Automatic spraying system and automatic spraying method based on point cloud and image matching

An automatic spraying and point cloud technology, applied in spraying devices and other directions, can solve problems such as the need to improve the production process customization technology, the time-consuming and laborious construction of process program models, and the limited working space and load of robots, so as to facilitate the adjustment and improvement of production plans. Efficiency and economic benefits, the effect of shortening the commissioning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

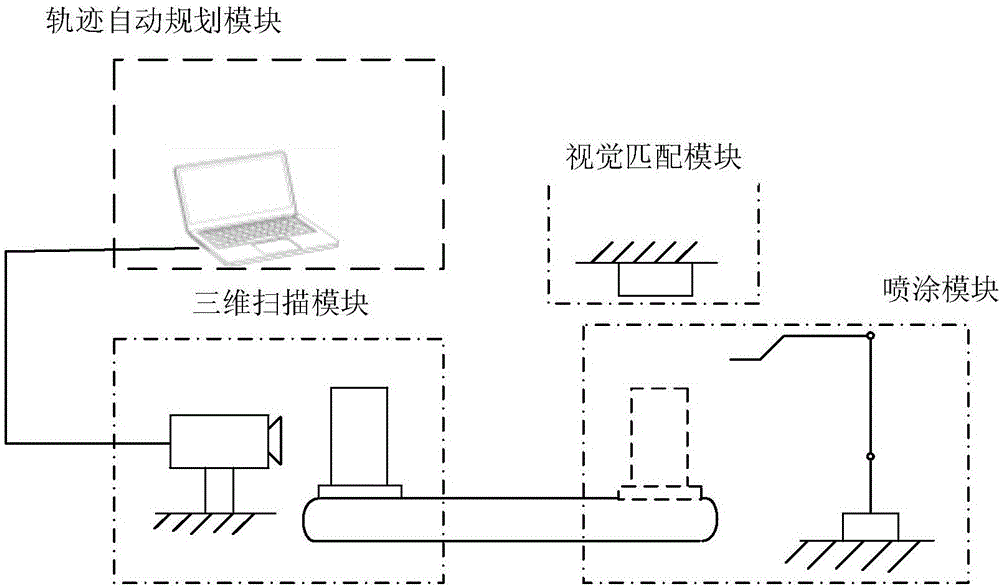

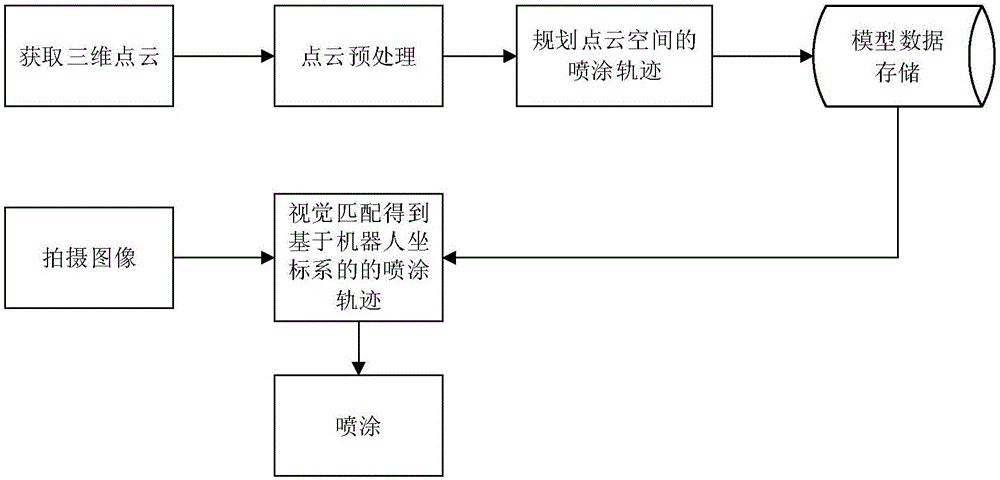

[0050] The present invention will be further described below in conjunction with accompanying drawing and embodiment: figure 1 It is a schematic diagram of the principle of the present invention.

[0051] Such as figure 1 As shown, the automatic spraying system based on point cloud and image matching in this embodiment includes

[0052] The 3D scanning module is used to scan the sprayed object and obtain the point cloud model according to the scanned 3D point cloud data,

[0053] The trajectory automatic planning module is used to plan the spraying trajectory located in the point cloud space,

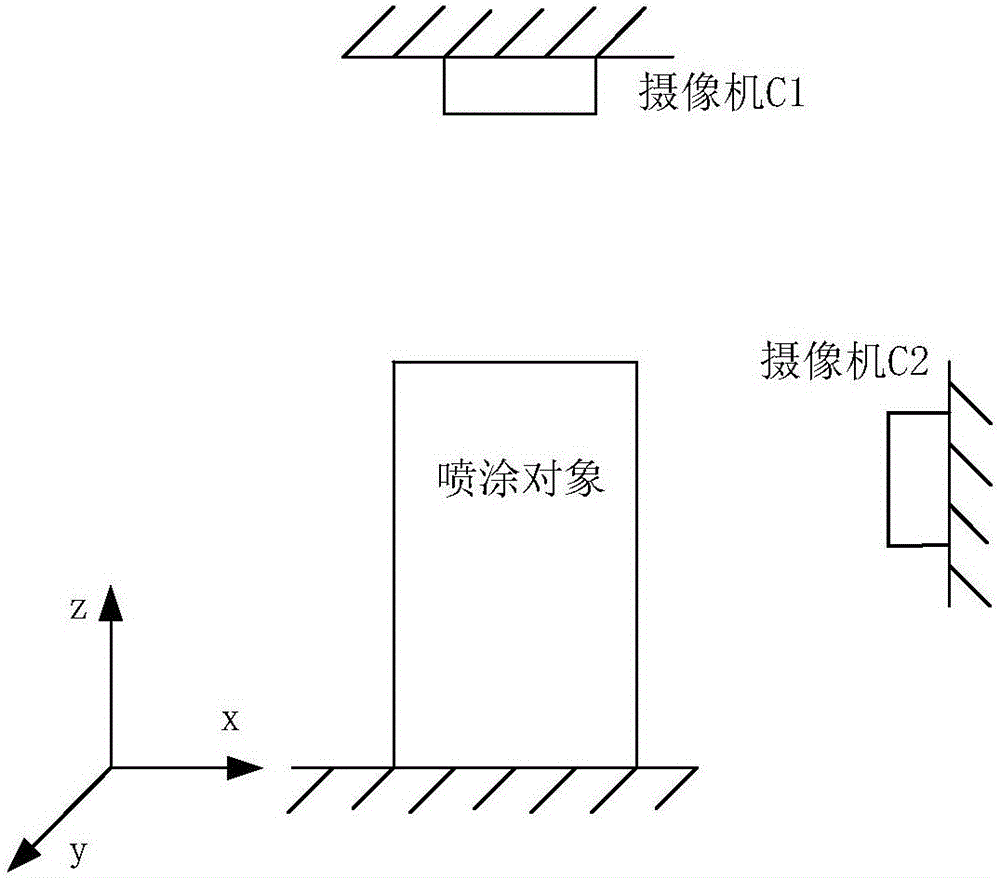

[0054] The visual matching module is used to obtain the conversion relationship between the point cloud coordinate system and the spraying robot coordinate system,

[0055] The spraying module is used for automatic spraying of spraying objects.

[0056] In this embodiment, the sprayed product is placed on the platform or on the hoisting frame, and the three-dimensional point cloud d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com