Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Send powder evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

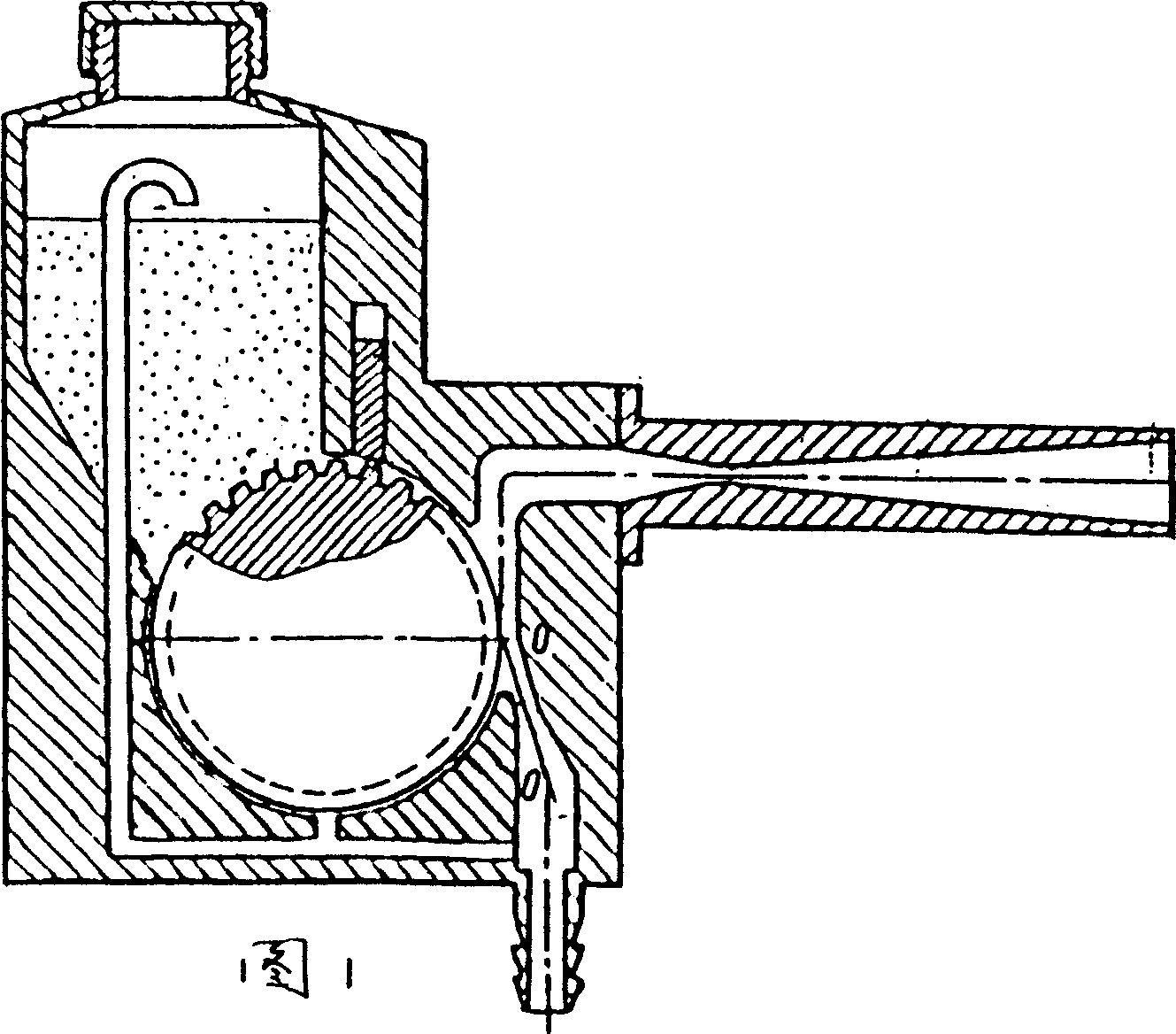

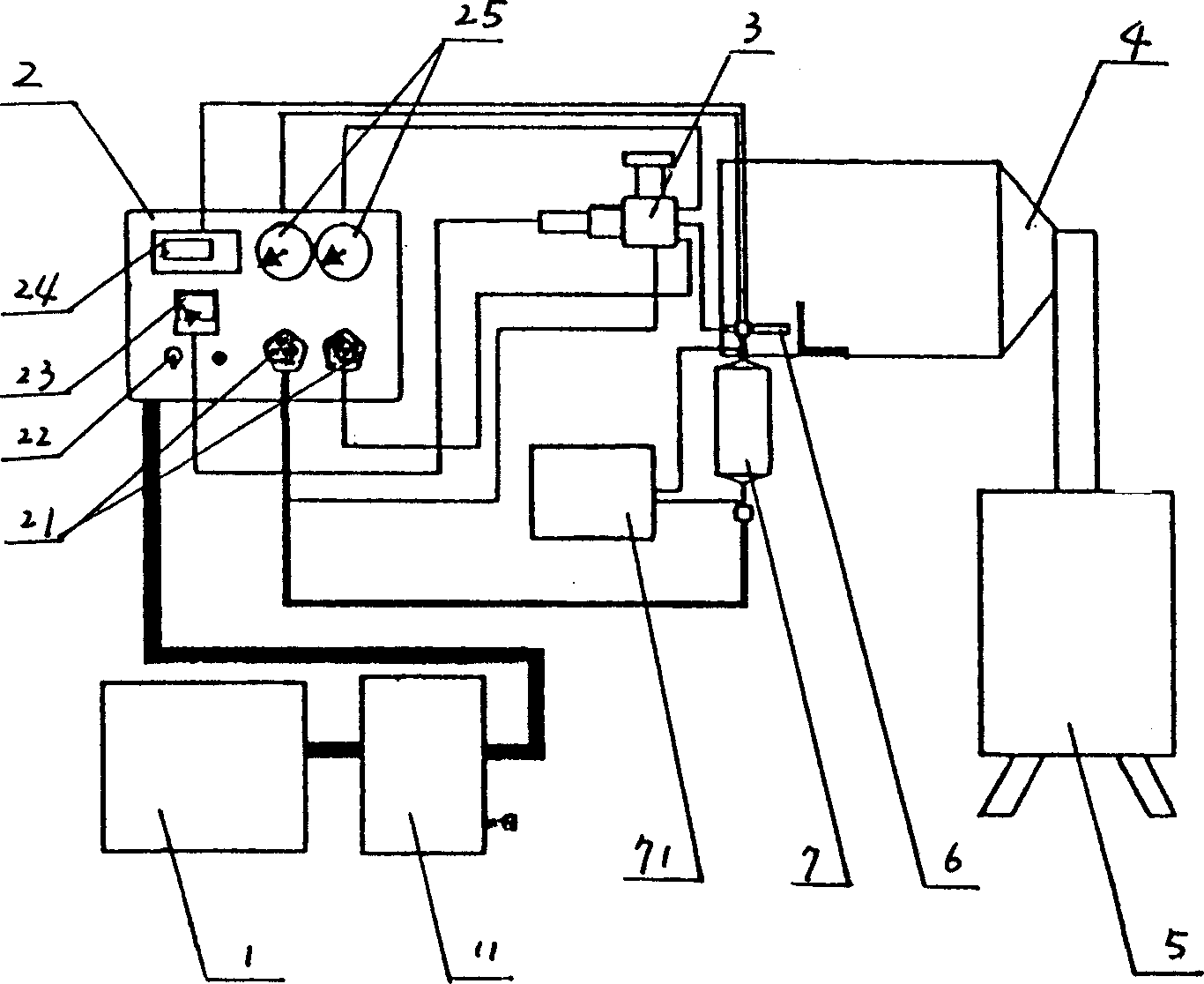

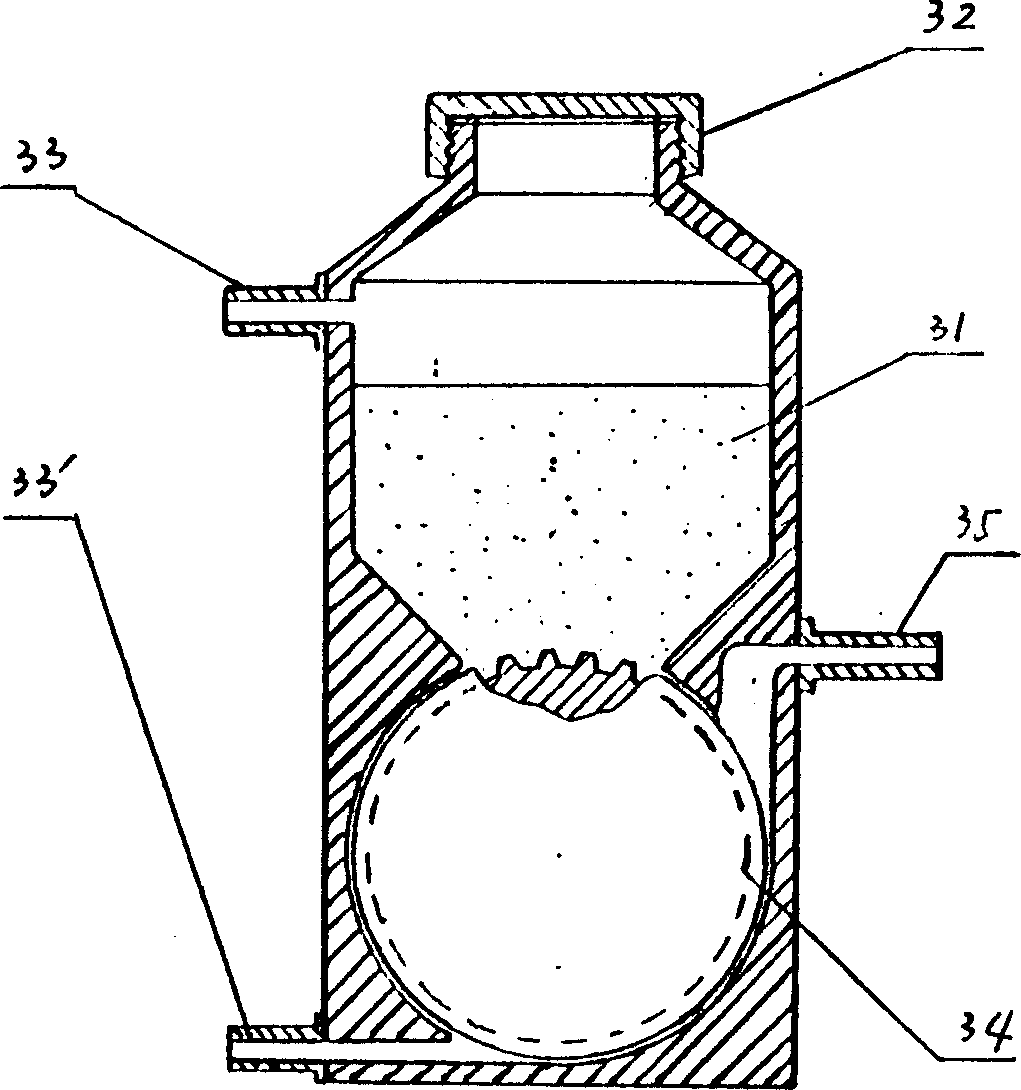

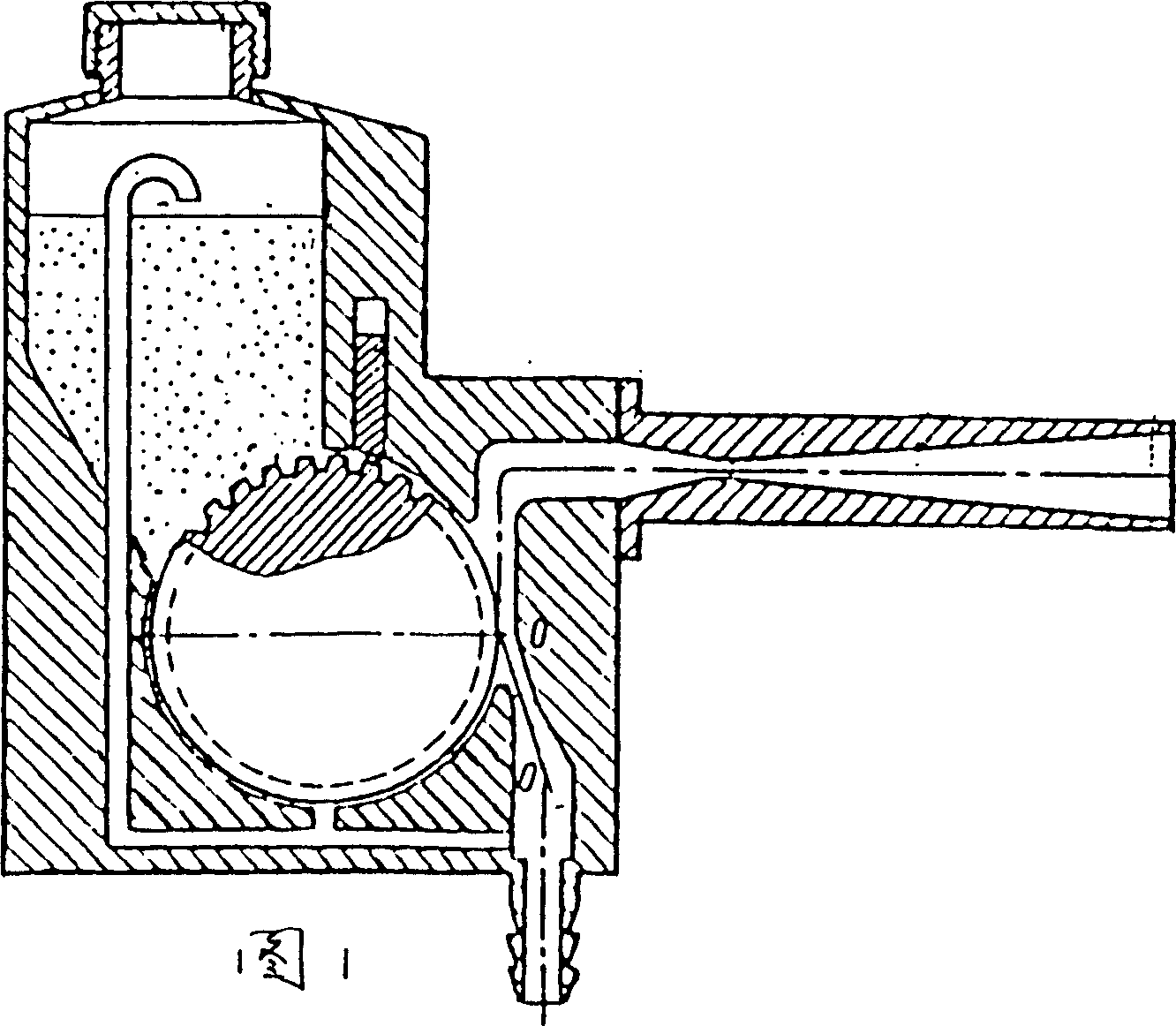

Cold air driven spray painter

InactiveCN1403210AImprove powder feeding methodImprove powder feeding efficiencyLiquid surface applicatorsMolten spray coatingCold airUltrasonic nozzle

The spray painter consists of ultrasonic nozzle, heater, powder feeder and other parts. The ultrasonic nozzle is mounted in the inlet of the spraying chamber, and the controller connected to the air compressor with air tank is connected via a powder feeding switch and pressure regulating switch to the heater and the powder feeder. The heater has one end connected to the ultrasonic nozzle. There is one powder recovering unit in the outlet of the spraying chamber. The ultrasonic nozzle is connected with the powder feeder and consists of three parts of contracting section, throat and expanding section. The present invention has high powder feeding efficiency, long service life and no oxidation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Cold air driven spray painter

InactiveCN1161188CImprove powder feeding methodImprove powder feeding efficiencyLiquid surface applicatorsMolten spray coatingCold airUltrasonic nozzle

The spray painter consists of ultrasonic nozzle, heater, powder feeder and other parts. The ultrasonic nozzle is mounted in the inlet of the spraying chamber, and the controller connected to the air compressor with air tank is connected via a powder feeding switch and pressure regulating switch to the heater and the powder feeder. The heater has one end connected to the ultrasonic nozzle. There is one powder recovering unit in the outlet of the spraying chamber. The ultrasonic nozzle is connected with the powder feeder and consists of three parts of contracting section, throat and expanding section. The present invention has high powder feeding efficiency, long service life and no oxidation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

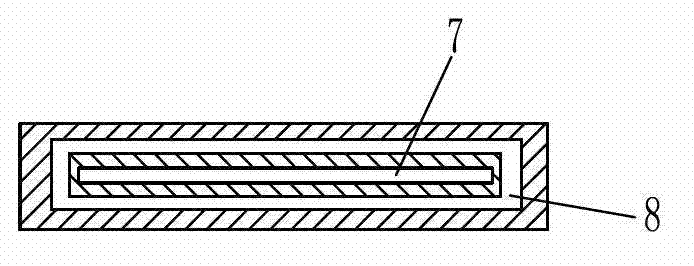

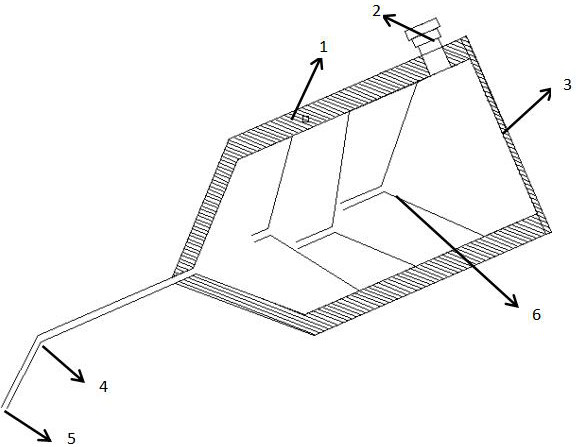

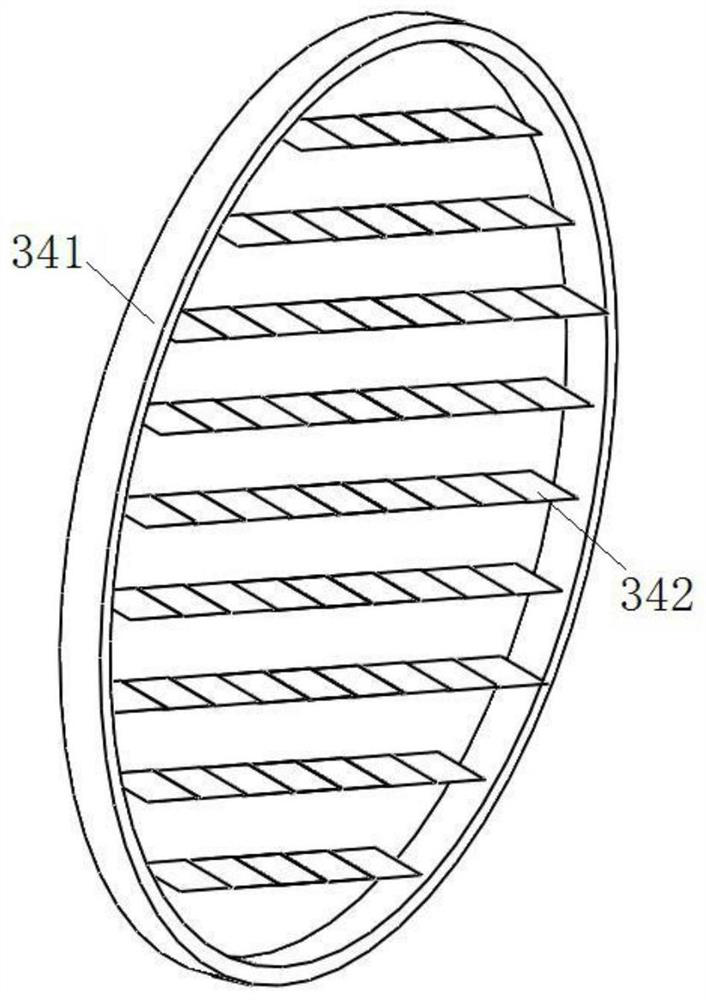

Wideband nozzle capable of uniformly feeding powder in laser processing

ActiveCN103205748AImprove continuityImprove stiffnessMetallic material coating processesLiquid spraying apparatusLaser processingMetallurgy

The invention discloses a wideband nozzle capable of uniformly feeding power in laser processing. The wideband nozzle comprises a rectangular nozzle and an annular powder cavity, the rectangular nozzle is provided with a rectangular powder feed channel and a protection gas channel, one end of the rectangular powder feed channel is a powder outlet, the protection gas channel is arranged at the periphery of the powder outlet and parallel to the powder outlet, the other end of the rectangular powder feed channel is a powder feed gas channel, the powder feed gas channel comprises a transition channel and a circular channel, the transition channel is used for realizing the smooth and uniform transition from the circular channel to the rectangular powder feed channel, the rectangular nozzle is installed and fixed in the annular powder cavity, the powder outlet end and the circular channel end of the rectangular nozzle extend out of the annular powder cavity, the powder is put in the annular powder cavity, and the gas channel is arranged in the annular powder cavity, and a powder inlet is arranged at the side of the rectangular powder feed channel of the rectangular nozzle. The nozzle disclosed by the invention can be used for greatly eliminating the phenomenon that the powder in middle is more than powder at two sides when the rectangular nozzle is used for feeding powder, the powder is capable of uniformly filling the powder outlet of the whole rectangle to realize the uniform powder feed.

