Method for modifying titanium surface

A titanium metal modification technology, applied in metal material coating process, prosthesis, vacuum evaporation plating, etc., can solve the problems of ion implantation modification process difficulties, high reactivity, low melting point, etc., to improve corrosion resistance Sexuality and biological activity, good biocompatibility, good corrosion resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

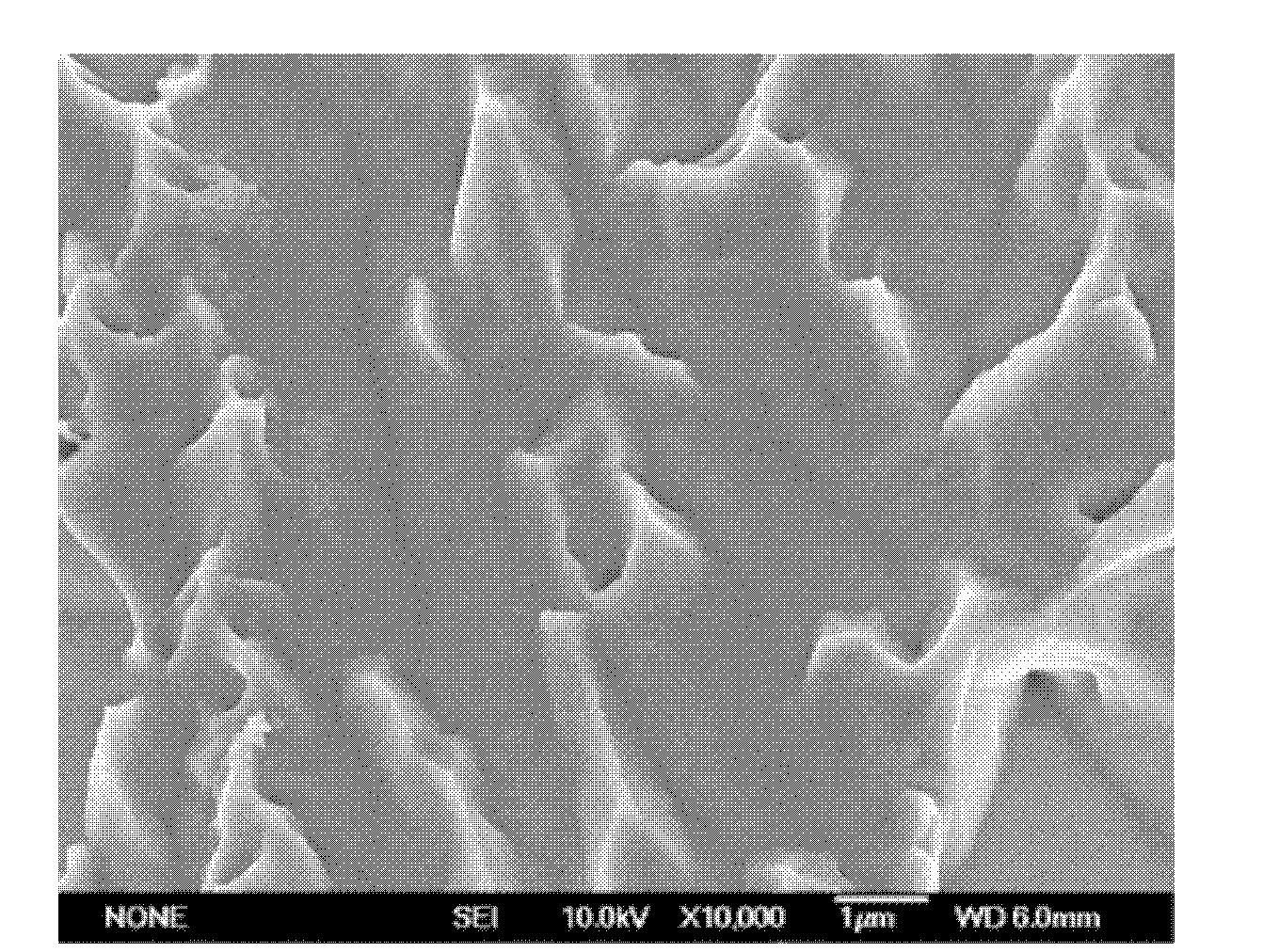

[0030] Pretreat pure titanium in 5% oxalic acid solution at 100°C for 2 hours to remove the natural oxide layer on the surface and obtain a clean surface with uniform roughness (see figure 1 shown).

