Enhanced process for the purification of anhydrous hydrogen chloride gas

a technology of anhydrous hydrogen chloride and purification process, which is applied in the direction of chemistry apparatus and processes, liquefaction, light and heating apparatus, etc., can solve the problems of high energy and expensive equipment, inability to dispose of, and contaminant levels that are sometimes unacceptable for use in vinyl chloride production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

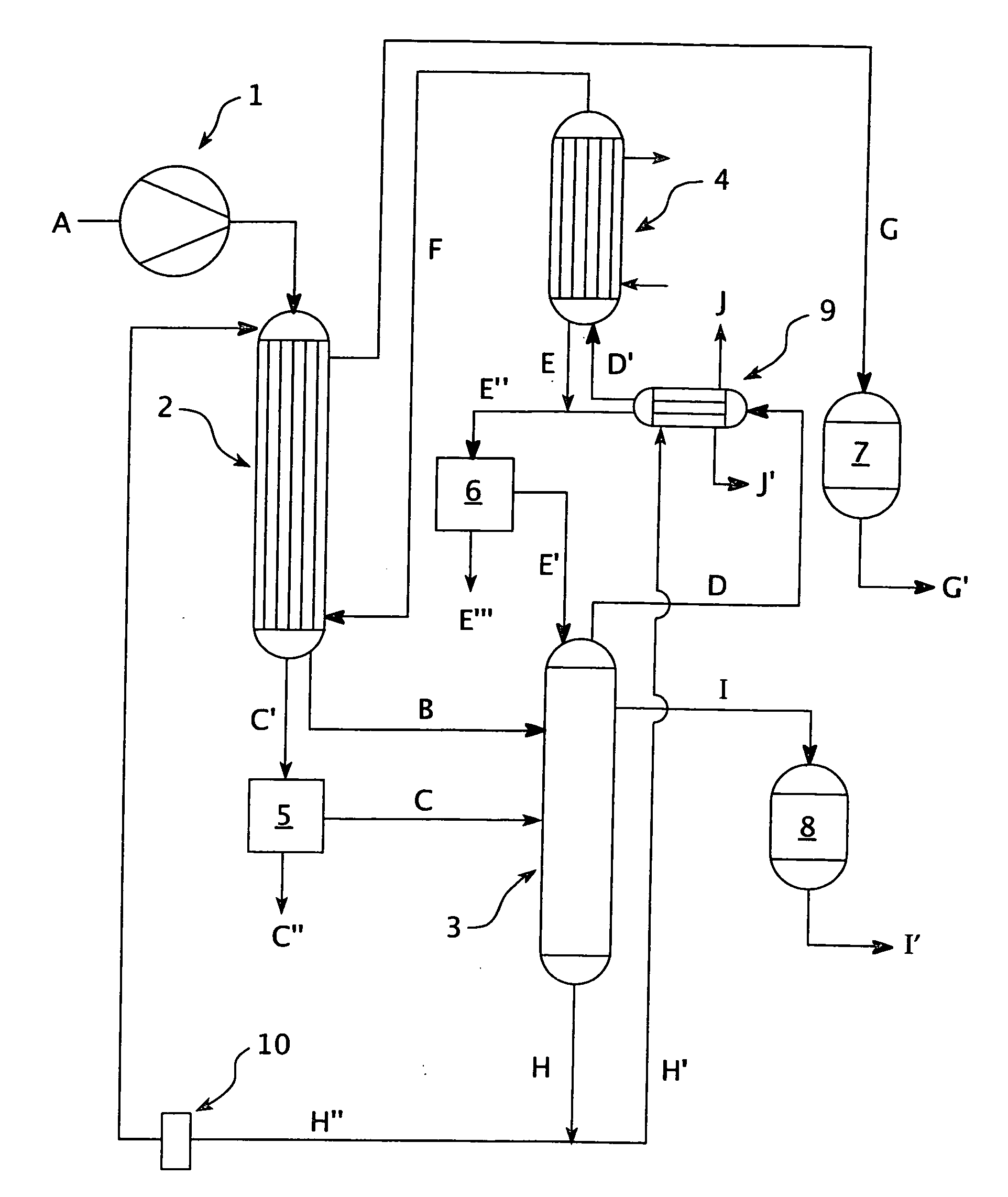