Owner:HANGZHOU BOHUA LASER TECH

Laser cladding device capable of recycling and reusing reflected light

PendingCN110438492AAchieve reuseReduce harmMetallic material coating processesLight beamOptoelectronics

The invention provides a laser cladding device capable of recycling and reusing reflected light. The laser cladding device capable of recycling and reusing reflected light comprises a reflecting cover, a laser head inner wall and a laser head outer wall, wherein the inner wall of the laser head is arranged inside the outer wall of the laser head, a laser beam channel used for transmitting a laserbeam is formed inside the inner wall of the laser head, a powder beam used for transmitting a powder beam is formed between the out wall of the laser head and the inner wall of the laser head, the laser beam passes through the laser beam channel and then is focused on the surface of a to-be-machined workpiece, the powder beam is focused on the surface of the to-be-machined workpiece after passingthrough the powder beam channel, the laser beam and the powder beam are focused on the same point on the surface of the to-be-machined workpiece, and a reflecting cover can reflect the laser reflectedby the surface of the to-be-machined workpiece back to the joint focus point where the laser beam and the powder beam located on the surface of to-be-machined the workpiece. According to the laser cladding device, a reflected light recycling and reusing mechanism and related cooling mechanism are arranged, so that the damage of the reflected laser to equipment and a human body is reduced, the laser utilization efficiency is improved, and the development bottleneck of an existing laser cladding technology is solved.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

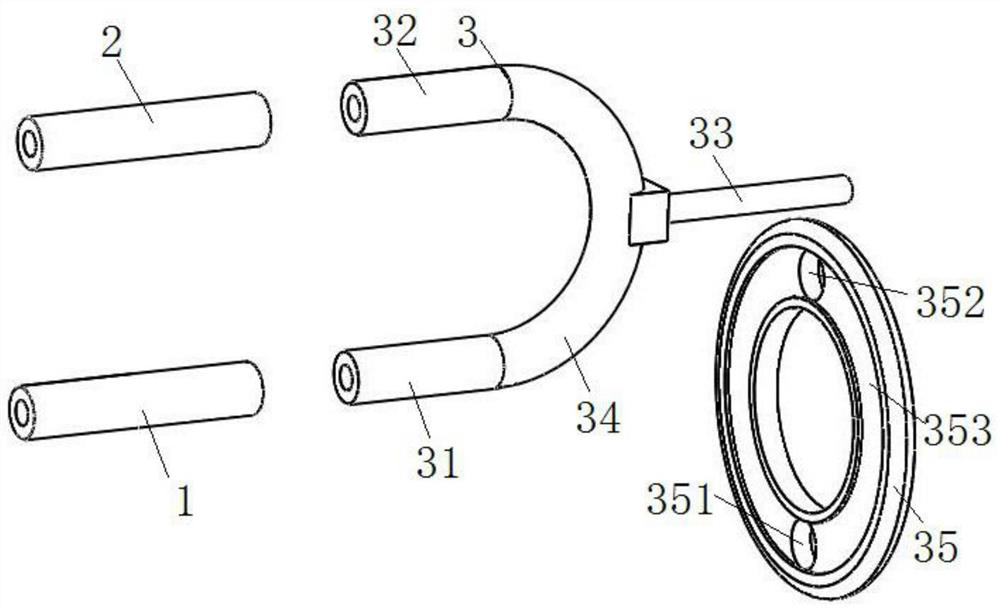

Coaxial powder-feeding mouth for inner wall laser metling covering and alloying treatment of hold pieces

InactiveCN1371779AEliminate dead endsOvercoming the disadvantages of uneven coolingMolten spray coatingLiquid spraying apparatusWater dischargeTelecommunications

The coaxial power-feeding nozzle, belonging to the field of laser processing equipment technology, is formed from laser channel, U-shaped fastener, outer ring, cone ring, cone cover, internal coolingwater channel, external cuoling water channel and powder feeding channel, in which the laser channel is formed from light guide tube, cooling cover, reflector and internal cone body, and its internalcooling water channel is formed from water intake pipe, water intake channel, water discharge pipe, water discharge channel, internal ring water channel and its partion, board, its powder-feeding channel is composed of power-feeding pipe, ring mixing cavity and conical ring groove, it has 2-8 powder-feeding pipes which are distributed along the radial direction, and its external cooling water channel is formed from water-intake pipe, water outlet pipe, external ring water channel and its partion board.

