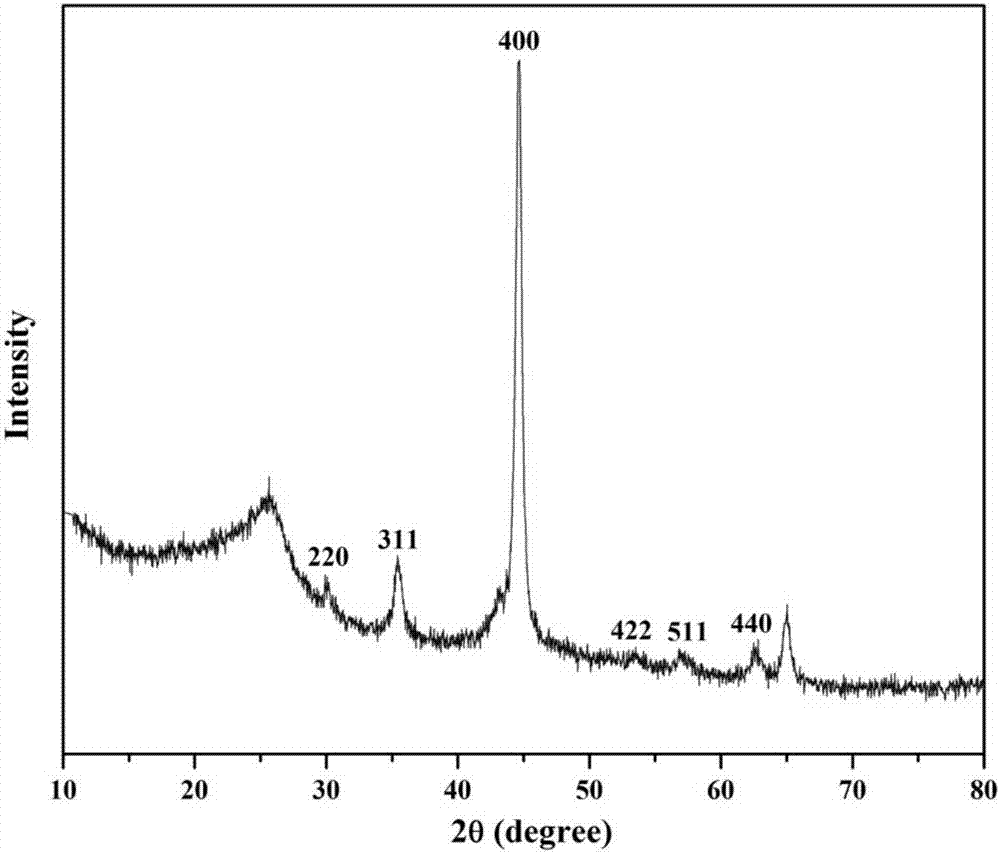

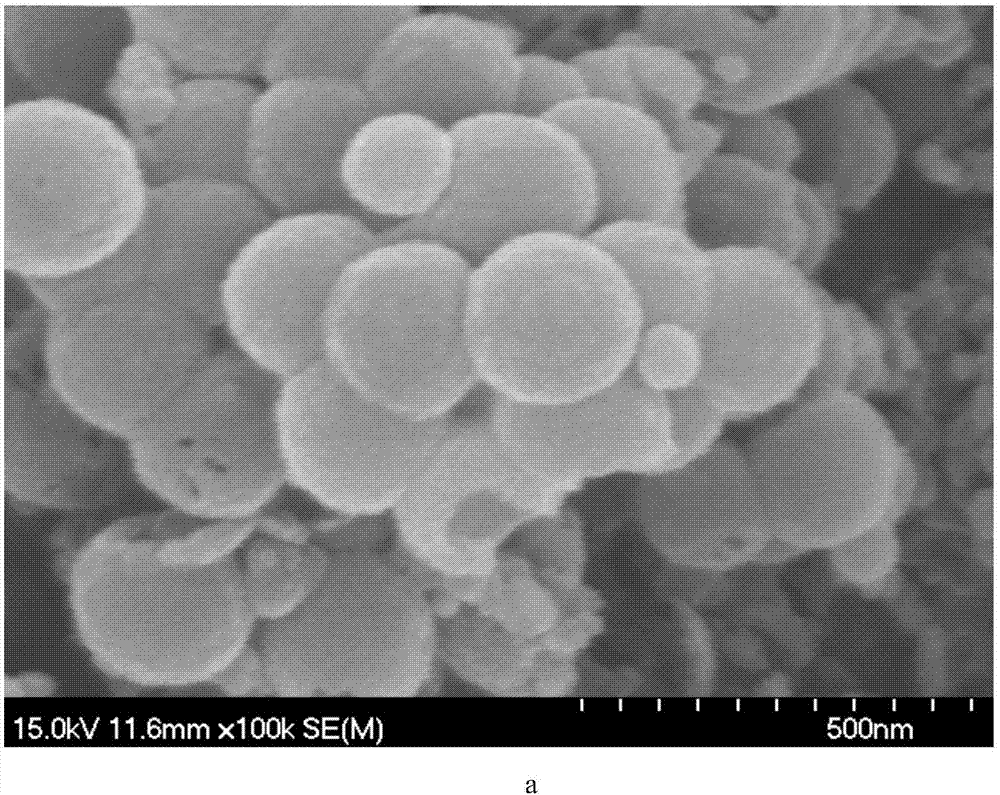

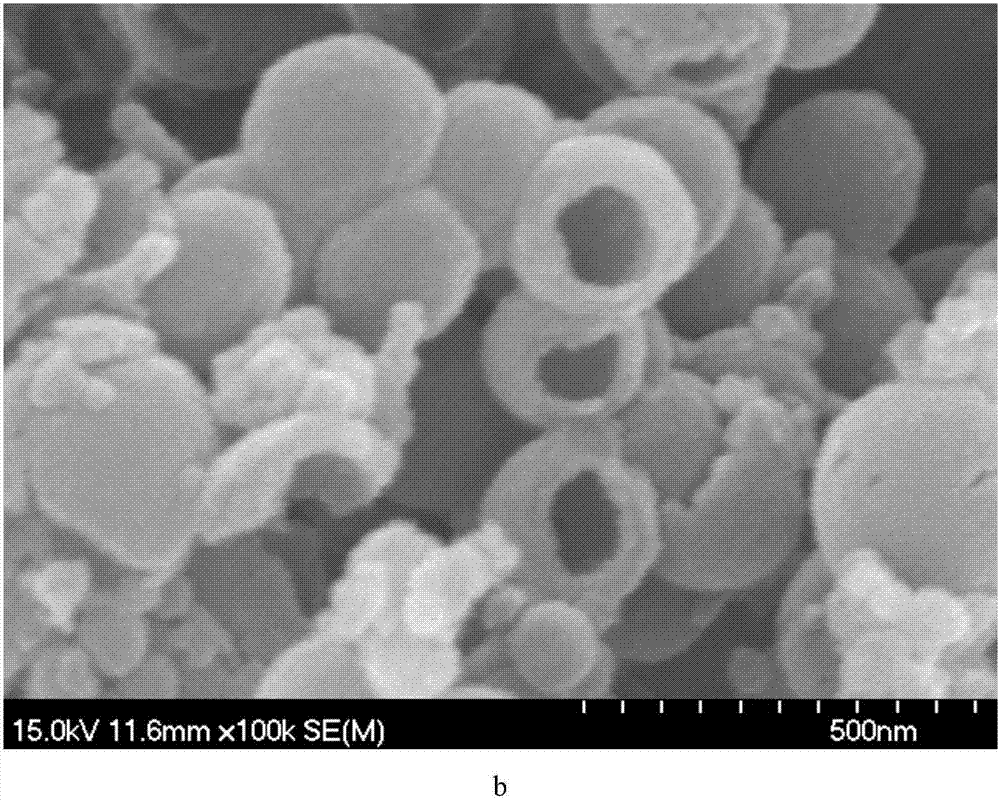

CoFe2O4/N/C hollow nanosphere and preparation and application thereof

InactiveCN106984261AImprove distributionImprove adsorption capacityPhysical/chemical process catalystsOther chemical processesMicrosphereCarbonization

The invention discloses a CoFe2O4 / N / C hollow nanosphere and preparation and application thereof. The preparation comprises: complexing dopamine with cobalt and iron metal ions under the condition of pH8-9 on a template as a SiO2 nanometer sphere to form a polymer shell layer, carbonization annealing to form N-doped carbon material loaded with CoFe2O4 metal nanoparticles, and finally, removing the SiO2 template with strong alkali to obtain CoFe2O4 / N / C hollow nanosphere. In the invention, the N / C matrix hollow structure is prepared by using the SiO2 nanosphere as the sacrificial template, theCoFe2O4 / N / C hollow nanosphere has a relatively large specific surface area and porosity, and can improve the distribution of CoFe2O4 nano metal particles loaded on the shell layer, enhance adsorption and catalytic activity on organic pollutants in waste water, and broaden the pH application range; the CoFe2O4 / N / C hollow nanosphere can be recycled due to magnetic performance, thus saving resources.

Owner:ZHEJIANG UNIV OF TECH

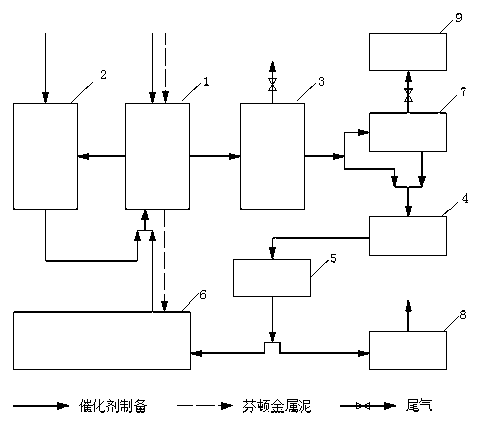

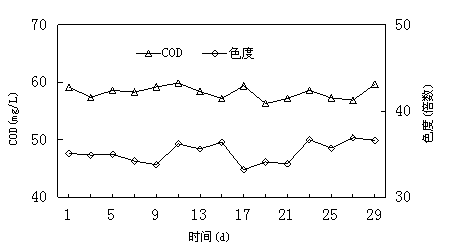

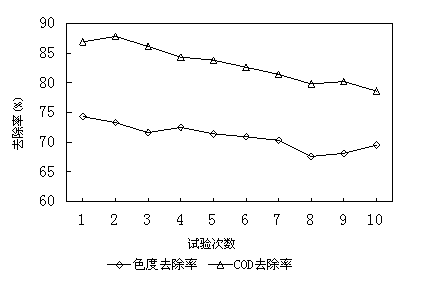

Catalytical ozonization catalyst utilizing multi-source sludge to prepare and application thereof

ActiveCN103007937ANo pollution in the processReduce manufacturing costOther chemical processesCarbon compoundsActivated carbonIndustrial waste water

The invention discloses a catalytical ozonization catalyst prepared by utilizing multi-source sludge and an application thereof, and establishes a method for preparing a sludge group active carbon catalyst for catalytical ozone oxidation organic industrial waste water. The method comprises the following steps of: utilizing multi-source sludge such as surplus sludge generated by urban sewage factory biochemical treatment and a metal sludge generated by a Fenton oxidation method, preparing a skeleton which is a sludge group active carbon through steps such as organic substance adding, actification, dehydration, drying, mixing, roasting and screening, wherein a surface layer contains a solid catalyst of metallic oxide, and the ratio of the sludge group active carbon and the metallic oxide in parts by weight is 1:(0.3-0.5). The catalyst is used for catalyzing ozone oxidation treatment organic industrial waste water and has higher catalytic activity and stability, the processing range is wide, the realization and popularization and application are easy, and the economic benefits are improved in an organic industrial waste water processing procedure.

