Double-layer conveying coating machine

A technology of double-layer conveying and coating machine, which is applied in the device, coating, spraying device and other directions of coating liquid on the surface, can solve the problems of uneven spraying, single function, poor spraying quality, etc., to improve the spraying quality, The effect of good atmospheric environment and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

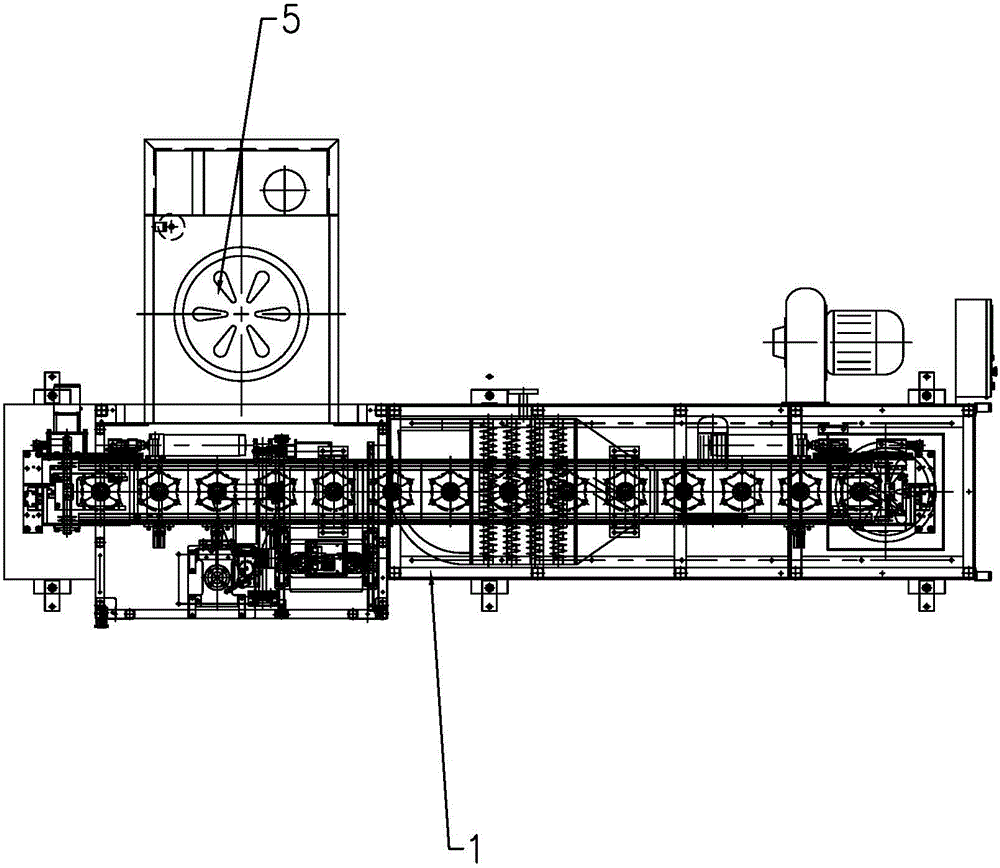

[0027] Such as Figure 1~3 As shown, the present invention mainly comprises frame 1, and the top of frame 1 is provided with pneumatic pusher part 3. Pneumatic pushing part 3 comprises slide rail 3.2, and slide rail 3.2 front end is provided with front push material cylinder 3.1, and slide rail 3.2 rear end is provided with rear push material cylinder 3.3. The workpiece enters from the right end of the frame 1 and advances along the slide rails through the push of the front and rear pushing cylinders.

[0028] The right part of the slide rail 3.2 is a pre-heating station, which is provided with a pre-heating oven 10, and the pre-heating oven 10 is used to heat the workpiece before spraying, which can increase the coating absorption rate, thereby improving the spraying quality. The left part of the slide rail 3.2 is the spraying station. From top to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com