A kind of natural organic fertilizer preparation system and its working method

A preparation system and working method technology, applied in the field of feed preparation, can solve the problems of increased burden on farmers, insufficient combustion, and air pollution by smoke and dust, and achieve the effects of avoiding mixing procedures, improving processing efficiency, and avoiding pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

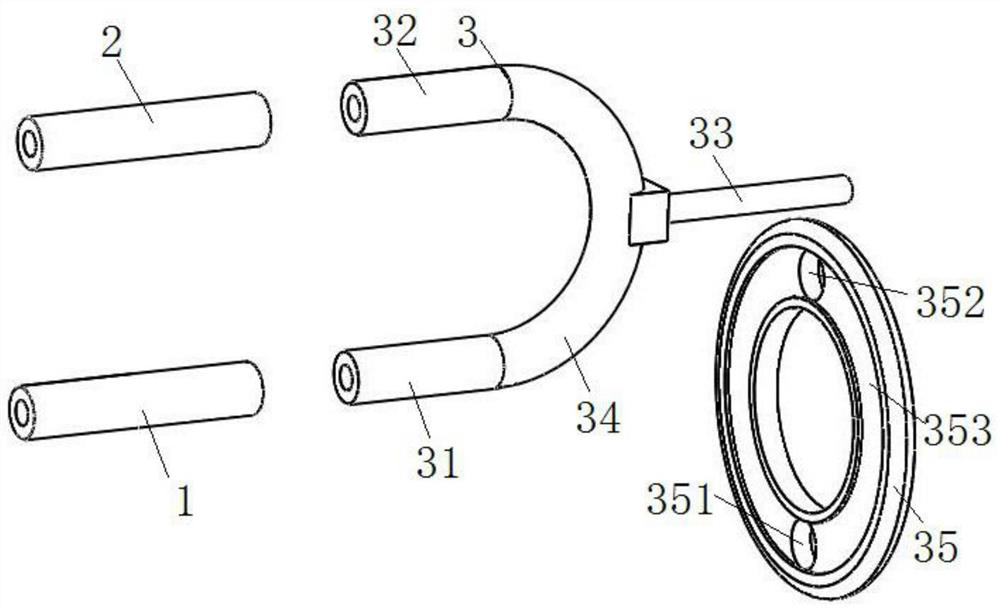

[0026] as attached figure 1 As shown, a natural organic fertilizer preparation system includes a sewage inlet pipe 1, a sewage outlet pipe 2 and a transfer device 3; the transfer device 3 includes a first connecting pipe 31, a second connecting pipe 32 and a first rotating shaft 33; The first connecting pipe 31 is arranged correspondingly to the sewage inlet pipe 1; the second connecting pipe 32 is arranged correspondingly to the sewage outlet pipe 2; the first connecting pipe 31 and the second connecting pipe 32 are symmetrical about the first rotation axis 33; The first connecting pipe 31 and the second connecting pipe 32 rotate around the first rotation axis 33; each time the first connecting pipe 31 and the second connecting pipe 32 rotate 180° around the first rotating axis 33, the positions of the two connecting pipes are exchanged.

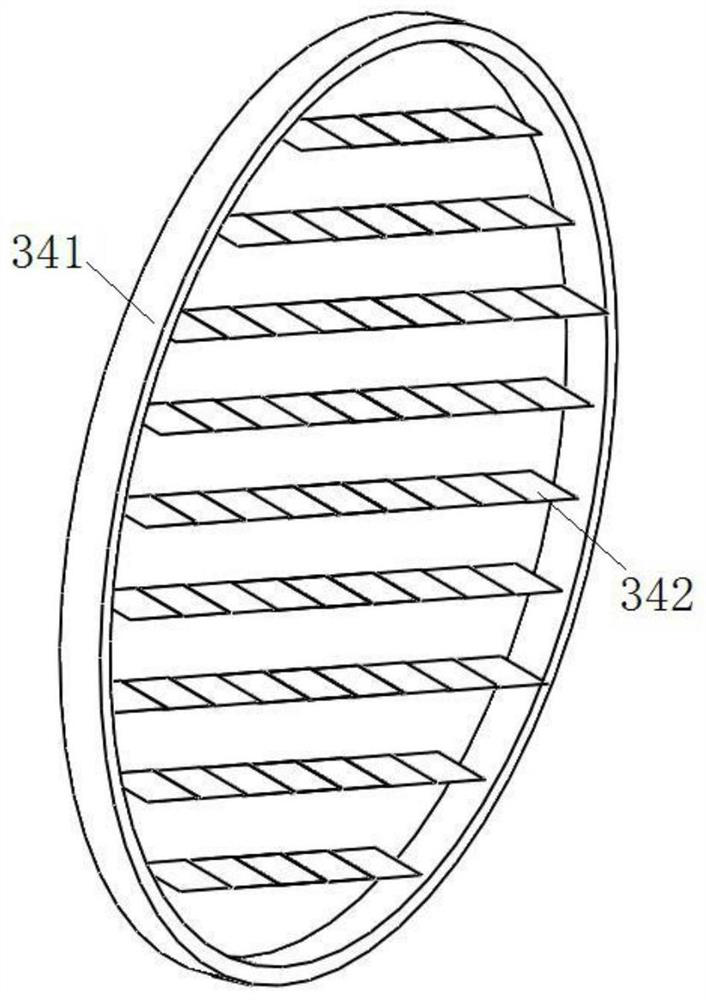

[0027] as attached figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com