Large-scale fluidized bed reactor used for trichlorosilane production

A technology of fluidized bed reactor and trichlorosilane, which is applied in the direction of silicon halide compounds, chemical instruments and methods, halosilane, etc., and can solve the problem of unstable yield of trichlorosilane and difficult control of reaction temperature, etc. problem, to achieve the effect of stable product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

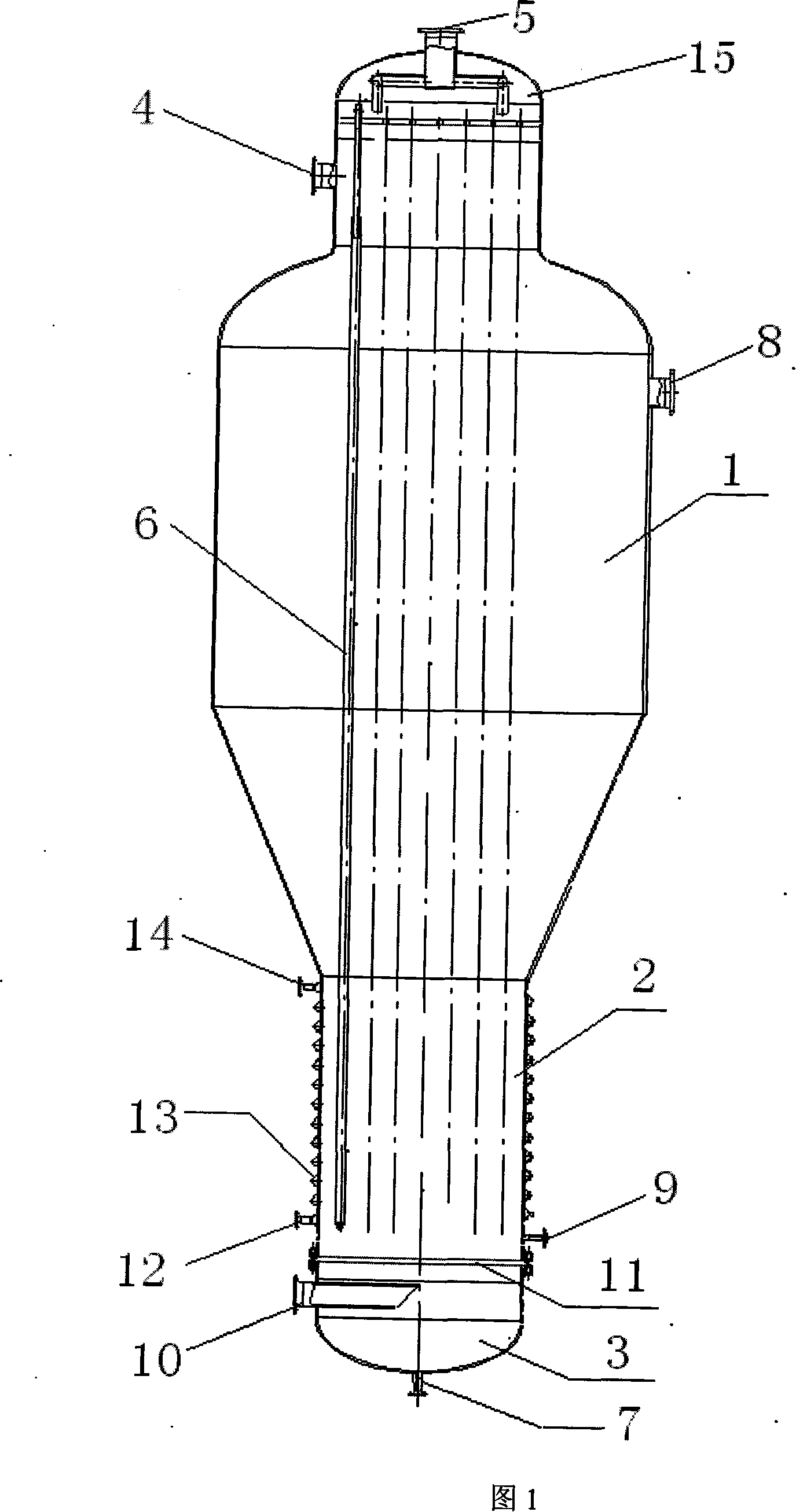

[0014] Referring to Fig. 1, the trichlorosilane large-scale fluidized-bed reactor of the present invention, this trichlorosilane large-scale fluidized-bed reactor is a vertical cylindrical structure, comprises the reaction section 2 of the bottom and the expansion section 1 of the top, and reacts The lower part of the section 2 is provided with a silicon powder feed port 9; the lower part of the reactor is provided with an inspection head 3; the inspection head 3 is provided with a hydrogen chloride inlet 10 and a slag discharge outlet 7; the expansion section 1 has a synthesis gas outlet 8; A hydrogen chloride gas distributor 11 is provided between the inspection head 3 and the reaction section 2;

[0015] Since the reaction is carried out at 250°C-350°C, the reactor must have a heating device. For this reason, a heat transfer oil finger tube 6 is provided in the reaction section 2 and the expansion section 1, and the heat transfer oil finger tube 6 starts from the expansion s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com