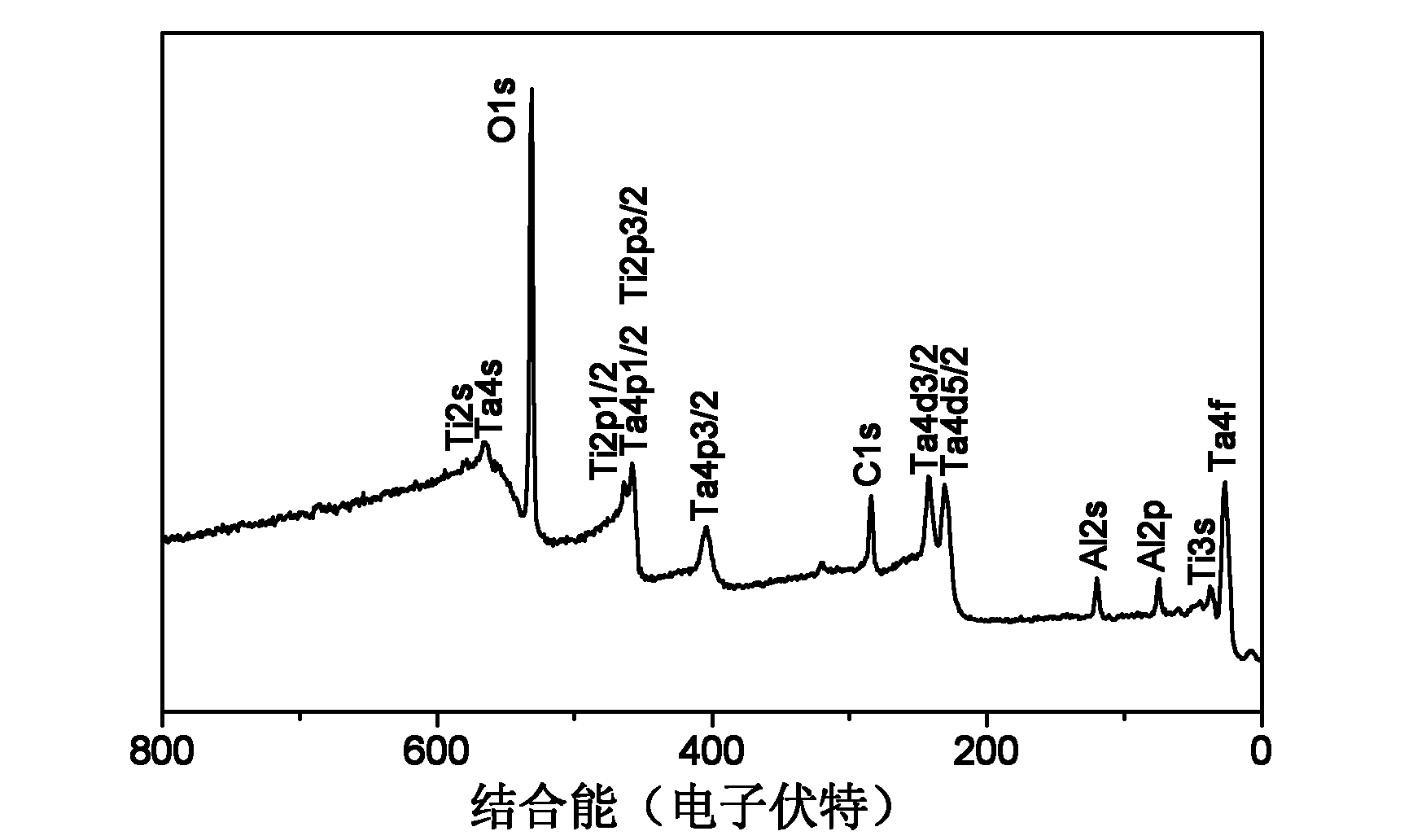

[0031] Using PIII&D technology, high-purity tantalum metal is used as the cathode, and tantalum ions are implanted on the pretreated medical titanium surface to obtain a titanium-tantalum surface alloy layer. The specific injection parameters are shown in Table 1. The surface XPS spectrum obtained under this injection parameter is shown in Figure 2a As shown, the results show the presence of tantalum element on the surface of the sample. Scanning electron microscope observation found that there was no significant difference in the surface morphology of tantalum before and after implantation. The reason may be that tantalum and titanium metal are easy to form alloys. During the implantation process, tantalum ions carry a certain amount of energy and can enter the crystal lattic...

Embodiment 2

[0036] Pure titanium was pretreated in 5% oxalic acid solution at 100°C for 2 hours to remove the natural oxide layer on the surface and obtain a clean surface with uniform roughness.

