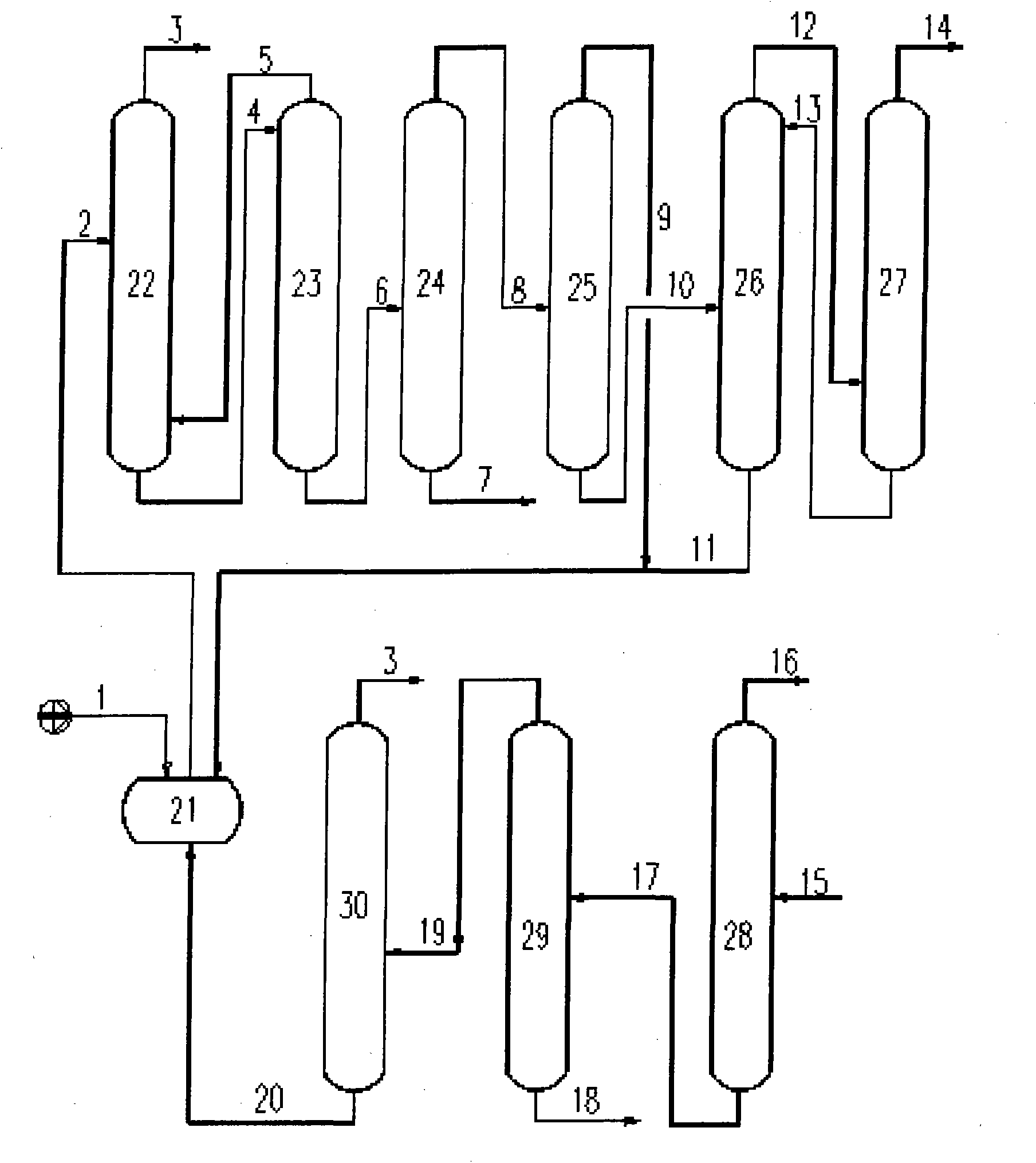

System for separating and purifying trichlorosilane in production process of polysilicon and operation method thereof

A technology for the production process of trichlorosilane, applied in the field of rectification, which can solve the problems of large reflux, high equipment investment and energy consumption, and high rectification tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] For the purification of trichlorosilane in the production of 2000 tons / year polysilicon, the feed composition is as follows:

[0024] The feed composition of the raw materials in the rectification section: the content of dichlorodihydrosilane is 1%; the content of trichlorosilane is 98%; the content of silicon tetrachloride is 1%.

[0025] The feed composition of the reduction and hydrogenation tail gas in the recovery and refining section: the content of dichlorodihydrosilane is 1.43%, the content of trichlorosilane is 37.41%, and the content of silicon tetrachloride is 61.16%.

[0026] Feed mass flow rate: 5,828kg for the rectification section, 17,484kg for the extraction section, and 23,312kg for the total feed.

[0027] The theoretical value of separation energy consumption per Kg of chlorosilane is 1500KCAL / HR.

[0028] The feed ratio of rectification section and recovery refining section is 1:3

[0029] The pressure at the top of the light removal tower 1 is 190...

Embodiment 2

[0040] Process the purification of trichlorosilane in the production of 1000 tons / year polysilicon, operating conditions are the same as embodiment 1, and different conditions are as follows:

[0041] The feed composition is as follows: the feed composition of the raw materials in the rectification section: the content of dichlorodihydrosilane is 1.5%, the content of trichlorosilane is 97.5%, and the content of silicon tetrachloride is 1%.

[0042] Feed mass flow rate: The rectification section feed is 2914kg, the extraction section feed is 4371kg, and the total feed volume is 7285kg.

[0043] The theoretical value of separation energy consumption per Kg of chlorosilane is 1800KCAL / HR.

[0044] The feed composition of the reduction and hydrogenation tail gas in the recovery section: the content of dichlorodihydrosilane is 1.43%, the content of trichlorosilane is 42%, and the content of silicon tetrachloride is 56.57%.

[0045] The feed ratio of the rectification section and t...

Embodiment 3

[0051] Process the purification of trichlorosilane in the production of 2000 tons / year polysilicon, operating conditions are the same as embodiment 1, different conditions are as follows:

[0052] Feed mass flow rate: the feed to the rectification section is 5828kg, the feed to the extraction section is 5828kg, and the total feed volume is 11656kg.

[0053] The theoretical value of separation energy consumption per Kg of chlorosilane is 2000KCAL / HR.

[0054] The feed ratio of rectification section and recovery refining section is 1:1

[0055] The loads of each tower in the trichlorosilane purification process are shown in the following table (table three):

[0056] Table three

[0057] cooling load

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com