Control method for laser cladding powder feeding

A control method and laser cladding technology, applied in metal material coating process, coating and other directions, can solve problems such as uneven powder feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0045] see figure 1 , the embodiment of the present invention provides a control method for laser cladding powder feeding, including:

[0046] S10: the driving part 240 drives the conveying part 140 at a certain driving speed to perform powder pollination, so as to transport the metal powder from the first powder feeding cylinder 110 to the second powder feeding cylinder 170;

[0047] S20: The sensor detects the quantity value H of the metal powder in the second powder feeding cylinder 170;

[0048] S30: The controller obtains the quantity value H, and generates a corresponding pollination control command by judging the relationship between the quantity value H and the preset threshold value H0;

[0049] S40: The driving unit 240 receives the pollination control command, so that the driving unit 240 adjusts its driving speed.

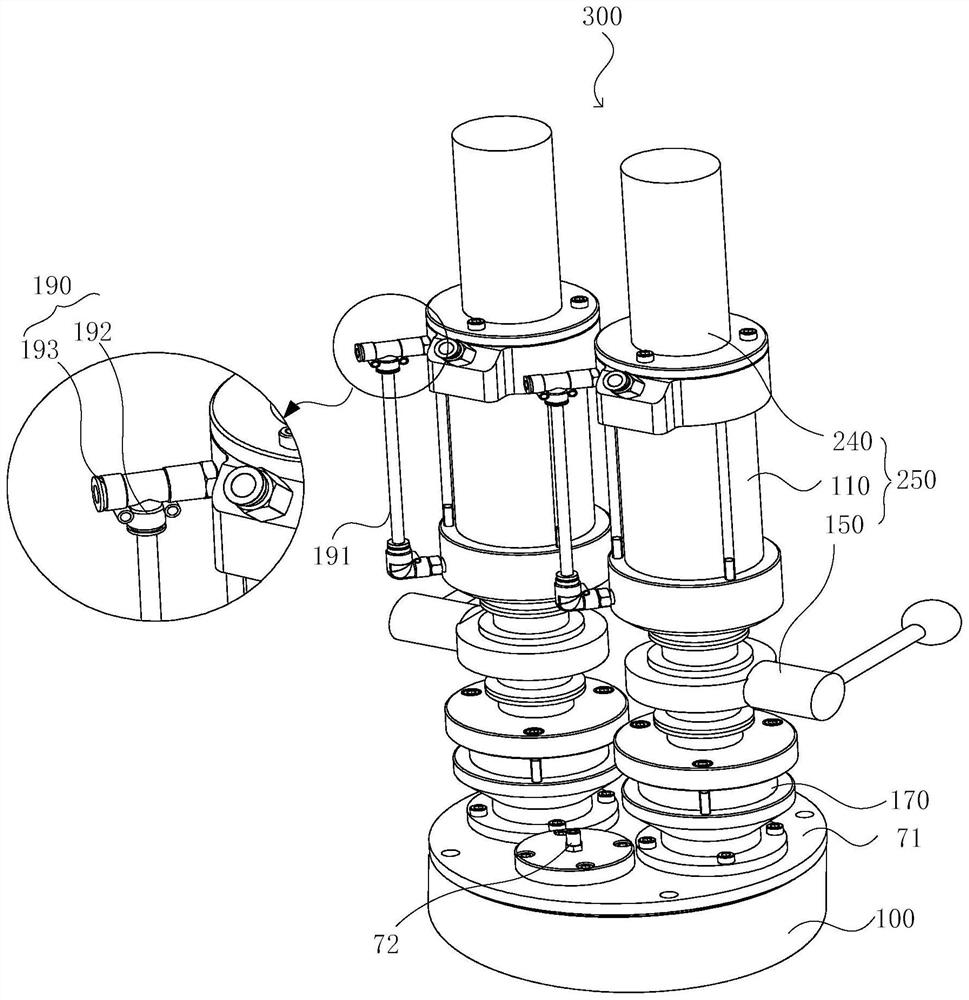

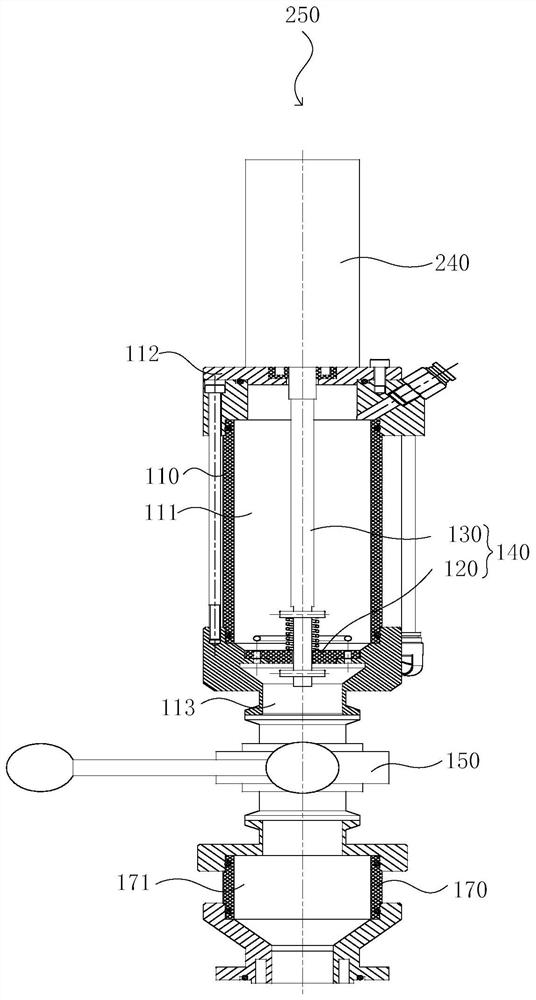

[0050] preferred, see figure 2 , the embodiment of the present invention provides a powder feeding device 300, including: at least two powder feedi...

no. 2 example

[0069] see Figure 8 In the second embodiment provided by the present invention, steps S31 and S41 are performed on the basis of the above-mentioned first embodiment S20.

[0070] Preferably, S31 is executed, the sensor transmits the quantity value H of metal powder detected in the second powder storage space to the controller, and the controller judges the quantity value H, if the controller judges that the quantity value H is less than The minimum threshold HO of the set normal threshold interval 小 , an accelerated pollination control instruction will be generated.

[0071] Further, step S41 is executed, the controller issues the accelerated pollination control instruction to the driving unit 240, and the driving unit 240 drives the transmission unit 140 to perform powder feeding according to the accelerated pollination control instruction at a speed greater than the driving speed in S10 .

[0072] Wherein, when steps S31 and S41 are executed, the control valve 150 is in ...

no. 3 example

[0074] see Figure 9 In the third embodiment provided by the present invention, steps S32 and S42 are performed on the basis of the above-mentioned first embodiment S20.

[0075] Preferably, S32 is executed, the sensor transmits the quantity value H of metal powder detected in the second powder storage space to the controller, and the controller judges the quantity value H, if the quantity value H is greater than the set value at this time Set the maximum value of the threshold HO 大 When , it will generate slow down or suspend pollination control instructions.

[0076] Further, step S42 is executed again. If it is a pollination suspension control instruction, the controller transmits the deceleration pollination control instruction to the drive part 240, and the drive part 240 uses the deceleration pollination control instruction to be smaller than the one in S10. The driving speed drives the conveying unit 140 to pollinate; if it is a pollination suspension control instruct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com