A kind of waste hydrochloric acid recovery process

A technology of waste hydrochloric acid and hydrochloric acid, applied in the direction of chlorine/hydrogen chloride purification, chlorine/hydrogen chloride, etc., can solve the problems of waste of resources and increase the cost of sewage treatment, and achieve the effect of avoiding waste and reducing the cost of treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

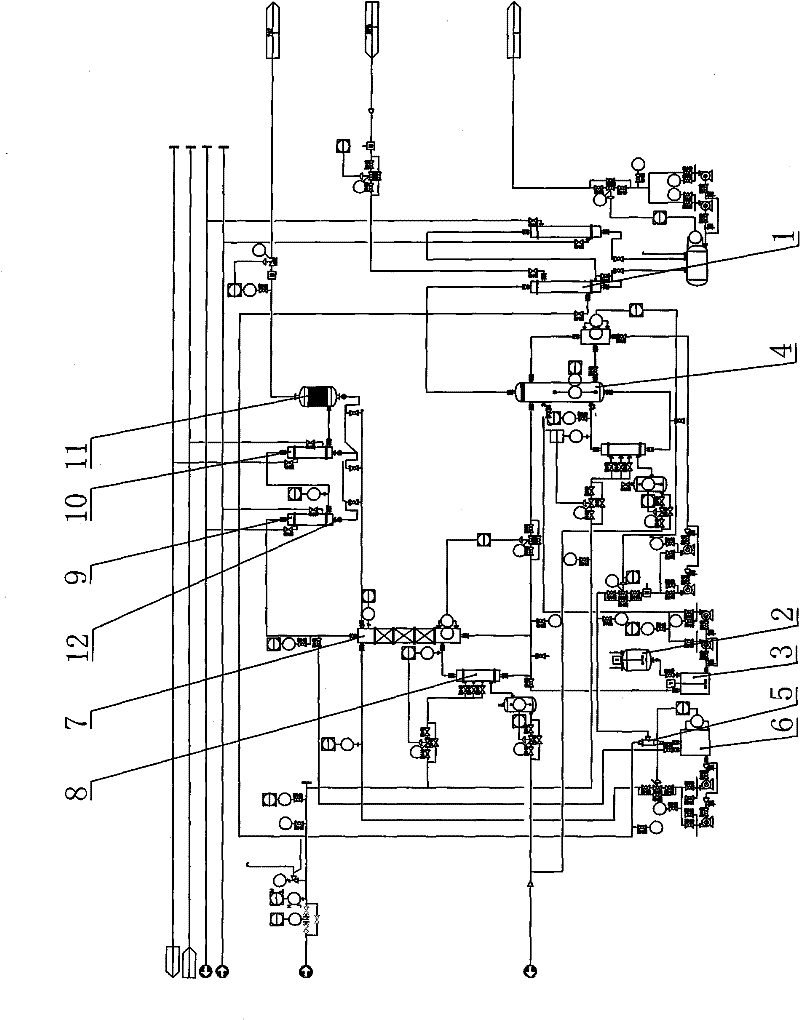

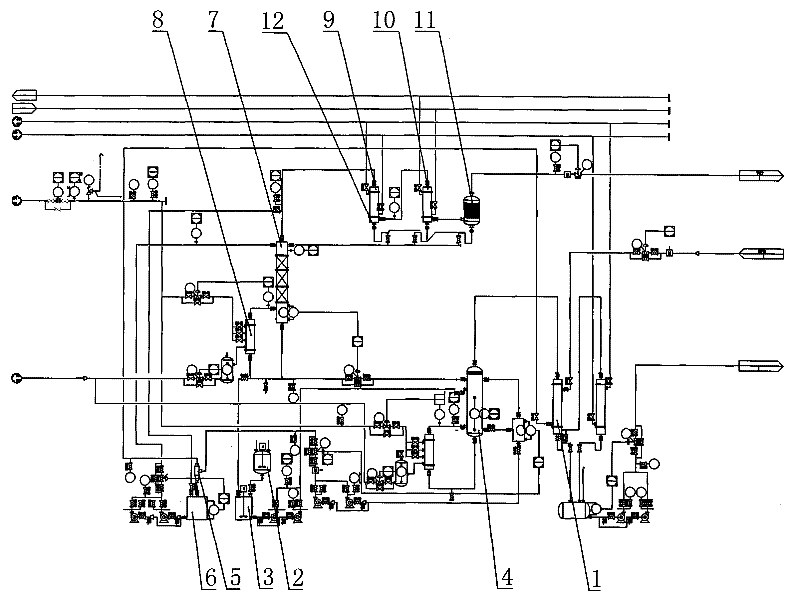

[0008] The processing steps of this embodiment are:

[0009] First, preheat the waste hydrochloric acid: pass the waste hydrochloric acid into the flow channel of the hydrochloric acid preheater 1, and exchange heat with the high-temperature medium in another flow channel to realize temperature rise, and the temperature after preheating is 78-82°C;

[0010] Carry out the preparation of catalyst: catalyst is calcium chloride solution, and its configuration is mainly to prepare its concentration, concrete preparation is: put granular calcium chloride in calcium chloride preparation kettle 2 and fully stir and mix with condensed water, store in The dilute calcium chloride solution storage tank 3 has a concentration of 50%; the calcium chloride solution in the calcium chloride solution storage tank 3 is pumped into the flash separation tank 4, and flashed to it. The evaporation of water realizes the allocation of its concentration, and the prepared calcium chloride solution is col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com