Owner:TIANJIN UNITED ENVIRONMENTAL ENG DESIGN

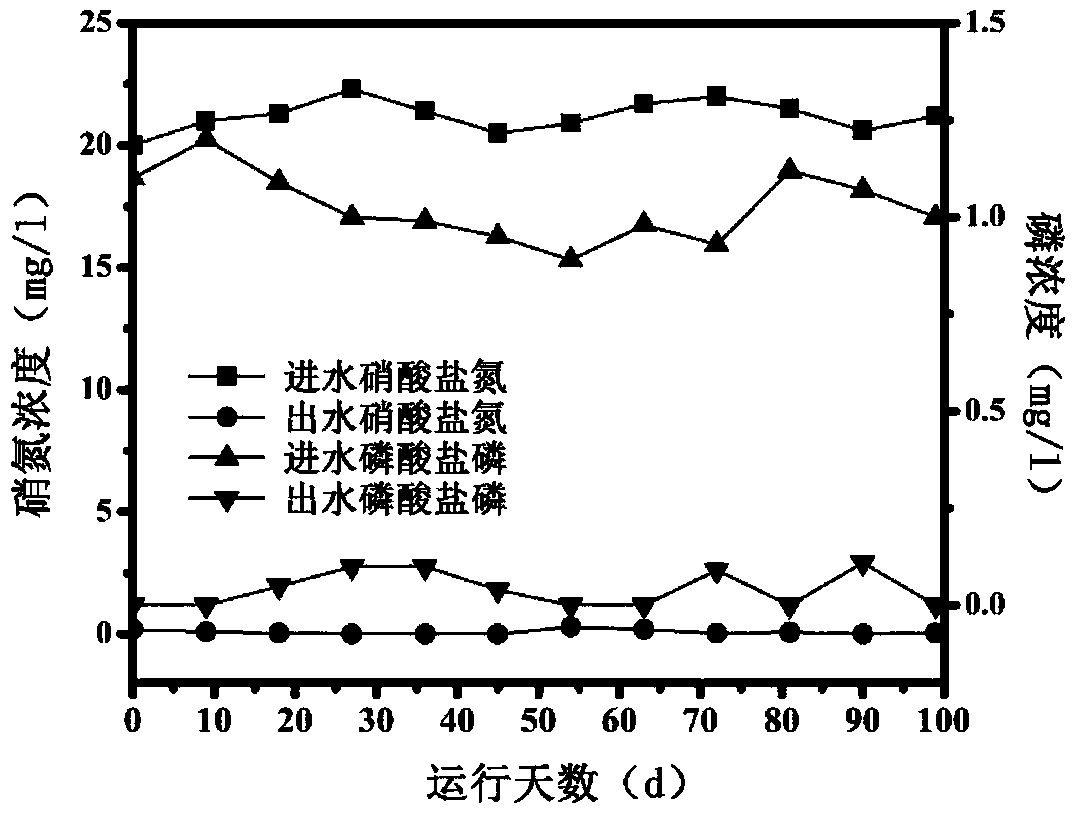

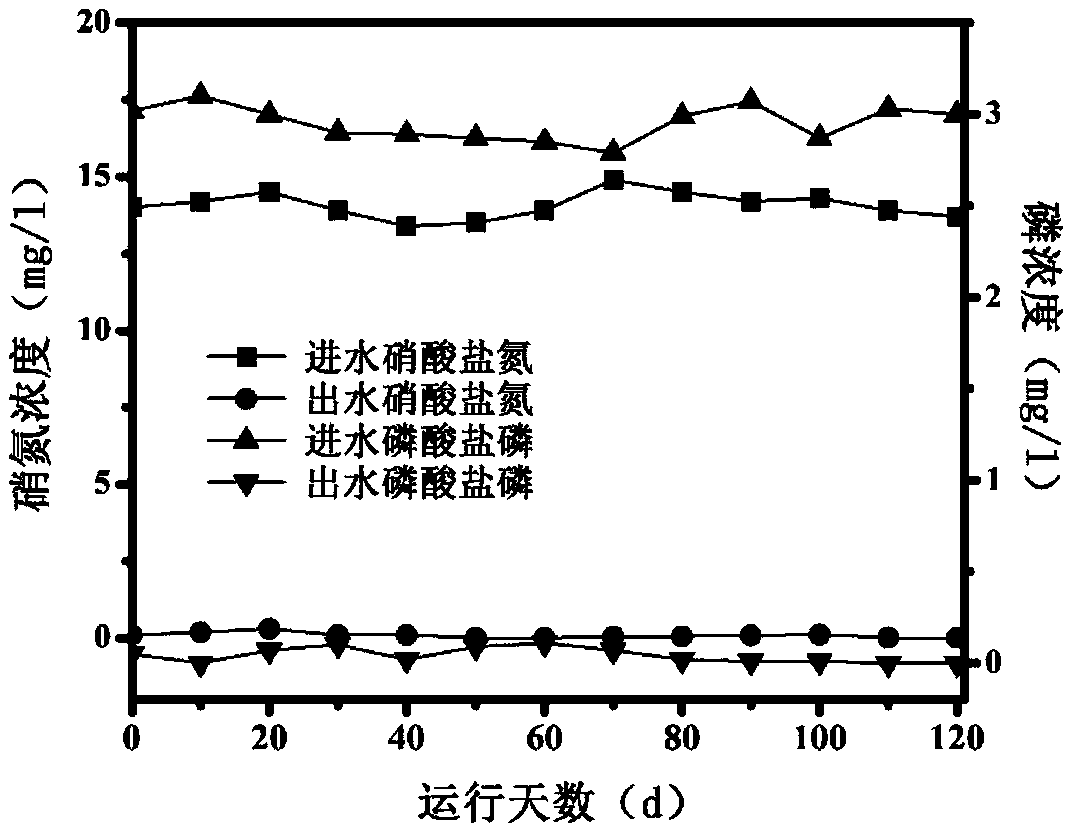

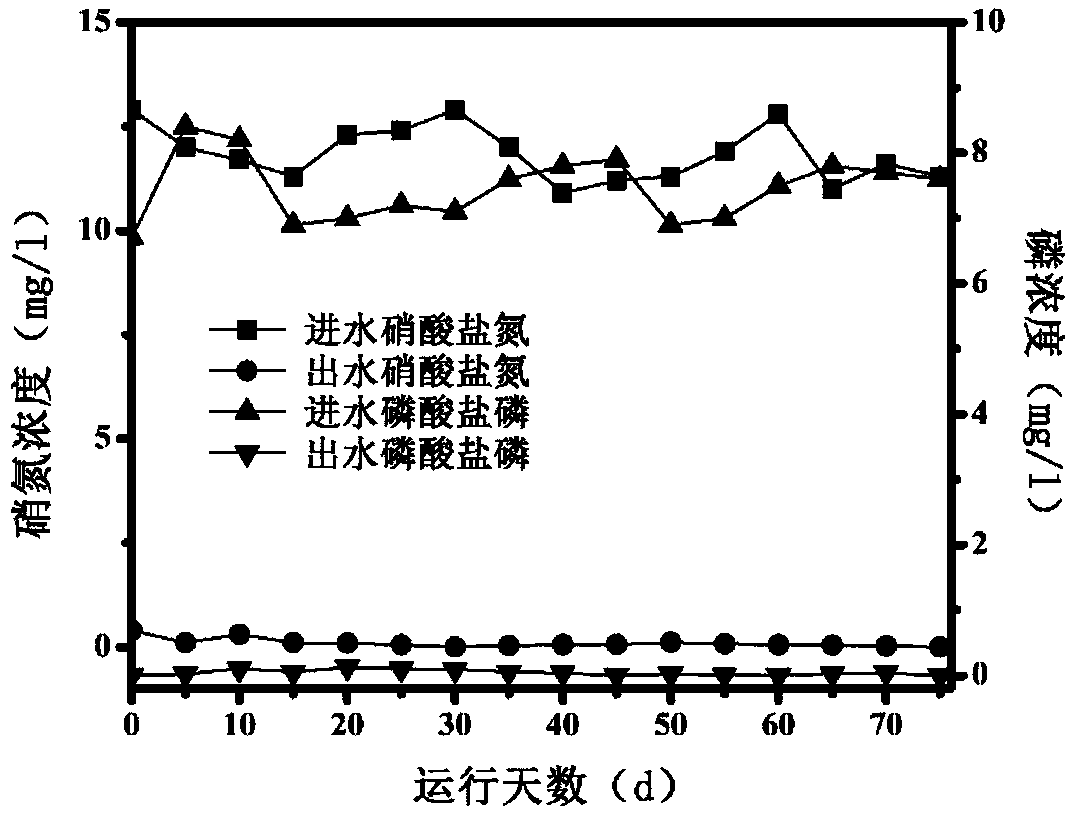

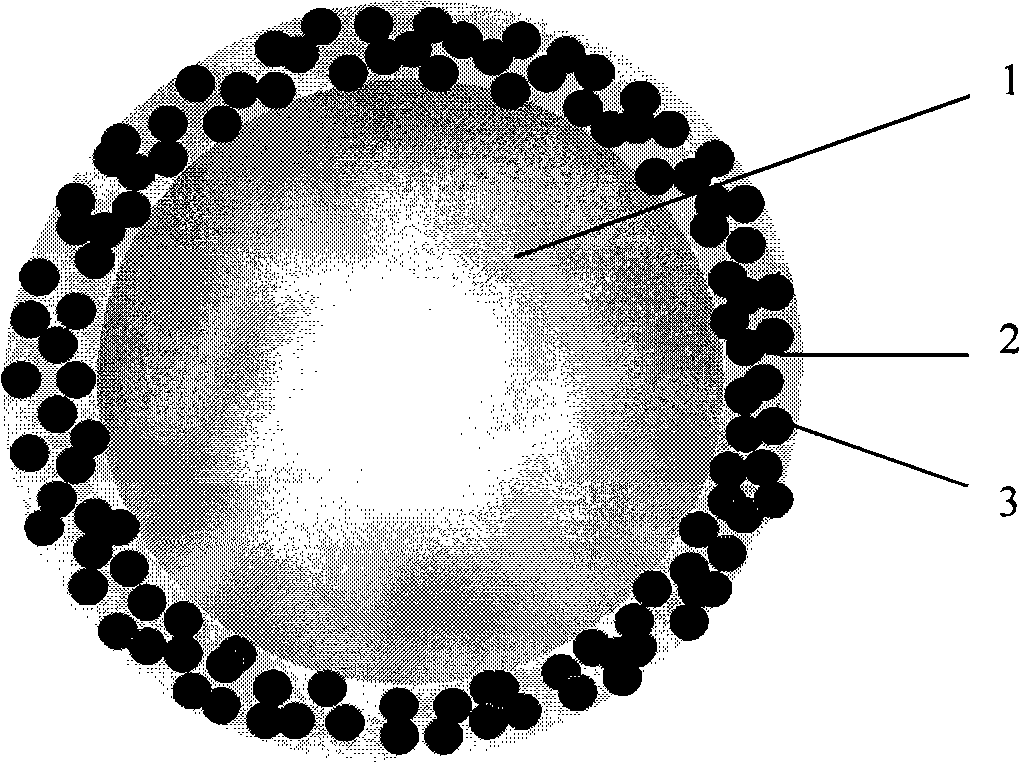

Coupling filler autotrophic denitrification biofilter and application

ActiveCN109052641ADifficult to dissolveIncrease speedWater treatment compoundsTreatment with anaerobic digestion processesBiofilmSewage