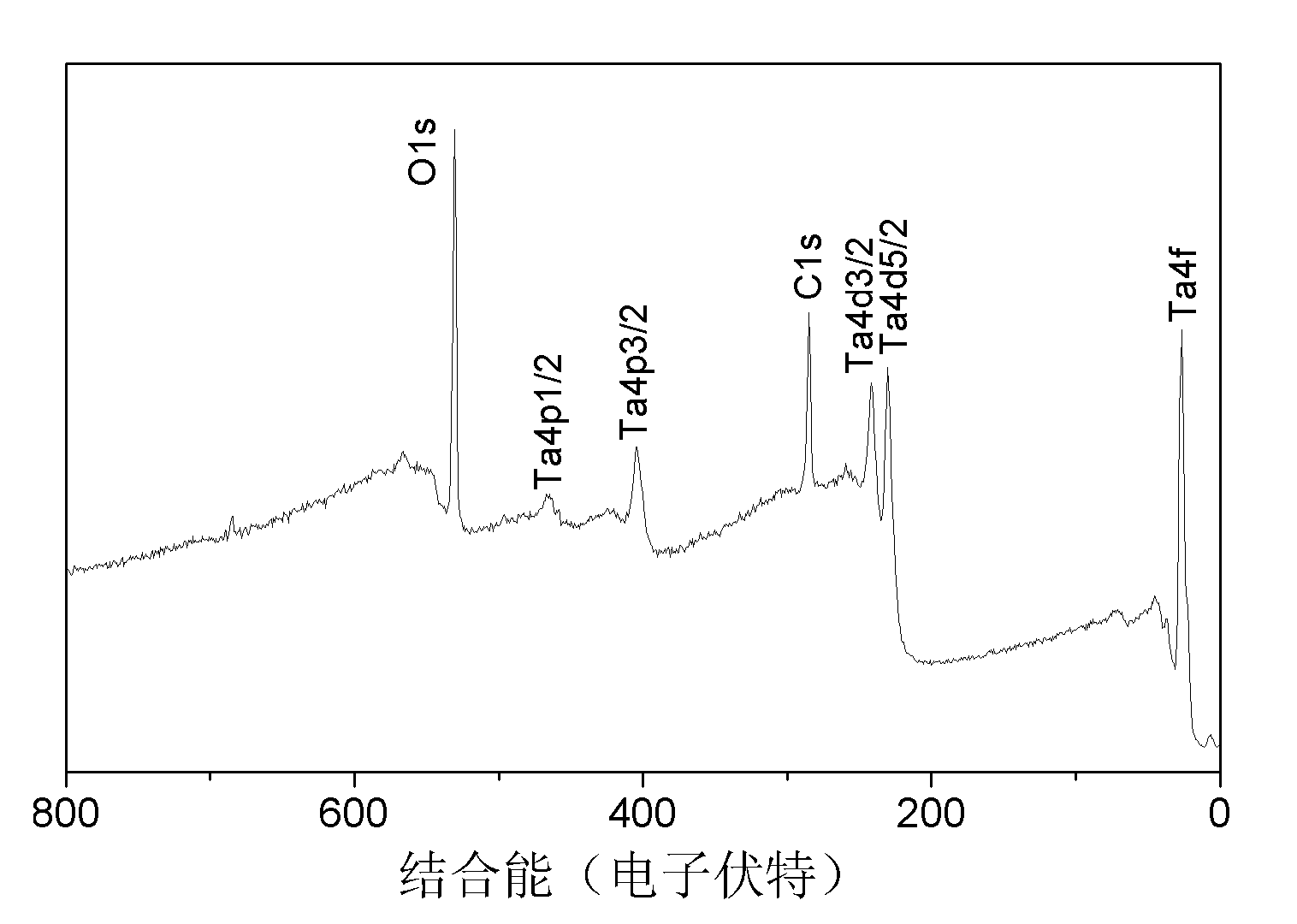

[0037] Using PIII&D technology, using high-purity tantalum metal as the cathode, tantalum ion plating is applied to the surface of pretreated medical titanium to obtain a nano-scale surface layer with tantalum and its oxides. The specific coating parameters are shown in Table 2. The surface XPS spectrum obtained under the coating parameters is shown in Figure 2b As shown, the results show that the outermost surface of the sample is tantalum and its oxides. The scanning electron microscope observation found that there was no significant difference in the surface morphology of the tantalum coating before and after coating. The reason may be that the tantalum film obtained under the experimental conditions was at the nanometer level, which was not enough to completely cover the micron protrusion...

Embodiment 3

[0042] Pure titanium was pretreated in 5% oxalic acid solution at 100°C for 2 hours to remove the natural oxide layer on the surface and obtain a clean surface with uniform roughness.

[0043] Using PIII&D technology, high-purity tantalum metal is used as the cathode, and oxygen is introduced into the vacuum chamber to coat tantalum ions on the pretreated medical titanium surface to obtain a nano-scale surface layer of tantalum oxide. The specific tantalum oxide coating parameters are shown in Table 3. Scanning electron microscope observation found that there was no significant difference in surface morphology before and after coating. The reason may be that the tantalum oxide film obtained under the experimental conditions was at the nanometer level, which was not enough to completely cover the micron protrusions on the pretreated medical titanium surface.

[0044] The potentiodynamic polarization curve of the titanium surface coated with tantalum oxide was measured in normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com