Owner:青岛启源泉能源设备有限责任公司

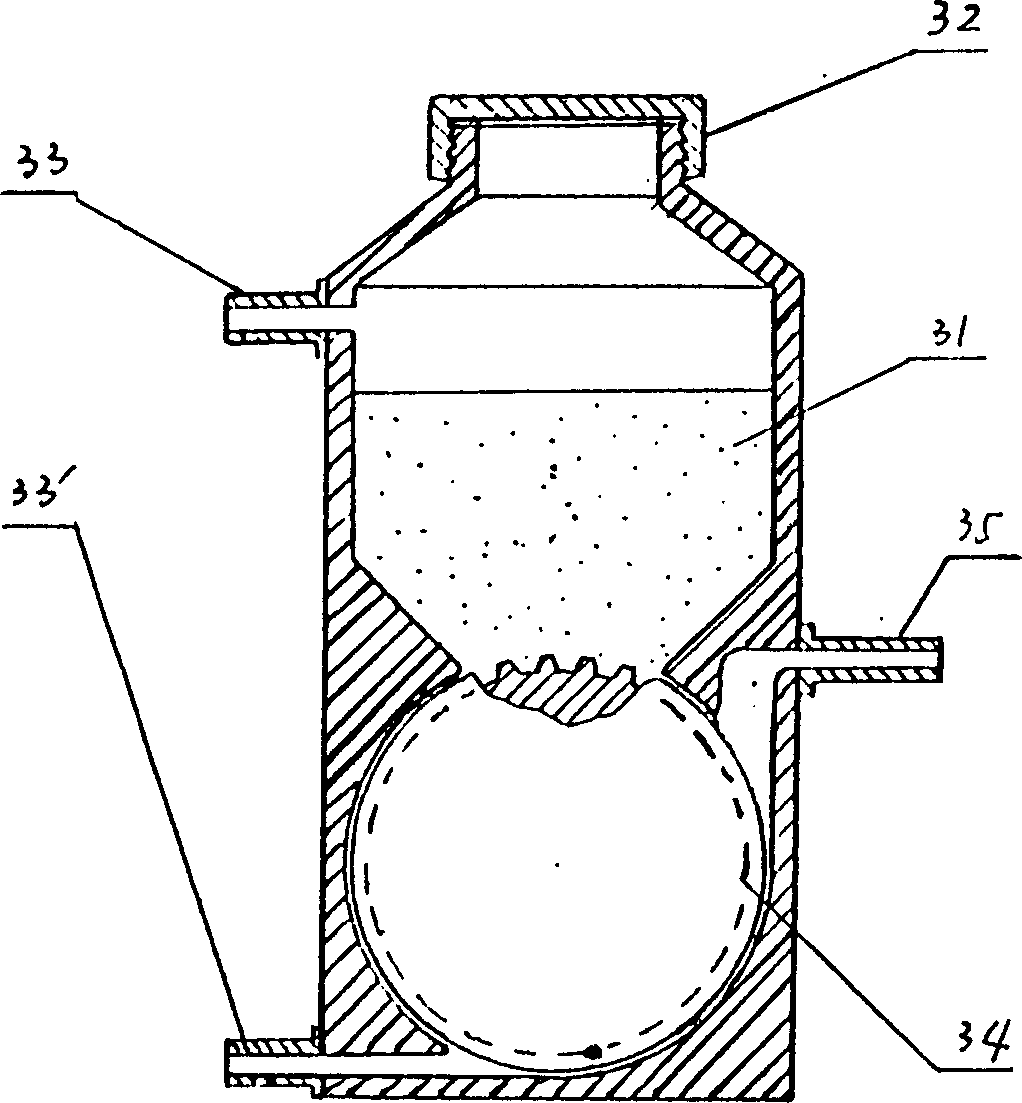

Additive manufacturing powder falling device

InactiveCN107520443AImprove molding qualitySend powder evenlyAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyAdditive layer manufacturing

The invention discloses an additive manufacturing powder falling device. The additive manufacturing powder falling device comprises a powder feeding box. A powder outlet is formed in the bottom of the powder feeding box. A powder homogenizing mechanism and a powder feeding mechanism are sequentially arranged below the powder feeding box and arranged in empty grooves with the upper portions and the lower portions opened. The empty grooves are in communication through a hollow structure with the upper portion and the lower portion opened. The upper opening of the powder homogenizing mechanism is connected with the powder outlet of the powder feeding box. The problems of uneven powder falling and the like are solved through the powder homogenizing mechanism, the powder feeding mechanism can accurately control the powder feeding amount of powder, quantitative powder feeding is achieved, meanwhile, powder waste is reduced, and the powder paving quality is improved.

Owner:ZRAPID TECH CO LTD

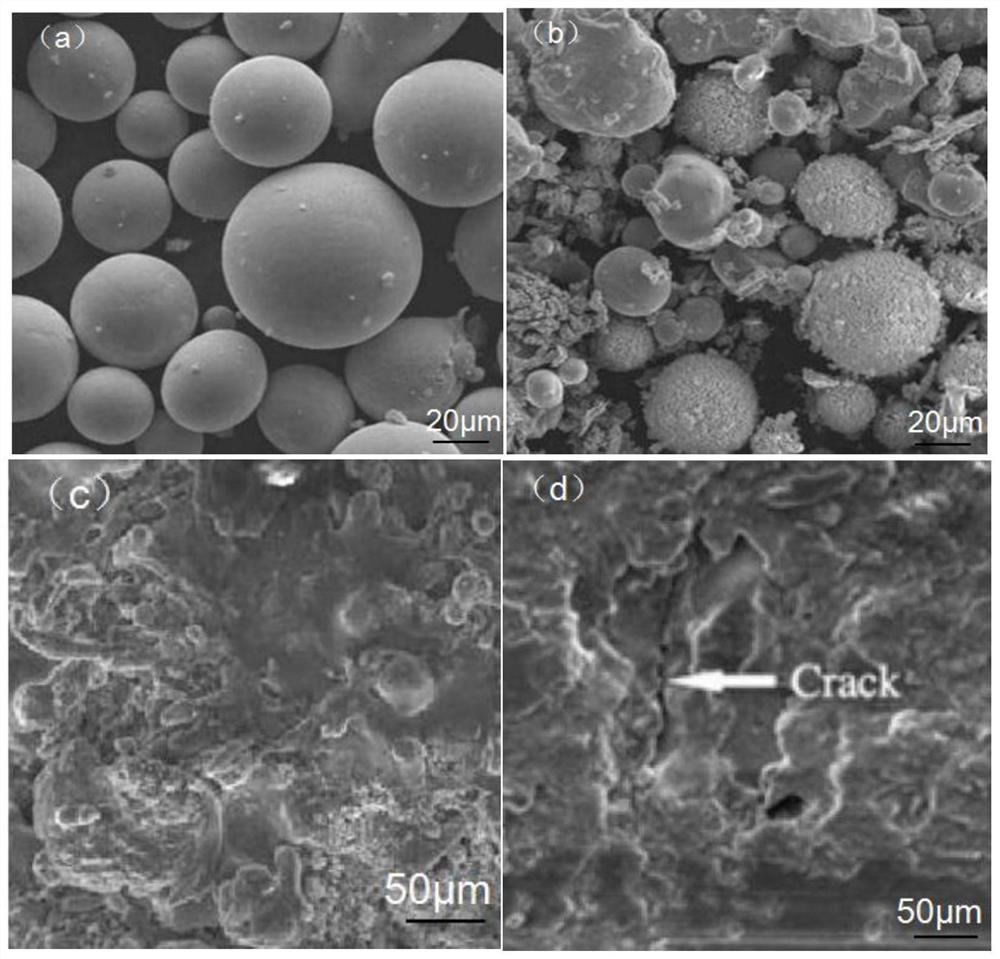

Cobalt-based alloy composite powder for plasma spray and preparation method of fusion covering coating

ActiveCN110923610AHigh hardnessImprove wear resistanceMolten spray coatingTransportation and packagingChromium carbideAlloy composite

The invention relates to cobalt-based alloy powder for plasma spray. The cobalt-based composite powder is prepared from the following raw materials in parts by weight: 90-120 parts of cobalt-based alloy powder, 3-5 parts of yttria powder, 7-12 parts of titanium boride powder and 10-15 parts of chromium carbide powder; the powder is mechanically and uniformly mixed after being treated by radio frequency induced plasma balling equipment to obtain subsphaeroidal cobalt-based composite powder; and the invention further discloses a method for manufacturing a hydraulic prop piston rod fusion covering coating by plasma spray. High bonding strength and hardness, good abrasive resistance and corrosion resistance and reduced cracking sensibility of the fusion covering coating are obtained through the treatment of the radio frequency induced plasma balling equipment and the optimization of plasma spray technological parameters; and the service life of a hydraulic prop piston rod is prolonged. Meanwhile, the cobalt-based composite powder can further be applied to the protection of other parts.

Owner:王爱平

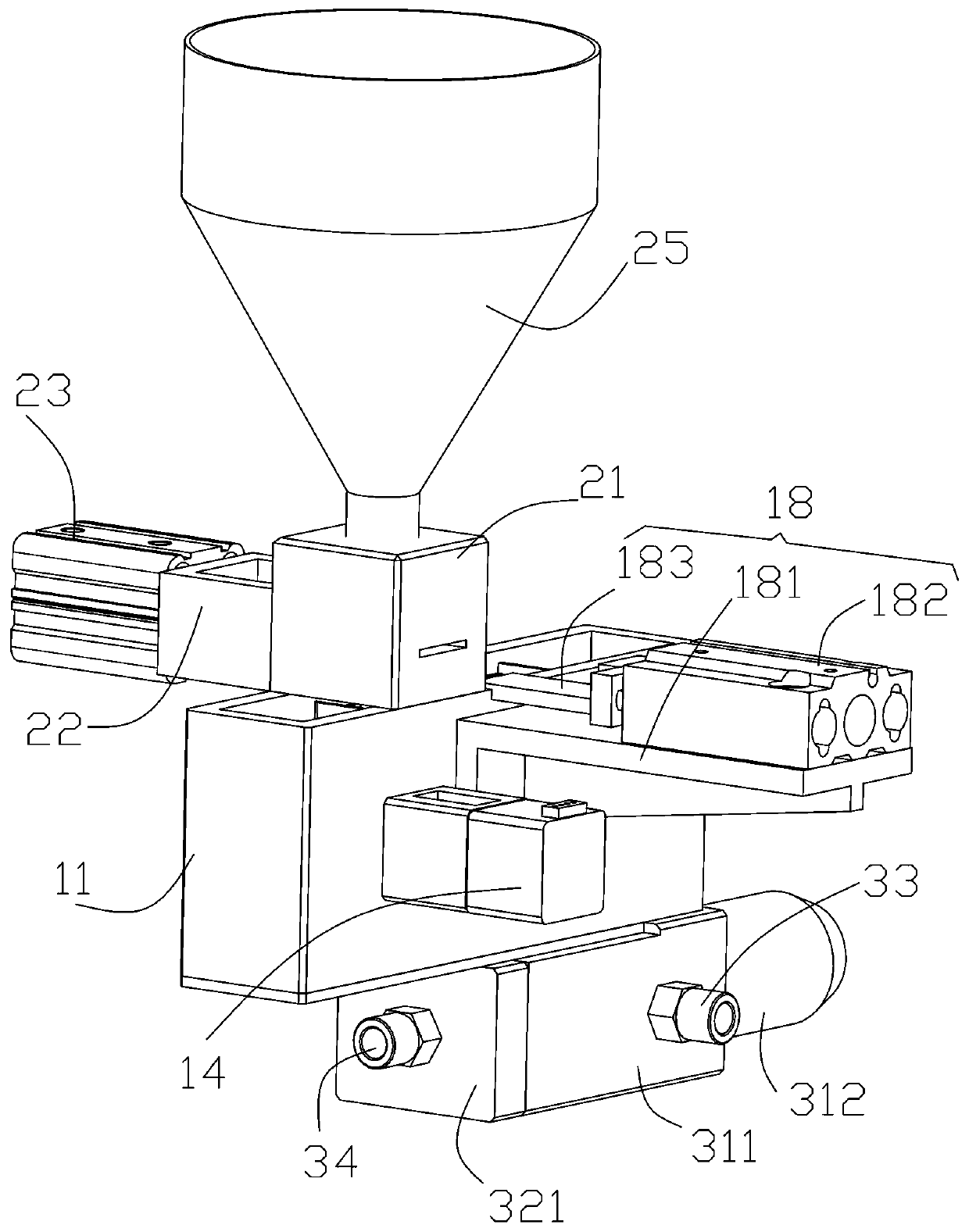

Material hanging type automatic wax injecting and quantitative powder spraying mechanism

The invention discloses a material hanging type automatic wax injecting and quantitative powder spraying mechanism. The material hanging type automatic wax injecting and quantitative powder spraying mechanism comprises a feeding device, a quantitative powder feeding device and a wax injecting and powder spraying nozzle; the wax injecting and powder spraying nozzle is used for spraying powder and injecting wax liquid into a mold; powder materials enter the quantitative feeding device through the feeding device; the quantitative feeding device communicates with the wax injecting and powder spraying nozzle; the quantitative powder feeding device comprises a belt wheel support, a driving motor, a driving belt heel, a driven belt wheel, a transmission belt and a material scraping part; the driving belt wheel and the driven belt wheel are both connected to the belt wheel support in a shaft connection manner; the driving motor is connected with the driving belt wheel; and the transmission belt is provided with powder feeding grooves at intervals, and the material scraping part is arranged on the belt wheel support. According to the material hanging type automatic wax injecting and quantitative powder spraying mechanism, due to cooperation of the feeding device and the quantitative powder feeding device, it is achieved that powder is quantitatively fed to the wax injecting and powder spraying nozzle, and therefore a quantitative powder spraying procedure is completed, manual operation is not needed, the work efficiency is greatly improved, powder spraying in the mold is uniform, itis avoided that due to the fact that manual powder spraying is not uniform, forming of a wax mold is affected, and the qualification rate of wax mold forming is increased.

