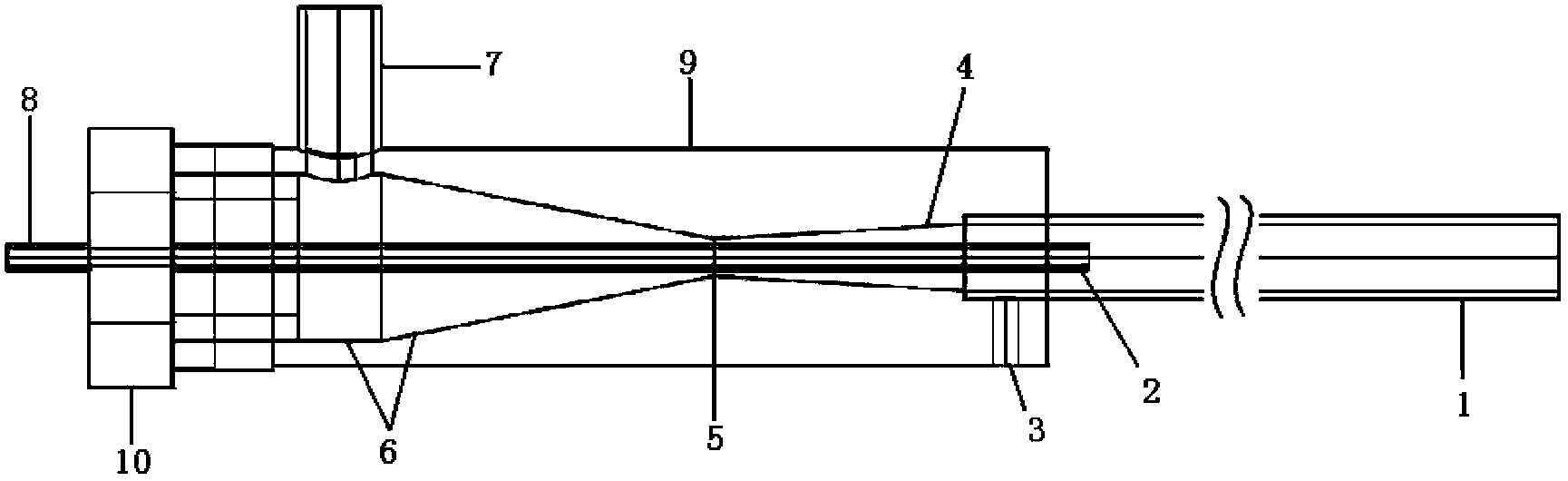

Nozzle for axial siphon powder delivering type cold spray

A technology of cold spraying and nozzles, applied in the field of cold spraying in surface treatment engineering, which can solve the problems of low central flow rate, unfavorable processing flexibility, low production efficiency, etc., and achieve the effect of stable flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The structural dimensions of a high-pressure nozzle involved in this embodiment are as follows: figure 2 As shown, its expansion ratio is 6.25, and its implementation result is compared with the acceleration effect of patent ZL00253384.7, such as image 3 , Figure 4 and Figure 5 Shown; Analysis of its flow field characteristics shows that the nozzle flow field rear part of the present embodiment can be uniform, and when the expansion ratio is 6.25, the rear flow field air velocity can also reach 850m / s, while the existing nozzle downstream The speed of part of the flow field can only reach about 700m / s, and the acceleration ability for 15um copper particles differs by more than 50m / s when other conditions are the same.

Embodiment 2

[0026] The structural dimensions of a low-pressure nozzle involved in this embodiment are as follows: Figure 6 As shown, its expansion ratio is 4, and its result is compared with the acceleration effect of the commercially available DYMET low-pressure cold spraying equipment nozzle. , when the expansion ratio is 4, the airflow velocity in the rear flow field can also reach 800m / s, and the particle flow is strictly limited on the axis. However, in the existing commercially available DYMET nozzle, the trajectory of the particle is to hit the inner wall of the nozzle back and forth, resulting in The nozzles are worn out after working for a period of time. Although the structure adopted by DYMET is very suitable for quick replacement of nozzles, it will cause a lot of inconvenience during long-term construction, especially when moisture and oxidation are considered in interval construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com