The invention discloses a coupling filler autotrophic denitrification biofilter and application and belongs to the technical field of sewage treatment. Pyrrhotite, sulfur and a carbon source are utilized to be mixed and coupled according to certain proportion; then the materials are put into a reactor, and the autotrophic denitrification biofilter can be formed after inoculating biofilm formation;sewage flows through the biofilter, and nitrogen and phosphorus in the water are removed. The biofilter disclosed by the invention has the advantages of simpleness, easiness, practicability and shortbiofilm formation time; when the biofilter is utilized to treat nitrogen and phosphorus containing sewage, hydraulic retention time is only 0.5 to 3 h, and yielding water can meet a requirement; furthermore, the biofilter has the advantages of excellent nitrogen and phosphorus removal effect, low cost and suitability for engineering application.

Owner:NANJING UNIV

Microparticle with double function of radiotheraphy and thermotherapy and preparation method thereof

InactiveCN101284161AGood chemical stabilityGood biocompatibilityRadioactive preparation carriersTherapeutic coolingParticulatesHysteresis

The invention discloses particulates with double functions of internal radiotherapy and thermal therapy, and a preparation method thereof. The particulates are mainly compounded and formed by glass containing radioactive species yttrium-90 or / and phosphorus-32, and solid ferrite with magnetocaloric effect. When the particulates intervene in vivo, the radioactive species yttrium-90 or / and the phosphorus-32 contained in the glass can release Beta rays in vivo to kill cancer cells intervening in surrounding tissues without damaging the distant healthy tissues; the solid ferrite has good hysteresis exothermicity and can transform exosomatic magnetic energy into heat energy so as to release heat under the action of an external alternating magnetic field, so that the temperature around the tumor area can raise to 43 to 47 DEG C within a short time, and tumour cells intervening in the surrounding tissues are burnt and killed without influencing normal cells with better heat tolerance, thereby realizing the purpose of treating tumor by combining the internal radiotherapy and the thermotherapy, and having double lethality to cancer cells. The method for combining the radiation treatment and the heat treatment is an indispensable supplementary therapy means to treat the malignant tumor with chemical drug resistance. In addition, the particulates have good chemical stability and biocompatibility, and have great application prospect in the aspect of treating the malignant tumor.

Owner:TONGJI UNIV

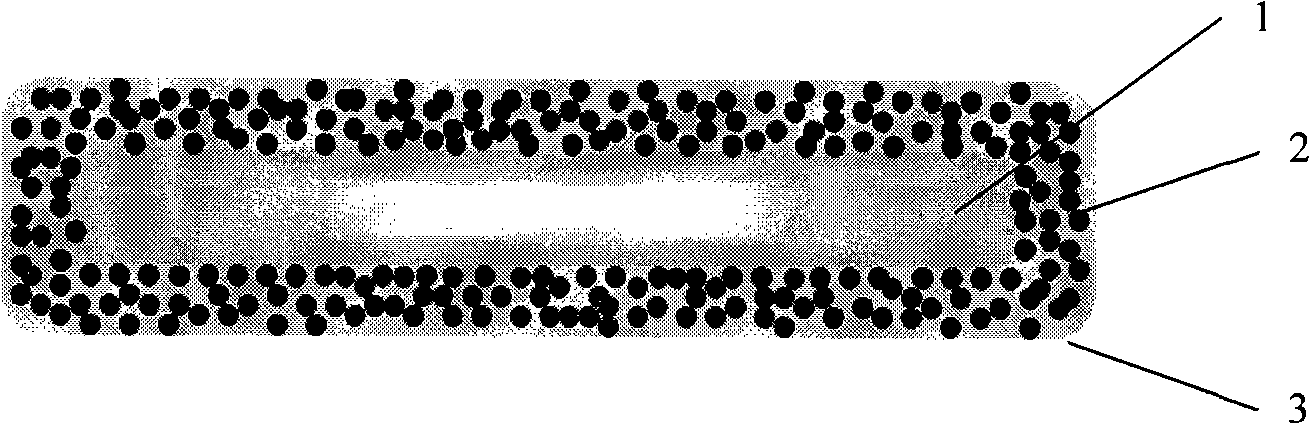

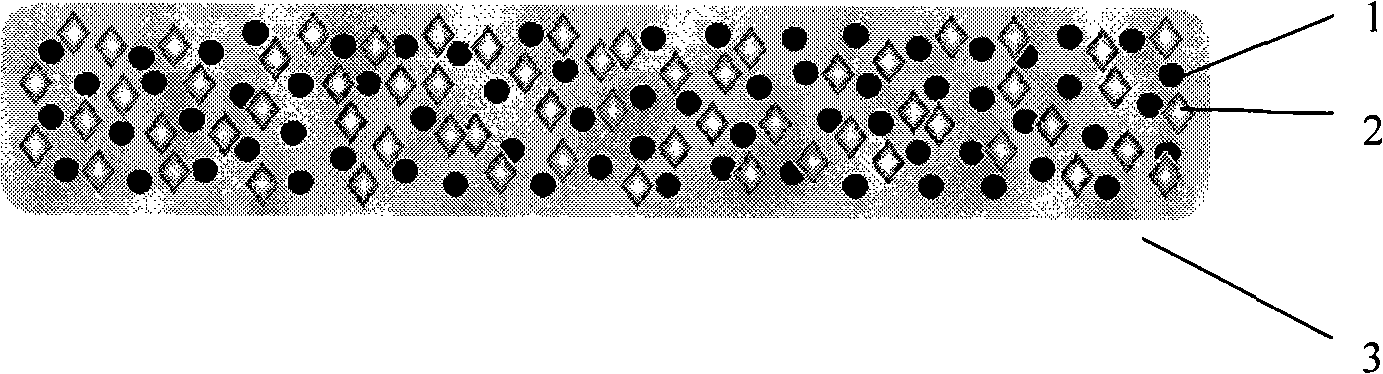

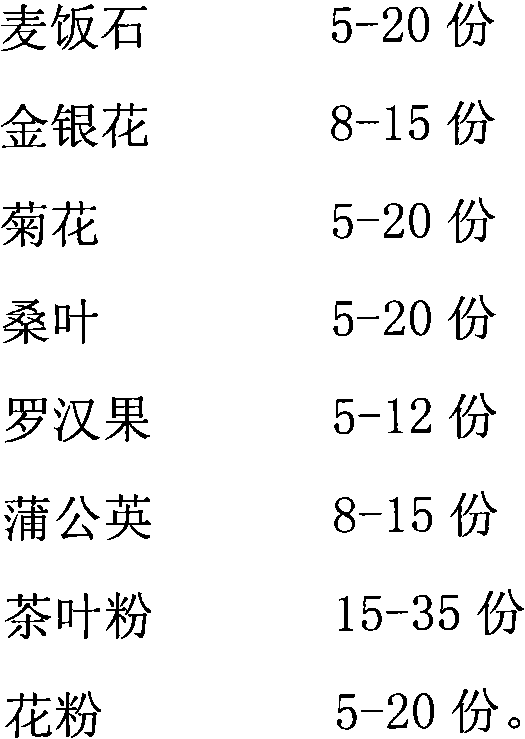

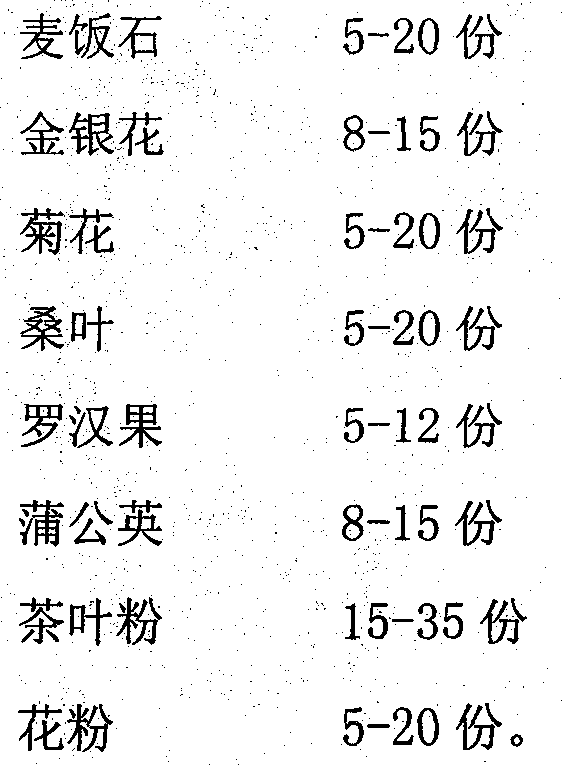

Cold brewed herbal tea and preparation method thereof

InactiveCN102326638AGreat tasteAcid-base balancePre-extraction tea treatmentLower blood pressureMomordica grosvenori

The invention relates to a method for processing a beverage by taking natural plants as raw materials, in particular to a cold brewed herbal tea and a preparation method thereof. The cold brewed herbal tea is processed by using the raw materials such as medical stone, honeysuckle, mulberry leaves, momordica grosvenori, dandelion, tea powder, pollen and the like. The cold brewed herbal tea has the good effects of clearing heat and detoxicating, protecting health, beautifying, treating anemopyretic cold, improving eyesight and removing heat from the liver, relieving cough, relieving summer heat and quenching thirst, relaxing bowel, regulating blood sugar level, reducing blood fat, lowering blood pressure, refreshing, digesting, promoting urination and the like.