Owner:昕致潮贸易(深圳)有限公司

Annular laser cladding nozzle

PendingCN113481507AReasonable structure layoutEasy to operateMetallic material coating processesMetal powderAnnular array

The invention discloses an annular laser cladding nozzle comprising an inner core and an outer sleeve arranged outside the inner core in a sleeving mode, a laser channel is formed in the center of the inner core, and an opening allowing laser to be emitted out is formed in the center of the inner core; a material mixing chamber is arranged between the inner core and the outer sleeve, and a second conveying channel for outputting metal powder is arranged between the material mixing chamber and the opening; the material mixing chamber is communicated with more than one first conveying channel for inputting the metal powder; and the inner core is also provided with grooves facing the material mixing chamber. Preferably, the number of the first conveying channels is two. The multiple grooves are formed in the surface of the inner core at equal intervals, when powder and gas are mixed and enter the material mixing chamber, due to the existence of the grooves, the powder continuously impacts the grooves and forms cyclone, the powder continuously impacts back and forth in the material mixing chamber, and therefore uniform powder feeding is achieved. In order to improve the powder mixing and feeding effect, the preferable scheme of the material mixing chamber and the second conveying channel is that the material mixing chamber and the second conveying channel are of a rotary structure with the central axis of the laser channel as the center. The grooves are arranged in the inner core in an annular array.

Owner:宁波海天激光科技有限公司

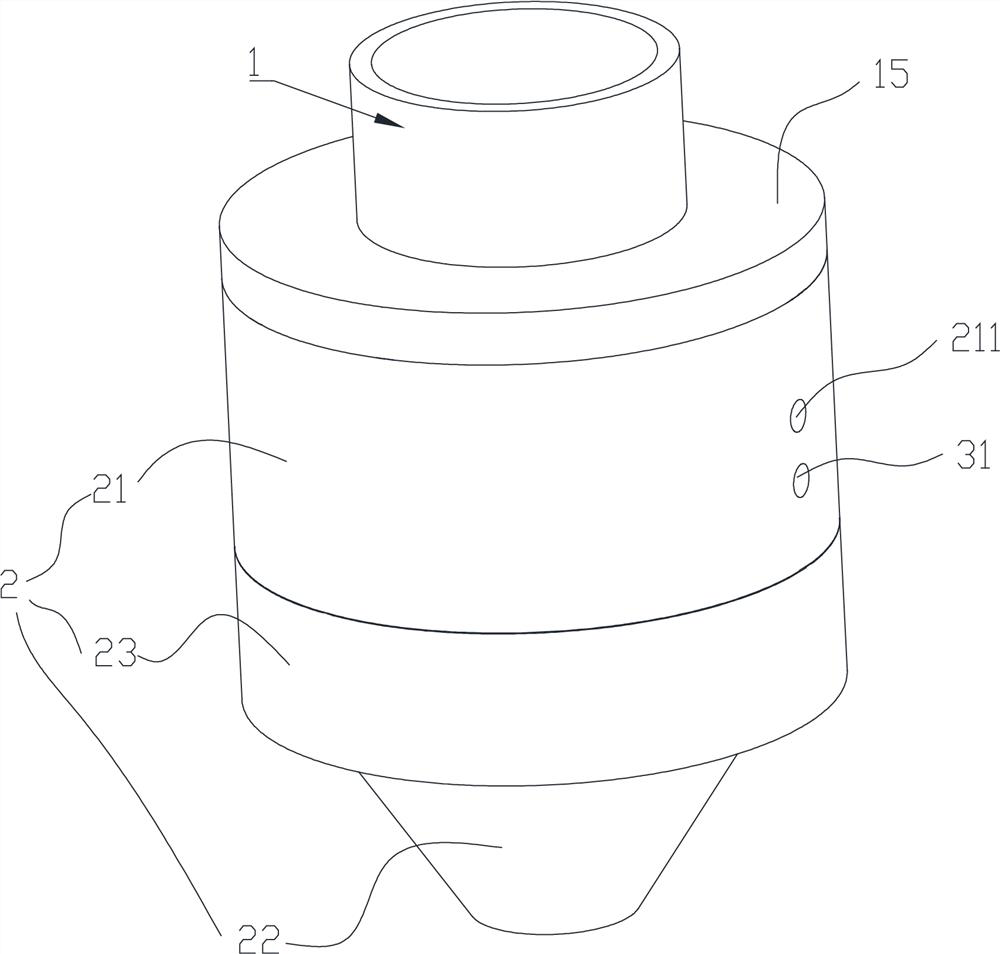

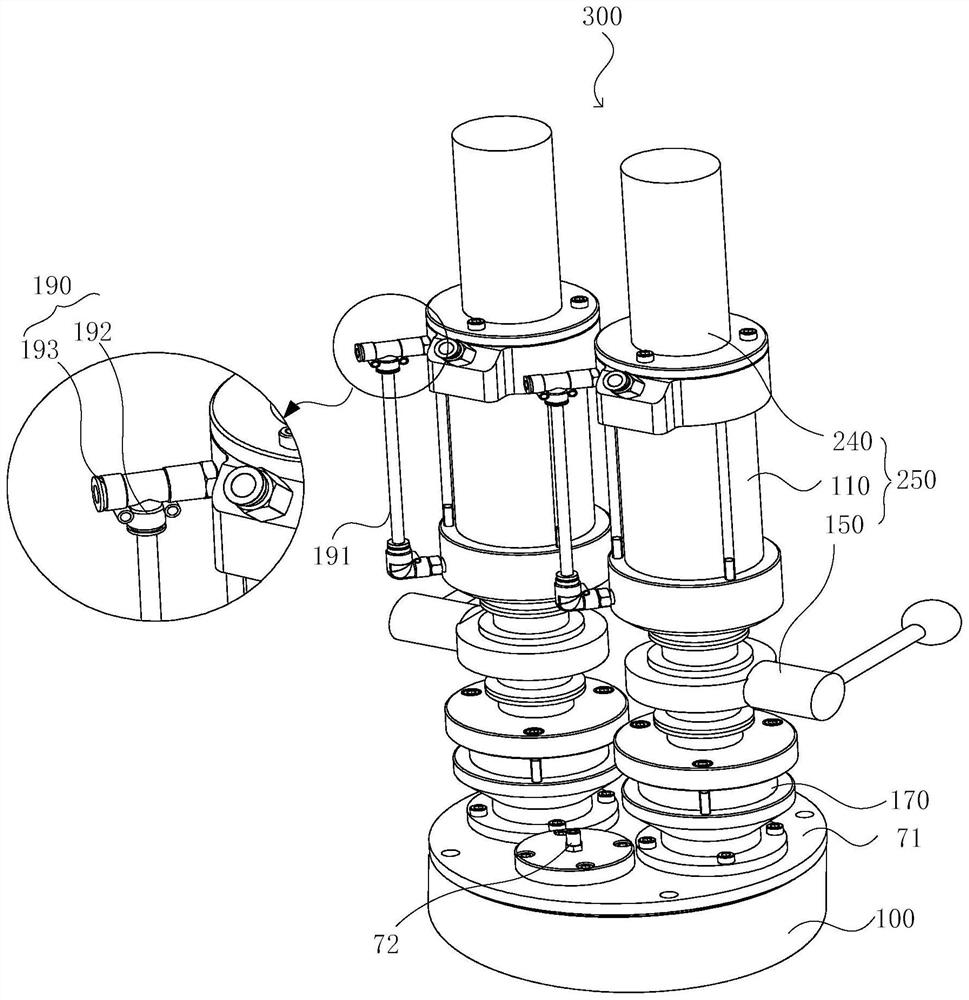

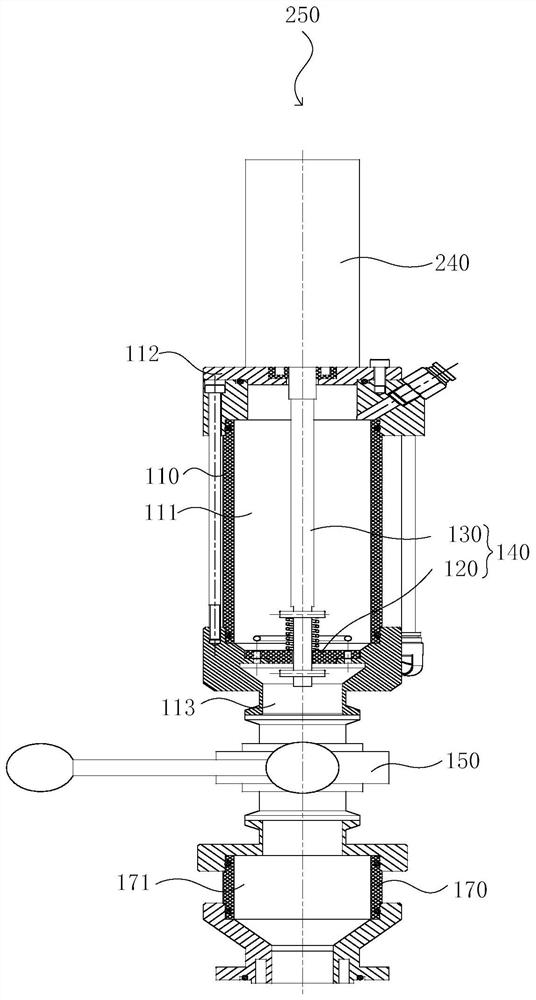

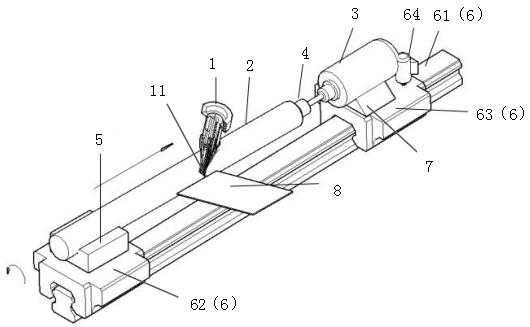

Material barrel special machine

InactiveCN108340060ASimple structureIngenious structurePlasma welding apparatusSpray nozzleCooling effect

The invention belongs to the technical field of material barrel special machines and particularly relates to a material barrel special machine. The material barrel special machine comprises a module support, a module connected with the module support, a plasma surfacing gun adjustably mounted on the module, a continuous powder feeder arranged at the upper end of the plasma surfacing gun for connection, a driving mechanism, a driven mechanism, a material barrel which is adjusted through the driving mechanism and the driven mechanism, and a plasma control power source which controls the plasma surfacing gun and the continuous powder feeder. The plasma surfacing gun comprises an upper gun body, an insulator, a lower gun body and a spray nozzle which are connected in sequence from top to bottom, wherein the insulator is connected with the upper gun body and the lower gun body through screw threads, and a protective cover is disposed on the outer side of the spray nozzle. The material barrel special machine disclosed by the invention is compact in structure, capable of achieving continuous feeding of powder and improving production efficiency, good in water path circulating cooling effect and long in working time.

