Process for producing high-purity hexafluoropropylene and cleaning gas

A kind of technology of hexafluoropropene and production method, which is applied in the field of production of high-purity hexafluoropropene and achieves the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

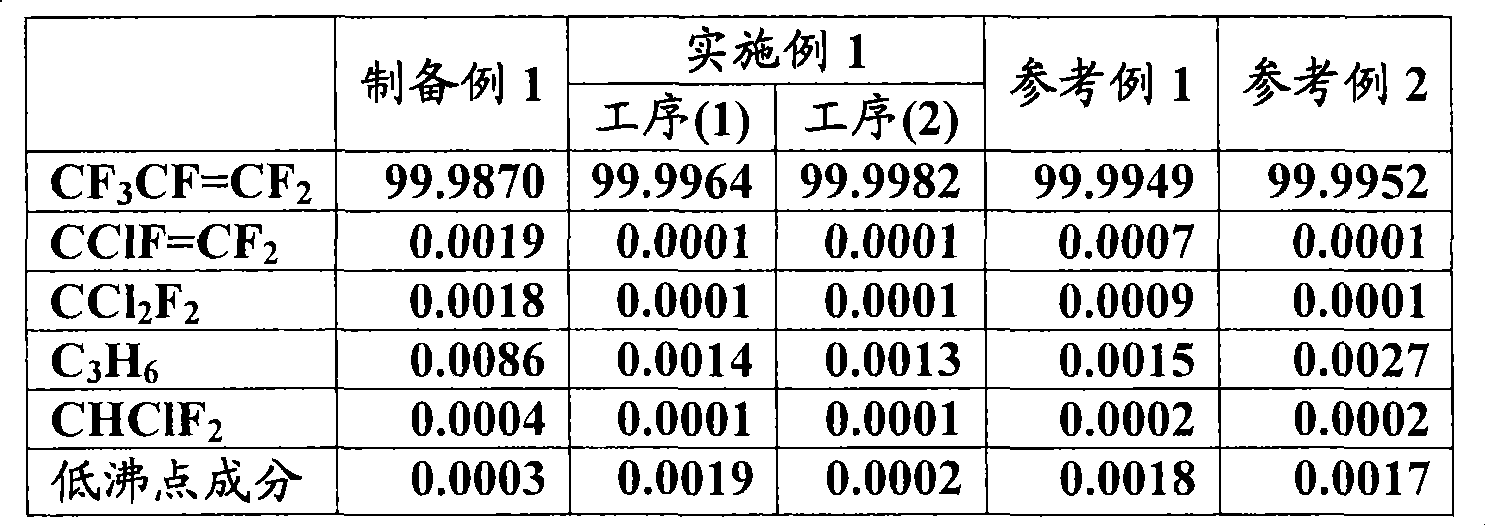

[0064] After thermal decomposition (thermal decomposition temperature 600 ° C) from chlorodifluoromethane (CHClF 2 ) When tetrafluoroethylene is produced, the product is distilled twice to recover tetrafluoroethylene, and then crude hexafluoropropylene is obtained. The crude hexafluoropropylene was analyzed by gas chromatography ["GC-14A" manufactured by Shimadzu Corporation, column: Porapack-Q (6m) manufactured by Shimadzu Corporation, measurement temperature: 80 to 200°C]. The results are shown in Table 1.

Embodiment 1

[0066] 80 g of molecular sieve 13X (manufactured by Union Showa Co., Ltd.: average pore diameter 10 , the ratio of silica / aluminum=0.81) and 70g of carbonaceous adsorbent (carbon molecular sieve 5A, manufactured by Takeda Pharmaceutical Co., Ltd.: average pore diameter ) were mixed and filled into a stainless steel cylinder with a capacity of 1000 ml, and vacuum-dried. Next, while cooling the cylinder, about 550 g of the crude hexafluoropropylene obtained in Preparation Example 1 above was filled thereinto, stirred constantly at room temperature, and the liquid phase was recovered after filling for about 12 hours [step (1)]. The liquid phase was analyzed by gas chromatography ["GC-14A" manufactured by Shimadzu Corporation, column: Porapack-Q (6m) manufactured by Shimadzu Corporation, measurement temperature: 80 to 200°C]. The results are shown in Table 1.

[0067] Next, the liquid phase obtained in the above step (1) is introduced into a distillation column, the low boiling...

reference example 1

[0069] 30 g of molecular sieve 13X (manufactured by Union Showa Co., Ltd.: average pore diameter 10 , the ratio of silica / aluminum=0.81) was filled in a stainless steel cylinder with a volume of 200 ml, and vacuum-dried. Next, while cooling the cylinder, about 70 g of the crude hexafluoropropylene obtained in Preparation Example 1 above was filled thereinto, stirred constantly at room temperature, and the liquid phase was recovered after filling for about 12 hours. The liquid phase was analyzed by gas chromatography ["GC-14A" manufactured by Shimadzu Corporation, column: Porapack-Q (6m) manufactured by Shimadzu Corporation, measurement temperature: 80 to 200°C]. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com