Owner:GUANGXI JINSAI HEALTH PRODS

Preparation method for oil cooked chili

ActiveCN101791103AFor long-term storageRefined completelyFood preparationFlavouring agentOil temperature

The invention discloses a preparation method for oil cooked chili, which comprises the following steps that: (1) primary oil refining: oil is poured into a frying pan and is heated for refining, the heating is stopped after oil temperature reaches 190-210 DEG C, and the oil is cooled to 34-36 DEG C; (2) secondary oil refining: oil obtained after the primary oil refining is heated to 165-175 DEG C; (3) chili refining: chili is poured into the oil obtained after the secondary oil refining and is continuously stirred and fried, and the heating is stopped after the chili is refined for 24-26 minutes; and (4) flavoring: 100kg of chili obtained after refining is taken out and flavoring additives are added for flavoring, wherein the flavoring additives are formed by gourmet powder, salt, beef, chicken, black salted turnip and peanuts. The prepared oil chili has the advantages of delicious taste and bright color.

Owner:遵义椒源食品有限公司

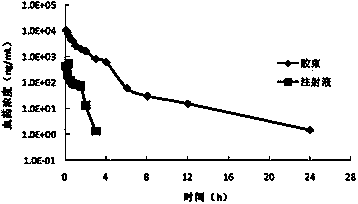

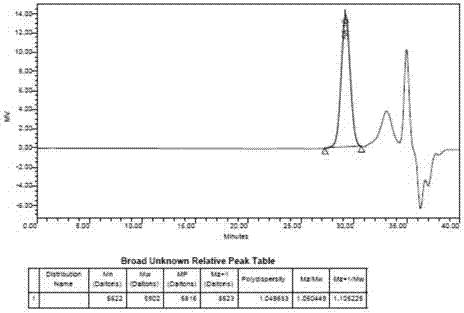

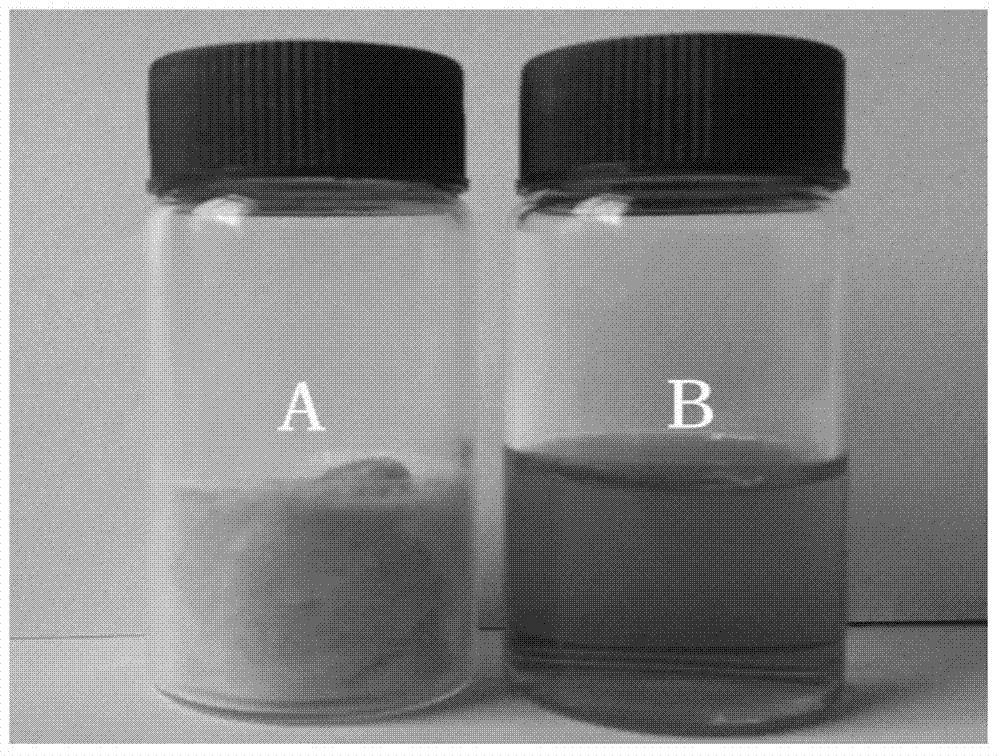

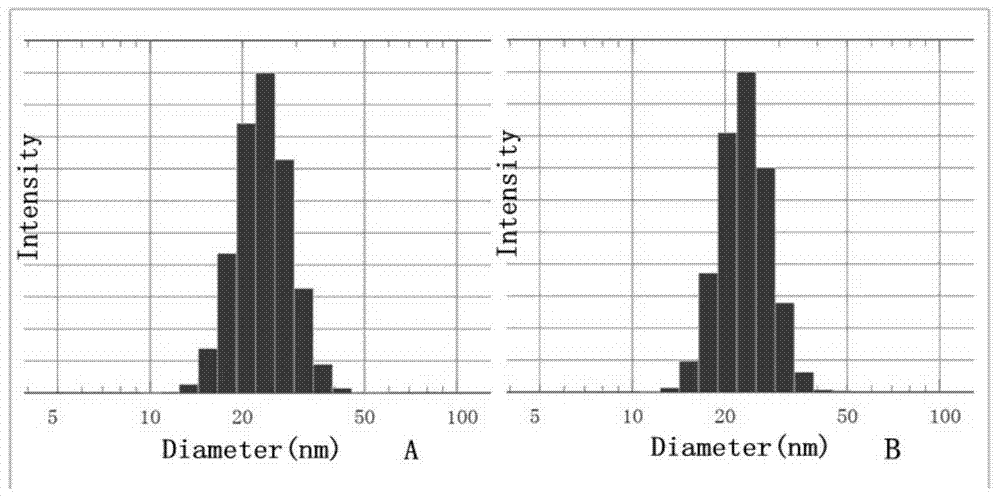

Curcumin micellar drug carrying system and preparation method thereof

InactiveCN104758255ABig spaceGood compatibilityPowder deliveryKetone active ingredientsTert-Butyloxycarbonyl protecting groupEnd-group

The invention relates to a novel micellar drug carrying system formed by an amphiphilic block copolymer and curcumin. The amphiphilic block copolymer comprises a hydrophilic chain segment and a hydrophobic chain segment, the hydrophilic chain segment is methoxypolyethylene glycols, the hydrophobic chain segment is polycaprolactone, and the hydrophobic chain segment end group is terminated with a hydrophobic group. The hydrophobic group is a group having a t-butyloxycarboryl or benzene ring structure, compatibility of drug molecules with the hydrophobic chain segment of the block copolymer is improved, the mutual force is increased, and besides, a greater space is provided for accommodating the drug molecules. Prepared micelles can more effectively limit the drug molecules in micelle cores so as to allow the drug molecules to be not easily dissolved out, and thus the drug carrying micelles having high stability are obtained.

Owner:CHANGZHOU TARGET MEDICINE TECH CO LTD

Graphene-rod-like aluminum-doped zinc oxide antistatic coating and preparation method thereof

ActiveCN103937350AAdd lessImprove conductivityElectrically-conductive paintsEmulsionAluminum doped zinc oxide

The invention belongs to the technical field of production of antistatic coating and in particular relates to a graphene-rod-like aluminum-doped zinc oxide antistatic coating and a preparation method thereof. The antistatic coating comprises the following components in parts by weight: 60-85 parts of waterborne acrylic emulsion, 0.5-1.0 part of antifoaming agent, 1-2.5 parts of flatting agent, 1-3.5 parts of thickening agent, 2-3 parts of graphene, 7.15-31.25 parts of rod-like aluminum-doped zinc oxide dispersion and 0.5-30 parts of deionized water. Flake graphene and the rod-like aluminum-doped zinc oxide can form a three-dimensional conductive network in a coating system, so that the conductive performance of the coating can be enhanced, and compared with a coating formed by singly graphene or aluminum-doped zinc oxide, the graphene-rod-like aluminum-doped zinc oxide antistatic coating has the advantages that the same conductive effect is achieved, and the addition amount is obviously reduced. Moreover, due to a special structure, the mechanical property of the coating can be obviously enhanced.

Owner:CHANGZHOU UNIV

Novel reclamation method of electroplating sludge

InactiveCN102701549ARealize recyclingImprove stabilitySludge treatmentWaste water treatment from metallurgical processIonHeavy metals

The invention relates to a novel reclamation method of electroplating sludge, belonging to the technical field of chemical and environmental science. The method takes the electroplating sludge as raw material, right amount of iron source is supplemented into the raw material, agricultural waste rice hulls treated by activating are added into the raw material, the reclamation for the electroplating sludge can be realized under the conditions of mild water heat, ventilation and proper alkaline condition, and porous loaded type ferrite new material is obtained. The novel reclamation method is energy-saving and high in efficiency, and can realize regenerating cyclic utilization of solid waste; the obtained porous loaded type ferrite new material is high in stability, difficult in dissolution of heavy metal ions and free from secondary pollution, and can be used for efficiently removing mercury ion in water; furthermore, the porous loaded type ferrite new material has good magnetism, thus being convenient to recover, separate and recycle, and achieving the aim of controlling waste by waste. The process route is high in efficiency, simple, mild and low in energy consumption, and does not easily generate secondary pollution; and the needed device is simple, convenient to operate, easy in control of conditions and low in production cost.

Owner:JIANGNAN UNIV

Method for extracting pectin from banana peels

InactiveCN102382205AStable structureDoes not affect physiological activityBanana peelUltrasonic radiation

The invention relates to a method for extracting pectin from banana peels, comprising the following steps of: (1) acid regulation of raw material: cleaning and drying the banana peels, smashing and slagging for use and preparing a material liquid in the weight proportion of material to liquid 1: (5-30); (2) surfactant solubilization: adding a surfactant into the material liquid subject to the acid regulation and stirring; (3) ultrasonic treatment: carrying out pectin extraction on the material liquid subject to the surfactant treatment by utilizing ultrasonic radiation; (4) enzyme treatment: adding enzyme into the material liquid subject to the ultrasonic treatment so as to carry out enzymatic extraction; (5) alcohol precipitation: carrying out filtering and deslagging on the material liquid subject to the enzyme treatment, adding alcohol into the obtained filtrate and precipitating; and (6) drying: putting precipitate in a constant-temperature drying oven, drying, smashing and obtaining pectin end products. The method provided by the invention has the advantages of high extracted pectin yield, obvious decolorizing effect, short extracting time, high pectin purity and stable activity, therefore, a mass of resources can be saved and obvious economic benefit is provided.