Owner:宁波驰迈激光科技有限公司

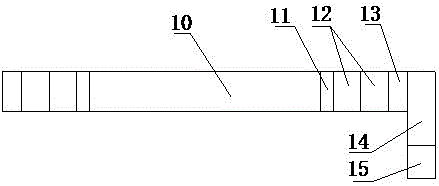

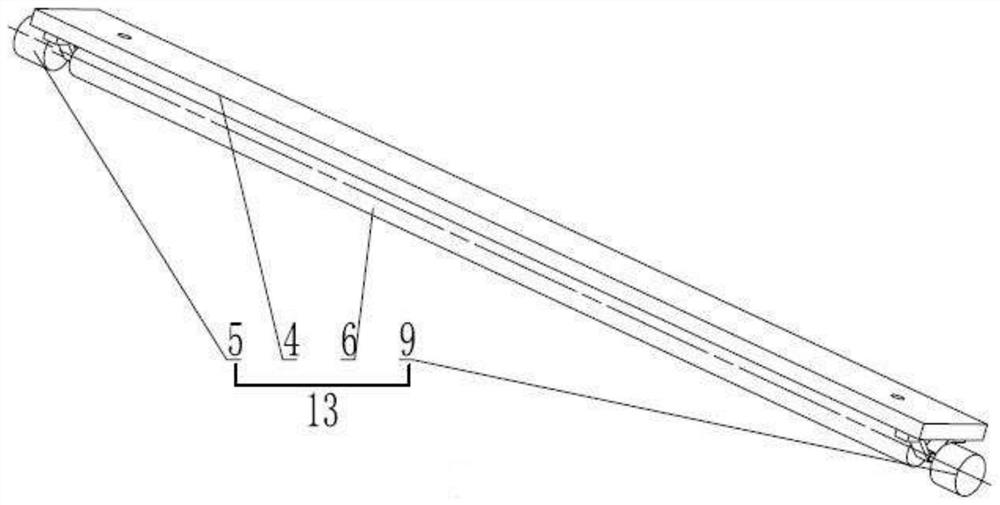

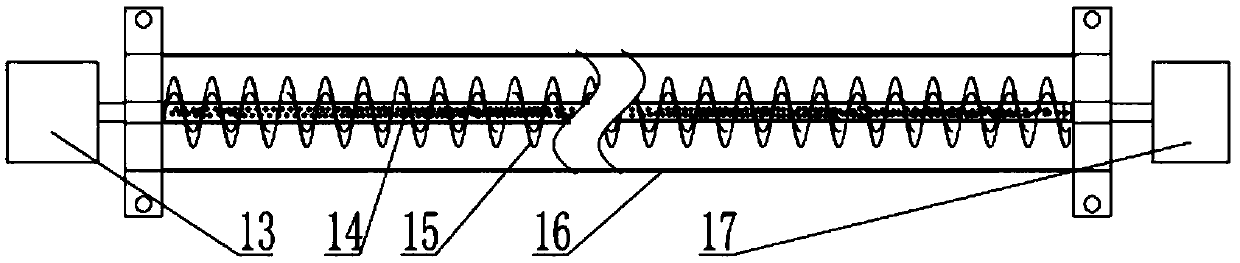

Powder feeding and spreading mechanism of laser sintering 3D printer

ActiveCN110549610AImprove efficiencySend powder evenly3D object support structuresAdditive manufacturing with solidsPower unitMaterials science

The invention discloses a powder feeding and spreading mechanism. The powder feeding and spreading mechanism comprises powder feeding barrels, a levelness detector, a cylinder, a working platform, power units, guide rails, a rack, a powder feeding and spreading sleeve and a spiral powder feeding mechanism. The powder feeding and spreading sleeve is a cylindrical ring. The length of the powder feeding and spreading sleeve is equal to that of the working platform. Any one-quarter circumference of the powder feeding and spreading sleeve is provided with a powder discharge screen, and the other three-quarter circumference of the powder feeding and spreading sleeve serves as a flattening device. The powder discharge screen is provided with micro powder discharge holes. The spiral powder feedingmechanism is arranged in the powder feeding and spreading sleeve. The powder feeding and spreading mechanism provided by the invention integrates flattening and powder spreading, implements powder spreading and flattening simultaneously to improve the efficiency, feeds powder from one end of the powder feeding and spreading sleeve to the other end of the powder feeding and spreading sleeve through the spiral powder feeding mechanism, realizes uniform powder feeding and improves the powder spreading quality.

Owner:SHAANXI HENGTONG INTELLIGENT MACHINE

Control method for laser cladding powder feeding

ActiveCN112226765AAdjust powder feed rateSend powder evenlyIncreasing energy efficiencyMetallic material coating processesEngineeringMetal powder

The invention discloses a control method for laser cladding powder feeding. The control method for laser cladding powder feeding comprises the steps that S10, a driving part drives a conveying part tofeed powder at a certain driving speed, so that metal powder is conveyed to a second powder feeding barrel from a first powder feeding barrel; S20, a sensor detects a quantity value H of the metal powder in the second powder feeding barrel; S30, a controller obtains the quantity value H and generates a corresponding powder conveying control instruction by judging the relation between the quantityvalue H and a preset threshold value H0; and S40, the driving part receives the powder conveying control instruction, so that the driving part adjusts the driving speed. The technical problem of uneven powder feeding can be effectively solved, and the technical effects of stable powder conveying and even powder feeding are achieved.

Owner:宁波中物力拓超微材料有限公司

Electronic powder injection powder conveyor

InactiveCN101767484ASimple structurePrecise control of quantitativePrinting press partsMaterials scienceSmall hole

The invention relates to an electronic powder injection powder conveyor which comprises a powder tank and is characterized in that the bottom of the powder tank is an isolation ring, the isolation ring is provided with a powder feeding hole, the bottom of the isolation ring is contacted with a powder storage sheet, the powder storage sheet is connected with a spindle, a plurality of quantitative small holes are uniformly arranged in the powder storage sheet, a blanking disc is arranged below the powder storage sheet and is provided with a blanking hole, and the powder feeding hole of the isolation ring and the blanking hole of the blanking disc are arranged in a staggering way. The invention has the advantages of simple structure and accurate fixed quantity control of blanking, thereby uniformly injecting powder.

Owner:上海华太数控技术有限公司 +1

Preparation method of nickel-based alloy composite powder for plasma spraying and cladding coating

ActiveCN110904361BHigh hardnessImprove wear resistanceMolten spray coatingCarbide siliconCerium(IV) oxide

The invention relates to nickel-based composite powder for plasma spraying. The nickel-based composite powder is prepared from the following raw materials in parts by weight: 70-80 parts of nickel-based alloy powder, 1-2 parts of cerium dioxide powder, 2-5 parts of aluminum oxide powder and 5-10 parts of silicon carbide powder. The powder is treated by radio frequency induction plasma spheroidizing equipment and then is mechanically and uniformly mixed to obtain the nearly spherical nickel-based composite powder. The invention further discloses a method for manufacturing a cladding coating ofa hydraulic prop piston rod by plasma spraying. Through treatment of the radio frequency induction plasma spheroidizing equipment and optimization of plasma spraying process parameters, the bonding strength and hardness are high, the wear resistance and corrosion resistance are good, and the cracking sensitivity of the cladding coating is reduced; and the service life of the hydraulic prop pistonrod is prolonged. Meanwhile, the method can also be applied to protection of other parts.

Owner:BEIJING JUNSHAN SURFACE TECH ENG

One-way valve type powder spraying and wax injecting integrated type structure

The invention discloses a one-way valve type powder spraying and wax injecting integrated type structure. The one-way valve type powder spraying and wax injecting integrated type structure comprises ascrew powder feeding device and a spray nozzle composite device; the screw powder feeding device is used for quantitatively conveying powder for the spray nozzle composite device which comprises a feeding spray nozzle head and a heat generating barrel; the feeding spray nozzle head is provided with a first through hole, and the heat generating barrel is arranged on the feeding spray nozzle head which is provided with a feeding port and a second through hole; the feeding spray nozzle head is provided with five powder outflow holes which correspondingly communicate with the feeding port; the second through hole further communicates with the powder outflow holes; the feeding port communicates with the screw powder feeding device; the first through hole is connected with a wax liquid pipe one-way valve; and the second through hole is connected with a vacuum pipe one-way valve. According to the one-way valve type powder spraying and wax injecting integrated type structure, due to the factthat the powder feeding work procedure and the wax injecting work procedure are integrated, manual powder spraying operation is not needed, and the work efficiency is improved; the powder spirally moves, quantitative conveying of the powder is completed in combination with the opening and closed states of an electromagnetic vacuum check valve, the efficiency is high, powder spraying in a mold is uniform, and the qualification rate of wax mold forming is increased.

Owner:昕致潮贸易(深圳)有限公司

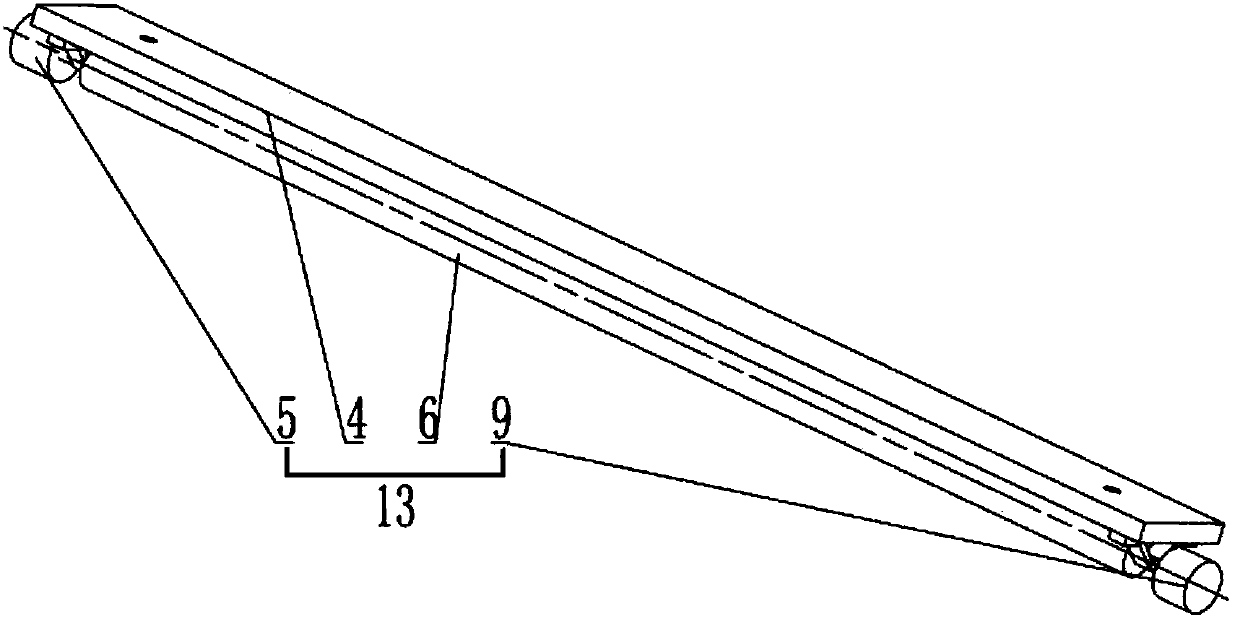

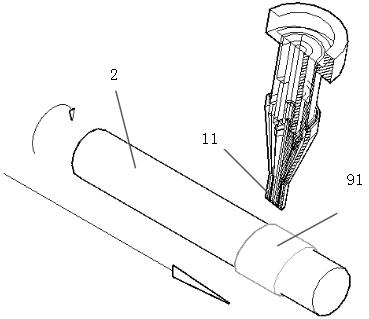

A powder feeding device and method of using the same

ActiveCN105063614BIncrease profitImprove flatnessMetallic material coating processesEngineeringAlloy

The invention relates to a powder feeding device and an application method thereof, and belongs to the technical field of laser cladding equipment. The powder feeding device comprises a first buffering component and a second buffering component which are movably connected through a first fastener. The first buffering component comprises a powder feeding pipe and a rotating head, wherein the rotating head is arranged at the tail end of the powder feeding pipe, and a curve is arranged inside the rotating head. The second buffering component comprises a powder feeding nozzle and an adjusting plate. The adjusting plate is arranged on the surface of the powder feeding nozzle. The powder feeding device has the beneficial effects that the powder feeding angle and height are flexile and adjustable, powder feeding is even, and the alloy powder utilization rate is high; and the surface flatness of a cladding layer is effectively improved, dismounting and maintaining are convenient, and practicability is high.

Owner:SHANDONG ENERGY HEAVY EQUIP GRP DAZU REMANUFACTURING CO LTD

A powder supply and powder spreading mechanism for a laser sintering 3D printer

ActiveCN110549610BImprove efficiencySend powder evenly3D object support structuresAdditive manufacturing with solidsComputer printing3d printer

The invention discloses a powder supply and spreading mechanism, comprising a powder supply cylinder, a level detector, a cylinder, a workbench, a power device, a guide rail, a frame, a powder supply and spread cover, and a screw powder supply mechanism. The powder cover is a cylindrical ring whose length is consistent with the length of the workbench; a powder outlet sieve is provided on any 1 / 4 circumference of the powder supply and spread powder cover, and the remaining 3 / 4 circumference is used as a scraper; The powder outlet sieve is provided with tiny powder outlet holes; the screw powder feeding mechanism is arranged in the powder supply and spreading sleeve. The powder supply and spreading mechanism proposed by the present invention combines scraping and spreading together, and scrapes while spreading the powder, so as to realize the improvement of efficiency; the screw powder feeding mechanism is used to send the powder from one end of the powder supply and spreading sleeve to the other end , to achieve uniform powder delivery and improve the quality of powder spreading.

Owner:武汉斑鹿科技股份有限公司

Composite material for plasma cladding and preparation method thereof

ActiveCN108468038BImprove liquidityImprove wettabilityMolten spray coatingLiquid/solution decomposition chemical coatingPolymer sciencePeptization

The invention provides a preparation method of an Al2(WO4)3 composite material. The method comprises the steps of A), activating Al2(WO4)3 particles; conducting peptization on activated Al2(WO4)3; B),conducting chemical nickel plating on the Al2(WO4)3 particles obtained in step A) in a nickel plating solution to obtain the Al2(WO4)3 composite material. The invention further provides the Al2(WO4)3composite material. The invention further provides a cladding material which is used for plasma cladding and comprises a binder phase and the Al2(WO4)3 composite material. The Al2(WO4)3 composite material is used for plasma cladding to improve the wear resistance of a coating and effectively prevent cracking of the coating.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

Coaxial powder-feeding mouth for inner wall laser metling covering and alloying treatment of hold pieces

InactiveCN1151895CEasy to adjustEliminate dead endsMolten spray coatingLiquid spraying apparatusWater dischargeLaser processing

The coaxial power-feeding nozzle, belonging to the field of laser processing equipment technology, is formed from laser channel, U-shaped fastener, outer ring, cone ring, cone cover, internal cooling water channel, external cuoling water channel and powder feeding channel, in which the laser channel is formed from light guide tube, cooling cover, reflector and internal cone body, and its internal cooling water channel is formed from water intake pipe, water intake channel, water discharge pipe, water discharge channel, internal ring water channel and its partion, board, its powder-feeding channel is composed of power-feeding pipe, ring mixing cavity and conical ring groove, it has 2-8 powder-feeding pipes which are distributed along the radial direction, and its external cooling water channel is formed from water-intake pipe, water outlet pipe, external ring water channel and its partion board.

