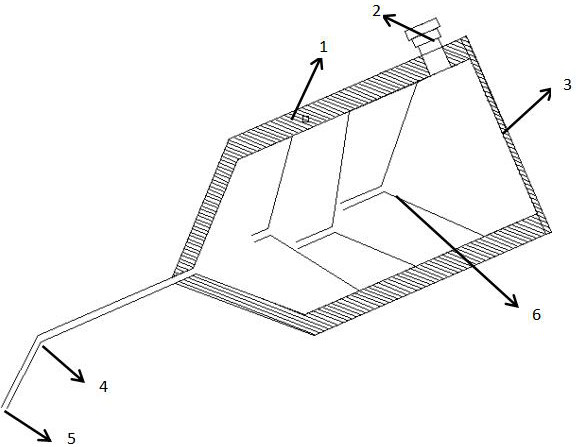

Lateral powder feeding device for high-speed laser cladding and its cladding process

A technology of lateral powder feeding and laser cladding, which is applied in the coating process and coating of metal materials, can solve the problems of inability to clad large components, low powder utilization rate, large heat-affected zone, etc., and achieve simple structure, The effect of high powder utilization rate and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

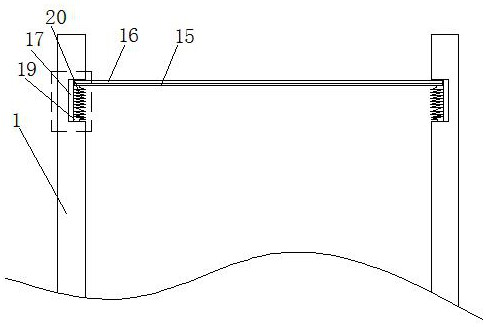

[0051] Embodiment 1: with reference to attached Figure 7 As shown, using this device to carry out high-speed laser cladding of nickel-based alloy powder on the surface of 45# steel, the parameters used are: laser power 1200W, scanning speed 120m / min, spot diameter 1mm, shielding gas is argon, The protective gas flow rate is 15g / L, the powder feeding speed is 15g / min, the overlap rate is 30%, and the defocusing amount is 10mm. Under these parameters, the fiber laser is used for cladding on the surface of 45# steel; the cladding layer 11 is shown in the figure below. It can be seen that the surface of the coating is smooth and free of defects such as inclusion holes. The cladding layer 11 was infiltrated, and no cracks were found. The surface hardness of the cladding layer 11 was about three times that of the substrate 10; the cladding layer 11 and the substrate 10 reached a metallurgical bond, and the thickness of the cladding layer 11 was between 20-60 μm , the diluted laye...

Embodiment 2

[0052] Embodiment 2: with reference to attached Figure 8 As shown, this device is used to perform high-speed laser cladding of IN625 alloy powder on the surface of the bearing. The cladding head remains stationary, and the bearing moves forward while rotating. The cladding parameters used are 1100W, the spot diameter is 1mm, and the shielding gas is argon. Gas, the protective gas flow rate is 15g / L, the powder feeding speed is 15g / min, the overlap rate is 30%, the defocusing amount is 10mm, the bearing speed is 120r / min, and the bearing travel speed is 120m / min; cladding layer 11 As shown below. It can be seen that the thickness of the cladding layer 11 is very thin and metallurgically combined with the bearing, the surface is flat and smooth, there are no unmelted powder particles, and there are no defects such as small holes. The cladding layer 11 is infiltrated, and no cracks are found on the surface. Compared with the bearing itself, the wear resistance of the cladding l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com