Technique for reducing impurity content in gas phase hydrogenchloride from hydrolysis of dimethyldichlorosilane

A technology of dimethyldichlorosilane and impurity content, applied in the direction of chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, etc., can solve the problems of reducing pressure, unable to synthesize with chloromethane, etc., avoiding treatment, low equipment cost, reducing impurities The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

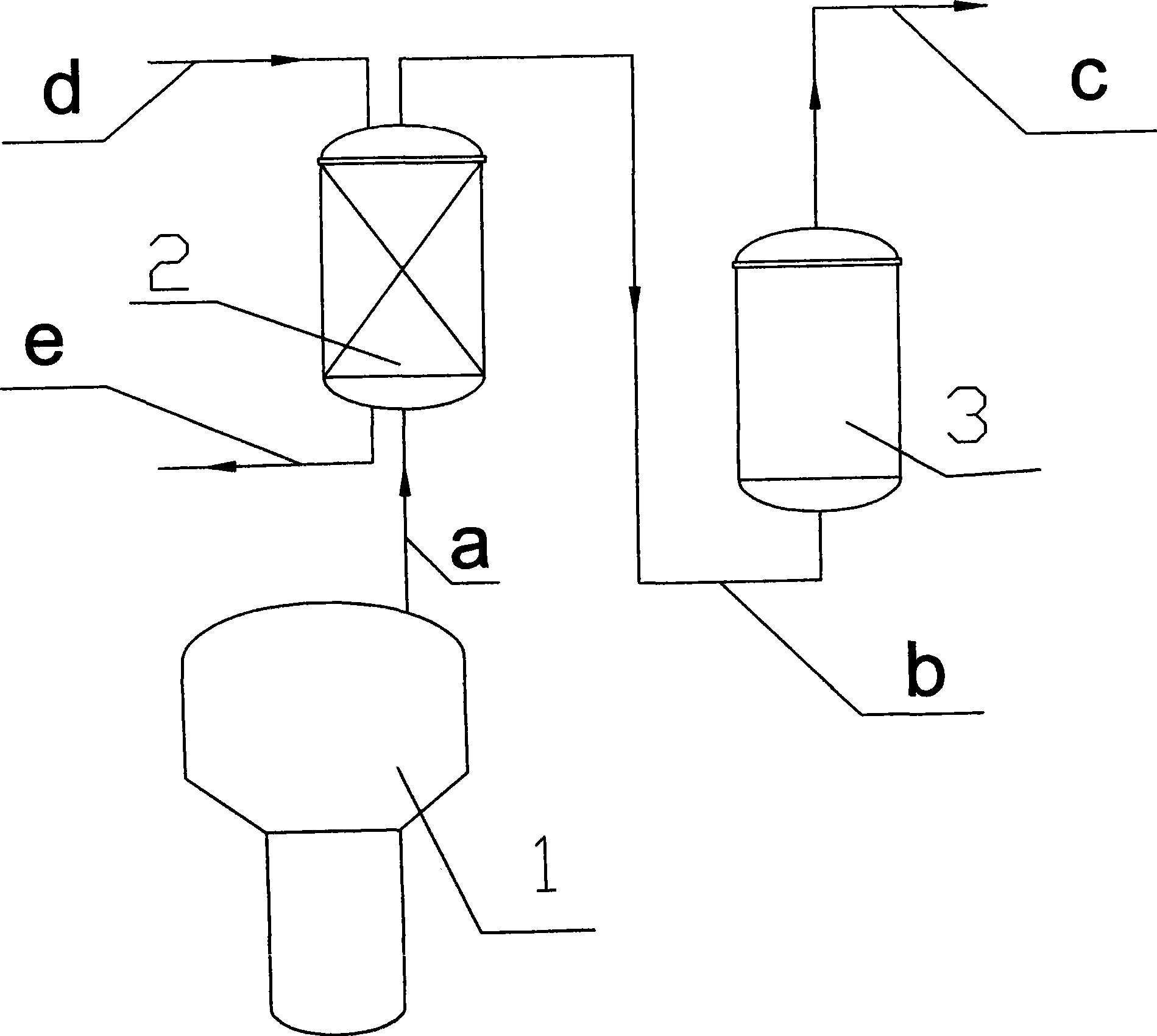

[0017] Such as figure 1 As shown, a secondary device is used to separate impurities. The gas-liquid separator 1 hydrolyzes dimethyldichlorosilane to produce mixed hydrogen chloride gas through the pipeline a and first enters the scrubber 2 of the diversion structure, and the scrubber 2 adopts supercooled saturation Hydrochloric acid enters the washing tower 2 from the top pipeline d for spray washing, and at the same time lowers the gas temperature at -25°C to remove most of the impurities, and the washed concentrated hydrochloric acid flows out from the tower bottom pipeline e; The hydrogen chloride gas is passed into the bottom of the demister 3 through the pipeline b, and the adsorption medium of the inner layer of the demister 3 is a porous fiber, which absorbs the siloxane impurities in the hydrogen chloride gas, and then mixes the siloxane impurities with the The hydrogen chloride gas is separated, and the liquid droplets adsorbed by the demister 3 flow back into the vap...

Embodiment 2

[0019] Such as figure 1 As shown, a secondary device is used to separate impurities. The gas-liquid separator 1 hydrolyzes dimethyldichlorosilane to produce mixed hydrogen chloride gas through the pipeline a and first enters the scrubber 2 of the diversion structure, and the scrubber 2 adopts supercooled saturation Hydrochloric acid enters the washing tower 2 from the top pipeline d for spray washing, and at the same time lowers the gas temperature at -30°C to remove most of the impurities, and the washed concentrated hydrochloric acid flows out from the tower bottom pipeline e; The hydrogen chloride gas is passed into the bottom of the demister 3 through the pipeline b, and the adsorption medium of the inner layer of the demister 3 is a porous fiber, which absorbs the siloxane impurities in the hydrogen chloride gas, and then mixes the siloxane impurities with the The hydrogen chloride gas is separated, and the liquid droplets adsorbed by the demister 3 flow back into the vap...

Embodiment 3

[0021] Such as figure 1 As shown, a secondary device is used to separate impurities. The gas-liquid separator 1 hydrolyzes dimethyldichlorosilane to produce mixed hydrogen chloride gas through the pipeline a and first enters the scrubber 2 of the diversion structure, and the scrubber 2 adopts supercooled saturation Hydrochloric acid enters the washing tower 2 from the top pipeline d for spray washing, and at the same time lowers the gas temperature at -40°C to remove most of the impurities, and the washed concentrated hydrochloric acid flows out from the tower bottom pipeline e; The hydrogen chloride gas is passed into the bottom of the demister 3 through the pipeline b, and the adsorption medium of the inner layer of the demister 3 is a porous fiber, which absorbs the siloxane impurities in the hydrogen chloride gas, and then mixes the siloxane impurities with the The hydrogen chloride gas is separated, and the liquid droplets adsorbed by the demister 3 flow back into the vap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com