Owner:青岛启源泉能源设备有限责任公司

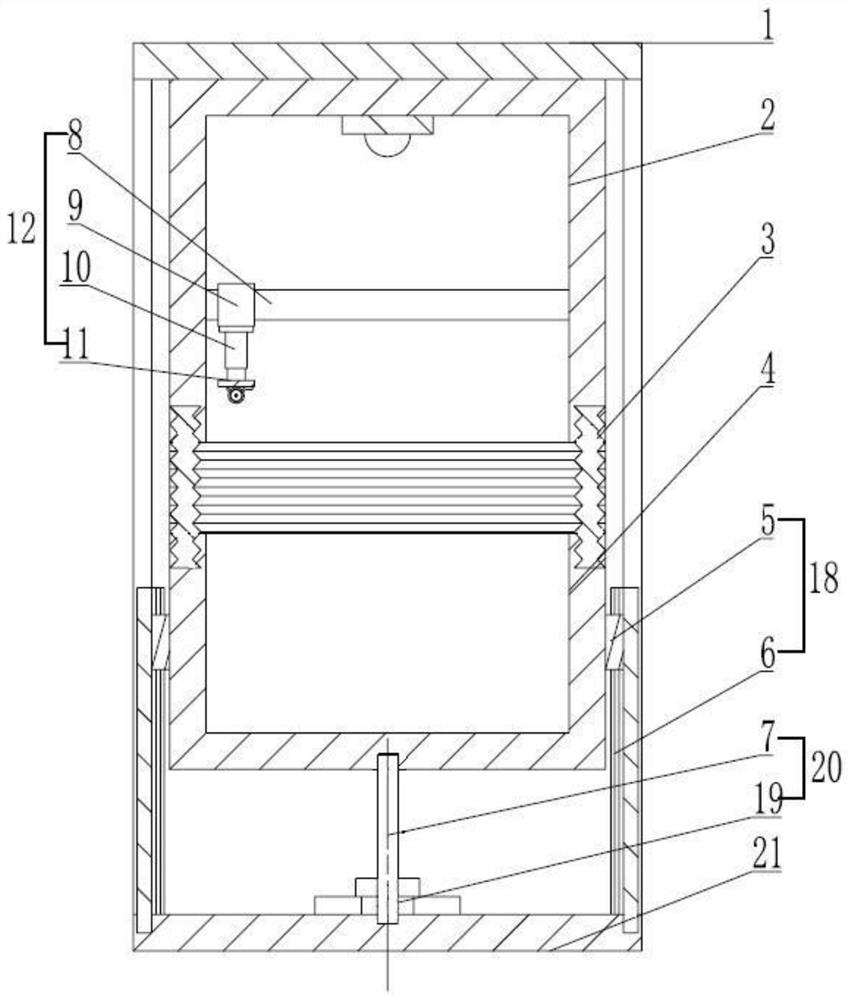

A kind of laser sintering equipment

ActiveCN110549600BSolve the sealing problemFix cleanupManufacturing platforms/substratesManufacturing enclosuresCylinder blockPowder coating

The invention discloses a laser sintering equipment, which belongs to the field of additive manufacturing, and includes a frame, a cylinder body, and a screw nut pair, and is characterized in that: the cylinder body includes an upper cylinder body and a lower cylinder body, and the upper and lower cylinder bodies Connected by a telescopic structure; the screw nut pair is located at the center of the bottom end of the lower cylinder body, which is consistent with the Z-axis direction of the cylinder body; the lower cylinder body is equipped with a supporting cylinder body and cooperates with the screw nut pair to make the lower cylinder body lift Moving directional guide rails; the powder supply and spreading mechanism includes a powder supply and spreading cover and a screw powder feeding mechanism; compared with the prior art, the scheme adopted by the present invention can completely solve the sealing and cleaning problems, and the scraping and spreading The powder is combined together, and the powder is scraped while spreading to improve the efficiency; the powder feeding mechanism is used to send the powder from one end of the powder supply and spreading sleeve to the other end, so as to achieve uniform powder feeding and improve the quality of powder spreading.

Owner:SHAANXI HENGTONG INTELLIGENT MACHINE

A laser sintering printer

ActiveCN110549609BReduce weightAchieve sealing3D object support structuresAdditive manufacturing with solidsComputer printingEngineering

The invention discloses a laser sintering printer, which belongs to the field of additive manufacturing and includes a frame, a cylinder body, a workbench, a lead screw and a nut pair, and a powder supply and spreading mechanism; the cylinder body includes an upper cylinder body and a lower cylinder body, The upper and lower cylinders are connected by a telescopic structure; the workbench is located inside the lower cylinder and is fixedly connected with the lower cylinder; the screw nut pair is located at the center of the outer bottom of the lower cylinder, and is aligned with the Z axis of the cylinder. Consistent; the outside of the lower cylinder is provided with a directional guide rail that supports the cylinder and cooperates with the screw nut pair to make the lower cylinder move up and down. The purpose of the present invention is to provide a retractable laser sintering printer which can solve the problems of sealing, cleaning, reducing the quality of the molding cylinder, and improving the quality and efficiency of powder spreading.

Owner:四川交大至信教育科技有限公司

Wideband nozzle capable of uniformly feeding powder in laser processing

ActiveCN103205748BImprove continuityImprove stiffnessMetallic material coating processesLiquid spraying apparatusLaser processingMetallurgy

The invention discloses a wideband nozzle capable of uniformly feeding power in laser processing. The wideband nozzle comprises a rectangular nozzle and an annular powder cavity, the rectangular nozzle is provided with a rectangular powder feed channel and a protection gas channel, one end of the rectangular powder feed channel is a powder outlet, the protection gas channel is arranged at the periphery of the powder outlet and parallel to the powder outlet, the other end of the rectangular powder feed channel is a powder feed gas channel, the powder feed gas channel comprises a transition channel and a circular channel, the transition channel is used for realizing the smooth and uniform transition from the circular channel to the rectangular powder feed channel, the rectangular nozzle is installed and fixed in the annular powder cavity, the powder outlet end and the circular channel end of the rectangular nozzle extend out of the annular powder cavity, the powder is put in the annular powder cavity, and the gas channel is arranged in the annular powder cavity, and a powder inlet is arranged at the side of the rectangular powder feed channel of the rectangular nozzle. The nozzle disclosed by the invention can be used for greatly eliminating the phenomenon that the powder in middle is more than powder at two sides when the rectangular nozzle is used for feeding powder, the powder is capable of uniformly filling the powder outlet of the whole rectangle to realize the uniform powder feed.

Owner:HANGZHOU BOHUA LASER TECH

One-way valve type powder spraying and wax injecting complete machine

The invention discloses a one-way valve type powder spraying and wax injecting complete machine. The one-way valve type powder spraying and wax injecting complete machine comprises a workbench. A conveying belt is arranged on the workbench. An air cooler is arranged on one side face of the conveying belt. A one-way valve type wax and powder injecting mechanism is arranged on one side of the air cooler. A feed inlet communicates with a screw powder feeding device. A first through hole is connected with a wax liquid pipe one-way valve. A second through hole is connected with a vacuum pipe one-way valve. According to the one-way valve type powder spraying and wax injecting complete machine, the powder feeding procedure and the wax injecting procedure are combined, and manual powder spraying is not needed, so that the work efficiency is improved; and powder moves spirally, and quantitative conveying of the powder is completed by opening or closing an electromagnetic vacuum check valve, sothat the efficiency is higher, powder is evenly sprayed in a mold, and the qualification rate of wax mold formation is increased.

Owner:昕致潮贸易(深圳)有限公司

Laser sintering equipment

ActiveCN110549600AImprove efficiencySend powder evenlyManufacturing platforms/substratesManufacturing enclosuresHelixMaterials science

The invention discloses laser sintering equipment, and belongs to the field of additive manufacturing. The laser sintering equipment comprises a rack, a cylinder body and a lead screw nut pair. The laser sintering equipment is characterized in that the cylinder body comprises an upper cylinder body and a lower cylinder body, and the upper cylinder body and the lower cylinder body are connected through a telescopic structure; the lead screw nut pair is located at the center position of the bottom end of the exterior of the lower cylinder body and consistent with the Z-axis direction of the cylinder body; directional guide rails used for supporting the cylinder body and cooperating with the lead screw nut pair to enable the lower cylinder body to rise and fall are arranged outside the lowercylinder body; and a powder supplying and spreading mechanism comprises a powder supplying and spreading sleeve and a spiral powder feeding mechanism. Compared with the prior art, by the adoption of the scheme, the problems about sealing and washing can be completely solved, strickling and powder spreading are combined together, powder spreading and strickling are carried out simultaneously, and therefore the efficiency is improved; and powder is fed from one end of the powder supplying and spreading sleeve to the other end of the powder supplying and spreading sleeve through the spiral powderfeeding mechanism, uniform powder feeding is achieved, and the powder spreading quality is improved.

