Method for recovering perfluoro propylene from technique of producing tetrafluoroethlene

A technology of perfluoropropylene and tetrafluoroethylene, applied in chemical instruments and methods, preparation of halogenated hydrocarbons, organic chemistry, etc., can solve the problems of difficult operation, low product quality, poor economy, etc., and reduce the amount of azeotrope , good extraction effect and cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

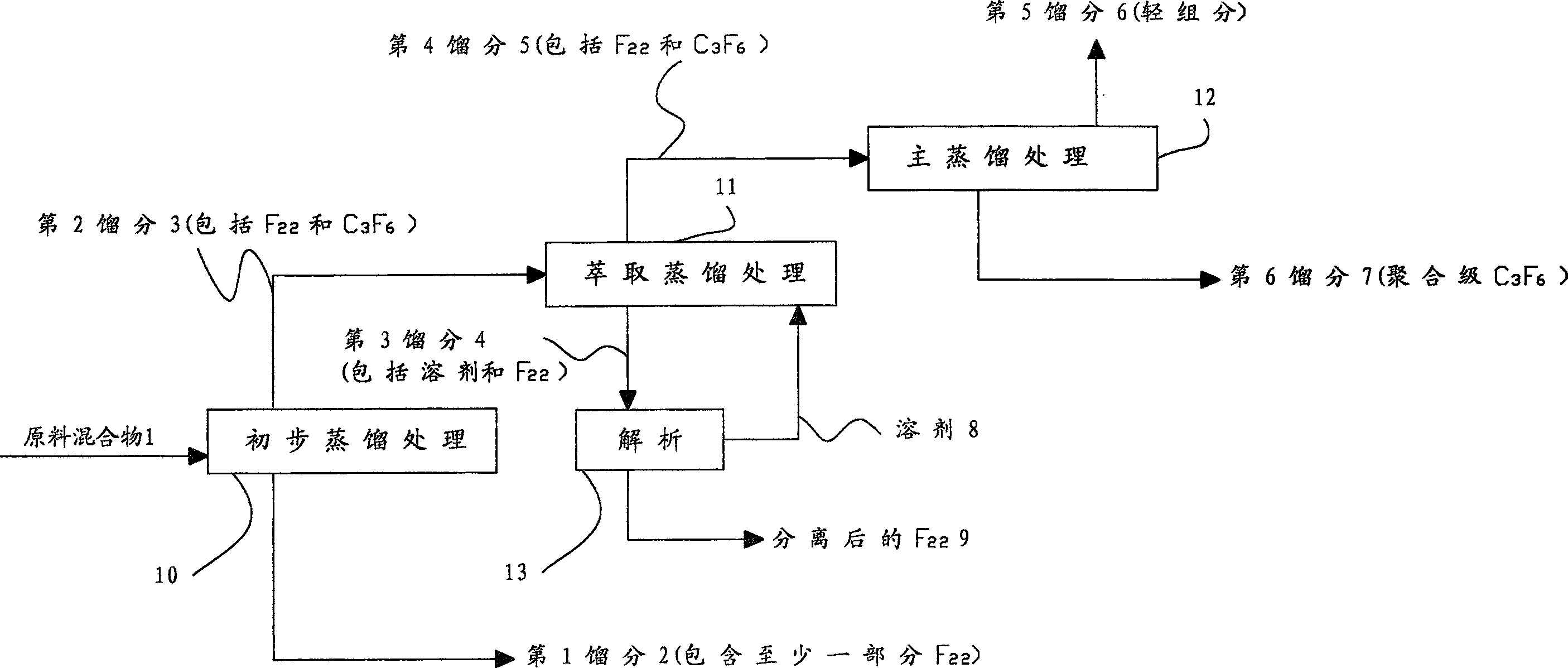

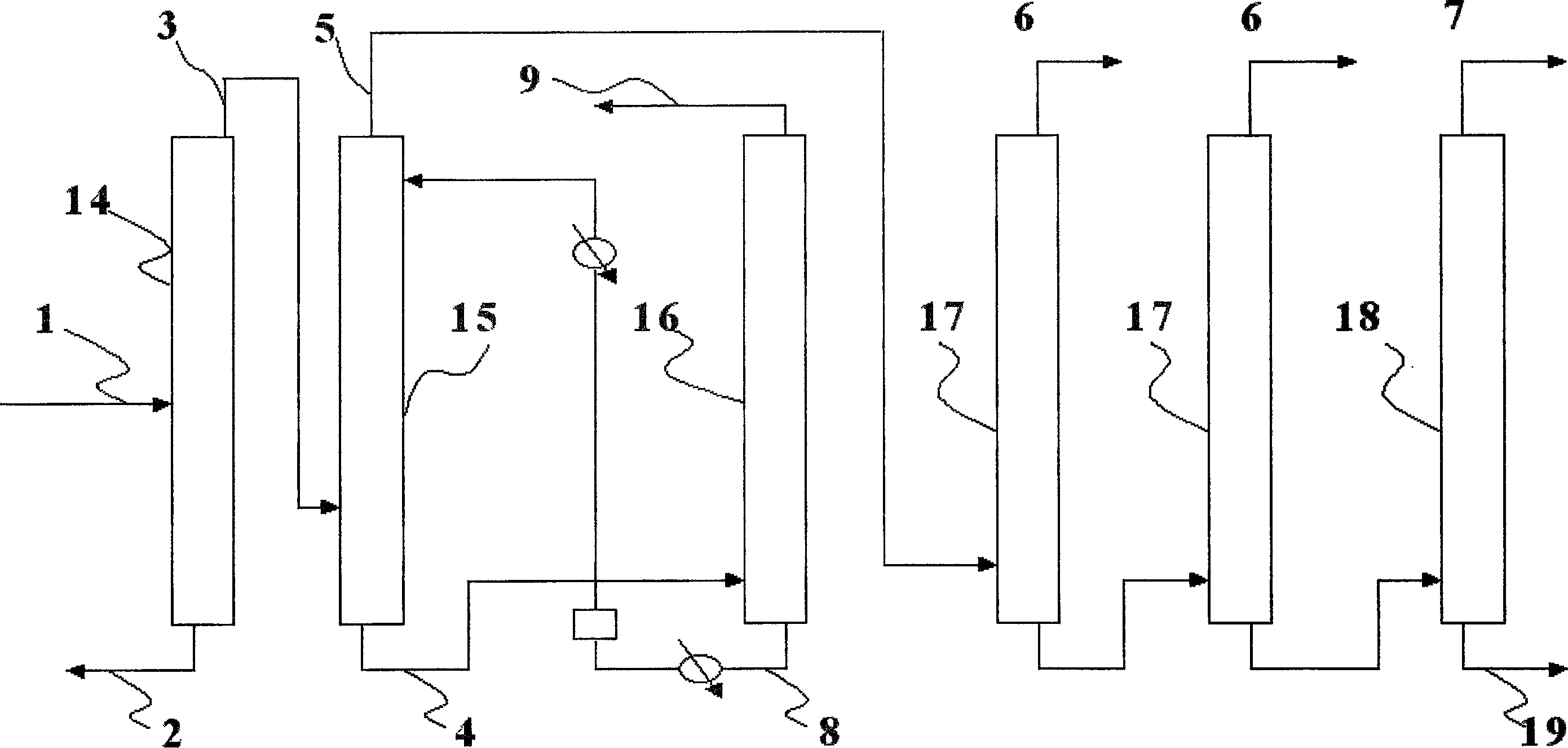

[0030] Embodiment 1: the method for reclaiming perfluoropropene from tetrafluoroethylene production process, to mainly contain 5-8% perfluoropropene (C 3 f 6 ) and the corresponding component F 22 Mixture 1 was used as starting material, from which perfluoropropene mixture 7 containing higher concentration of perfluoropropene was isolated, using figure 2 The recovery equipment in is equipped with deazeotrope tower 14, extraction tower 15, analysis tower 16, three dehydrogenation towers 17 and rectification tower 18 in series successively, certainly, also comprise the pipeline of connection, the pipeline of reflux and corresponding Conventional components such as valves and pumps, the method is:

[0031] (1) Due to the low content of perfluoropropylene in the production system of tetrafluoroethylene, if the F containing perfluoropropylene 22 It is all used for extraction treatment, and the processing capacity is large, so it is not easy to recover perfluoropropylene, and it...