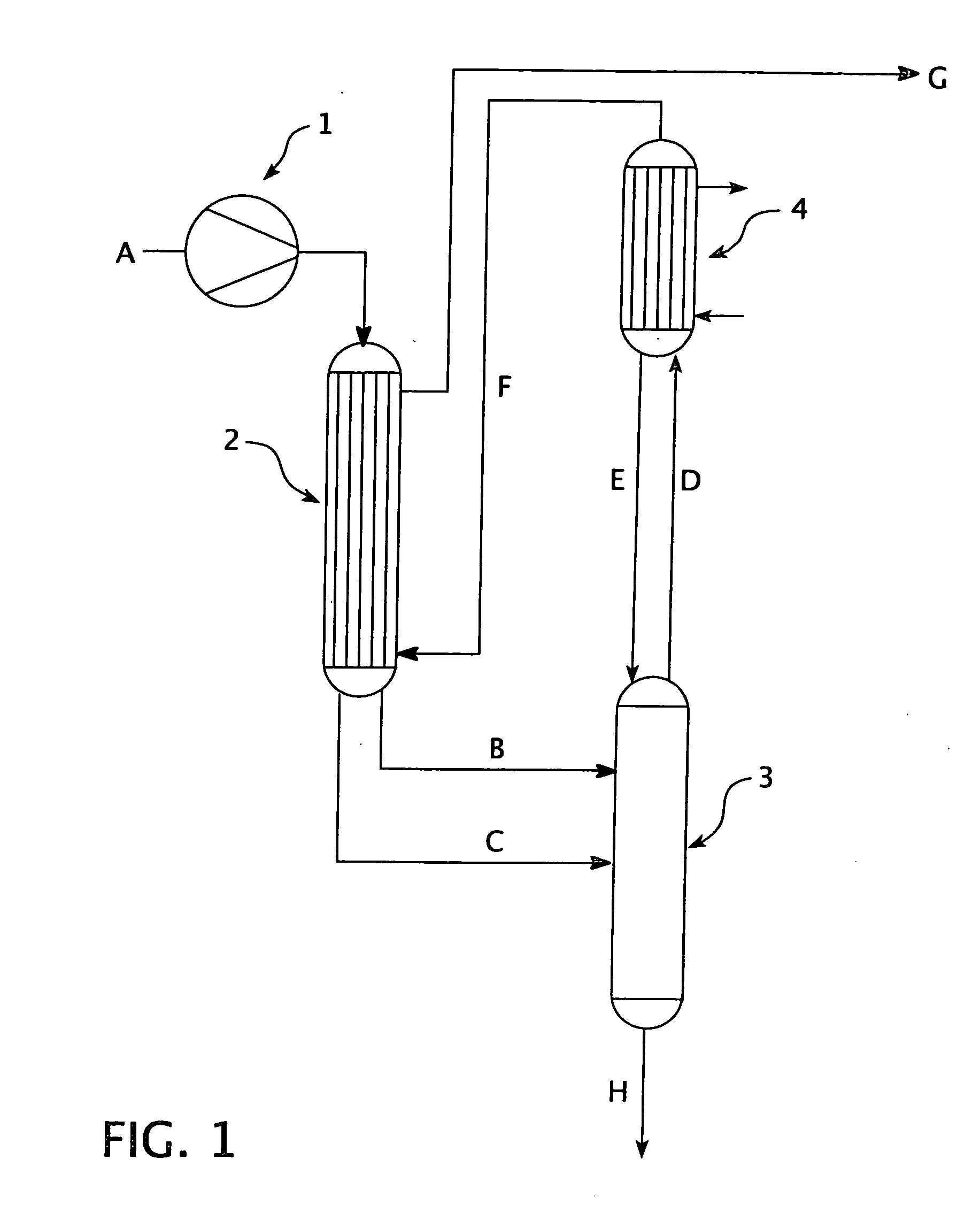

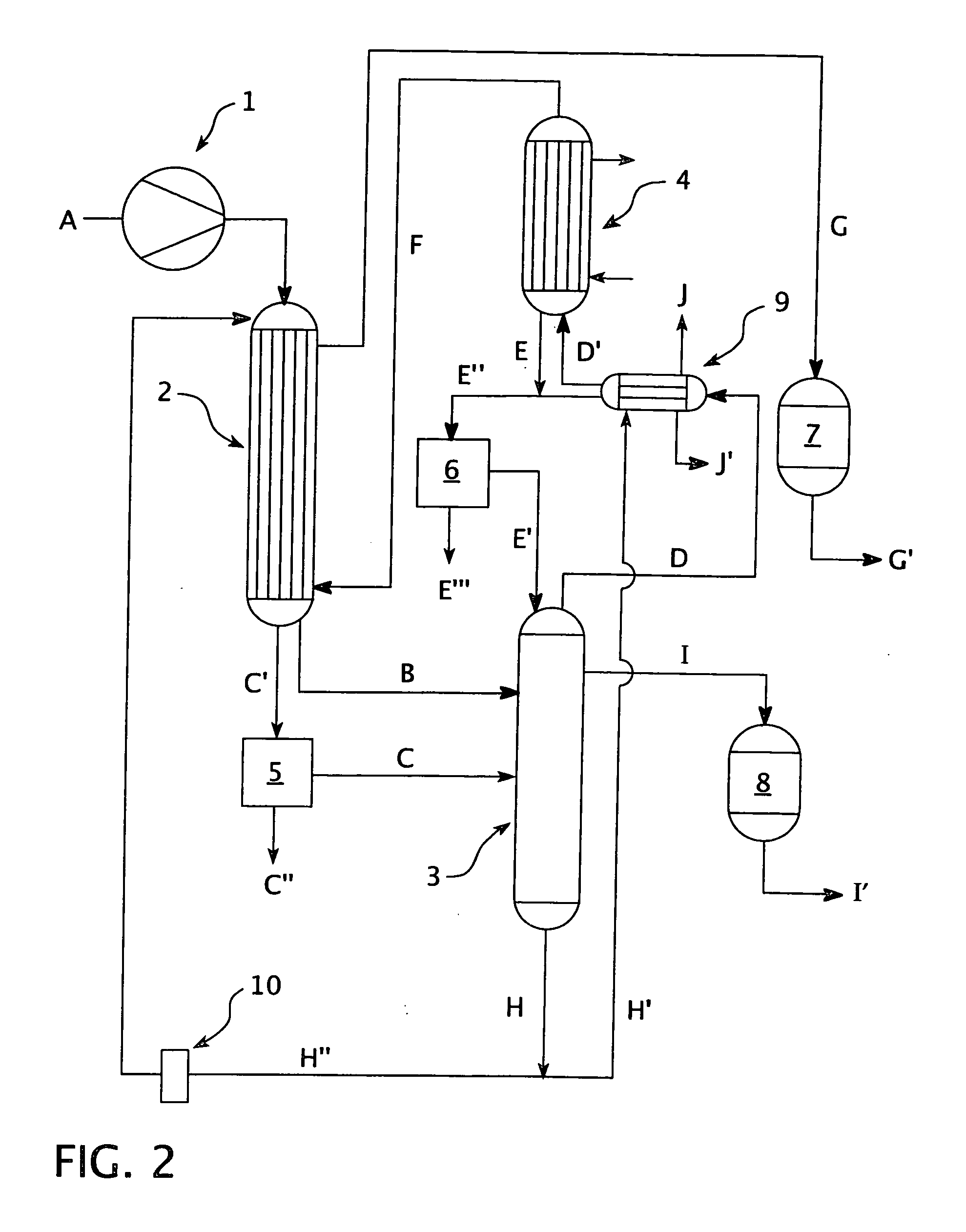

[0012] The present invention is broadly directed to a cooling and distillation process to remove contaminants having boiling points higher than hydrogen chloride from a hydrogen chloride-containing gas comprising: [0013] a) compressing said hydrogen chloride-containing gas, [0014] b) cooling the resultant compressed gas in a first heat exchanger resulting in a first condensate stream and a first gas stream, wherein said compressed gas is cooled to a temperature low enough to partially condense said contaminants and at a rate sufficiently low that fog formation is prevented, [0015] c) feeding said first gas stream from said first heat exchanger to a distillation column having a top portion and a bottom portion to a point between said top portion and said bottom portion, to cause mass transfer between liquid and gas and to thereby concentrate the contaminants in the bottom portion of said column and hydrogen chloride gas in the top portion of said column, [0016] d) feeding said hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com