Owner:SHAANXI HENGTONG INTELLIGENT MACHINE

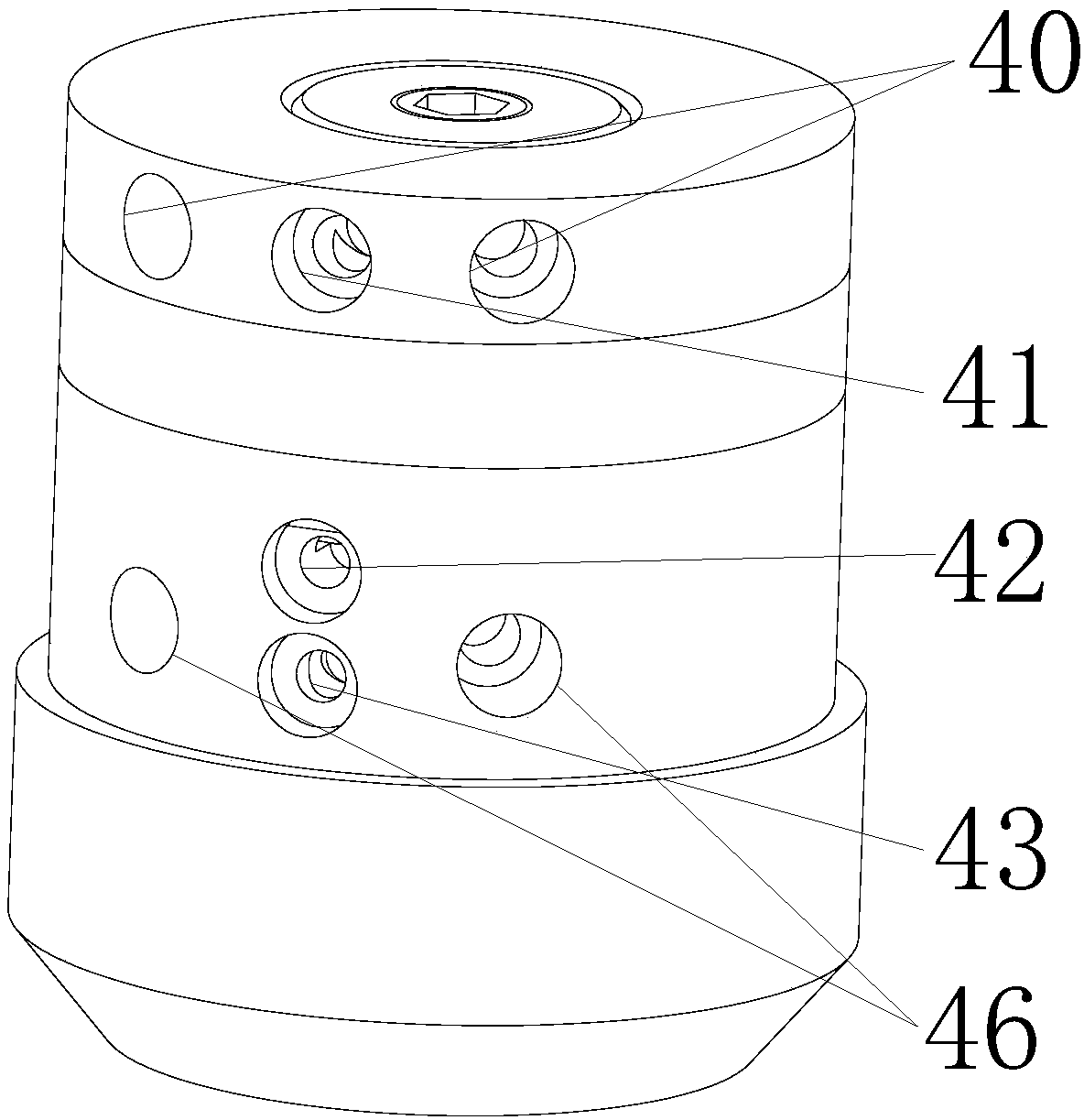

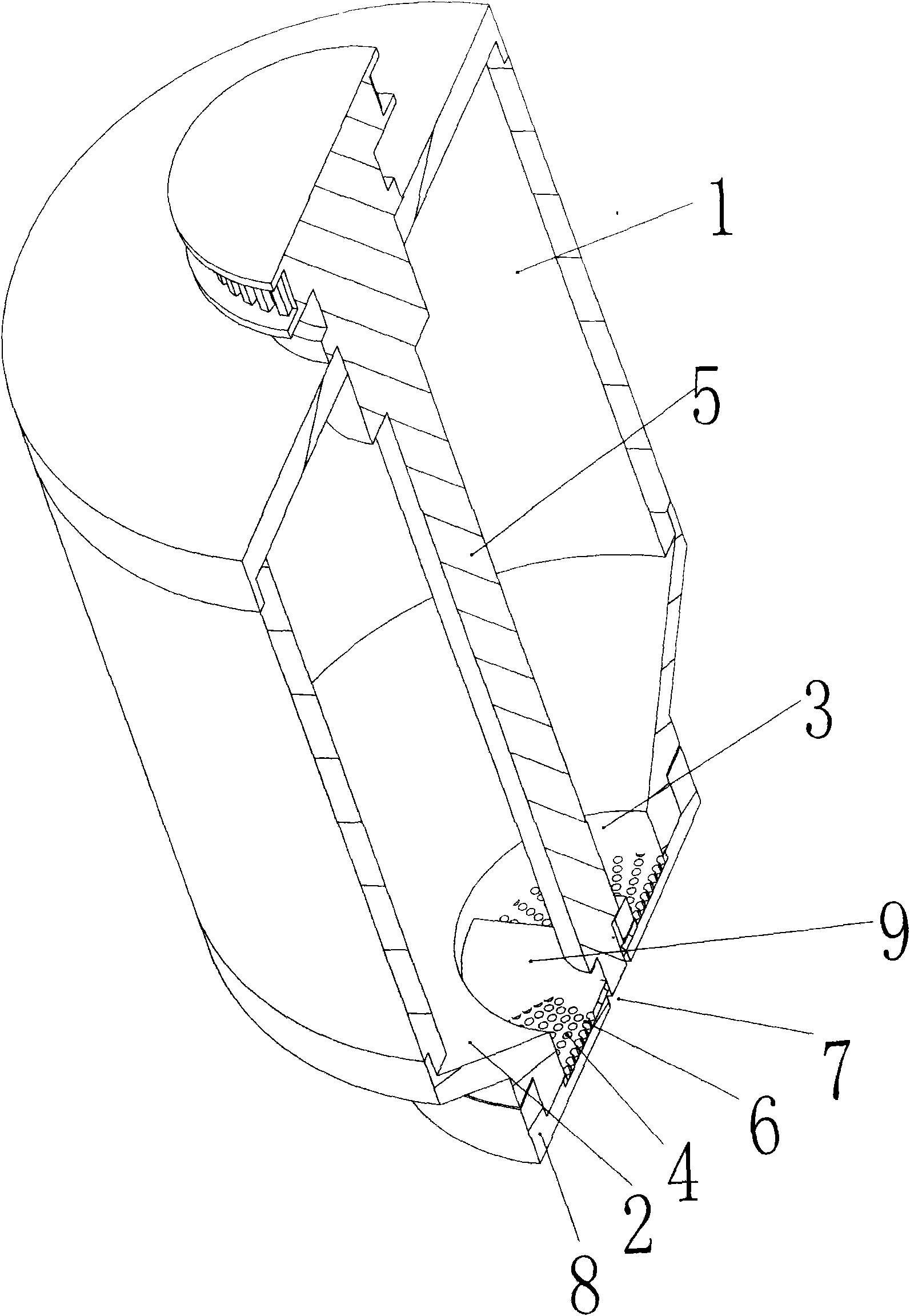

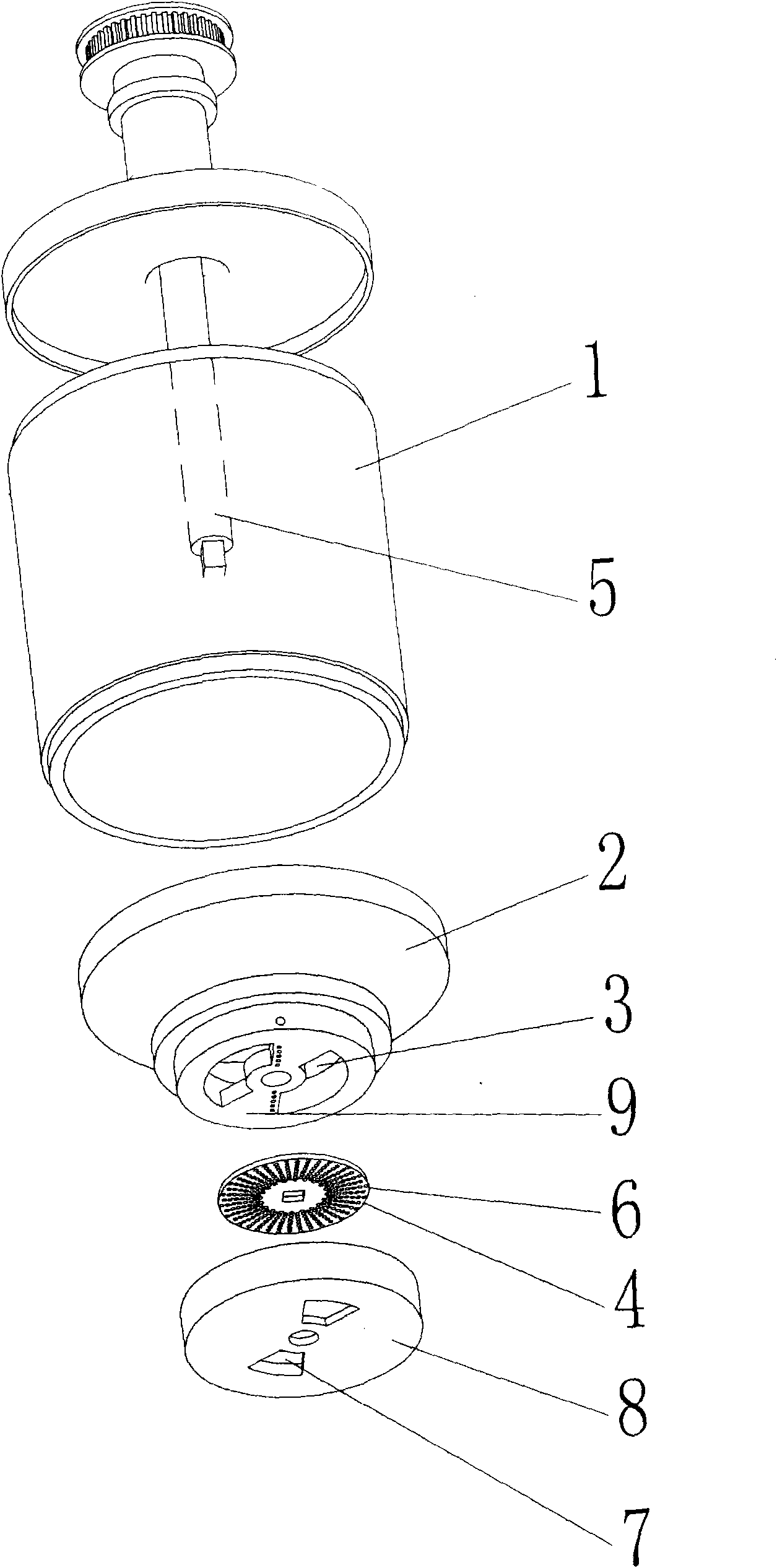

A powder feeding mechanism, powder feeder and spraying equipment

ActiveCN114107946BPrecise quantitative deliveryRealize small amount of powder feedingChemical vapor deposition coatingMetallurgyStucco

The invention discloses a powder feeding mechanism, a powder feeding device and spraying equipment. The powder feeding mechanism includes a powder storage cavity (1), and a powder inlet (10) and a heating gas inlet are arranged above the powder storage cavity (1). (11), the powder storage cavity (1) is provided with a stucco, and the stucco includes a rotating body (3) and a brush body (2) fixed on the rotating body (3); Driven by the drive, it rotates along the rotation axis (4); there is a screen (5) under the paint, and the screen (5) is connected to the powder storage cavity (1); the brush body (2) protruding from the paint surface touches the powder storage The inner surface of the cavity (1) is matched with different brush body materials for powders of different particle sizes. The present invention can precisely control the powder feeding rate, realize a small amount of uniform powder feeding, and increase the range of powder feeding particle sizes. There is no requirement for fluidity, and it is suitable for the transportation of various powders.

Owner:BEIHANG UNIV

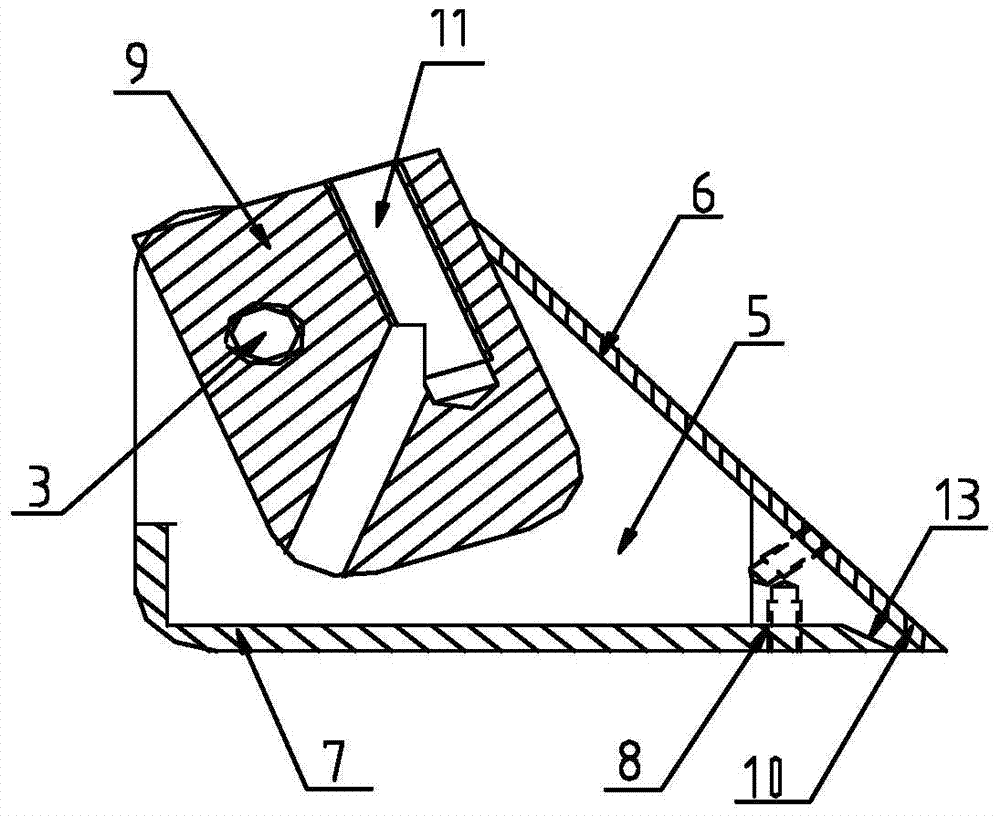

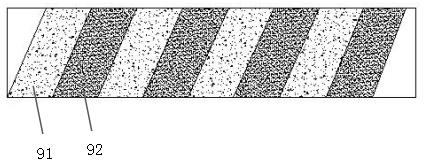

Lateral powder feeding device for high-speed laser cladding and its cladding process

ActiveCN109183028BReduce thicknessImprove performanceMetallic material coating processesLaserComposite material

The invention discloses a lateral powder feeding device for high-speed laser cladding and a cladding process thereof. The lateral powder feeding device includes a shell, a powder carrying air channel, a powder nozzle and a powder outlet end, and the powder carrying air channel is arranged on the side of the shell. , the powder nozzle and the discharge end of the shell, the powder outlet end is bent at the end of the powder nozzle, a reciprocating groove is opened on the inner wall of the shell body at the top of the shell, and an elastic reciprocating detachable filter assembly is arranged in the reciprocating groove; According to the above-mentioned powder feeding device and the cladding process using the powder feeding device, the beneficial effects are: the thickness of the cladding layer is greatly reduced, which can reach below 250 μm; the cladding speed is significantly increased, which can reach 150 m / min. The following is 100‑250 times faster than conventional laser cladding. At the same time, the dilution layer is reduced to ensure the excellent performance of the cladding layer; the powder is fed under the action of gravity, so the powder is fed evenly and the powder utilization rate is high; the structure is simple, the powder feeding is flexible, and it is suitable for various forms of structural parts and various cladding environments. .