Owner:NANJING COLLEGE OF CHEM TECH

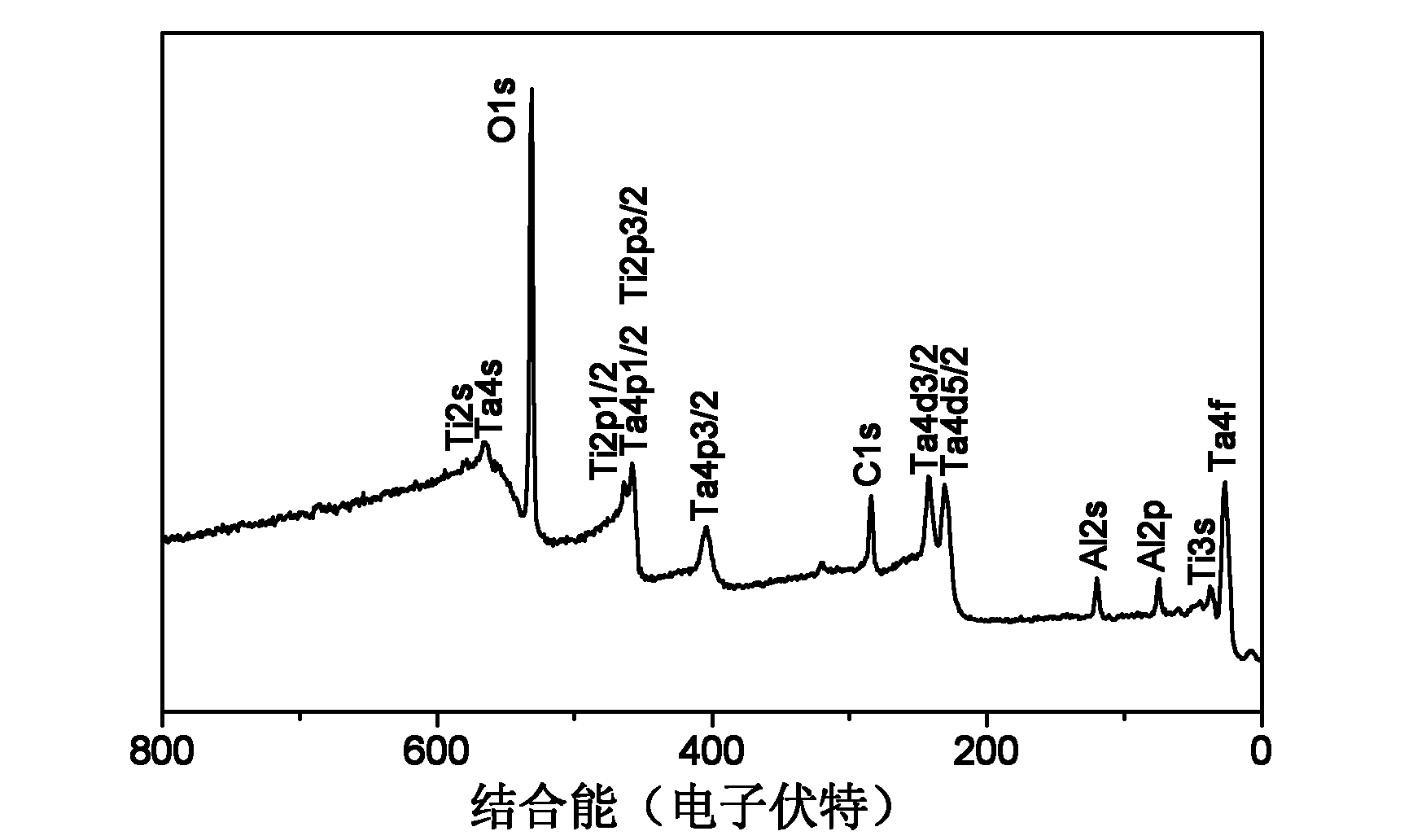

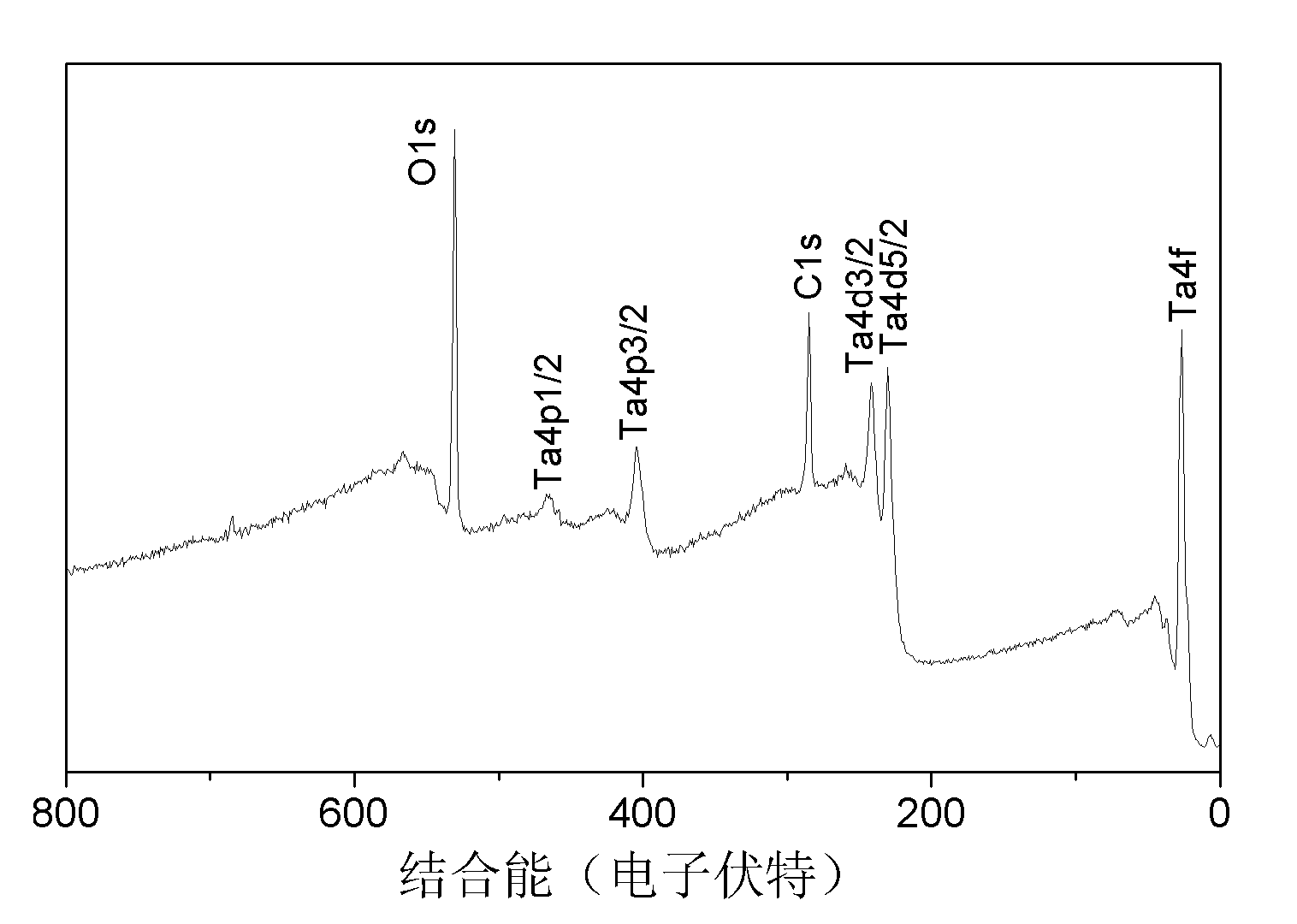

Method for modifying titanium surface

InactiveCN102181842ASolve solubilitySolve peelingVacuum evaporation coatingSputtering coatingTitanium metalApatite

The invention discloses a method for modifying titanium surface. The method comprises the following step of: performing tantalum ion implantation or plating on the titanium surface by using a plasma immersion ion implantation and deposition technology to obtain a tantalum and / or tantalum oxide modified layer. The titanium surface is modified, so that a high mechanical property of titanium can be preserved, the corrosion resistance and the bioactivity of a material can be improved, and high biocompatibility of the material can be kept; and the modified titanium surface which is subjected to tantalum ion implantation or plating is not required to be subjected to any aftertreatment, bone-like apatite can be induced to form and grow on the surface when the titanium surface is soaked in simulated body fluid, and an artificial bone substitutional material with high comprehensive performance can be obtained.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Zirconia powder added with trace elements and preparation method thereof

The invention discloses zirconia powder added with trace elements, which comprises yttrium. The zirconia powder added with the trace elements is characterized in that trace La, Ce, Al, Ca, Ti and Mg elements are added into the zirconia powder, and the mass ratio of ZrO2 to (La, Ce, Al, Ca, Ti and Mg)Ox is 1:0.0001-0.008. The invention also discloses a preparation method for the zirconia powder. After the technical scheme is adopted, the trace La, Ce, Al, Ca, Ti and Mg elements are added when the yttrium-contained zirconia powder is prepared, and a reaction condition is controlled. After the produced zirconia powder is prepared into a ceramic body, the crystal structure of the ceramic body can be greatly reinforced by trace added ingredients, so that the produced ceramic body produced by the powder is unlikely to dissolve out yttrium and zirconium under the conditions of intermediate temperate (RT(range temperature)-200DEG C) and concentration below 15%, and the ceramic body has good structure stability, so the service life of the ceramic body is greatly prolonged.