Embodiment 2

[0039] Embodiment 2: the processing capacity and composition of mixture 1 are unchanged, and ethanol is used to replace ethylene glycol, and all the other methods are the same as in embodiment 1, and the flow and composition of different fractions are obtained in the following table:

[0040] project

mixture

Fraction 1

Fraction 2

Fraction 3

Fraction 4

Fraction 6

Mixture flow(kg / h)

140

115

25

18.4

6.6

5.4

Volume contains

quantity%

C 3 f 6

3

0.09

18.20

2.17

92

99.99

F 22

97

99.91

81.8

97.83

8

Quality contains

quantity%

C 3 f 6

5.1

0.16

27.84

3.7

95.22

F 22

94.9

99.84

72.16

96.3

4.78

Each component flow

Quantity(kg / h)

C 3 f 6

7.14

0.18

6.96

0.68

6.28

5.4

...

Embodiment 3

[0043] Embodiment 3: the processing capacity of mixture 1 is halved, mixture 1 is basically the same as embodiment 1, and extractant 8 is the same as embodiment 1, that is, adopts ethylene glycol, and all the other methods are the same as embodiment 1, and the flow and composition of different fractions are obtained. The following table:

[0044] project

mixture

Fraction 1

Fraction 2

Fraction 3

Fraction 4

Fraction 6

Mixture flow(kg / h)

70

54.16

15.84

12.20

3.64

3.1

Volume contains

quantity%

C 3 f 6

3.2

0.20

14.5

0.95

89

99.98

F 22

96.8

99.80

85.5

99.05

11

Quality contains

quantity%

C 3 f 6

5.42

0.35

22.73

1.64

93.35

F 22

94.58

99.65

77.27

98.36

6.65

Each component flow

Quantity(kg / h)

C 3 f 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com