Owner:JIANGSU UNIV OF SCI & TECH

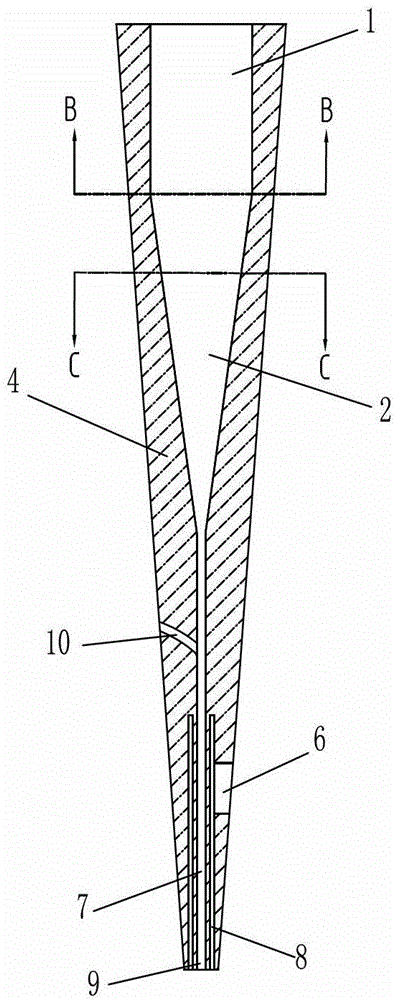

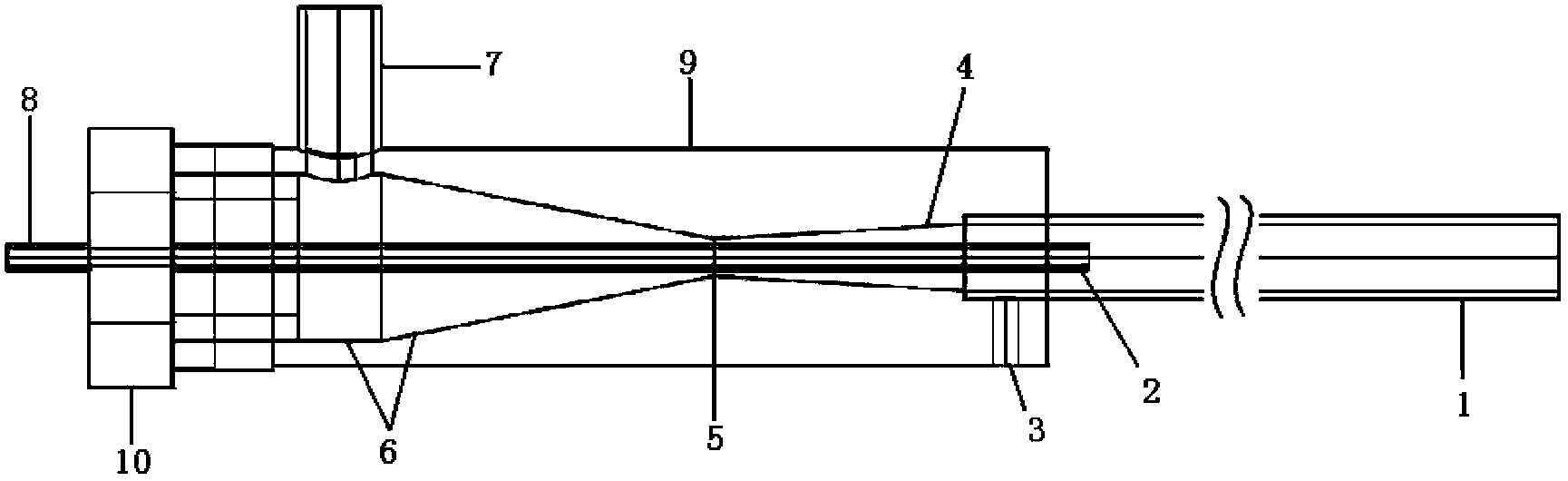

Nozzle for axial siphon powder delivering type cold spray

ActiveCN102814248BSimple structureReliable design principleLiquid spraying apparatusSiphonButt joint

The invention belongs to the technical field of cold spraying, and relates to a nozzle for axial siphon powder delivering type cold spray, wherein a rear end part of a cylindrical nozzle body is fixed with a butt-jointed screw cap, a working gas inlet is arranged on a top side face of the rear end part, a conical cylinder shaped front nozzle air chamber is arranged in an inner cavity of the rear end, and a powder delivering pipe is fixed on a central axis of the inner cavity in a serial connection manner; the rear end opening of the powder delivering pipe is abutted with a scaling pipe, and the rear end of the scaling pipe is extended out of the screw cap; a joint between the powder delivering pipe and the scaling pipe is provided with an extension pipe interface in an outer sheathing manner; the front end opening is fixedly connected with a long cylindrical nozzle extending pipe in an outer sheathing manner through a fixing screw hole of an extension pipe, the rear end part of the nozzle extending pipe is in communication with the extension pipe interface, and a nozzle throat part is arranged at the center of the inner cavity of the nozzle body; the length of the nozzle extending pipe can be adjusted according to the pressure of the working environment and the sprayed raw material. The nozzle is simple in structure, reliable in principle, mature in preparing technology, stable in siphon air flow, uniform in powder delivery, low in production cost, high in efficiency, friendly in environment and good in application prospect.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

A kind of natural organic fertilizer preparation system and its working method

ActiveCN107954766BAvoid cloggingAvoid mixing processBio-organic fraction processingBioloigcal waste fertilisersWater flowEngineering

The invention discloses a natural organic fertilizer preparation system, which includes a sewage inlet pipe, a sewage outlet pipe and a transfer device; the transfer device includes a first connecting pipe, a second connecting pipe and a first rotating shaft; the first connecting pipe and the The second connecting pipe is symmetrical about the first rotation axis; the first connecting pipe and the second connecting pipe rotate around the first rotating axis; the transfer device also includes a U-shaped pipe; The second connecting pipe is connected; the corners on both sides of the U-shaped pipe are provided with fixed rings; a number of fragments are installed in the fixed ring; when the switching device is in operation, the positions of the first connecting pipe and the second connecting pipe are alternately exchanged, and the water flow is used to Two-way scouring of the fragments on the fixed ring, the fragments can break up the larger mud in the sewage, and the bidirectional flow of sewage can wash away the silt adhering to the fragments to achieve self-cleaning.

Owner:恩施神力生物科技有限公司

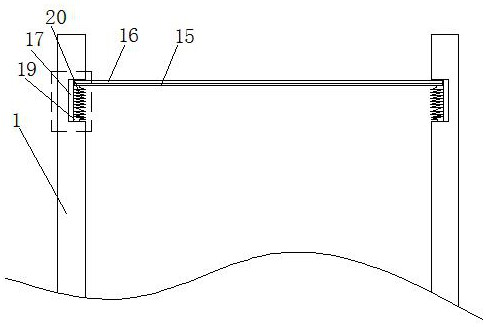

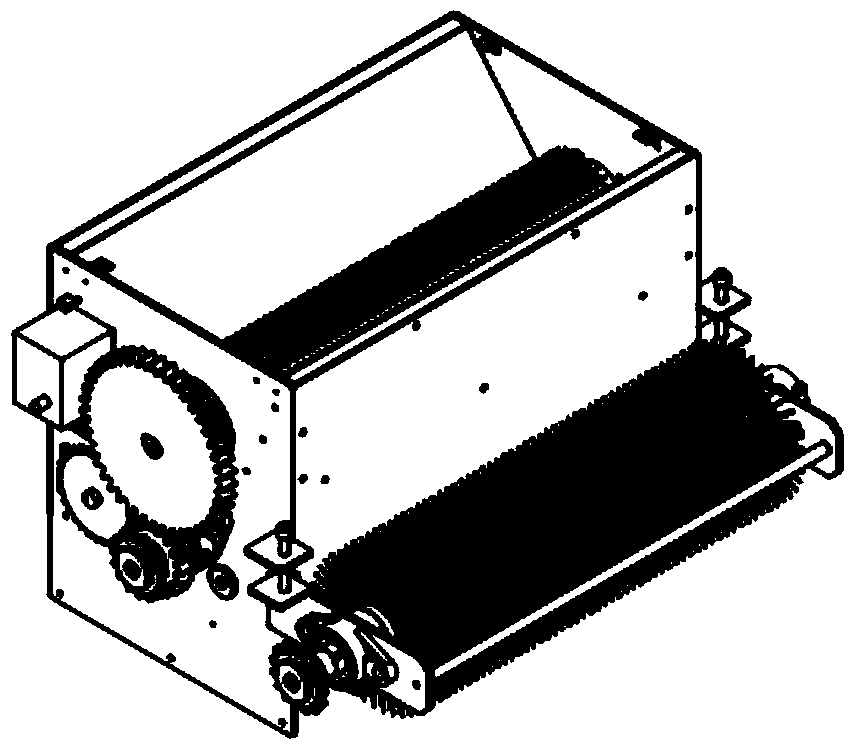

A kind of automatic flour spreading device and fresh noodle machine based on fresh noodle machine

ActiveCN105410089BAutomatic dusting evenlyEven and controllable automatic powder spreadingDough processingMechanical engineering

The invention discloses an automatic flour scattering device based on a fresh noodle maker and the fresh noodle maker. The automatic flour scattering device comprises a shell, a flour storing bin, a flour feeding mechanism, a flour scattering mechanism and a transmission mechanism. The flour storing bin is fixedly installed in the shell, and a leakage net is arranged at the bottom of the flour storing bin. The flour feeding mechanism comprises a first brush roller, the first brush roller is arranged above the leakage net and rotationally installed on the shell, the tail end of a brush of the brush roller makes contact with the surface of the leakage net, and the first brush roller is in transmission connection with the transmission mechanism. The flour scattering mechanism comprises a second brush roller, the second brush roller is arranged below the leakage net and rotationally installed on the shell, and the second brush roller is in transmission connection with the first brush roller. In this way, the automatic flour scattering device can scatter flour on fresh noodles or wrappers automatically, evenly and controllably.

Owner:安徽综科智能装备有限公司

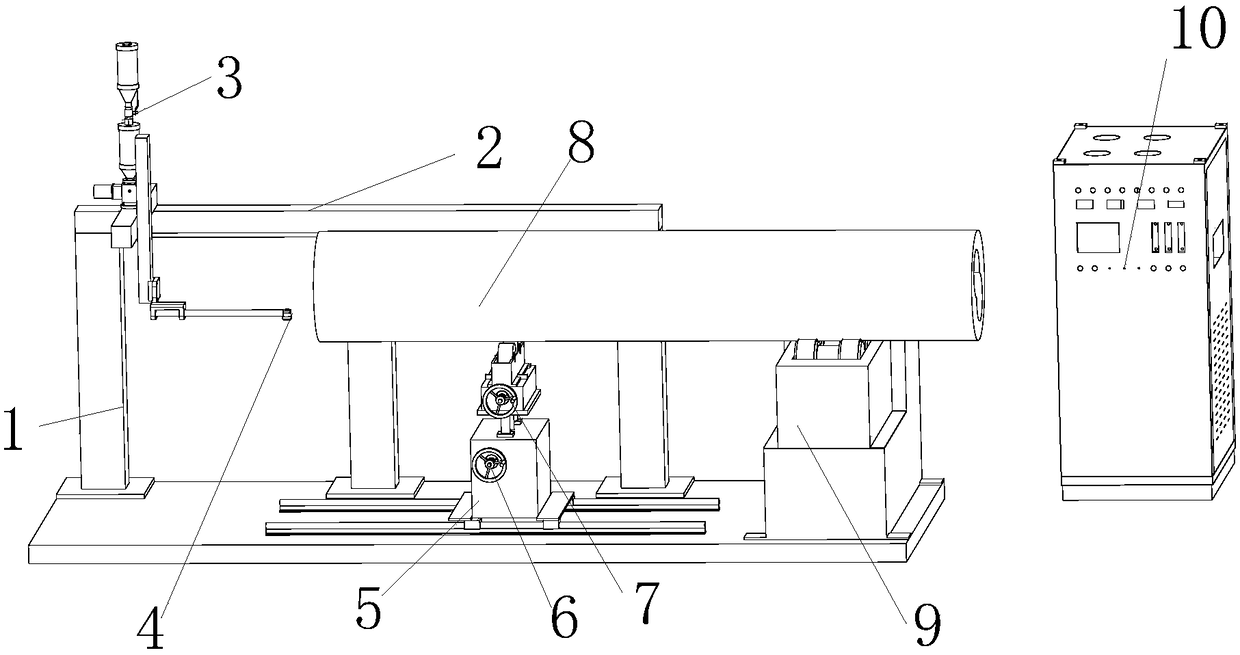

Laser cladding method and device for metal round rod surface

ActiveCN109252160BImprove performanceGuarantee the final qualityMetallic material coating processesEngineeringErbium lasers

The invention belongs to the field of laser cladding, and discloses a method and device for laser cladding of the surface of a metal round rod. A laser is prepared; a laser cladding nozzle of the laser is located near the peripheral surface of the end of the metal round rod, so that the metal round rod can move at a uniform speed in the axial direction while rotating at a uniform speed, and the movement trajectory of the laser cladding nozzle relative to the metal round rod is a spiral line along the surface of the metal round rod. The method of laser cladding on the surface of the metal roundrod subverts a traditional idea of cladding by moving the laser cladding nozzle, but a way that the laser cladding nozzle is stationary while the metal round rod moves in a straight line and in a whirling way simultaneously is adopted. Therefore, the final cladding layer on the surface of the metal round rod is a spiral line and the performance of the cladding connection part is stable.

Owner:HUNAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com