Owner:FUJIAN JOHNSON MINING

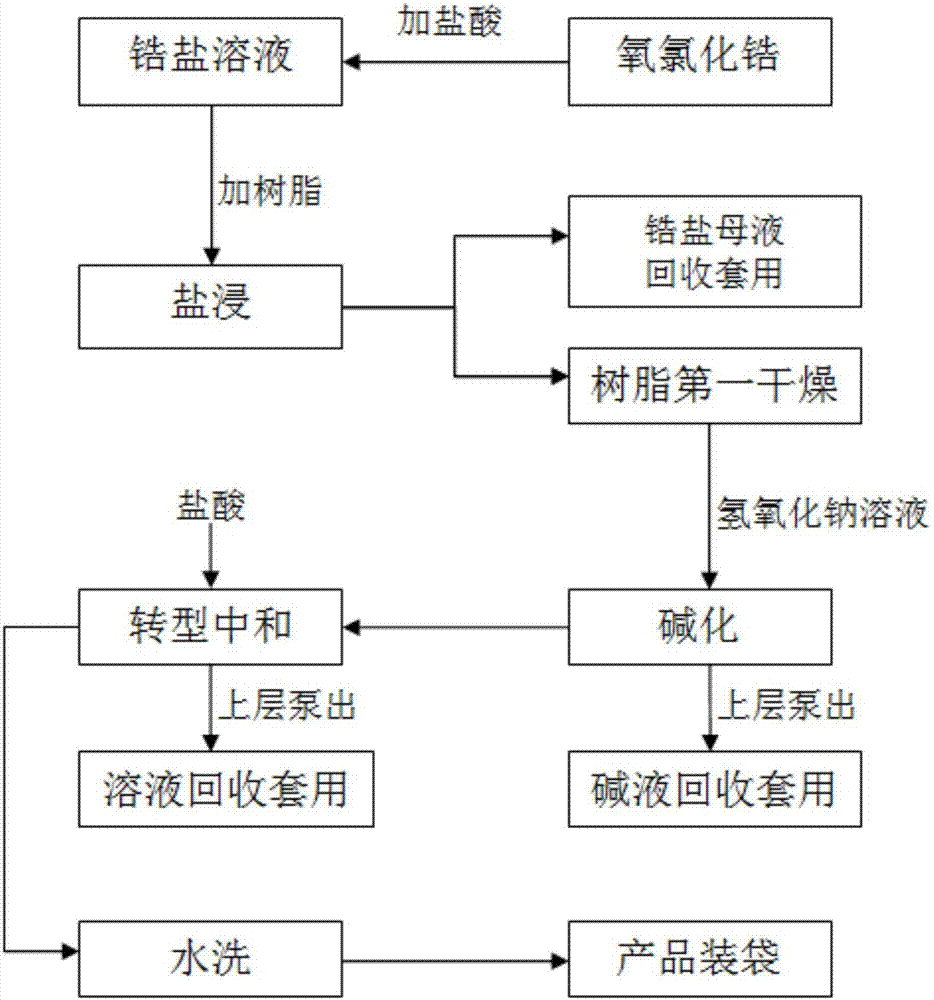

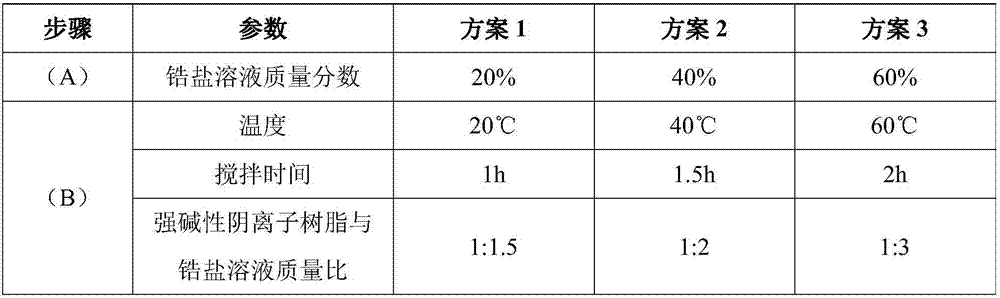

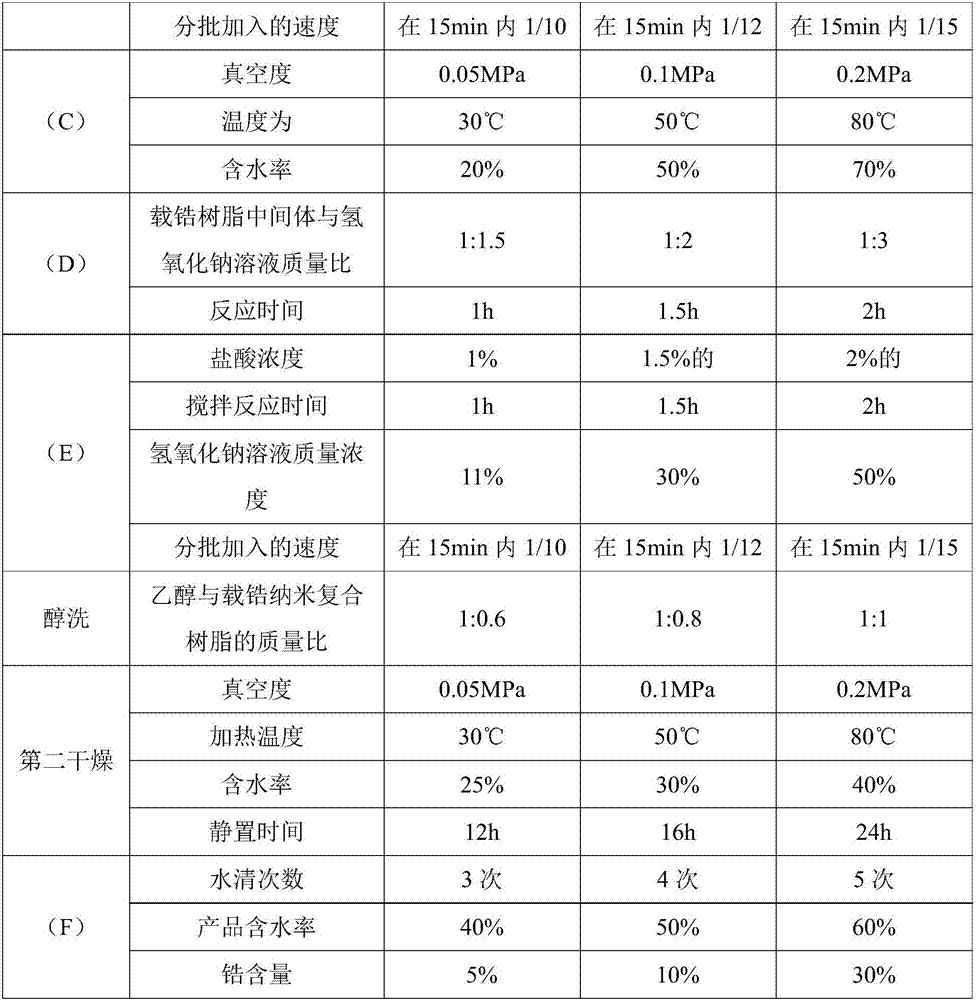

Industrial preparation method of zirconium loaded nanocomposite resin adsorbent

ActiveCN107262072AReduce turnoverEasy accessOther chemical processesWater contaminantsAlcoholSorbent

The invention discloses an industrial preparation method of a zirconium loaded nanocomposite resin adsorbent, belongs to the fields of industrial production of nanocomposite resin adsorbents for wastewater treatment and particularly relates to the industrial preparation method of the zirconium loaded nanocomposite resin adsorbent recycled and reused with reaction mass. The industrial preparation method includes the steps: A), preparing a zirconium salt solution; B), adding strongly-basic anion resin to the zirconium salt solution in batches prior to stirring and soaking, wherein the zirconium salt solution is recycled and reused; C), performing drying; D), performing alkalization by adding a sodium hydroxide solution to obtain zirconium loaded nanocomposite resin, wherein alkaline liquor is recycled and reused; E), adding a hydrochloric acid solution for neutralization; F), performing washing. With the method, all the materials of cleaning fluid, the zirconium salt solution, the alkaline liquor, acid liquor, ethyl alcohol and the like can be recycled and reused, production cost and environment pollution are greatly reduced, energy conservation and emission reduction industrial policy of the current state is conformed, and the method is suitable for industrialized promotion.

Owner:NANJING UNIV

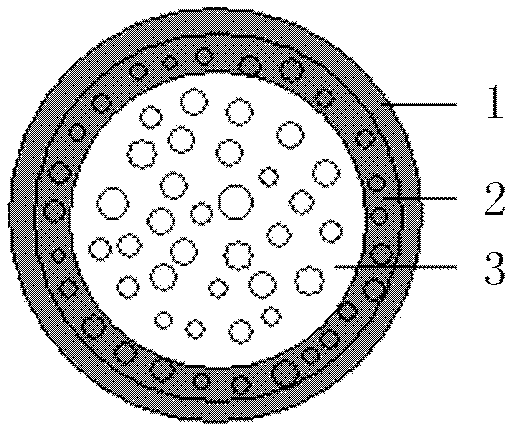

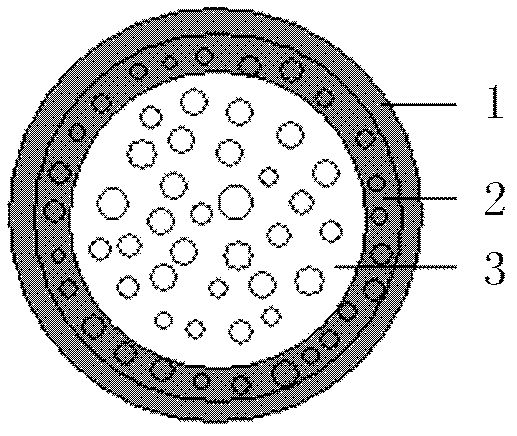

Method for producing alkaline residue ceramsite with high efficiency, waste utilization, low energy consumption and light weight

InactiveCN102515821AImprove matchHigh strengthSolid waste disposalCeramicwareExpanded clay aggregateDissolution

The invention relates to a method for producing an alkaline residue ceramsite with high efficiency, waste utilization, low energy consumption and light weight, which belongs to the building material field. The ceramsite is in a three-layer composite structure, which comprises a site substitution porous core layer, an intermediate foaming layer and a hard shell layer, the site substitution porous core layer is characterized in that crushed poly benzene particles are mixed with alkaline residue, an interface agent and a VAE emulsion are added and stirred with water to forming balls, the intermediate foaming layer is composed of waste glass, shale, powdered carbon and methyl cellulose ether, the hard shell layer is composed of glass powder, shale and boric acid; the crushed poly benzene particles are added in the interface agent for treating the surface, then a layer of film is formed, alkaline residue, waste glass powder and water are mixed and stirred by adding water to form balls; then the balls are placed in a balling plate equipped with intermediate foaming layer siccative for warping, moisture spray is carried out on the surface of the wrapped balls, the balls are continuously placed in the balling disc equipped with the casing layer siccative to form ceramsite green compact with a three layers wrapping structure; the green compact is dried and roasted. The invention has the advantages of low energy consumption, and can better inhibit the dissolution of the chloride ions in alkaline residue.

Owner:BEIJING UNIV OF TECH

Ceramsite prepared from residues generated in oil containing sludge pyrolysis and preparation method thereof

InactiveCN109851323AExpand application channelsHigh porosityCeramic materials productionCeramicwarePorositySludge

The invention provides a ceramsite prepared from residues generated in oil containing sludge pyrolysis and a preparation method thereof. The ceramsite is prepared from following raw materials in percentage by weight through burning: 45 to 50% of residues generated in oil containing sludge pyrolysis, 35 to 40% of fly ash, and 10 to 20% of waste glass powder. Residues generated in oil containing sludge pyrolysis are taken as the main raw material and is mixed with fly ash and waste glass powder to prepare the ceramsite having the advantages of lightness, high porosity, high cylinder compressivestrength, low bulk density, and low water absorption; the application range of residues generated in oil containing sludge pyrolysis is enlarged; a new approach is provided for converting residual solid phases in oil containing sludge processing into valuable resources; the residue utilization rate can reach 50%; the problem that the residues generated in oil containing sludge pyrolysis cannot beeffectively processed and radically utilized is solved, sustainable development of oil fields is realized, and good social benefits and economic benefits are generated.

Owner:WUHAN UNIV OF TECH

Method for carbonizing and activating waste concrete recycled micro powder by wet process and application of regenerated micro-powder

ActiveCN112125541AHigh activityEasy to achieve continuous productionCement productionSilica fumeIndustrial waste

The invention provides a method for carbonizing and activating waste concrete recycled micro powder by a wet process, which comprises the following steps of: taking powder generated in the process ofproducing recycled aggregate by crushing waste concrete as recycled micro powder, dispersing the recycled micro powder into water to form mixed slurry, and continuously introducing industrial waste gas containing carbon dioxide into the mixed slurry, in the process, carbon dioxide contained in the industrial waste gas and the regenerated micro powder are subjected to a carbonization reaction. According to the invention, the regenerated micro-powder is subjected to the carbonization reaction in an aqueous solution, the activity of calcium carbonate and silicon dioxide generated by carbonizationis higher, the volcanic ash activity is superior to that of common auxiliary cementing materials such as fly ash and silica fume, and the regenerated micro-powder can be used as an auxiliary cementing material.

Owner:HENAN POLYTECHNIC UNIV

Chili oil with quail meat

InactiveCN104095215ADeliciousFull of nutritionFood ingredient functionsFood preparationChemistryCitric acid

The invention relates to chili oil with quail meat. The chili oil comprises main materials, auxiliary materials and condiments, wherein the main materials comprise the following components of 150-250g of quail meat skeletons, 1000-1200g of vegetable oil, and 100-150g of dried chilies, the auxiliary materials comprise 50-80g of laver, 200g of peanuts, 200g of salt black beans and 250g of shredded potatoes, and the condiments comprise 50-60g of garlic, adequate ginger, adequate soy sauce, adequate vinegar, adequate cooking wine, adequate salt, adequate sugar, adequate spices, 1-2g of citric acids, and 10-15g of honey. A preparation method comprises the steps of the pretreatment of raw materials and the preparation of the chili oil. The chili oil with the quail meat is delicious in eating taste, is hot, fragrant and crispy, and is rich in nutrition. The chili oil has the advantages of nourishing bodies and stimulating the appetite. A new taste is provided for the market of the chili oil, and the chili oil is convenient in market promotion.

Owner:GUIZHOU MENGRUN QUAIL

Method for extracting peppermint oil

The invention discloses a method for extracting peppermint oil, which comprises the following steps: feeding peppermint stem and leaves dried in the shade into an extracting tank, and adding warm water of which the weight is 8 to 10 times that of the peppermint into the extracting tank; adding an acid and alkali modifier, stirring the mixture for 0.5 to 1h, and regulating the PH of the extracting solution to be 4.5 to 5.0; activating cellulase in water of 38 to 40 DEG C for 5 to 10min, and heating the extracting solution in the extracting tank to 40 to 50 DEG C; adding cellulase of which the dry weight is 0.2 to 0.4% of that of peppermint into the extracting solution, and keeping the temperature constant and stirring continuously for 1.5 to 2h; and heating the extracting solution in the extracting tank to boiling, passing distillate through a condenser and then feeding the distillate into an extraction pot, cooling and layering, and obtaining the upper layer, which is the peppermint oil. The peppermint oil extracted by the method is high in yield and content of menthol.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

Bone meal nutritious fresh wet noodle and making method thereof

InactiveCN102028146AIncrease elasticityImprove extensibilityDough treatmentFood preparationChemistryFineness

The invention relates to a bone meal nutritious fresh wet noodle. According to the formula, the noodle comprises the following components in part by weight: 100 parts of flour, 32 to 38 parts of water, 0.8 to 1.5 parts of table salt, 0.15 to 0.3 part of dietary alkali, 1.2 parts of bone meal, 0.5 part of soya bean lecithin and 3 parts of potato starch, wherein the fineness of the bone meal is between 120 and 200 meshes. The bone meal nutritious fresh wet noodle is produced by the following steps of: mixing raw materials and auxiliary materials according to the formula; kneading dough; performing secondary curing and tabletting; and finally shredding. The invention has the characteristics that: the bone meal is added into the flour; and the bone meal nutritious fresh wet noodle which has high tensile property and bright color and can difficultly thicken soup can be produced by optimizing the formula of an additive and improving a making process.

Owner:HEFEI UNIV OF TECH

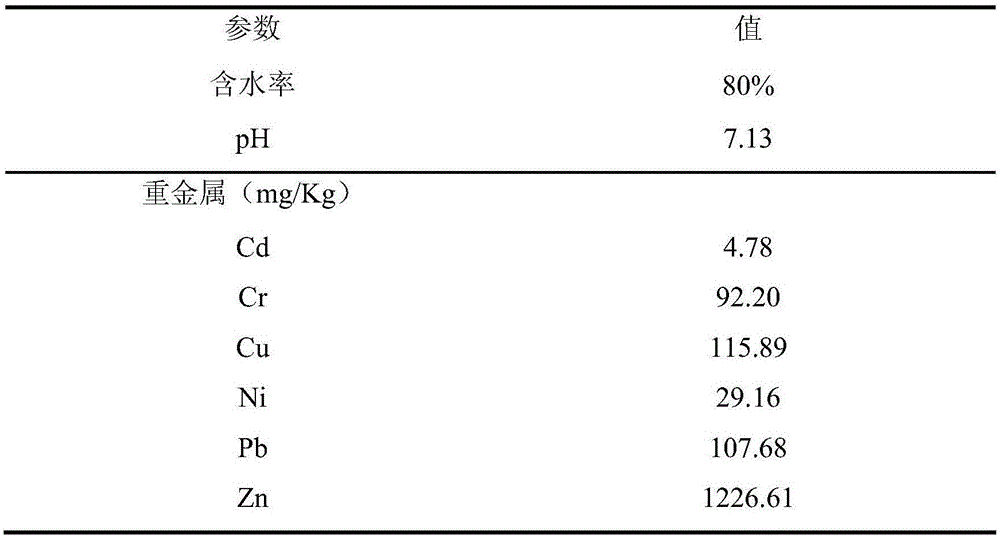

Preparation method and use method of urban sewage plant sludge heavy metal stabilizing agent

InactiveCN106430875ANo secondary sludgeImproved shape stabilitySludge treatmentWater contaminantsThioureaPollution

The invention discloses a preparation method and a use method of an urban sewage plant sludge heavy metal stabilizing agent. The preparation method comprises the preparation of carboxymethyl chitosan grafted thiourea and the preparation of grafted thiourea chitosan compounded activated carbon, wherein the preparation of the carboxymethyl chitosan grafted thiourea comprises the steps of carboxymethylation of chitosan, and grafting of thiourea; the preparation of the grafted thiourea chitosan compounded activated carbon comprises the steps of compounding of chitosan and activated carbon, and grafting of thiourea. The use method of the prepared stabilizing agent comprises the following steps of: naturally air-drying sewage sludge taken back from a sewage treatment plant and having a water ratio reaching about 80%, and then screening the dried sludge through a 20-mesh sieve; uniformly adding the stabilizing agent into the screened sludge with the added amount of the stabilizing agent of being 0.25%, 0.5%, 1% and 2% of the amount of the screened sludge, adding deionized water at a water-sludge ratio of 1.5 to 1, and stirring them uniformly; standing the sludge added with the stabilizing agent for a certain period of time, and periodically stirring the sludge uniformly once in this period of time; and drying and grinding the sludge which is stabilized for a certain period of time. The stabilizing agent can stabilize Cd, Ni and Zn at the same time. The preparation method of the stabilizing agent is simple, safe and environmentally friendly, and does not generate secondary pollution.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

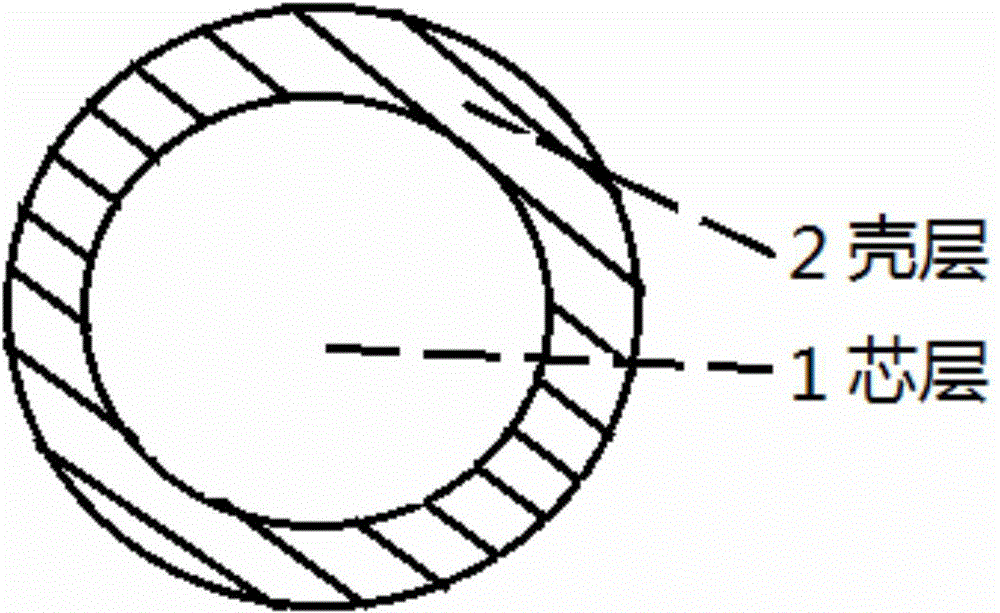

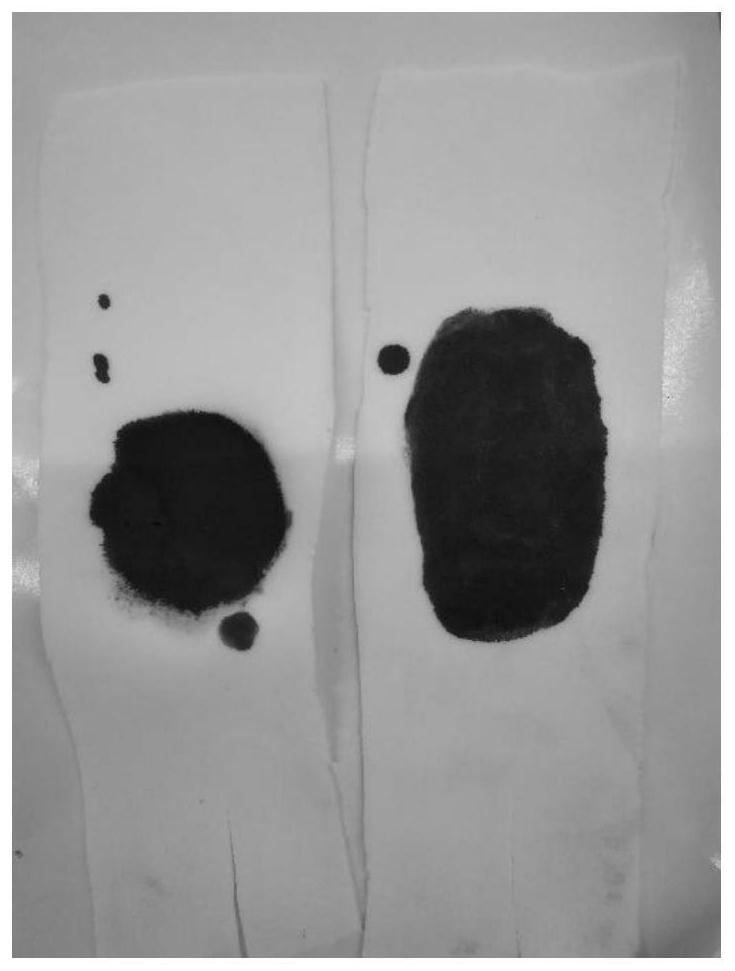

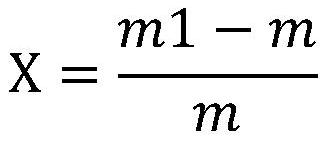

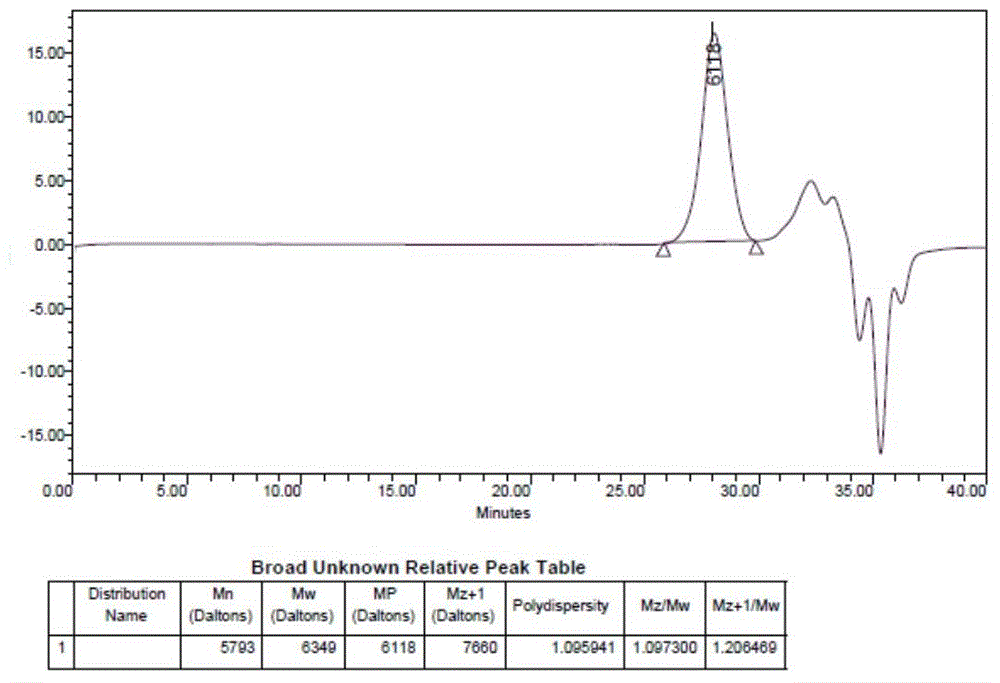

Non-sintered alkaline-residue ceramsite with high alkaline residue mixing amount and manufacturing method thereof

A non-sintered alkaline-residue ceramsite with a high alkaline residue mixing amount and a manufacturing method thereof belong to the technical field of building materials. The non-sintered alkaline-residue ceramsite has a core-shell composite structure, and comprises an alkaline residue core layer and a cement shell layer, wherein the core layer dry material comprises 40%-50% of alkaline residues, 20%-30% of glass powder, and 20%-30% of fly ash, and the shell layer dry material comprises 30%-50% of cement, 20%-30% of glass powder, and 20%-30% of fly ash. The manufacturing method comprises the following steps: adding 2 wt% of a sodium hydroxide aqueous solution into the core layer dry material to obtain a water cement ratio of 0.2, uniformly stirring, performing pelleting to obtain pellets with a diameter of 7-12 mm, and curing for 1 day; adding 2 wt% of a sodium hydroxide aqueous solution into the shell layer dry material to obtain a water cement ratio of 0.3, so as to form slurry; putting the core layer pellets in a balling tray with the shell layer slurry, performing ball rolling to form ceramsites with a wrapping structure; taking the ceramsites out, sprinkling fly ash, shaking to allow the surface to be solidified slightly, performing natural curing to obtain the product. The manufacturing method of the invention inhibits the dissolution of chloride ions in the alkaline residues, and improves the strength of the ceramsite.

Owner:长沙柳腾科技有限公司

Modified high-blood-absorption polyurethane sponge as well as preparation method and application thereof

ActiveCN112266455AAdjust mechanical propertiesRegulated degradabilityAbsorbent padsBandagesPolymer scienceAntioxidant

The invention provides a modified high-blood-absorption polyurethane sponge as well as a preparation method and application thereof. The polyurethane sponge is prepared from the following raw materials: isocyanate, polyol, super absorbent resin, fluff pulp, cationic polysaccharide, water, a hydrophilic surfactant, a chain extender, an inorganic filler and an antioxidant. The prepared polyurethanesponge has the advantages of being high in liquid guiding performance, high in absorption foam utilization rate, high in blood absorption capacity, low in blood reverse osmosis rate, low in swelling rate after blood absorption and the like, high strength of the sponge can be maintained after blood absorption, and the polyurethane sponge is suitable for the field of disposable blood absorption hygienic products such as sanitary towels and medical dressings.

Owner:WANHUA CHEM GRP CO LTD

Carrier for waste water biological treatment and its preparation

InactiveCN1613798ALarge amount of adsorbed biomassPromote dissolutionSustainable biological treatmentBiological water/sewage treatmentCross-linkWastewater

A carrier for treating waste water and its production are disclosed. It is produced by: mixing PVA and batching, freezing initial forming, formaldehyde cross-linking liquid pre-cross-linking, drying, breaking, screening, cross-linking, washing and drying. Its advantages include easy formation, good microbial fixing performance and simple process.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

Method for improving elasticity and stewing property of extruded rice noodles

InactiveCN103535597AGood elasticityExcellent cooking propertiesMulti-step food processesFood shapingBiologyToughness

The invention relates to a method for improving the elasticity and stewing property of extruded rice noodles, which belongs to the technical field of food processing. The method comprises the steps of with long-shaped rice flour and green bean starch being raw materials, firstly, grinding the long-shaped rice flour, sieving the ground long-shaped rice flour with an 80-mesh sieve, fully and uniformly mixing 75%-95% of long-shaped rice flour with 5%-25% of green bean starch, adding water for humidification, steaming the flour, and carrying out processes of extrusion forming, gelatinization, slitting and packaging. According to the method provided by the invention, the quality defects of traditional extruded rice noodles that the rice noodles are easily broken, soup easily becomes paste, and the elasticity and toughness of the rice noodles are insufficient are overcome; compared with extruded rice noodles produced by conventional methods, the extruded rice noodles produced according to the method provided by the invention have the advantages that the stewing property is excellent, the breaking rate, the water absorption after cooking and the cooking loss are obviously controlled, and the elasticity and toughness are obviously improved.

Owner:JIANGNAN UNIV

Maca wine and preparation method thereof

ActiveCN105199927AGuaranteed efficacyKeep the aromaDigestive systemAlcoholic beverage preparationFlavorAfter treatment

The invention discloses a maca wine and a preparation method thereof. The maca wine is prepared from the following raw materials in part by weight: 900-1000 parts of base liquor, 10-30 parts of maca, 1-2 parts of cultivated ginseng, 6-8 parts of the fruit of Chinese wolfberry, 1-5 parts of longan, 2-10 parts of jujubes, 2-8 parts of raspberry, 1-5 parts of sealwort extracts, 1-5 parts of extracts from pueraria and 0.5-3 parts of cordyceps militaris extracts. The preparation method comprises the following steps of pretreatment, extraction, mixing and after-treatment. The maca wine does not have traditional drug flavor, tastes good, and has effects of nourishing yin, reinforcing qi, refreshing and boosting immunity; and after drinking the maca wine, a person does not have a headache.

Owner:CHUXIONG BAICAOLING PHARMA DEV

Method for preparing conductive powder by recoating aluminum-doped nano zinc oxide with aluminum

InactiveCN103570056AImprove dispersionSmall particle sizeMaterial nanotechnologyZinc oxides/hydroxidesIonNano zinc oxide

The invention discloses a method for preparing conductive powder by recoating aluminum-doped nano zinc oxide with aluminum. The method comprises the following steps: firstly, preparing aluminum-doped zinc oxide powder; secondly, coating the aluminum-doped zinc oxide powder with an aluminum-containing film; finally, mixing the coated aluminum-doped zinc oxide powder with zinc powder, grinding, and calcining in an inert gas atmosphere to obtain the conductive powder. The method has the advantages that the zinc oxide conductive powder is prepared through primary aluminum doping and secondary aluminum coating, the primary aluminum doping improves the whiteness and the water dispersion of the nano zinc oxide and reduces the particle size of the nano zinc oxide, and the secondary aluminum coating further increases the defect concentration of zinc oxide crystals and improves the conductivity of the nano zinc oxide; the aluminum-doped zinc oxide is coated with a thin oxide film, so that zinc ions in water are unlikely to dissolve out, and the ball milling process of the zinc powder and the aluminum-doped zinc oxide is facilitated; the prepared conductive powder is high in conductive ability, small in particle size, light in color, wide in sources of raw materials, low in production cost, simple in preparation method, high in security, relatively light in environmental pollution, and suitable for industrial mass production.

Owner:JIANGSU DONGTAI FINE CHEM

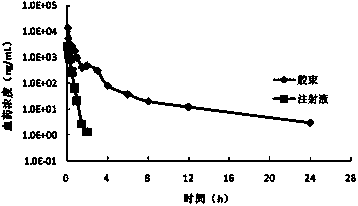

Paclitaxel micelle drug load system and preparation method thereof

InactiveCN104856950ABig spaceGood compatibilityOrganic active ingredientsPowder deliveryTert-Butyloxycarbonyl protecting groupEnd-group

The invention relates to a novel micelle drug load system formed by an amphiphilic segmented copolymer and paclitaxel. The amphiphilic segmented copolymer comprises a hydrophilic chain segment and a hydrophobic chain segment, the hydrophilic chain segment is polyethylene glycol monomethyl ether, the hydrophobic chain segment is polycaprolactone, and the end group of the hydrophobic chain segment is terminated by a hydrophobic group. The hydrophobic group is tertbutyloxycarbonyl phenylalanine, so the compatibility of a drug molecule with the hydrophobic chain segment in the segmented copolymer is improved, the interaction between the drug molecule and the segmented copolymer is increased, a large space is provided for accommodating the drug molecule, and a prepared micelle can effectively restrict the drug molecule in the core of the micelle, thereby a drug loaded micelle with high stability is obtained.

Owner:CHANGZHOU TARGET MEDICINE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com